Page 1

User guide Please read the Important notice and the Safety precautions and the Warnings V1.0

www.infineon.com page 1 of 31 2020-10-16

UG-2020-19

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

About this document

Scope and purpose

This user guide provides an overview of the reference design board REF_Fridge_D111T_MOS including its main

features, key data, pin assignments and mechanical dimensions, and the guidance on how to run and design

the motor with board.

The REF_Fridge_D111T_MOS board is a complete reference design board designed for refrigerator

compressors. It demonstrates the whole Infineon solution including digital motor control IC iMOTIONTM Smart

Driver IMD111T-6F040 and the 600 V CoolMOSTM PFD7 super junction MOSFET.

The REF_Fridge_D111T_MOS board is developed to support customers in designing their refrigerator

compressor drivers with Infineon products.

Intended audience

This user guide is intended for technical specialists working with the REF_Fridge_D111T_MOS board and

refrigerator compressor driver design.

Reference Board/Kit

Product(s) embedded on a PCB, with focus on specific applications and defined use cases that can include

Software. PCB and auxiliary circuits are optimized for the requirements of the target application.

Note: Boards do not necessarily meet safety, EMI, quality standards (for example UL, CE) requirements.

Page 2

User guide 2 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

Important notice

Important notice

“Evaluation Boards and Reference Boards” shall mean products embedded on a printed circuit board

(PCB) for demonstration and/or evaluation purposes, which include, without limitation, demonstration,

reference and evaluation boards, kits and design (collectively referred to as “Reference Board”).

Environmental conditions have been considered in the design of the Evaluation Boards and Reference

Boards provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards

has been tested by Infineon Technologies only as described in this document. The design is not qualified

in terms of safety requirements, manufacturing and operation over the entire operating temperature

range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the

same procedures as regular products regarding returned material analysis (RMA), process change

notification (PCN) and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production.

The Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards

(including but not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other

requirements of the country in which they are operated by the customer. The customer shall ensure that

all Evaluation Boards and Reference Boards will be handled in a way which is compliant with the relevant

requirements and standards of the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and

managed according to the terms and conditions set forth in this document and in other related

documentation supplied with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the

Evaluation Boards and Reference Boards for the intended application, and to evaluate the completeness

and correctness of the information provided in this document with respect to such application.

The customer is obliged to ensure that the use of the Evaluation Boards and Reference Boards does not

cause any harm to persons or third party property.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is"

and Infineon Technologies disclaims any warranties, express or implied, including but not limited to

warranties of non-infringement of third party rights and implied warranties of fitness for any purpose, or

for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation

Boards and Reference Boards and/or from any information provided in this document. The customer is

obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or

damages arising out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided

herein at any time without further notice.

Page 3

User guide 3 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

Safety precautions

Safety precautions

Note: Please note the following warnings regarding the hazards associated with development systems.

Table 1 Safety precautions

Warning: The DC link potential of this board is up to 400 VDC. When measuring voltage

waveforms by oscilloscope, high voltage differential probes must be used. Failure to do

so may result in personal injury or death.

Warning: The evaluation or reference board contains DC bus capacitors which take

time to discharge after removal of the main supply. Before working on the drive

system, wait five minutes for capacitors to discharge to safe voltage levels. Failure to

do so may result in personal injury or death. Darkened display LEDs are not an

indication that capacitors have discharged to safe voltage levels.

Warning: The evaluation or reference board is connected to the grid input during

testing. Hence, high-voltage differential probes must be used when measuring voltage

waveforms by oscilloscope. Failure to do so may result in personal injury or death.

Darkened display LEDs are not an indication that capacitors have discharged to safe

voltage levels.

Warning: Remove or disconnect power from the drive before you disconnect or

reconnect wires, or perform maintenance work. Wait five minutes after removing

power to discharge the bus capacitors. Do not attempt to service the drive until the bus

capacitors have discharged to zero. Failure to do so may result in personal injury or

death.

Caution: The heat sink and device surfaces of the evaluation or reference board may

become hot during testing. Hence, necessary precautions are required while handling

the board. Failure to comply may cause injury.

Caution: Only personnel familiar with the drive, power electronics and associated

machinery should plan, install, commission and subsequently service the system.

Failure to comply may result in personal injury and/or equipment damage.

Caution: The evaluation or reference board contains parts and assemblies sensitive to

electrostatic discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with electrostatic

control procedures, refer to the applicable ESD protection handbooks and guidelines.

Caution: A drive that is incorrectly applied or installed can lead to component damage

or reduction in product lifetime. Wiring or application errors such as undersizing the

motor, supplying an incorrect or inadequate AC supply, or excessive ambient

temperatures may result in system malfunction.

Caution: The evaluation or reference board is shipped with packing materials that

need to be removed prior to installation. Failure to remove all packing materials that

are unnecessary for system installation may result in overheating or abnormal

operating conditions.

Page 4

User guide 4 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

Table of contents

Table of contents

About this document ....................................................................................................................... 1

Important notice ............................................................................................................................ 2

Safety precautions .......................................................................................................................... 3

Table of contents ............................................................................................................................ 4

1 The reference board at a glance ............................................................................................... 5

1.1 Delivery content ...................................................................................................................................... 5

1.2 Block diagram .......................................................................................................................................... 5

1.3 Main features ........................................................................................................................................... 6

1.4 Board parameters and technical data .................................................................................................... 7

2 System and functional description ........................................................................................... 8

2.1 Commissioning ........................................................................................................................................ 8

2.1.1 Hardware connection ........................................................................................................................ 9

2.1.2 Software/firmware preparation ........................................................................................................ 9

2.1.3 Program firmware/parameters/script............................................................................................. 10

2.1.4 Open-loop diagnostic ...................................................................................................................... 12

2.1.5 Closed-loop run ................................................................................................................................ 13

2.2 Description of the functional blocks ..................................................................................................... 14

2.2.1 Inverter stage ................................................................................................................................... 14

2.2.2 DC bus sensing and MCEWizard configuration ............................................................................... 15

2.2.3 Current sensing and over-current protection ................................................................................. 16

2.2.3.1 Current sensing ........................................................................................................................... 16

2.2.3.2 Over-current protection.............................................................................................................. 18

2.2.4 NTC sensing and thermal protection .............................................................................................. 18

2.3 Frequency-signal interface ................................................................................................................... 20

3 System design ...................................................................................................................... 22

3.1 Schematics ............................................................................................................................................ 22

3.2 Layout .................................................................................................................................................... 22

3.3 Bill of material ....................................................................................................................................... 23

3.4 Connector details .................................................................................................................................. 24

4 System performance ............................................................................................................. 26

4.1 Thermal characterization test .............................................................................................................. 26

4.2 MOSFET dV/dt test................................................................................................................................. 27

5 Reference and appendices ..................................................................................................... 29

5.1 Abbreviations and definitions ............................................................................................................... 29

5.2 References ............................................................................................................................................. 29

5.3 Additional information .......................................................................................................................... 29

Revision history............................................................................................................................. 30

Page 5

User guide 5 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

The reference board at a glance

1 The reference board at a glance

The REF_Fridge_D111T_MOS reference design kit is a part of the iMOTION™ reference design kit for motor

drives, which is aimed at refrigerator-compressor driver applications. The kit is a ready-to-use solution in

combination with full Infineon products such as 600 V CoolMOSTM PFD7 super-junction MOSFET in a small

SOT223 package, and motor-control smart driver iMOTIONTM IMD111T-F040. It can easily be switched to a final

mass production application board, and has a fast time to market.

