Page 1

User Guide Please read the Important Notice and Warnings at the end of this document V 1.0

www.infineon.com page 1 of 22 2020-10-20

UG2020-10

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge

modules

About this document

The purpose of this board is to enable the evaluation of the FF6MR12KM1, FF3MR12KM1 and FF2MR12KM1

CoolSiC™ MOSFET modules. The evaluation board allows users to evaluate the device performance via doublepulse measurements.

Scope and purpose

The properties of this board are described in the design features’ chapter of this document. The remaining

sections provide information to enable designers to copy, modify and qualify the design for production,

according to the customer-specific requirements.

Environmental regulations have been considered in the design of the EVAL-FFXMR12KM1DR board.

Components qualified for a lead-free, reflow soldering process have been selected. The design has been tested

as described in this document, but not qualified regarding manufacturing and operation over the whole

operating temperature range or lifetime.

Intended audience

This document is intended for engineers who want to document and evaluate the switching performance of

Infineon CoolSiC™ 62 mm modules.

Evaluation board

This board will be used during design-in, for evaluation and measurement of characteristics, and proof of

datasheet specifications.

Note: PCB and auxiliary circuits are NOT optimized for final customer design.

Page 2

User guide 2 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

Important notice

Important notice

“Evaluation Boards and Reference Boards” shall mean products embedded on a printed circuit board

(PCB) for demonstration and/or evaluation purposes, which include, without limitation, demonstration,

reference and evaluation boards, kits and design (collectively referred to as “Reference Board”).

Environmental conditions have been considered in the design of the Evaluation Boards and Reference

Boards provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards

has been tested by Infineon Technologies only as described in this document. The design is not qualified

in terms of safety requirements, manufacturing and operation over the entire operating temperature

range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the

same procedures as regular products regarding returned material analysis (RMA), process change

notification (PCN) and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production.

The Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards

(including but not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other

requirements of the country in which they are operated by the customer. The customer shall ensure that

all Evaluation Boards and Reference Boards will be handled in a way which is compliant with the relevant

requirements and standards of the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and

managed according to the terms and conditions set forth in this document and in other related

documentation supplied with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the

Evaluation Boards and Reference Boards for the intended application, and to evaluate the completeness

and correctness of the information provided in this document with respect to such application.

The customer is obliged to ensure that the use of the Evaluation Boards and Reference Boards does not

cause any harm to persons or third party property.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is"

and Infineon Technologies disclaims any warranties, express or implied, including but not limited to

warranties of non-infringement of third party rights and implied warranties of fitness for any purpose, or

for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation

Boards and Reference Boards and/or from any information provided in this document. The customer is

obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or

damages arising out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided

herein at any time without further notice.

Page 3

User guide 3 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

Safety precautions

Safety precautions

Note: Please note the following warnings regarding the hazards associated with development systems.

Warning: The DC link potential of this board is up to 1000 VDC. When measuring voltage

waveforms by oscilloscope, high voltage differential probes must be used. Failure to do

so may result in personal injury or death.

Warning: The evaluation or reference board is connected to the grid input during

testing. Hence, high-voltage differential probes must be used when measuring voltage

waveforms by oscilloscope. Failure to do so may result in personal injury or death.

Darkened display LEDs are not an indication that capacitors have discharged to safe

voltage levels.

Caution: Only personnel familiar with the drive, power electronics and associated

machinery should plan, install, commission and subsequently service the system.

Failure to comply may result in personal injury and/or equipment damage.

Caution: The evaluation or reference board contains parts and assemblies sensitive to

electrostatic discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with electrostatic

control procedures, refer to the applicable ESD protection handbooks and guidelines.

Caution: The evaluation or reference board is shipped with packing materials that

need to be removed prior to installation. Failure to remove all packing materials that

are unnecessary for system installation may result in overheating or abnormal

operating conditions.

