Page 1

CoolMOS™ CE Selection Guide

High voltage MOSFETs for consumer applications

500 V, 600 V, 650 V, 700 V and 800 V

www.infineon.com/ce

Page 2

Powering a green world with CoolMOS™ CE

2

Page 3

Content

CoolMOS™ CE – overview

CoolMOS™ CE – smartphone and tablet chargers

CoolMOS™ CE – notebook adapters

CoolMOS™ CE – TV sets

CoolMOS™ CE for lighting applications

CoolMOS™ CE – demonstrator boards

CoolMOS™ CE – target topologies

CoolMOS™ CE – product portfolio

CoolMOS™ CE portfolio package overview

CoolMOS™ CE – cross reference

3

Page 4

Ictam quodita dolorepCoolMOS™ CE

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0.18

CoolMOS™ comes with a DPM of less than 0.1 and FIT rate of less than 0.15

DPM (data code related)

80

10-2014

11-2014

12-2014

01-2015

02-2015

03-2015

04-2015

05-2015

06-2015

07-2015

08-2015

09-2015

82

84

86

88

90

92

94

96

98

Wish date

10%

Wish date

Longer

CoolMOS™ CE – overview

CoolMOS™ CE is a product family launched by Infineon to address consumer and lighting applications. It oers

benefits in eiciency and thermal behavior versus standard MOSFETs and has been optimized for ease-of-use and costcompetitiveness, while at the same time delivering state-of-the-art performance and Infineon quality and supply security.

Powered by Infineon multi-source program, CoolMOS™ CE is determined to support customers’ success in various consumer

markets by full FAE (field application engineer) support, short lead time and fast quote response.

CoolMOS™ quality - benchmark in short term and long

Potentially additional

defects reported in 2016

based on 130 million

0

2011 2012 2013 2014 2015

+

FIT rate < 0.15

device hours

term reliability

CoolMOS™ technology is legendary in the industry

dierentiated for its high quality, which has been proven

over the past years across billions of devices shipped with

continuous improved DPM down to less than 0.10 DPM.

Infineon has implemented firm and proven measures

from the beginning with design-for-quality program

and continuous improvement in production. There is

a constant proactive collaboration among technology,

design, quality, reliability and manufacturing teams to

achieve this result. This eort is above and beyond the

fact that all Infineon sites are ISO/TS16949 certified.

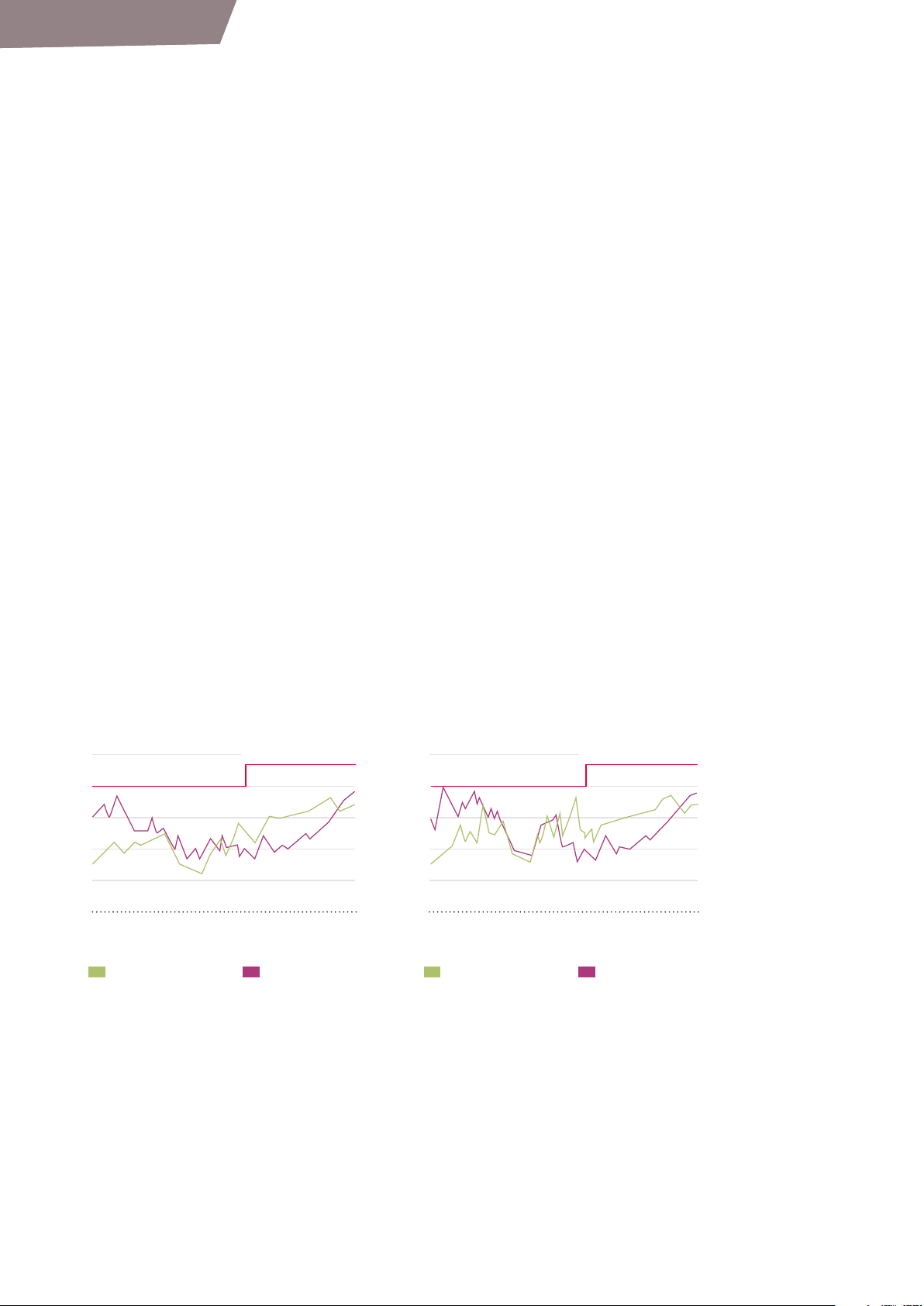

CoolMOS™ supply chain – delivery reliability, flexibility and supply security

Our customers value CoolMOS™ not only for its technical merits but also for the outstanding delivery reliability: once a

CoolMOS™ order date is committed, more than 96 percent of orders are shipped at or before the committed date. And

CoolMOS™ orders are committed to more than 80 percent to the date that the customers request. Security of supply and

flexibility to demand changes are focus targets and enabled by a well balanced production network. For example more than

90 percent of our products are qualified for production in at least two back end locations and more than 80 percent of the

volumes in two wafer fabs. This enables CoolMOS™ supply chain to react fast to changes in customer and market requirements.

Delivery reliability: ship date = committed date Delivery capability: confirm customers’ wish date

≥ 96% of CoolMOS™ orders are shipped by the committed date and ≥ 80% of wish dates can be met

4

Wish date

+1 week

+2 weeks

6%

4%

80%

www.infineon.com/ce

Page 5

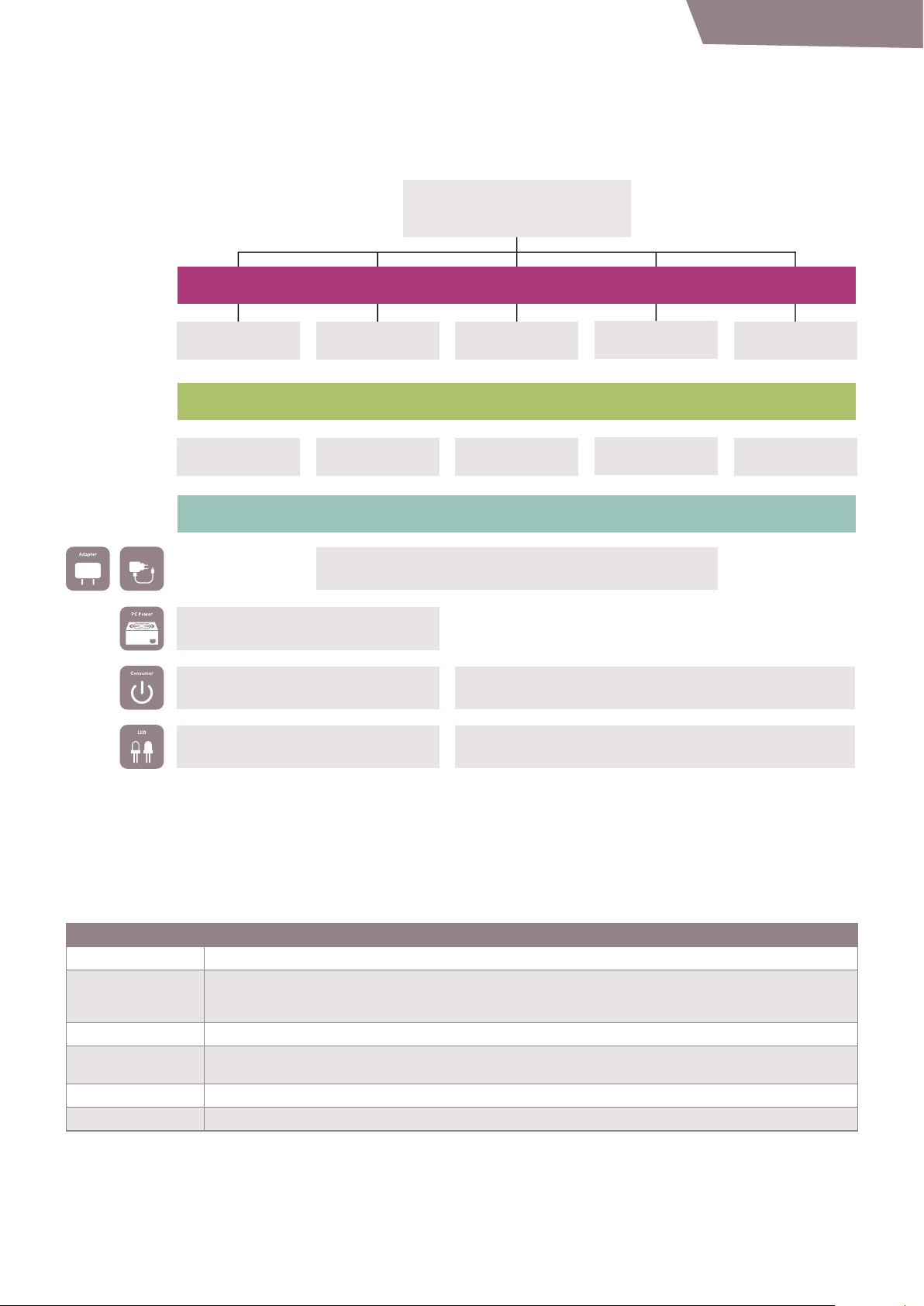

Voltage range

This selection guide takes you to explore the advantages of CoolMOS™ CE in charger, adapter, TV and lighting applications

Soloreiust cone pratendeCoolMOS™ CE

CoolMOS™ CE

Charger

500 V

Product family and R

0.19 Ω – 3 Ω

600 V 650 V

range

DS(on)

0.19 Ω – 3.4 Ω 0.4 Ω – 1.5 Ω

Power supply topology and market segment

Adapter/charger

Quasi-resonant flyback

PC power

PFC/TTF 80+; PFC/LLC 90+

LCD TV

LLC half-bridge

LED retrofit/LED drivers

PFC/LLC/Non-isolated bulk

700 V

0.6 Ω – 2.1 Ω

LCD TV adapter

Quasi-resonant flyback

LED retrofit/LED drivers

Quasi-resonant flyback

800 V

0.31 Ω – 2.8 Ω

Reasons to choose CoolMOS™ CE

Non-technical benefits provided by CoolMOS™ CE

Product portfolio We own a broad portfolio covering five voltage classes in both through-hole and surface-mount packages.

