Page 1

AN2017-44

1200V HighSpeed 3 IGBT in TO-247PLUS

Evaluation Board

User Manual

About this document

Scope and purpose

This application note is a user guide for the 1200V HighSpeed 3 IGBT in TO-247PLUS evaluation board.

It explains the board’s hardware and provides detailed instructions on how to use it for addressing

various measurement tasks. Finally, practical examples demonstrate the benefits of both, TO-247PLUS

and TO-247PLUS 4pin packages.

Intended audience

This document is intended for owners and users of the evaluation board.

Table of Contents

About this document .............................................................................................................................. 1

Table of Contents ................................................................................................................................... 1

1 Introduction .......................................................................................................................... 3

1.1 Purpose of the board .............................................................................................................. 3

1.2 Scope of delivery .................................................................................................................... 4

2 Hardware ............................................................................................................................... 5

2.1 Circuit and main components ................................................................................................. 5

2.2 Recommended accessories ................................................................................................... 6

3 Usage .................................................................................................................................... 8

3.1 Settings .................................................................................................................................. 8

3.1.1 Replacing switches or diodes ............................................................................................ 8

3.1.2 Changing between 3pin and 4pin packages ................................ ...................................... 9

3.1.3 Tuning gate voltages and resistors .................................................................................. 10

3.1.4 Adjusting and monitoring the heat sink temperature ........................................................ 11

3.2 Operation ............................................................................................................................. 11

3.2.1 Configurations ................................................................................................................. 11

3.2.2 Switching loss measurements ......................................................................................... 13

3.2.3 Efficiency or temperature measurements ......................................................................... 14

4 Examples ............................................................................................................................ 15

4.1 Turn-on loss reduction with a 4pin package ......................................................................... 15

4.2 Substituting parallel 40A devices with a 75A device ............................................................. 16

5 Appendix ............................................................................................................................. 18

5.1 Schematic drawing ............................................................................................................... 18

5.2 Board layout ......................................................................................................................... 19

5.3 Bill of materials ..................................................................................................................... 21

References ............................................................................................................................................ 24

Revision History ................................................................................................................................... 25

Application Note Please read the Important Notice and Warnings at the end of this document Revision 1.0

www.infineon.com 2017-11-15

Page 2

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Introduction

Dangerous Equipment!

High Voltage

Do NOT touch the board during operation.

Depending on the configuration of the board and the chosen

supply-voltage, life-threatening voltages might be present!

Even brief accidental contact during operation

might result in severe injury or death!

Always make sure that the capacitors are discharged

before touching the board.

Only qualified personnel are allowed to handle this board!

Read the instructions provided in this application note before putting

the evaluation board into operation

The board described is an evaluation board dedicated for laboratory environment only. It operates at

high voltages and must only be operated by qualified and skilled personnel familiar with all applicable

safety standards.

Application Note 2 Revision 1.0

2017-11-15

Page 3

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Introduction

(a)

(b)

1 Introduction

The evaluation board EVAL-IGBT-1200V-TO247PLUS was developed as a test platform for 1200V

IGBTs in TO-247PLUS and TO-247PLUS 4pin packages but can also be used for standard TO-247 and

TO-247 4pin packages.

This introductory section provides an overview of the potential applications of the evaluation board and

lists the components included in the delivery.

1.1 Purpose of the board

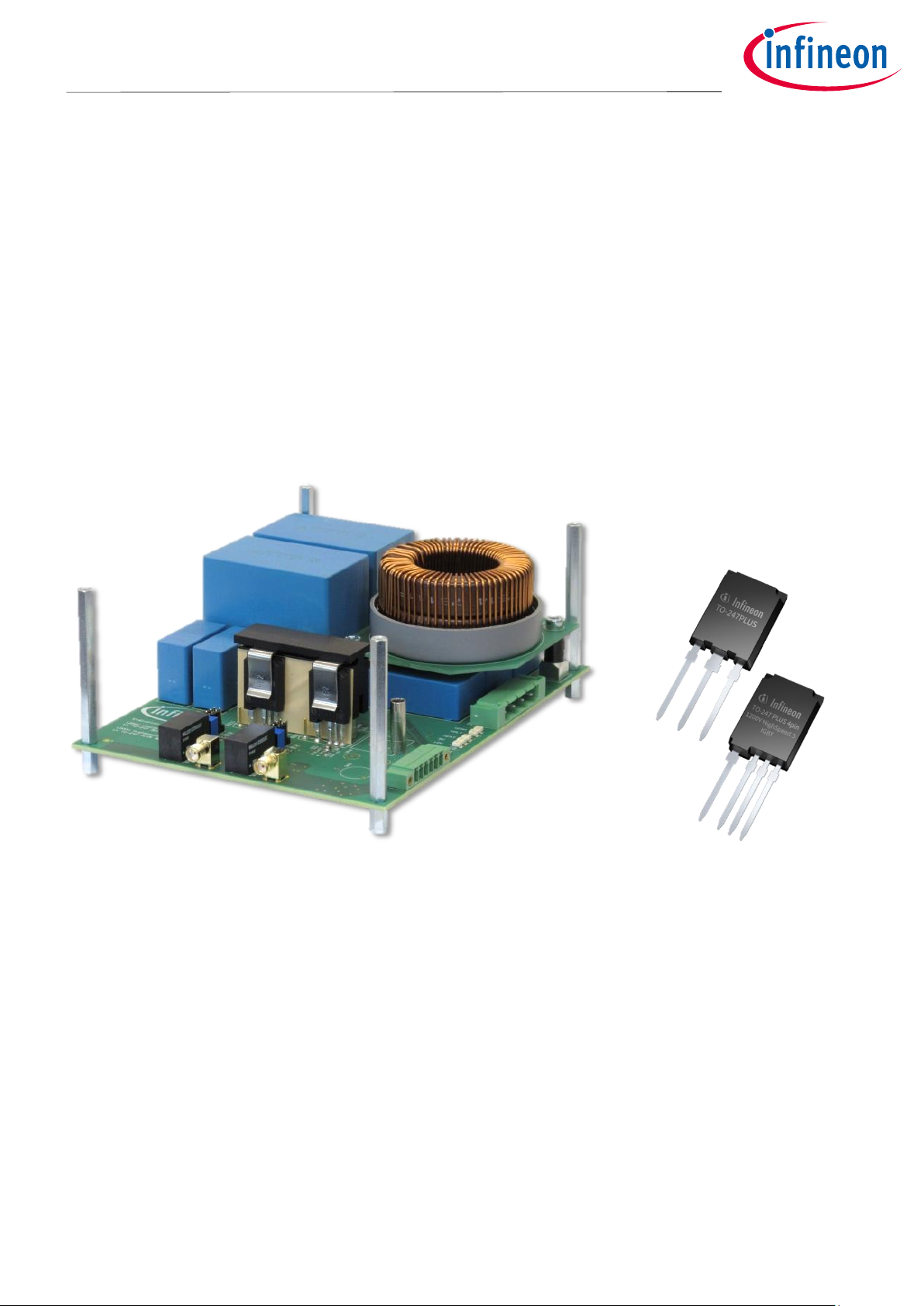

The main motivation to develop the evaluation board shown in Figure 1 was to have one universal test

platform for 1200V IGBTs in TO-247 as well as TO-247PLUS packages with three as well as four leads.