Page 4

User guide 4 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

Table of contents

Table of contents

About this document ....................................................................................................................... 1

Important notice ............................................................................................................................ 2

Safety precautions .......................................................................................................................... 3

Table of contents ............................................................................................................................ 4

1 The board at a glance .............................................................................................................. 5

1.1 Delivery content ...................................................................................................................................... 5

1.2 Main features ........................................................................................................................................... 5

1.3 Typical applications ................................................................................................................................ 5

1.4 Board parameters and technical data .................................................................................................... 6

2 System and functional description ........................................................................................... 7

2.1 Commissioning ........................................................................................................................................ 7

2.2 Description of the functional blocks ....................................................................................................... 7

2.3 Active voltage clamping .......................................................................................................................... 8

3 System design........................................................................................................................ 9

3.1 Schematics .............................................................................................................................................. 9

3.2 Layout .................................................................................................................................................... 10

3.3 Bill of material ....................................................................................................................................... 12

3.4 Connector details .................................................................................................................................. 12

4 System performance ............................................................................................................. 14

4.1 Switching performance ......................................................................................................................... 15

4.1.1 MOSFET switch-on behavior ............................................................................................................ 15

4.1.2 MOSFET switch-off behavior ............................................................................................................ 17

4.1.3 Switching behavior of body diode ................................................................................................... 18

4.1.4 Conclusion of the measurement results: ........................................................................................ 19

4.2 Thermal performance ........................................................................................................................... 19

5 References and appendices .................................................................................................... 20

5.1 Abbreviations and definitions ............................................................................................................... 20

5.2 References ............................................................................................................................................. 20

5.3 Additional information .......................................................................................................................... 20

Revision history ............................................................................................................................. 21

Page 5

User guide 5 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

The board at a glance

1 The board at a glance

An industrial benchmark technology in a 62 mm package, the CoolSiC™ Trench MOSFET opens and enlarges the

semiconductor module market for high-volume applications. CoolSiC™ Trench MOSFETs allow modern inverter

designs with never-before-seen levels of efficiency and power density. The evaluation board allows the

customer to begin initial characterization measurements very quickly.

1.1 Delivery content

The board appears as shown in Figure 1. It is important to note that the gate resistors are left empty to be

equipped with individual values in line with the customer’s needs. The recommended resistor type is shown in

Chapter 2.2. A suitable connection of the active-clamp solder pins has to be established to use this function and

make the device safe in case of an overvoltage event at turn-off.

Figure 1 EVAL-FFXMR12KM1DR connected to a 62 mm CoolSiC™ Trench MOSFET moduleBlock

diagram

1.2 Main features

Half-bridge driver for 62 mm modules with CoolSiC™ Trench MOSFET technology

Electrically and mechanically suitable for 600 V 62 mm modules with CoolSiC™ Trench MOSFET technology

Negative voltage adjustment from -5 V to 0 V

Positive voltage adjustment for high switching frequencies

Proper PCB design to limit the PCB heating during operation

1.3 Typical applications

High frenquency switching applications

DC/DC converter

Solar application

UPS systems

Page 6

User guide 6 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

The board at a glance

1.4 Board parameters and technical data

The EVAL-FFXMR12KM1DR is a gate driver board for driving 62 mm modules with our latest CoolSiC™ Trench

MOSFET technology in a half-bridge configuration. It shows a reliable and fast controllability of such devices

using the famous 1EDI20I12AH compact driver together with a booster stage to increase the driver output

power.

The EVAL-FFXMR12KM1DR operates with a supply voltage of up to 24 V. It generates an output voltage of up to

18 V at the gate terminals, depending on the load conditions. To switch the device, a pulse width modulation

(PWM) for both, the top and the bottom side need to be applied at the connector input. A negative signal at the

enable pin turns off the device. The detailed description of the functional blocks is shown in the next chapter.

Table 1 Parameter

Parameter

Symbol

Conditions

Value

Unit

Input voltage

Vin +24

V

PWM input for top switch

PWMTOP

0/+15

V

PWM input for bottom switch

PWMBOT

0/+15

V

Enable signal

ENABLE

Set to 0V to disable

0/+15

V

Negative gate source voltage

V

GS,neg

-5,9…0

V

Positive gate source voltage

V

GS,pos

+15…+18

V

Page 7

User guide 7 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System and functional description

2 System and functional description

2.1 Commissioning

The EVAL-FFXMR12KM1DR is powered up at the phoenix-MCV, two-pin connector as shown in Figure 2. The

input signals are attached by using a 10-pin, flat cable connector. Further details about the pin connector are

shown in Chapter 3.4.

Proper gate resistors need to be soldered onto the board, based on the customer switching conditions. A

detailed explanation for selecting the suitable resistors is explained in the next chapter.

The module is soldered onto the gate terminals of the 62 mm module. A suited probe tip adaptor can be

soldered next to the gate terminals to measure the gate source voltage (VGS).

Figure 2 Overview of the functional blocks of the EVAL-FFXMR12KM1DR

2.2 Description of the functional blocks

The most important functional blocks are shown in Figure 2.

