Page 1

Driver SBC

Evaluation Board

Getting Started

Rev 1.0 2013-08-02

Automoti v e Power

Page 2

Driver SBC Evaluation Board

Revision History: Rev 1.0, 2013-08-02

Previous Version: none

Page Subjects (major changes since last revision)

Driver SBC Evaluation Board

Getting Started

Driver SBC Evaluation Board 2 Rev 0.2, 2011-11-14

Page 3

Driver SBC Evaluation Board

Getting Started

Table of Contents

Table of Contents

1 Abstract...............................................................................................................................................4

2 Introduction ........................................................................................................................................4

3 Hardware .............................................................................................................................................5

3.1 Box Contents........................................................................................................................................5

3.2 Application Board overview ..................................................................................................................6

3.2.1 Circuit Description and Layout .............................................................................................................6

3.3 Hardware Settings................................................................................................................................8

3.3.1 Power Settings .....................................................................................................................................8

3.3.2 Jumper Overview & Settings ................................................................................................................8

4 Software ..............................................................................................................................................9

4.1 Software Installation .............................................................................................................................9

4.2 Getting Started ...................................................................................................................................10

4.2.1 Infineon Driver SBC Evaluation Board GUI .......................................................................................11

4.2.2 ‘Driver SBC Functional Test’ tab ........................................................................................................12

4.2.3 ‘SPI Command’ tab ............................................................................................................................16

4.2.4 ‘SPI Program’ tab ...............................................................................................................................19

4.2.5 ‘Run SPI Program’ tab .......................................................................................................................22

5 Additional Information .....................................................................................................................24

Driver SBC Evaluation Board 3 Rev 0.2, 2011-11-14

Page 4

Driver SBC Evaluation Board

Getting Started

1 Abstract

Note: The following information is given as a hint for the implementation of the device only and shall not be

regarded as a description or warranty of a certain functionality, condition or quality of the device.

This Evaluation Board description is intended to provide an overview to the hardware and software operation of

the Driver SBC Evaluation Board. The Evaluation Board can work with the following devices:

TLE9264QX/-2QX

TLE9266QX/-2QX

TLE9268QX/-2QX

For simplification reasons, the document it will be referred to the Driver SBC Evaluation Board

2 Introduction

Driver SBC family is designed specifically for automotive applications such as Door, Seat Control, HVAC, Body

Controller. The devices include a LIN and/or CAN physical interface.

The Driver SBC Evaluation Board is intended to provide a simple, easy-to-use tool for getting familiar with the

device and for first application tests. The Evaluation Board contains a Driver SBC application board, which is

equipped with a 96-pin connector to interface to the Power Easy kit (microcontroller board).

The Power Easy Kit is a testing and development platform to be used with Infineon devices. This kit uses a

16-bit microcontroller of the XC2000 processor family based on the high-performance C166S V2 core. The

Power Easy Kit board is designed with a special 96-pin connector for board extension test capability, i.e. to

interface with an application board such as the Driver SBC.

The Driver SBC SPI communication is emulated by the Power Easy Kit which is controlled by a PC-Software

(also included in the demo-kit wih installation instructions).

Please note that the uC Power Easy Kit needs to be obtained separately.

Driver SBC Features:

Very low quiescent current consumption in Stop- and Sleep Mode

Periodic cyclic sense in Normal-, Stop- and Sleep Mode

Periodic cyclic wake in Normal- and Stop Mode

Low-Drop Voltage Regulator 5V, 250mA

Low-Drop Voltage Regulator 5V, 100mA, robust against short to VS

High-Speed CAN Transceiver ISO11898-2/5 with Partial Networking

LIN Transceiver LIN2.1, J2602

Two Low-Side Outputs for Relay Drive with active zener clamping

Two High-Side Output 2Ω typ., four High-Side Outputs 7Ω typ., e.g. for LED lighting, cyclic sensing, etc.

