Data Sheet, V 1.0, May 2003

C868

8-Bit Single-Chip Microcontroller

Microcontrollers

Never stop thinking.

Edition 2003-05

Published by Infineon Technologies AG,

St.-Martin-Strasse 53,

D-81541 München, Germany

© Infineon Technologies AG 2003.

All Rights Reserved.

Attention ple ase!

The information herein is given to describe certain components and shall not be considered as warranted

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide (see address

list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon T echnologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Data Sheet, V 1.0, May 2003

C868

8-Bit Single-Chip Microcontroller

Microcontrollers

Never stop thinking.

C868

Revision History: 2003-05 V 1.0

Previous Version: Page Subjects (major changes since last revision)

Current data updated

Description of I2C included

We Listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continuously improve the quality of this document.

Please send your proposal (including a reference to this document) to:

mcdocu.comments@infineon.com

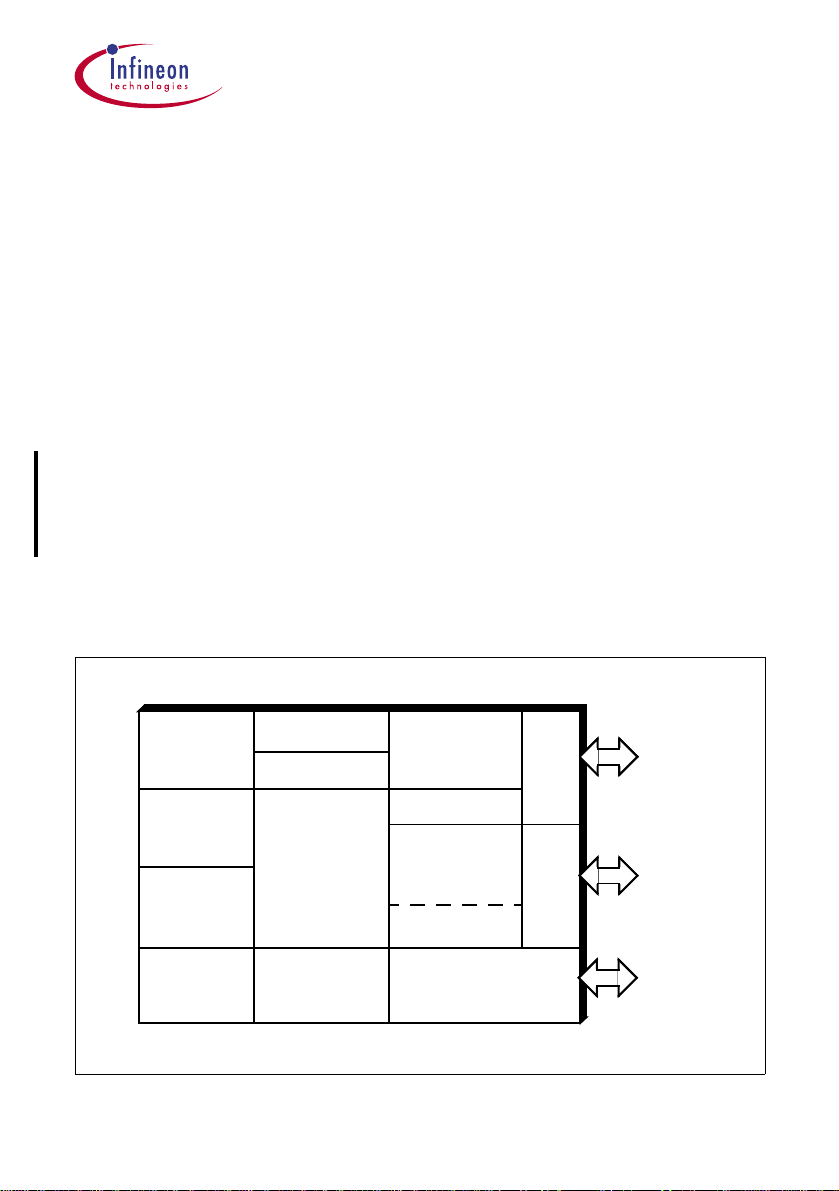

C8688-Bit Single-Chip Microcontroller

C800 Family

C868

Advance Information

• C800 core :

–Fully compatible to standard 8051 microcontroller

–Superset of the 8051 architecture with 8 datapointers

• 40 MHz internal CPU clock

–external clock of 6.67 - 10.67 MHz at 50% duty cycle

–300 ns instruction cycle ti me (@37.5 MHz CPU cloc k)

• 8 Kbyte on-chip Program ROM for C868-1R and 8 KByte on-chip Program RAM for

C868-1S

• In-system programming support for programming the XRAM(C868-1R) or XRAM/

Program RAM(C868-1S)

–This feature is realized through 4KB Boot ROM

• 256 byte on-chip RAM

• 256 byte on-chip XRAM

(further features are on the next page)

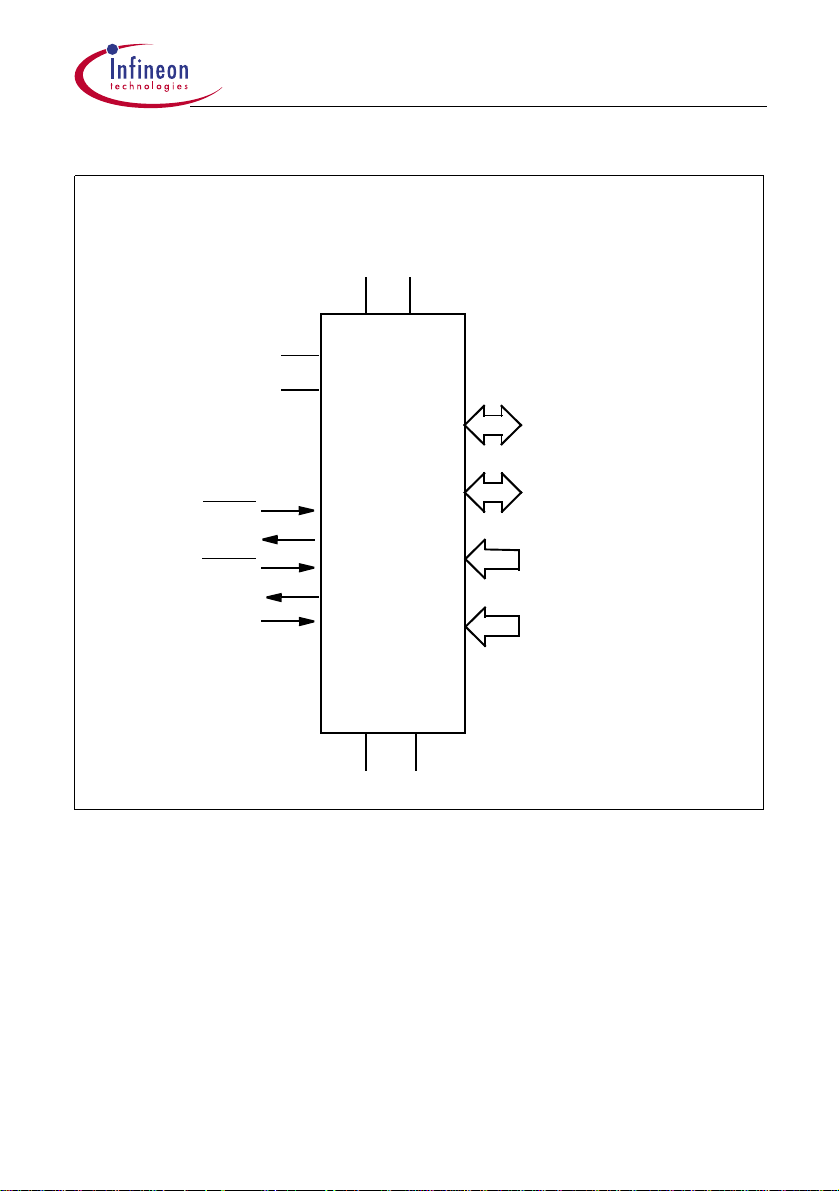

RAM

256 × 8

XRAM

256 × 8

ROM/RAM

8K × 8

Boot ROM

4K x 8

Timer 0

Timer 1

CPU

8 datapointers

Watchdog Timer

8-bit

UART

Timer 2

16-bit

Capture/

Compare

Unit

16-bit Compare

Unit

8-Bit ADC

Port 1

Port 3

I/O

5-bit

Input

3-bit

I/O

8-bit

Analog/

Digital

Input

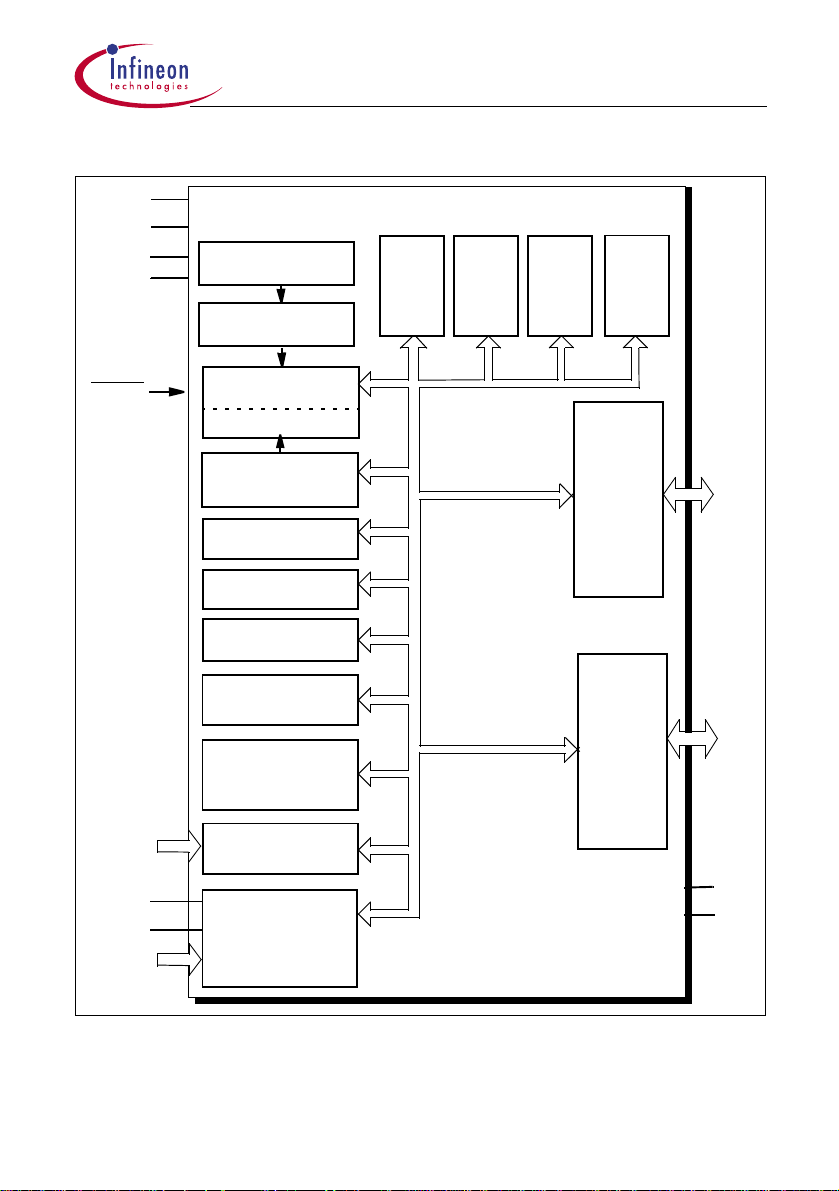

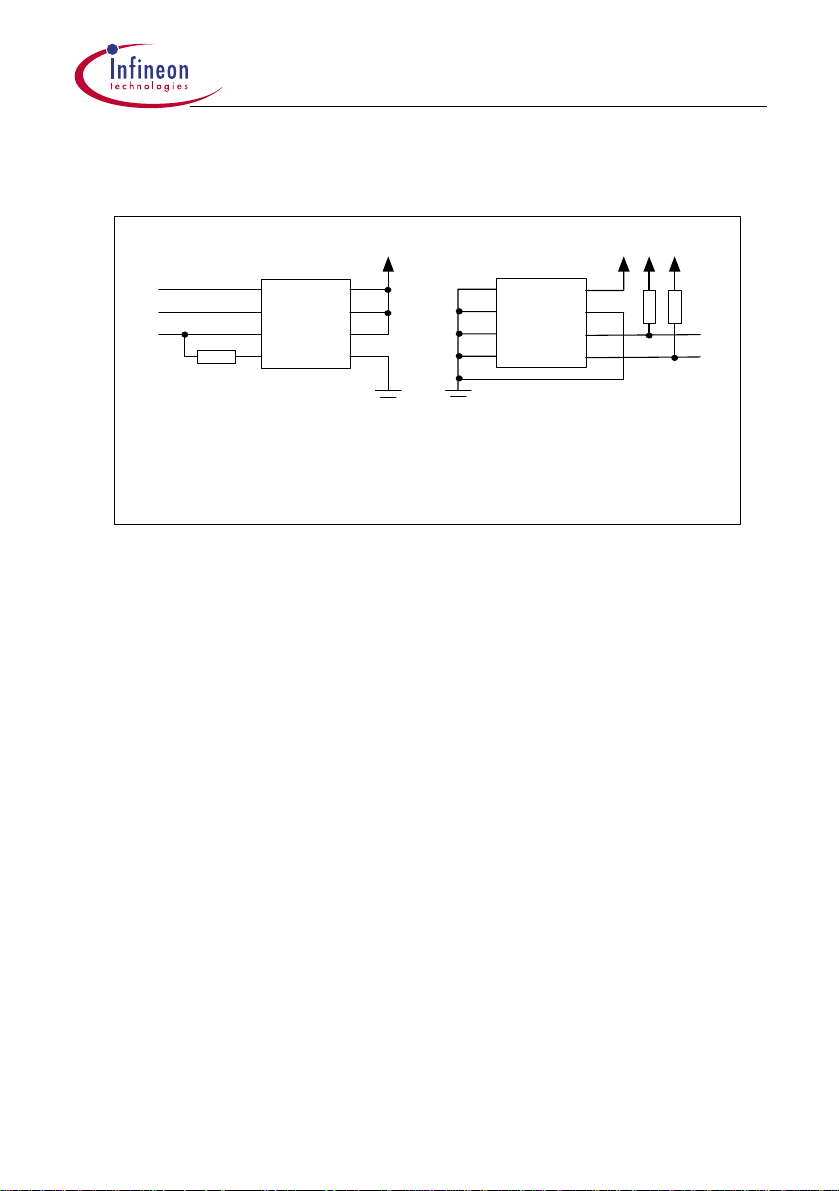

Figure 1 C868 Functional Units

Data Sheet 5 V 1.0, 2003-05

C868

• One 8-bit and one 5 bits general purpose push-pull I/O ports

– Enhanced sink current o f 10 mA on Port 1/3 (total max current of 43 mA @ 100

• Three 16-bit timers/counters

–Timer 0 / 1 (C501 compatible)

–Timer 2 (up/down counter feature)

–Timer 1 or 2 can be used for serial baudrate generator

• Capture/compare unit for PWM signal generation

–3-channel, 16-bit capture/compare unit

–1-channel, 16-bit compare unit

• Full duplex serial interface (UART)

• 5 channel 8-bit A/D Converter

– Start of conversion can be synchronized to capture/compare timer 12/13.

• 13 interrupt vectors with four priority levels

• Programmable 16-bit Watchdog Timer

• Brown out detection

• Power Saving Modes

–Slow-down mode

–Idle mode (can be combined with slow-down mode)

–Power-down mode with wake up capability through INT0

or RxD pins.

• Single power supply of 3.3V, internal voltage regulator for core voltage of 2.5V.

