Page 1

UM_201709_PL21_011

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

About this document

Scope and purpose

CDM10V programming user manual describes the “COOLDIM_PRG_BOARD” burner board usage, the UART

protocol handling and the fusing details.

Intended audience

CDM10V programming board user.

Table of contents

About this document ....................................................................................................................... 1

Table of contents ............................................................................................................................ 1

1 CDM10V BURNER .................................................................................................................... 2

1.1 Introduction ............................................................................................................................................. 2

1.2 Chip orientation ...................................................................................................................................... 2

1.3 Control buttons ....................................................................................................................................... 3

1.4 Switches ................................................................................................................................................... 3

1.5 Connectors / Jumper .............................................................................................................................. 4

2 Fusing details ........................................................................................................................ 5

2.1 UART configuration ................................................................................................................................. 5

2.2 Fusing conditions .................................................................................................................................... 5

2.3 Fusing procedure .................................................................................................................................... 6

Revision history ............................................................................................................................. 8

User Manual Please read the Important Notice and Warnings at the end of this document V 1.0

www.infineon.com page 1 of 9 2017-09-19

Page 2

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

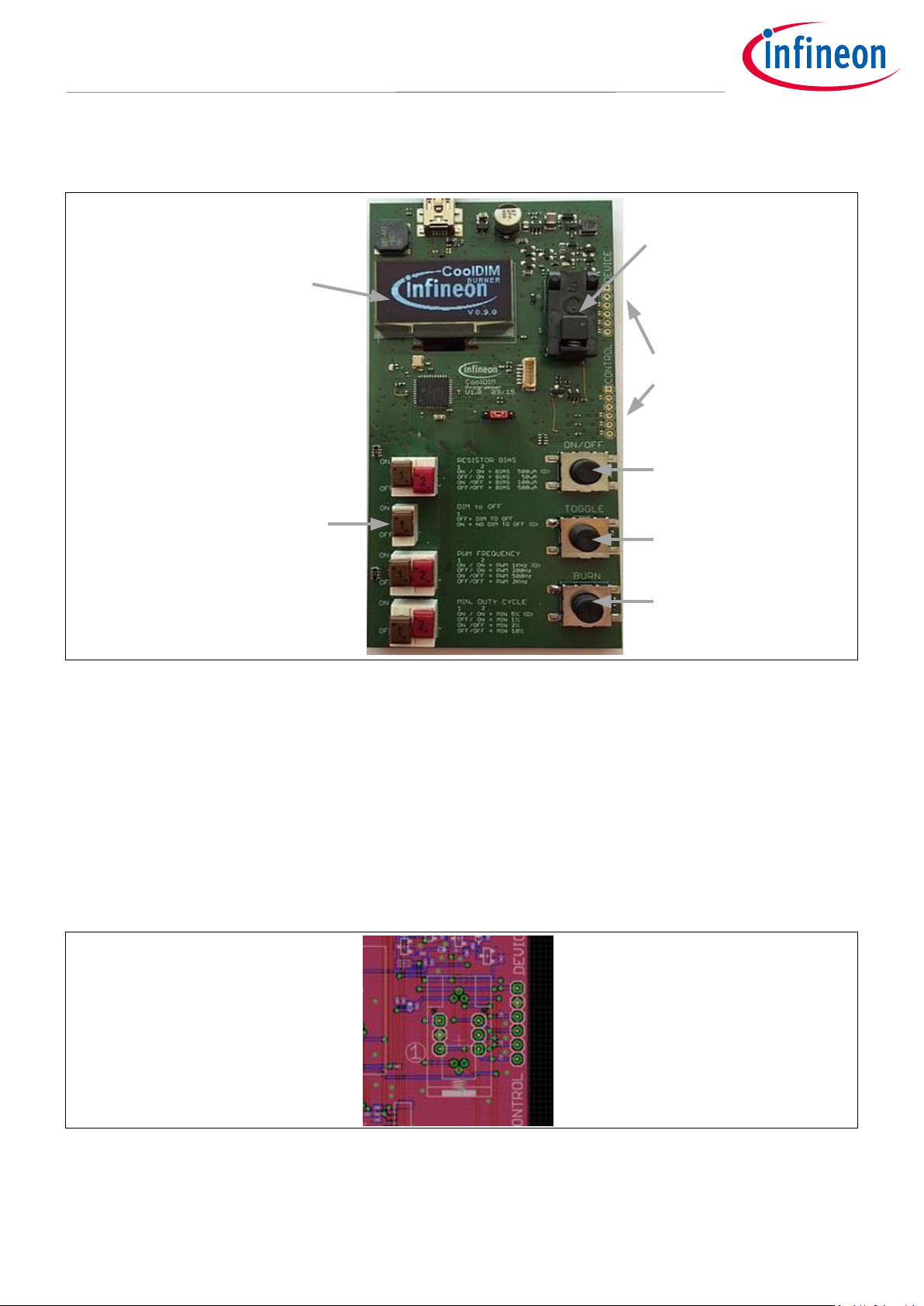