Four independent PWM generators and two On/Off Timers

Three universal High-Voltage Wake Inputs for voltage level monitoring with cyclic sense functionality

Alternate High-Voltage Measurement Function, e.g. for battery voltage sensing

One universal Low-Voltage Wake Input for voltage level monitoring with cyclic sense functionality

SYNC input for external cyclic sense control via micro controller

Reset Output and Fail Output

Over temperature and short circuit protection feature

Wide input voltage and temperature range

Green Product (RoHS compliant) & AEC Qualified

Driver SBC Evaluation Board 4 Rev 0.2, 2011-11-14

Page 5

Driver SBC Evaluation Board

96-pin

connector

Getting Started

3 Hardware

The Driver SBC Evaluation Board is designed to be compatible with the Easy Kit Microcontroller Evaluation

Board. The Easy Kit plugs into the Evaluation Board via a standard 96-pin connector and allows easy interface

to the microcontroller via USB for SPI, CAN, LIN communication etc.

3.1 Box Contents

The following items are included in the Driver SBC Evaluation Board box:

Application Evaluation Board (Connection to the Power Easy Kit via 96-pin connector)

Note: The uC Power Easy Kit needs to be obtained separately

Figure 1 Power Easy Kit (left) connecting to the Driver SBC Evaluation Board (right)