• P-DSO-28-1, P-TSSOP-38-1 packages

• Temperature ranges:

SAF-C868-1RR BA, SAF-C868-1SR BA, SAF-C868-1RG BA, SAF-C868-1SG BA,

SAF-C868A-1RR BA, SAF-C868A-1SR BA, SAF-C868A-1RG BA, SAF-C868A-1SG

BA, SAF-C868P-1SR BA, SAF-C868P-1SG BA T

= – 40 to 85 oC

A

SAK-C868-1RR BA, SAK-C868-1SR BA, SAK-C868-1RG BA, SAK-C868-1SG BA,

SAK-C868A-1RR BA, SAK-C868A-1SR BA, SAK-C868A-1RG BA, SAK-C868A-1SG

BA, SAK-C868P-1SR BA, SAK-C868P-1SG BA T

= – 40 to 125 oC

A

o

C)

Data Sheet 6 V 1.0, 2003-05

C868

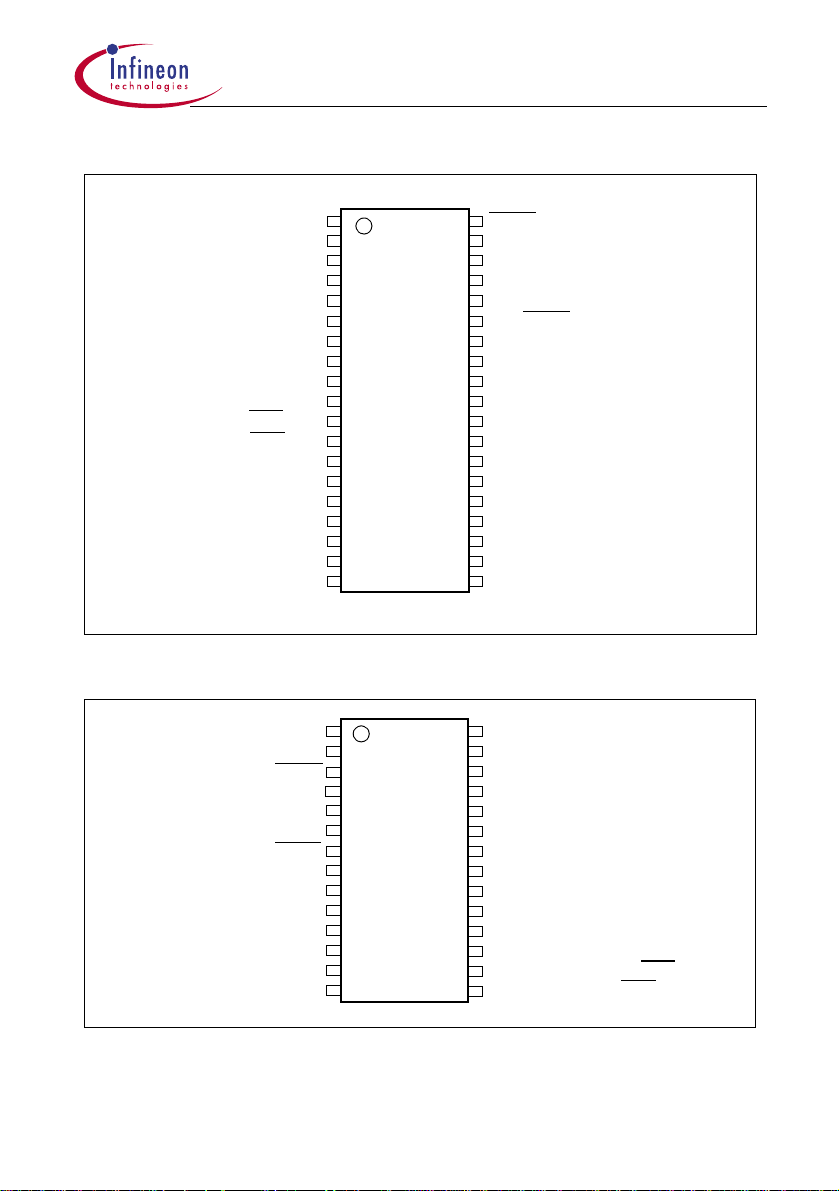

V

DDPVSSP

V

AREF

V

AGND

Port 1

5-bit Digital I/O

3-bit Digial Input

Port 3

RESET

ALE/BSL

CTRAP

TxD

RxD

C868

8-bit Digital I/O

5 ADC channels

4 External

Interrupts

V

V

DDC

SSC

Figure 2 Logic Symbol

Data Sheet 7 V 1.0, 2003-05

C868

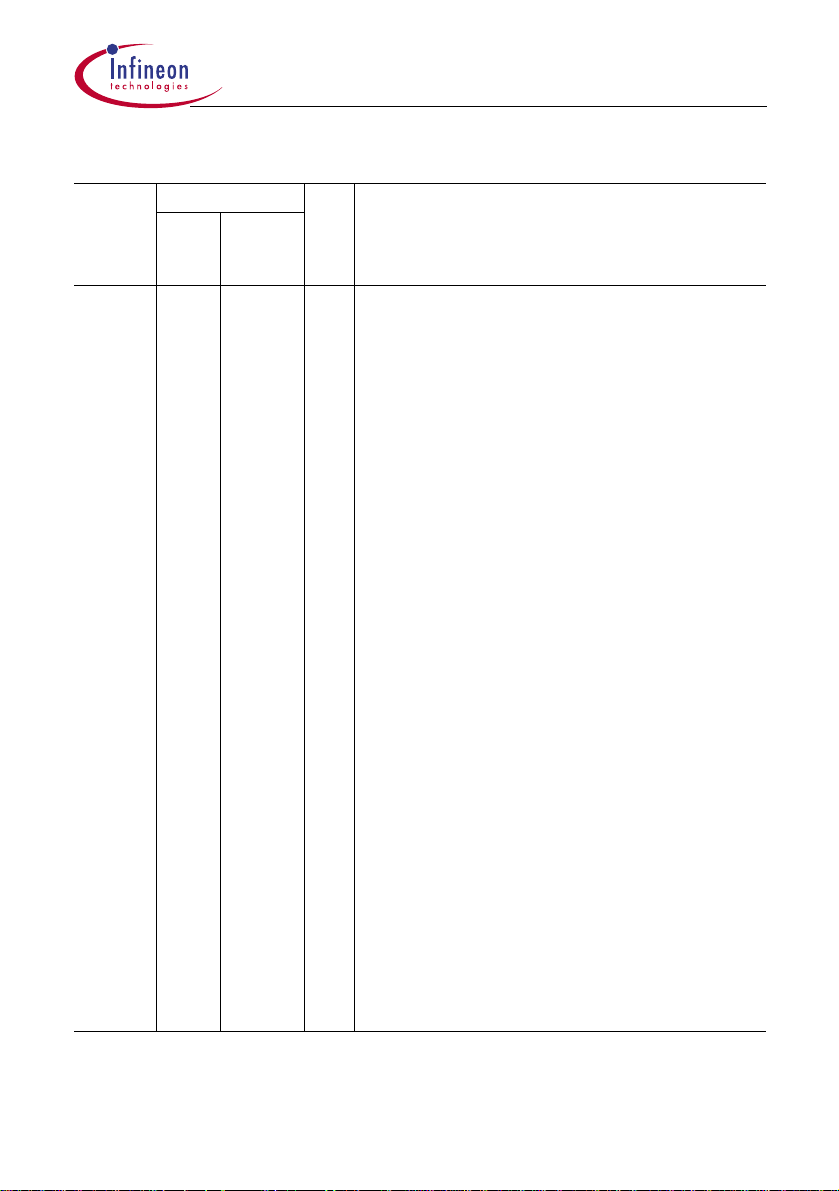

P1.4/RxD

P1.3/INT3

P1.1/EXF2

P1.0/TxD

P1.5/CCPOS0/T2/INT0

P1.6/CCPOS1/T2EX/INT1

P1.7/CCPOS2/INT2/AN2

V

/AN0

/AN1

V

AGND

V

P1.2

NC

NC

NC

DDP

V

SSP

AREF

AN3

AN4

NC

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

C868

RESET

38

37

P3.7/CC60

36

P3.6/COUT60

35

NC

34

ALE/BSL

33

P3.1/CTRAP

32

P3.0/COUT63

31

P3.4/COUT61

30

XTAL2

29

XTAL1

28

V

27

V

26

P3.3/CC62

25

P3.2/COUT62

24

P3.5/CC61

23

NC

22

NC

21

NC

20

NC

DDC

SSC

Figure 3 C868 Pin Configuration P-TSSOP-38 Package (top view)

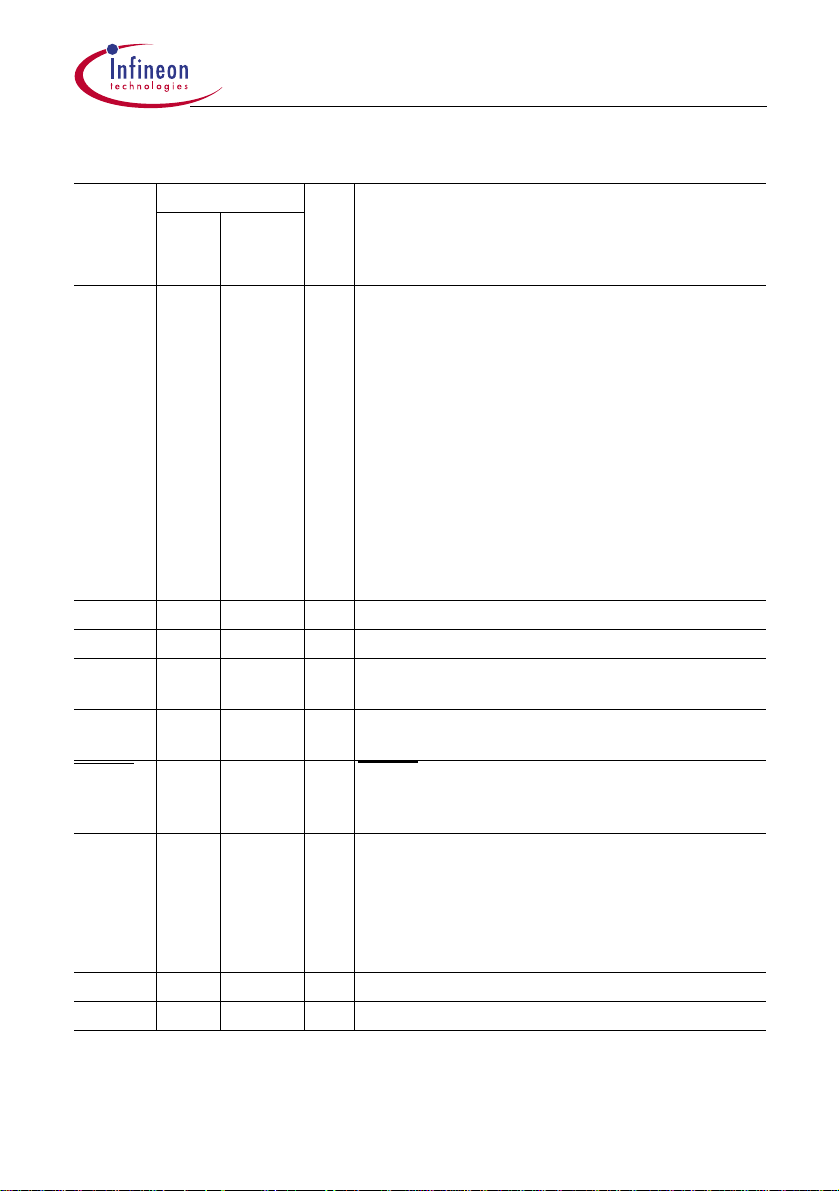

P3.4/COUT61

P3.0/COUT63

P3.1/CTRAP

ALE/BSL

P3.6/COUT60

P3.7/CC60

RESET

P1.4/RxD

P1.3/INT3

P1.2

P1.1/EXF2

P1.0/TxD

V

DDP

V

SSP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

C868

XTAL2

28

27

XTAL1

26

V

DDC

25

V

SSC

P3.3/CC62

24

P3.2/COUT62

23

P3.5/CC61

22

21

AN4

20

AN3

19

V

AREF

18

V

AGND

17

P1.7/CCPOS2/INT2/AN2

16

P1.6/CCPOS1/T2EX/INT1/AN1

15

P1.5/CCPOS0/T2/INT0

/AN0

Figure 4 C868 Pin Configuration P-DSO-28 Package (top view)

Data Sheet 8 V 1.0, 2003-05

Table 1 Pin Definitions and Functions

Symbol Pin Numbers I/O*) Function

P1.0–

P1.4

P1.5P1.7

PDSO28

12-8

15-17

PTSSOP38

6,4-1

11-13

I/OIPort 1

is a combination of 5 bits of pus h-pull bi directiona l I/

O ports and 3 bits of input ports.

As alternate digital functions, port 1 contains the

interrupt 3, timer 2 overflow flag, rece ive data input

and transmit data output of serial interface. The

alternate functions are assigned to the pins of port

1 as follows:

12

11

10

9

8

6

4

3

2

1

P1.0/TxD Transmit data of serial interface

P1.1/EXF2 Timer 2 overflow flag

P1.2

P1.3/INT3 Interrupt 3

P1.4/RxD Receive data of serial interface, Use as

wakeup source from powerdown if bit WS of

PMCON0 is set.

C868

The input ports are a ls o i nte rrupt po rts , i npu t to th e

timer2, CCU6 modules and ADC:

15 11 I P1.5/Input to Counter 2/External Interrupt 0 Input/

Analog Input Channel 0

External interrupt input or Hall input signal , counte r

2 input or input channel 0 to the ADC unit. Use as

wakeup source from powerdown if bit WS of

PMCON0 is cleared.

16 12 I P1.6/Timer 2 Trigger/External Interrupt 1 Input/

Analog Input Channel 1

External interrupt input or Hall input signal, input

channel 1 to the ADC unit, trigger to Timer 2.

17 13 I P1.7/External Interrupt 2 Input/

Analog Input Channel 2

External interrupt input or Hall input signal and inpu t

channel 2 to the ADC unit.

*)I=Input

O=Output

Data Sheet 9 V 1.0, 2003-05

Table 1 Pin Definitions and Functions

Symbol Pin Numbers I/O*) Function

P3.0–

P3.7

PDSO28

2,3,23,

24,1,

22,5,6

PTSSOP38

32,33,25,

26,31,24,

36,37

I/O Port 3

is an 8-bit push-pull bidirec tio nal I/O po rt. Thi s po rt

also serves as alternate functions for the CCU6

functions. The functions are assigned to the pins of

port 3 as follows :

C868

V

AREF

V

AGND

2

3

23

24

1

22

5

6

19 15 – Reference voltage for the A/D converter.

18 14 – Reference ground for the A/D converter.

32

33

25

26

31

24

36

37

P3.0/COUT63 16 bit compare channe l outp ut

P3.1/CTRAP CCU trap input

P3.2/COUT62 Output of capture/compare ch 2

P3.3/CC62 Input/output of capture/compare ch 2

P3.4/COUT61 Output of capture/compare ch 1

P3.5/CC61 I nput/outpu t of capture/compare ch 1

P3.6/COUT60 Output of capture/compare ch 0

P3.7/CC60 Input/output of capture/compare ch 0

AN4 21 17 I Analog Input Channel 4

is input channel 4 to the ADC unit.

AN3 20 16 I Analog Input Channel 3

is input channel 3 to the ADC unit.

RESET

738 IRESET

A low level on this pin for two machine cycle while

the oscillator is running resets the device.