It allows evaluating the advantages provided by the larger lead frame area of the TO-247PLUS package

as well as the performance improvement given by the Kelvin emitter connection of the TO-247PLUS 4pin

package. For detailed information on these packages refer to application notes [1] and [2], respectively.

Figure 1 Evaluation board and devices under test: (a) 1200V HighSpeed 3 IGBT in TO-247PLUS

Evaluation Board, (b) TO-247PLUS and TO-247PLUS 4pin package

Two different modes of operation can be implemented with this board. First, it can be used to investigate

the switching behavior and measure the switching losses of IGBTs and diodes at different conditions.

Parameters like the DC link voltage, the load current, the device temperature as well as the gate

voltages and resistors are easily adjustable. If desired, snubbers can be assembled as well. Second, the

board can be operated as a step-up or step-down DC/DC converter. Thus, it is possible to characterize

and run devices in a continuous mode of operation in the same setup.

Care was taken to minimize the parasitic inductances and capacitances of this board wherever possible.

If needed, board users can tune the parasitic circuit elements by simply adding small capacitances and

inductances.

Application Note 3 Revision 1.0

2017-11-15

Page 4

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Introduction

1.2 Scope of delivery

The evaluation board is delivered together with spare parts and complete documentation in an

environmentally friendly carton box as illustrated in Figure 2. As depicted, the carton box contains:

Evaluation board EVAL-IGBT-1200V-TO247PLUS with a size of 172mm x 133mm x 72mm (LxWxH)

1200V HighSpeed 3 IGBTs IKQ50N120CH3, IKQ75N120CH3, IKY50N120CH3 and IKY75N120CH3

1ED Compact isolated gate-driver ICs 1EDI60I12AH in a 300mil wide-body package

USB flash drive containing all related application notes and data sheets

Wire-to-board plugs for connecting the evaluation board to sources and loads

Figure 2 Scope of delivery: evaluation board, spare parts and USB drive with documentation

For high accuracy switching loss measurements, it is highly recommended to use these additional

components which are not included in the delivery:

Coaxial shunt SDN-414-xxx (IB Billmann) for high accuracy current measurements

Probe adapter A-PCB-5,0-L (PMK) for connecting a passive high voltage oscilloscope probe

Probe adapters PK106-4 (LeCroy) for connecting passive low voltage oscilloscope probes

Application Note 4 Revision 1.0

2017-11-15

Page 5

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Hardware

(a)

(b)

2 Hardware

This section provides a short description of the board hardware. First, it explains the power circuitry, the

main components and the connectors. Then, the application of the recommended accessories is

discussed.

2.1 Circuit and main components

As shown in the block diagram of Figure 3, the evaluation board essentially is a half bridge converter

consisting of two IGBTs, S1 and S2. Due to the clip-based heat sink mounting and the universal socket

on the PCB it is possible to assemble standard TO-247 and TO-247PLUS packages with three as well

as four leads.

The switches are driven using EiceDriver™ 1ED Compact driver ICs. Due to the robust nature of the

coreless transformer technology combined with the 300mil wide-body package, these drivers are well

suited for applications that require high voltages, frequencies and switching speeds. Both drivers are

controlled with independent PWM signals on the connectors SIG-HS and SIG-LS. The driving voltages

are provided using the 12V auxiliary supply and isolated DC/DC converters.

For versatility reasons, the evaluation board was equipped with input and output capacitors Cin and C

out

as well as a load inductor L. While the input capacitor and the load inductor where designed having

mainly switching loss measurements in mind, the output capacitor is required for continuous operation,

for instance as a buck converter. The provided filter inductor might not meet the requirements for the

latter case but it is straightforward to replace it with a custom solution.

The same applies to the heat sink: its size and shape reveals that it cannot provide the cooling

performance required for continuous operation. Rather, it is intended to serve as a heating element for

performing high temperature switching loss measurements. Using the power resistor R

thermistor R

, the heat sink temperature can be adjusted and monitored, respectively. Again, it is

NTC

and the

POW

easily possible to replace the provided heat sink with a high performance solution.

Figure 3 Overview of the board schematics (a) and components (b)

Application Note 5 Revision 1.0

2017-11-15

Page 6

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Hardware

(a)

(b)

An experimental analysis of a device’s switching behavior requires oscilloscope measurements of the

gate voltage, the collector-emitter voltage as well as the collector current. While voltage measurements

are straightforward, current measurements are more difficult to do, particularly in the presence of steep

current slopes. This evaluation board contains a basic SMD shunt resistor solution. It gives an

impression of the collector current waveform but is not considered an ideal solution for high accuracy

measurements.