Capacity We own the world’s largest capacity for power devices, with three dedicated frontends and four backends.

Thanks to factors such as the continued investment in our production facilities, we ensure a secure supply during a market

upswing.

Lead time We understand consumer and lighting market dynamics and oer a lead time for middle-sized orders of 4-6 weeks.

Delivery performance Our supply chain performance is constantly greater than or equal to 96 percent

(adhering to the customer committed date).

Quality Our field failure rates are as low as 0.1 PPM.

Design-in support We have a large field application engineering team dedicated to providing professional and flexible support for your design.

www.infineon.com/ce

5

Page 6

Ictam quodita dolorepChargers

10 W design: IPS65R1K5CE

15 W design: IPS65R1K0CE

Level [dBµV/m]

1G

Horizontal direction Vertical direction Horizontal direction Vertical direction

CoolMOS™ CE – smartphone and tablet chargers

Chargers for smartphones and tablets as well as other mobile applications demand for a growing output power at same

or smaller form factors, leading to increasing power density, and stringent requirements on thermal management, EMI

emissions and overall system cost. For example, many OEMs request a device temperature less than 90°C with an open

case and close case temperature less than 50°C.

Infineon recommends its series of 700 V CoolMOS™ CE superjunction MOSFETs for this application, which are used by

leading charger OEMs and design houses in their charger applications. Compared to planar MOSFETs the 700 V CoolMOS™

CE oers reduced switching and thus higher eiciency while passing EMI standards and ringing requirements. Several

reference designs have been developed by Infineon to help customers to simplify charger design and thus providing fast

time-to-market (see reference design selection table at end of section).

Value proposition of 700 V CoolMOS™ CE:

›

High eiciency, meeting application requirements

›

More than enough safety margin in thermals, for 10 W-25 W chargers

›

Good EMI performance – meets the EMI EN55022B standard without extra design-in eort

›

Easy-to-use product due to good controllability via gate resistor

›

Large breakdown voltage of nominal 700 V (and additional guard band typical) for safety on voltage spikes

Infineon recommends CoolMOS™ CE in 700 V for charger applications to secure suicient margin for voltage spikes.

CoolMOS™ CE products are also available in 650 V and 600 V for use in less sensitive designs.

EN 55022 B radiated HF-field

30 MHz – 1 GHz position

40

30

20

10

0

-10

30M 50 60 80 100M

EN 55022 B RE 10 m OP EN 55022 B RE 10 m OP

200 300400 500 800 1G

Frequency [Hz]

40

30

20

10

Level [dBµV/m]

0

-10

30M 50 60 80 100M 200 300 400 500 800

EN 55022 B radiated HF-field

30 MHz – 1 GHz position

Frequency [Hz]

This figure shows the CoolMOS™ CE EMI performance in 10 W and 15 W charger applications. Maximum EMI limits are

indicated in the figure. CoolMOS™ CE could meet the EMI requirement thus oering design in flexibilities.

6

www.infineon.com/ce

Page 7

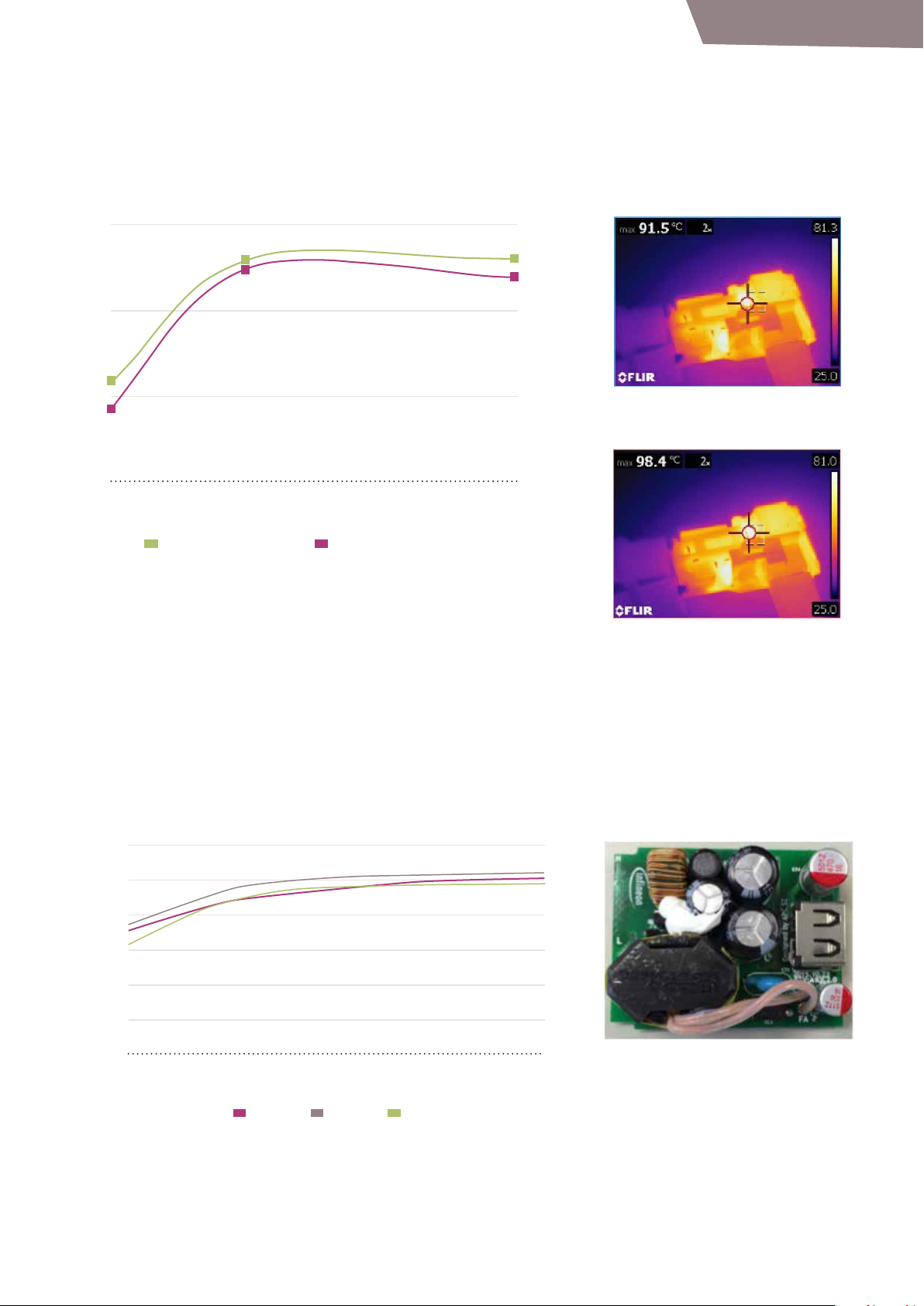

15 W QC 2.0 charger powered by IPS70R2K0CE IPS70R2K0CE

86

100

IPS70R2K0CE

Competitor 700 V, 1.6 Ω

Eiciency [%]

92

100

Eiciency [%]

5 V 9 V 12 V

Soloreiust cone pratendeChargers

85.19

84.98

85.22

84.80

84

82.32

82

81.73

Competitor 700 V, 1.6

80

25 50 75

Load [%]

Infineon CoolMOS™ CE oers higher eiciency and better thermals than planar MOSFETs: When replacing a 1.6 Ω planar

MOSFET with an Infineon 2.0 Ω CoolMOS™ CE in a 15 W QC 2.0 charger we measured ≥0.2 percent eiciency improvement. At the

same time, the MOSFET temperature was 7°C cooler, showing a clear benefit of using CoolMOS™ CE for charger applications.

Infineon’s 24 W QC 2.0 charger powered by IPS70R950CE Infineon’s 24 W quick charger

90

88

86

84

82

80

Also for 24 W quick chargers CoolMOS™ CE oers excellent eiciency, e.g., with the IPS70R950CE. Besides eiciency it

passes other spec requirements. The board is orderable through Infineon’s sample center.

www.infineon.com/ce

25 50 75

Load \[%]

DEMO_24W_QUICKCHARGER

7

Page 8

Ictam quodita dolorepChargers

CoolMOS™ CE – package options for charger application

IPAK Short Lead and DPAK

Standard packages used in chargers

today with excellent reliability and

wide usage in the industry

SOT-223

Highly cost optimized surface-mount

package with small footprint. The

SOT-223 shows slightly worse thermal

performance than DPAK, however this

can be compensated with little eort

by oering a slightly larger copper

area (~15 mm²) around the package

for heatsinking on the PCB (see

page 14, lighting application)

IPAK Short Lead with

Isolation Stando:

Innovative package for charger

applications providing a defined

stando between package and PBC

ThinPAK 5x6

Very flat package (0.8 mm height)

package targeting slim charger

solutions. Bottom side cooling is

applied by many customers, but heat

sinking through the top side is also

possible

I2PAK

Larger package with better thermal

performance than IPAK short lead for

more than 20 W charger application.

The package carries higher cost yet

saves eorts in heat sinking

www.infineon.com/ce

8

Page 9

Soloreiust cone pratendeChargers

IPAK Short Lead with Isolation Stando

The new IPAK Short Lead with Mold Stopper will provide a defined stando

between package body and PCB for proper cleaning aer wave soldering to

avoid leakage current on board level. Mold bumps at the bottom of the package

body allow to fully insert the MOSFET into the PCB leaving a well-defined

isolation distance of 0.3 mm between the PCB and package body. Creepage

distance is increased and production yield is improved as area between

package and PCB can eectively be cleaned.

CoolMOS™ CE solutions for charger application

CoolMOS™ CE portfolio for charger – 700 V recommended for most designs

R

DS(on)

[m]

600 > 20

950/1000 18-25

1400/1500 10-18

2000/2100 < 10

General

proposal

[W] TO-262

(IPAK)

IPI70R950CE IPS70R950CE IPSA70R950CE IPD70R950CE IPN70R1K0CE

For 18 W-25 W charger Standard package

TO-251

(IPAK Short Lead)

IPS70R600CE IPSA70R600CE IPD70R600CE

IPS70R1K4CE IPSA70R1K4CE IPD70R1K4CE IPN70R1K5CE

IPS70R2K0CE IPSA70R2K0CE IPD70R2K0CE IPL70R2K1CES

for charger

TO-251

(IPAK Short Lead with

ISO Stando)

Standard package

for charger

TO-252

(DPAK)

For slim charger For slim charger Low cost/thermal

ThinPAK 5x6 SOT-223

adjustment needed

www.infineon.com/ce

9

Page 10

Ictam quodita dolorepNotebook adapters

DS

V

89.5

Eiciency [%]

Average eiciency

CoolMOS™ CE – notebook adapters

The CoolMOS™ CE series has been widely chosen by leading OEMs in notebook adapters. With ease-of-use, cost

competitiveness and short lead time as well as corresponding reference designs, customers can easily design CoolMOS™ CE

products in their adapters and have a faster time-to-market.