ALE/BSL 4 34 I/O Address Latch Enable/Bootstrap Mode

A low level on th is pin during res et allows the d evice

to go into the bootstrap mode. After reset, this pin

will output the address latch enable signal. The

ALE can be disabled by bit EALE in SFR

SYSCON0.

V

V

SSP

DDP

14 10 – IO Ground (0V)

13 9 – IO Power Supply (+3.3V)

*)I=Input

O=Output

Data Sheet 10 V 1.0, 2003-05

Table 1 Pin Definitions and Functions

Symbol Pin Numbers I/O*) Function

V

V

SSC

DDC

PDSO28

25 27 – Core Ground (0V)

26 28 O Core Internal Reference (+2.5V)

PTSSOP38

Connect 2*68 - 470nF ceramic capacitor across

this pin and core ground.

NC – 5,7,8,18,

– Not connected

19,20,21,

22,23,35

XTAL1 27 29 I XTAL1

Output of the inverting oscillator amplifier.

XTAL2 28 30 O XTAL2

Input to the inverting os cillator amplifier an d input to

the internal clock generation circuits.

To drive the device from an external clock sourc e,

XTAL2 should be driven, while XTAL1 is left

unconnected.

*)I=Input

O=Output

C868

Data Sheet 11 V 1.0, 2003-05

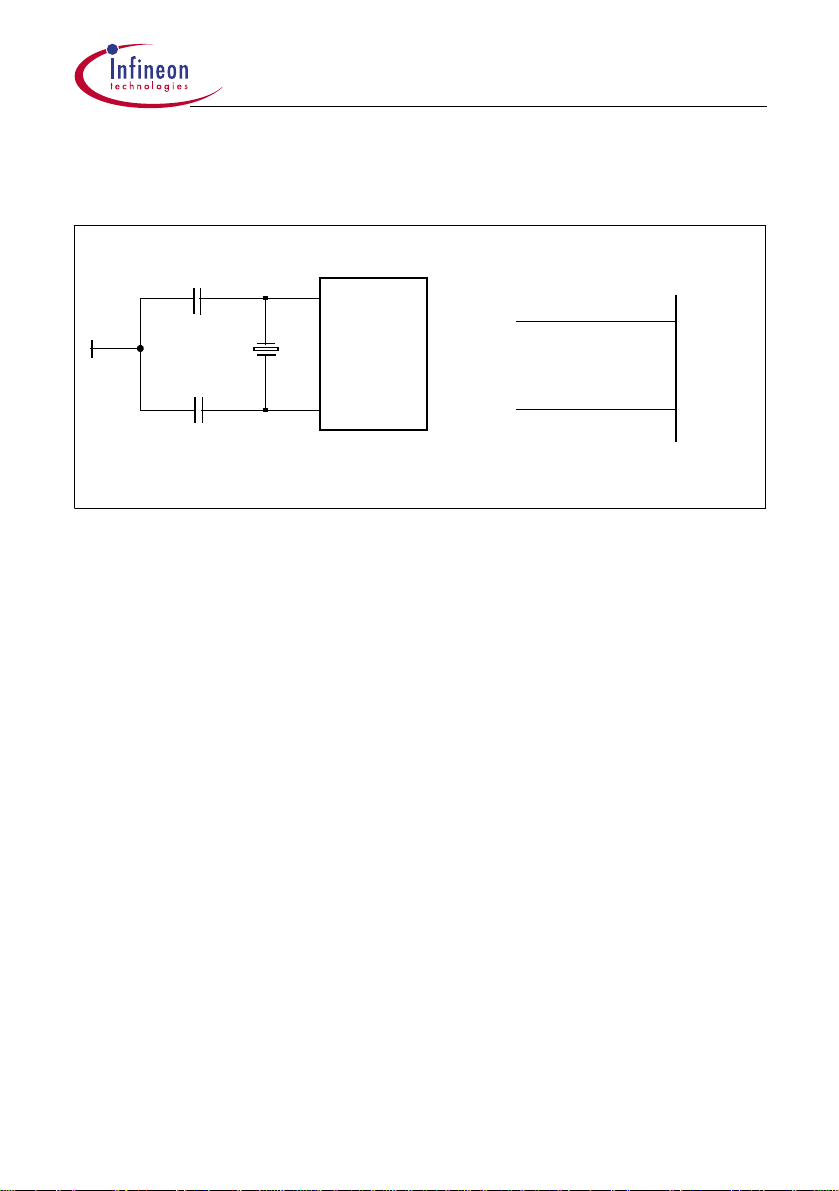

V

DDC

V

SSC

XTAL1

XTAL2

C868

OSC

PLL

XRAM

256 x 8

RAM

256 x 8

ROM/

RAM

8k x 8

C868

Boot/

Self

Test

ROM

4k x 8

RESET

4 external

interrupts

V

AREF

V

AGND

5-Bit

Analog In

CPU

8 datapointers

Programmable

Watchdog Timer

Timer 0

Timer 1

Timer 2

UART

Capture/Compare

Unit

Interrupt Unit

A/D Converter

8-Bit

Port 1

Port 3

Port 1

5-bit

digital

I/O

and

3-bit

digital

input

Port 3

8-bit

digital

I/O

V

DDP

V

SSP

Figure 5 Block Diagram of the C868

Data Sheet 12 V 1.0, 2003-05

C868

CPU

The C868 is efficient both as a controller and as an arithmeti c processor. It has extens ive

facilities for bi nary and BCD ar ithmetic and e xcels in i ts bit-handli ng capabili ties. Efficie nt

use of program memory results from an instruction set consisting of 44% one-byte, 41%

two-byte, and 15% three-byte instructions. With a 10.67 MHz external crystal (giving a

40MHz CPU clock), 58% of the instructions execute in 300 ns.

PSW

Program Status Word Register [Reset value: 00

D7

H

CY AC F0 RS1 RS0 OV F1 P

rwh rwh rw rw rw rwh rw rwh

D6

H

D5

H

D4

H

D3

H

D2

H

D1

H

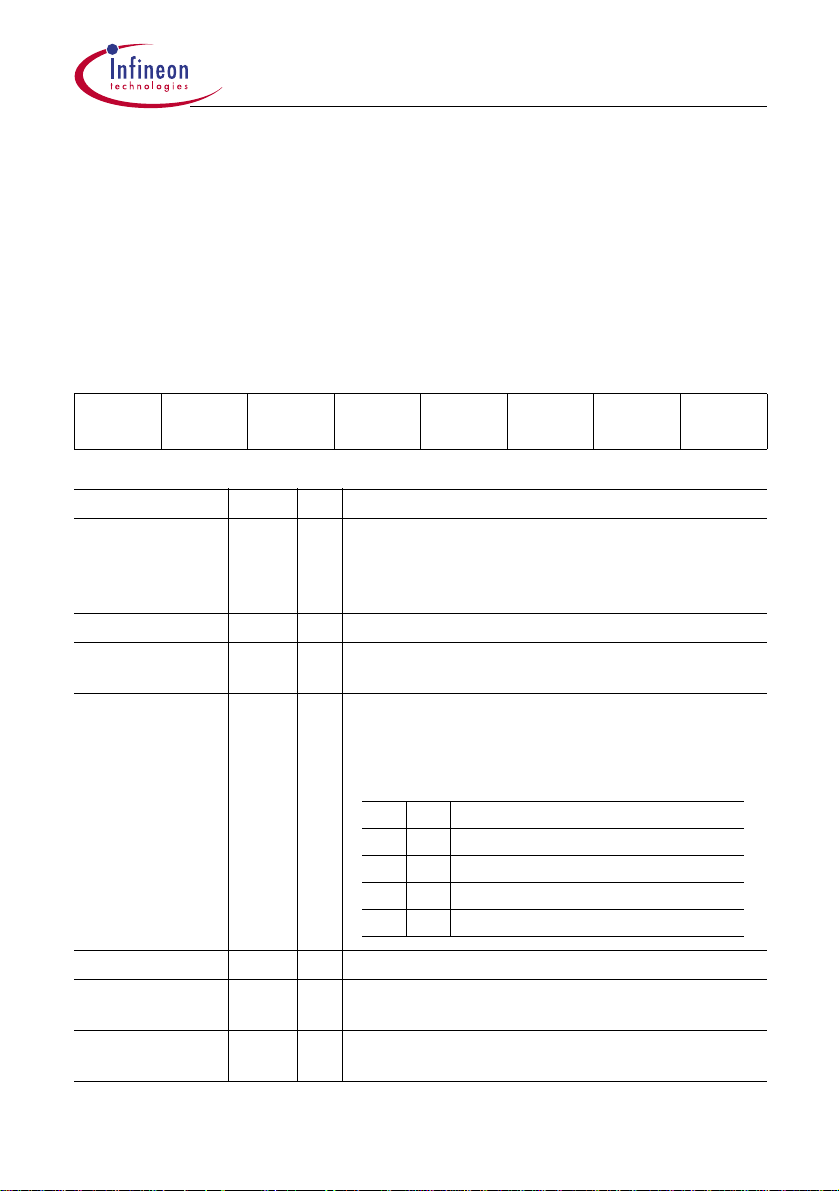

Field Bits Typ Description

P 0rwhParity Flag

Set/cleared by hardware after each instruction to

indicate an odd/even number of "one" bits in the

accumulator, i.e. even parity.

F1 1rwGeneral Purpose Flag

OV 2rwhOverflow Flag

Used by arithmetic in structions.

RS0

RS1

3

4

rw Register Bank select control bits

These bits are used to select one of the four register

banks.

Table 2 :

RS1 RS0 Function

0 0 Bank 0 selected, data address 00H-07

0 1 Bank 1 selected, data address 08H-0F

1 0 Bank 2 selected, data address 10H-17

1 1 Bank 3 selected, data address 18H-1F

D0

H

H

H

H

H

H

]

F0 5rwGeneral Purpose Flag

AC 6rwhAuxiliary Carry Flag

Used by instruction s which exec ute BCD operations .

CY 7rwhCarry Flag

Used by arithmetic in structions.