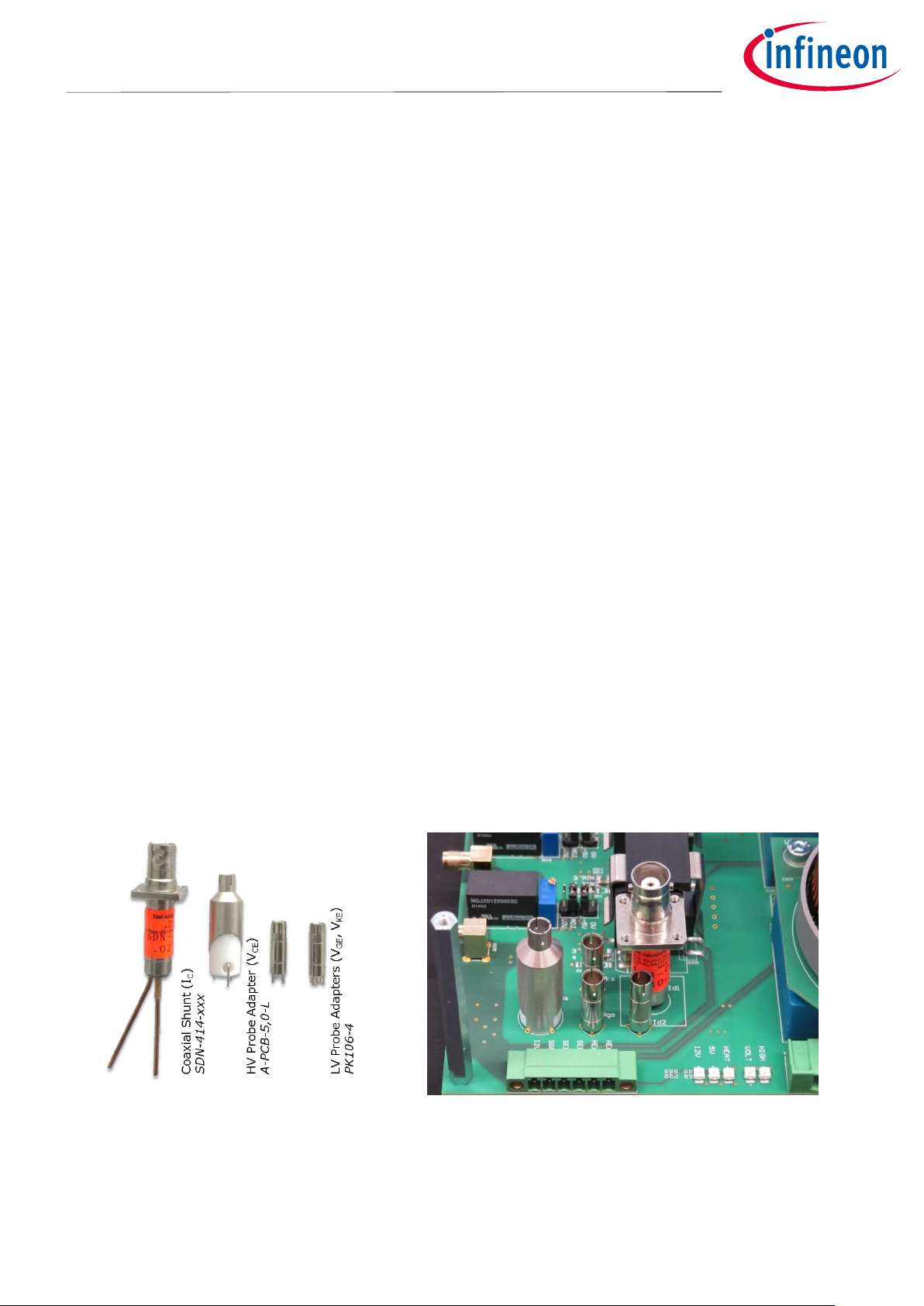

2.2 Recommended accessories

The introductory section already clarified which components are delivered with the evaluation board and

which are not. Although the board can be used for switching loss measurements right away, it is strongly

recommended to use additional components for the highest accuracy and signal quality.

Coaxial shunt

Performing oscilloscope measurements of an IGBT’s collector current waveform is typically a non-trivial

task, particularly during switching events where extremely steep current slopes of several Amperes per

nanosecond are reached. An ideal current measurement for this purpose would be non-invasive – at

least it should not require significant changes of the circuit – and have a very high bandwidth.

By default, this evaluation board contains a 50mΩ metal foil SMD shunt resistor and an RC low-pass

filter in order to suppress disturbances caused by parasitic circuit elements. Due to the substantial

filtering, this approach might be considered a current estimation rather than a measurement. For high

accuracy measurements it is recommended to use a coaxial shunt SDN-414-xxx.[3] It has a bandwidth in

the gigahertz range and can be connected to any oscilloscope with a standard BNC cable.

To assemble the coaxial shunt:

1. Unsolder the 50mΩ metal foil resistor R201 and the 100Ω thin film resistor R200 on the bottom side

of the board.

2. Optionally, remove the capacitor C201 and the probe adapter Id2 as they are inoperable.

3. Strip the isolation at the central terminal of the shunt and solder it to the PCB.

As visible in Figure 4, the shunt should be positioned as close to the PCB as possible to minimize

parasitic inductances.

Figure 4 Recommended accessories for switching loss measurements: (a) pictures of the

components, (b) assembly of the components on the board

Application Note 6 Revision 1.0

2017-11-15

Page 7

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Hardware

25°C

100°C

800V

400V

800V

400V

Turn-On

Turn-Off

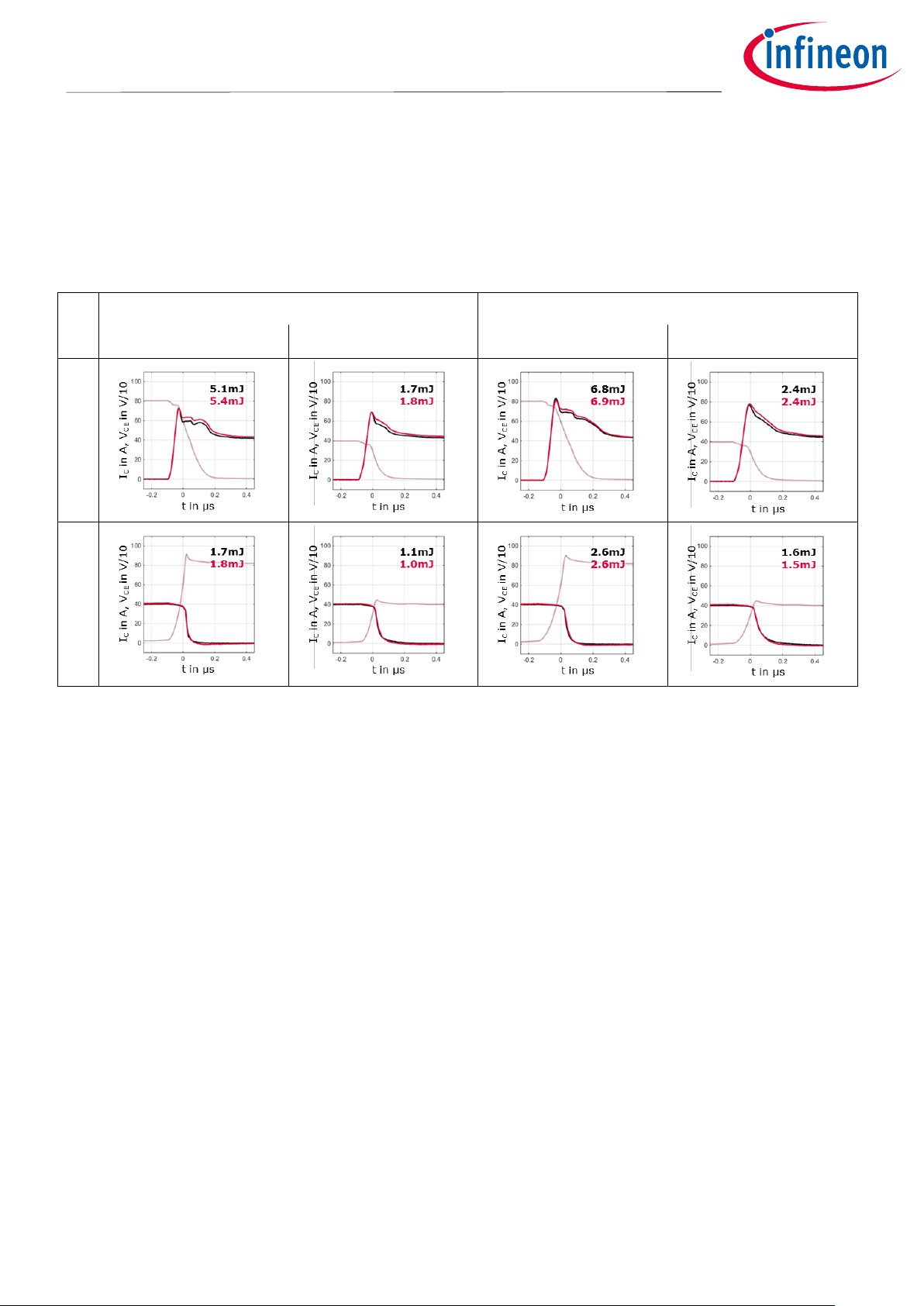

Table 1 compares waveforms as well as switching losses measured with the metal foil SMD resistor and

the coaxial shunt at various temperatures and voltages. As all measurements are done with exactly the

same semiconductor devices, the differences can be attributed to the different current sensors. It is

clearly visible that the SMD solution estimates the basic waveform of the collector current relatively well.