Value proposition of 600 V and 650 V CoolMOS™ CE for adapters

›

High eiciency exceeding values achieved with planar MOSFETs

›

Good thermals, especially for high density, small form factor designs

›

High breakdown voltage corridor – typical breakdown voltage by far exceeds specified max. value and is higher than

typical MOSFETs from other vendors

›

Easy-to-use product due to good controllability via gate resistor

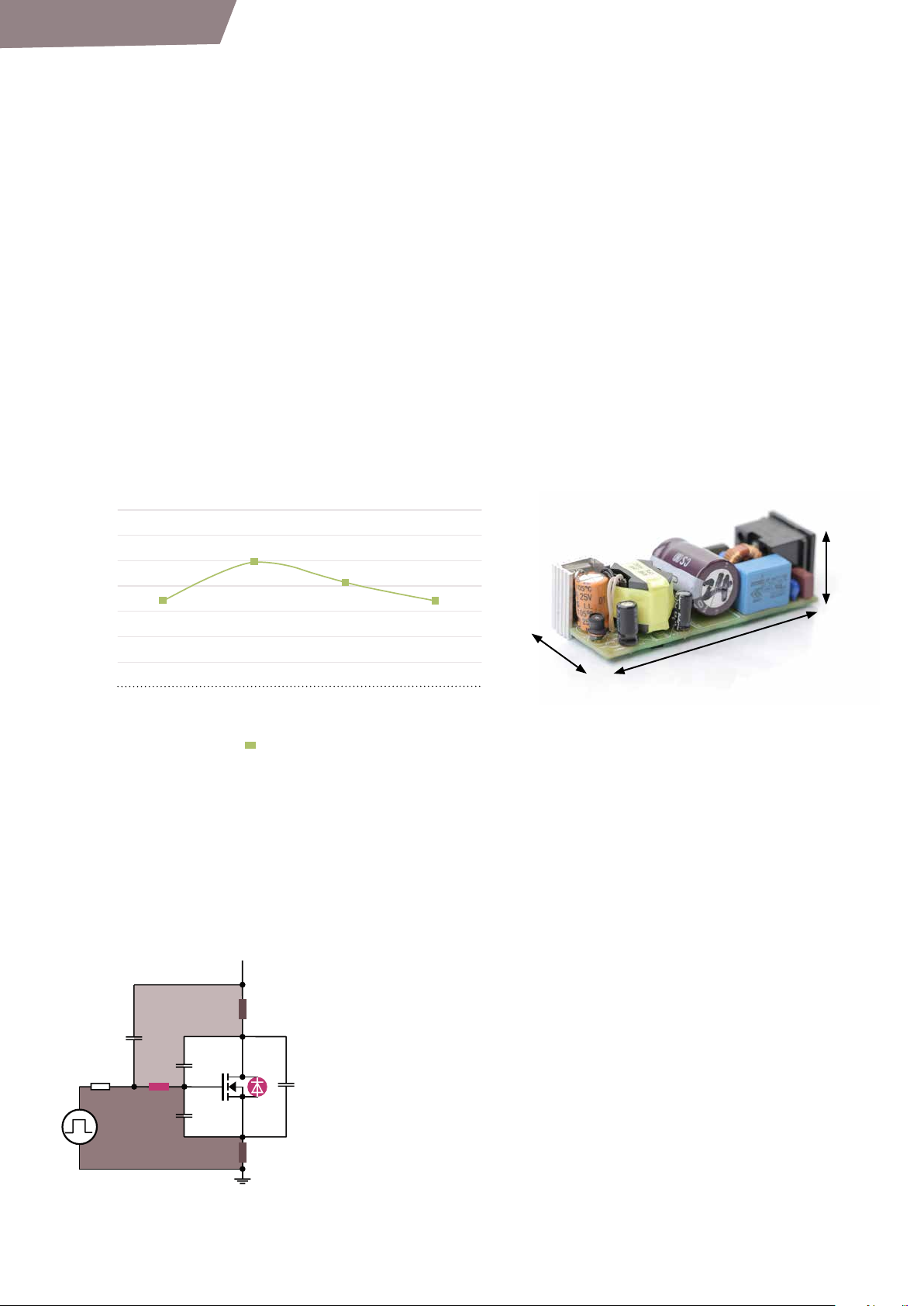

Infineon’s 35 W adapter powered by IPD60R650CE:

Active-mode eiciency versus AC line input voltage

Infineon’s 35 W adapter reference design has been powered by IPD60R650CE, which oers an eiciency of more than

87 percent and a peak power of 45 W for 2 ms. The dynamic load response is only ±2 percent and standby power is below

100 mW. Customers could modify this board according to their requirements, gaining time-to-market. The board is

orderable through Infineon’s sample center.

89.0

88.5

88.0

87.5

87.0

86.5

86.0

R

G,ext

Oscillation due to di/dt

88.72

Oscillation due to dV/dt

C

par

R

88.45

88.06

87.70

90 115 230 264

AC line input voltage [VAC]

Optimization for EMI and eiciency/thermals

EMI and eiciency/thermals need a careful trade-o in notebook adapters

DS

– better eiciency/thermals require faster switching, which leads to worse

EMI, e.g., due to the oscillations triggered by a high dV/dt (di/dt). With a small

L

C

GD

G

G,in

C

GS

par

D

S

L

source

adjustment this challenge can be overcome. We recommend our customers to

optimize EMI when designing-in high voltage superjunction MOSFETs by:

›

C

Adding additional drain-source capacitor CDS, e.g., 100 pF

›

Adjusting external RG, e.g., 5 Ω–30 Ω

›

Optimizing PCB layout for short path from controller to MOSFET gate and a

small loop inductance

›

Adjusting EMI filter (only if other measures are insuicient)

27 mm

35 mm 89 mm

REF-35W Adapter

10

www.infineon.com/ce

Page 11

Soloreiust cone pratendeNotebook adapters

Standard adapter

T

Narrow Lead

EMI optimization for a 45 W adapter

Radiation (db) in vertical direction

115 V

AC

IPA60R800CE -2.18* 187.78 -1.67* 186.22

Competitor A (planar MOS) -7.74* 120.13 -8.72 161.13

IPA60R800CE C

* Quasi-peak

: 100 pF -8.17* 182.24 -8.80* 183.28

DS

Frequency [MHz] 230 V

AC

Frequency [MHz]

The figure above shows a typical

Semi-slim adapter

example of adjusting EMI. It has been

done on a common 45 W adapter from

Slim adapter

the market, using a planar MOSFET.

Simply replacing the planar MOSFET

with IPA60R800CE leads to a worse

EMI performance. However, adding a

100 pF CDS significantly improves the

O-220 FullPAK TO-220 FullPAK

DPAK

EMI while meeting other specifications

such as eiciency, temperature, etc.

CoolMOS™ CE – Package options for notebook adapter application (35 W-65 W)

TO-220 FullPAK

Standard package used in

adapters today

TO-220 FullPAK Narrow Lead

Package for semi-slim adapter solution,

where height is smaller compared to

standard adapters. The legs of the

TO-220 FullPAK Narrow Lead package

have been modified with stando

height reduced from about 3.3 mm to

approximately 1.8 mm such that the

leads can be fully inserted into the PCB

without any production concerns. As a

result, MOSFET height is reduced while

creepage distance is preserved

DPAK

The DPAK solution has no concerns on

the package height for semi-slim and

slim adapter solutions, as its height

is far below the allowed height, and

it is on the other side of the package,

meaning space saving and power

density increasing, however better

thermal management is required

CoolMOS™ CE portfolio for 30 W to 65 W adapter

Voltage class

[V]

600

650

General proposal

R

DS(on)

[m]

400 IPA60R400CE IPD60R400CE

460 IPA60R460CE IPD60R460CE

650 IPA60R650CE IPD60R650CE IPAN60R650CE

800 IPA60R800CE IPD60R800CE IPAN60R800CE

400 IPA65R400CE IPD65R400CE

650 IPA65R650CE IPD65R650CE IPAN65R650CE

For standard adapter For slim adapter For semi-slim adapter

TO-220 FullPAK TO-252 DPAK TO-220 FullPAK Narrow Lead

www.infineon.com/ce

11

Page 12

Ictam quodita dolorep

95

Eiciency [%]

TV sets

CoolMOS™ CE – TV sets

CoolMOS™ CE oers a wide range of products for the TV SMPS application and is selected by the world’s leading TV manufacturers

due to high quality, reliability and ease-of-use. Together with XDP™ digital power, OptiMOS™, EiceDRIVER™ and other components

from Infineon, we oer system solutions as demonstrated by a wide range of reference designs. Our dedication for TV application has

been further demonstrated by developing 600 V CoolMOS™ CE in TO-220 FullPAK Wide Creepage products mainly for TV application.

Value proposition of 500 V, 600 V, 650 V and 700 V CoolMOS™ CE for TV applications:

For the AC-DC power supply in TV applications, CoolMOS™ CE devices come in dierent voltage classes of 500 V, 600 V, 650 V

and 700 V so as to be used in both PFC and LLC stages. The CoolMOS™ CE devices are oered in dierent packages such as TO-220

FullPAK, TO-220 FullPAK Wide Creepage, DPAK and SOT-223. This variety enables customer to use these packages in dierent stages

of the power supply to ease the PCB layout design and manufacturing. As an example, the TO-220 FullPAK can be used in the topside PFC stage and the DPAK or SOT-223 can be used in the bottom side LLC stage making the layout simpler, and eiciently meeting

the thermal and EMI requirements. When CoolMOS™ CE devices are driven with optimal gate driving techniques, they exhibit low

temperature rise and provide high eiciency performance. These devices are robust and are capable of withstanding higher stress

under fault conditions. This high reliability feature makes them suitable for operation in environments which have unstable power

conditions. As an example, the stress on the PFC MOSFETs can be high under input line transient or faulty load conditions. The

CoolMOS™ CE devices safely carry high peak currents until the PWM controller responds to the transient condition.

Infineon’s 120 W TV SMPS design powered by IPD60R400CE and IPD60R1K5CE

Infineon oers a reference design for a 120 W TV SMPS which combines the advantages of XDP™ digital power and

CoolMOS™ CE to oer the state-of-the-art performance, where IDP2302 is used to control system, and IPD60R400CE and

IPD60R1K5CE are used in the PFC and LLC stages respectively. It is a slim design and cost optimized for customers.

CoolMOS™ CE portfolio for TV

91

87

83

79

75

Voltage class

[V]

R

DS(on)

[m]

190

280

800

400/380

500/460

650/600

950/1000

1500/1400

General

proposal

150 mm

200 mm

30 60 90 120

Load [W]

90 V

AC

TO-220 FullPAK TO-252

IPA50R190CE IPAW60R190CE

IPA50R280CE IPD50R280CE IPAW60R280CE

IPA50R800CE IPD50R800CE IPA60R800CE IPD60R800CE

IPA50R380CE IPD50R380CE IPA60R400CE IPD60R400CE IPAW60R380CE IPA65R400CE IPD65R400CE

IPA50R500CE IPD50R500CE IPA60R460CE IPD60R460CE

IPA50R650CE IPD50R650CE IPA60R650CE IPD60R650CE IPAW60R600CE IPA65R650CE IPD65R650CE IPAW70R600CE

IPA50R950CE IPD50R950CE IPA60R1K0CE IPD60R1K0CE IPA65R1K0CE IPD65R1K0CE IPAW70R950CE

PFC: 190 mΩ – 600 mΩ

LLC: 400 mΩ – 1500 mΩ

110 V

AC

500 600 650 700

(DPAK)

IPD50R1K4CE IPA60R1K5CE IPD60R1K5CE IPA65R1K5CE IPD65R1K5CE

230 V

AC

TO-220 FullPAK TO-252

PFC: 190 mΩ – 600 mΩ LLC: 400 mΩ – 1500 mΩ

265 V

AC

(DPAK)

Flyback: 400 mΩ – 1500 mΩ

TO-220 FullPAK

Wide Creepage

DEMO-IDP2302-120W

TO-220 FullPAK TO-252

(DPAK)

Flyback: 400 mΩ – 1500 mΩ Flyback

TO-220 FullPAK

Wide Creepage

www.infineon.com/ce

14 mm

12

Page 13

Soloreiust cone pratende

10.6

16.013.7

11.3

2.3

TV sets

New TO-220 FullPAK Wide Creepage package for CoolMOS™

TO-220 FullPAK

standard

3.3

2.54

Wider creepage for applications

susceptible to pollution

TO-220 FullPAK

The

to increase creepage distance: the application of potting, the usage of sleeves, pre-bending of leads and other

workarounds come at an extra cost of estimated 2-5 USD cents. This cost and the additional process steps can be

removed with the Wide Creepage package.

