Page 1

Datasheet , Ver s i o n 2. 3 , 02 Ap r 20 1 3

CoolSET ™ -F3

ICE3A(B)036 5 / 0 565/1065/ 15 6 5

ICE3A(B)206 5 / 2 565

ICE3A0565Z/2 0 6 5Z

ICE3A(B)206 5 I / 3 065I/3565 I

ICE3A(B)506 5 I / 5 565I

ICE3A(B)206 5 P /3065P/356 5P

ICE3A(B)506 5 P /5565P

Off-Line SMPS Current Mode

Controller with integrated 650V

Startup Cell/Dep le t io n C o olMOS™

Pow er Ma na g e m en t & Sup p l y

N e v e r s t o p t h i n k i n g .

Page 2

CoolSET™-F3

Revision History: 2013-04-02 Datasheet

Previous Version: V2.2

Page Subjects (major changes since last revision)

29 revised outline dimension for PG-DIP-8

For questions on technology, delivery and prices please contact the Infineon Technologies Offices in Germany or

the Infineon Technologies Companies and Representatives worldwide: see our webpage at http://

www.infineon.com

CoolMOS™ , CoolSET™ are trademarks of Infineon Technologies AG.

Edition 2013-04-02

Published by

Infineon Technologies AG,

81726 Munich, Germany,

© 2012 Infineon Technologies AG.

All Rights Reserved.

Legal disclaimer

The information given in this document shall in no event be regarded as a guarantee of conditions or

characteristics. With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Infineon Technologies hereby disclaims any and all warranties

and liabilities of any kind, including without limitation, warranties of non-infringement of intellectual property rights

of any third party.

Information

For further information on technology, delivery terms and conditions and prices, please contact your nearest

Infineon Technologies Office (www.infineon.com).

Warnings

Due to technical requirements, components may contain dangerous substances. For information on the types in

question, please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may be used in life-support devices or systems only with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Page 3

Off-Line SMPS Current Mode Controller

with integrated 650V Startup Cell/

Depletion CoolMOS™

Product Highlights

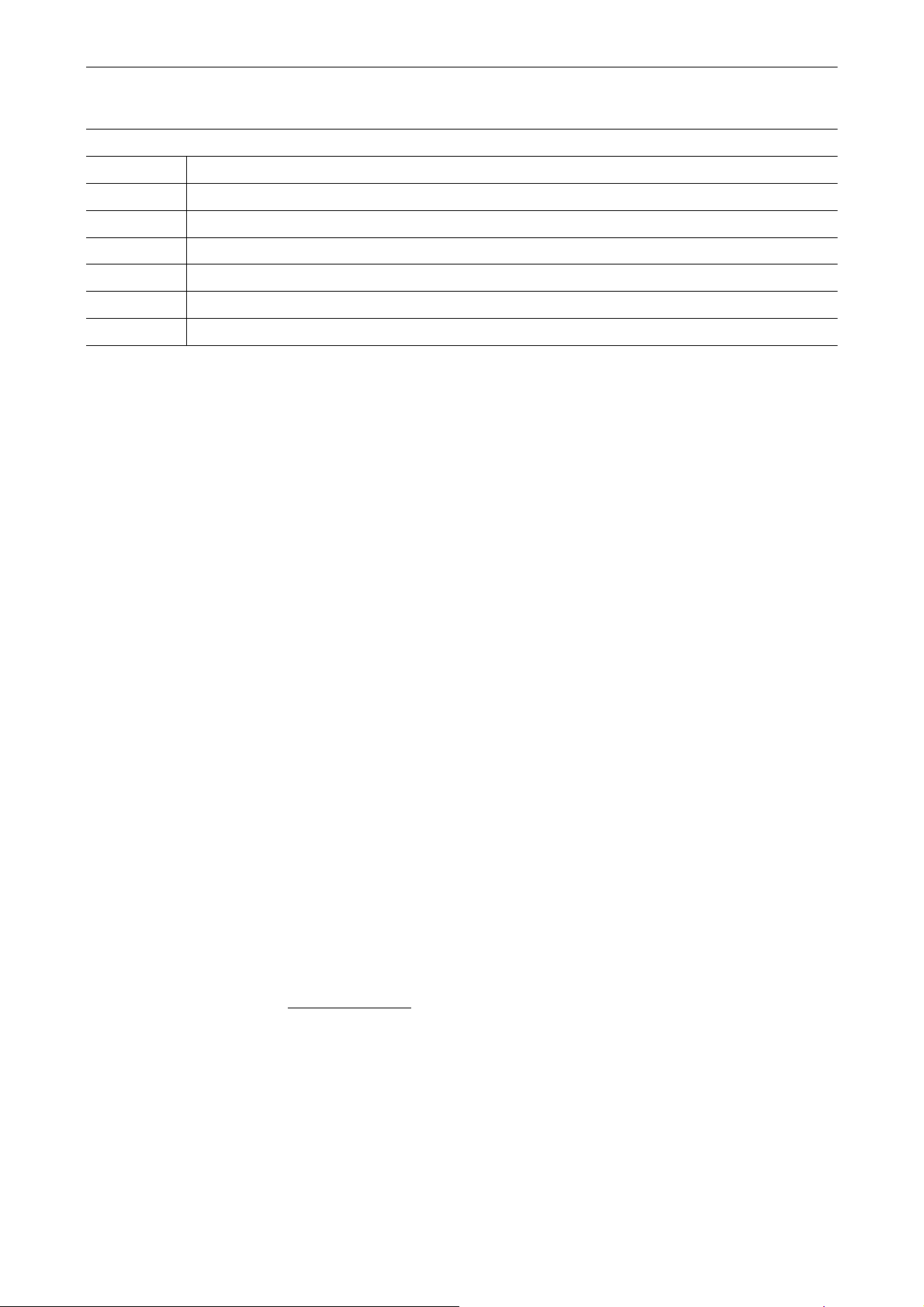

• Best in class in DIP7, DIP8, TO220/I2Pak packages

• Active Burst Mode to reach the lowest Standby Power

Requirements < 100mW

• Protection features (Auto Restart Mode) to increase

robustness and safety of the system

• Adjustable Blanking Window for high load jumps to

increase system reliability

• Isolated drain package for TO220/I2Pak

• Wide creepage distance for DIP7/TO220/I2Pak

• Wide power class of products for various applications

• Pb-free lead plating for all packages; RoHS compliant

CoolSET™-F3

PG-DIP-7-1

PG-DIP-8

PG-TO220-6-46 (I2Pak)

PG-TO220-6-47

Features

• 650V avalanche rugged CoolMOS™ with built in

switchable Startup Cell

• Active Burst Mode for lowest Standby Power

@ light load controlled by Feedback signal

• Fast load jump response in Active Burst Mode

• 67/100 kHz fixed switching frequency

• Auto Restart Mode for Overtemperature Detection

• Auto Restart Mode for Overvoltage Detection

• Auto Restart Mode for Overload and Open Loop

• Auto Restart Mode for VCC Undervoltage

• Blanking Window for short duration high current

• User defined Soft Start

• Minimum of external components required

• Max Duty Cycle 72%

• Overall tolerance of Current Limiting < ±5%

• Internal PWM Leading Edge Blanking

• Soft driving for low EMI

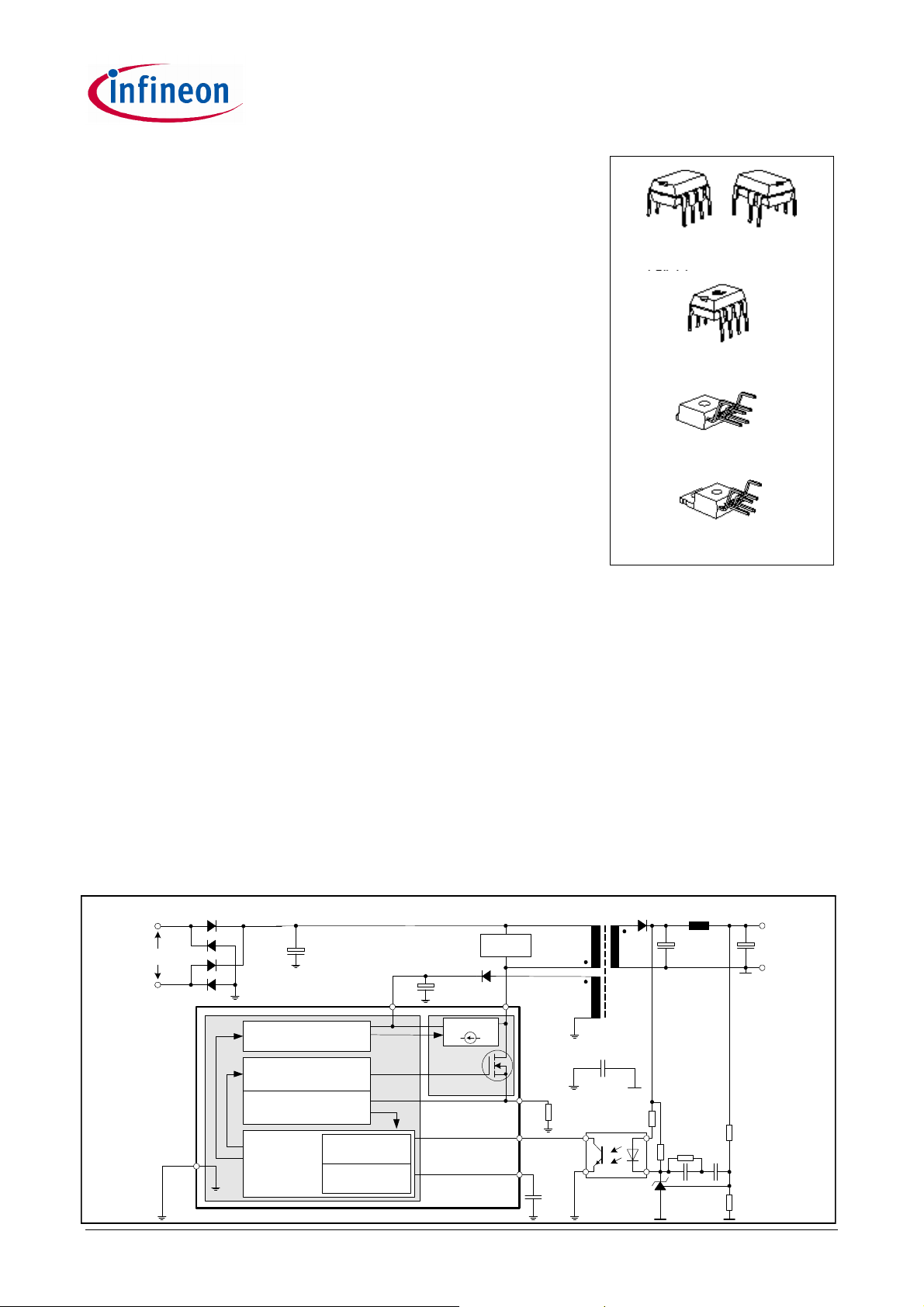

Typical Application

C

85 ... 270 VAC

Power Management

Bulk

VCC

Description

The new generation CoolSET™-F3 provides Active Burst

Mode to reach the lowest Standby Power Requirements

<100mW at no load. As the controller is always active

during Active Burst Mode, there is an immediate response

on load jumps without any black out in the SMPS. In Active

Burst Mode the ripple of the output voltage can be reduced

<1%. Furthermore, to increase the robustness and safety

of the system, the device enters into Auto Restart Mode in

the cases of Overtemperature, VCC Overvoltage, Output

Open Loop or Overload and VCC Undervoltage. By means

of the internal precise peak current limitation, the

dimension of the transformer and the secondary diode can

be lowered which leads to more cost efficiency. An

adjustable blanking window prevents the IC from entering

Auto Restart or Active Burst Mode unintentionally during

high load jumps. The CoolSET™-F3 family consists a wide

power class range of products for various applications.