However, the exact determination of switching slopes and losses requires a coaxial shunt.

Table 1 Comparison of the coaxial (black) and the SMD shunt (red) at various conditions. The

double pulse tests were performed with IKY75N120CH3.

Oscilloscope probe adapters

In contrast to current measurements, the acquisition of voltage waveforms is straightforward. By

selecting the emitter potential of the low side IGBT S2 as common ground, the gate voltage, the collectoremitter voltage and the collector current can be measured with ordinary passive probes.

While voltage probes can be connected using grounding wires and clips, the use of PCB adapters is

considered advantageous for several reasons. First and foremost, the grounding of the probe is

improved which leads to a proper and reproducible signal quality, especially in the presence of

disturbances caused by switching transients. Additionally, connecting the probes becomes more

convenient and less error-prone.

The evaluation board was designed to accommodate one PMK high voltage probe adapter A-PCB-5,0-L

and two LeCroy low voltage probe adapters PK106-4 [4][5]. They share the emitter of the low-side switch

as common ground and measure the voltage on the collector, on the gate and on the Kelvin connection

terminal, respectively. Assembling the probe adapters can be done as depicted in Figure 4.b.

Application Note 7 Revision 1.0

2017-11-15

Page 8

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

(a)

(b)

(c)

(d)

3 Usage

Due to its flexibility, the evaluation board can address a variety of measurement problems. While the

previous sections explained the basic purpose as well as the hardware of the board, this section

provides detailed instructions on how to set it up and operate it. Section 3.1 describes how to modify

certain board settings, section 3.2 deals with the preparation and execution of different experiments.

3.1 Settings

The evaluation board is capable of testing TO-247 and TO-247PLUS packages with three as well as four

leads under many different conditions. This section provides exemplary instructions on how to assemble

different package variants and make the most important adjustments, particularly in the driving circuitry.

Attention: Prevent potential exposure to hazardous voltages by turning off all power supplies

and discharging the DC link capacitors before undertaking any of the modifications

described in the remainder of this section.

3.1.1 Replacing switches or diodes

A PCB is subject to severe thermomechanical stress when soldering and unsoldering components. As a

consequence, the adhesion between the copper layers and the core material gets weaker and

eventually, copper pads or traces may lift off and break. In order to allow a large number of IGBT and

diode replacements, this evaluation board uses press fit pins for connecting the TO packages and the

PCB. As the device is not soldered directly to the board but to the pins, the stress to the PCB is limited.

There are several ways of removing the TO packages from the heat sink and the board. A simple

approach is to cut the package leads, remove the package body from the heat sink and unsolder one

lead after another from the press fit pins. Figure 5 illustrates a different strategy where the

semiconductor device remains intact.

1. Put the board in an upright position so that the IGBT packages face upwards (a).

2. Push a flat screw driver between the clip and the package body and twist it to pull the clip out of the

heat sink’s groove (b).

3. Use two soldering irons to heat up all leads at the same time. When the solder melts on all leads,

gently pull the package away from the board (c).

4. Finally, clean the press fit pins using solder wick (d).

Figure 5 Disassembling a device from the heat sink and the PCB

The assembly of a new device is easier. Figure 6 presents a possible sequence of steps.

1. Prepare the TO package by cutting the leads to a length of around 5mm (a).

2. Place the package freely and perfectly flat on the heat sink (b).

3. Put the spring clip on the package and the heat sink groove and fasten it using pliers (c).

4. Solder one lead after the other to the press fit pins (d).

Application Note 8 Revision 1.0

2017-11-15

Page 9

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

(a)

(b)

(c)

(d)

Package

TO-247 4pin

TO-247PLUS 4pin

TO-247

TO-247PLUS

Connected

press fit pins

Pins 2-5

Pins 1-3

Reference of

driver output

Pin 3

(0Ω resistor at R2_4)

Pin 4

(0Ω resistor at R2_3)

Pin 3

(0Ω resistor at R2_4)

Pin 4

(0Ω resistor at R2_3)

Connection

Scheme

Picture

Comment

Operation of the

4pin package as a

3pin package

Intended operation

of the 4pin package

Intended operation

of the 3pin package

Attention: floating

gate; setting can

cause device and

circuit destruction

Figure 6 Assembling a device onto the heat sink and the PCB

3.1.2 Changing between 3pin and 4pin packages

Since the evaluation board has to serve as a universal test platform for TO-247-like packages with three

as well as four leads, it contains special five pin sockets which can accommodate all package variants.

The connection schemes for switches and drivers are described in Table 2.

1. Solder the discrete semiconductor package to the proper socket pins: four lead packages to pins 2-5,

three lead packages to pins 1-3.

2. Ensure that the reference of the driver output is connected to the proper Emitter lead using a 0Ω

resistor: assemble R214/R224 for a three-pin, R213/R223 for a four pin configuration.

Table 2 Assembly of TO-247-like packages with three and four pins

Application Note 9 Revision 1.0

2017-11-15

Page 10

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

(b)

(a)

(c)

3.1.3 Tuning gate voltages and resistors

Figure 7.a illustrates the schematics of the driving circuitry implemented for both, the high side and the

low side switch. It includes the relevant components of the circuitry and highlights the most important

part labels which consist of a letter and a three-digit number. The second digit is replaced by a wildcard

underscore in the picture but would normally indicate whether the component belongs to the high side

(“1”) or the low side (“2”).

A galvanically isolated EiceDriver™ 1ED Compact IC with a nominal current of 6A, separate source and

sink outputs and a wide-body package forms the core of the driving circuitry. The input or primary side of

the driver is powered with a voltage of 5V referring to SGND – this voltage is generated based on the

12V auxiliary input using a linear regulator – and controlled with a PWM signal on the input Sig-X. Please

note that since the driver already contains high accuracy input filters, there is no need to use an external

RC low-pass on the signal path. Such a filter would require additional components, introduces a higher

propagation delay tolerance and is thus not recommended.

The driving voltages on the output or secondary side of the driver are provided by an isolated DC/DC

converter and adjusted using the jumpers X1_1, X1_2 as well as the potentiometer R1_0. These

components are assembled on the top side of the board and highlighted in Figure 7.b.

To adjust the gate voltages levels:

1. Set the jumper X1_1 to ADJ and tune the potentiometer with a flat screw driver until the

recommended value of 15V is reached.

2. Select a turn-off voltage of either -5V or 0V using the jumper X1_2.

3. Monitor or check the gate voltage levels on an oscilloscope or multimeter.

Separate turn-on and –off resistors R2_1 and R2_2 are assembled on the bottom side of the board. As

depicted in Figure 7.c, resistors in a Mini-MELF mounting form were selected and highlighted with the

labels ON and OFF. The gate resistance values can be adapted using a soldering iron.

Figure 7 Explanation of the driving settings: (a) schematics of the driving circuitry, (b) gate

voltage settings, (c) gate resistors

Application Note 10 Revision 1.0

2017-11-15

Page 11

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

(a)

(b)

3.1.4 Adjusting and monitoring the heat sink temperature

Switching losses are not only measured at room temperature but also at temperatures of 100°C and

above. Consequently, a measurement setup must offer the possibility to adjust and monitor the case

temperature of the devices under test.