Data Sheet 13 V 1.0, 2003-05

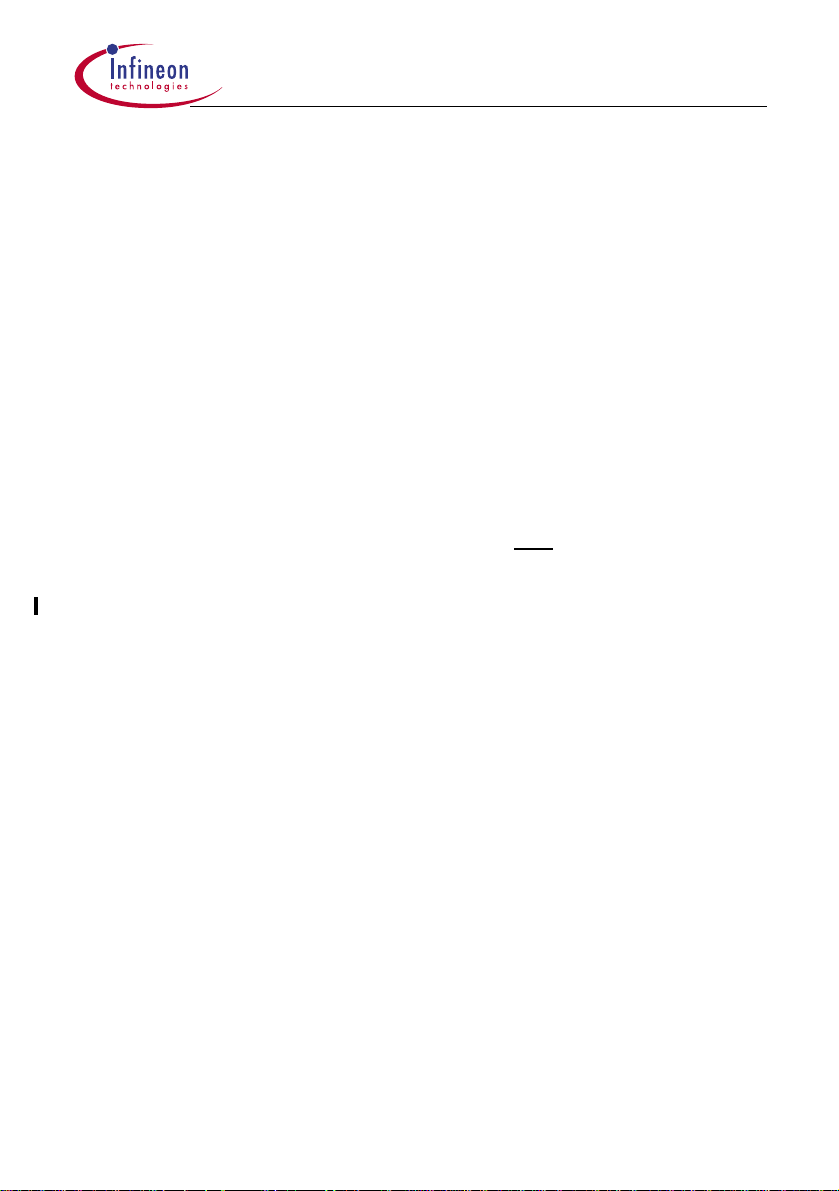

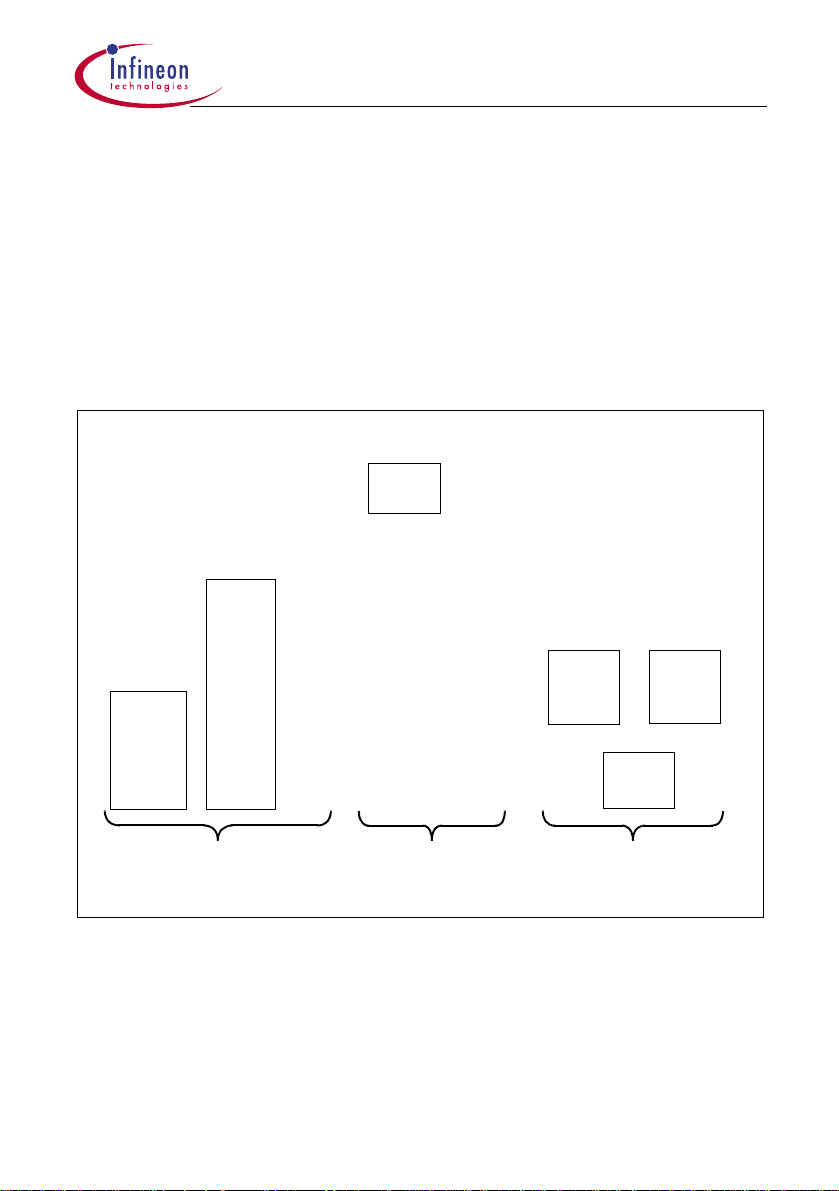

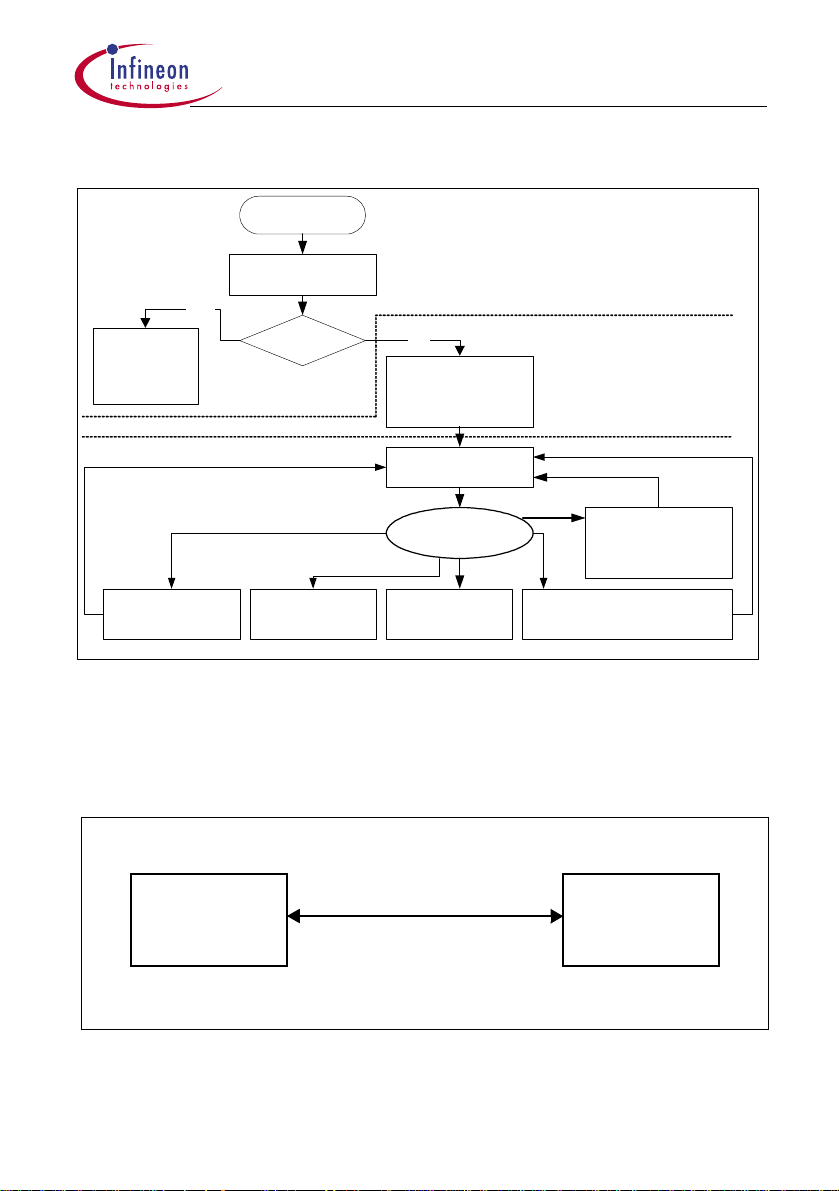

Memory Organization

The C868 CPU manipulates operands in the following five address spaces:

– up to 8 Kbyte of RAM internal program memory : 8K ROM for C868-1R

: 8K RAM for C868-1S

– 4 Kbyte of internal Self test and Boot ROM

– 256 bytes of internal data memory

– 256 bytes of internal XRAM data memory

– 128 byte special function register area

Figure 0-1 illustrates the memory address spaces of the C868.

FFFF

FF00

H

H

indirect

addr.

Internal

RAM

Function

Internal

RAM

Internal

Self Test

and Boot

ROM

(4 KByte)

Internal

1FFF

0000

Internal

XRAM

H

H

direct

addr.

Special

Regs.

7F

00

H

H

C868

FF

H

80

H

"Code Space"

"Data Space"

"Internal Data Space"

Figure 0-1 C868 Memory Map

Data Sheet 14 V 1.0, 2003-05

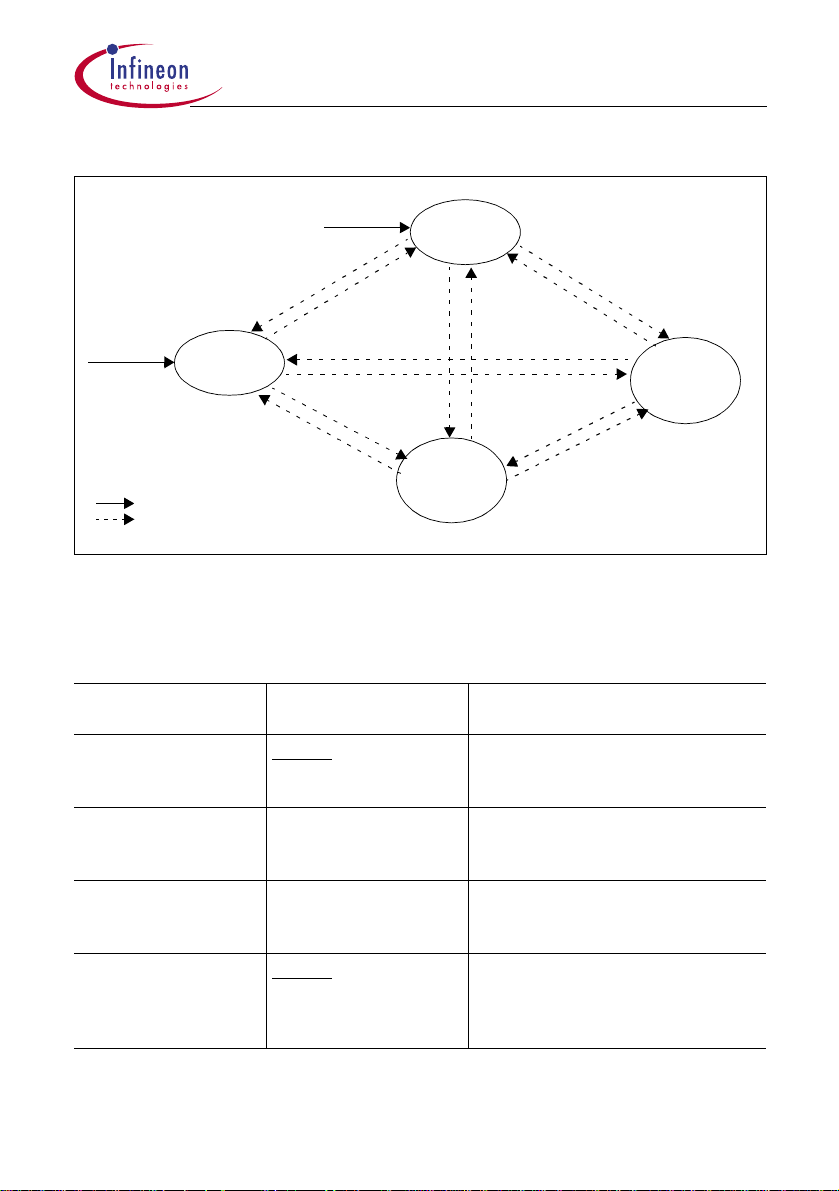

The various chip modes supported are shown in Figure 6.

Normal

Mode

C868

Bootstrap

Mode

Normal

XRAM

Mode

Bootstrap

XRAM

Hardware

Software

Mode

Figure 6 Entry and exit of Chip Modes

A valid hardware reset would, of course, override any of the above entry or exit

procedures.

Table 0-1 Hardware and Software Selection of Chipmodes

Operating Mode

Hardware Selection Software Selection

(Chipmode)

Normal Mode ALE/BSL pin = high

RESET

rising edge

ALE/BSL = don’t care;

setting bits BSLEN, SWAP = 0,0;

execute unlocking sequence

Normal XRAM Mode Not possible setting bits BSLEN,SWAP = 0,1;

execute unlocking sequence

Bootstrap XRAM Mode Not possible setting bits BSLEN,SWAP = 1,1;

execute unlocking sequence

Bootstrap Mode ALE/BSL pin = low

RESET rising edge

ALE/BSL = don’t care;

setting bits BSLEN, SWAP = 1,0;

execute unlocking sequence

Data Sheet 15 V 1.0, 2003-05

Table 3 Normal Memory Configuration

C868

Chip

Memory Space Memory Boundary

Mode

Normal Code Space ROM/RAM: 0000

Internal Data Space XRAM: FF00H to FFFF

to 1FFF

H

H

Bootstrap Code Space Boot ROM: 0000H to 0FFF

Internal Data Space XRAM: FF00H to FFFF

H

ROM/RAM: 0000H to 1FFF

Normal

XRAM

Bootstrap

XRAM

Code Space XRAM: FF00H to FFFF

H

Data Space ROM/RAM: 0000H to 1FFF

Code Space Boot ROM: 0000H to 0FFF

XRAM: FF00H to FFFF

H

Data Space ROM/RAM: 0000H to 1FFF

H

H

H

H

H

H

Data Sheet 16 V 1.0, 2003-05

C868

Bootstrap loader

The C868, includes a bootstrap mode, which is activated by setting the ALE/BSL pin at

logic low with a pul ld ow n and Tx D p in at logic high with a pu llup at the rising e dg e o f th e

. Or it can be entered by software, that is by setting BSLEN bit and resetting

RESET

SWAP bit in SFR SYSCON1 accompany by an unlock sequence.

In the bootstrap mode , software routi nes of the b ootstrap load er located in th e boot ROM

will be executed. Its pur pos e i s to allow the easy and quick programmin g of the int ernal

SRAM (0000

the MCU is in-circuit. It also provides a way to program SRAM or XRAM through

bootstrapping from an external SPI or I2C EEPROM.

The first action of the bootstrap lo ader is to detect the presence of EEPROM and its type,

SPI or I2C, and check the first byte of the serial EEPROM. If the first byte is 0A5

MCU would enter Phase A to download from the EEPROM. Otherwise, it will enter

Phase B to establish a serial communication with the connected host. Bootstrapping

from the serial EEPROM can also be done in phase B if it is invoked by the host.

Phase B consists of two functional parts that represent two phases:

• Phase I: Establish a serial connection and automatically synchronize to the transfer

speed (baud rate) of the serial communication partner (host).

• Phase II: Perform the serial communication with the host. The host controls the

communication by sending special header information, which select one of the

working modes. These modes are:

to 1FFFH) or XRAM (FF00H to FFFFH) via serial interface (UART) while

H

H

, the

Table 4 Serial Communication Modes of Phase B

Modes Description

0 Transfer a customer program from the host to the SRAM (0000

) or XRAM (FF00H -FFFFH). Then return to the beginning of

1FFF

H

to

H

phase II and wait for the next command from the host.

1 Execute a customer program in the XRAM at start address FF00

2 Execute a customer program in the SRAM at start address 0000

.

H

.

H

3 Transfer a customer program from the SPI EEPROM to the SRAM

(0000H to 1FFFH) or XRAM (FF00H -FFFFH). Then return to the

beginning of phase II and wait for the next command from the host.

4 Transfer a customer program from the I2C EEPROM to the SRAM

(0000

to 1FFFH) or XRAM (FF00H -FFFFH). Then return to the

H

beginning of phase II and wait for the next command from the host.