The on-board isolated DC/DC converter generates an output voltage of up to 18 V depending on the load

conditions. The transformer used has a working voltage of 848 V

rms

, providing a sufficient safety margin to

handle our 62 mm devices. The positive voltage is fed to the secondary side of the driver circuit directly,

whereas the negative voltage is adjustable from -5.9 V to -0.4 V by using the jumper settings shown in Figure 4.

Figure 3 Jumper settings for the negative voltage adjustment V

neg

Page 8

User guide 8 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System and functional description

The adjustable output voltage (Vneg) can be calculated by the equation given in Figure 4.

Figure 4 Equation to calculate Vneg for the negative gate voltage adjustments

The EVAL-FFXMR12KM1DR is equipped with the single-channel isolated gate driver 1EdI20H12AH. This compact

driver has two input modes IN+ and IN- to control the switch. The PWM is connected to the IN+ pin, whereas the

IN- pin is used for the enable signal. The enable signal can be used to switch off the device with an external

signal that is set to low.

The output of the driver is connected to a push-pull booster stage to increase the output power of the driver

stage. Further details about the design of booster stages can be found in External Booster for Driver IC [1].

The gate resistors are not included and need to be soldered on the board according to customer needs. Metal

electrode leadless faces (MELF) packages are recommended, since they are very robust in terms of impulse

currents, and offer a long-term reliability under thermal stress. Two resistors can be attached in parallel for

both the external gate turn-on resistance (R

G,on

) and the external gate turn-off resistance (R

G,off

) signal path.

2.3 Active voltage clamping

Please make sure to also connect the drain sense contacts of the EVAL-FFXMR12KM1DR driver board as shown

in Figure 5. This picture shows a vertical positioning of the driver board that is also possible in case other

components, e.g. the DC link do not allow a horizontal placement of the driver that is close to the module.

Active clamping is used to keep the V

DS

overvoltage below V

DSS

when switching off the MOSFET. A series

connection of TVS diodes is used to protect the device once an overvoltage occurs while turning off a short

cicuit or overcurrent. During such an event, a current is shared between the gate of the MOSFET and the driver

output once the overvoltage is exceeding the breakdown voltage of the diodes. This leads to an increasing gate

source voltage and the turn off event is interrupted.

Figure 5 Example of a vertical connection and the drain sense connection of the driver board.

Page 9

User guide 9 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System design

3 System design

The FFXMR12KM1DR is a simple driver board for evaluating the switching performance of our 62 mm module

including our new CoolSiC™ Trench MOSFET technology. All functional blocks are designed to show a simple

circuit approach to accommodate the best performance of our new SiC devices.

3.1 Schematics

The schematics that are shown here are just an excerpt from the entire documentation that can be found in the

PCB design data of the EVAL-FFXMR12KM1DR board homepage at www.infineon.com.

Figure 6 Positive power supply VDRV

The linear voltage regulator IFX27001 in a DPAK package is used to deliver an accurate supply voltage (VDRV),

which is used as supply voltage of the push-pull stage at the isolated DC-DC converter. The positive voltage

(VDRV) can be adjusted by the external voltage devider of and

as shown in Figure 7. Please also see the

datsheet of the IFX27001 for additional information. Please consider that the actual isolated supply voltage of

the driver section (VISO) depends on the load conditions.

Figure 7 Calculation to set the positive output voltage of the IFX27001

The widely-known IR2085S is used as half-bridge driver as shown in Figure 8. This approach can also be used to

generate a galvanic isolation of two independent driver stages, e.g. of a full bridge or a 3-phase topology as

shown in the CoolSiC™ MOSFET motor drives evaluation board for 7.5 kW [2].

Page 10

User guide 10 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System design

Figure 8 Isolated DC-DC converter using the IR2085S

3.2 Layout

The layer stack of the board consists of four layers, including the top, bottom and two internal layers. The top

layer is used for the direct connection of signals of most of the components as shown in Figure 9. The bottom

layer is used to feed in the negative output signals –VISO on the secondary side that is the driver output side of

the board. The internal layers 1 and 2 are used to improve the driver output signals against noise as shown in

Figure 11 and Figure 12. The internal layer 1 is used for the ground signal of the secondary side and to route the

signals of the driver output to the booster stage. The Gerber and ODB++ files can also be accessed via the PCB

design data tab of the EVAL-FFXMR12KM1DR board homepage at www.infineon.com.