This evaluation board contains a small heat sink that has been designed to serve as a small heating

element. The temperature of this element can be set and measured using the power resistor E200 and

the NTC B200, respectively. Both devices are assembled on the back of the heat sink, on the opposite

side of the devices under test.

In order to adjust the heat sink temperature:

1. Connect a laboratory power supply to the HEAT+/HEAT- terminals of the power resistor.

2. Connect an ohmmeter to the SENSE+/SENSE- terminals of the NTC thermistor.

3. Use the power supply to adjust the heat sink temperature. A rough guide is provided by Figure 8.a.

4. Monitor the actual temperature value using the ohmmeter and the NTC characteristic in Figure 8.b.

The heat sink behavior can be approximated with a thermal resistance of around 6 K/W to the ambient

and a thermal time constant of approximately 7 minutes. This analytic description is valid if the heat sink

is facing upwards and not exposed to a forced air cooling.

Figure 8 Characteristics for temperature adjustments: (a) heat sink temperature as a function of

power, (b) NTC value as a function of the heat sink temperature

3.2 Operation

As described in section 2.1 the evaluation board implements a half bridge circuit with independent driver

stages for the high side and the low side semiconductor device. Due to the universal nature of this

topology, the board can be operated in various modes of operation. The remainder of this section

explains the possible measurement configurations and procedures.

Attention: Prior to starting measurements ensure that the board settings are correct. Take

special care that no physical short circuits or floating gates are present. Increase the

input voltages slowly and monitor that the circuit behaves as expected.

3.2.1 Configurations

Table 3 provides a summary of the main board configurations. The first two lines illustrate how to study

the switching behavior of a certain IGBT and diode combination. By switching the IGBT according to a

double pulse signal it is possible to generate a turn-off as well as a turn-on event with a specific voltage

Application Note 11 Revision 1.0

2017-11-15

Page 12

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

(4) Boost Converter

Switch S2

Diode S1

TS1, TS2,

T

heatsink

, η,

VCE and

VGE

waveforms,

…

VDC / (1-d)

f

sw

P

out

V

GE(on)

V

GE(off)

R

G

Package

< 900V 1

-

- 5

0/-5V

12- 20V

TO-247x-3/4 4

Do not operate a boost converter without a load!

Ensure that the DC link voltage does not exceed 900V!

1

2

3

4

5

Conf.

DUTs

Results

Parameters and limits

Simplified circuit drawing

(1) Switching Cell

(Switch characterization)

Switch S2

Diode S1

VCE, IC and

VGE

waveforms,

Eon, E

off

,

Qrr, I

rrm

,

V

CE(peak)

dv/dt, di/dt,

…

V

CE

I

C

T

C

V

GE(on)

V

GE(off)

R

G

Package

< 900V 1

< 150A 2

< 150°C 3

0/-5V

12- 20V

TO-247x-3/4 4

(2) Switching Cell

(Diode characterization)

Diode S2

Switch S1

VCE, IC and

VGE

waveforms,

E

rec Qrr

,

I

rrm

, dv/dt,

di/dt, …

V

CE

I

C

T

C

V

GE(on)

V

GE(off)

R

G

Package

< 900V 1

< 150A 2

< 150°C 3

0/-5V

12- 20V

TO-247x-3/4 4

(3) Buck Converter

Switch S1

Diode S2

TS1, TS2,

T

heatsink

, η,

VCE and

VGE

waveforms,

…

VDC

f

sw

P

out

V

GE(on)

V

GE(off)

R

G

Package

< 900V 1

-

- 5

0/-5V

12- 20V

TO-247x-3/4 4

and current. Measuring the current and voltage waveforms of the devices on the oscilloscope gives an

impression of the switching behavior and allows a calculation of the switching losses. In order to

maximize the accuracy and minimize the effort, it is recommended to make oscilloscope measurements

on the low side device S2: use configuration (1) to study the IGBT and configuration (2) to study the

diode behavior. More detailed information on this mode of operation can be found in section 3.2.2.

Configuration (3) and (4) correspond to a buck and a boost converter, respectively. Since these

configurations are actually processing power in a continuous manner, both the heat sink and the inductor

need to meet the individual voltage, power and switching frequency requirements. It is straightforward to

replace those components with appropriate custom solutions. Refer to section 3.2.3 for more detailed

information on how to use the board in this mode of operation.

Table 3 Board configurations for switching loss measurements and continuous operation

Limited by the ceramic DC link capacitors C201 and C202 on the bottom side of the PCB.

Not a hard limit due to the soft saturation behavior of the inductor core.

Limited by the maximum temperature of the power resistor.

TO-247x-3/4 refers to TO-247 and TO-247PLUS as well as TO-247 4pin and TO-247PLUS 4pin packages.

Limit depends on the device selection and the cooling performance.

Application Note 12 Revision 1.0

2017-11-15

Page 13

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

(a)

(b)

3.2.2 Switching loss measurements

Switching losses can be determined using a double pulse test. It generates both a turn-off and a turn-on

event by applying two consecutive pulses on the gate of the switch – hence the expression double pulse.

Due to the fact that the circuit is not operated in a continuous fashion the self-heating of the

semiconductors and the inductor is negligible. This is particularly convenient since the junction

temperatures of S1 and S2 correspond to the heat sink temperature and are therefore well known.

The remainder of this section describes how to perform double pulse tests based on configuration (1). It

is worth noting, however, that configuration (2) is operated in an analogous manner. Figure 9.a shows

the principle current and voltage waveforms of S2 during the double pulse test. Initially, S2 is blocking the

full DC link voltage, thus VCE=VDC. At T0 the switch is turning on and the current IC(t) rises with a rate

V

/L. When the switch is turned off at T1, the load current commutates from S2 to the diode of S1 where

BUS

it is freewheeling until T

microseconds S2 is turned off again. The load current is commutating to the diode one last time and

slowly decaying to zero in tens or hundreds of milliseconds. Using this approach it is simple to produce

defined turn-off and turn-on events at T1 and T2, respectively: while the voltage level is set directly with

the DC link voltage VDC the current value is adjusted with the width of the first pulse (T1-T0). Figure 9.b

shows the current value as a function of the pulse width for the provided inductor and different DC link

voltages.

Then, the switch S2 is turning on and taking over the current again. After a few

2.

Figure 9 Double pulse testing: (a) schematic drawing of the current and voltage waveforms

during a double pulse test, (b) saturation behavior of the provided inductor

To perform a double pulse test on the evaluation board

1. Assemble the devices under test S1 and S2 as described in section 3.1.1.

2. Connect the driver to the proper emitter pin according to section 3.1.2.

a) Solder 0Ω resistors to R214/R224 when using three pin packages.

b) Solder 0Ω resistors to R213/R223 when using four pin packages.

3. Adjust the driving circuitry for S2 and, if necessary, also for S1 according to section 3.1.3.

a) Set the jumper X111/X121 to ADJ.

b) Use the jumper X112/X122 to set the turn-off voltage to 0V or -5V.

c) Adjust the turn-on and turn-off gate resistors R211/R221 and R212/R222, respectively.