5-9 reserved

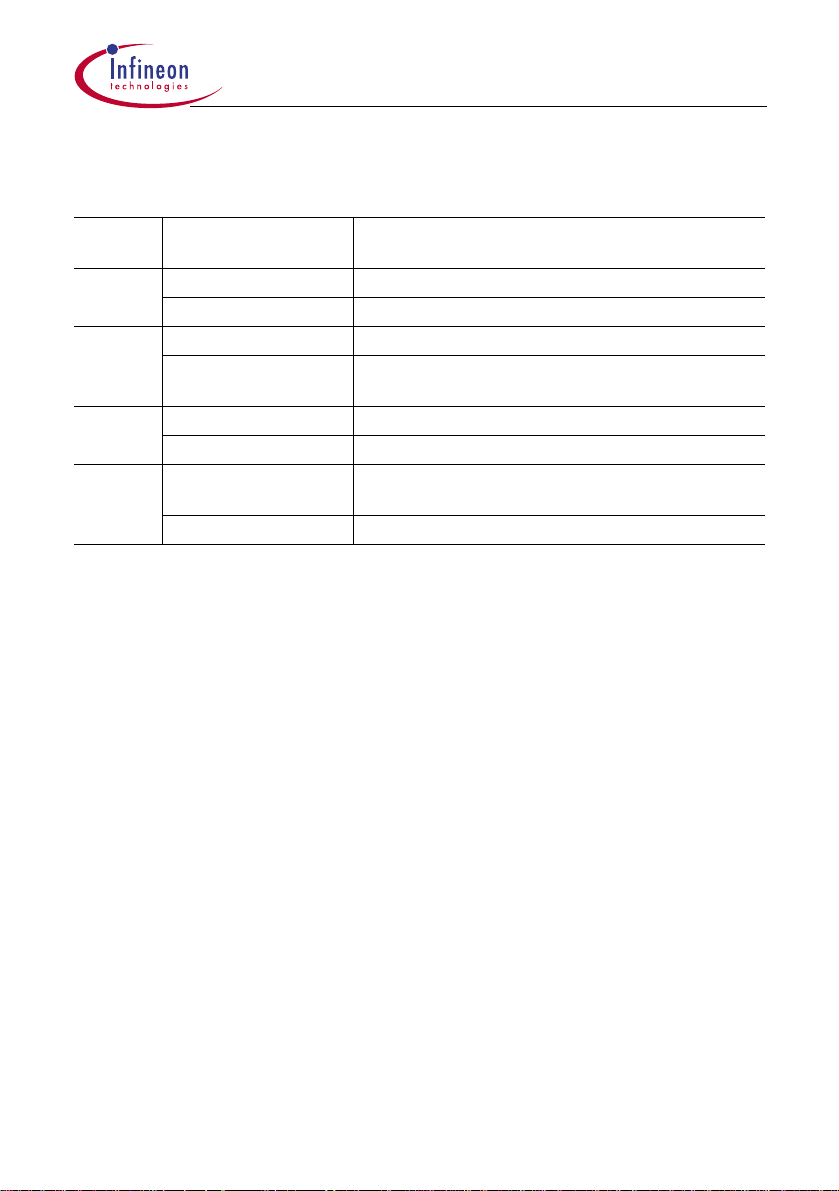

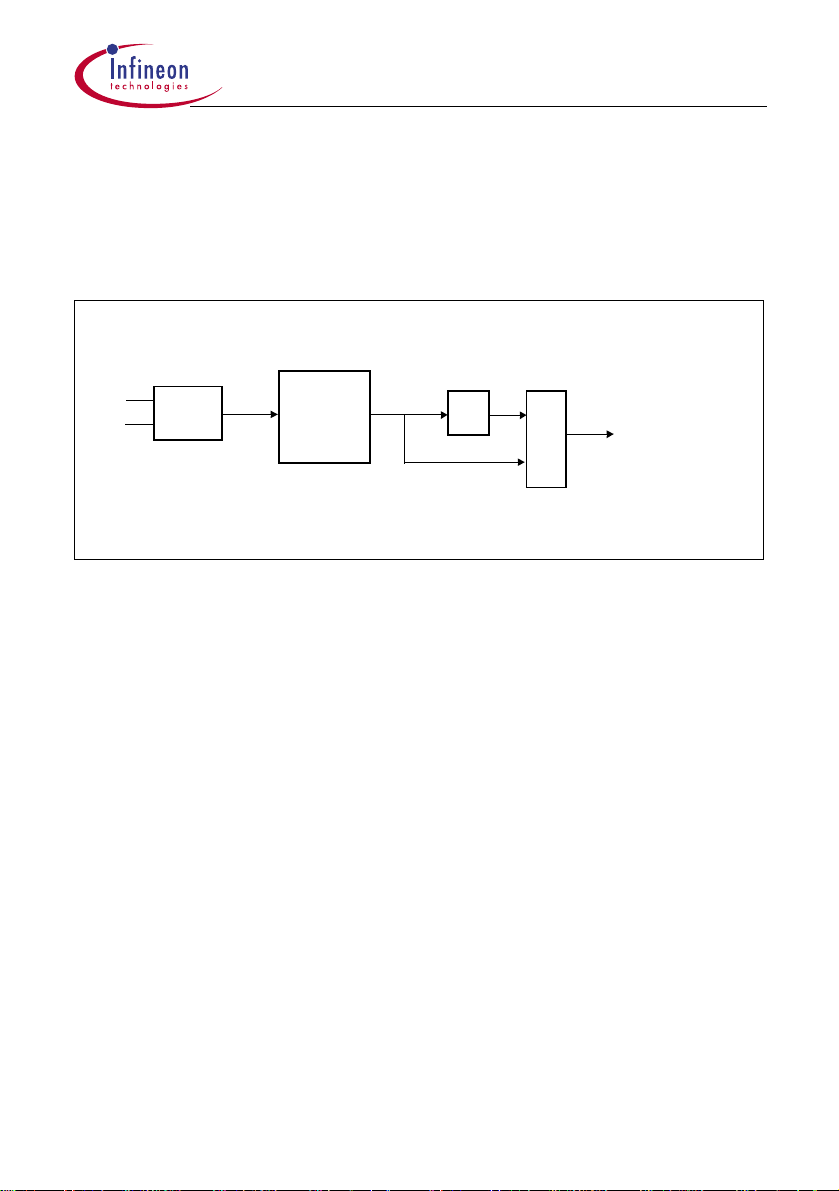

The phases of the bootstrap loader are illustrated in Figure 7.

Data Sheet 17 V 1.0, 2003-05

Phase A

Bootstrap from

serial

EEPROM

EEPROM (first byte)

Yes

Start

Read serial

byte=A5H? No

Init serial interface 0

and synchronize to

the host baud rate

Phase B

Receive header

block from host

C868

Phase B, Phase I

Phase B, Phase II

Activate Mode 4

Load program from

I2C serial EEPROM

to SRAM/XRAM

Activate Mode 3

Activate mode 0

Load custom code

to SRAM/XRAM

Activate Mode 1

Execute custom

program in XRAM

Select working

mode

Activate Mode 2

Execute custom

program in SRAM

Load program from SPI serial

EEPROM to SRAM/XRAM

Figure 7 The phases of the Bootstrap Loader

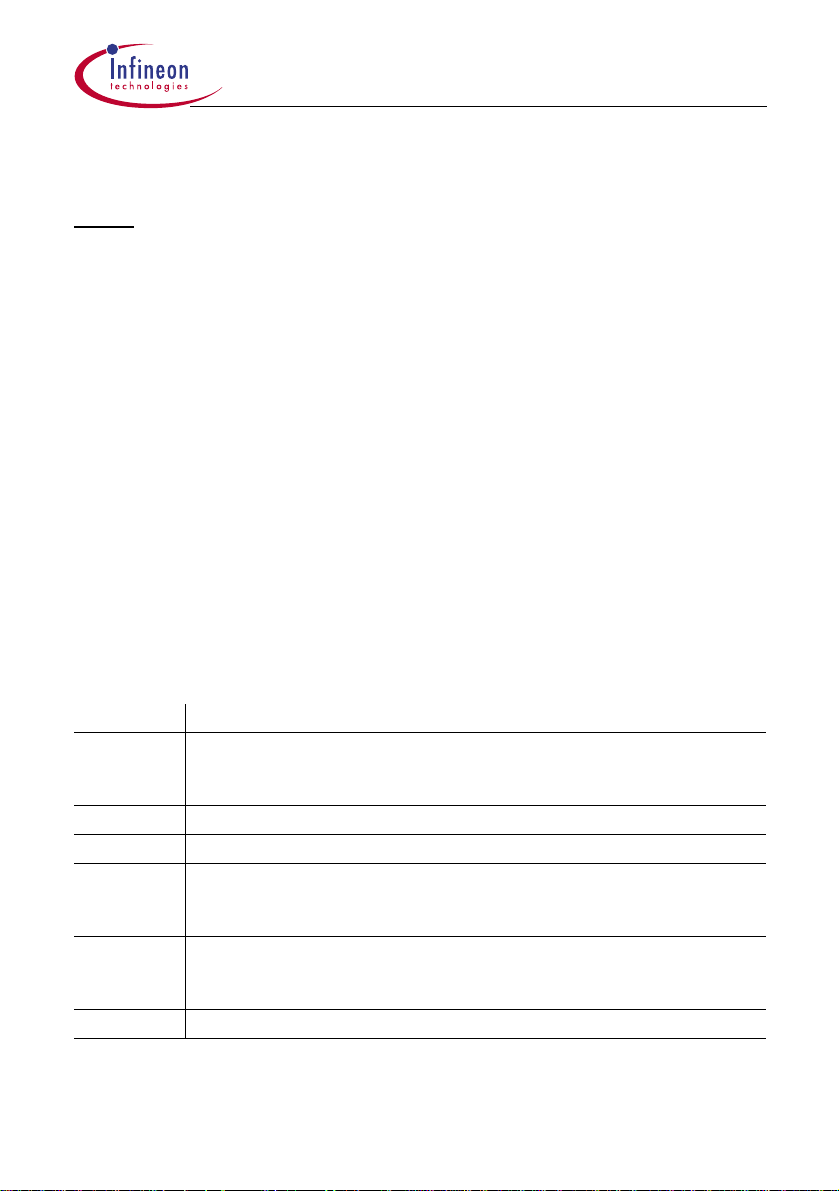

The serial communication is activated in phase B. Using a full duplex serial cable

(RS232), the MCU must be connected to the serial port of the host computer as shown

in Figure 8.

Serial Cable

PC

full duplex, RS232

C868

Host Computer

Serial Interface

(asynchronous, 8N1)

Serial Interface,

UART Mode 1

(asynchronous, 8N1)

Figure 8 Bootstrap Loader Interface to the PC

Data Sheet 18 V 1.0, 2003-05

C868

VCC VCC

P1.3

P1.1

P1.2

240R

1

/CS

6

SCK

5

SI

2

SO

/HOLD

/WP

VCC

GN

7

3

8

4

D

1

A0

6

A1

5

A2

2

GN

D

VCC

WP

SCL

SDA

7

3

8

4

3K3

P1.1

P1.2

a) SPI EEPRO M connection

b) I2C EEPROM connection

Figure 9 EEPROM connections for a) SPI and b) I2C

Data Sheet 19 V 1.0, 2003-05

C868

Reset and Brownout

The reset input is an active low input. An internal Schmitt trigger is used at the input for

noise rejection. The RESET

only exit from reset condition after the PLL lock had been detected.

During RESET

at transition from low to high, C868 will go into normal mode if ALE/BSL

is high and bootstrap loading mode if ALE/BSL is low. A pullup to V

ground is recommended for pin ALE/BSL. TXD should have a pu llup to V

not be stimulated externally during reset, as a logic low at this pin will cause the chip to

go into test mode if ALE/BSL is low.

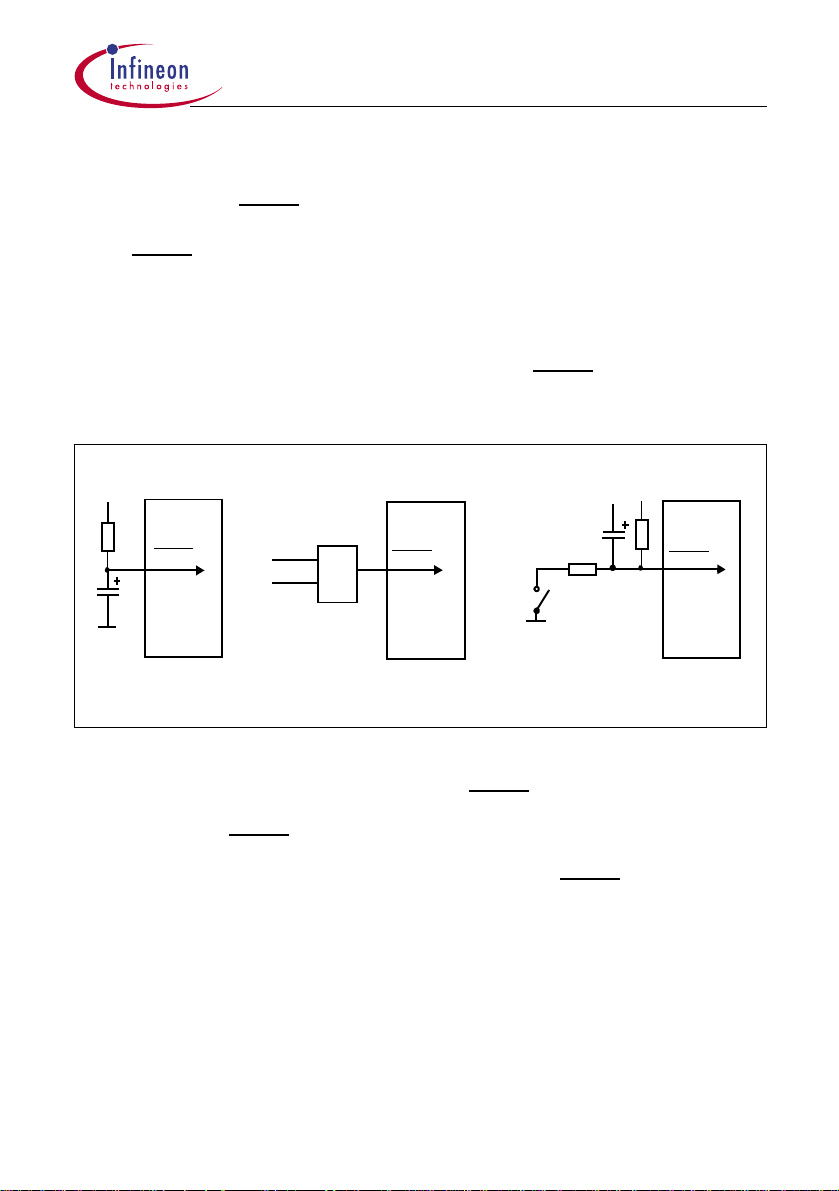

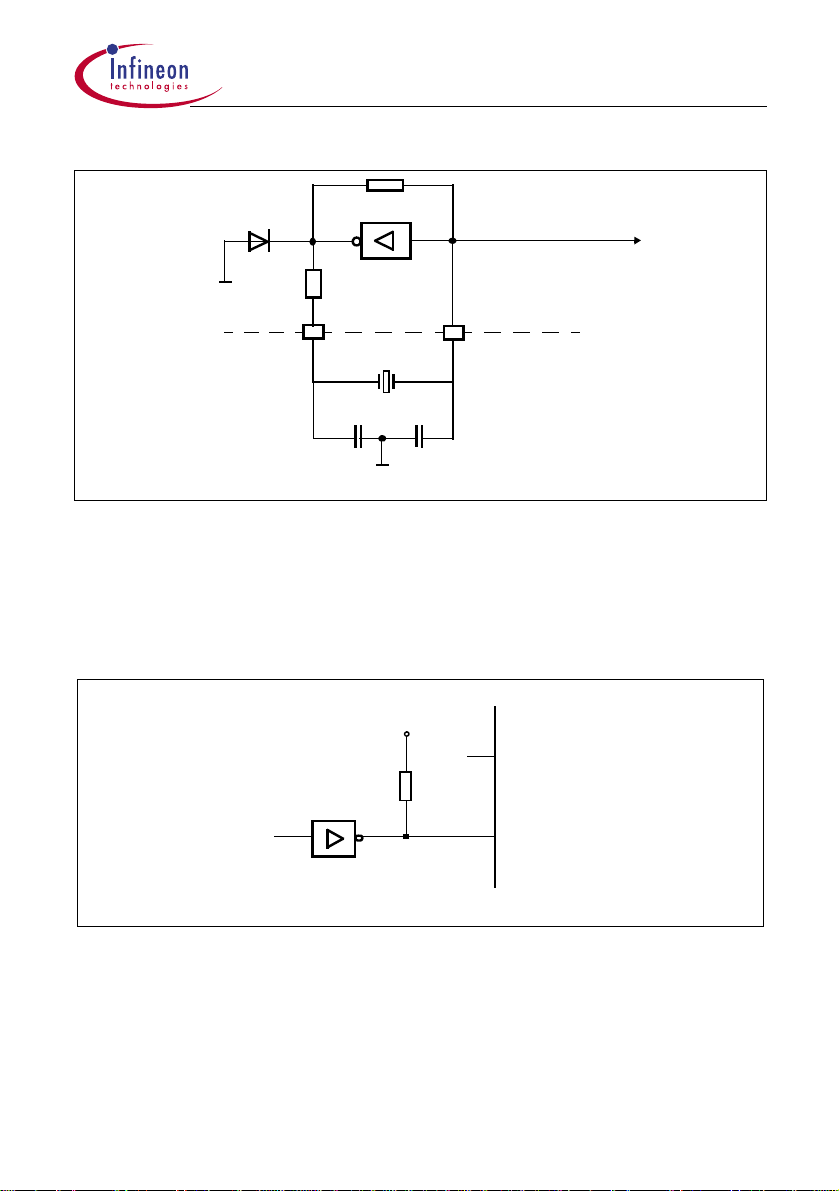

Figure 10 shows the possible reset circuits, note that the RESET

internal pullup resistance.

pin must be held low fo r at l east tbd usec . Bu t the CPU will

or pulldown to

DDP

and should

DDP

pin does not have an

a)

V

DDP

C868 BA

RESET

b) c)

C868 BA

&

RESET

V

DDP

C868 BA

RESET

Figure 10 Reset Circuitries

An on-chip analog circuit detects brownout, if the core voltage V

threshold voltage V

THRESHOLD

active for tbd usec then the device will reset. When V

V

THRESHOLD

while RESET is high, the reset is released once PLL is locked for 4096

momentarily while RESET pin is high. If this detect ion is

recovers by exceeding

DDC

dips below the

DDC

clocks. Bit BO in the PMCON0 register is set when brownout detected if brownout

detection was enabled, this bit is cleared by hardware reset RESET and software. All

ports are tristated during brownout.

The V

THRESHOLD

has a nominal value of 1.47V, a minimum value of 1.1V and a

maximum value of 1.8V.