+

Converter

DC Output

-

C

VCC

Startup Cell

Snubber

Drain

PWM Controller

GND

Current Mode

Precise Low Tolerance Peak

Current Limitation

Control

Unit

Active Burst Mode

AutoRestart Mode

Depl.

CoolMOS™

CoolSET™-F3

CS

FB

SoftS

R

Sense

C

SoftS

Version 2.3 3 02 Apr 2013

Page 4

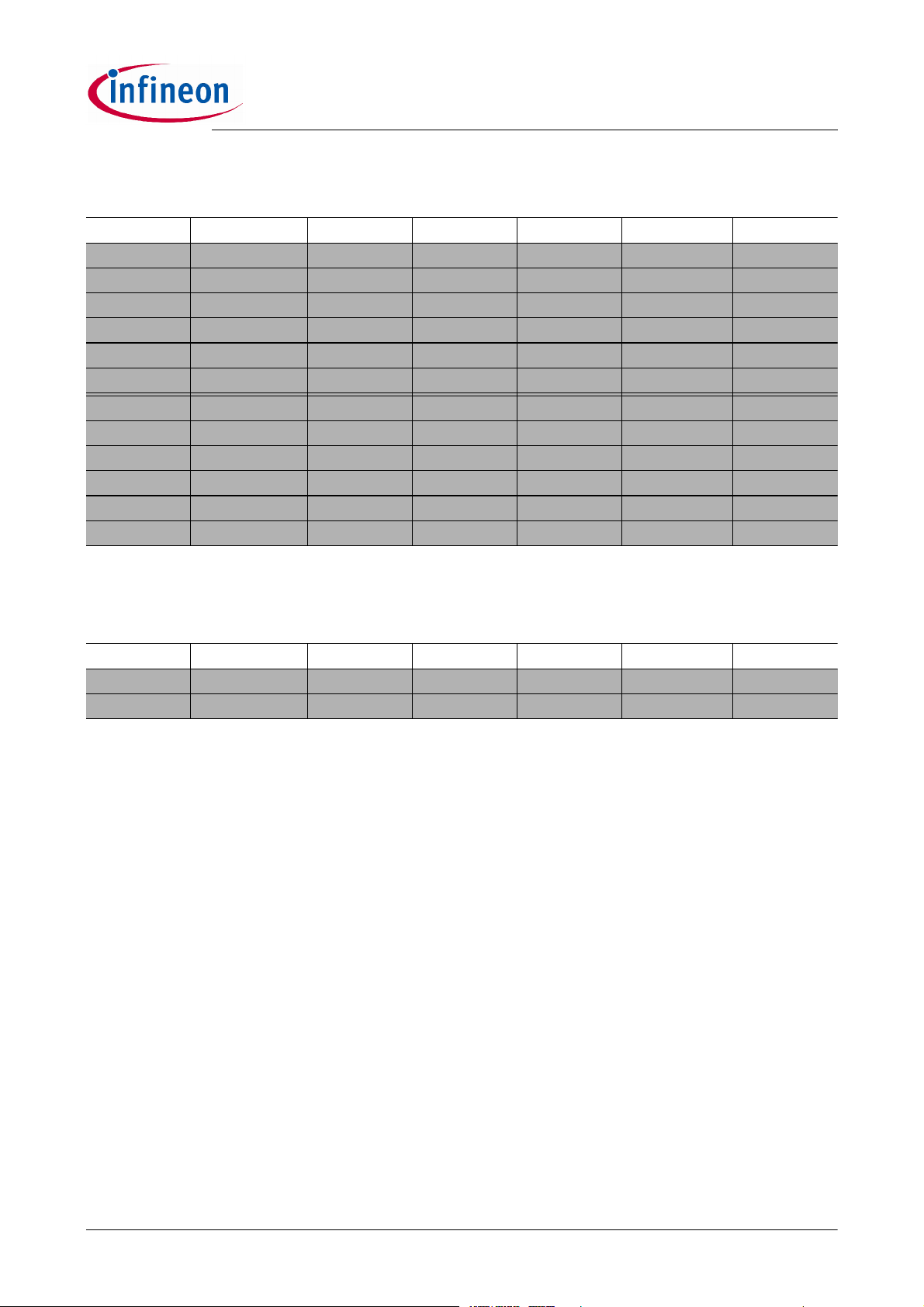

Overview

CoolSET™-F3

Type Package V

DS

F

OSC

R

DSon

1)

230VAC ±15%

2)

85-265 VAC

ICE3A0365 PG-DIP-8 650V 100kHz 6.45 22W 10W

ICE3A0565 PG-DIP-8 650V 100kHz 4.70 25W 12W

ICE3A1065 PG-DIP-8 650V 100kHz 2.95 32W 16W

ICE3A1565 PG-DIP-8 650V 100kHz 1.70 42W 20W

ICE3A2065 PG-DIP-8 650V 100kHz 0.92 57W 28W

ICE3A2565 PG-DIP-8 650V 100kHz 0.65 68W 33W

ICE3B0365 PG-DIP-8 650V 67kHz 6.45 22W 10W

ICE3B0565 PG-DIP-8 650V 67kHz 4.70 25W 12W

ICE3B1065 PG-DIP-8 650V 67kHz 2.95 32W 16W

ICE3B1565 PG-DIP-8 650V 67kHz 1.70 42W 20W

ICE3B2065 PG-DIP-8 650V 67kHz 0.92 57W 28W

ICE3B2565 PG-DIP-8 650V 67kHz 0.65 68W 33W

1)

typ @ T=25°C

2)

Calculated maximum input power rating at Ta=75°C, Tj=125°C and without copper area as heat sink.

Type Package V

DS

F

OSC

R

DSon

1)

230VAC ±15%

2)

85-265 VAC

ICE3A0565Z PG-DIP-7-1 650V 100kHz 4.70 25W 12W

ICE3A2065Z PG-DIP-7-1 650V 100kHz 0.92 57W 28W

1)

typ @ T=25°C

2)

Calculated maximum input power rating at Ta=75°C, Tj=125°C and without copper area as heat sink.

2)

2)

Version 2.3 4 02 Apr 2013

Page 5

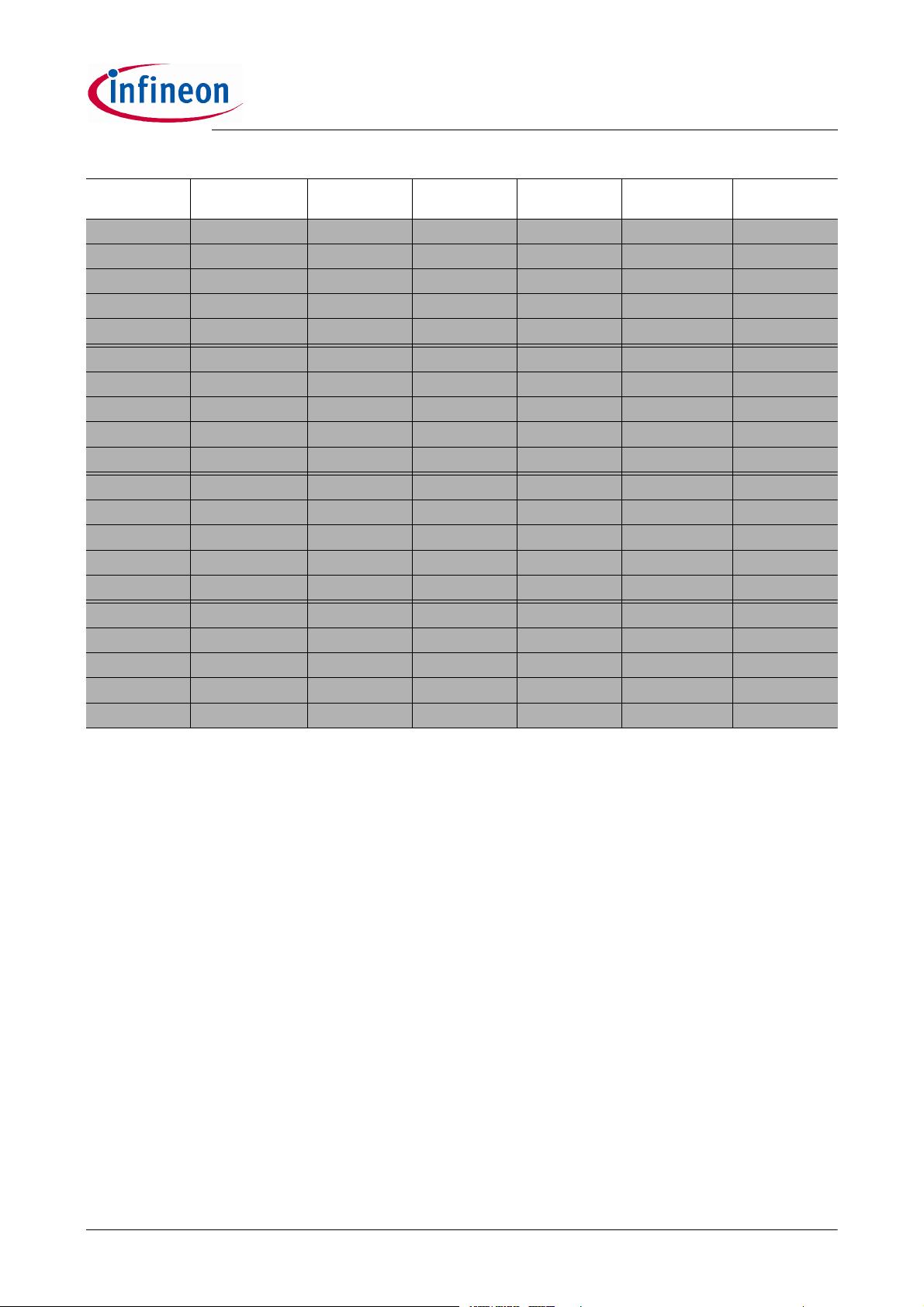

CoolSET™-F3

Type Package V

DS

F

OSC

R

DSon

1)