Wide Creepage reduces system cost by oering an alternative to frequently used approaches

TO-220 FullPAK

Wide Creepage

16.313.2

4.25

The TO-220 FullPAK Wide Creepage increases the creepage distance

to 4.25 mm compared to 2.54 mm for a standard TO-220 package. It

fully meets requirements of the EN60664-1 standard that requires

at least 3.6 mm for open frame electrical power supplies which are

oen found in LED TV, PC power or industrial power supplies: in these

applications, air vents in the external casing to allow some air flow

which will assist in cooling the internal components. This makes

the inside susceptible to pollutants such as dust particles. These

pollutants reduce the eective creepage between pins. High voltage

arcing can destroy the MOSFET used in SMPS when the pollutants

reduce the eective creepage distance.

Benefits

›

Wide creepage of 4.25 mm to avoid arcing even in polluted environment

›

Cost savings of 2-5 USD cent in creepage protection by removing additional process steps

›

Fully automated PCB assembly eliminating process variation

›

FullPAK benefit of isolation, lower package capacitances, lower EMI

CoolMOS™ CE oers 500 V, 600 V, 650 V and 700 V products in TO-220 FullPAK, TO-252 (DPAK) and TO-220 FullPAK Wide

Creepage for TV SMPS solutions. For the PFC section 500 V/600 V products with an R

preferred. We recommend 400 mΩ to 1500 mΩ 500 V/600 V products in the LLC section. For flyback 400 mΩ to 1500 mΩ

600 V/ 650 V parts are recommended for customer design.

www.infineon.com/ce

between 190 mΩ and 600 mΩ are

DS(on)

13

Page 14

Ictam quodita dolorepLighting

3.5

6.5

CoolMOS™ CE for lighting applications

Good eiciency, ease-of-use and EMI performance at an attractive cost position make the CoolMOS™ CE series the product of choice for LED drivers or LED tubes in buck, flyback, PFC and LLC topology. Its benefits include an improvement in

eiciency and thermal behavior compared to standard MOSFETs.

CoolMOS™ products aimed at lighting bring the benefits of highest quality and delivery reliability as outlined in the overview section for the CoolMOS™ portfolio. However, the CoolMOS™ CE series has been defined with a particular focus on the

customers’ needs, for an attractive price and fastest supply availability.

CoolMOS™ CE in SOT-223 package

With the rapid conversion from CFL to LED lighting, customer requirements are rapidly changing: On the one hand, power

levels are further decreasing, while on the other hand, increasing cost pressure compels power designers to optimize designs to a fraction of a cent. The completion of the CoolMOS™ CE portfolio with the SOT-223 package is Infineon’s answer to

this challenge: It facilitates a further reduction in BOM cost – and additional footprint optimization in some designs – with

only a minor compromise in terms of thermal behavior.

SOT-223 as drop-in replacement for DPAK at a lower cost

The SOT-223 package with a decapped middle pin is fully compatible with the footprint of a DPAK, therefore allowing

one-on-one drop-in replacements and second sourcing.

DPAK SOT-223

6.2

6.7

6.5

3.5

14

www.infineon.com/sot-223

Page 15

Soloreiust cone pratendeLighting

T [°C]

P

= 250 mW

Thermal behavior – on a par with DPAK

The thermal behavior of the SOT-223 primarily depends on the layout of the board where the package is used and on the

power consumed. We have measured the thermals in a test environment and compared them with a simulation. Compared to a DPAK positioned on a typical DPAK footprint, the SOT-223 displays the following thermal behavior:

70

65

60

55

57.8

DPAK on DPAK

footprint (reference)

loss

68.0

+10°C

SOT-223 on SOT-223

footprint

Good for low

›

power levels

Footprint savings

›

vs. DPAK

62.8

+5°C

SOT-223 on DPAK

footprint

Drop-in replacement

›

for DPAK

Good for designs

›

with thermal margin

Recommended use case

59.8

+2°C

SOT-223 on footprint

of DPAK + 20 mm

Replacement for DPAK

›

Good for designs

›

with suicient

cooling area

2

Cu

›

Same footprint as DPAK – when mounted on a standard DPAK footprint, the SOT-223 package shows a temperature

elevated by 4–5 K. This behavior makes the SOT-223 suitable for designs with a thermal margin

›

Footprint of DPAK plus ~20 mm2 additional copper area – in many designs, the MOSFET is mounted on a larger

Cu area which serves as a heatsink embedded in the PCB. As soon as 20 mm2 Cu or more is available in addition to the DPAK

footprint, the temperature increase is no more than 2–3 K above DPAK and the SOT-223 can be used as a drop-in replacement

›

SOT-223 on SOT-223 footprint – when mounted on the SOT-223 footprint without an additional surrounding Cu area, the

package leads to a 10 °C temperature increase compared to a DPAK. This means that the option of space savings via the

SOT-223 is only useful for very low power applications

www.infineon.com/sot-223

15

Page 16

Ictam quodita dolorepLighting

footprint ~40 mm

Min. SO

footprint

350

Simulation result: P

= 250 mW, T

= 70°C, board 76 x 114 mm

Thermal behavior – on a par with DPAK

100

B

95

90

85

[°C]

j

T

80

75

70

65

T-223

loss

98°C

C

A

85°C

0

D

50 100

Standard DPAK

amb

SOT-223 slightly higher temperature on

DPAK standard footprint – ∆T ~ 4–5°C

Same thermal performance of SOT-223 as

DPAK with a Cu footprint of ~60 mm

(increase of ~20 mm2 board space)

+4°C

150 200

2

Cu area [mm

2

SOT-223

DPAK

2

]

250 300

The laboratory findings on thermal behavior are confirmed by a thermal simulation with T

= 70°C and P

ambient

= 250 mW.

loss

The size of the copper area in the footprint is shown on the x-axis, while the y-axis displays the temperature of the package top side. In the case of an SOT-223 on DPAK footprint, the 4–5 K temperature increase over DPAK is confirmed. But

when used in conjunction with an enlarged copper area of ~20 mm2, a temperature increase of 2–3 K is measured.

CoolMOS™ CE SOT-223 product portfolio

R

[m] 500 V 600 V 650 V 700 V

DS(ON)

3400 IPN60R3K4CE

3000 IPN50R3K0CE

2000/2100 IPN50R2K0CE IPN60R2K1CE

1400/1500 IPN50R1K4CE IPN60R1K5CE IPN65R1K5CE IPN70R1K5CE

950/1000 IPN50R950CE IPN60R1K0CE IPN70R1K0CE

800 IPN50R800CE

650 IPN50R650CE

www.infineon.com/sot-223

16

Page 17

CoolMOS™ CE – demonstrator boards

Soloreiust cone pratendeDemonstrator boards

ICL8201 demoboard with 500 V CoolMOS™

End application: 5 W-10 W LED lamp

Parameter Value

Output power 7.5 W

Input voltage 90 V

Frequency 50 Hz/60 Hz

Power factor > 0.95 at low line

THD < 20% at low line

Eiciency 85%

Output voltage 33 V

Output current 180 mA

Infineon order code

1)

–265 V

AC

AC

> 0.80 at high line

< 30% at high line

–47 V

DC

DC

EVALLEDICL8201F1 / SP001339448

ICL5101 demoboard with 600 V CoolMOS™

2)

End applications: indoor and outdoor high power LED lighting,

high-bay and low-bay lighting, street lighting, parking garages

and area lighting, oice panel and shop lighting

Parameter Value

Output power 110 W

Input voltage 85 V

Output voltage 54 V

Output current 2060 mA

Eiciency ~ 94%

Power factor > 99%

THD < 10%

TAmbient 80°C–100°C

Infineon order code

1)

–305 V

AC

AC

DC

EVALLEDICL5101E1 / SP001296078

ICL8201 demoboard with 650 V CoolMOS™

End application: Single end cap T8 form factor LED lamp

Parameter Value

Output power 18 W

Input voltage 170 V

Frequency 50 Hz

Power factor > 0.95

THD < 20%

Eiciency > 90%

Output voltage 55 V

Output current 270 mA

Infineon order code

1)

Go to our website for more specific information about the demoboard

2)

Also suitable for 500 V due to excellent V

3)

Launch in 09/2016, higher eiciency and lower price

1)

–277 V

AC

AC

–75 V

DC

DC

EVALLEDICL8201F2 / SP001339450

regulation and error protection

bulk

ICL8105 demoboard with 800 V CoolMOS™

End application: Electronic control gear

for LED luminaires (20 W–80 W)

Parameter Value

Output power 40 W

Nominal input voltage 90 V–300 V~

Input overvoltage 310 V~

Output voltage 15 V–45 V

Output overvoltage threshold 50 V

Output current 880 mA

Eiciency <91%

Power factor >0.95

THD

Infineon order code:

20 W-80 W version:

1)

<16%

EVALLEDICL8105F2 / SP001296076

EVALLEDICL8105E1 / SP001296074

3)

www.infineon.com/ce

17

Page 18

Ictam quodita dolorepTarget topologies

CoolMOS™ CE – target topologies

Single switch topologies – boost/PFC

Typically used in high power adapters, PC power, TV power supplies front-end

PFC stage

MOSFET driver

Digital/analog controller

Design equations for MOSFET selection

= V

V

DS

out

ID = I

* 1 / (1-D)

out

= 1.5 * VDS (with derating for all variables on board)

V

DS_FET

max. 25°C for acceptable power dissipation in MOSFET package

R

DS(on)

= (1.5 * P

case operation conditions. Ipk = 1.5 * I

P

device

) / (Ipk² * D). Ipk is derated value of ID to cover all worst

device

= (Tj – Ta) / R

thJA

D

400 V at 0.5 A

18

* Two in parallel

Output power

[W]

200 85 V

150 85 V

100 85 V

75 85 V

Input voltage

[V]

…265 V

AC

…265 V

AC

…265 V

AC

…265 V

AC

PFC output load current at 400 V

output voltage

CoolMOS™ CE

device options

[A]

AC

AC

AC

AC

0.60 IPx60R400CE*

0.40 IPx60R460CE

0.30 IPx60R650CE

0.20 IPx60R800CE

www.infineon.com/ce

Page 19

CoolMOS™ CE – target topologies

Quasi-resonant flyback topologies

Typically used in chargers, adapters, auxiliary power supplies

Soloreiust cone pratendeTarget topologies

PFC stage

MOSFET driver

Digital/analog controller

Design equations for MOSFET selection

= Vin + VR, where VR = (0.8 * V

V

DS

= Vin * ton / L

I

D

V

DS_FET

R

DS(on)

= (1.5 * P

case operation conditions. Ipk = 1.5 * I

P

= (Tj – Ta) / R

device

p

= 1.5 * VDS (with derating for all variables on board)

max. 25°C for acceptable power dissipation in MOSFET package

) / (Ipk² * D). Ipk is derated value of ID to cover all worst

device

thJA

* (NP / NS))

out

D

Snubber/

active clamp

MOSFET driver

PWM/QR stage - flyback

12 V at 3 A

Isolation

Selection is based for 85 V

to 265 VAC input voltage,

AC

100 kHz switching frequency. Reflected voltage (VR) design greatly aects MOSFET VDS selection criteria. Mode

of operation – CCM (continuous conduction mode) or

DCM (discontinuous conduction mode) also aects

MOSFET R

selection criteria.