CDM10V BURNER

Display

Socket

7 DIP switsches

fuse settings

Power

ON/OFF

Toggle

Display

view

Burn

button

Connectors

1 CDM10V BURNER

Figure 1 CDM10V BURNER

1.1 Introduction

The COOLDIM_PRG_BOARD is used to set fuses inside CDM10V chip. It is supplied from a USB power supply

(5 V / 1 A) or could also be connected to a USB port of the PC. User will be guided through the burning process

by the microcontroller firmware. If an error occur during handling user will be advised by firmware how to

proceed. When no button is pressed during 5 minutes the display is switched off automatically and the LED

below the display is flashing once per second, pressing any button will switch on the display again.

1.2 Chip orientation

Figure 2 Chip orientation

Pin “1” of the chip shall be located in the lower left corner of the open socket. This is marked with a “1” on the

PCB.

User Manual 2 of 9 V 1.0

2017-09-19

Page 3

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

CDM10V BURNER

Dimmer / resistor

bias

00

200 µA

DEFAULT

01

100 µA

10

50 µA

11

500 µA

Dim-to-off

0

NOT ENABLED

DEFAULT

1

ENABLE DIM-TO-OFF

PWM frequency

00

1000 Hz

DEFAULT

01

500 Hz

10

200 Hz

11

2000 HZ

Minimum duty cycle

00

5%

DEFAULT

01

2% 10

1% 11

10%

1.3 Control buttons

ON/OFF

Check if chip is applied in correct position and turn supply voltage on or off. When supply is turned on all 4

parameters are measured and shown in display. If one parameter could not be measured a contact fail is

expected supply is turned off and the user is informed to check the socket. If none of the parameter could be

measured user is informed that it is expected that socket is empty and supply is turned off. Only if all

parameter could be measured correctly (+/- 10%) supply stays on and allows the use to proceed.

Toggle

Toggle screen to show either chip settings or board settings. To burn the board settings user has to switch to

board settings view.

Burn

Start the fuse burning procedure. Fuse burning will only be started if:

1. The board settings differ from chip settings

2. Setting one (or several) bit to “1”

If these conditions are not fulfilled, burn procedure is aborted.

1.4 Switches

The switches are used to set the state of the fuses. Please note: user is only able to set a fuse bit from “0” to “1”.

If a bit is already set to “1” it could be not reversed and burn fuse will be aborted. The decoding of the switches

is printed on the board and will be shown in board settings view on the display.