Figure 9 FFXMR12KM1DR with the top layer highlighted

Page 11

User guide 11 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System design

Figure 10 FFXMR12KM1DR with the bottom layer highlighted

Figure 11 FFXMR12KM1DR with the internal layer 1 highlighted

Page 12

User guide 12 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System design

Figure 12 FFXMR12KM1DR with the internal layer 2 highlighted

3.3 Bill of material

Please see the most important components of the board in Table 2. Please note that the detailed BOM of the

EVAL-FFXMR12KM1DR is available at www.infineon.com.

Table 2 BOM of the most important/critical parts of the evaluation or reference board (example)

S. No.

Ref Designator

Description

Manufacturer

Manufacturer P/N

55

U1

INFINEON_SiC_62mm_Module

Infineon

FF6MR12KM1

56

U2_R1, U2_R2

INFINEON_IFX20001MBV50HTSA1

Infineon

IFX20001MBV50HTSA1

58

U4_P1, U4_P2

INFINEON_1EDI20H12AH

Infineon

1EDI20H12AH

59

U5

IR2085S

Infineon

AUIR2085STR

60

U6

INFINEON_IFX27001TFV

Infineon

IFX27001TFV

61

U7

INFINEON_IFX30081SJVXUMA1

Infineon

IFX30081SJVXUMA1

3.4 Connector details

Table 3 Connector X1

PIN

Label

Function

X1.1

+24VIN

24 V input

X1.2

GND

Input ground

Page 13

User guide 13 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System design

Table 4 Connector X2

PIN

Label

Function

X2.1

+24VIN

24 V output

X2.2

GND

Input ground

X2.3

PWMTOP

PWM for high side

X2.4

GND

Input ground

X2.5

PWMBOT

PWM for bottom side

X2.6

GND

Input ground

X2.7

ENABLE

Enable signal // Set to low to disable the output of the drivers

X2.8

GND

Input ground

X2.9

+15V

15 V output

X2.10

GND

Input ground

Page 14

User guide 14 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System performance

4 System performance

Figure 13 captures the test setup and voltage measurement techniques for double-pulse testing. The first turnon pulse of the low-side device (S2) establishes the desired current value (e.g. nominal data sheet current in

this case) in the inductive load, and the turn-off pulse makes the current flow in the freewheeling diode (e.g.

body diode of the top device S1 in this case). An external inductance value was used in the actual test setup.

The second turn-on pulse measures the low-side device turn-on characteristics, which also include the reverse

recovery of the freewheeling body diode.

Figure 13 Test setup and voltage measurement techniques

Page 15

User guide 15 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System performance

4.1 Switching performance

This chapter presents some examples of extracted waveforms of the module FF2MR12KM1, which has been

characterized with the help of the evaluation board.

One key aspect in designing half-bridge topologies with SiC MOSFET devices is to investigate the parasitic turnon of the upper switch during switching of the lower switch, and vice versa. This effect may be caused by a high

dv/dt of a SiC MOSFET, which can exceed 50 kV/µs for a CoolSiC™ MOSFET.

To mitigate the situtation, two approaches have been considered here.

As a first approach, different gate source voltages (VGS = -5…0 V / +15…18 V) are used to drive the gate of the

device. In the case of unipolar switching, the dv/dt can be reduced by using larger gate resistance to mitigate

the parasitic turn-on events. This is a significant advantage demonstrating the simple gate controllability of

CoolSiC™ MOSFET devices.

4.1.1 MOSFET switch-on behavior

The negative output voltage of the board was adjusted from -5 V to 0 V as shown in Figure 14.

The closer the voltage gets to the edge of a gate source voltage of 0 V, the fewer oscillations can be observed for

the drain current (ID) and the drain source voltage (VDS).

Figure 14 Turn-on waveforms with different gate source voltages(V

GS

= -5 … 0 V / +15 V)

Page 16

User guide 16 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System performance

Figure 15 Turn-on losses (E

on

) with different gate source voltages (VGS = -5V … 0 V/ +15 V) and different

driver cable lengths

The influence of the length of the gate cable was observed by soldering drilled cables (8 cm/ 20 cm) onto the

gate-source terminals of the board and the gate-source terminals of the module. The results of the measured

turn-on losses (Eon) are shown in Figure 15. One can see the influence of both, the different negative gate source

voltages VGS and the different cable lengths from the driver to the device. The influence of the negative value of

VGS has a small impact on the switching curves and therefore on the switching losses. The influence of the

length of the gate/ source connection remains within the range of measurement uncertainty. Figure 16 shows

the influence of a typical value for VGS, where a higher value for the positive voltage leads to faster switching,

reducing the turn on losses with a smaller R

DS on

.