The REF_Fridge_D111T_MOS reference board is available from Infineon. The features of this board are

described in Chapter 1.3 of this document (UG-2020-19). The remaining sections provide information to enable

customers to copy, modify and qualify the design for production according to their own specific requirements.

Environmental conditions have been considered in the design of the REF_Fridge_D111T_MOS. The design was

tested as described in this document, but not qualified in terms of safety requirements or manufacturing and

operation over the whole operating temperature range or lifetime. The boards provided by Infineon are subject

to functional testing only.

The boards are not subject to the same procedures as regular products in terms of returned material analysis

(RMA), process change notification (PCN) and product discontinuation (PD). Evaluation boards are intended to

be used under laboratory conditions by specialists only.

1.1 Delivery content

The delivery content only contains the board as Figure 2 shown, the detail ordering information is indicated in

the Table 2.

The iMOTION

TM

Link cable shown in the Figure 4 is mandatory for the tuning, and it is not included in the

delivery content, please order it if you do not have, ordering information can be found in the Section 5.3.

Table 2 Delivery content

1.2 Block diagram

Figure 1 Block diagram of the REF_Fridge_D111T_MOS reference board

Base part number

Package

Standard pack

Orderable part number

Form

Quantity

REF_Fridge_D111T_MOS

Boxed

1

REFFRIDGED111TMOSTOBO1

Page 6

User guide 6 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

The reference board at a glance

Figure 1 shows the block diagram of reference design kit REF_Fridge_D111T_MOS, and this document explains

the features and details.

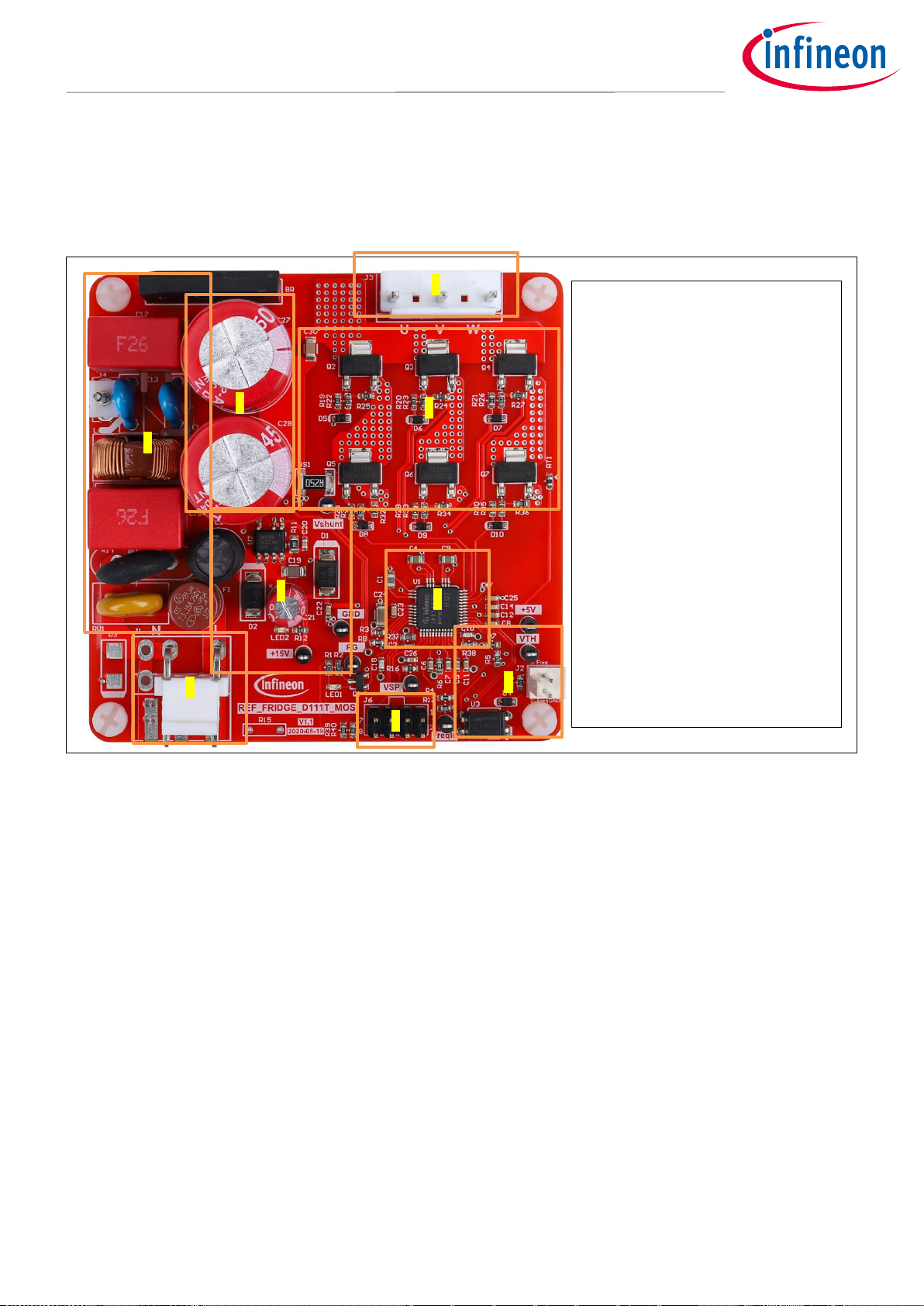

Figure 2 depicts the functional groups of the board. Connecter definition details are described in section 3.4.

Please see this section if you need more information.

Figure 2 Functional groups on top side of board

1.3 Main features

REF_Fridge_D111T_MOS is a complete reference design board for refrigerator-compressor applications. Main

features of the board include:

iMOTION™ Smart Driver IMD111T-6F040

Ready-to-use motion controller with scripting engine and 6-channel silicon on insulator (SOI) driver

600 V CoolMOS™ PFD7 – optimized technology with lowest Q

rr

, ESD protection and compact SOT223 surface

mounted device (SMD) package

System solution enables best light-load efficiency and compact design

Key features of iMOTION™ Smart Driver IMD111T-6F040 include:

Motor controller with integrated high-voltage gate driver and voltage regulator

Integrated 5 V low dropout regulator (LDO) allows single 15 V supply voltage

Robust 600 V gate driver in thin-film SOI technology

Gate driver integrated with ultra-fast bootstrap diodes

Space saving LQFP 40-pin package with high-voltage creepage

Motion control engine (MCE) as ready-to-use solution for variable speed drives

1. EMI filter and rectifier

group

2. DC bus capacitors

3. Motor phase connector

(J3)

4. CoolMOS

TM

MOSFET

5. Auxiliary power supply

6. IMD111T-6F040

7. AC line input connector

(J1)

8. iMOTION

TM

Link connector

(J6)

9. Frequency input signal

connector (J2)

3

2

7

1

4

5

8

6

9

Page 7

User guide 7 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

The reference board at a glance

Sensorless field-oriented control (FOC) for permanent magnet synchronous motor (PMSM)

Flexible space vector PWM (3-phase PWM or 2-phase PWM)

Motor-current sensing via single or leg shunt

Optional analog or digital hall sensor interface

Flexible host interface options for motor control commands: universal asynchronous receiver/transmitter

(UART), frequency/duty cycle or analog VSP

IEC60335-1/UL60730 Class B Safety Software certificate

For more information about the above-mentioned products, refer to the corresponding reference materials.