230VAC

±15%

2)

85-265 VAC

ICE3A2065I PG-TO-220-6-46 650V 100kHz 3.00 102W 50W

ICE3A3065I PG-TO-220-6-46 650V 100kHz 2.10 128W 62W

ICE3A3565I PG-TO-220-6-46 650V 100kHz 1.55 170W 83W

ICE3A5065I PG-TO-220-6-46 650V 100kHz 0.95 220W 105W

ICE3A5565I PG-TO-220-6-46 650V 100kHz 0.79 240W 120W

ICE3B2065I PG-TO-220-6-46 650V 67kHz 3.00 102W 50W

ICE3B3065I PG-TO-220-6-46 650V 67kHz 2.10 128W 62W

ICE3B3565I PG-TO-220-6-46 650V 67kHz 1.55 170W 83W

ICE3B5065I PG-TO-220-6-46 650V 67kHz 0.95 220W 105W

ICE3B5565I PG-TO-220-6-46 650V 67kHz 0.79 240W 120W

ICE3A2065P PG-TO-220-6-47 650V 100kHz 3.00 102W 50W

ICE3A3065P PG-TO-220-6-47 650V 100kHz 2.10 128W 62W

ICE3A3565P PG-TO-220-6-47 650V 100kHz 1.55 170W 83W

ICE3A5065P PG-TO-220-6-47 650V 100kHz 0.95 220W 105W

ICE3A5565P PG-TO-220-6-47 650V 100kHz 0.79 240W 120W

ICE3B2065P PG-TO-220-6-47 650V 67kHz 3.00 102W 50W

ICE3B3065P PG-TO-220-6-47 650V 67kHz 2.10 128W 62W

ICE3B3565P PG-TO-220-6-47 650V 67kHz 1.55 170W 83W

ICE3B5065P PG-TO-220-6-47 650V 67kHz 0.95 220W 105W

ICE3B5565P PG-TO-220-6-47 650V 67kHz 0.79 240W 120W

1)

typ @ T=25°C

2)

Calculated maximum continuous input power in an open frame design at Ta=50°C, Tj=125°C and R

(external heatsink)=2.7K/W

thCA

2)

Version 2.3 5 02 Apr 2013

Page 6

CoolSET™-F3

Table of Contents Page

1 Pin Configuration and Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.1 Pin Configuration with PG-DIP-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2 Pin Configuration with PG-DIP-7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3 Pin Configuration with PG-TO220-6-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.4 Pin Configuration with PG-TO220-6-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.5 Pin Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

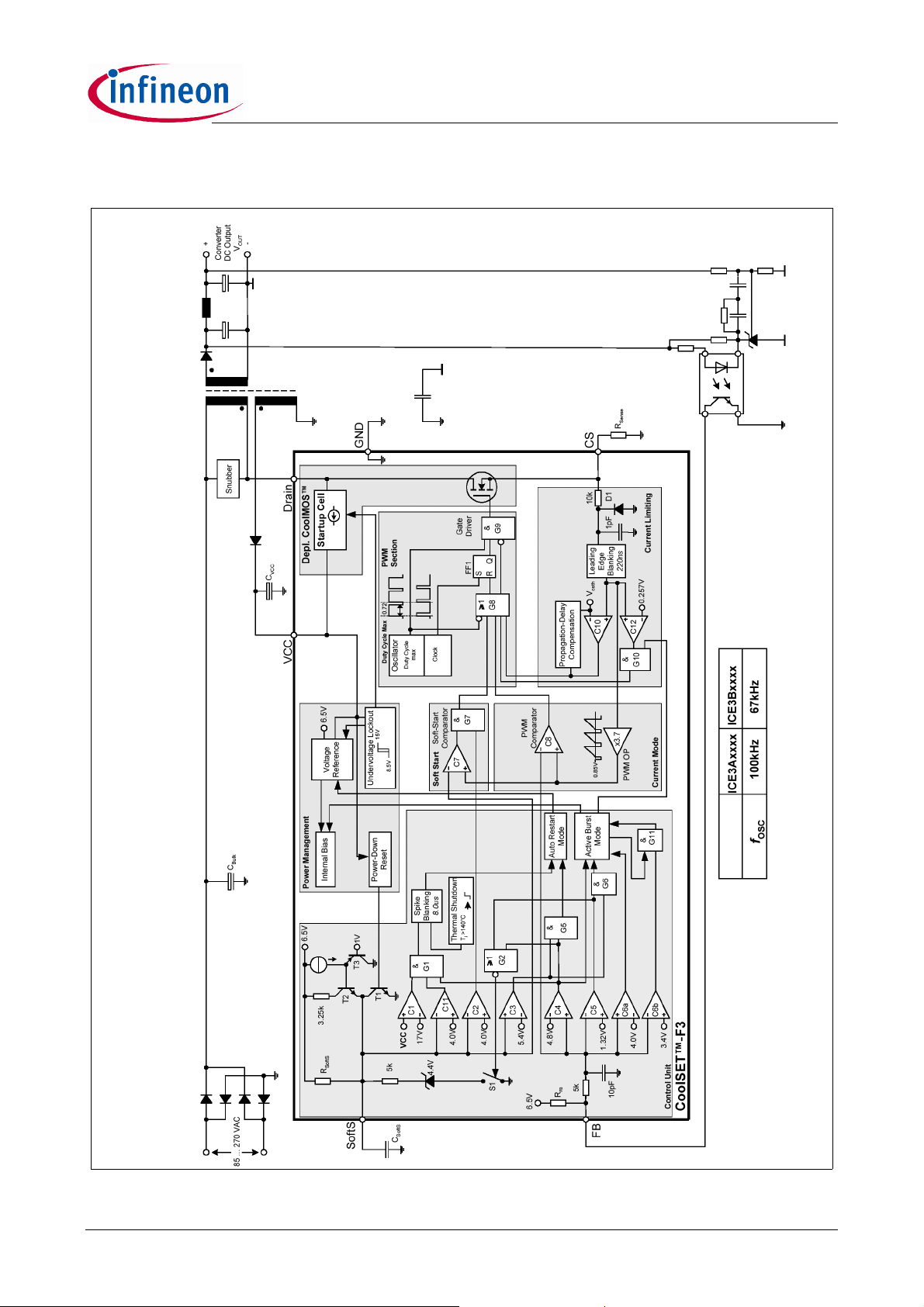

2 Representative Blockdiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Startup Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4 PWM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4.1 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4.2 PWM-Latch FF1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4.3 Gate Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.5 Current Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5.1 Leading Edge Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5.2 Propagation Delay Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.6 Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.6.1 Adjustable Blanking Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.6.2 Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.6.2.1 Entering Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.6.2.2 Working in Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.6.2.3 Leaving Active Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.6.3 Protection Mode (Auto Restart Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.1 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.2 Operating Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.1 Supply Section 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.3.2 Supply Section 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.3.3 Internal Voltage Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.3.4 PWM Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.3.5 Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.3.6 Current Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.3.7 CoolMOS™ Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5 Outline Dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Version 2.3 6 02 Apr 2013