Figure 16 Turn on waveforms of typical bipolar voltage values with V

GS

= -3…+15 V /…+18 V.

Page 17

User guide 17 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System performance

4.1.2 MOSFET switch-off behavior

The turn-off switching with different bipolar voltage levels was observed by changing the R

G,off

in a way that the

gate current stays the same for each testing sequence. The waveforms during turn-off are shown in Figure 17

showing the same course of the current and voltage curves for the different negative values of VGS.

Figure 17 Turn-off waveforms with different gate source voltages (V

GS

= -5… 0 V/ +15 V)

The previous findings can also be applied when considering Figure 18, where the turn-off losses (E

off

) for

different negative gate source voltages and different lengths of the driver connection are shown. Please notice

that for each individual negative gate-source voltage, the gate current was the same by adjusting the R

G,off

.

Figure 18 Turn-off losses with different gate-source voltages (V

GS

= -5… 0 V/ +15 V) and different driver

cable lengths

-5 -4 -3 -2 -1 0

0,000

0,005

0,010

0,015

0,020

0,025

0,030

0,035

E

off

[J]

V

GS

[V]

direct

8cm cable

20cm cable

-1,5

Page 18

User guide 18 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System performance

4.1.3 Switching behavior of body diode

Although the body diode causes few losses, it is a good illustration of parasitic switch-on. Observing the

switching curves during the recovery of the body diode, one can see that both the curve of the drain current as

well as the drain-source voltage become very smooth. This is dependent on the value of the negative VGS,

leading to a parasitic switch-on.

Figure 19 Body diode turn-off with different gate source voltages (V

GS

= -5…0 V /+15 V)

The influence of the cable length on the parasitic switch-on was observed, and shows an influence on the

recovery losses (E

rec

) of the body diode as illustrated in Figure 20. Although the influence of the cable length on

the recovery losses is relatively high, the total value of E

rec

is still very low in comparison to the total switching

losses. The recovery losses are not shown in the datasheets, since the typical recovery losses are close to zero.

Figure 20 Recovery losses of body diode with different gate source voltages (V

GS

= -5…0 V /+15 V) and

different cable length

Page 19

User guide 19 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

System performance

4.1.4 Conclusion of the measurement results:

Adapted gate-source voltage (V

GS

= -5… 0 V / +15… +18 V)

− Turn-on losses rise slightly with higher V

GS

going from -5 V to 0 V

− Turn-off losses at the same level (same gate current modified with R

g

)

− Turn-on losses with a gate-source voltage of 18 V for faster switching and lower conduction losses due to

lower R

DS on

− We recommend switching to a device with a gate-source voltage that is V

GS

= -3 V/+18 V to gain the

highest power-handling capability (lowest R

DS on

)

Different gate-cable lengths (direct / 8 cm / 20 cm)

− Turn-on losses and turn-off losses at the same level

− Gate cable length longer than 20 cm were not considered

Parasitic turn-on

− Parasitic turn-on rises from V

GS

= -3…0 V leading to a reduction of oscillations and slightly higher turn-on

losses

− Turn-off losses at the same level (gate current modified with R

goff

)

− A slight parasitic turn-on can be targeted to keep oscillation low, with slightly higher losses. CoolSiC™