1.4 Board parameters and technical data

Table 3 depicts the important specifications of the reference design REF_Fridge_D111T_MOS.

Table 3 REF_Fridge_D111T_MOS board specifications

Parameter

Symbol

Conditions / comments

Value

Unit

Operation input voltage

Vac

Lower AC input, less motor power output

165 ~ 265

V

rms

Maximum input current

I

ac(max)

Input 220 VAC, Ta=25C

1.7

A

rms

Maximum input power

P

in(max)

Input 220 VAC, f

PWM

=5 kHz, Ta=25°C, T

case

= 100°C

without heat sink

250

W

Maximum motor current

I

mtr(max)

Input 220 VAC, f

PWM

=5 kHz, Ta=25°C, T

case

= 100°C

without heat sink

0.69

A

rms

Maximum DC bus voltage

V

dc(max)

400

V

Shunt Resistance

Rsh 250

mΩ

Protection

Current protection

trigger level

I

trip

Set in the MCEWizard

-

A

peak

Thermal protection level

T

protection

Temperature gap between MOSFET’s case and NTC

(negative temperature coefficient) sensor needs to

be considered; recommended is a setting of

maximum 105°C for the case temperature,

considering the gap, set 75°C in the MCEWizard.

75

°C

Auxiliary power supply 1 - 15V

Output voltage

V

out1

Used for IMD111T-6F040,integrate 5 V LDO in the

IMD111T-6F040

15 ± 5%

V

Maximum output current

I

out1

100

mA

PCB characteristics

Dimension

Length × width × height

78×78×46

mm

Material

1.6 mm thickness, 1 oz. copper

FR4 System environment

Ambient temperature

Ta

Non-condensing, maximum RH of 95%

0 ~ 50

°C

Page 8

User guide 8 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

2 System and functional description

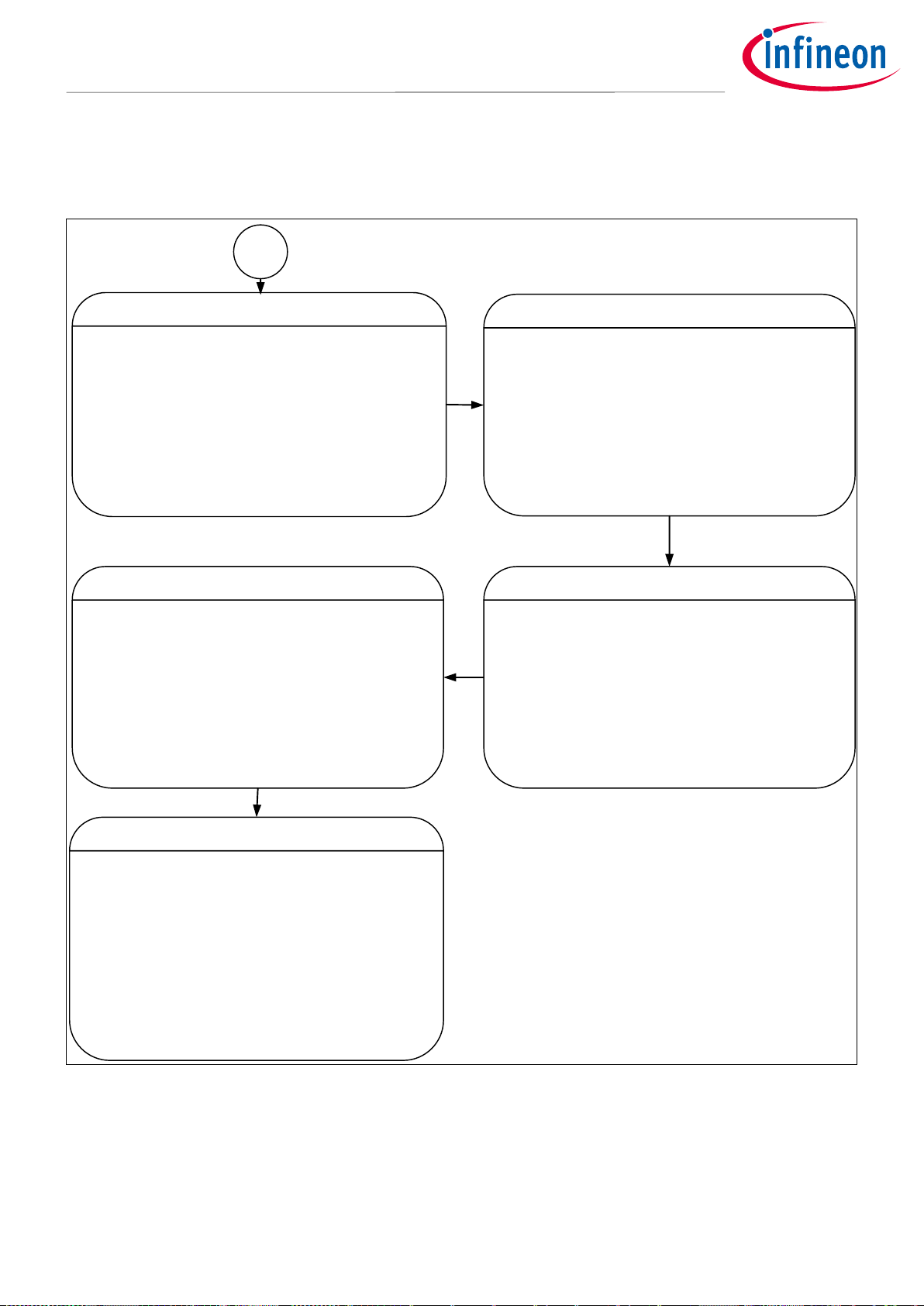

2.1 Commissioning

Hardware connection

Programm firmware/parameters/script

Software/firmware preparation

Open-loop diagnostic

Closed-loop run

1- iMOTIONTM Link to bridge the MCE and PC

2- Connect AC source (J1) and motor (J3)

1- Program the firmware/parameters through

the iMOITIONTM Link by MCEDesigner,

IMD111T can be powered up by iMOTIONTM

Link, or be powered by auxiliary power supply

on the board after the AC source is powered

2- Program script file if available

1 - Install MCEDesigner/MCEWizard

2 - Download the firmware of MCE

3 - Generate parameters file (.txt) by

MCEWizard, Which is used to transfer the

hardware/motor parameters to register s

values

4 - Generate script file if available

1- Power up AC power supply

2- Run build-in function VF diagnostic to

verify current/DC bus sensing, hardware

connection and parameters

1- Run motor in closed-loop mode by start

motor function, tune the parameters

Figure 3 Basic process for running the motor the first time

This section describes how to get the system working when user first installs the board (refer to Figure 3 for

general steps). The following items detail these steps. For those who are already familiar with the system, or

have already run the board, unnecessary steps can be skipped depending on user’s actual situation. For more

in-depth commissioning process requirements, please refer to the MCE reference manual or the corresponding

reference material

[4][5][6]

.