DS(on)/ID

Output

power

[W]

120 19 6 71 143 IPx65R650CE IPx65R650CE

100 24 5 107 214 IPx65R650CE IPx65R1k0CE

75 19 6 107 214 IPx65R650CE IPx65R1k0CE

50 12 10 107 214 IPx65R650CE IPx65R1k0CE

36 12 10 143 286 IPx70R600CE IPx70R1K4CE

25 9 13 143 286 IPx70R950CE IPx70R1K4CE

15 5 24 143 286 IPx70R950CE IPx70R1K4CE

10 5 24 214 429 IPx70R1K4CE IPx70R1K4CE

5 5 24 429 857 IPx70R2K0CE IPx70R1K4CE

www.infineon.com/ce

Output

voltage

[V]

Turns ratio

NP/NS

Primary

inductance

DCM

[uH]

Primary

inductance

CCM

[uH]

CoolMOS™ CE

device options

DCM

CoolMOS™ CE

device options

CCM

19

Page 20

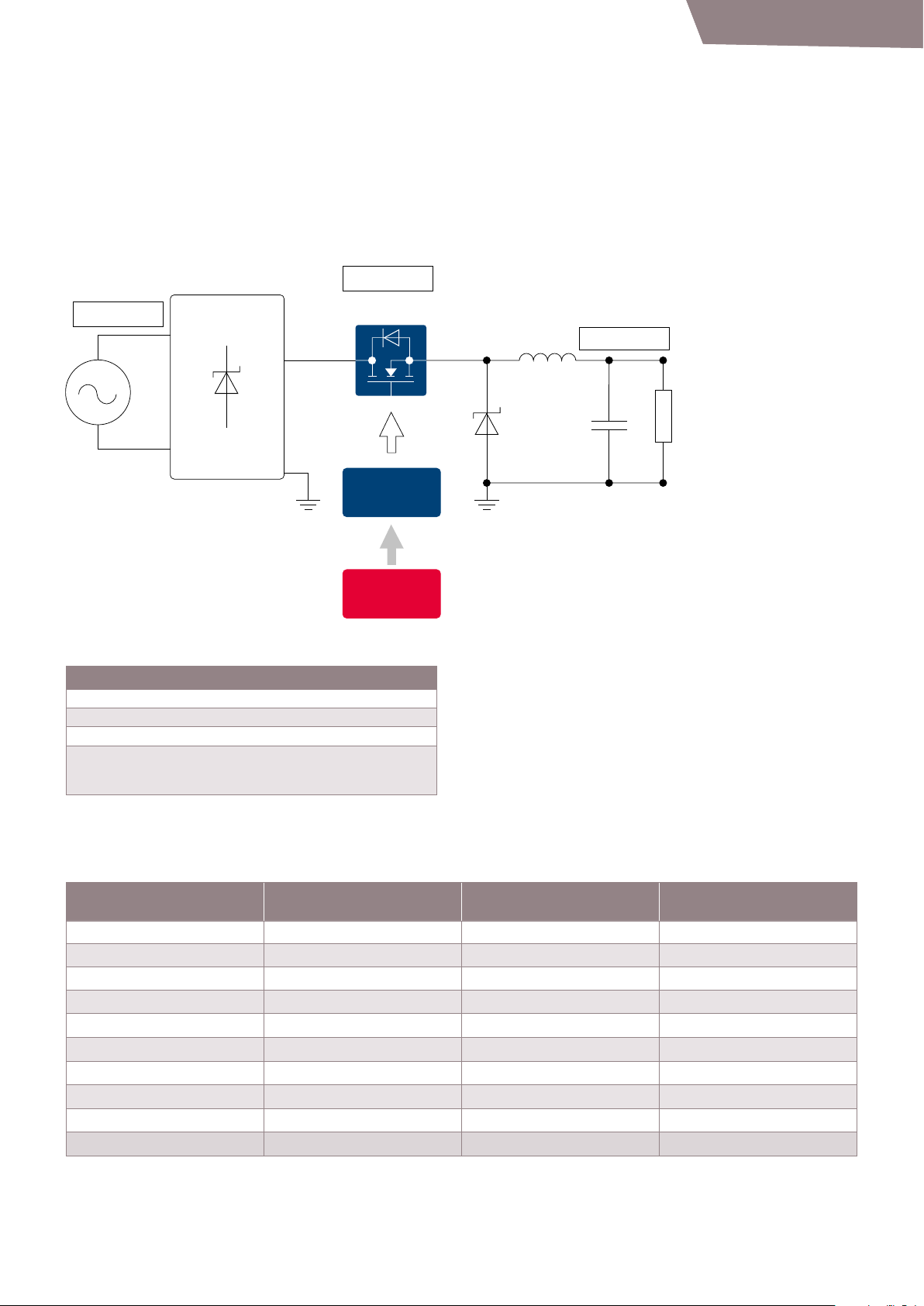

Ictam quodita dolorepTarget topologies

CoolMOS™ CE – target topologies

Wide input range flyback topologies

Typically used in LED drivers and adapters

90 Vto 300 V

AC AC

Bridge rectifier

Digital/analog controller

Design equations for MOSFET selection

= V

+ VR, where VR = (0.8 * V

V

DS

in

= Vin * ton / L

I

D

V

DS_FET

max. 25°C for acceptable power dissipation in MOSFET pack-

R

DS(on)

age = (1.5 * P

case operation conditions. Ipk = 1.5 * I

P

= (Tj – Ta) / R

device

p

= 1.5 * VDS (with derating for all variables on board)

) / (Ipk² * D). Ipk is derated value of ID to cover all worst

device

thJA

* (NP / NS))

out

D

Snubber/

active clamp

MOSFET driver

PWM/QR stage - flyback

Isolation

Selection is based for 85 VAC to 300 VAC input voltage,

100 kHz switching frequency. Reflected voltage (VR) design

aects MOSFET VDS selection criteria. 800 V devices allow

greater VR range. Mode of operation – CCM (continuous

conduction mode) or DCM (discontinuous conduction

mode) also aects MOSFET R

selection criteria.

DS(on)/ID

5 V at 3 A

20

Output

power

[W]

Output

voltage

[V]

Turns ratio

NP/NS

Primary

inductance

DCM

[uH]

Primary

inductance

CCM

[uH]

CoolMOS™ CE

device options

DCM

CoolMOS™ CE

device options

CCM

150 24 5 71 143 IPA80R310CE IPA80R460CE

100 24 5 107 214 IPA80R310CE IPA80R650CE

50 12 10 107 214 IPA80R310CE IPA80R650CE

36 12 10 143 286 IPA80R460CE IPA80R1K0CE

25 9 13 143 286 IPA80R460CE IPA80R1K0CE

15 5 24 143 286 IPA80R460CE IPA80R1K0CE

10 5 24 214 429 IPA80R650CE IPA80R1K4CE

5 5 24 429 857 IPA80R1K0CE IPx80R2K8CE

www.infineon.com/ce

Page 21

CoolMOS™ CE – target topologies

Single switch topologies – buck

Typically used in LED drivers, motor controllers, high power adapters, TV power supplies front-end

Buck

to 265 V

85 V

AC AC

24 V at 2 A

Soloreiust cone pratendeTarget topologies

Design equations for MOSFET selection

= V

V

DS

in

ID = I

out

V

= 1.5 * VDS (with derating for all variables on board)

DS_FET

max. 25°C for acceptable power dissipation in MOSFET package

R

DS(on)

= (1.5 * P

case operation conditions

) / (Ipk² * D). Ipk is derated value of ID to cover all worst

device

Input voltage

Output load current

[V]

110 V

AC

110 V

AC

85 V

…265 V

85 V

85 V

85 V

85 V

85 V

85 V

85 V

AC

AC

AC

AC

AC

AC

AC

AC

…265 V

…265 V

…265 V

…265 V

…265 V

…265 V

…265 V

AC

AC

AC

AC

AC

AC

AC

AC

[A]

Driver

Microcontroller

Output power

[W]

CoolMOS™ CE

device options

7 200 IPx50R190CE*

6 180 IPx50R280CE*

5 150 IPx60R400CE

4 120 IPx60R460CE

4 100 IPx60R650CE

3 75 IPx60R650CE

3 50 IPx60R1k0CE

2 25 IPx60R1k5CE

2 10 IPx60R2k1CE

1 5 IPx60R3k4CE

* Two in parallel

www.infineon.com/ce

21

Page 22

Ictam quodita dolorepTarget topologies

CoolMOS™ CE – target topologies

Two switch topologies – half-bridge LLC

Typically used in PC power and TV power supplies

The ideal MOSFET for the LLC converter would allow for zero dead time (maximum power transfer) and no conduction

loss. Hence selecting a lower R

appropriate MOSFET QG, Q

caused by E

can be considered negligible, and to this extent, E

oss

oss

MOSFET will help lower condition losses. Since LLC operates fully in ZVS-mode (given

DS(on)

, selected Q

and m-values – and ample pre-programmed deadtime), switching loss

max

is not a critical MOSFET parameter for LLC.

oss

From PFC

output

Half-bridge driver

Digital/

analog controller

Design equations for MOSFET selection

= V

V

DS

in

ID = I

* (NS / NP)

out

= 1.5* VDS (with derating for all

V

DS_FET

variables on board)

max. 25°C for acceptable power

R

DS(on)

dissipation in MOSFET package = (1.5 * P

(Ipk² * D). Ipk is derated value of ID to cover all

worst case operation conditions

device

LLC half-bridge

Isolation

12 V at 10 A

In LLC topology, the MOSFET body diode could potentially experience hard

current commutation in abnormal conditions, if steps are not taken specifically to avoid this either by a good control scheme or additional circuitry in the

topology. The CoolMOS™ CE addresses the potential issue of reverse recovery of

body diode by employing a self-snubbing scheme causing the channel to partial-

) /

ly turn on at high dV/dt (induced by C

voltage divider) in order to prevent

GD/CGS

avalanche breakdown, thus providing the extra measure of protection during

hard body diode commutation.