MOSFET technology has a high robustness against parasitic turn-on

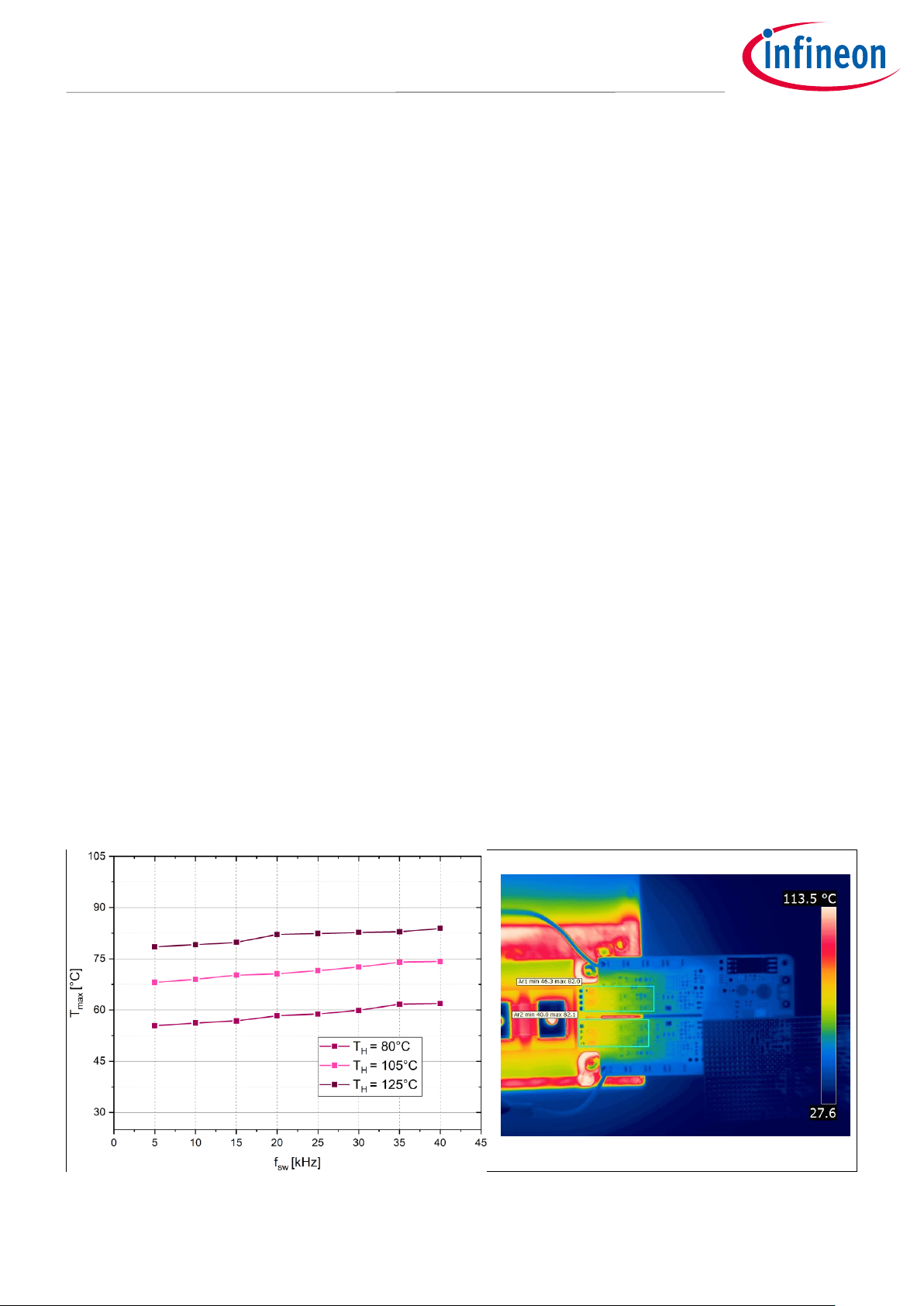

4.2 Thermal performance

The thermal performance of the device for switching a FF2MR12KM1 with up to 40 kHz was tested. The module

was attached to a heat plate. The temperature of the heat plate (TH) was set to 80°C, 105°C and 125°C for 10

minutes each, before the observation of the board was recorded. The surface of the evaluation board was

scanned with an IR camera to observe the temperature of the components, e.g. the driver IC, booster stage and

the gate resistors. The gates were switched with an amplitude of -5 V to +18 V. The results of the thermal

analysis is shown in Figure 21. The observed temperatures of the components remain far below the critical

value of 105 °C.

Figure 21 Thermal performance of the board (left) and an IR picture of the setup (right).

Page 20

User guide 20 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

References and appendices

5 References and appendices

5.1 Abbreviations and definitions

Table 5 Abbreviations

Abbreviation

Meaning

CE

Conformité Européenne

TVS

Transient Voltage Suppressor

PWM

Pulse Width Modulation

UL

Underwriters Laboratories

5.2 References

[1] Infineon Technologies AG. AN2013-10 (Rev. 2014): External Booster for Driver IC V 1.6 www.infineon.com

[2] Infineon Technologies AG. AN2019-25: CoolSiC™ MOSFET motor drives evaluation board for 7.5 kW - Eval-

M5-E1B1245N-SiC www.infineon.com

5.3 Additional information

The power board is now available for customers in small order quantities.

Page 21

User guide 21 of 22

2020-10-20

EVAL-FFXMR12KM1DR user guide

Evaluation board for 1200 V CoolSiC™ MOSFET 62 mm half-bridge modules

Revision history

Revision history

Document

version

Date of release

Description of changes

1.0

2020-10-20

Initial version

Page 22

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-10-19

UG 2020-10

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Loading...

Loading...