4. Connect oscilloscope probes in order to measure VCE, VGE and IC of S2.

a) Measure VCE and VGE with ordinary voltage probes and grounding clips on the package. If

possible use the probe adapters introduced in section 2.2.

b) Measure IC using the probe adapter Id2. If possible use a coaxial shunt as recommended in 2.2.

5. Connect an auxiliary supply to the 12V/SGND terminals of the board and provide a voltage of 12V.

6. Connect a signal generator to X220 and provide a double pulse pattern with 5V amplitude. Please

note that this signal is referenced to SGND.

7. Check the gate voltage waveform on the oscilloscope and adjust it according to section 3.1.3.

Application Note 13 Revision 1.0

2017-11-15

Page 14

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Usage

8. If required, connect a power supply to the HEAT+/HEAT- terminals and set the voltage level

according to 3.1.4. Monitor the temperature using an ohmmeter connected to SENSE+/SENSE-.

9. Connect a high voltage source to VIN and PGND and short VIN and VOUT.

10. Slowly increase the voltage and monitor the current and voltage waveforms on the oscilloscope.

3.2.3 Efficiency or temperature measurements

Testing a particular semiconductor device inside a switching cell is essential for understanding its

switching behavior. However, it requires some calculation or simulation effort to translate the acquired

switching loss data into quantities that are more relevant for an application, such as the efficiency of the

converter, the temperature of the devices or the required cooling effort. By operating the evaluation

board in a continuous manner these values can be determined in a purely experimental and thus

straightforward way. The remainder of this section explains how to configure and run the board as a

buck converter as sketched in configuration (3) of Table 3.

Prior to running the evaluation board as a buck converter, some preparations are required:

1. Short circuit the shunt resistor R201 in order to avoid unnecessary power dissipation.

2. Disable the LEDs that indicate the presence of the DC link voltage by removing R134, R138 and

R142. Otherwise consider the power dissipation of this block: 1.6W at 800V.

3. Replace the heat sink

a) Unfasten the M3 screws that fix the heat sink to the board.

b) Pull the heat sink away from the board so that the spring clips fall off.

c) Unsolder the power resistor E200 and the NTC B200.

d) Remove the probe adapter Id2 from the board.

e) If necessary, solder the film capacitors C203 and C204 to the other side of the board.

f) Mount a reasonable heat sink. If possible put an insulation sheet between heat sink and board.

4. Replace the filter inductor

a) Disconnect the daughter card containing the inductor by unfastening the M4 screws.

b) Connect a custom inductor between the VMID and the VOUT potential.

After the preparation steps, the efficiency measurements can be performed.

1. Assemble the devices under test S1 and S2 as described in section 3.1.1.

2. Connect the driver to the proper emitter pin according to section 3.1.2.

a) Solder 0Ω resistors to R214/R224 when using three pin packages

b) Solder 0Ω resistors to R213/R223 when using four pin packages

3. Adjust the driving circuitry for S1 and, if necessary, also for S2 according to section 3.1.3.

a) Set the jumper X111/X121 to ADJ.

b) Use the jumper X112/X122 to set the turn-off voltage to 0V or -5V.

c) Adjust the turn-on and turn-off gate resistors R211/R221 and R212/R222, respectively.

4. Connect isolated voltage probes to measure the gate as well as the collector-emitter voltage of S1

and use a current probe to measure the inductor current.

5. Connect an auxiliary power supply to the 12V/SGND terminals of the board and provide a supply

voltage of 12V.

6. Connect a signal generator to X210 and provide a PWM signal with 5V amplitude. Please note that

this signal is referenced to SGND.

7. Check the gate voltage signal on the oscilloscope and adjust the turn-on voltage level to +15V using

the potentiometer R110.

8. Connect a high voltage source to VIN and PGND.

9. Connect an Ohmic load to VOUT and PGND.

10. If possible, measure the input and output power using a power meter and the device temperatures

using an infrared camera.

11. Slowly increase the input voltage while monitoring the waveforms and device temperatures.

Application Note 14 Revision 1.0

2017-11-15

Page 15

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Examples

Solution 1

Solution 2

Part number (IGBT and diode)

IKQ75N120CH3

IKY75N120CH3

Package

TO-247PLUS

TO-247PLUS 4pin

Junction temperature Tj=Tc

25°C

25°C

Switched voltage VCE

800V

800V

Switched current IC

5A-80A

5A-80A

Gate voltages V

GE(on)

+15V

+15V

Gate resistors R

G(on)

10Ω

10Ω

Driver Ground Connection

0Ω at R214 and R224

0Ω at R213 and R223

(a)

(b)

4 Examples

After the in-depth explanation of possible test settings and procedures that were provided in the previous

section, this section shows two practical examples: a switching loss and a temperature measurement.

4.1 Turn-on loss reduction with a 4pin package

As extensively explained in [2] on the basis of 650V TRENCHSTOP™ 5 IGBTs, the main advantage of

four-pin packages over three-pin packages is the reduction of turn-on losses, particularly at higher

current levels. The reason for that is the virtual elimination of the inductive coupling between the gate

and the commutation loop. This section demonstrates the positive impact of the Kelvin Emitter

connection, i.e. the fourth pin, on 1200V/75A HighSpeed 3 IGBTs. Table 4 summarizes the test cases.

Table 4 Turn-on loss comparison of TO-247PLUS 3pin and 4pin: test conditions

The evaluation board was set up as explained in section 3.2.2. Following the recommendations in

section 2.2, current measurements were made using a coaxial shunt and voltage probes were connected

via PCB adapters. Figure 10.a shows the evaluation board and the measurement hardware as the main

part of the setup – power supplies and the signal generator are not included in the picture.

Figure 10 Turn-on loss comparison of TO-247PLUS 3pin and 4pin: (a) main parts of the test

setup, (b) absolute and relative comparison of the measured losses

By multiplying VCE and IC on the oscilloscope the waveform of the momentary power dissipation was

calculated. Integration of this power waveform resulted in the turn-on energy values Eon which are shown

in Figure 10.b for different current levels and for both package variants. It is clearly visible that the

switching losses can be significantly reduced by going to a 4pin package. Since the Kelvin Emitter is

increasing di/dt, this is particularly true for higher current levels.