Driver SBC Evaluation Board 5 Rev 0.2, 2011-11-14

Page 6

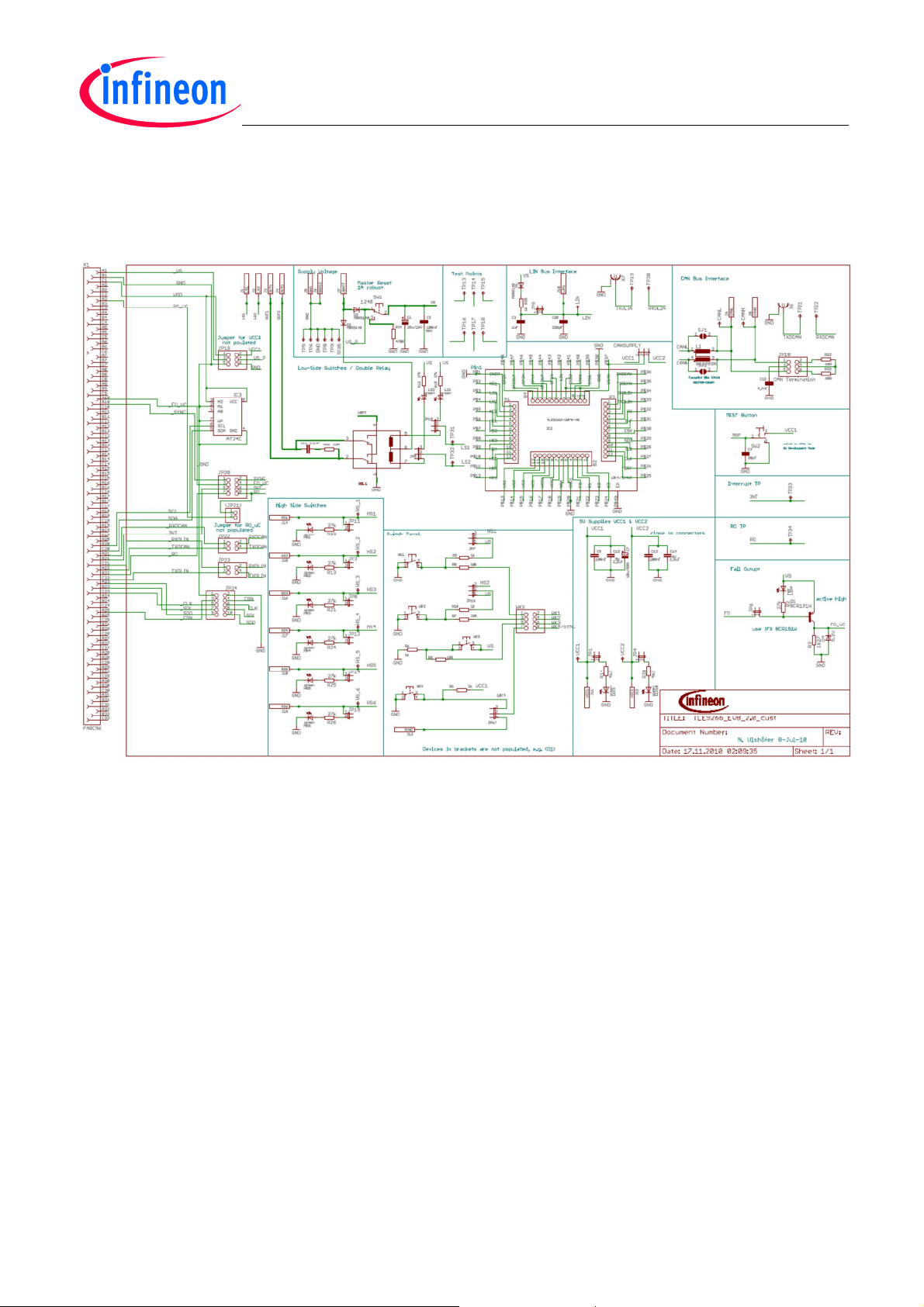

3.2 Application Board overview

3.2.1 Circuit Description and Layout

Driver SBC Evaluation Board

Getting Started

Figure 2 Driver SBC Evaluation Board Schematic

Driver SBC Evaluation Board 6 Rev 0.2, 2011-11-14

Page 7

Driver SBC Evaluation Board

Getting Started

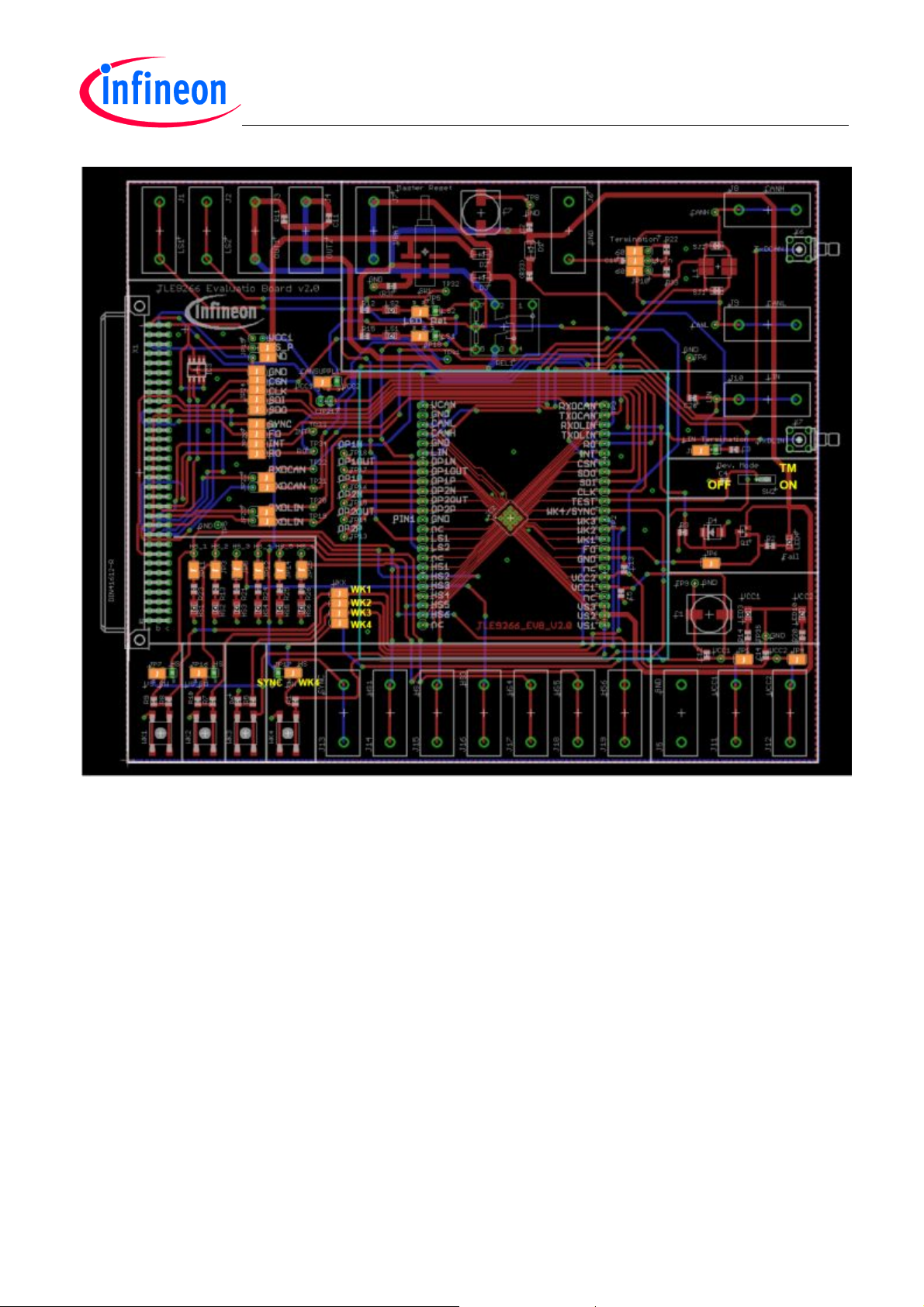

Figure 3 Driver SBC Evaluation Board Layout including default jumper settings.