Data Sheet 20 V 1.0, 2003-05

C868

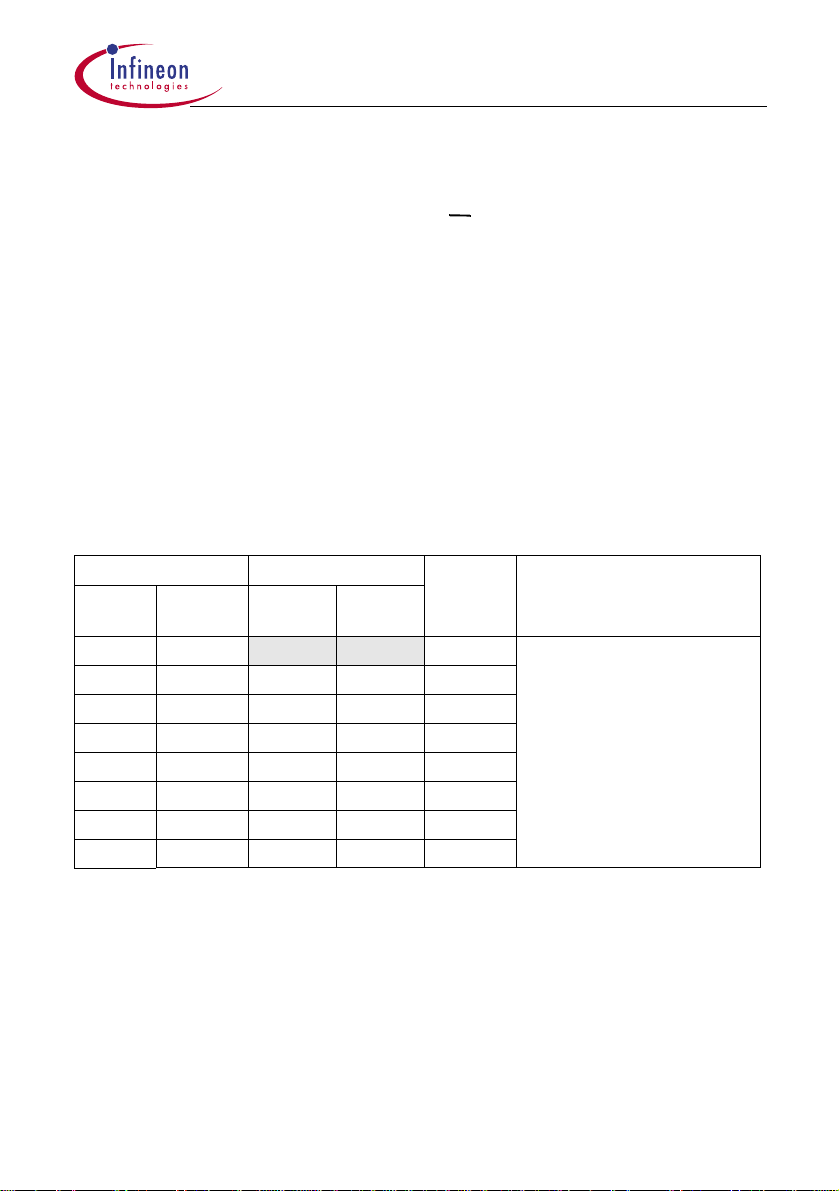

Clock system

The C868 clock system cons ist of the on-chip oscillat or, PLL and m ultipl exer sta ge. The

programmable Slow Down Divider (SDD) divides the PLL output clock frequency by a

factor of 1...32 which is specified via CMCON.REL. The system clock is switched from

the PLL output to the output from the SDD when slowdown mode is selected.

clkin

PLL

clkout

f

PLL

SDD

XTAL1

XTAL2

On-Chip

Osc

f

OSC

Figure 11 Block Diagram of the Clock Generation

MUX

system

clock (

f

SYS

)

Data Sheet 21 V 1.0, 2003-05

The PLL output frequency is determined by:

C868

f

PLL

= f

VCO

15

/ K = × f

K

OSC

The range for the VCO frequency is given by:

100 MHz ≤ f

≤ 160 MHz [2]

VCO

The relationship between the input frequency and VCO frequency is given by:

f

=15× f

VCO

OSC

This gives the range for the input frequency which is given by:

6.67 MHz ≤ f

Table 5 Output Frequencies

K-Factor f

Selected

Factor

2 000

4 010

1)

5

6 100

8 101

1)

9

10 111

16 001

1)

These odd factors should not be used (not tested because off the unsymmetrical duty cycle).

2) Shaded combinations should not be used because they are above the maximum CPU frequency of 40MHz.

KDIV f

100 MHz

50 80 50 linear depending on f

25 40 50

20 32 40

16.67 26.67 50

12.5 20 50

11.11 17.78 44

10 16 50

6.25 10 50

011

110

B

B

B

B

B

B

B

B

≤ 10.67 MHz [4]

OSC

f

Derived from Various Output Factors

PLL

VCO

=

Duty

Cycle [%]

PLL

=

f

VCO

Jitter

160 MHz

at f

=100MHz: +/-300ps

VCO

=160MHz: +/-250ps

at f

VCO

additional jitter for odd Kdiv

factors tbd.

[1]

[3]

VCO

Data Sheet 22 V 1.0, 2003-05

C868

Figure 12 shows the recommended oscillator circuitries for crystal and external clock

operation.

Crystal Oscillator Mode

XTAL2

6.67-10.67

MHz

C = 20 pF ± 10 pF for crystal operation

(incl. StrayCapacitance)

C868

XTAL1

Driving from External Source

External Oscillator

Signal

N.C.

XTAL2

XTAL1

Figure 12 Recommended Oscillator Circuit

In this application the on-chip oscillator is used as a crystal-controlled, positivereactance oscillator (a more detailed schematic is given in Figure 13). lt is operated in

its fundamental response mode as an inductive reactor in parallel resonance with a

capacitor external to the chip. The crystal specifications and capacitances are noncritical. In this circ uit tbd pF can b e used as single capacitanc e at any freque ncy together

with a good quality crystal. A ceramic resonator can be used in place of the crystal in

cost-critical applications. If a ceramic resonator is used, the two capacitors normally

have different values depending on the oscillator frequency. We recommend consulting

the manufacturer of the ceramic resonator for value specifications of these capacitors.

Data Sheet 23 V 1.0, 2003-05

C868

To internal

timing circuitry

XTAL1

*) Crystal or ceramic resonato r

XTAL2

*)

C

C

1

2

C868

Figure 13 On-Chip Oscillator Circuitry

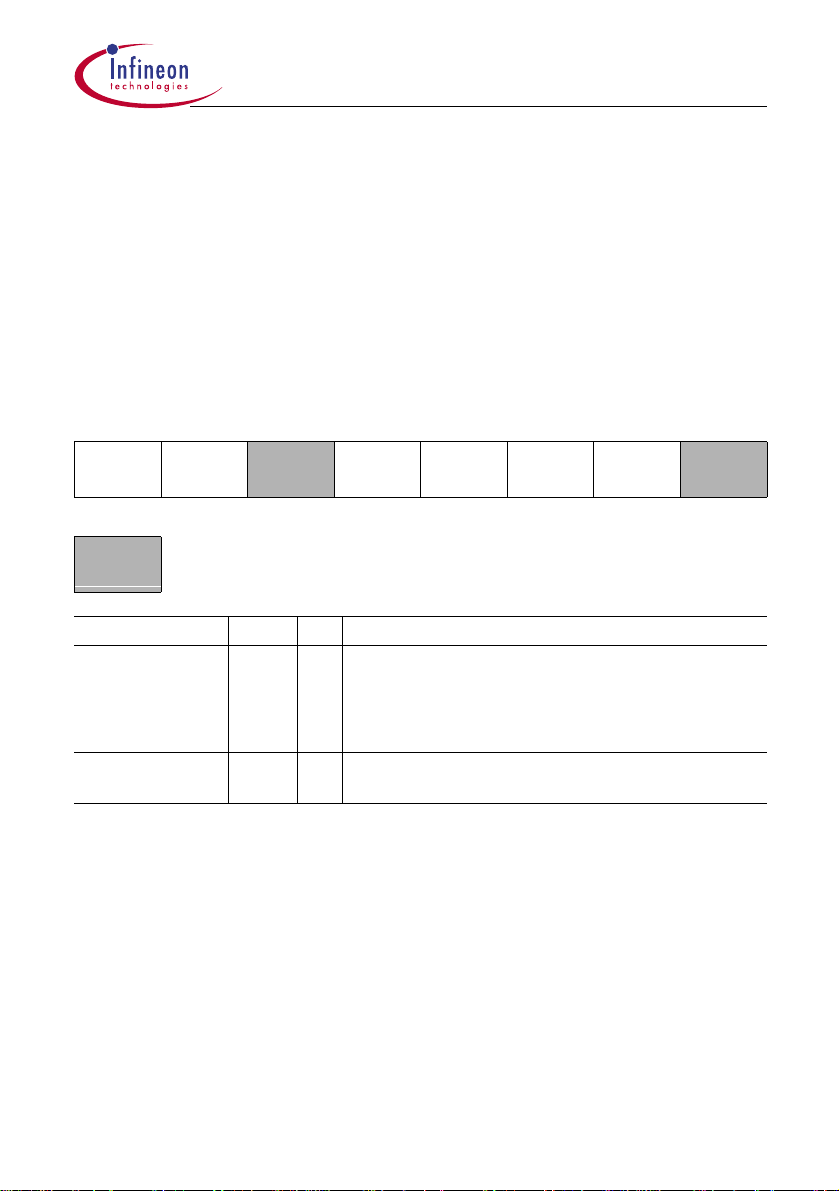

To drive the C868 with an external clock source, the external clock signal has to be

applied to XTA L2, as show n in Figure 14. XTAL1 has to be left unconnected. A pullup

resistor is s ugges ted ( to incr ease t he nois e marg in), bu t is op tion al if VOH of the drivi ng

V

gate corresponds to the

External

Clock

Signal

specification of XTAL2.

IH2

V

DDC

N.C.

C868

XTAL1

XTAL2

Figure 14 External Clock Source

Data Sheet 24 V 1.0, 2003-05

C868

0.1 Special Function Registers

All registers, except the program counter and the four general purpose register banks,

reside in the special function register area. The special function register area consists

of two portions: the standard special function register area and the mapped special

function register area. For accessing the mapped special function area, bit RMAP in

special function register SYSCON0 must be set. All other special function registers are

located in the standard special function register area which is accessed when RMAP is

cleared (“0“).

SYSCON0

System Control Register 0 [Reset value: XX10XXX1

76543210

--EALE RMAP - - - XMAP0

r r rw rw r r r rw

Field Bits Typ Description

RMAP

- [7:2] r reserved;

The functions of the shaded bits are not described here

4rw

Special Function Register Map Control

RMAP = 0 : The access to the non-mapped (standard)

special function register area is enabled.

RMAP = 1 : The access to the mapped special function

register area is enabled.

returns ’0’ if read; should be written with ’0’;

B

]

As long as bit R MA P is s et , th e mapped special fun cti on reg is ter area can be accessed.

This bit is not cleared automatically by hardware. Thus, when non-mapped/mapped

registers are to be accessed, the bi t RMAP must be cleared/se t respectively by softwa re.

The 109 special function registers (SFR) include pointers and registers that provide an

interface between the CP U and the other on-c hip peri pherals. Al l avail able SFRs whose

address bits 0-2 are 0 (e.g. 80H, 88H, 90H, ..., F0H, F8H ) are bit- ad dressabl e. Tot ally

there are 128 directly addressable bits within the SFR area.

All SFRs are list ed in Table 6 and Table 7.In Table 6 they are organized in groups w hich

refer to the functional blocks of the C868-1R, C868-1S. Table 7 illustrates the contents

(bits) of the SFRs

Data Sheet 25 V 1.0, 2003-05

Table 6 Special Function Registers - Functional Blocks

C868

Block Symbol Name Add-

ress

C800

ACC

core

B

DPH

DPL

DPSEL

PSW

SP

SCON

SBUF

IEN0

IEN1

IEN2

IP0

IP1

TCON

TMOD

TL0

TL1

TH0

TH1

PCON

Sys-

PMCON0

tem

CMCON

EXICON

IRCON0

IRCON1

PMCON1

PMCON2

SCUWDT

VERSION

SYSCON0

SYSCON1

1) Bit-addressable special function registers

2) “X“ means that the value is undefined and the location is reserved

3) Register is mapped by bit RMAP in SYSCON0.4=1

4) Register is mapped by bit RMAP in SYSCON0.4=0

Accumulator

B-Register

Data Pointer, High Byte

Data Pointer, Low Byte

Data Pointer Select Register

Program Status Word Register

Stack Pointer

Serial Channel Control Register

Serial Data Buffer

Interrupt Enable Register 0

Interrupt Enable Register 1

Interrupt Enable Register 2

Interrupt Priority Register 0

interrupt Priority Register 1

Timer 0/1 Control Register

Timer Mode Register

Timer 0, Low Byte

Timer 1, Low Byte

Timer 0, High Byte

Timer 1, High Byte

Power Control Register

Wake-up Control Register

Clock Control Register

External Interrupt Control Register

External Interrupt Request Register

Peripheral Interrupt Request Register

Peripheral Management Ctrl Register

Peripheral Management Status Register

SCU/Watchdog Control Register

ROM Version Register

System Control Register 0

System Control Register 1

E0

F0

83

82

84

D0

81

98

99

A8

A9

AA

B8

AC

88

89

8A

8B

8C

8D

87

8E

8F

91

92

93

E8

F8

C0

F9

AD

AF

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

Contents

after

Reset

1)

00

H

1)

00

H

00

H

00

H

00

H

1)

00

H

07

H

1)

00

H

00

H

1)

0X000000

XXXXX000

XX0000XX

1)

XX000000

XX000000

1)

00

H

00

H

00

H

00

H

00

H

00

H

0XXX0000

XXX00000

10011111

XXXXXX00

XXXXXX00

XX0000X0

1)

XXXXX000

1)

XXXXX000

1)

X0X00000

00

H

XX10XXX1

00XXX0X0

2)

B

2)

B

2)

B

2)

B

2)

B

2)

B

2)

B

B

2)

B

2)

B

2)

B

2)

B

2)

B

2)

B

2)

B

2)

B

Data Sheet 26 V 1.0, 2003-05

Table 6 Special Function Registers - Functional Blocks (cont’d)

C868

Block Symbol Name Add-

ress

A/D-

ADCON0

Converter

Ports P1

ADCON1

ADDATH

4)

3)

P1DIR

4)

P3

3)

P3DIR

P3ALT

P1ALT

Watch

WDTCON

dog

WDTREL

WDTL

WDTH

Timer 2T2CON

T2MOD

RC2H

RC2L

T2H

T2L

1) Bit-addressable special function registers

2) “X“ means that the value is undefined and the location is reserved

3) Register is mapped by bit RMAP in SYSCON0.4=1

4) Register is mapped by bit RMAP in SYSCON0.4=0

A/D Converter Control Register 0

A/D Converter Control Register 1

A/D Converter Data Register

Port 1 Register

Port 1 Direction Register

Port 3 Register

Port 3 Direction Register

Port 3 Alternate Function Register

Port 1 Alternate Function Register

Watchdog Timer Control Register

Watchdog Timer Reload Register

Watchdog Timer, Low Byte

Watchdog Timer, High Byte

Timer 2 Control Register

Timer 2 Mode Register

Timer 2 Reload/Capture, High Byte

Timer 2 Reload/Capture, Low Byte

Timer 2, High Byte

Timer 2, Low Byte

D8

D9

DB

90

90

B0

B0

B1

B4

A2

A3

B2

B3

C8

C9

CB

CA

CD

CC

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

Contents

after

Reset

1)

00

H

XX000000

00

H

1)

FF

1)

FF

1)

FF

1)

FF

00

H

XXX00X00

XXXXXX00

00

H

00

H

00

H

1)

00

H

XXXXXXX0

00

H

00

H

00

H

H

00

H

H

2)

B

H

H

H

H

2)

B

2)

B

2)

B

Data Sheet 27 V 1.0, 2003-05

Table 6 Special Function Registers - Functional Blocks (cont’d)