Table 1 CDM10V settings

User Manual 3 of 9 V 1.0

2017-09-19

Page 4

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

CDM10V BURNER

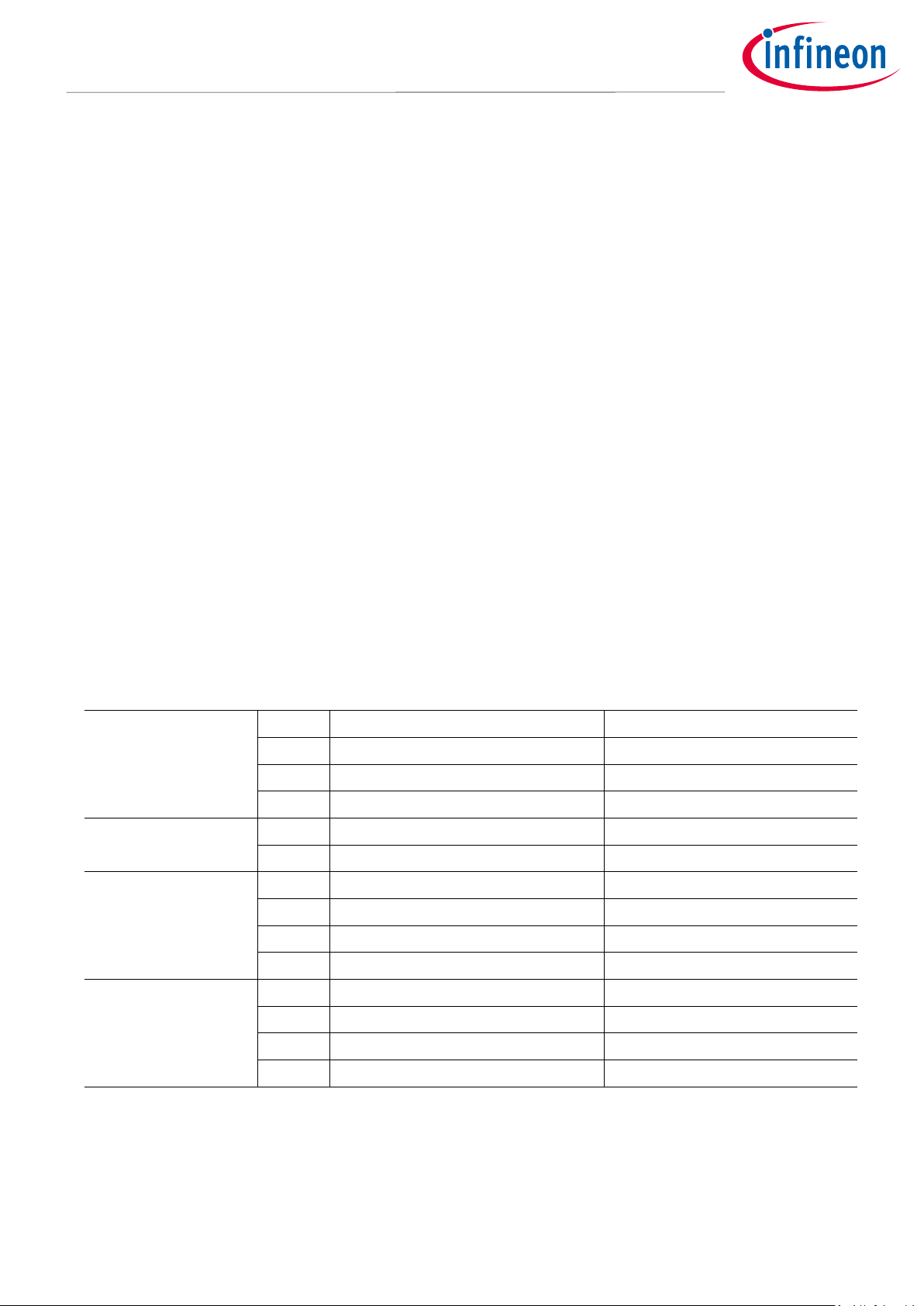

1.5 Connectors / Jumper

Optional connectors for external socket board.