22

Input voltage

VDC [V]

400 250 24 128 109 356 20 IPx60R400CE IPx50R380CE

400 200 24 160 136 445 16 IPx60R460CE IPx50R500CE

400 150 24 213 181 594 12 IPx60R650CE IPD50R650CE

400 100 24 320 272 890 8 IPx60R800CE IPD50R800CE

400 75 24 427 363 1187 6 IPx60R1k0CE IPD50R950CE

Output

voltage

[V]

Output volt-

age Vo [V]

Rac

[]

Lr

[uH]

Lp

[uH]

Cr

[nF]

600 V

CoolMOS™ CE

device

options

CoolMOS™ CE

www.infineon.com/ce

500 V

device

options

Page 23

Soloreiust cone pratendeSoloreiust cone pratende

Infineon support for high voltage MOSFETs

Useful links and helpful information

Further information, datasheets and documents

www.infineon.com/ce

›

www.infineon.com/coolmos

›

www.infineon.com/coolmos-500V

›

www.infineon.com/coolmos-600V

›

Videos

www.infineon.com/mediacenter

›

Simulation

www.infineon.com/coolmos-650V-700V

›

www.infineon.com/coolmos-800V

›

www.infineon.com/powermosfet-simulationmodels

›

23

Page 24

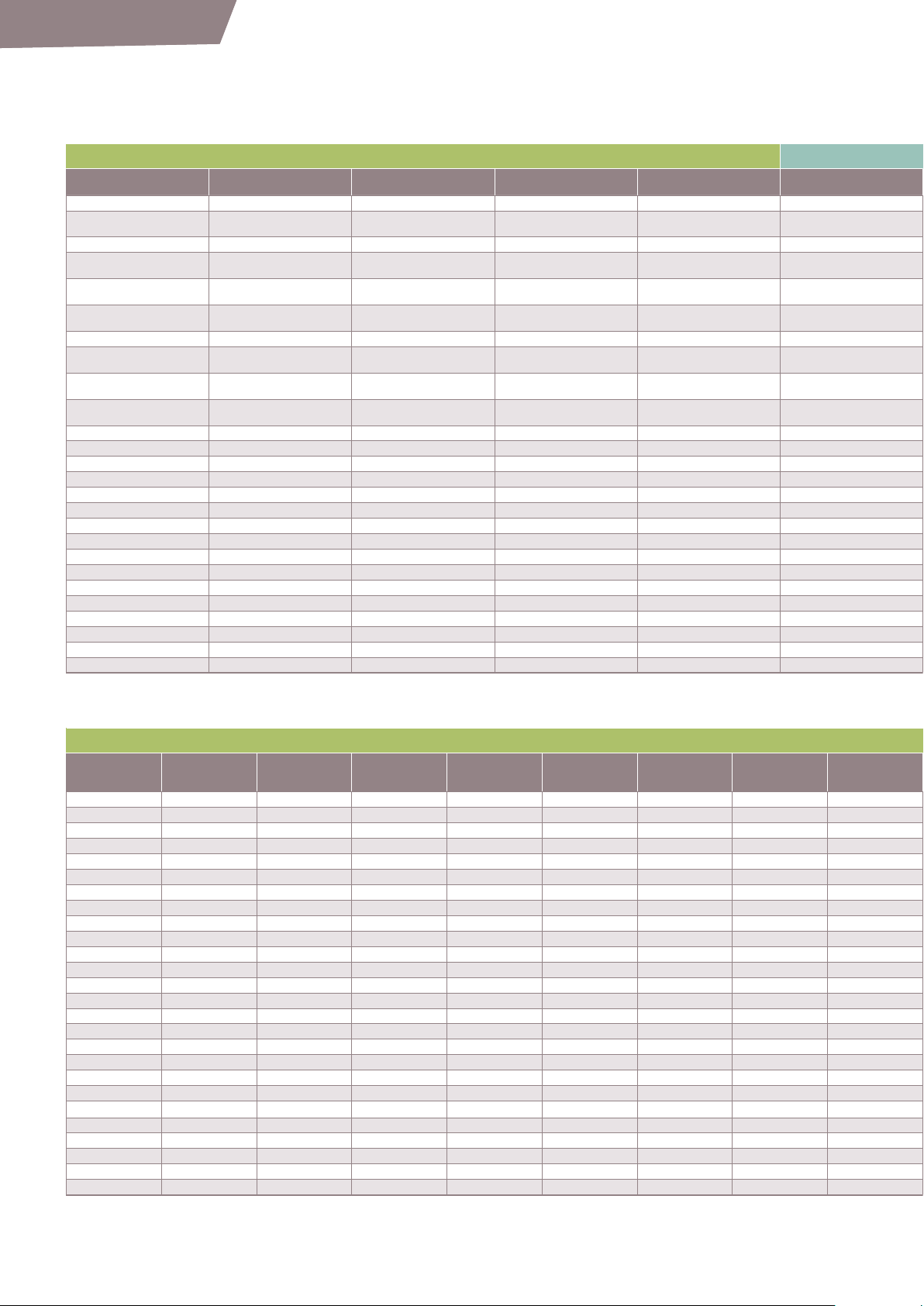

Ictam quodita dolorepProduct portfolio

500V CoolMOS™ CE

R

DS(on)

[mΩ]

190

280 IPP50R280CE IPA50R280CE IPW50R280CE IPD50R280CE

380

500 IPP50R500CE IPA50R500CE IPAN50R500CE IPD50R500CE

650 IPA50R650CE IPD50R650CE IPN50R650CE

800 IPA50R800CE IPD50R800CE IPN50R800CE

950 IPA50R950CE IPD50R950CE IPU50R950CE IPN50R950CE

1400 IPD50R1K4CE IPU50R1K4CE IPN50R1K4CE

2000 IPD50R2K0CE IPU50R2K0CE IPN50R2K0CE

3000

TO-220 TO-220 FullPAK

IPP50R190CE IPA50R190CE IPW50R190CE

IPP50R380CE IPA50R380CE IPD50R380CE

600V CoolMOS™ CE

R

DS(on)

[mΩ]

190

280 IPAW60R280CE

380 IPAW60R380CE

400 IPA60R400CE IPD60R400CE IPS60R400CE

460 IPA60R460CE IPD60R460CE IPS60R460CE

600 IPAW60R600CE

650 IPA60R650CE IPAN60R650CE IPD60R650CE IPS60R650CE

800 IPA60R800CE IPAN60R800CE IPD60R800CE IPS60R800CE

1000 IPA60R1K0CE IPD60R1K0CE IPU60R1K0CE IPS60R1K0CE IPN60R1K0CE

1500

2100 IPD60R2K1CE IPU60R2K1CE IPS60R2K1CE IPN60R2K1CE

3400 IPD60R3K4CE IPU60R3K4CE IPS60R3K4CE IPN60R3K4CE

TO-220 FullPAK

IPA60R1K5CE IPD60R1K5CE IPU60R1K5CE IPS60R1K5CE IPN60R1K5CE

650V CoolMOS™ CE

R

DS(on)

[mΩ]

400 IPA65R400CE IPD65R400CE IPS65R400CE

650

1000 IPA65R1K0CE IPD65R1K0CE IPS65R1K0CE

1500 IPA65R1K5CE IPD65R1K5CE IPS65R1K5CE IPN65R1K5CE

TO-220 TO-220 FullPAK

700V CoolMOS™ CE

R

DS(on)

[mΩ]

600

950

1000

1400

1500

2000

2100

TO-220

ACTIVE & PREFERRED

ACTIVE & PREFERRED

TO-220 FullPAK

Wide Creepage

IPAW60R190CE

ACTIVE & PREFERRED

IPA65R650CE IPAN65R650CE IPD65R650CE IPS65R650CE

ACTIVE & PREFERRED

TO-220 FullPAK

Wide Creepage

IPAW70R600CE IPD70R600CE IPSA70R600CE IPS70R600CE

IPAW70R950CE IPI70R950CE IPD70R950CE IPSA70R950CE IPS70R950CE

TO-220 FullPAK

Narrow Lead

TO-220 FullPAK

Narrow Lead

TO-220 FullPAK

Narrow Lead

TO-262

(I2PAK)

TO-247

TO-252

(DPAK)

IPD50R3K0CE IPU50R3K0CE IPN50R3K0CE

TO-251

(IPAK)

TO-252

(DPAK)

TO-252

(DPAK)

TO-252

(DPAK)

IPD70R1K4CE IPSA70R1K4CE IPS70R1K4CE

IPN70R1K5CE

IPD70R2K0CE IPSA70R2K0CE IPS70R2K0CE

TO-251

(IPAK Short Lead

with ISO Stando)

TO-251

(IPAK)

TO-251

(IPAK)

TO-251

(IPAK Short Lead)

(IPAK Short Lead)

(IPAK Short Lead)

TO-251

(IPAK Short Lead)

TO-251

TO-251

SOT-223 ThinPAK 5x6

IPN70R1K0CE

IPL70R2K1CES

SOT-223

Charger

SOT-223

SOT-223

Charger

Charger

800V CoolMOS™ CE

R

DS(on)

[mΩ]

310

460 IPA80R460CE

650 IPA80R650CE

1000 IPA80R1K0CE IPD80R1K0CE IPU80R1K0CE

1400 IPA80R1K4CE IPD80R1K4CE IPU80R1K4CE

2800

24

ACTIVE

TO-220 TO-220 FullPAK TO-247

IPA80R310CE

TO-252

(DPAK)

IPD80R2K8CE IPU80R2K8CE

TO-251

(IPAK)

TO-251

(IPAK Short Lead)

www.infineon.com/ce

Page 25

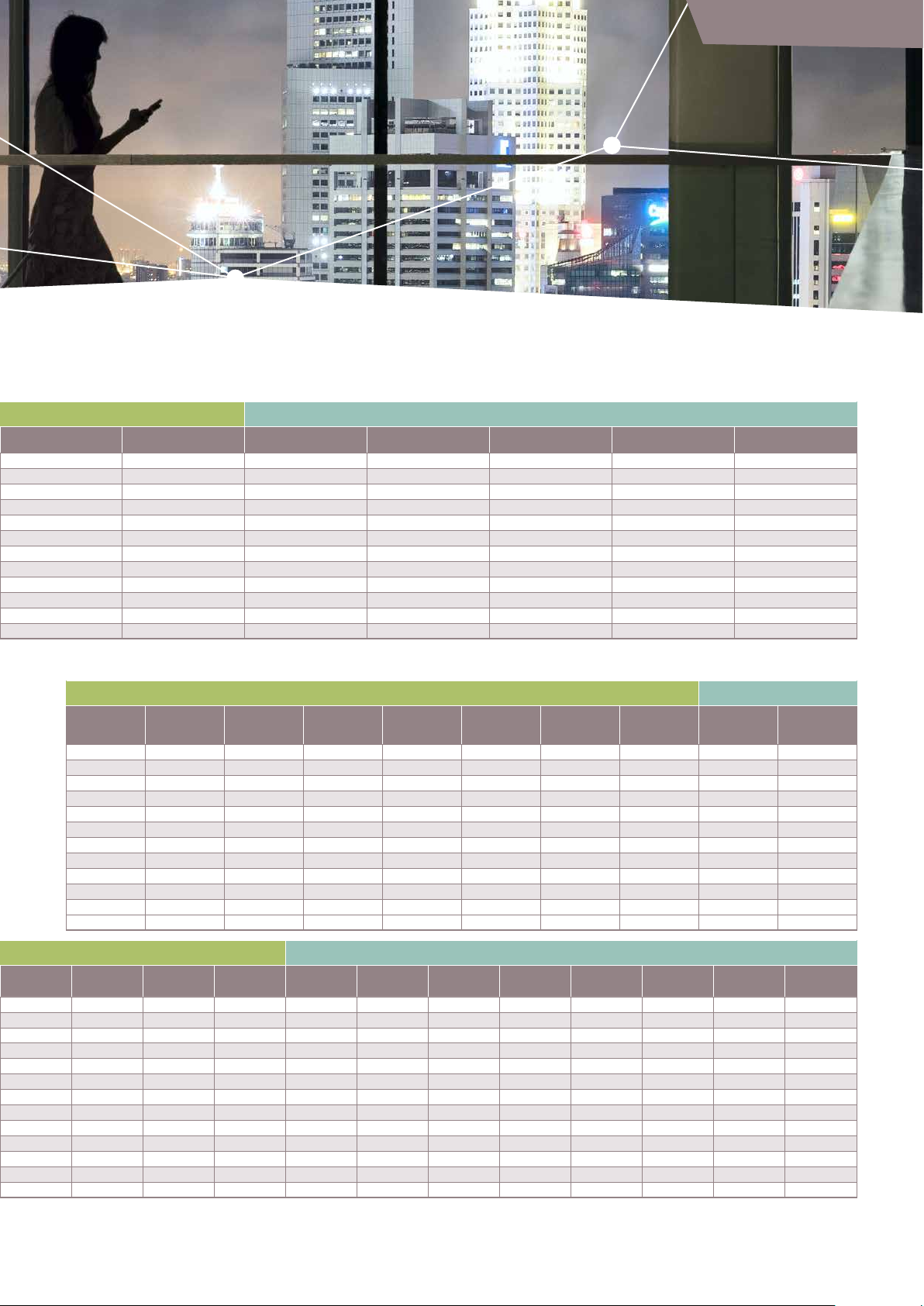

Soloreiust cone pratendePackage overview

CoolMOS™ CE portfolio package overview

Package Vol-

SOT-223

TO-247 500

IPAK

IPAK Short Lead

IPAK Short Lead with

ISO Stando

DPAK

IPAK 700

TO-220 FullPAK

TO-220 Standard 500

TO-220 FullPAK Narrow Lead

TO-220 FullPAK Wide Creepage

ThinPAK 5x6 700

tage

[V]