The Evaluation board comprises of 2 layers, 35µm Cu. A small adapter board with a socket for a VQFN-48

package and a connector row on each side for easy measurement acces connects to the double connector row

(please note to connect in the right pinning order to avoid short circuits).

The PG-VQFN-48 package has an exposed pad and for good thermal performance. It is also possible to solder

the device directly on the PCB. Overall 9 thermal vias are placed directly below the exposed pad island. The

footprint is an absolute minial with no additional copper area. The most obvious heat flow is via the exposed pad

through the thermal vias.

Driver SBC Evaluation Board 7 Rev 0.2, 2011-11-14

Page 8

Driver SBC Evaluation Board

Getting Started

3.3 Hardware Settings

3.3.1 Power Settings

Connect VBATT and GND via standard power supply, with a nominal voltage of 13.5V. The Driver SBC is only

powered through this power supply.

3.3.2 Jumper Overview & Settings

For configuration purposes, there are several jumpers on the application board:

JP1 :

To be added in a table overview

Driver SBC Evaluation Board 8 Rev 0.2, 2011-11-14

Page 9

Driver SBC Evaluation Board

Getting Started

4 Software

4.1 Software Installation

The Power Easy Kit software delivered with the µC board must be installed first. Instruction details to the Power

Easy Kit software installation can be found in the Power easy Kit getting started V1_3.pdf document.

The latest ‘version file’ (Version 1.12 at the time this document was created) is required to be installed first. This

version is not compatible for the Driver SBC (another version will be released later). Therefore, additional standalone Power Easy Kit software needs to be installed by first uninstalling the existing Power Easy Kit version and

then installing the new version. This version is currently only available via our FAE team.

There is a version file called “version.txt”, which ensures that the correct GUI for the TLE9264/66/68 is selected.

The version file must be located in the same directory as the Power Easy Kit directory (\My

Documents\LabVIEW Data\power_easy_kit_data\version.txt).

In addition, the programmed firmware for the Power Easy Kit XC2287 microcontroller needs to have a revision

R15 or higher. If an existing uC-Power Easy Kit is used, it could be necessary to program the new .hex file to

the microcontroller (My Documents\LabVIEW Data\power_easy_kit_data\DemoEvalKitVX2.1R15.hex). Please

click the “Version Check” button in the main menu of the Power Easy Kit GUI to find out the programmed

version for the uC. Please use the “Update” button the main menu of the Power Easy Kit GUI to program a new

firmware on the microcontroller.

For older Power Easy Kit versions it could be necessary to modify the “version.txt” file for the latest GUI version.

Driver SBC Evaluation Board 9 Rev 0.2, 2011-11-14

Page 10

Driver SBC Evaluation Board

Getting Started

4.2 Getting Started

The Power Easy Kit software is executed by starting the ‘Power Easy Kit.exe’ in the installation directory or via

the Start Menu.

The following window will appear:

‘Start Demo’: A new window will open up to operate the Driver SBC. The device is automatically

indentified by the EEPROM located on the evaluation board and the respective GUI is started.

‘Stop’: The Power Easy Kit software will be closed. This is the safest way to end the program and is

recommended to avoid error messages or ‘bluescreens’.

‘Version check’: The actual firmware version of the microcontroller is displayed. Furthermore the

EEPROM of the evaluation board is read out.

‘Update’: The firmware of the microcontroller can be updated.

Notes:

Windows will resize all application fonts if your Windows font size is set to anything other than normal. This will

only affect compiled executables and not code running in the LabVIEW development environment.

Windows font size can be changed by navigating to Start Menu»Settings»Control Panel»Display»Appearance

Tab»Font Size (smaller 100%).

The window size of the GUI is fixed by LabView, i.e. it cannot be resized. To achieve a bigger font size the

screen resolution can be changed.