Application Note 15 Revision 1.0

2017-11-15

Page 16

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Examples

Solution 1

Solution 2

Solution 3

Part number IGBT

IKW40N120H3

IKQ75N120CH3

IKQ75N120CH3

Part number diode

IDW40G120C5B (1 leg)

IDW40G120C5B (2 legs)

IDW40G120C5B (2 legs)

Package

TO-247

TO-247PLUS

TO-247PLUS

Electrical isolation

(IGBT and heat sink)

Insulation sheet

Kapton, 1.3W/mK, 150µm

Insulation sheet

Kapton, 1.3W/mK, 150µm

Ceramic plate

Al2O3, 25W/mK, 1mm

Thermal grease

None

None

High performance: 6W/mK

Heat sink assembly

Clip 60N

Clip 60N

Clip 60N

Gate voltages VGE

+15V/-5V

+15V/-5V

+15V/-5V

Gate resistors RG

20Ω

10Ω

10Ω

Topology

Boost

Boost

Boost

Sw. frequency fsw

16kHz

16kHz

16kHz

Voltages Vin/V

out

400V/800V

400V/800V

400V/800V

Output power P

out

2kW

4kW

4kW

Heat sink temp. THS

60°C

60°C

60°C

Inductance L

2mH

1mH

1mH

4.2 Substituting parallel 40A devices with a 75A device

With IKQ75N120CH3 and IKY75N120CH3 Infineon has pioneered assembling 1200V/75A IGBTs and

full-rated diodes inside packages with a footprint of a standard TO-247. One interesting aspect of such

high current ratings is the potential to limit the number of parallel devices. This section demonstrates that

two parallel 40A IGBTs can be substituted by a single 75A IGBT.

Note: Reducing the number of parallel devices by using IGBTs with higher current ratings might

require a slight re-work of the isolation solution but simplifies both the power and the driving

circuitry, reduces the space required on PCB and heat sink, and eliminates potential current

sharing problems as well as the need for an according de-rating.

As listed in Table 5, three boost converter solutions consisting of 1200V HighSpeed 3 IGBTs and 1200V

CoolSiC™ Schottky diodes were compared. Solution 1 was considered as reference and used a 40A

IGBT together with a 20A diode operating at 2kW. Both devices were assembled on the same heat sink

using Kapton-based insulation sheets. Solution 2 and 3, on the other hand, consisted of 75A IGBTs and

40A diodes operating at 4kW. Thus, twice the power was processed with twice the chip size. While the

latter solutions were electrically identical, they differed in the insulation: solution 2 maintained the Kapton

sheets; solution 3 was equipped with an Al2O3 plate for insulating the IGBT. In order to achieve

comparability, care was taken to scale the semiconductor losses with the respective chip size. Besides

the output power, also the switching speed and the ripple current were adjusted accordingly.

Table 5 Comparison of the thermal performance of 40A and 75A IGBTs: test conditions

The evaluation board was set up as explained in section 3.2.3 with one exception: a boost converter was

implemented instead of a buck converter. Figure 11 shows the test setup including the custom inductor

and the custom heat sink. While the inductor was handmade, a LAM 3 K miniature cooling aggregate

from Fischerelektronik was used as heat sink. Since fan speed of this cooling aggregate is variable, the

temperature could be adjusted to the same value during all measurements. An infrared-camera was

used to monitor the heat sink and device temperatures, an oscilloscope to acquire the most relevant

waveforms. Due to the boost converter configuration, the gate and collector-emitter voltage could be

measured with simple passive probes. The inductor current was measured using a caliper-style current

probe.

Application Note 16 Revision 1.0

2017-11-15

Page 17

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Examples

Solution 1

Solution 2

Solution 3

IR camera picture

(same scale for all pictures)

IGBT temperature T

IGBT

79.4°C

98.1°C

82.8°C

Heat sink temperature THS

62.9°C

62.8°C

62.9°C

Temperature difference ΔT

16.5°C

35.3°C

19.9°C

The picture of the setup does not show the sources and loads. Besides the auxiliary supply which

provides the driving voltages, a high voltage DC source and an active DC load were utilized to provide

the required testing power of up to 4kW.

Figure 11 Comparison of the thermal performance of 40A and 75A IGBTs: test setup

Table 6 shows the resulting device and heat sink temperatures for all tested solutions. Please note that

the scale of the IR camera is kept the same throughout all cases. Thus not only the numeric values but

also the color shades are comparable.

Solution 1 is considered the reference solution because it resembles a situation with two parallel

40A IGBTs processing 4kW in total. While the test was only done with one IGBT processing 2kW one

can imagine a second, parallel IGBT which processes another 2kW. Assuming perfect current sharing

and a constant heat sink temperature, the temperature of the second IGBT would be equal to the one of

the first.

Table 6 Results of the temperature measurement: thermal performance of the solutions 1-3

Comparing the IGBT temperatures of solution 1 and solution 2 indicates that replacing two parallel 40A

devices with one 75A device can lead to a temperature increase if the insulation layer is kept the same.

Particularly for large chips with low thermal resistance values R

, the insulation sheet can become a

th(JC)

bottleneck in terms of thermal performance. To overcome this, it is recommended to use insulators with

a high thermal conductivity. One exemplary case is solution 3 where an Al2O3 ceramic is used to bring

the thermal performance of the 75A device to a level that is competitive with parallel 40A device.

Application Note 17 Revision 1.0

2017-11-15

Page 18

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Appendix

5 Appendix

5.1 Schematic drawing

Figure 12 Power and driving circuitry

Figure 13 Auxiliary supply and LED indicators

Application Note 18 Revision 1.0

2017-11-15

Page 19

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Appendix

5.2 Board layout

Figure 14 Layer 1 (top layer)

Figure 15 Layer 2

Application Note 19 Revision 1.0

2017-11-15

Page 20

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Appendix

Figure 16 Layer 3

Figure 17 Layer 4 (bottom layer)