500 650/800 950/1400 2000/3000

600 1000/1500 2100/3400

650 1500

700

600

800

600

650

700

700

500

600

650

700

800

500

600 400 460 650/800 1000/1500

650 400 650 1000/1500

800

500

600

650

600

700

0-59 60-89 90-149 150-199 200-299 300-400 401-600 601-899 900-1500 >1500

190 280

190 280 380 500 650/800 950

190 280 380 500

190 280 380 600

R

[m]

DS(on)

1000/1500

1000/1500 2100

1000/1400 2800

400 460 650/800 1000/1500 2100/3400

400 650 1000/1500

600 950/1400 2000

600 950/1400 2000

280 380 500 650/800 950/1400 2000/3000

400 460 650/800 1000/1500 2100/3400

400 650 1000/1500

600 950/1400 2000

1000/1400 2800

950

310 460 650 1000/1400

500

650/800

650

600

950

2100

ACTIVE & PREFERRED ACTIVE

www.infineon.com/ce

25

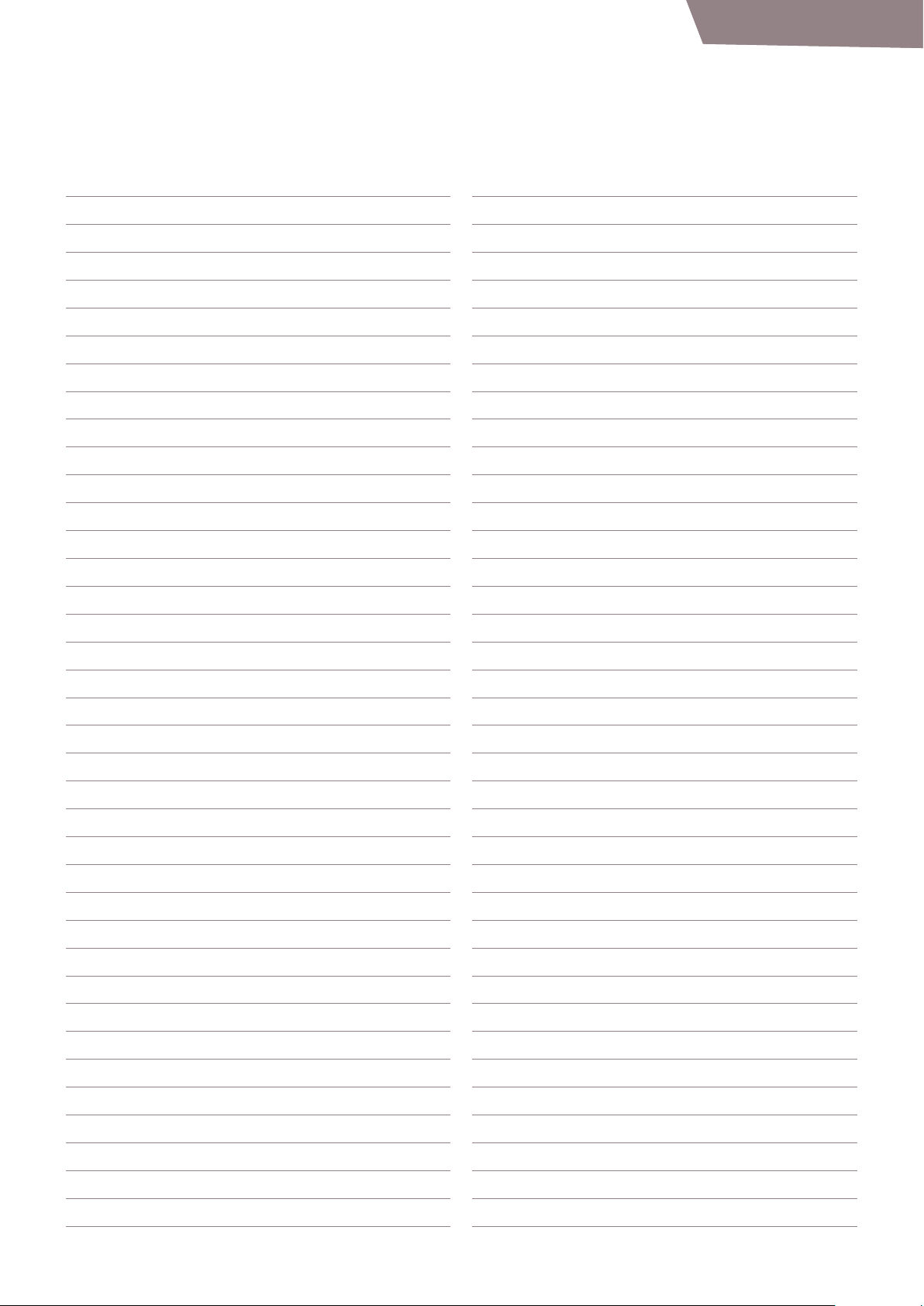

Page 26

Ictam quodita dolorepCross reference

500 V CoolMOS™ CE

CoolMOS™ CE

IPA50R950CE

IPA50R800CE

IPA50R650CE

IPA50R500CE

IPA50R380CE

IPA50R280CE

IPA50R190CE

IPP50R500CE

IPP50R380CE

IPP50R280CE

IPP50R190CE

IPD50R3K0CE

IPD50R2K0CE

IPD50R1K4CE

IPD50R950CE

IPD50R800CE

IPD50R650CE

IPD50R500CE

IPD50R380CE

IPD50R280CE

IPU50R3K0CE

IPU50R2K0CE

IPU50R1K4CE

IPU50R950CE

IPW50R280CE

IPW50R190CE

Superjunction MOSFET Planar MOSFET

STMicroelectronics

STF8NM50N AOTF8T50P SiHFI840G

STF10NM50N

STF11NM50N AOTF12N50 SiHFIB7N50A FMV12N50E

STF19NM50N SiHF18N50D FMV20N50E

STF23NM50N

STP11NM50N SiHP12N50C FMP12N50E

STP12NM50 SiHP12N50E FMP16N50E

STP19NM50N SiHP15N50E FMP20N50E

STP23NM50N SiHP20N50E

STD8NM50N AOD9N50

STD10NM50N

STD11NM50N

STD14NM50N SiHD12N50E

STW19NM50N AOK22N50 SiHG460B

STW23NM50N SiHFP31N50L

Alpha and Omega

Semiconductor

AOTF14N50 SiHF16N50C FMV16N50E

AOD3N50 SiHFR420 TK3P50D

AOD6N50 SiHD5N50D TK5P50D

AOU3N50 SiHFU420

Vishay Fuji Electric Toshiba

FMV08N50E

SiHF8N50D

FMV12N50ES

FMV16N50ES

FMV21N50ES

FMP12N50ES

FMP16N50ES

FMP20N50ES

SiHU5N50D CS830 A3RD SVF830M MDIS5N50TH

TK12A50D

TK13A50D

TK18A50D

TK7P50D

600 V CoolMOS™ CE

CoolMOS™ CE

IPA60R1K5CE

IPA60R1K0CE

IPA60R800CE

IPA60R650CE

IPA60R460CE

IPA60R400CE

IPD60R3K4CE

IPD60R2K1CE

IPD60R1K5CE

IPD60R1K0CE

IPD60R800CE

IPD60R650CE

IPD60R460CE

IPD60R400CE

IPU60R3K4CE

IPU60R2K1CE

IPU60R1K5CE

IPU60R1K0CE

IPS60R3K4CE

IPS60R2K1CE

IPS60R1K5CE

IPS60R1K0CE

IPS60R800CE

IPS60R650CE

IPS60R460CE

IPS60R400CE

Semiconductor

FCPF600N60Z STF10NM60N STF10N60M2 TK7A60W AOTF7S60 SiHF7N60E MMF60R580PTH NCE60R540F

FCPF380N60 STF13NM60N STF13N60M2 TK10A60W SiHF12N60E MMF60R360PTH NCE60R360F

FCD900N60Z STD7NM60N STD7N60M2 TK5P60W AOD4S60 NCE60R900K

FCD600N60Z STD10NM60N STD10N60M2 TK7P60W AOD7S60 SiHD7N60E MMD60R580PRH NCE60R540K

FCU900N60Z TK5Q60W AOI4S60 MMIS60R900PTH

Fairchild

Superjunction MOSFET Planar MOSFET

STMicroelectronics STMicroelectronics Toshiba

STF5N60M2 NCE60R1K2F

STF7NM60N STF7N60M2 TK5A60W AOTF4S60 NCE60R900F

STF9NM60N STF9N60M2 TK6A60W MMF60R750PTH

STF12N60M2 TK8A60W AOTF11S60

STD5N60M2 NCE60R1K2K

STD9NM60N STD9N60M2 TK6P60W

STD12N60M2 TK8P60W

STD13NM60N STD13N60M2 TK10P60W AOD11S60 MMD60R360PRH NCE60R360K

STU5N60M2 NCE60R1K2I

STU7NM60N STU7N60M2 AOU4S60 NCE60R900I

TK6Q60W

TK7Q60W SiHU7N60E

TK8Q60W

TK10Q60W AOI11S60

Alpha and Omega

Semiconductor

Vishay

MagnaChip

Semiconductor

chip

NCE Micro- and

Nanotechnology

NCE60R2K2K

NCE60R2K2I

26

www.infineon.com/ce

Page 27

Soloreiust cone pratende

STMicroelectronics Vishay Huajing Rectifier Silan MagnaChip Semiconductor Fairchild Semiconductor