The “version.txt” file is in \MyDocuments\LabViewData\Power_easy_kit_data\version.txt

Driver SBC Evaluation Board 10 Rev 0.2, 2011-11-14

Page 11

After a click on ‘Start-Demo’ the following window will appear:

Driver SBC Evaluation Board

Getting Started

6

4.2.1 Infineon Driver SBC Evaluation Board GUI

The window above contains four tabs ‘Functional Test’, ‘SPI Command’, ‘SPI Programm’ and ‘Run SPI

Program’ to control and observe the Driver SBC.

The bar at the bottom of the window displays the connection status to the Driver SBC:

‘Communicating’

A light green flashing symbol indicates SPI data transmission between software and the Driver SBC.

‘Power EasyKit Comms OK’

If the symbol remains blue, the communication is working fine. Otherwise if the symbol is flashing

yellow, this indicates a communication problem between software and microcontroller. The safest way

to re-establish the connection is to close the software, reset the evalution and microcontroller board and

start the program again.

‘Update Rate’

The sliding controller allows configuring the update rate of the status register in the “Status Information”

field and the MS_CTRL register read out periodically. The period ranges from 64ms to 1.15s.

In the ‘File’ menu at the top the user can open and save his self-provided commands and programs (XML data

format). This functionalty will be described in detail later.

Driver SBC Evaluation Board 11 Rev 0.2, 2011-11-14

Page 12

Driver SBC Evaluation Board

Getting Started

4.2.2 ‘Functional Test’ tab

This tab informs the user about the chip status and allows controlling the most important Driver SBC settings.

In the upper left corner the section ‘Failure and Reset’ is located.

The button ‘SBC Soft Reset’ will send an SPI command to return all SPI

registers back to default and set the chip to “INIT MODE”.

The three symbols ‘INT’, ‘RO’ and ‘FO’ have a kind of “artificial glow” to

visualize the according signals to the user.

On the left side a section for SPI debugging can be found.

The 16 bit SPI words sent and received by the microcontroller can be

recorded by enabling the green checkbox on the left of ‘SPI Debug’.

In the listbox below the SPI data are displayed and the checkbox is flashing

light green and yellow to indicate data recording.

The recorded data are separated into transmitted and received SPI words,

each consisting out of a 4-bit hexadecimal number. At the top of the list the

last SPI sequence sent/received is displayed.

At the bottom of the section the SPI Clock frequency can be modified.

Note: In the GUI the SPI word is displayed with the MSB on the left. The

microcontroller in contrast is sending the SPI word inversely, starting with

the LSB!

Driver SBC Evaluation Board 12 Rev 0.2, 2011-11-14

Page 13

Driver SBC Evaluation Board

Getting Started

The framed sequence in the picture is taken as an example to illustrate the relevance of the individual Tx and

Rx bits:

Tx: 0046h= 0000 0000 0100 0110

Rx: 0411h= 0000 0100 0001 0001

b

b

Transmitted SPI word

Data Bits to the Driver SBC

R/

W

Address Bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 0 0 1 0 0 1 1 0

Bit 7 (Read/Write) is set to zero, i.e. the program is reading the register addressed by the

bits 6...0; In this case the address “0100110” belongs to the WK_STAT register.

Received SPI word

Data Bits from the Driver SBC Status Information

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 1 0 0 0 0 0 1 0 0 0 1

The data from the WK_STAT register are received in the bits 15...8. In the example the WK3_WU bit is

set. The bits 7...0 show if a bit is set in one of the according status register. [see data sheet 16.3]

Driver SBC Evaluation Board 13 Rev 0.2, 2011-11-14

Page 14

Driver SBC Evaluation Board

Getting Started

The section ‘Control Functions’ allows the user to change the main Driver SBC settings and is divided into

several sub-sections:

‘Mode and Supply Control’:

The SBC Mode can be changed by selecting

the respective entry in the ‘SBC Mode

Select’ dropdown menu, the actual mode is

displayed in the textbox below.

‘VCC1 Reset Threshold’ allows the user to

choose between four different values of

VCC1 undervoltage detection

‘VCC2 Configuration’ is used to

enable/disable VCC2 in the different modes.

‘Automatic Watchdog Trigger’:

It is possible to enable/disable the automatic

watchdog triggering and select between four

timer periods.

‘Bus Control’

The two dropdown menus ‘CAN

Configuration’ and ‘LIN Configuration’ are

used to configure the CAN- and LIN Bus

settings.