Page 9

User guide 9 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

2.1.1 Hardware connection

Figure 4 shows the hardware connection details for the reference design board.

iMOTIONTM Link cable is needed to bridge the PC/debugger side and motor drive system (the target iMOTION™

device, hot side) with 1 kV DC galvanic isolation. Users can go to Section 5.3 for more information about

iMOTION

TM

Link.

1. Connect iMOTION

TM

Link’s 8-pin cable to J6 with default pin order, and connect PC and iMOTION

TM

Link with

the USB wire.

2. Then connect AC power supply (J1) and the motor (J3).

Figure 4 Hardware connection details

2.1.2 Software/firmware preparation

1. The iMOTION™ software tools MCEDesigner and MCEWizard are required to set up the system, as well as to

control and fine-tune the system performance to match users' exact needs. These tools are available for

download via the Infineon website (http://www.infineon.com/imotion-software). Please check this page

periodically for tool/software updates.

2. The MCE firmware then has to be downloaded on our website; select the proper version of the firmware

based on your requirements. Included in the package are the firmware (‘.ldf’), default parameters (‘.txt’),

default map file (‘.map’), the file for the MCEDesigner (‘.irc’) and other documents.

3. Generate your parameters’ file.

Use MCEWizard to enter the target motor’s system and operating parameters, as well as reference board’s

hardware parameters, which will then be used to calculate the controller’s digital parameter set

representing the complete motor drive system.

Page 10

User guide 10 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

After system and operating parameters are set, go to the “Verify & Save Page” and click on “Calculate”

button. If no errors are reported, then save the drive parameter set in your project directory by clicking

“Export to Designer file (.txt)” (Figure 7); if some errors are detected, double-click on the error message

(highlighted in RED) and adjust the related parameters. Saved Drive System Parameter File will be later used

for programmers.

Note: After you log-in on myInfineon, you could download the default MCEwizard file (.mc2) for this

board, you only need to modify the parameters related to your motor to make things easier and

save time

4. Generate the script if available. For users who are running the board for the first time, it is recommended

not to use this function first, but to add the script function after the motor performance commissioning is

completed.

2.1.3 Program firmware/parameters/script

The REF_Fridge_D111T_MOS reference design kit is shipped with pre-programmed firmware and default

parameters, since the functional tests were done before the shipment. Users need to program their

parameters, as the motor is different from the one under test.

The following steps have to be performed in order to make a blank IMD111T working:

Program the firmware of the MCE

Program parameter sets for system and motor

Program customer script file (optional)

Or

Program the combined file, which is combined by MCEWizard containing all three items above. Customer

script file is optional depending on whether it is available. The combined file is usually used for production,

since it only needs to be programmed once.

The programming process is as follows:

1. Start the MCEDesigner tool and open MCEDesigner default configuration file (‘.irc’) for IMD111T device

(IMD111T_Vxxx.irc) by clicking “File” > “Open.”

Note: The IMD111T_Vxxx.irc file is included in the downloaded firmware package “IMD111T MCE

Software Package.”

2. Power the iMOTION

TM

control IC with 3.3 V. It is recommended to program the IC with the 3.3 V isolated

power supply that comes from the iMOTIONTM Link; there is a switch on the iMOTIONTM Link to enable the 3.3

V output. The iMOTIONTM control IC will also be powered by the on-board auxiliary power supply after the AC

source is powered, but caution due to high voltage.

Note: The output voltage of LDO combined in the IMD111T-6F040 is 5 V, i.e. the controller of IMD111T-

6F040 is powered by 5 V. However, it is also possible to use the 3.3 V power supply in the iMOTIONTM

Link to power the IMD111T-6F040 (for programmers).

3. MCEDesigner should automatically connect to the board using default COM port (Indicated by green circle

next to “COMx Up” status in the bottom frame of the MCEDesigner GUI) when iMOTIONTM control IC is

powered. If it cannot establish the connection due to an incorrect COM port, change COM port by doing the

Page 11

User guide 11 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

following: click on the “System Page” window and then click on “Preferences > Connection > Connect

using,” and choose one of the other available COM ports from the drop-down list.

4. (In case blank IC) If the firmware has been erased from the IMD111T, the following warning message will pop

up “Target device firmware and parameters file are not programmed! Please program firmware and

parameters file” as Figure 5. Then you can program the firmware and parameters as described in the Step 5.

If it is not the blank IC, no such message will be indicated.

Figure 5 MCEDesigner warning message

5. Use the following steps to program the firmware and the parameters’ file into the internal Flash memory of

iMOTION™ Control IC: click on system page, click “Tools” > “Programmer” and select “Program Firmware

and Parameters.” Shown as Figure 6 below. The encrypted firmware is available at “IMD111T MCE Software

Package;” regarding the parameters file, browse and select the’.txt’ file in the section 2.1.2.

Figure 6 Program the parameters and firmware

Page 12

User guide 12 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Figure 7 MCEWizard verify and save page