C868

Block Symbol Name Add-

ress

Capture/

Compare

Unit

T12L

T12H

T13L

T13H

T12PRL

T12PRH

T13PRL

T13PRH

CC60RL

CC60RH

CC61RL

CC61RH

CC62RL

CC62RH

CC63RL

CC63RH

T12DTCL

T12DTCH

CMPSTATL

CMPSTATH

CMPMODIFL

CMPMODIFH

TCTR0L

TCTR0H

TCTR2L

TCTR4L

3)

4)

TCTR4H

ISL

ISH

PISELH

Timer T12 Counter Regi ster, Low By te

Timer T12 Counter Register, High Byte

Timer T13 Counter Regi ster, Low By te

Timer T13 Counter Register, High Byte

Timer T12 Period Register, Low Byte

Timer T12 Period Register, High Byte

Timer T13 Period Register, Low Byte

Timer T13 Period Register, High Byte

Capture/Compare Ch 0 Reg, Low Byte

Capture/Compare Ch 0 Reg, High Byte

Capture/Compare Ch 1 Reg, Low Byte

Capture/Compare Ch 1 Reg, High Byte

Capture/Compare Ch 2 Reg, Low Byte

Capture/Compare Ch 2 Reg, High Byte

T13 Compare Register, Low Byte

T13 Compare Register, High Byte

Timer T12 Dead Time Ctrl, Low Byte

Timer T12 Dead Time Ctrl, High Byte

Compare Timer Status, Low Byte

Compare Timer Status, High Byte

Compare Timer Modificatio n, Low Byte

Compare Timer Modification, High Byte

Timer Control Register 0, Low Byte

Timer Control Register 0, High Byte

Timer Control Register 2, Low Byte

Timer Control Register 4, Low Byte

4)

Timer Control Register 4, High Byte

Cap/Com Interrupt Register, Low Byte

Cap/Com Interrupt Register, High Byte

Port Input Selector Register, High Byte

EC

ED

EE

EF

DE

DF

D2

D3

C2

C3

C4

C5

C6

C7

D4

D5

E6

E7

F4

F5

EA

EB

E2

E3

F2

F2

F3

E4

E5

BB

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

Contents

after

Reset

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

0

H

00

H

00

H

00

H

00

H

1) Bit-addressable special function registers

2) “X“ means that the value is undefined and the location is reserved

3) Register is mapped by bit RMAP in SYSCON0.4=1

4) Register is mapped by bit RMAP in SYSCON0.4=0

Data Sheet 28 V 1.0, 2003-05

Table 6 Special Function Registers - Functional Blocks (cont’d)

C868

Block Symbol Name Add-

ress

Capture/

Compare

Unit

3)

ISSL

3)

ISSH

4)

ISRL

4)

ISRH

3)

INPL

3)

INPH

4)

IENL

4)

IENH

CC60SRL

CC60SRH

CC61SRL

CC61SRH

CC62SRL

CC62SRH

CC63SRL

CC63SRH

MODCTRL

3)

MODCTRH

TRPCTRL

TRPCTRH

PSLRL

MCMOUTL

3)

MCMOUTH

MCMOUTSL

MCMOUTSH

MCMCTRLL

T12MSELL

T12MSELH

Cap/Com Int Status Set Reg, Low Byte

Cap/Com Int Status Set Reg, High Byte

Cap/Com Int Status Rese t Reg, Low Byte

Cap/Com Int Status Reset Reg,High Byte

Cap/Com Int Node Ptr Reg, Low Byte

Cap/Com Int Node Ptr Reg, High Byte

Cap/Com Interrupt Register, Low Byte

Cap/Com Interrupt Register, High Byte

Cap/Com Channel 0 Shadow, Low Byte

Cap/Com Channel 0 Shadow, High Byte

Cap/Com Channel 1 Shadow, Low Byte

Cap/Com Channel 1 Shadow, High Byte

Cap/Com Channel 2 Shadow, Low Byte

Cap/Com Channel 2 Shadow, High Byte

T13 Compare Shadow Reg, Low Byte

T13 Compare Shadow Reg, High Byte

Modulation Control Register, Low By te

3)

Modulation Control Register, High Byte

Trap Control Register, Low Byte

Trap Control Register, High Byte

Passive State Level Register, Low Byte

MCM Output Register, Low Byte

3)

MCM Output Register, High Byte

4)

MCM Output Shadow Regist er, Low Byte

4)

MCM Output Shadow Regis ter,H igh Byte

4)

MCM Control Register, Low Byte

T12 Cap/Com Mode Sel Reg, Low Byte

T12 Cap/Com Mode Sel Reg, High Byte

BC

BD

BC

BD

BE

BF

BE

BF

FA

FB

FC

FD

FE

FF

B6

B7

D6

D7

CE

CF

A6

DC

DD

DC

DD

D6

F6

F7

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

Contents

after

Reset

00

00

00

00

40

39

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

H

00

H

00

H

00

H

00

00

00

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

1) Bit-addressable special function registers

2) “X“ means that the value is undefined and the location is reserved

3) Register is mapped by bit RMAP in SYSCON0.4=1

4) Register is mapped by bit RMAP in SYSCON0.4=0

Data Sheet 29 V 1.0, 2003-05

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

81

SP 07

H

82

DPL 00

H

83

DPH 00

H

84

DPSEL00

H

Content

after

1)

Reset

H

H

H

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

–––––D2 D1 D0

C868

PCON 0XX0

87

H

0000

88HTCON 00

89

TMOD 00

H

TL0 00

8A

H

8B

TL1 00

H

8C

TH0 00

H

8D

TH1 00

H

8E

PMCON0XXX0

H

0000

8FHCMCON1001

1111

2)

90

P1 FF

H

3)

90

P1DIR FF

H

91

EXICONXXXX

H

XX00

92HIRCON0XXXX

XX00

93

IRCON1XX00

H

00X0

98HSCON 00

99

SBUF 00

H

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

SMOD ––SD GF1 GF0 PDE IDLE

B

TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0

H

GATE1C/NT1 M1(1) M0(1) GATE0C/NT0 M1(0) M0(0)

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

–––EBO BO SDSTATWS EPWD

B

KDIV2 KDIV1 KDIV0 REL4 REL3 REL2 REL1 REL0

B

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

––––––ESEL3 ESEL2

B

––––––EXINT3EXINT

B

––INP3 INP2 INP1 INP0 – IADC

B

SM0 SM1 SM2 REN TB8 RB8 TI RI

H

.7 .6 .5 .4 .3 .2 .1 .0

H

2

Data Sheet 30 V 1.0, 2003-05

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

A2HWDTCONXXXX

WDTREL00

A3

H

Content

after

1)

Reset

XX00

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

–––––––WDTI

B

.7 .6 .5 .4 .3 .2 .1 .0

N

C868

PSLRL 00

A6

H

A8HIEN0 0X00

0000

A9HIEN1 XXXX

X000

IEN2 XX00

AA

H

00XX

ACHIP1 XX00

0000

SYSC

AD

H

ON0

AFHSYSC

ON1

2)

B0

P3 FF

H

3)

B0

P3DIR FF

H

B1

P3ALT 00

H

B2

WDTL 00

H

B3

WDTH 00

H

B4

P1ALT XXX0

H

XX10

XXX1

00XX

X0X0

0X00

B6

CC63

H

00

PSL63 – PSL5 PSL4 PSL3 PSL2 PSL1 PSL0

H

EA – ET2 ES ET1 EX1 ET0 EX0

B

–––––EX3 EX2 EADC

B

––EINP3 EINP2 EINP1 EINP0 ––

B

––.5 .4 .3 .2 .1 .0

B

––EALE RMAP –––XMAP

B

ESWC SWC _ _ _ BSLEN_SWAP

B

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

CC60 COUT60CC61 COUT61CC62 COUT62CTRAPCOUT

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

___RxDINT3_EXF2TxD

B

.7 .6 .5 .4 .3 .2 .1 .0

H

SRL

B7HCC63

00

.7 .6 .5 .4 .3 .2 .1 .0

H

SRH

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

0

63

Data Sheet 31 V 1.0, 2003-05

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

B8HIP0 XX00

PISELH00

BB

H

3)

BC

ISSL 00

H

Content

after

1)

Reset

0000

B

H

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

– – .5 .4 .3 .2 .1 .0

––ISPOS

2.1

ISPOS

2.0

ISPOS

1.1

ISPOS

1.0

ISPOS

0.1

ISPOS

0.0

ST12PMST12OMSCC62FSCC62RSCC61FSCC61RSCC60FSCC60

R

2)

BC

H

ISRL 00

RT12PMRT12OMRCC62FRCC62RRCC61FRCC61RRCC60FRCC6

H

0R

3)

BD

ISSH 00

H

– SIDLE SWHE SCHE – STRPFST13PMST13C

H

M

2)

BD

H

ISRH 00

– RIDLE RWHE RCHE – RTRPFRT13PMRT13C

H

M

2)

BE

BE

BF

H

3)

H

2)

H

IENL 00

INPL 00

IENH 00

ENT12PMENT12OMENCC

H

62F

INPCH

H

E.1

– ENIDLEENWHEENCHE– ENTRPFENT13PMENT13

H

INPCH

E.0

INPCC

62.1

ENCC

62R

INPCC

62.0

ENCC

61F

INPCC

61.1

ENCC

61R

INPCC

61.0

ENCC

60F

INPCC

60.1

ENCC

60R

INPCC

60.0

CM

3)

BF

INPH 00

H

C0HSCUWDT00

––INPT1

H

3.1

– PLLR – WDTR WDTEOIWDTDISWDTRSWDTR

H

INPT1

3.0

INPT1

2.1

INPT1

2.0

INPER

R.1

INPER

R.0

E

C2HCC60RL00

.7 .6 .5 .4 .3 .2 .1 .0

H

C868

CC60RH00

C3

H

C4HCC61RL00

CC61RH00

C5

H

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

Data Sheet 32 V 1.0, 2003-05

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

C6HCC62RL00

Content

after

1)

Reset

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

.7 .6 .5 .4 .3 .2 .1 .0

C868

CC62RH00

C7

H

C8HT2CON00

H

H

C9HT2MODXXXX

XXX0

RC2L 00

CA

CB

CC

CD

CE

H

RC2H 00

H

TL2 00

H

TH2 00

H

TRPC

H

00

H

H

H

H

H

TRL

CF

TRPC

H

00

H

TRH

D0HPSW 00

D2

T13PRL00

H

D3HT13PRH00

CC63RL00

D4

H

D5HCC63RH00

H

H

H

H

H

.7 .6 .5 .4 .3 .2 .1 .0

TF2 EXF2 RCLK TCLK EXEN2TR2 C/T2 CP/

–––––––DCEN

B

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

–––––TRPM2TRPM1TRPM

TRPPENTRPE

TRPEN5TRPEN4TRPEN3TRPEN2TRPEN1TRPE

N13

CY AC F0 RS1 RS0 OV F1 P

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

RL2

0

N0

2)

MCMC

D6

H

TRLL

3)

D6

MODC

H

TRL

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

Data Sheet 33 V 1.0, 2003-05

00

00

––SWSYN1SWSYN0– SWSEL2SWSEL1SWSE

H

MCMEN– T12M

H

ODEN

5

T12M

ODEN

4

T12M

ODEN

3

T12M

ODEN

2

T12M

ODEN

1

L0

T12M

ODEN

0

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

3)

D7

MODC

H

TRH

D8HADCON000

ADCON1XX00

D9

H

ADDATH00

DB

H

3)

DC

MCMO

H

UTL

2)

MCMO

DC

H

UTSL

3)

DD

MCMO

H

UTH

2)

MCMO

DD

H

UTSH

DE

T12PRL00

H

Content

after

1)

Reset

00

H

H

0000

B

H

00

H

00

H

00

H

00

H

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

ECT13O– T13M

ODEN

5

ADST ADBSYADM1 ADM0 CCU-

T13M

ODEN

4

T13M

ODEN

3

ADEX

T13M

ODEN

2

T13M

ODEN

1

T13M

ODEN

0

ADCH2ADCH1ADCH

0

––ADSTC2ADSTC1ADSTC0ADCTC2ADCTC1ADCT

C0

.7 .6 .5 .4 .3 .2 .1 .0

– RMCMP

5

MCMP4MCMP3MCMP2MCMP1MCMP

0

STRMCM– MCMPS5MCMPS4MCMPS3MCMPS2MCMPS1MCMP

S0

––CURH2CURH1CURH0EXPH2EXPH1EXPH

0

STRHP– CURHS2CURHS1CURHS0EXPHS2EXPHS1EXPH

S0

.7 .6 .5 .4 .3 .2 .1 .0

C868

T12PRH00

DF

H

E0HACC 00

E2

TCTR0L00

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

CTM CDIR STE12 T12R T12PRET12CLK2T12CLK1T12CL

H

K0

E3

H

TCTR0H10

––STE13 T13R T13PRET13CLK2T13CLK1T13CL

H

K0

E4HISL 00

T12PM T12OMICC62FICC62RICC61FICC61RICC60FICC60

H

R

E5

H

ISH 00

– IDLE WHE CHE TRPS TRPF T13PM T13C

H

M

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

Data Sheet 34 V 1.0, 2003-05

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

E6HT12DTCL00

Content

after

1)

Reset

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

– DTM5 DTM4 DTM3 DTM2 DTM1 DTM0

C868

T12DTCH00

E7

H

E8HPMCON1XXXX

X000

EAHCMPM

00

– DTR2 DTR1 DTR0 – DTE2 DTE1 DTE0

H

– – – – – CCUDIST2DIS ADCDI

B

– MCC63S–––MCC62SMCC61SMCC6

H

ODIFL

EB

H

CMPM

00

– MCC63R–––MCC62RMCC61RMCC6

H

ODIFH

ECHT12L 00

ED

T12H 00

H

EEHT13L 00

EF

T13H 00

H

F0HB 00

2)

F2

TCTR4L00

H

3)

TCTR2L00

F2

H

2)

F3

TCTR4H00

H

F4

CMPS

H

00

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

T12STDT12STR––DTREST12REST12RS T12RR

H

– T13TED1T13TED0T13TEC2T13TEC1T13TEC0T13SSCT12SS

H

T13STDT13STR–––T13REST13RS T13RR

H

– CC63ST–––CC62STCC61STCC60S

H

TATL

F5HCMPS

TATH

T12M

F6

H

SELL

F7HT12M

00

00

00

T13IM COUT

H

63PS

MSEL

H

613

––––MSEL

H

MSEL

612

COUT

62PS

MSEL

611

CC62PSCOUT

MSEL

610

SELH

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

61PS

MSEL

603

623

CC61PSCOUT

60PS

MSEL

602

MSEL

622

MSEL

601

MSEL

621

S

0S

0R

C

T

CC60P

S

MSEL

600

MSEL

620

Data Sheet 35 V 1.0, 2003-05

Table 7 Contents of the SFRs, SFRs in numeric order of their addresses

Addr Reg-

ister

F8HPMCON2XXXX

VERSION00

F9

H

Content

after

1)

Reset

X000

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

– – – – – CCUSTT2ST ADCS

B

PROT VER6 VER5 VER4 VER3 VER2 VER1 VER0

T

C868

CC60RL00

FA

H

FBHCC60RH00

CC61RL00

FC

H

FDHCC61RH00

CC62RL00

FE

H

FFHCC62RH00

1) X means that the value is undefined and the location is reserved

2) This register is mapped with RMAP (SYSCON0.4)=0

3) This register is mapped with RMAP (SYSCON0.4)=1

Shaded registers are bit-addressable special function registers

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

.7 .6 .5 .4 .3 .2 .1 .0

H

Data Sheet 36 V 1.0, 2003-05

C868

Ports

The C868 has two kinds of po rts. The first kind is pu sh-pull ports in stead of the traditiona l

quasi-bidirectional ports. The ports belonging to this kind are lsb of port 1 which is a 5bit I/O port and port 3 which is an eight-bit I/O port. When configured as inputs, these

ports will be high impedan ce with Sch mitt tri gger featu re. Port 3 is alternate for captu re/

compare functions whereas, port 1 has alternate functions for some of the pins.