Page 7

Pin Configuration and Functionality

1 Pin Configuration and Functionality

CoolSET™-F3

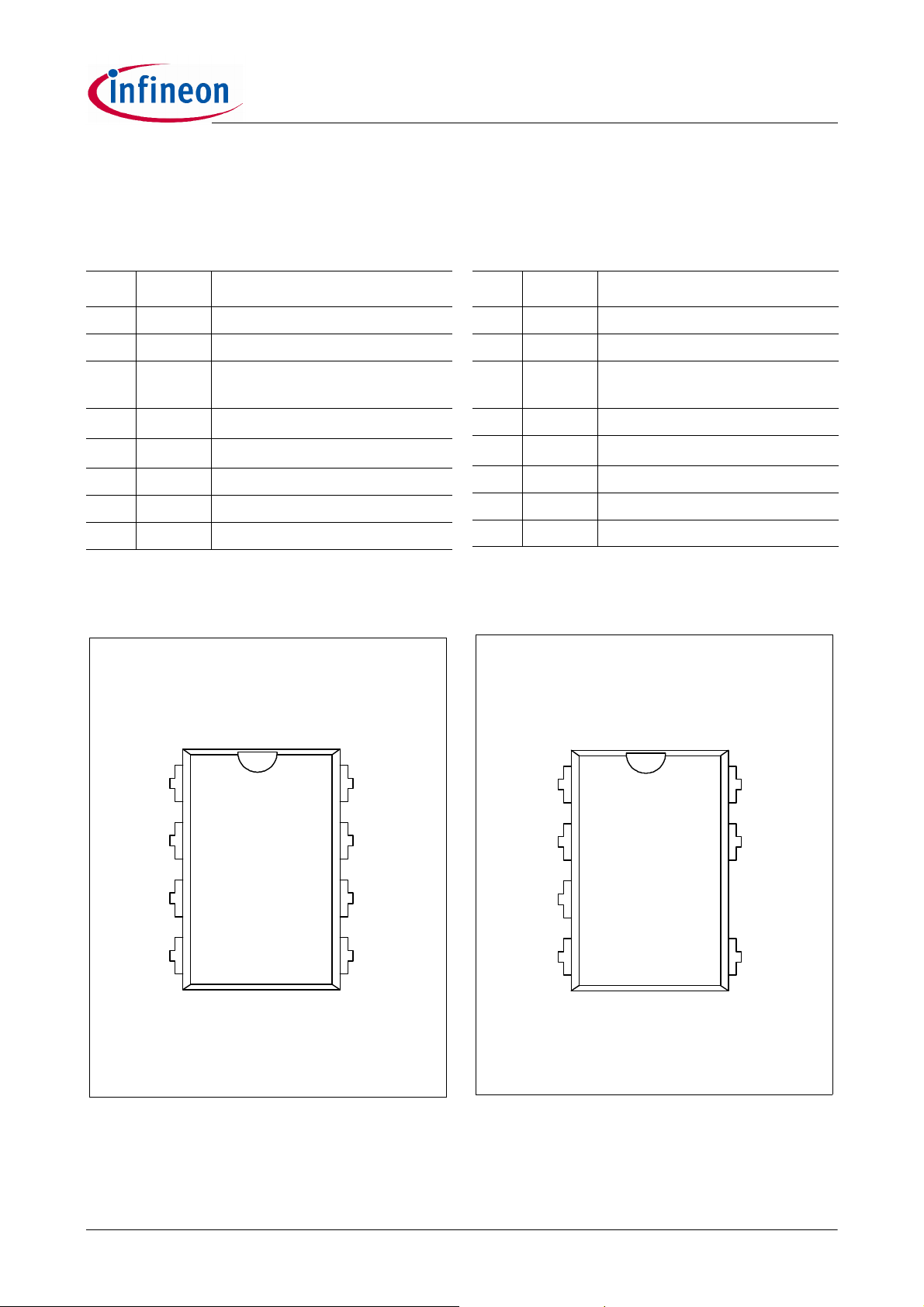

1.1 Pin Configuration with PG-DIP-8

Pin Symbol Function

1 SoftS Soft-Start

2 FB Feedback

3 CS Current Sense/

650V1)Depl. CoolMOS™ Source

4 Drain

5 Drain

6 n.c. Not Connected

7 VCC Controller Supply Voltage

8 GND Controller Ground

1)

at Tj= 110°C

650V1)Depl. CoolMOS™ Drain

650V1)Depl. CoolMOS™ Drain

Package PG-DIP-8

1.2 Pin Configuration with PG-DIP-7-1

Pin Symbol Function

1 SoftS Soft-Start

2 FB Feedback

3 CS Current Sense/

650V1)Depl. CoolMOS™ Source

4 n.c. Not connected

5 Drain

- - 7 VCC Controller Supply Voltage

8 GND Controller Ground

1)

at Tj= 110°C

650V1)Depl. CoolMOS™ Drain

Package PG-DIP-7-1

1

FB

CS

Drain Drain

Figure 1 Pin Configuration PG-DIP-8(top view)

Note: Pin 4 and 5 are shorted within the DIP 8 package.

2

3

4

8

7

6

5

GNDSoftS

VCC

n.c.

1

FB

CS

n.c. Drain

Figure 2 Pin Configuration PG-DIP-7-1(top view)

2

3

4

8

7

5

GNDSoftS

VCC

Version 2.3 7 02 Apr 2013

Page 8

CoolSET™-F3

Pin Configuration and Functionality

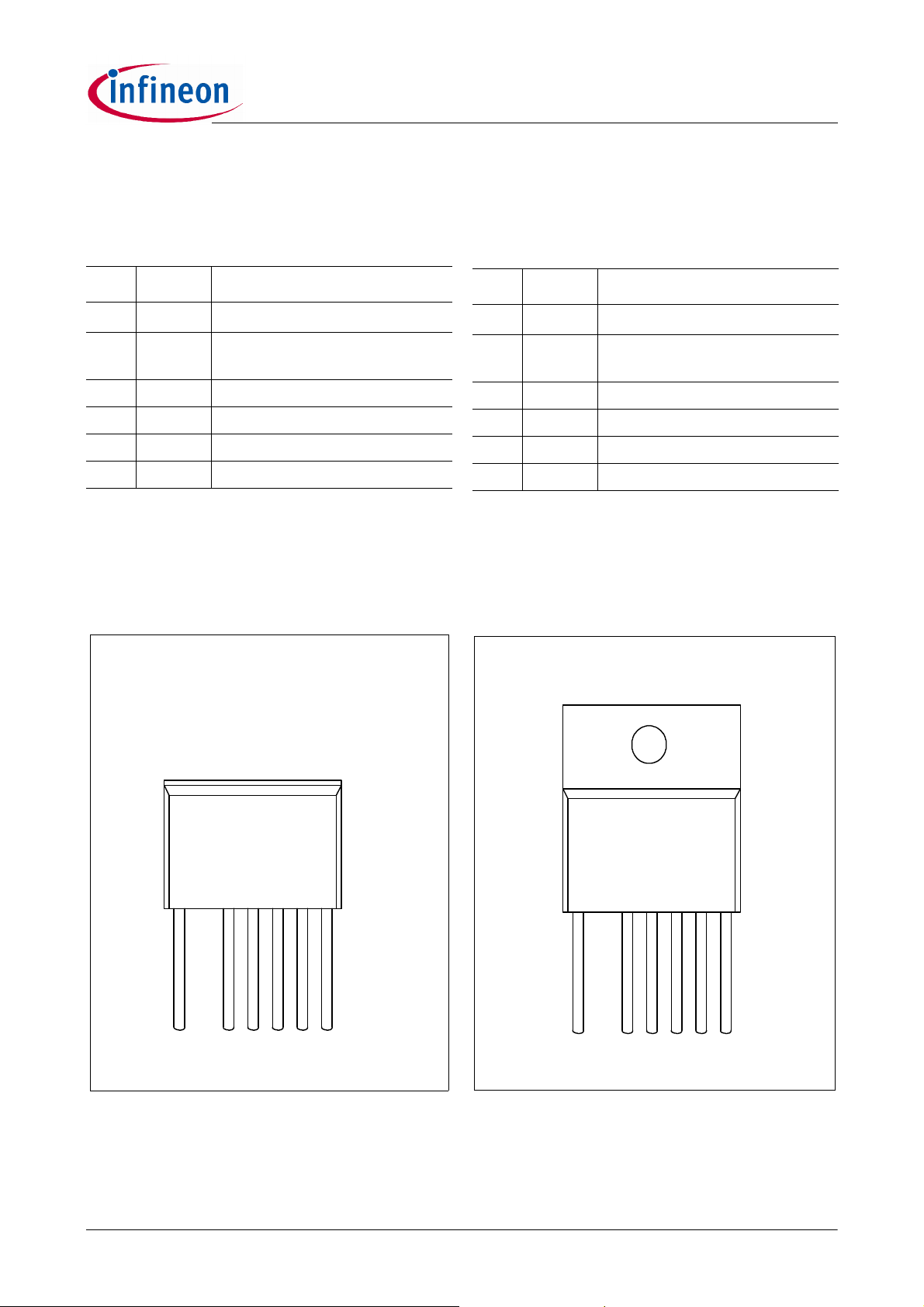

1.3 Pin Configuration with PG-TO220-6-46

Pin Symbol Function

1 Drain

650V1)Depl. CoolMOS™ Drain

3 CS Current Sense/

650V1)Depl. CoolMOS™ Source

4 GND Controller Ground

5 VCC Controller Supply Voltage

6 SoftS Soft-Start

7 FB Feedback

1)

at Tj= 110°C

Package PG-TO220-6-46 (I2Pak)

1.4 Pin Configuration with PG-TO220-6-47

Pin Symbol Function

1 Drain

650V1)Depl. CoolMOS™ Drain

3 CS Current Sense/

650V1)Depl. CoolMOS™ Source

4 GND Controller Ground

5 VCC Controller Supply Voltage

6 SoftS Soft-Start

7 FB Feedback

1)

at Tj= 110°C

Package PG-TO220-6-47

1

2 3 4 5 6 7

Drain

CS

GND

VCC

SoftS

FB

Figure 3 Pin Configuration PG-TO220-6-46 I2Pak

(front view)

Figure 4 Pin Configuration PG-TO220-6-47

1

2 3 4 5 6 7

Drain

(front view)

CS

GND

VCC

SoftS

FB

Version 2.3 8 02 Apr 2013

Page 9

1.5 Pin Functionality

SoftS (Soft Start & Auto Restart Control)

The SoftS pin combines the functions of Soft Start

during Start Up and error detection for Auto Restart

Mode. These functions are implemented and can be

adjusted by means of an external capacitor at SoftS to

ground. This capacitor also provides an adjustable

blanking window for high load jumps, before the IC

enters into Auto Restart Mode.

FB (Feedback)

The information about the regulation is provided by the

FB Pin to the internal Protection Unit and to the internal

PWM-Comparator to control the duty cycle. The FBSignal controls in case of light load the Active Burst

Mode of the controller.

CS (Current Sense)

The Current Sense pin senses the voltage developed

on the series resistor inserted in the source of the

integrated Depl. CoolMOS™. If CS reaches the internal

threshold of the Current Limit Comparator, the Driver

output is immediately switched off. Furthermore the

current information is provided for the PWMComparator to realize the Current Mode.

CoolSET™-F3

Pin Configuration and Functionality

Drain (Drain of integrated Depl. CoolMOS™)

Pin Drain is the connection to the Drain of the internal

Depl. CoolMOSTM.

VCC (Power supply)

The VCC pin is the positive supply of the IC. The

operating range is between 8.5V and 21V.

GND (Ground)

The GND pin is the ground of the controller.

Version 2.3 9 02 Apr 2013

Page 10

2 Representative Blockdiagram

CoolSET™-F3

Representative Blockdiagram

Figure 5 Representative Blockdiagram

Version 2.3 10 02 Apr 2013

Page 11

3 Functional Description

CoolSET™-F3

Functional Description

All values which are used in the functional description

are typical values. For calculating the worst cases the

min/max values which can be found in section 4

Electrical Characteristics have to be considered.

3.1 Introduction

CoolSET™-F3 is the further development of the

CoolSET™-F2 to meet the requirements for the lowest

Standby Power at minimum load and no load

conditions. A new fully integrated Standby Power

concept is implemented into the IC in order to keep the

application design easy. Compared to CoolSET™-F2

no further external parts are needed to achieve the

lowest Standby Power. An intelligent Active Burst

Mode is used for this Standby Mode. After entering this

mode there is still a full control of the power conversion

by the secondary side via the same optocoupler that is

used for the normal PWM control. The response on

load jumps is optimized. The voltage ripple on V

minimized. V

is further on well controlled in this

out

mode.