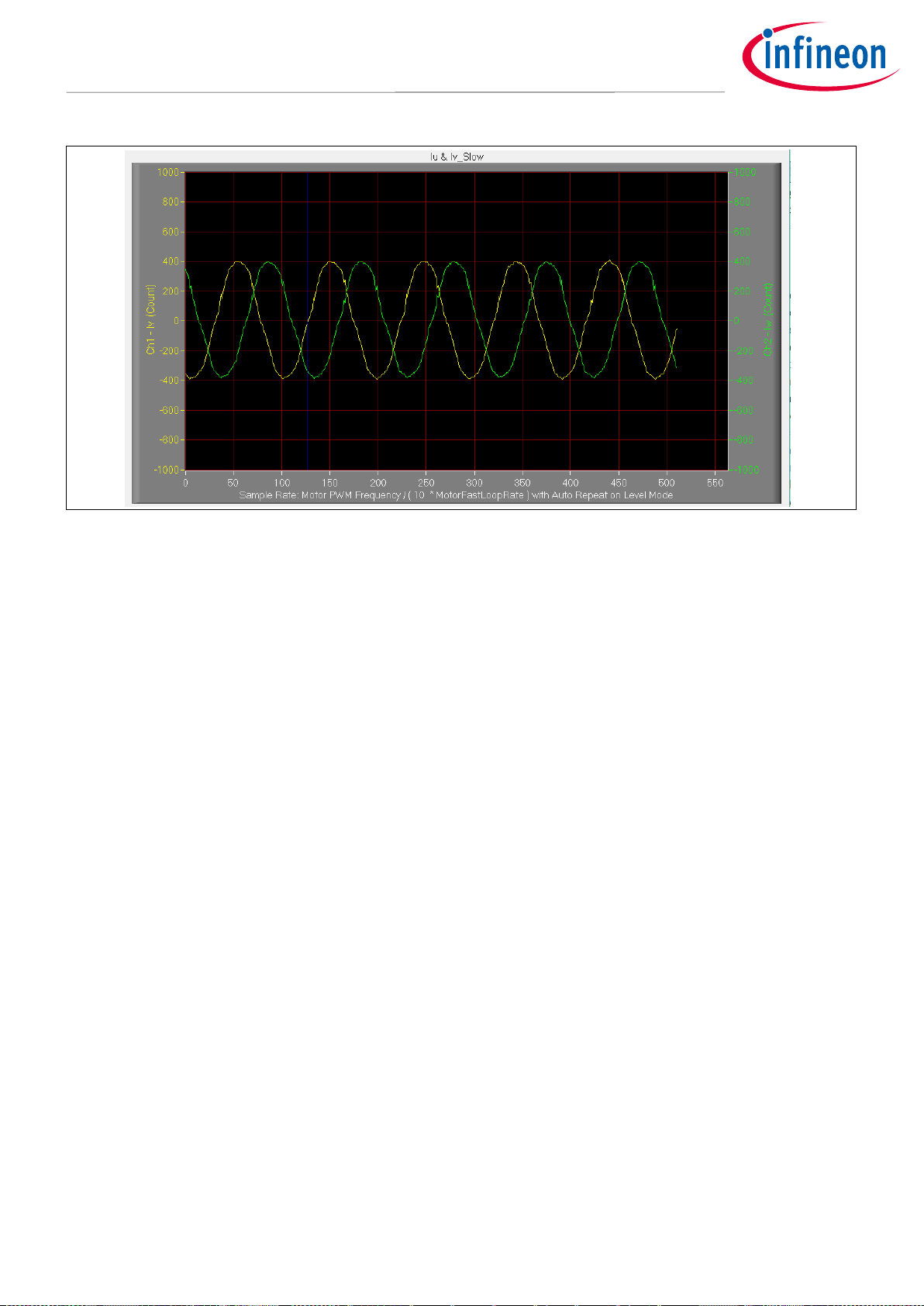

2.1.4 Open-loop diagnostic

Double-click the “VF Diagnostic” function in the window of motor1, and monitor motor current with

oscilloscope. If motor current is not sinusoidal, change register TargetSpeed and Vd_Ext in VF Diagnostic subfunction, then double-click “VF Diagnostic” until the oscilloscope shows a steady sinusoidal current with an

amplitude of 30~50% motor rate current.

Double-click “Iu & Iv_Slow” in System page > Monitor Definitions, the motor current feedback should be very

clean and sinusoidal, as shown in Figure 8; otherwise please tune “Gating Propagation Delay & Phase Shift

Window Size” in MCEWizard.

“VF Diagnostic” sub-function can verify:

If motor is connected correctly

If IGBT(or MOSFET ) and gate driver work as expected

If current-sensing related parameters are correctly configured

If PCB layout and DC bus decoupling have been done correctly

After “VF Diagnostic” is done, click STOP button (the red traffic light button) or run “stop motor” function to

stop the motor.

Page 13

User guide 13 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Figure 8 Trace waveform for Iu & Iv open loop diagnostic

2.1.5 Closed-loop run

If the VF Diagnostic works correctly, the hardware circuit and signal sampling will work normally, at which point

we can try to run the motor in a closed-loop mode. The steps are listed below.

1. Start the motor by clicking the green traffic light button in the control bar (or double click Start Motor sub-

function in the window of motor1 , which is in the group of User Application Function Definitions), the motor

will run if above step works well.

2. Check the motor spin direction, adjust the connection order of the motor’s winding, or set negative

TargetSpeed in MCEDesigner if the direction is wrong.

3. Set TargetSpeed to about 50% of maximum speed, start “Iu & Flx_M” trace with “Auto Repeat On Level,” see

Figure 9. Flx_M is good within the range of 2000~2500 (rated value is 2048), and must be steady and DC-like.

Here are some key tips for better motor performance tuning:

If Flx_M is not steady (swing or oscillation), motor parameters, speed loop PI gain, flux estimator time

constant and PLL PI bandwidth (parameters PLLKp and PLLKi) and releated setup need to be checked.

If Flx_M is very noisy, current feedback and V

dc

-related hardware and parameters need to be checked.

If Flx_M does not come close to 2048, “Motor Back EMF Constant (K

e

)” needs to be adjusted in MCEWizard.

Page 14

User guide 14 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Figure 9 Trace waveform for Iu & Flx-M at 50% speed

4. Once the firmware has been programmed, and a new parameters’ file has to be programmed, follow the

same instructions given in Section 2.1.3. In this case, the firmware programming is no longer needed, and

you can select the first option “Program Parameters.”

Note: For detailed information on controller programming, refer to AN2018-33 iMOTION™ 2.0 Device

Programming, MCEDesigner documentation and MCEWizard documentation.

2.2 Description of the functional blocks

2.2.1 Inverter stage

The inverter section is implemented with the 600 V CoolMOSTM PFD7 super-junction MOSFET in a small SOT223

package. The PFD7 high-voltage, n-channel MOSFET series combines best-in-class performance with state-of-

the-art ease of use, shaped by Infineon’s experience of more than 20 years as a pioneer in super-junction

technology innovation. The products come with an integrated fast body diode ensuring a robust device, and in

turn, a reduced BOM for the customer. Figure 10 shows the diagram of the inverter and peripheral circuit.

Page 15

User guide 15 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Figure 10 Inverter and peripheral circuit

2.2.2 DC bus sensing and MCEWizard configuration

Figure 11 provides the DC bus sensing resistor details on the reference design.

The high-side resistors are 2 MΩ and the low-side resistor is 20 kΩ, the default DC bus sensing voltage results in

a range of 0 to 5 V on the ADC input, reflecting a range of 0 to 505 V.

Figure 11 DC bus sensing

Page 16

User guide 16 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

The hardware parameters need to be configured in MCEWizard as shown in Figure 12.

Figure 12 DC bus sensing configuration in MCEWizard

The Vdc-sensing, low-pass-filter time constant is ((R10 + R13) // R15) * C4= (2 MΩ // 20 kΩ) * 4.7 nF = 93.1 µs, C17

can be adjusted to higher capacitance for clean Vdc sensing.

2.2.3 Current sensing and over-current protection

2.2.3.1 Current sensing

The current sensing on this board uses only the RC network for operational bias and low-pass filter to minimize

the cost. No additional operational amplifier is needed.