‘Wake Control’

The pins WK1/2/3 can be configured as wake capable by activating the respective checkbox.

If a pin is set to be wake capable, a voltage level change form low to high or high to low will cause a wake

event.

Each wake input can be connected to an internal pull-up/down resistor by selecting the respective entry from the

dropdown menu. Automatic means, that if a high level is detected the pull-up is activated, otherwise the pulldown resistore for a low level.

Furthermore the alternate measurement function with WK1 and WK2 can be enabled.

‘Switch Control’

The ‘Low-side Switches’ and ‘High-side Switches’ can be enabled/disabled manually by klicking the

corresponding HSx oder LSx checkbox.

Note: Once the watchdog triggering has been enabled in the “Functional Test” tab, it continues regardless of

which tab (‘Functional Test’, ‘SPI Command’, ‘SPI Program’ or ‘Run SPI Program’) is selected. The watchdog

trigger period can be changed in the other tabs but the automatic trigger function will overwrite this setting with

the next WD trigger.

Note: If the settings are modified in one of the other tabs (‘SPI Command’, ‘SPI Programm’ or ‘Run SPI

Program’) and you return back to the ‘Functional Test’ tab, the controls are not updated!

For example if the HS1 has been enabled in the SPI Command tab, the HS1 checkbox however will be grey. It

would be a high effort to read out the current state of all registers.

Driver SBC Evaluation Board 14 Rev 0.2, 2011-11-14

Page 15

Driver SBC Evaluation Board

Getting Started

The ‘Status Information’ section displays the bit mapping of the Driver SBC’s status register.

The software is only updating the status register automatically, when the ‘Functional Test’ tab is active.

A symbol is glowing light green, if the

respective bit in the status register is set.

Additional information of a bit is given when

the mouse pointer stays above the

corresponding symbol (hover tip):

Each status register can be cleared through

the button on the right.

All status registers are set to default by

pressing the ‘CLEAR ALL’ button in the

lower right corner.

Driver SBC Evaluation Board 15 Rev 0.2, 2011-11-14

Page 16

Driver SBC Evaluation Board

Getting Started

4.2.3 ‘SPI Command’ tab

This tab allows the definition of SPI commands. A command consists of one or more SPI words which can be

defined bit by bit and it can also contain a defined delay

When switching to ‘SPI Command’ for the first time after the program starts the tab will look like the following:

At the beginning almost every control device is greyed out and the ‘Build Command’ list is empty.

To edit/open a pre-saved command select the corresponding XML file via ‘File’ -> ‘Open’:

‘…TLE9266\Software\TLE9266 programs.xml’

To simply start with defining a new command press the ‘New’ button above

After opening the xml file or defining a new command, the tab will look like the following and every control

device is now accessible:

Driver SBC Evaluation Board 16 Rev 0.2, 2011-11-14

Page 17

Driver SBC Evaluation Board

Getting Started

At the top of the ‘SPI Command’ tab is a bar to manage the SPI commands:

In the middle is a dropdown symbol which enlists the commands from the XML file. The actual command is

displayed in the textbox on the left.

On the right are four buttons to edit the SPI commands in the xml file:

‘Edit Name’: A popup window will appear where the user is able to change the name of the actual

command

‘New’: A blank SPI command will be created and a popup window will appear to enter the name.

‘Duplicate’: The actual command is copied and inserted into the list as ‘…(copy)’

‘Delete’: The actual command is removed from the list

Note: New or changed commands are not automatically saved to the xml file! Always save your list to the XML

file via ‘File’ -> ‘Save’.

The sub-section ‘SPI Word Definition’ is divided into two sub-tabs, ‘SPI Write Register’ and ‘Delay’

Driver SBC Evaluation Board 17 Rev 0.2, 2011-11-14

Page 18

Driver SBC Evaluation Board

Getting Started

‘SPI Write Register’ is used to define a SPI word.

The name of the actual SPI word is displayed in

the ‘Word Name’ textbox and can be edited

there.

Below, the 16 bits of the word sent to the Driver

SBC can be arranged; their relevance is equal to

4.2.2 SPI Debug.

The address bits 0...6 are configured by selecting

an entry from the ‘Address Selection’ dropdown

list. By doing so the respective register is read

from the Driver SBC and the result is returned in

the ‘Data Back’ row to display the actual bit

mapping.