The usually external connected RC-filter in the

feedback line after the optocoupler is integrated in the

IC to reduce the external part count.

Furthermore a high voltage Startup Cell is integrated

into the IC which is switched off once the Undervoltage

Lockout on-threshold of 15V is exceeded. This Startup

Cell is part of the integrated Depl. CoolMOS™. The

external startup resistor is no longer necessary as this

Startup Cell is connected to the Drain. Power losses

are therefore reduced. This increases the efficiency

under light load conditions drastically.

The Soft-Start capacitor is also used for providing an

adjustable blanking window for high load jumps. During

this time window the overload detection is disabled.

With this concept no further external components are

necessary to adjust the blanking window.

An Auto Restart Mode is implemented in the IC to

reduce the average power conversion in the event of

malfunction or unsafe operating condition in the SMPS

system. This feature increases the system’s

robustness and safety which would otherwise lead to a

destruction of the SMPS. Once the malfunction is

removed, normal operation is automatically initiated

after the next Start Up Phase.

The internal precise peak current limitation reduces the

costs for the transformer and the secondary diode. The

influence of the change in the input voltage on the

power limitation can be avoided together with the

integrated Propagation Delay Compensation.

Therefore the maximum power is nearly independent

on the input voltage which is required for wide range

SMPS. There is no need for an extra over-sizing of the

SMPS, e.g. the transformer or the secondary diode.

out

3.2 Power Management

VCC Drain

Startup Cell

Depl. CoolMOS™

Power

Undervoltage Lockout

8.5V

15V

is

T1

SoftS

Figure 6 Power Management

The Undervoltage Lockout monitors the external

supply voltage V

. When the SMPS is plugged to the

VCC

main line the internal Startup Cell is biased and starts

to charge the external capacitor C

connected to the VCC pin. This VCC charge current

which is provided by the Startup Cell from the Drain pin

is 1.05mA. When V

V

=15V the internal voltage reference and bias

CCon

exceeds the on-threshold

VCC

circuit are switched on. Then the Startup Cell is

switched off by the Undervoltage Lockout and therefore

no power losses present due to the connection of the

Startup Cell to the Drain voltage. To avoid uncontrolled

ringing at switch-on a hysteresis is implemented. The

switch-off of the controller can only take place after

Active Mode was entered and V

The maximum current consumption before the

controller is activated is about 160mA.

When V

falls below the off-threshold V

VCC

internal reference is switched off and the Power Down

reset let T1 discharging the soft-start capacitor C

pin SoftS. Thus it is ensured that at every startup cycle

the voltage ramp at pin SoftS starts at zero.

Management

Internal Bias

Voltage

Reference

Auto Restart

Mode

Active Burst

Mode

VCC

falls below 8.5V.

VCC

CCoff

6.5V

which is

=8.5V the

SoftS

at

Version 2.3 11 02 Apr 2013

Page 12

CoolSET™-F3

Functional Description

The internal Voltage Reference is switched off if Auto

Restart Mode is entered. The current consumption is

then reduced to 300mA.

Once the malfunction condition is removed, this block

will then turn back on. The recovery from Auto Restart

Mode does not require disconnecting the SMPS from

the AC line.

When Active Burst Mode is entered, the internal Bias is

switched off in order to reduce the current consumption

to below 1.05mA while keeping the Voltage Reference

active as this is necessary in this mode.

3.3 Startup Phase

6.5V

3.25k

R

SoftS

T2

T3

1V

SoftS

DC

which is controlled by comparator C7 since

max

comparator C2 blocks the gate G7 (see Figure 7). This

maximum charge current in the very first stage when

V

is below 1V, is limited to 1.32mA.

SoftS

V

SoftS

max.StartupPhase

5.4V

4V

1V

max.SoftStart Phase

DC

DC

DC

max

1

2

t

C

SoftS

4V

0.85V

SoftStart

C7

C2

PWMOP

Soft-Start

Comparator

&

G7

x3.7

GateDriver

CS

Figure 7 Soft Start

At the beginning of the Startup Phase, the IC provides

a Soft Start duration whereby it controls the maximum

primary current by means of a duty cycle limitation. A

signal V

capacitor C

resistor R

which is generated by the external

SoftS

in combination with the internal pull up

Softs

, determines the duty cycle until V

SoftS

SoftS

exceeds 4V.

When the Soft Start begins, C

is immediately

SoftS

charged up to approx. 1V by T2. Therefore the Soft

Start Phase takes place between 1V and 4V. Above

V

= 4V there is no longer duty cycle limitation

SoftsS

t1 t2

t

Figure 8 Startup Phase

By means of this extra charge stage, there is no delay

in the beginning of the Startup Phase when there is still

no switching. Furthermore Soft Start is finished at 4V to

have faster the maximum power capability. The duty

cycles DC1and DC2are depending on the mains and

the primary inductance of the transformer. The

limitation of the primary current by DC2is related to

V

= 4V. But DC1is related to a maximum primary

SoftS

current which is limited by the internal Current Limiting

with CS = 1V. Therefore the maximum Startup Phase

is divided into a Soft Start Phase until t1 and a phase

from t1 until t2 where maximum power is provided if

demanded by the FB signal.

Version 2.3 12 02 Apr 2013

Page 13

CoolSET™-F3

Functional Description

3.4 PWM Section

0.72

Oscillator

DutyCycle

max

Clock

SoftStart

Comparator

PWM

Comparator

Current

Limiting

Figure 9 PWM Section

1

G8

3.4.3 Gate Driver

PWMSection

VCC

PWM-Latch

1

Gate

FF1

CoolMOS™

Q

GateDriver

&

G9

Internal

CoolMOS™

Gate

Gate Driver

Figure 10 Gate Driver

The driver-stage is optimized to minimize EMI and to

provide high circuit efficiency. This is done by reducing

S

R

the switch on slope when exceeding the internal

CoolMOS™ threshold. This is achieved by a slope

control of the rising edge at the driver’s output (see

Figure 11).

3.4.1 Oscillator

The oscillator generates a fixed frequency. The

switching frequency of ICE3Axx65x is f

and for ICE3Bxx65x f

= 67kHz. A resistor, a

OSC

OSC

= 100kHz

capacitor and a current source and current sink which

determine the frequency are integrated. The charging

and discharging current of the implemented oscillator

capacitor are internally trimmed, in order to achieve a

very accurate switching frequency. The ratio of

controlled charge to discharge current is adjusted to

reach a maximum duty cycle limitation of D

max

=0.72.

3.4.2 PWM-Latch FF1

The oscillator clock output provides a set pulse to the

PWM-Latch when initiating the internal CoolMOS™

conduction. After setting the PWM-Latch can be reset

by the PWM comparator, the Soft Start comparator or

the Current-Limit comparator. In case of resetting, the

driver is shut down immediately.

(internal)V

5V

Gate

ca.t =130ns

t

Figure 11 Gate Rising Slope

Thus the leading switch on spike is minimized. When

the integrated CoolMOS™ is switched off, the falling

shape of the driver is slowed down when reaching 2V

to prevent an overshoot below ground. Furthermore the

driver circuit is designed to eliminate cross conduction

of the output stage.

During powerup when VCC is below the undervoltage

lockout threshold V

is low to disable power transfer to the seconding side.

, the output of the Gate Driver

VCCoff

Version 2.3 13 02 Apr 2013

Page 14

CoolSET™-F3

Functional Description

3.5 Current Limiting

PWMLatch

FF1

CurrentLimiting

Propagation-Delay

Compensation

V

csth

C10

PWM-OP

&

G10

ActiveBurst

Mode

C12

0.257V

10k

CS

Figure 12 Current Limiting Block

There is a cycle by cycle Current Limiting realized by

the Current-Limit comparator C10 to provide an

overcurrent detection. The source current of the

internal CoolMOS™ is sensed via an external sense

resistor R

is transformed to a sense voltage V

into the pin CS. If the voltage V

internal threshold voltage V

immediately turns off the gate drive by resetting the

PWM Latch FF1. A Propagation Delay Compensation

is added to support the immediate shut down without

delay of the internal CoolMOS™ in case of Current

Limiting. The influence of the AC input voltage on the

maximum output power can thereby be avoided.

To prevent the Current Limiting from distortions caused

by leading edge spikes a Leading Edge Blanking is

integrated in the current sense path for the

comparators C10, C12 and the PWM-OP.

The output of comparator C12 is activated by the Gate

G10 if Active Burst Mode is entered. Once activated the

current limiting is thereby reduced to 0.257V. This

voltage level determines the power level when the

Active Burst Mode is left if there is a higher power

demand.

. By means of R

Sense

Sense

the comparator C10

csth

Leading

Edge

Blanking

220ns

1pF

D1

the source current

which is fed

Sense

exceeds the

Sense

3.5.1 Leading Edge Blanking

V

Sense

V

csth

t

LEB

=220ns

t

Figure 13 Leading Edge Blanking

Each time when the internal CoolMOS™ is switched

on, a leading edge spike is generated due to the

primary-side capacitances and secondary-side rectifier

reverse recovery time. This spike can cause the gate

drive to switch off unintentionally. To avoid a premature

termination of the switching pulse, this spike is blanked

out with a time constant of t

time, the gate drive will not be switched off.

3.5.2 Propagation Delay Compensation

In case of overcurrent detection, the switch-off of the

internal CoolMOS™ is delayed due to the propagation

delay of the circuit. This delay causes an overshoot of

the peak current I

which depends on the ratio of dI/

peak

dt of the peak current (see Figure 14).

I

Sense

I

peak2

I

peak1

I

Limit

I

Overshoot2

Figure 14 Current Limiting

The overshoot of Signal2 is bigger than of Signal1 due

to the steeper rising waveform. This change in the

slope is depending on the AC input voltage.

Propagation Delay Compensation is integrated to limit

the overshoot dependency on dI/dt of the rising primary

current. That means the propagation delay time

between exceeding the current sense threshold V

and the switch off of the internal CoolMOS™ is

compensated over temperature within a wide range.

= 220ns. During this

LEB

Signal2Signal1

t

PropagationDelay

I

Overshoot1

t

csth

Version 2.3 14 02 Apr 2013

Page 15

CoolSET™-F3

Functional Description

Current Limiting is now possible in a very accurate way.