Based on the principle of Kirchhoff's voltage law, and assuming the AD port input impedance is infinite, you

obtain the equation below.

The equation can be transformed to two parts as shown here:

The impedance of the RC network is much larger than the

, so it can be assumed that:

Page 17

User guide 17 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

V

ADC

can then be written as:

Where

is the offset, and

is the gain of the shunt current.

Figure 13 Current-sensing topology

Use this board with, for example, R1 = R20 = 2 k, R2 = R8 = 22.1 k, Vcc = 5 V, offset = 0.415V, gain =

= 229.3 mV/A.

Note the following points concerning current sampling:

R8 & R20 also determine ADC operational bias for current sensing, which corresponds to the motor

regeneration operation range. For those applications that do not work at regenerative brake mode, the bias

can be as low as possible to reserve enough ADC range for the drive mode, since negative current to DC bus

does not occur.

Since the gain of the external RC circuit is less than 1, internal signal amplification is required to increase the

ADC input voltage range with lower shunt value. If a larger shunt is chosen, the power loss and size are both

larger. MCE provides an inner current sampling amplifier with *1, *3, *6 and *12 gain selections, which can

be configured in the MCEWizard.

There is no common mode noise-rejection ability without an outer operational amplifier, so the GND

network of the PCB needs to be dealt with very carefully, since any voltage difference between IMD111T’s

ADC ground and shunt resistor ground will be considered as an “input signal,” and will deteriorate control

performance or increase audible noise.

Page 18

User guide 18 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Figure 14 Current-sensing circuit on the board

2.2.3.2 Over-current protection

The over-current condition can be detected by IMD111T-6F040 by the input sources as shown in Figure 15.

Internal comparator in the IMD111T-6F040

Figure 15 Over-current protection on the board

For more details about the over-current protection (OCP) in the IMD111T, refer to chapter on motor overcurrent protection in the reference material

[6]

.

The internal comparator’s reference level is set by the internal DAC, the level can be set in the MCEWizard by

“Device over-current trigger level setting for comparator” and “Motor1 current input to ADC offset voltage.” The

DAC output pin REFU needs to be connected to a capacitor; 10 nF/16 V is used on the board.

2.2.4 NTC sensing and thermal protection

Pin 35 of IMD111T-6F040 is the ADC port dedicated to NTC temperature sampling. On the board, an NTC is

connected to the ADC channel by the circuit shown in Figure 16. The position of the NTC on the board is shown

in the Figure 17

Page 19

User guide 19 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Figure 16 NTC sensing circuit

NTC

Figure 17 NTC position on the board

The parameters of the NTC are: B-constant = 4050 K 1%, R

25

= 47 k 1%. Based on the typical value of the

thermistor resistance, voltage of the Vth can be obtained in Table 4.

The firmware inside the IMD111T integrates the over-temperature protection device, which will be triggered by

the voltage V

th.

Simply set the proper trigger level in the MCEWizard. More information can be found in the over-

temperature protection section of the reference material

[6]

.

Page 20

User guide 20 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

Table 4 Thermistor characteristics with V = 5 V,R5=4.87 k

Temperature (C)

Resistance typ. (k)

V

th

(V)

Vth register value

15.00

75.31

4.70

3846

20.00

59.25

4.62

3784

25.00

47.00

4.53

3711

30.00

37.57

4.43

3625

35.00

30.25

4.31

3527

40.00

24.52

4.17

3416

45.00

20.01

4.02

3293

50.00

16.43

3.86

3159

55.00

13.58

3.68

3014

60.00

11.28

3.49

2860

65.00

9.42

3.30

2700

70.00

7.92

3.10

2535

75.00

6.68

2.89

2369

80.00

5.67

2.69

2202

85.00

4.83

2.49

2039

90.00

4.13

2.30

1880

95.00

3.55

2.11

1727

100.00

3.06

1.93

1582

105.00

2.65

1.76

1445

110.00

2.31

1.61

1317

115.00

2.01

1.46

1198

2.3 Frequency-signal interface

Since current refrigerator applications mainly use frequency signals to control the compressor speed, the

board is designed with a frequency-signal interface. Figure 18 shows the interface circuit. The input signal is

isolated from the control and power parts on the board.

The board has two types of input interface:

1. Square-wave interface (default, remove the D3, R15 )

2. AC 220 V as the control input (you need to remove R18, and install D3, R15)

Type 1 is a more common signal type, while type two is used less, leaving only the interface for customers who

need it.

Figure 18 Frequency-interface circuit

Page 21

User guide 21 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System and functional description

A typical square wave input signal for refrigerator applications is shown in Table 5 for reference.

Table 5 Typical frequency/speed characteristic

Signal frequency fn (Hz)

Motor speed n (RPM)

fn < 30

Stop

30 ≤ fn < 40

Minimum speed

40 ≤ fn < 150

30 * f

n

150 ≤ fn < 200

Maximum speed

fn ≥ 200

Stop

Page 22

User guide 22 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System design

3 System design

This section provides the complete details of the schematics, layout and connectors. Please note that the

schematics, routing and Gerber generation are done in Altium Designer. Customers who are interested in the

original Altium format files or pdf files for better clarity can visit www.Infineon.com.

3.1 Schematics

The major function blocks are introduced in Section 2.2. Customers who are interested in further details can

download the design files after logging in your account on infineon webpage.