A hover tip on the address displays additional

information about the register function.

The bit 7 (Access Mode) can be selected write/read for control register and read/clear for status register.

The remaining bits 8…15 are the data bits and can be set to one/zero by enabling/disabling the

respective checkbox. Their function is displayed in the white textbox above.

The four buttons at the bottom have the following functionality:

‘Clear’: All bits in ‘Cmd Sent’ and ‘Data Back’ and the ‘Word Name’ are cleared

‘Test’: The actual configuration is directly sent to the Driver SBC

‘Insert’: The actual configuration is inserted into the neighboring ‘Build Command’ list on the right.

‘Update’: The actual configuration overwrites the word selected in the ‘Build Command’ list

In the ‘Delay’ tab a specific delay time can be

defined.

The time is configured by adjusting the slider or

directly writing the value into the white textbox.

‘Insert Delay’:

Adds the selected value to the ‘Build

Command’ list on the right.

‘Update Delay’: Modifies the delay value

selected in the ‘Build Command’ list

The sub-section ‘Command Definition’ is used to arrange the individual words of the SPI command that is

selected in the textbox ‘Command Name’. The list can contain up to 20 entries.

Driver SBC Evaluation Board 18 Rev 0.2, 2011-11-14

Page 19

Driver SBC Evaluation Board

Getting Started

‘Move Up/Down’: Changes the order of

the SPI words in the list

‘Delete’: Removes an entry from the list

‘Clear All’: Cleares the whole list

‘Single Step’: The SPI word marked blue

is executed an the cursor jumps to the

next entry. This allows sequential testing

of the words in the list.

‘Test’: Executes the whole list in the given

order.1At the end a window pops up

showing a summary of the transmitted

and received data, which can be stored in

a text file. [Figure 1]

‘View Output’: Opens a window showing

the transmitted data. [Figure 2]

‘Undo’: Revokes the last change made.

In this example the build command is a “running light” through the high side LED’s on the evaluation board.

Note: If there is an empty command or a command which only contains a delay, this will result in an error. In

each command the use of SPI is necessary; otherwise the program is stuck when executing the SPI program.

Figure 1

Figure 2

4.2.4 ‘SPI Program’ tab

1

In the actual software version the Fail Output may be triggered by mistake.An internal software error triggers chip select,

without sending data. The Driver SBC interprets this as SPI Stuck and activates the Fail Output.

Just clear the ‘Device Status’ register in the Driver SBC Functional Tab and continue working.

Driver SBC Evaluation Board 19 Rev 0.2, 2011-11-14

Page 20

Driver SBC Evaluation Board

Getting Started

The ‘SPI Program’ tab allows creating and modifying SPI programs. An SPI program is a list of SPI commands

which are executed sequentially.

The structure of the ‘SPI Program’ tab is very similar to the the ‘SPI Command’ tab described in the chapter

before.

Opening the tab for the first time after program start, most control devices are greyed out until a new program is

created or a pre-saved program is loaded from the XML file. It is the same file the SPI commands are stored in.

At the top of the ‘SPI Program’ tab is a bar to manage the available SPI programs:

In the middle is a dropdown symbol which enlists the programs from the XML file. The actual program is

displayed in the textbox on the left.

On the right are four buttons to edit the SPI programs in the xml file:

‘Edit Name’: A popup window will appear where the user is able to change the name of the actual

program

‘New’: A blank SPI program will be created and a popup window will appear to enter the name.

‘Duplicate’: The actual program is copied and inserted into the list as “….(copy)”

‘Delete’: The actual program is removed from the list

Note: New or changed programs are not automatically saved to the xml file! Always save your list to the XML

file via ‘File’ -> ‘Save’.

Driver SBC Evaluation Board 20 Rev 0.2, 2011-11-14

Page 21

Driver SBC Evaluation Board

Getting Started

The sub-section ‘SPI Commands Available’ displays the configured SPI commands from the list.

‘Insert’: The selected command is inserted into the neighboring ‘Build Programm’ list on the right.

‘Update’: The selected command overwrites the command selected in the ‘Build Program’ list

The sub-section ‘Program Definition’ allows arranging the commands of the actual SPI program.