E.g. I

= 0.5A with R

peak

= 2. Without Propagation

Sense

Delay Compensation the current sense threshold is set

to a static voltage level V

dI/dt = 0.4A/µs, that means dV

propagation delay time of i.e. t

leads then to an I

peak

=1V. A current ramp of

csth

/dt = 0.8V/µs, and a

Sense

Propagatio n Delay

=180ns

overshoot of 14.4%. By means of

propagation delay compensation the overshoot is only

about 2% (see Figure 15).

dV

Sense

without compensation

V

s

with compensation

V

1,3

1,25

1,2

1,15

Sense

1,1

V

1,05

1

0,95

0,9

0 0,2 0,4 0,6 0,8 1 1,2 1,4 1,6 1,8 2

dt

Figure 15 Overcurrent Shutdown

The Propagation Delay Compensation is realized by

means of a dynamic threshold voltage V

(see Figure

csth

16). In case of a steeper slope the switch off of the

driver is earlier to compensate the delay.

V

OSC

max. DutyCycle

3.6 Control Unit

The Control Unit contains the functions for Active Burst

Mode and Auto Restart Mode. The Active Burst Mode

and the Auto Restart Mode are combined with an

Adjustable Blanking Window which is depending on the

external Soft Start capacitor. By means of this

Adjustable Blanking Window, the IC avoids entering

into these two modes accidentally. Furthermore it also

provides a certain time whereby the overload detection

is delayed. This delay is useful for applications which

normally works with a low current and occasionally

require a short duration of high current.

3.6.1 Adjustable Blanking Window

SoftS

6.5V

R

SoftS

5k

4.4V

1

S1

5.4V

G2

C3

off time

V

Sense

V

csth

PropagationDelay

Signal1 Signal2

Figure 16 Dynamic Voltage Threshold V

csth

4.8V

&

C4

G5

Auto

Restart

Mode

Active

t

Burst

Mode

&

FB

G6

C5

1.32V

t

ControlUnit

Figure 17 Adjustable Blanking Window

V

is clamped at 4.4V by the closed switch S1 after

SoftS

the SMPS is settled. If overload occurs VFBis

exceeding 4.8V. Auto Restart Mode can’t be entered as

the gate G5 is still blocked by the comparator C3. But

after VFBhas exceeded 4.8V the switch S1 is opened

Version 2.3 15 02 Apr 2013

Page 16

CoolSET™-F3

Functional Description

via the gate G2. The external Soft Start capacitor can

now be charged further by the integrated pull up

resistor R

G5 and G6 once V

. The comparator C3 releases the gates

SoftS

has exceeded 5.4V. Therefore

Softs

there is no entering of Auto Restart Mode possible

during this charging time of the external capacitor

C

. The same procedure happens to the external

SoftS

Soft Start capacitor if a low load condition is detected

by comparator C5 when VFBis falling below 1.32V.

Only after V

has exceeded 5.4V and VFBis still

SoftS

below 1.32V Active Burst Mode is entered.

3.6.2 Active Burst Mode

The controller provides Active Burst Mode for low load

conditions at V

. Active Burst Mode increases

OUT

significantly the efficiency at light load conditions while

supporting a low ripple on V

and fast response on

OUT

load jumps. During Active Burst Mode which is

controlled only by the FB signal the IC is always active

and can therefore immediately response on fast

changes at the FB signal. The Startup Cell is kept

switched off to avoid increased power losses for the

self supply.

SoftS

6.5V

R

5k

4.4V

SoftS

InternalBias

The Active Burst Mode is located in the Control Unit.

Figure 18 shows the related components.

3.6.2.1 Entering Active Burst Mode

The FB signal is always observed by the comparator

C5 if the voltage level falls below 1.32V. In that case the

switch S1 is released which allows the capacitor C

SoftS

to be charged starting from the clamped voltage level

at 4.4V in normal operating mode. If V

SoftS

exceeds

5.4V the comparator C3 releases the gate G6 to enter

the Active Burst Mode. The time window that is

generated by combining the FB and SoftS signals with

gate G6 avoids a sudden entering of the Active Burst

Mode due to large load jumps. This time window can be

adjusted by the external capacitor C

SoftS

.

After entering Active Burst Mode a burst flag is set and

the internal bias is switched off in order to reduce the

current consumption of the IC down to approx. 1.05mA.

In this Off State Phase the IC is no longer self supplied

so that therefore C

has to provide the VCC current

VCC

(see Figure 19). Furthermore gate G11 is then released

to start the next burst cycle once VFBhas 3.4V

exceeded.

It has to be ensured by the application that the VCC

remains above the Undervoltage Lockout Level of 8.5V

to avoid that the Startup Cell is accidentally switched

on. Otherwise power losses are significantly increased.

The minimum VCC level during Active Burst Mode is

depending on the load conditions and the application.

The lowest VCC level is reached at no load conditions

at V

OUT

.

S1

C3

5.4V

4.8V

C4

FB

1.32V

4.0V

3.4V

C5

C6a

C6b

Control Unit

Figure 18 Active Burst Mode

&

G6

&

G11

Current

Limiting

G10

Active

Burst

Mode

3.6.2.2 Working in Active Burst Mode

After entering the Active Burst Mode the FB voltage

&

PWM section. Comparator C6a observes the FB signal

rises as V

starts to decrease due to the inactive

OUT

if the voltage level 4V is exceeded. In that case the

internal circuit is again activated by the internal Bias to

start with switching. As now in Active Burst Mode the

gate G10 is released the current limit is only 0.257V to

reduce the conduction losses and to avoid audible

noise. If the load at V

is still below the starting level

OUT

for the Active Burst Mode the FB signal decreases

down to 3.4V. At this level C6b deactivates again the

internal circuit by switching off the internal Bias. The

gate G11 is released as after entering Active Burst

Mode the burst flag is set. If working in Active Burst

Mode the FB voltage is changing like a saw tooth

between 3.4V and 4V (see Figure 19).

3.6.2.3 Leaving Active Burst Mode

The FB voltage immediately increases if there is a high

load jump. This is observed by comparator C4. As the

current limit is ca. 26% during Active Burst Mode a

certain load jump is needed that FB can exceed 4.8V.

At this time C4 resets the Active Burst Mode which also

Version 2.3 16 02 Apr 2013

Page 17

CoolSET™-F3

Functional Description

blocks C12 by the gate G10. Maximum current can now

be provided to stabilize V

V

FB

4.80V

4.00V

3.40V

1.32V

V

SoftS

5.40V

4.40V

V

CS

1.00V

0.257V

V

VCC

Currentlimit levelduring

ActiveBurstMode

EnteringActive

BurstMode

BlankingWindow

OUT

.

LeavingActive

BurstMode

t

t

t

3.6.3 Protection Mode (Auto Restart Mode)

In order to increase the SMPS system’s robustness

and safety, the IC provides the Auto Restart Mode as a

protection feature. The Auto Restart Mode is entered

upon detection of the following faults in the system:

• VCC Overvoltage

• Overtemperature

• Overload

• Open Loop

• VCC Undervoltage

• Short Optocoupler

SoftS

C

SoftS

FB

S1

4.4V

R

SoftS

5k

VCC

C1

17V

4.0V

4.8V

C11

C4

6.5V

&

G1

ThermalShutdown

Tj>140°C

Spike

Blanking

8.0us

&

G5

Control Unit

AutoRestart

Mode

8.5V

I

VCC

7.2mA

1.05mA

V

OUT

Max.Ripple<1%

Figure 19 Signals in Active Burst Mode

C3

5.4V

Figure 20 Auto Restart Mode

The VCC voltage is observed by comparator C1 if 17V

t

is exceeded. The output of C1 is combined with both

the output of C11 which checks for SoftS<4.0V, and the

output of C4 which checks for FB>4.8V. Therefore the

overvoltage detection is can only active during Soft

Start Phase(SoftS<4.0V) and when FB signal is

outside the operating range > 4.8V. This means any

small voltage overshoots of V

during normal

VCC

operating cannot trigger the Auto Restart Mode.

t

In order to ensure system reliability and prevent any

false activation, a blanking time is implemented before

the IC can enter into the Auto Restart Mode. The output

of the VCC overvoltage detection is fed into a spike

blanking with a time constant of 8.0ms.

The other fault detection which can result in the Auto

Restart Mode and has this 8.0ms blanking time is the

Overtemperature detection. This block checks for a

t

junction temperature of higher than 140°C for

malfunction operation.

Voltage

Reference

Version 2.3 17 02 Apr 2013

Page 18

Once the Auto Restart Mode is entered, the internal

Voltage Reference is switched off in order to reduce the

current consumption of the IC as much as possible. In

this mode, the average current consumption is only

300mA as the only working block is the Undervoltage

Lockout(UVLO) which controls the Startup Cell by

switching on/off at V

VCCon/VVCCoff

.

As there is no longer a self supply by the auxiliary

winding, VCC starts to drop. The UVLO switches on the

integrated Startup Cell when VCC falls below 8.5V. It

will continue to charge VCC up to 15V whereby it is

switched off again and the IC enters into the Start Up

Phase.

As long as all fault conditions have been removed, the

IC will automatically power up as usual with switching

cycle at the GATE output after Soft Start duration. Thus

the name Auto Restart Mode.

Other fault detections which are active in normal

operation is the sensing for Overload, Open Loop and

VCC undervoltage conditions. In the first 2 cases, FB

will rise above 4.8V which will be observed by C4. At

this time, S1 is released such that V

its earlier clamp voltage of 4.4V. If V

can rise from

SoftS

exceeds 5.4V

SoftS

which is observed by C3, Auto Restart Mode is entered

as both inputs of the gate G5 are high.

This charging of the Soft Start capacitor from 4.4V to

5.4V defines a blanking window which prevents the

system from entering into Auto Restart Mode unintentionally during large load jumps. In this event, FB

will rise close to 6.5V for a short duration before the

loop regulates with FB less than 4.8V. This is the same

blanking time window as for the Active Burst Mode and

can therefore be adjusted by the external C

SoftS

.

In the case of VCC undervoltage, ie. VCC falls below

8.5V, the IC will be turn off with the Startup Cell

charging VCC as described earlier in this section. Once

VCC is charged above 15V, the IC will start a new

startup cycle. The same procedure applies when the

system is under Short Optocoupler fault condition, as it

will lead to VCC undervoltage.

CoolSET™-F3

Functional Description

Version 2.3 18 02 Apr 2013

Page 19

CoolSET™-F3

Electrical Characteristics

4 Electrical Characteristics

Note: All voltages are measured with respect to ground (Pin 8). The voltage levels are valid if other ratings are

not violated.