3.2 Layout

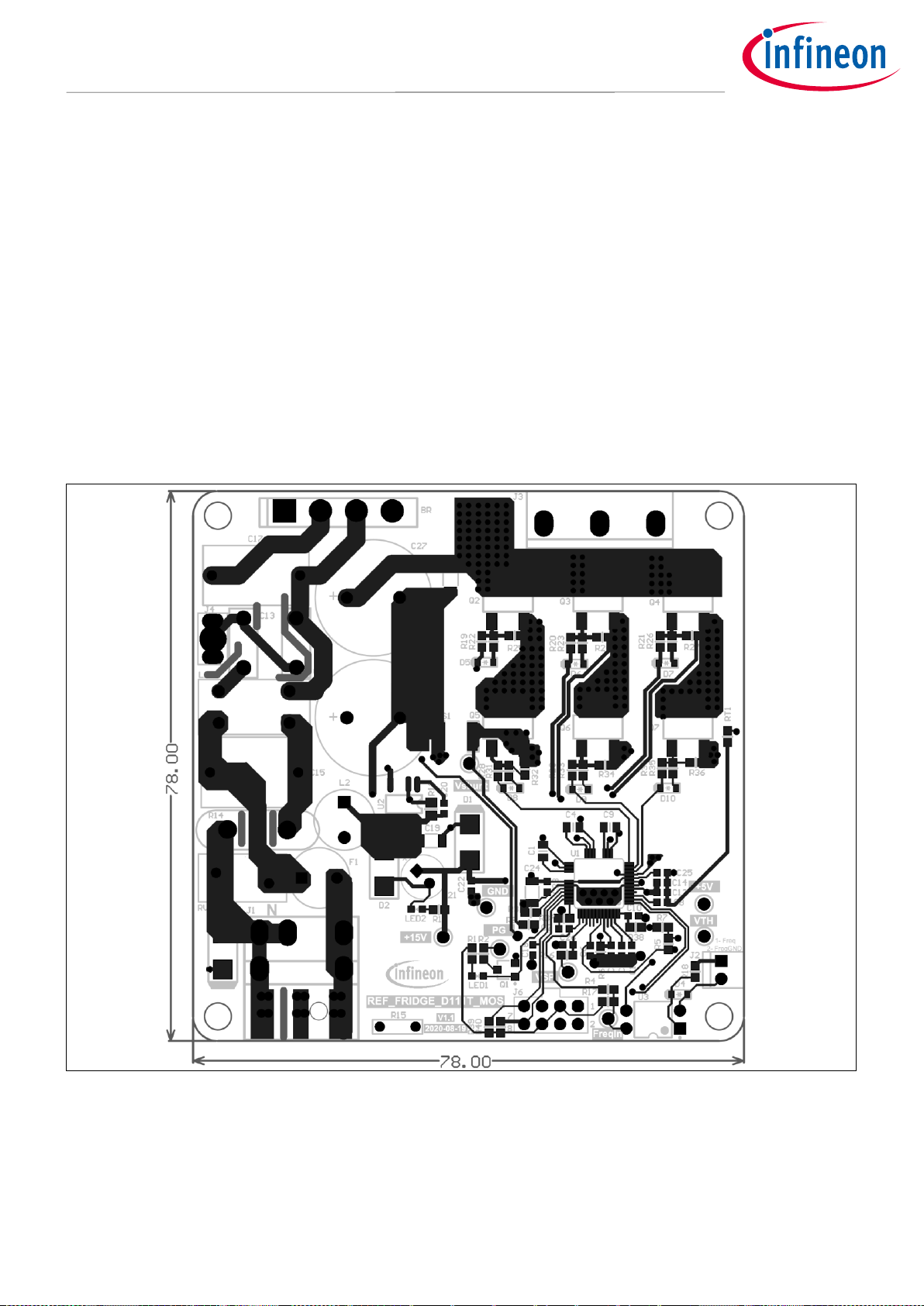

The board is designed in two layers, and its dimensions are 78 mm × 78 mm, manufactured with 1 oz. (35 µm)

copper thickness. The project is designed with Altium Designer, and all design files can be downloaded after

logging in your account on Infineon webpage.

Figure 19 Top view of the board

Page 23

User guide 23 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System design

Figure 20 Bottom view of the board

Here are a few design tips to note for your reference:

Thermal performance

Maximizing the copper area of the collector could effectively reduce the IGBT junction temperature, so the

board can deliver more power.

Ground layout

Since current sampling is non-differential and without op-amp, the ground area should be carefully laid out;

the digital ground should refer to the shunt ground to ensure the sampling noise is correct.

3.3 Bill of material

The complete bill of material is available on the download section of the Infineon homepage. A log-in is

required to download this material.

Page 24

User guide 24 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System design

Table 6 BOM of the most important/critical parts of the reference board

S. No.

Ref Designator

Description

Manufacturer

Manufacturer P/N

1

U1

IC iMOTION SMART DRIVER

Infineon

Technologies

IMD111T-6F040

2

Q2, Q3, Q4, Q5, Q6,

Q7

600 V CoolMOS PFD7 SJ Power

Device

Infineon

Technologies

IPN60R1K0PFD7S

3

Q1

MOSFET N-CH 30 V 2.7 A SOT-23-3

Infineon

Technologies

IRLML2030TRPBF

4

C19, C24

WCAP-CSGP General Purpose

Ceramic Capacitors, size 1206, 10

uF, +/-10%, 25 VDC

Wurth Elektronik

885012208069

5

C21

WCAP-ATG8 Aluminum

Electrolytic Capacitors, 6.3x11

mm, 25 Vdc, 220 uF

Wurth Elektronik

860010473011

6

C27, C28

WCAP-AT1H THT Aluminum

Electrolytic Capacitors, D16mm x

L35.5 mm, 100 uF, +/-20%, 450

VDC

Wurth Elektronik

860241480001

7

C29, C30

WCAP-CSST Soft Termination

Ceramic Capacitors, size 1206, 22

nF, +/-10%, 500 VDC

Wurth Elektronik

885382208010

8

J2

WR-WTB 2.54 mm Male Locking

Header, 2p

Wurth Elektronik

61900211121

9

J6

CONN HEADER VERT 8POS 2.54

mm

Wurth Elektronik

61300821121

10

L1

WE-CMB Common Mode Power

Line Choke, Type XS, 4 mH, 1.5 A,

250 V

Wurth Elektronik

744821240

11

RV1

WE-VD Disk Varistor, size 10 mm,

300 Vrms, 385 Vdc

Wurth Elektronik

820513011

12

RS1

RES 0.25 OHM 1% 3/4 W 2010

3.4 Connector details

Table 7 J1- AC line connector

PIN

Label

Function

1 L AC line input

2 N AC neutral input

3 N AC neutral input

Table 8 J2- Frequency input signal connector

PIN

Label

Function

1

Frequency input

Frequency input signal, isolated by optocoupler

2

Frequency ground

Frequency input signal ground, isolated by optocoupler

Page 25

User guide 25 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System design

Table 9 J3- Motor side connector

PIN

Label

Function

1 W Connected to motor phase W

2 V Connected to motor phase V

3 U Connected to motor phase U

Table 10 J4- Earth connector

PIN

Label

Function

1

Earth

Table 11 J6- iMOTION

TM

link connector

PIN

Label

Function

1

TXD1

User UART for script communication

2

RXD1

User UART for script communication

3 & 6

+3.3V

On board 3.3 V supply

4 & 5

GND

Ground

7

RXD0

MCEDesigner & firmware download

8

TXD0

MCEDesigner & firmware download

Page 26

User guide 26 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System performance