Figure 3 Connectors

User Manual 4 of 9 V 1.0

2017-09-19

Page 5

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

Fusing details

Resistor

Bias

Dim-

to-

OFF

PWM

frequency

PWM

min. duty

cycle

Startbit

Stopbit

D1 D2

0 0 : 200 µA

0 1 : 100 µA

1 0 : 50 µA

1 1 : 500 µA

CMD

D0 D1 D2 D3 D4 D5 D6 D7

D4 D5

0 0 : 1 kHz

0 1 : 500 Hz

1 0 : 200 Hz

1 1 : 2kHz

D6 D7

0 0 : 5 %

0 1 : 2 %

1 0 : 1 %

1 1 : 10 %

VFss

UART

interface

RxD

Vcc

6

5

4

1

2

3

Dimming

IC

Iout

Condition

Nom. value

Limits

Vcc

11.0 V

V

Fss

4.1 V

+-0.1 V

I

Fss

20 mA

Temperature

25°C

2 Fusing details

2.1 UART configuration

The serial port (9600 Baud, 1 stop bit, no parity) enables a onetime reconfiguration of parameters for device

function. The reserved CMD bit has to be set to HIGH. After this bit the 7 programming has to be sent in the

order shown in the picture below.

Figure 4 UART data frame format

The figure below shows the minimal fuse programming circuit diagram. The LED is optional and can be used to

signalize the correct fusing procedure.

Figure 5 FUSE programming minimal circuit

2.2 Fusing conditions

Table 2 Fusing conditions

User Manual 5 of 9 V 1.0

2017-09-19

Page 6

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

Fusing details

IDLE

UART

commad

received

FUSE

PRGM

RXD = VSS

WAIT

RXD

FUSE

CHECK

DONE

Iout = HIGH

Iout = LOW

Iout = HIGH if fuse programming / check correct

Iout = LOW if fuse programming / check wrong

Iout = HIGH if fuse programming / check correct

Iout = LOW if fuse programming / check wrong

YES

YES

NO

NO

2.3 Fusing procedure

To ensure the correct efuse burning automatic programming and checking procedure is implemented. Remark

that fusing can be done one time only per device.

Figure 6 Fusing procedure

IDLE

The device is awaiting the correct UART frame. After correct frame is received (CMD bit is set to HIGH) the fuse

programming procedure is started.

FUSE PRGM

Here the actual fuse procedure is performed. This takes at least ~10.5 ms. The end of the procedure signalized

by setting the I

WAIT RXD

The FUSE programming is done, this is signalized by setting I

should be set to HIGH within 100 ms to procced with the next state, the I

FUSE CHECK

pad to high state.

out

to HIGH state. After detecting this state the RXD

out

is set to LOW.

out

In this state the fuses will be read out and compared with the received UART byte. This step takes ~100 µs.

User Manual 6 of 9 V 1.0

2017-09-19

Page 7

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

Fusing details

DATA

FUSE PRGM. (10.5ms)

FUSE READ

(50us)

RXD

FSS

Iout

Start compare with RXD = 0

Iout = 1 when compare correct

Iout = 1 after prgm. is done

Prgm. is started after UART frame

Set FSS = 0V, after Iout = 1

(timeout 100ms)

Set FSS = 4.1V, start UART

CMD

START

STOP

DONE

If the compared data it correct the I

is set to HIGH if not this will say in LOW in this state. Remark that the

out

power down/up step is required to return to the normal operation after the whole efuse burning procedure is

performed.

The detailed fusing timing is shown in the figure below. Remark the 100ms timing after the FUSE PRGM state.

Figure 7 Fuse timing

User Manual 7 of 9 V 1.0

2017-09-19

Page 8

COOLDIM_PRG_BOARD

User manual for CDM10V programming board

Fusing details

Document

version

Date of release

Description of changes

Revision history

User Manual 8 of 9 V 1.0

2017-09-19

Page 9

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2017-09-19

UM_201709_PL21_011

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2017 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information contained in this application note

is given as a hint for the implementation of the

product only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby

disclaims any and all warranties and liabilities of

any kind (including without limitation warranties of

non-infringement of intellectual property rights of

any third party) with respect to any and all

information given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may

contain dangerous substances. For information on

the types in question please contact your nearest

Infineon Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of

the product or any consequences of the use thereof

can reasonably be expected to result in personal

injury.

Loading...

Loading...