Application Note 20 Revision 1.0

2017-11-15

Page 21

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Appendix

Designator

Description

Value

Package

Power Semiconductors

Q211

Power Semiconductor Switch

Infineon IKY75N120CH3

TO-247PLUS 4pin

Q221

Power Semiconductor Switch

Infineon IKY75N120CH3

TO-247PLUS 4pin

U211

Isolated Single Channel Driver

Infineon Technologies 1EDI60I12AH

PG-DSO-8-59

U221

Isolated Single Channel Driver

Infineon Technologies 1EDI60I12AH

PG-DSO-8-59

Ceramic Capacitors

C100 4u7 X7R 25V

C 0805

C101 100n X7R 25V

C 0805

C102 4u7 X7R 25V

C 0805

C110 100n X7R 25V

C 0805

C111 10u X7R 35V

C 0805

C112 10u X7R 35V

C 0805

C113 10u X7R 35V

C 0805

C120 100n X7R 25V

C 0805

C121 10u X7R 35V

C 0805

C122 10u X7R 35V

C 0805

C123 10u X7R 35V

C 0805

C200 470pF C0G 50V

C 0805

C201 TDK Z63000Z2910Z 1 Z21

C202 TDK Z63000Z2910Z 1 Z21

C211 4u7 X7R 25V

C 0805

C212 4u7 X7R 25V

C 0805

C221 4u7 X7R 25V

C 0805

C222 4u7 X7R 25V

C 0805

C312 100n X7R 25V

C 0805

C322 100n X7R 25V

C 0805

Film Capacitors

C203 EPCOS TDK B32654A7224

C204 EPCOS TDK B32654A7224

C205 EPCOS B32778G1276

C206 EPCOS B32778G1276

C207 EPCOS B32776T1275

C208 EPCOS B32776T1275

C209 EPCOS B32776T1275

Light Emitting Diodes

D131 Vishay VLMT3100-GS08

D132 Vishay VLMT3100-GS08

D133 Vishay VLMT3100-GS08

D134 Vishay VLMT3100-GS08

D151 Vishay VLMC3100-GS08

D152 Vishay VLMC3100-GS08

D161 Vishay VLMC3100-GS08

D162 Vishay VLMC3100-GS08

D171 Vishay VLMA3100-GS08

D172 Vishay VLMA3100-GS08

Thick Film Resistors

R111 2k (1.8k) 1%

R 0805

R112 1k 1%

R 0805

R121 2k (1.8k) 1%

R 0805

R122 1k 1%

R 0805

R131 300k

R 2512

R132 300k

R 2512

R133 300k

R 2512

R134 300k

R 2512

R135 300k

R 2512

R136 300k

R 2512

5.3 Bill of materials

Application Note 21 Revision 1.0

2017-11-15

Page 22

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Appendix

R137 300k

R 2512

R138 300k

R 2512

R139 300k

R 2512

R140 300k

R 2512

R141 300k

R 2512

R142 300k

R 2512

R151 2k2

R 0805

R161 270R

R 0805

R171 1k0

R 0805

R200 100R 1%, 25ppm/K

R 0805

R215 4k7

R 0805

R225 4k7

R 0805

R311 4k7

R 0805

R312 0R

R 0805

R321 4k7

R 0805

R322 0R

R 0805

Metal Foil Resistors

R201 Ohmite FCSL76R050FER

MiniMELF Resistors

R211 10R 1%

R MMA 0204

R212 10R 1%

R MMA 0204

R213 0R 1%

R MMA 0204

R221 10R 1%

R MMA 0204

R222 10R 1%

R MMA 0204

R223 0R 1%

R MMA 0204

Connectors

X111 Samtec TSW-102-07-L-D

X112 Samtec TSW-102-07-L-D

X121 Samtec TSW-102-07-L-D

X122 Samtec TSW-102-07-L-D

X201 Phoenix Contact 1812885

X202 Phoenix Contact 1827907

X204 Wurth Elektronik 93473

X205 Wurth Elektronik 93473

X206 Wurth Elektronik 93473

X210 TE Connectivity 5-1814400-1

X220 TE Connectivity 5-1814400-1

X801 Phoenix Contact GMSTB 2,5 HCV/ 4-ST-7,62-LR - 1812775

X802 Phoenix Contact MC 1,5/ 6-STF-3,81 - 1827745

Mechanical

A201

Heat Sink

Fischer Elektronik SK 492 50 SA

MC821

Screw

M3 x 15mm, metal

MC822

Screw

M3 x 15mm, metal

MP801

Spacer bolt, hexagon

M3 x 60mm

MP802

Spacer bolt, hexagon

M3 x 60mm

MP803

Spacer bolt, hexagon

M3 x 60mm

MP804

Spacer bolt, hexagon

M3 x 60mm

MP805

Spacer bolt, hexagon

M3 x 10mm

MP806

Spacer bolt, hexagon

M3 x 10mm

MP807

Spacer bolt, hexagon

M3 x 10mm

MP808

Spacer bolt, hexagon

M3 x 10mm

MP811

Metal tube

ETTINGER 05.53.053

MP812

Metal tube

ETTINGER 05.53.053

MP813

Metal tube

ETTINGER 05.53.053

MP814

Metal tube

ETTINGER 05.53.053

MP831

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP832

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP833

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP834

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

Application Note 22 Revision 1.0

2017-11-15

Page 23

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Appendix

MP835

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP836

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP837

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP838

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP839

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP840

Press Fit Pin

Mill-Max 8979-0-00-15-00-00-03-0

MP841

Isolation Foil

Bergquist Sil-Pad K10

MP842

Isolation Foil

Bergquist Sil-Pad K10

MP851

Spring Clip for TO-247

Fischerelektronik THFU 2

MP852

Spring Clip for TO-247

Fischerelektronik THFU 2

MP853

Spring Clip for TO-247

Fischerelektronik THFU 2

MP854

Spring Clip for TO-220

Fischerelektronik THFU 3

Others

B200

NTC Resistor

US Sensor TO103J2F

E200

Power Resistor

Vishay LTO100F4R700FTE3

G100

Voltage Regulator

Infineon Technologies TLE4264-2G

G111

Isolated DC/DC

MuRata MGJ2D122005SC

G112

Voltage Regulator

Infineon Technologies IFX25401TEV

G121

Isolated DC/DC

MuRata MGJ2D122005SC

G122

Voltage Regulator

Infineon Technologies IFX25401TEV

Id2

Oscilloscope Probe Adapter

LeCroy PK106-4

R110

Potentiometer

Vishay T93YA502KT20

R120

Potentiometer

Vishay T93YA502KT20

Application Note 23 Revision 1.0

2017-11-15

Page 24

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

References

References

[1] Infineon Technologies AG: AN2017-01, TO247PLUS – Description of the packages and assembly

guidelines, Revision 2.0, 2017-02-10

[2] Infineon Technologies AG: TRENCHSTOP™ 5 IGBT in a Kelvin Emitter Configuration –

Performance Comparison and Design Guidelines, Revision 1.0, 2014-10-16

[3] Markus Billmann: Coaxial Shunts – Technical Data, http://www.ib-billmann.de/, May 2014

[4] PMK: Products – 5mm-L Probe Acessories, http://www.pmk.de/en/products/5_0_mm_l_zubehoer,

September 2017

[5] Teledyne LeCroy: Probes – Probe Parts and Kits – Probe Tip to PCB Adapter – PK106-4,

http://teledynelecroy.com/probes/probemodel.aspx?modelid=96&categoryid=3&mseries=434,

September 2017

Application Note 24 Revision 1.0

2017-11-15

Page 25

1200V HighSpeed 3 IGBT in TO-247PLUS Evaluation Board

User Manual

Revision History

Page or Reference

Description of change

--

Revision 1.0 – First Release – Klaus Sobe

Revision History

Major changes since the last revision

Application Note 25 Revision 1.0

2017-11-15

Page 26

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2017-11-15

AN2017-44

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2017 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information contained in this application

note is given as a hint for the implementation of

the product only and shall in no event be

regarded as a description or warranty of a

certain functionality, condition or quality of the

product. Before implementation of the product,

the recipient of this application note must verify

any function and other technical information

given herein in the real application. Infineon

Technologies hereby disclaims any and all

warranties and liabilities of any kind (including

without limitation warranties of non-infringement

of intellectual property rights of any third party)

with respect to any and all information given in

this application note.

The data contained in this document is

exclusively intended for technically trained staff.

It is the responsibility of customer’s technical

departments to evaluate the suitability of the

product for the intended application and the

completeness of the product information given in

this document with respect to such application.

For further information on the product,

technology, delivery terms and conditions and

prices please contact your nearest Infineon

Technologies office (www.infineon.com).

Please note that this product is not qualified

according to the AEC Q100 or AEC Q101

documents of the Automotive Electronics

Council.

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information

on the types in question please contact your

nearest Infineon Technologies office.

Except as otherwise explicitly approved by

Infineon Technologies in a written document

signed by authorized representatives of Infineon

Technologies, Infineon Technologies’ products

may not be used in any applications where a

failure of the product or any consequences of the

use thereof can reasonably be expected to result

in personal injury.

Loading...

Loading...