‘Move Up/Down’: Changes the order of the SPI commands in the list

‘Delete’: Removes an entry from the list

‘Clear All’: Cleares the whole list

‘Test’: Executes the whole list in the given order.1The active command is highlighted by a yellow

background. At the ending a window pops up showing a summary of the transmitted and received data,

which can be stored in a text file. [Figure 1 on page 19]

‘View Output’: Opens a window showing the transmitted data. [Figure 2 on page 19]

‘Undo’: Revokes the last change made.

1

In the actual software version the Fail Output may be triggered by mistake.An internal software error triggers chip select,

without sending data. The Driver SBC interprets this as SPI Stuck and activates the Fail Output.

Just clear the ‘Device Status’ register in the Driver SBC Functional Tab and continue working.

Driver SBC Evaluation Board 21 Rev 0.2, 2011-11-14

Page 22

Driver SBC Evaluation Board

Getting Started

‘Run SPI Program’ tab

The ‘Run SPI Program’ tab allows multiple programs to be run sequentially or a single program to be run in

loops. This window is suitable for regression testing under various application conditions:

The ‘Programs Available’ section displays the SPI programs stored in the xml file. If the respective entry is

checked by a mouseclick, the program is added to the ‘Decoded SPI Program’ list.

The order of the programs can be modified by using the two arrows on the left.

The ‘Decoded SPI Program’ section itemizes the selected programs down to the lowest level and displays the

pre-configured SPI words.

Driver SBC Evaluation Board 22 Rev 0.2, 2011-11-14

Page 23

Driver SBC Evaluation Board

Getting Started

At the bottom are further control elements:

The loop button on the left allows running the ‘Decoded SPI Program’ several times.

‘Execute’: Starts to execute the ‘Decoded SPI Program’list.1A small window opens up showing the

current number of iterations.

Via the ‘STOP’ button the excecution of the sequence can be interrupted.

The active part of the program is highlighted by a yellow background in the Program Available section.

[Figure 3]

After the execution of the program was successful, a window pops up showing a summary of the

transmitted and received data. Again these data can can be stored in a text file. [Figure 4]

‘Save’: The ‘Decoded SPI Program’ can be stored to a text file for documentation only. It is not

possible to use the text file like the xml file as a template.

Figure 3

Figure 4

1

In the actual software version the Fail Output may be triggered by mistake.An internal software error triggers chip select,

without sending data. The Driver SBC interprets this as SPI Stuck and activates the Fail Output.

Just clear the ‘Device Status’ register in the Driver SBC Functional Tab and continue working.

Driver SBC Evaluation Board 23 Rev 0.2, 2011-11-14

Page 24

Driver SBC Evaluation Board

Getting Started

5 Additional Information

For further information you may contact http://www.infineon.com/SBC or your regional FAE.

Driver SBC Evaluation Board 24 Rev 0.2, 2011-11-14

Page 25

Edition 2011-11-14

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2013 Infineon Technologies AG

All Rights Reserved.

LEGAL DISCLAIMER

THE INFORMATION GIVEN IN THIS APPLICATION NOTE IS GIVEN AS A HINT FOR THE

IMPLEMENTATION OF THE INFINEON TECHNOLOGIES COMPONENT ONLY AND SHALL NOT BE

REGARDED AS ANY DESCRIPTION OR WARRANTY OF A CERTAIN FUNCTIONALITY, CONDITION OR

QUALITY OF THE INFINEON TECHNOLOGIES COMPONENT. THE RECIPIENT OF THIS APPLICATION

NOTE MUST VERIFY ANY FUNCTION DESCRIBED HEREIN IN THE REAL APPLICATION. INFINEON

TECHNOLOGIES HEREBY DISCLAIMS ANY AND ALL WARRANTIES AND LIABILITIES OF ANY KIND

(INCLUDING WITHOUT LIMITATION WARRANTIES OF NON-INFRINGEMENT OF INTELLECTUAL

PROPERTY RIGHTS OF ANY THIRD PARTY) WITH RESPECT TO ANY AND ALL INFORMATION GIVEN IN

THIS APPLICATION NOTE.

Information

For further information on technology, delivery terms and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact the nearest Infineon Technologies Office.

Infineon Technologies components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the

failure of that life-support device or system or to affect the safety or effectiveness of that device or system. Life

support devices or systems are intended to be implanted in the human body or to support and/or maintain and

sustain and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other

persons may be endangered.

Page 26

w w w . i n f i n e o n . c o m

Published by Infineon Technologies AG

Loading...

Loading...