4.1 Absolute Maximum Ratings

Note: Absolute maximum ratings are defined as ratings, which when being exceeded may lead to destruction

of the integrated circuit. For the same reason make sure, that any capacitor that will be connected to pin 7

(VCC) is discharged before assembling the application circuit.

Parameter Symbol Limit Values Unit Remarks

min. max.

Drain Source Voltage

ICE3Axx65/xx65I/xx65P

ICE3Bxx65/xx65I/xx65P

Pulse drain current, t

p

limited by max. Tj=150°C

ICE3x0365 I

ICE3x0565

ICE3A0565Z

ICE3x1065 I

ICE3x1565 I

ICE3x2065

ICE3A2065Z

ICE3x2565 I

ICE3x2065I

ICE3x2065P

ICE3x3065I

ICE3x3065P

ICE3x3565I

ICE3x3565P

V

DS

D_Puls1

I

D_Puls2

D_Puls3

D_Puls4

I

D_Puls5

D_Puls6

I

D_Puls7

I

D_Puls8

I

D_Puls9

- 650 V Tj=110°C

- 1.6 A

- 2.3 A

- 3.4 A

- 6.1 A

- 10.3 A

- 15.7 A

- 3.4 A

- 4.3 A

- 6.5 A

ICE3x5065I

I

D_Puls10

- 9.4 A

ICE3x5065P

ICE3x5565I

I

D_Puls11

- 10.7 A

ICE3x5565P

Version 2.3 19 02 Apr 2013

Page 20

CoolSET™-F3

Electrical Characteristics

Parameter Symbol Limit Values Unit Remarks

min. max.

Avalanche energy,

repetitive tARlimited by

max. Tj=150°C

1)

ICE3x0365 E

ICE3x0565

ICE3A0565Z

ICE3x1065 E

ICE3x1565 E

ICE3x2065

ICE3A2065Z

ICE3x2565 E

ICE3x2065I

ICE3x2065P

ICE3x3065I

ICE3x3065P

ICE3x3565I

ICE3x3565P

ICE3x5065I

ICE3x5065P

ICE3x5565I

ICE3x5565P

E

E

E

E

E

E

E

AR1

AR2

AR3

AR4

AR5

AR6

AR7

AR8

AR9

AR10

AR11

- 0.005 mJ

- 0.01 mJ

- 0.07 mJ

- 0.15 mJ

- 0.40 mJ

- 0.47 mJ

- 0.07 mJ

- 0.11 mJ

- 0.17 mJ

- 0.40 mJ

- 0.44 mJ

Version 2.3 20 02 Apr 2013

Page 21

CoolSET™-F3

Electrical Characteristics

Parameter Symbol Limit Values Unit Remarks

min. max.

Avalanche current,

repetitive tARlimited by

max. Tj=150°C

ICE3x0365 I

ICE3x0565

ICE3A0565Z

ICE3x1065 I

ICE3x1565 I

ICE3x2065

ICE3A2065Z

ICE3x2565 I

ICE3x2065I

ICE3x2065P

ICE3x3065I

ICE3x3065P

ICE3x3565I

ICE3x3565P

ICE3x5065I

ICE3x5065P

ICE3x5565I

ICE3x5565P

AR1

I

AR2

AR3

AR4

I

AR5

AR6

I

AR7

I

AR8

I

AR9

I

AR10

I

AR11

- 0.3 A

- 0.5 A

- 1.0 A

- 1.5 A

- 2.0 A

- 2.5 A

- 2.0 A

- 3.0 A

- 3.5 A

- 5.0 A

- 5.5 A

1)

Repetitive avalanche causes additional power losses that can be calculated as PAV=EAR*f

Version 2.3 21 02 Apr 2013

Page 22

CoolSET™-F3

Electrical Characteristics

Parameter Symbol Limit Values Unit Remarks

min. max.

Thermal Resistance

Junction-Ambient

Thermal Resistance

Junction-Case

ICE3x0365

ICE3x0565

ICE3x1065

ICE3x1565

ICE3x2065

ICE3x2565

ICE3A0565Z

ICE3x2065Z

ICE3x2065I

ICE3x3065I

ICE3x3565I

ICE3x5065I

ICE3x5565I

ICE3x2065P

ICE3x3065P

ICE3x3565P

ICE3x5065P

ICE3x5565P

ICE3x2065I

ICE3x2065P

ICE3x3065I

ICE3x3065P

R

R

R

R

R

R

thJA1

thJA2

thJA3

thJA4

thJC1

thJC2

90 K/W PG-DIP-8

96 K/W PG-DIP-7-1

103 K/W PG-TO220-6-46

Free standing without

heatsink

82 K/W PG-TO220-6-47

Free standing without

heatsink

3.30 K/W PG-TO220-6-46

PG-TO220-6-47

3.08 K/W PG-TO220-6-46

PG-TO220-6-47

ICE3x3565I

ICE3x3565P

ICE3x5065I

ICE3x5065P

ICE3x5565I

ICE3x5565P

VCC Supply Voltage V

FB Voltage V

SoftS Voltage V

CS Voltage V

Junction Temperature T

Storage Temperature T

ESD Capability(incl. Drain Pin) V

1)

According to EIA/JESD22-A114-B (discharging a 100pF capacitor through a 1.5kW series resistor)

R

R

R

thJC3

thJC4

thJC5

VCC

FB

SoftS

CS

j

S

ESD

2.94 K/W PG-TO220-6-46

PG-TO220-6-47

2.79 K/W PG-TO220-6-46

PG-TO220-6-47

2.75 K/W PG-TO220-6-46

PG-TO220-6-47

-0.3 22 V

-0.3 6.5 V

-0.3 6.5 V

-0.3 6.5 V

-40 150 °C Controller & CoolMOS™

-55 150 °C

- 3 kV Human body model

1)

Version 2.3 22 02 Apr 2013

Page 23

CoolSET™-F3

Electrical Characteristics

4.2 Operating Range

Note: Within the operating range the IC operates as described in the functional description.

Parameter Symbol Limit Values Unit Remarks

min. max.

VCC Supply Voltage V

Junction Temperature of

Controller

Junction Temperature of

VCC

T

jCon

T

jCoolMOS

V

VCCoff

21 V

-25 130 °C Max value limited due to thermal

shut down of controller

-25 150 °C

CoolMOS™

4.3 Characteristics

4.3.1 Supply Section 1

Note: The electrical characteristics involve the spread of values within the specified supply voltage and junction

temperature range T

related to 25°C. If not otherwise stated, a supply voltage of V

Parameter Symbol Limit Values Unit Test Condition

Start Up Current I

VCC Charge Current I

Leakage Current of

Start Up Cell and CoolMOS™

from – 25 °C to 130 °C. Typical values represent the median values, which are

J

= 15 V is assumed.

CC

min. typ. max.

VCCstart

VCCcharg e1

I

VCCcharg e2

I

StartLeak

- 160 220 mA V

0.55 1.05 1.60 mA V

- 0.88 - mA V

- 0.2 50 mA V

VCC

VCC

VCC

VCC

=14V

= 0V

=14V

=16V, V

Drain

= 450V

at Tj=100°C

Supply Current with

I

VCCsup1

- 5.5 7.0 mA

Inactive Gate

Supply Current in

Auto Restart Mode with

I

VCCrestart

- 300 - mA IFB= 0

I

Softs

= 0

Inactive Gate

Supply Current in

Active Burst Mode

with Inactive Gate

VCC Turn-On Threshold

VCC Turn-Off Threshold

VCC Turn-On/Off Hysteresis

I

VCCburst1

I

VCCburst2

V

VCCon

V

VCCoff

V

VCChys

- 1.05 1.25 mA V

- 0.95 1.15 mA V

14.2

8.0

-

15.0

8.5

6.5

15.8

9.0

-

V

V

V

=15V

VCC

VFB= 3.7V, V

= 9.5V

VCC

VFB= 3.7V, V

SoftS

SoftS

= 4.4V

= 4.4V

Version 2.3 23 02 Apr 2013

Page 24

CoolSET™-F3

Electrical Characteristics

4.3.2 Supply Section 2

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Supply Current

with Active Gate

Supply Current

with Active Gate

ICE3A0365 I

ICE3B0365 I

ICE3A0565

ICE3A0565Z

ICE3B0565 I

ICE3A1065 I

ICE3B1065 I

ICE3A1565 I

ICE3B1565 I

ICE3A2065

ICE3A2065Z

ICE3B2065 I

ICE3A2565 I

ICE3B2565 I

ICE3A2065I

ICE3A2065P

ICE3B2065I

ICE3B2065P

ICE3A3065I

ICE3A3065P

VCCsup2

VCCsup2

I

VCCsup2

VCCsup2

VCCsup2

VCCsup2

VCCsup2

VCCsup2

I

VCCsup2

VCCsup2

VCCsup2

VCCsup2

I

VCCsup2

I

VCCsup2

I

VCCsup2

- 5.6 7.1 mA V

- 5.5 7.0 mA

- 5.7 7.2 mA

- 5.6 7.1 mA

- 5.9 7.5 mA

- 5.7 7.2 mA

- 6.3 8.0 mA

- 6.0 7.6 mA

- 7.1 8.9 mA

- 6.5 8.2 mA

- 8.1 10.2 mA

- 7.2 9.0 mA

- 5.9 7.5 mA V

- 5.7 7.2 mA

- 6.1 7.7 mA

SoftS

IFB= 0

SoftS

IFB= 0

= 4.4V

= 4.4V

ICE3B3065I

ICE3B3065P

ICE3A3565I

ICE3A3565P

ICE3B3565I

ICE3B3565P

ICE3A5065I

ICE3A5065P

ICE3B5065I

ICE3B5065P

ICE3A5565I

ICE3A5565P

ICE3B5565I

ICE3B5565P

I

VCCsup2

I

VCCsup2

I

VCCsup2

I

VCCsup2

I

VCCsup2

I

VCCsup2

I

VCCsup2

- 5.9 7.4 mA

- 6.4 8.0 mA

- 6.0 7.6 mA

- 7.2 9.0 mA

- 6.6 8.3 mA

- 7.6 9.5 mA

- 6.8 8.5 mA

Version 2.3 24 02 Apr 2013

Page 25

CoolSET™-F3

Electrical Characteristics

4.3.3 Internal Voltage Reference

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Trimmed Reference Voltage V

REF

6.37 6.50 6.63 V measured at pin FB

IFB= 0

4.3.4 PWM Section

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Fixed Oscillator

Frequency

Fixed Oscillator

Frequency

Max. Duty Cycle D

Min. Duty Cycle D

PWM-OP Gain A

Voltage Ramp Max Level V

VFBOperating Range Min Level V

ICE3Axx65

ICE3Axx65Z

ICE3Axx65I

ICE3Axx65P

ICE3Bxx65

ICE3Bxx65I

ICE3Bxx65P

f

OSC1

f

OSC2

f

OSC1

f

OSC2

max

min

V

Max-Ramp

FBmin

92 100 108 kHz

94 100 106 kHz Tj= 25°C

61 67 73 kHz

63 67 71 kHz Tj= 25°C

0.67 0.72 0.77

0 - - VFB< 0.3V

3.5 3.7 3.9

- 0.85 - V

0.3 0.7 - V

VFBOperating Range Max level V

FB Pull-Up Resistor R

SoftS Pull-Up Resistor R

1)