4 System performance

4.1 Thermal characterization test

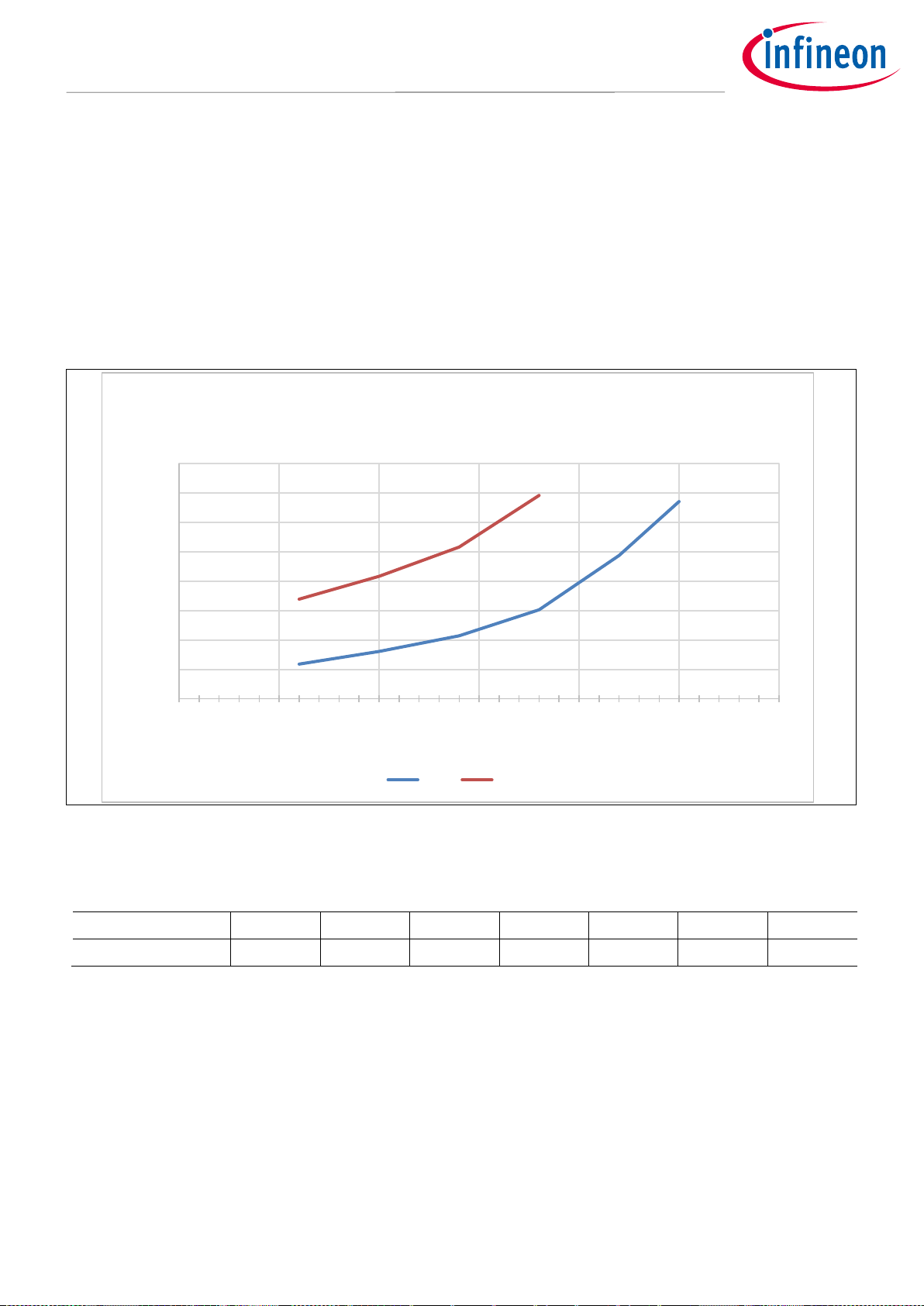

Figure 21 and Figure 22 show the thermal characterizations of REF_Fridge_D111T_MOS, based on 2 layers FR4

PCB with 1 oz. copper.

The tests reported on were performed under the following conditions: t

amb

=25°C, Vac = 220 V with different input

power until the MOSFET case reaches 100°C. There are two PWM frequencies (5 kHz and 16 kHz), and 3-phase

modulation mode only.

Figure 21 REF_Fridge_D111T_MOS thermal characterization case temperature – input power, t

a

=

25°C

Table 12 Input power and current characterization

Input power (W)

30

60

100

140

180

220

260

Input current (A)

0.24

0.45

0.72

1.03

1.32

1.6

1.81

30

40

50

60

70

80

90

100

110

0 50 100 150 200 250 300

Case Temperature (

)

Input Power(W)

REF_Fridge_D111T_MOS

Thermal characterization, Ta = 25

5kHz 16kHz

Page 27

User guide 27 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System performance

Figure 22 REF_Fridge_D111T_MOS thermal characterization, case temperature - motor phase

current, ta = 25°C

4.2 MOSFET dV/dt test

This section indicates the MOSFET turn-on and turn-off waveform, the oscilloscope probe is connected as

shown in Figure 23. On the board, R

g (on)

= 1 k, and R

g (off)

= 47 . The dV/dt is calculated by the voltage varying

from 10% to 90%.

Figure 23 Drain-to-source voltage test - dV/dt control

As shown in Figure 24 and Figure 25, when the low-side MOSFET turns on, the Vds dV/dt = 245 V/28.1 ns = 8.7

V/ns. When the low-side MOSFET turns off, the dV/dt = 247.9 V/ 29.8 ns = 8.3 V/ns. Users may further adapt the Rg

value to control MOSFET dv/dt if needed.

30

40

50

60

70

80

90

100

110

0.2 0.4 0.6 0.8

Case Temperature (

)

Phase current (A)

REF_Fridge_D111T_MOS

Thermal characterization, Ta = 25

5kHz 16kHz

Page 28

User guide 28 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

System performance

Figure 24 MOSFET turn-on waveform

Figure 25 MOSFET turn-off waveform

Page 29

User guide 29 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

Reference and appendices

5 Reference and appendices

5.1 Abbreviations and definitions

Table 13 Abbreviations

Abbreviation

Meaning

CE

Conformité Européenne

EMI

Electromagnetic interference

UL

Underwriters Laboratories

5.2 References

[1] Infineon Technologies AG. Datasheet of IPN60R1K0PFD7S (2019) V2.0 www.infineon.com

[2] Infineon Technologies AG. Datasheet of IMD111T-6F040 (2020) V1.0 www.infineon.com

[3] Infineon Technologies AG. Datasheet of IRLM2030TRPbF (2009) www.infineon.com

[4] Infineon Technologies AG. MCEWizard_V2.3.0.0 User Guide (2019) www.infineon.com

[5] Infineon Technologies AG. MCEDesigner_V2.3.0.0 Application Guide (2019) www.infineon.com

[6] Infineon Technologies AG. iMOTION™ Motion Control Engine Software Reference Manual (2020) V1.3

www.infineon.com

5.3 Additional information

In order to initiate testing, customers are advised to order the iMOTIONTM Link, the information is listed in the

Table 14.

The Infineon’s components on the board are listed in the Table 14 as well, the customers can visit the

corresponding webpage for more information.

Table 14 Additional information of tools and infineon’s components

Base part number

Package

Standard pack

Orderable part number

Form

Quantity

iMOTIONTM Link

Container

1

IMOTIONLINK

IMD111T-6F040

PG-LQFP-40

Tape and reel

1500

IMD111T6F040XUMA1

IPN60R1K0PFD7S

PG-SOT223-3

Tape and reel

3000

IPN60R1K0PFD7SATMA1

IRLML2030TRPBF

SOT-23

Tape and reel

3000

IRLML2030TRPBF

Page 30

User guide 30 of 31 V1.0

2020-10-16

REF_Fridge_D111T_MOS user guide

Refrigerator compressor driver reference design kit

Revision history

Revision history

Document

version

Date of release

Description of changes

1.0

2020/10/16

Initial version

Page 31

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-10-16

UG-2020-19

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2021 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Loading...

Loading...