CS8N50F A9R SVF840F MDF7N50BTH FDPF8N50NZ

IRFI840G CS10N50F A9R SVF9N50F MDF10N50TH FQPF9N50C

MDF12N50BTH FDPF12N50T

STF13NK50Z IRFIB7N50A CS13N50F A9R SVF13N50F MDF13N50BTH FDPF12N50NZ

STP14NK50ZFP CS15N50F A9R SVF18N50F MDF16N50GTH FDPF16N50

STF20NK50Z SVF20N50F MDF18N50BTH FDPF18N50

STP11NK50Z CS13N50 A8R SVF13N50T MDP13N50BTH FDP12N50NZ

STP14NK50Z CS15N50 A8R MDP16N50GTH

STP20NK50Z SVF18N50T MDP18N50BTH FDP18N50

STD3NK50Z IRFR420 MDD3N50GRH

Cross reference

STD5NK50Z SVF830D MDD5N50RH FDD5N50

STD6NK50Z SVF840D FDD6N50

IRFU420 CS3R50 A3 FQU4N50TU_WS

STW20NK50Z IRFP460B

Silikron

Semiconductor

SSF7N60F LSDO4N60 TK9A60D CS8N60F A9H SVF10N60F MDF8N60BTH

SSF10N60F TK10A60D STP10NK60ZFP CS10N60F A9HD SVF11N60F MDFS10N60DTH FDPF10N60NZ

SSF7NS60F LSD07N60 TK11A60D STP13NK60ZFP CS12N60F A9HD MDF11N60TH FDPF12N60NZ

SSF11NS60F LSD11N60F TK15A60D MDF15N60GTH FDPF17N60NT

LSG02N60

SSF5N60D STD4NK60Z CS6N60 A4TY SVF5N60D MDD4N60BRH FDD5N60NZ

LSG03N60 STD5NK60Z CS6N60 A4D SVF6N60D MDD6N60GRH FDD7N60NZ

LSG04N60

IRFP31N50L

Lonten Toshiba STMicroelectronics Huajing Rectifier Silan

TK5A60D CS6N60F A9TY SVF6N60F MDF6N60BTH

TK13A60D CS20N60F A9H SVF18N60F

MagnaChip

Semiconductor

FDD8N50NZ

FQU3N50C

Fairchild

Semiconductor

SSF7NS60D LSG07N60

SSF11NS60D LSG11N60

CS3N60 A3

SSF5N60G STD4NK60Z-1 CS6N60 A3TY SVF5N60MJ

SSF6N60G CS6N60 A3D SVF6N60MJ FDU7N60NZTU

MDI4N60BTH

MDI6N60BTH

www.infineon.com/ce

27

Page 28

Ictam quodita dolorepCross reference

650 V CoolMOS™ CE

CoolMOS™ CE

IPA65R1K5CE

IPA65R1K0CE

IPA65R650CE

IPA65R400CE

IPD65R1K5CE

IPD65R1K0CE

IPD65R650CE

IPD65R400CE

IPS65R1K5CE

IPS65R1K0CE

IPS65R650CE

IPS65R400CE

Superjunction MOSFET Planar MOSFET

STMicroelectronics STMicroelectronics Toshiba

Alpha and Omega

Semiconductor

Vishay

NCE Micro- and

Nanotechnology

STF6N65M2 TK5A65W

STF9N65M2 TK6A65W NCE65R900F

STF11N65M2 TK8A65W SiHF6N65E NCE70R540F

STF15NM65N STF16N65M2 TK11A65W AOTF11S65 SiHF12N65E NCE65R360F

STD6N65M2 TK5P65W

STD9N65M2 TK6P65W NCE65R900K

STD11N65M2 TK8P65W AOD7S65 SiHD6N65E NCE70R540K

STD11NM65N STD16N65M2 TK11P65W NCE65R360K

STU6N65M2 TK5Q65W

STU9N65M2 TK6Q65W NCE65R900L

STU11N65M2 TK8Q65W AOI7S65 SiHU6N65E NCE65R540I

STU16N65M2 TK11Q65W

700 V CoolMOS™ CE

Superjunction MOSFET Planar MOSFET

CoolMOS™ CE

IPD70R2K0CE

IPD70R1K4CE

IPD70R950CE

IPD70R600CE

IPS70R2K0CE

IPS70R1K4CE

IPS70R950CE

IPS70R600CE

IPI70R950CE

CoolMOS™ CE

(IPAK Short Lead

with ISO Stando)

MagnaChip

Semiconductor

NCE Micro- and

Nano-technology

Silikron

Semiconductor

Lonten SemiHow

NCE70R2K2K CS6N70 A4D-G

MMD70R1K4PRH NCE70R1K2K SSF5NS70D HCD6N70S TSM70N1R4CP

MMD70R900PRH NCE70R900K LSG04N70 TSM70N900CP

MMD70R600PRH NCE70R540K LSG07N70 HCD70R600S TSM70N600CP

IPSA70R2K0CE NCE70R2K2I SSF6N70G CS6N70

IPSA70R1K4CE MMIS70R1K4PTH NCE70R1K2I SSF5NS70G HCU6N70S TSM70N1R4CH

IPSA70R950CE MMIS70R900PTH NCE70R900I SSF7NS70UG LSH04N70 TSM70N900CH

IPSA70R600CE NCE70R540I LSH07N70 HCU70R600S TSM70N600CH

LSF04N70

Taiwan

Semiconductor

Manufacturing

Huajing Rectifier

CoolMOS™ CE in SOT-223 package

Superjunction MOSFET Planar MOSFET

CoolMOS™ CE

SOT-223

IPN70R1K5CE IPD70R2K0CE NCE70R2K2K CS6N70 A4D-G

IPN70R1K5CE IPD70R1K4CE

IPN65R1K5CE IPD65R1K5CE STD6N65M2 TK5P65W SSF5NS65UD LSG03N65 AOD7N65 CS7N65 A4R

IPN60R3K4CE IPD60R3K4CE LSG02N60

IPN60R2K1CE IPD60R2K1CE NCE60R2K2K SSF5N60D STD4NK60Z CS6N60 A4TY SVF5N60D MDD4N60BRH FDD5N60NZ

IPN60R1K5CE IPD60R1K5CE STD5N60M2 NCE60R1K2K LSG03N60 STD5NK60Z CS6N60 A4D SVF6N60D MDD6N60GRH FDD7N60NZ

IPN60R1K0CE IPD60R1K0CE FCD900N60Z STD7NM60N STD7N60M2 TK5P60W AOD4S60 NCE60R900K LSG04N60 SVS4N60D

IPN50R3K0CE IPD50R3K0CE AOD3N50 SiHFR420 TK3P50D STD3NK50Z IRFR420 MDD3N50GRH

IPN50R2K0CE IPD50R2K0CE

IPN50R1K4CE IPD50R1K4CE AOD6N50 SiHD5N50D TK5P50D STD5NK50Z SVF830D MDD5N50RH FDD5N50

IPN50R950CE IPD50R950CE TK7P50D STD6NK50Z SVF840D FDD6N50

IPN50R800CE IPD50R800CE STD8NM50N AOD9N50 FDD8N50NZ

IPN50R650CE IPD50R650CE STD10NM50N

CoolMOS™ CE

DPAK

Fairchild

Semiconductor

STMicro

electronics

STMicro

electronics

Toshiba

Alpha and

Omega Semi-

conductor

Vishay

MagnaChip

Semiconductor

MMD70R1K4PRH

Fuji Electric

NCE Micro-

and Nanotechnology

NCE70R1K2K SSF5NS70D HCD6N70S TSM70N1R4CP

Silikron Semi-

conductor

28

www.infineon.com/ce

Page 29

Soloreiust cone pratende

Cross reference

Silikron Semiconductor Lonten Toshiba

Alpha and Omega

Semiconductor

Huajing Rectifier Silan

Semiconductor

SSF7N65F TK5A65D AOTF7N65 CS7N65FB9D SVF7N65F MDF7N65BTH

SSF5NS65UF LSD04N65 TK7A65D AOTF10N65 CS10N65F A9R SVF10N65F MDF10N65BTH

LSD07N65 TK11A65D AOTF12N65 CS12N65F A9H SVF18N65F MDF11N65BTH

SSSF11NS65UF LSD11N65F TK13A65D AOTF18N65

SSF5NS65UD LSG03N65 AOD7N65 CS7N65 A4R

LSG04N65

LSG07N65

LSG11N65F

SSF5NS65G LSH03N65 AOI7N65 CS7N65 A3R MDI6N65BTH

LSH04N65

SSF7NS65G LSH07N65

LSH11N65F

800 V CoolMOS™ CE

Superjunction MOSFET Planar MOSFET

CoolMOS™ CE

IPA80R1K4CE

IPA80R1K0CE

IPA80R650CE

IPA80R460CE

IPA80R310CE

IPD80R2K8CE

IPD80R1K4CE

IPD80R1K0CE

IPU80R2K8CE

IPU80R1K4CE

IPU80R1K0CE

Fairchild Semi-

conductor

STMicroelectronics STMicroelectronics

Toshiba

MagnaChip

Semiconductor

chip

NCE Micro- and

Nanotechnology

FCPF1300N80Z STF6N80K5 TK10A80E STP7NK80ZFP

FCPF850N80Z STF7NM80 STF8N80K5

FCPF650N80Z STF10N80K5 TK10A80W

FCPF400N80Z STF11NM80 STF13N80K5 TK12A80W

MMF80R900PTH

MMF80R650PTH

MMF80R450PTH

NCE80R900F TK10A80E STP10NK80ZFP

FCPF290N80 STF18NM80 STF23N80K5 TK17A80W

FCD2250N80Z STD4N80K5

FCD1300N80Z STD6N80K5

FCD850N80Z STD7NM80 STD8N80K5 TK6P80W

MMD80R900PRH

NCE80R900K TSM80N950CP

FCU2250N80Z STU4N80K5

FCU850N80Z STU8N80K5 TK6Q80W NCE80R900I TSM80N950CH

Taiwan Semi-

conductor

Manufacturing

Toshiba

MagnaChip

STMicroelectronics

STP8NK80ZFP

Lonten SEMIHOW Silan

www.infineon.com/ce

Taiwan Semi-

conductor

Manufacturing

Toshiba

STMicro

electronics

Vishay

Alpha and

Omega Semi-

conductor

Huajing Rectifier Silan

MagnaChip

Semiconductor

Fairchild Semi-

conductor

29

Page 30

Ictam quodita dolorepNotes

Notes

30

Page 31

Notes

Soloreiust cone pratendeNotes

31

Page 32

Where to buy

Infineon distribution partners and sales oices:

www.infineon.com/WhereToBuy

Service hotline

Infineon oers its toll-free 0800/4001 service hotline as one central number,

available 24/7 in English, Mandarin and German.

›

Germany .................... 0800 951 951 951 (German/English)

›

China, mainland ....... 4001 200 951 (Mandarin/English)

›

India .......................... 000 800 4402 951 (English)

›

USA ............................ 1-866 951 9519 (English/German)

›

Other countries ......... 00* 800 951 951 951 (English/German)

›

Direct access ............. +49 89 234-0 (interconnection fee, German/English)

* Please note: Some countries may require you to dial a code other than “00” to access this international number,

please visit www.infineon.com/service for your country!

Mobile product catalog

Mobile app for iOS and Android.

www.infineon.com

Published by

Infineon Technologies AG

9500 Villach, Austria

© 2016 Infineon Technologies AG.

All rights reserved.

Order number: B152-I0298-V1-7600-EU-EC-P

Date: 11 / 2016

Please note!

THIS DOCUMENT IS FOR INFORMATION PURPOSES ONLY AND

ANY INFORMATION GIVEN HEREIN SHALL IN NO EVENT BE

REGARDED AS A WARRANTY, GUARANTEE OR DESCRIPTION OF

ANY FUNCTIONALITY, CONDITIONS AND/OR QUALITY OF OUR

PRODUCTS OR ANY SUITABILITY FOR A PARTICULAR PURPOSE.

WITH REGARD TO THE TECHNICAL SPECIFICATIONS OF OUR

PRODUCTS, WE KINDLY ASK YOU TO REFER TO THE RELEVANT

PRODUCT DATA SHEETS PROVIDED BY US. OUR CUSTOMERS AND

THEIR TECHNICAL DEPARTMENTS ARE REQUIRED TO EVALUATE

THE SUITABILITY OF OUR PRODUCTS FOR THE INTENDED

APPLICATION.

WE RESERVE THE RIGHT TO CHANGE THIS DOCUMENT AND/OR

THE INFORMATION GIVEN HEREIN AT ANY TIME.

Additional information

For further information on technologies, our products, the

application of our products, delivery terms and conditions

and/or prices, please contact your nearest Infineon Technologies

oice (www.infineon.com).

Warnings

Due to technical requirements, our products may contain

dangerous substances. For information on the types in question,

please contact your nearest Infineon Technologies oice.

Except as otherwise explicitly approved by us in a written

document signed by authorized representatives of Infineon

Technologies, our products may not be used in any

life-endangering applications, including but not limited to medical, nuclear, military, life-critical or any other applications where

a failure of the product or any consequences of the use thereof

can result in personal injury.

Loading...

Loading...