The parameter is not subjected to production test - verified by design/characterization

FBmax

FB

SoftS

- - 4.75 V CS=1V, limited by

16 20 27 kW

39 50 62 kW

Comparator C4

1)

Version 2.3 25 02 Apr 2013

Page 26

CoolSET™-F3

Electrical Characteristics

4.3.5 Control Unit

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Deactivation Level for SoftS

Comparator C7 by C2

Clamped V

Voltage during

SoftS

Normal Operating Mode

Activation Limit of

Comparator C3

SoftS Startup Current I

Over Load & Open Loop Detection

Limit for Comparator C4

Active Burst Mode Level for

Comparator C5

Active Burst Mode Level for

Comparator C6a

Active Burst Mode Level for

Comparator C6b

Overvoltage Detection Limit V

Thermal Shutdown

1)

Spike Blanking t

V

SoftSC2

V

SoftSclmp

V

SoftSC3

SoftSstart

V

FBC4

V

FBC5

V

FBC6a

V

FBC6b

VCCOVP

T

jSD

Spike

3.85 4.00 4.15 V VFB> 5V

4.23 4.40 4.57 V VFB= 4V

5.20 5.40 5.60 V VFB> 5V

- 1.3 - mA V

4.62 4.80 4.98 V V

1.23 1.30 1.37 V V

SoftS

SoftS

SoftS

= 0V

> 5.6V

> 5.6V

3.85 4.00 4.15 V After Active Burst

Mode is entered

3.25 3.40 3.55 V After Active Burst

Mode is entered

16.1 17.1 18.1 V VFB> 5V

V

< 4.0V

SoftS

130 140 150 °C

- 8.0 - ms

1)

The parameter is not subjected to production test - verified by design/characterization

Note: The trend of all the voltage levels in the Control Unit is the same regarding the deviation except V

and V

VCCPD

4.3.6 Current Limiting

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Peak Current Limitation

(incl. Propagation Delay)

Peak Current Limitation during

V

csth

0.97 1.02 1.07 V dV

/ dt = 0.6V/ms

sense

(see Figure 16)

V

CS2

0.232 0.257 0.282 V

Active Burst Mode

Leading Edge Blanking t

CS Input Bias Current I

LEB

CSbias

- 220 - ns V

SoftS

= 4.4V

-1.0 -0.2 0 mA VCS=0V

VCCOVP

Version 2.3 26 02 Apr 2013

Page 27

CoolSET™-F3

Electrical Characteristics

4.3.7 CoolMOS™ Section

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Drain Source Breakdown Voltage

ICE3Axx65/xx65I/xx65P

ICE3Bxx65/xx65I/xx65P

Drain Source

On-Resistance

ICE3A0365

ICE3B0365

ICE3A0565

ICE3A0565Z

ICE3B0565

ICE3A1065

ICE3B1065

ICE3A1565

ICE3B1565

ICE3A2065

ICE3A2065Z

ICE3B2065

ICE3A2565

ICE3B2565

Drain Source

On-Resistance

ICE3A2065I

ICE3A2065P

ICE3B2065I

ICE3B2065P

V

(BR)DSS

R

DSon1

R

DSon2

R

DSon3

R

DSon4

R

DSon5

R

DSon6

R

DSon7

600

650

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

6.45

13.7

4.70

10.0

2.95

6.6

1.70

3.57

0.92

1.93

0.65

1.37

3.00

6.6

-

-

7.50

17.0

5.44

12.5

3.42

7.56

1.96

4.12

1.05

2.22

0.75

1.58

3.47

7.63

V

V

W

W

Tj= 25°C

Tj= 110°C

Tj= 25°C

Tj=125°C

1)

at ID= 0.3A

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 0.5A

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 1.0A

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 1.5A

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 2.0A

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 2.5A

W

W

Tj= 25°C

Tj=125°C

1)

at ID=1.0A

ICE3A3065I

ICE3A3065P

ICE3B3065I

ICE3B3065P

ICE3A3565I

ICE3A3565P

ICE3B3565I

ICE3B3565P

ICE3A5065I

ICE3A5065P

ICE3B5065I

ICE3B5065P

ICE3A5565I

ICE3A5565P

ICE3B5565I

ICE3B5565P

R

DSon8

R

DSon9

R

DSon10

R

DSon11

-

-

2.10

4.41

2.43

5.10

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 1.5A

-

-

1.55

3.26

1.80

3.78

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 1.8A

0.95

2.00

1.10

2.31

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 2.5A

-

-

0.79

1.68

0.91

1.92

W

W

Tj= 25°C

Tj=125°C

1)

at ID= 2.8A

Version 2.3 27 02 Apr 2013

Page 28

CoolSET™-F3

Electrical Characteristics

Parameter Symbol Limit Values Unit Test Condition

min. typ. max.

Effective output

capacitance,

energy related

Effective output

capacitance,

energy related

ICE3A0365

ICE3B0365

ICE3A0565

ICE3A0565Z

ICE3B0565

ICE3A1065

ICE3B1065

ICE3A1565

ICE3B1565

ICE3A2065

ICE3A2065Z

ICE3B2065

ICE3A2565

ICE3B2565

ICE3A2065I

ICE3A2065P

ICE3B2065I

ICE3B2065P

ICE3A3065I

ICE3A3065P

ICE3B3065I

ICE3B3065P

C

C

C

C

C

C

C

C

o(er)1

o(er)2

o(er)3

o(er)4

o(er)5

o(er)6

o(er)7

o(er)8

- 3.65 - pF VDS= 0V to 480V

- 4.75 - pF

- 7.0 - pF

- 11.63 - pF

- 21 - pF

- 26.0 - pF

- 7.0 - pF VDS= 0V to 480V

- 10.0 - pF

ICE3A3565I

C

o(er)9

- 14.0 - pF

ICE3A3565P

ICE3B3565I

ICE3B3565P

ICE3A5065I

C

o(er)10

- 20.5 - pF

ICE3A5065P

ICE3B5065I

ICE3B5065P

ICE3A5565I

C

o(er)11

- 23.0 - pF

ICE3A5565P

ICE3B5565I

ICE3B5565P

Rise Time t

Fall Time t

1)

The parameter is not subjected to production test - verified by design/characterization

2)

Measured in a Typical Flyback Converter Application

rise

fall

- 30

- 30

2)

2)

- ns

- ns

Version 2.3 28 02 Apr 2013

Page 29

5 Outline Dimension

PG-DIP-8

(Plastic Dual In-Line Package)

CoolSET™-F3

Outline Dimension

Figure 21 PG-DIP-8 (Pb-free lead plating Plastic Dual In-Line Outline)

Version 2.3 29 02 Apr 2013

Page 30

PG-DIP-7-1

(Plastic Dual In-Line package)

CoolSET™-F3

Outline Dimension

Figure 22 PG-DIP-7-1 (Pb-free lead plating Plastic Dual In-Line Outline)

Version 2.3 30 02 Apr 2013

Page 31

PG-TO220-6-46

(Isodrain I2Pak Package)

CoolSET™-F3

Outline Dimension

Figure 23 PG-TO220-6-46 (Pb-free lead plating Isodrain I2Pak Package)

PG-TO220-6-47

(Isodrain Package)

Figure 24 PG-TO220-6-47 (Pb-free lead plating Isodrain Package)

Dimensions in mm

Version 2.3 31 02 Apr 2013

Page 32

Total Quality Management

Qualität hat für uns eine umfassende

Bedeutung. Wir wollen allen Ihren

Ansprüchen in der bestmöglichen

Weise gerecht werden. Es geht uns also

nicht nur um die Produktqualität –

unsere Anstrengungen gelten

gleichermaßen der Lieferqualität und

Logistik, dem Service und Support

sowie allen sonstigen Beratungs- und

Betreuungsleistungen.

Dazu gehört eine bestimmte

Geisteshaltung unserer Mitarbeiter.

Total Quality im Denken und Handeln

gegenüber Kollegen, Lieferanten und

Ihnen, unserem Kunden. Unsere

Leitlinie ist jede Aufgabe mit „Null

Fehlern“ zu lösen – in offener

Sichtweise auch über den eigenen

Arbeitsplatz hinaus – und uns ständig

zu verbessern.

Unternehmensweit orientieren wir uns

dabei auch an „top“ (Time Optimized

Processes), um Ihnen durch größere

Schnelligkeit den entscheidenden

Wettbewerbsvorsprung zu verschaffen.

Geben Sie uns die Chance, hohe

Leistung durch umfassende Qualität zu

beweisen.

Quality takes on an allencompassing

significance at Semiconductor Group.

For us it means living up to each and

every one of your demands in the best

possible way. So we are not only

concerned with product quality. We

direct our efforts equally at quality of

supply and logistics, service and

support, as well as all the other ways in

which we advise and attend to you.

Part of this is the very special attitude of

our staff. Total Quality in thought and

deed, towards co-workers, suppliers

and you, our customer. Our guideline is

“do everything with zero defects”, in an

open manner that is demonstrated

beyond your immediate workplace, and

to constantly improve.

Throughout the corporation we also

think in terms of Time Optimized

Processes (top), greater speed on our

part to give you that decisive

competitive edge.

Give us the chance to prove the best of

performance through the best of quality

– you will be convinced.

Wir werden Sie überzeugen.

h t t p : / / w w w . i n f i n e o n . c o m

Published by Infineon Technologies AG

Loading...

Loading...