The second kind is input ports which are shared by msb of port 1 which is a 3-bit input

port, the interrupts, timer 2 inputs, capture/compare hall inputs and analog inputs.

Data Sheet 37 V 1.0, 2003-05

C868

Timer 0 and 1

Timer 0 and 1 can be used in four operating modes as listed in Table 8:

Table 8 Timer 0 and 1 Operating Modes

Mode Description TMOD System Clock

M1 M0

f

0 8-bit timer with a divide-by-32 prescaler 0 0

1 16-bit timer 0 1

2 8-bit timer with 8-bit autoreload 1 0

3 Timer 0 used as one 8-bit timer and one 8-bit

11

timer

timer 1 stops

The register is incremented every machine cycle. Since the machine cycle consist of

twelve oscillator periods, the count rate is 1/12th of the system frequency. External

inputs INT0 and INT1 can be programmed to function as a gate to facilitate pulse width

measurements. Figure 15 illustrates the input clock logic.

SYS

f

SYS

/(12*32)

/12

f

÷ 12

SYS

C/T = 0

Timer 0/1

Input Clock

Control

INT0

Gate

Pin

=1

TR0

≥1

&

Figure 15 Timer 0 and 1 Input Clock Logic

Data Sheet 38 V 1.0, 2003-05

C868

Timer/Counter 2 with Compare/Capture/Capture

Timer 2 is a 16-bit timer/counter with an up/down count feature. It has three operating

modes:

• 16-bit auto-reload mode (up or down counting)

• 16-bit capture mode

• Baudrate generator

Table 9 Timer/Counter 2 Operating Modes

Mode T2CON T2MOD T2CON T2EX Remarks System

Clock

RCLK

or

TR2 DCEN EXEN Inte-

CP/

RL2

TCLK

16-bit

Autoreload

0010 0 Xreload upon

overflow

0 0 X 0 1 reload trigger

(falling edge)

0011 X 0down counting

0011 X 1up counting

16-bit

Capture

011X 0 X16-bit Timer/

Counter (only

up-counting)

011X 1 capture

T2H,T2L->

RC2H,RC2L

Baudrate

Generator

1X1X 0 Xno overflow

interrupt

request(TF2)

1X1X 1 extra external

interrupt

(“Timer 2“)

off X X 0 X X X Timer 2 stops - -

rnal

f

SYS

/12

f

SYS

/12

f

SYS

/2

T2

max

f

SYS

/24

max

f

SYS

/24

-

Note: denotes a falling edge

Data Sheet 39 V 1.0, 2003-05

C868

Serial Interface (UART)

The serial port is a full duplex port capable of simultaneous transmit and receive

functions. It is also receive-b uffered; it ca n commence re ception of a second by te before

a previously-received byte has been read from the receive register. The serial port can

operate in 3 modes as illustrated in Table 10.

Table 10 UART Operating Modes

Mode SCON Description

SM1 SM0

0 0 0 Reserved

1 0 1 8-bit UART, variable baudrate

10 bits are transmitted (th rough TxD) or rec eived (RxD)

2 1 0 9-bit UART, fixed baudrate

11 bits are transmitted (th rough TxD) or rec eived (RxD)

3 1 1 9-bit UART, variable baudrate

Similar to mode 2, except for the variable baudrate.

For clarification, some terms regarding the difference between “baudrate clock“ and

“baudrate“ should be mentioned.

The serial interface requires a clock rate which is 16 times the baudrate for internal

synchronization. Th erefore, t he b audrate generat ors must p rovi de a “ba udrate c lock“ to

the serial interface which divides it by 16, thereby resulting in the actual “baudrate“.

Data Sheet 40 V 1.0, 2003-05

C868

The baudrates in Mode 1 and 3 are determined by the timer overflow rate. These

baudrates can be det ermined by Timer 1 or by Timer 2 o r both (one for tran smit, the other

for receive.

Table 11 Serial Interface - Baud Rate Dependencies

Serial Interface

Operating Modes

Mode 1 (8-bit UART)

Mode 3 (9-bit UART)

Mode 2 (9-bit UART) – 0 f

1)

Timer 2 functioning as baudrate generator

Active Control Bits Baud Rate Calculation

TCLK/

SMOD

RCLK

0 x Controlled by timer 1 overflow:

1 x Controlled by baud rate generator

1

SMOD

× Timer 1 overflow rate) / 32

(2

SMOD

(2

× Timer 21) overflow rate) / 32

/ 64

SYS

f

/ 32

SYS

Data Sheet 41 V 1.0, 2003-05

C868

Capture/Compare Unit (CCU6)

The CCU6 provides two independent timers (T12, T13), which can be used for PWM

generation, especia lly for AC-m otor cont rol. Additi onally, special control mod es for bl ock

commutation and multi- ph ase mach in es are supported.

Timer 12 Fe atures

• Three capture/compare channels, each channel can be used either as capture or as

compare channel.

• Generation of a three-phase PWM supported (six outputs, individual signals for

highside and lowside switches)

• 16 bit resolution, maximum count frequency = system clock

• Dead-time control for each channel to avoid short-circuits in the power stage

• Concurrent update of the required T12/13 registers

• Center-aligned and edge-aligned PWM can be generated

• Single-shot mode supported

• Many interrupt request sources

• Hysteresis-like control mode

Timer 13 Fe atures

• One independent compare channel with one output

• 16 bit resolution, maximum count frequency = system clock

• Can be synchronized to T12

• Interrupt generation at period-match and compare-match

• Single-shot mode supported

Additional Features

• Block commutation for Brushless DC-drives implemented

• Position detection via Hall-sensor pattern

• Automatic rotational speed measurement for block commutation

• Integrated error handling

• Fast emergency stop without CPU load via external signal (CTRAP

)

• Control modes for multi-channel AC-drives

• Output levels can be selected and adapted to the power stage

• Capture/compare unit can be powerdown in normal, idle and slow-down modes

The timer T12 can work in capture and/or compare mode for its three channels. The

modes can also be co mbined. The tim er T13 can work in com pare mode only . The multichannel control unit generates output patterns which can be modulated by T12 and/or

T13. The modulation sources can be selected and combined for the signal modulation.

Data Sheet 42 V 1.0, 2003-05

Switching Examples

C868

T12clk

T12P

T12P-1

T12P-2

compare-ma tch =

period-match

0

10

active

zero-match

0

0< T12P-3

T12 shadow transfer

1

T12P

T12P-1

T12P-2

compare-match =

period-match

10

passive

active

zero-match

0

0

T12PT12P

T12 shadow transfer

1

T12

CDIR

STE12

CC6x

compare

state

Figure 16 Edge-aligned mode with duty cycles near 100% and near 0%.

Applicable to T13 as well.

T12clk

compare-match

2

1

10

1

0

2

2

compare-match

1

10

1

0

T12

2

CDIR

10

21

passiveactive

T12 shadow transf er

10

01

active

T12 shadow transfer

STE12

CC6x

compare

state

Figure 17 Centre-aligned mode with duty cycles near 100% and near 0%.

Data Sheet 43 V 1.0, 2003-05

C868

Dead-time Generation

The dead-time generation logic is built in a similar way for all three channels of T12.

Each of the three ch ann els w o rks in de pen den tly w it h i ts ow n de ad-t im e c oun ter and the

trigger and enable signals.

T12

Centre-aligned

T12

Edge-aligned

CC6xST

CC6xST

DTCx_o

COUT6x (CC6xPS=0)

CC6x (CC6xPS=0)

Figure 18 Dead-time generation for centre and edge aligned modes

Capture Mode

In capture mode the bits CC6xST indicate the occurrence of the selected capture event

according to the bit fields MSEL6x. A rising and/or a falling edge on the pins CC6x can

be selected as capture event, that is used to transfer the contents of timer T12 to the

CC6xR and CC6xSR registers. In order to wo rk in ca ptu re mod e, the captu re pin s hav e

to be configured as inputs.

Data Sheet 44 V 1.0, 2003-05

C868

Single Shot Mode

In single shot mode, the timer T12 stops automatically at the end of the its counting

period.

edge-aligned mode center-aligned mode

T12P

T12P-1

T12P-2

period-match

while counting up

one-match while

counting down

1

0

T12

T12R

CC6xST

if T12SSC = ’1’

0

T12

T12R

CC6xST

2

if T12SSC = ’1’

Figure 19 Single Shot Mode of T12, T13 is edge-aligned mode only.

Hysteresis-Like Control Mode

The hysteresis-lik e control mode (MSEL6x = ’1001’) offers the possib ility to swi tch off the

PWM output i f the input CCPOSx becomes ’0’. This can be used as a simple motor

control feature by using a comparator indicating e.g. over current.

T12

COUT6x

CC6x

CCPOSx

Figure 20 Hysteresis-like control mode

Data Sheet 45 V 1.0, 2003-05

C868

Synchronization of T13 to T12

The timer T13 can be synchronized on a T12 event. Combined with the single shot

mode, this feature can be used to generate a programmable delay after a T12 event.

5

compare-match while

counting up

T12

0

T13

T13R

2

1

Synchronization of T13 to T12

Multi-channel Mode

The multi-channel mode offers a po ssibility to modulate all six T12-related outp ut signals

within one instruct ion. The bits in bit field MC MP are us ed to sel ect the ou tputs tha t ma y

become active. If the multi-channel mode is enabled (bit MCMEN=’1’), only those

outputs may become ac tive, whi ch hav e a ’1’ at the co rrespon ding bi t posit ion in bi t field

MCMP.

This bit field has its own shadow bit field MCMPS, which can be written by SW. The

transfer of the new value in MCMPS to the bit field MCMP can be triggered by and

synchronized to T12 or T13 eve nts. This structure permit s the SW to write the new value,

which is then tak en in to a cc oun t b y t he H W a t a w ell -def ined moment and synch ronized

to a PWM period. This avoids unintended pulses due to unsynchronized modulation

sources (T12, T13, SW).

4

3

2

1

0

Data Sheet 46 V 1.0, 2003-05

C868

Trap Handling

The trap functionality permits the PWM outputs to react on the state of the input pin

. This functionality can be used to switch off the power devices if the trap input

CTRAP

becomes active (e.g. as emergency stop).

T12

T13

TRPF

TRPS

TRPS

TRPS

CTRAP active

sync. to T13

sync. to T12

no sync.

Figure 21 Trap State Synchronization (with TRM2=’0’)

Data Sheet 47 V 1.0, 2003-05

C868

Modulation control

The modulation control part combines the different modulation sources, six T12-related

signals from the three compare channels, the T13-related signal and the multi-channel

modulation sig nal s. ea ch m odulation source c an b e ind iv idu ally enabled for e ach output

line. Furthermore, the trap funct ionality is taken into account to disable the mo dulation of

the corresponding output line during the trap state (if enabled).

T13

CC60 (MCMP0, no modulation)

COUT60 (MCMP1, no modulation)

CC60 (T12, no modulation)

COUT60 (T12, no modulation)

CC60

(MCMP0 modulated with T12)

COUT60

(MCMP1 modulated with T12)

CC60

(MCMP0 modulated with T12 and 13)

COUT60

(MCMP1 modulated with T12 and T13)

Figure 22 Modulation Control example for CC60 and COUT60.

Data Sheet 48 V 1.0, 2003-05

C868

Hall Sensor Mode

In Brushless-DC motors the next multi-channel state values depend on the pattern of

the Hall inputs. There is a strong correlation between the Hall pattern (CURH) and the

modulation pattern (MCMP). Because of different machine types the modulation

pattern for driving the motor can be different. Therefore it is wishful to have a wide

flexibility in defining the correlation between the Hall pattern and the corresponding

modulation pattern. The CCU6 offers this by having a register which contains the actual

Hall pattern (CURHS), the next expected Hall pattern (EXPHS) and its output pattern

(MCMPS). At ev ery cor re ct H all even t (C HE, se e fi gur e Hall Event Actions) a new Hall

pattern with its correspo ndi ng outp ut p atte rn c an be l oad ed (from a p redefined table) by

software into the register M CMOUTS. Lo ading this shadow regist er can also be done by

a write action on MCMOUTS with bit STRHP = ’1’

The sampling of the Hall patter n (on CCP OSx) is don e with th e T12 clock . By using the

dead-time counter DTC0 (mode MSEL6x= ’1000’) a hardware noise filter can be

implemented to suppress spikes on the Hall inputs due to high di/dt in rugged inverter

environment. In case of a Hall eve nt the DTC0 is relo aded and starts counting. When the

counter value of one is reached, the CCPOSx inputs are sampled (without noise and

spikes) and are compared to the current Hall pattern (CURH) and to the expected Hall

pattern (EXPH). If the sampled pattern equals to the current pattern the edge on

CCPOSx was due to a noise s pike and no ac tion w ill be trig gered (im plic it noise filter). If

the sampled pattern equals to the next expected pattern the edge on CCPOSx was a

correct Hall event, the bit CHE is set which causes an interrupt and the resets T12 (for

speed measurement, see description mode ’1000’ below).

This correct Hall event c an be u se d as a tra ns fer re que st e ve nt fo r regi st er M CMO UTS.

The transfer from MCMOUTS to MCMOUT transfers the new CURH-pattern as well as

the next EXPH-pattern. In case of the sampled Hall inputs were neither the current nor

the expected Hall pattern, the bit WHE (wrong Hall event) is set which also can cause

an interrupt and sets the IDLE mode clearing MCMP (modulation outputs are inactive).

To restart from IDLE the tran sf er req ues t o f MC M OUT S hav e to be i ni tiat ed by software

(bit STRHP and bitfields SWSEL/SWSYN).

Data Sheet 49 V 1.0, 2003-05

C868

Below is a table listing output (MCMP) for a BLDC motor.

Block Commutation Control Table

Mode CCPOS0-

CCPOS2 Inputs

CCP

CCP

CCP

OS0

OS1

OS2

Rotate left,

0° phase shift

1 0 1 inactive inactive active inactive active inactive

1 0 0 inactive inactive active active inactive inactive

1 1 0 inactive active inactive active inactive inactive

0 1 0 inactive active inactive inactive inactive active

0 1 1 active inactive inactive inactive inactive active

0 0 1 active inactive inactive inactive active inactive

Rotate right 1 1 0 active inactive inactive inactive active inactive

1 0 0 active inactive inactive inactive inactive active

1 0 1 inactive active inactive inactive inactive active

0 0 1 inactive active inactive active inactive inactive

0 1 1 inactive inactive active active inactive inactive

0 1 0 inactive inactive active inactive active inactive

Slow down X X X inactive inactive inactive active active active

1)

Idle

1)

In case of the sampled Hall inputs were neither the current nor the expected Hall pattern, the bit WHE (wrong

Hall event) is set which also can cause an interrupt and se ts the IDLE mode clearing MCMP (m odulation

outputs are inactive).

X X X inactive inactive inactive inactive inactive inactive

CC60 - CC62

Outputs

COUT60 - COUT62

Outputs

CC60 CC61 CC62 COUT60COUT61COUT6

2

Data Sheet 50 V 1.0, 2003-05

C868

For Brushless-DC motors there is a special mode (MSEL6x = ’1000b’) which is

triggered by a chang e of the Hall -inputs (CCPOS x). T his mo de sho ws the c apabil ities of

the CCU6. Here T12’s channel 0 acts in capture function, channel 1 and 2 in compare

function (without output modulation) and the multi-channel-block is used to trigger the

output switching together with a possible modulation of T13.

After the detection of a valid Hall edge the T12 count value is captured to channel 0

(representing the actual motor speed) and resets the T12. When the timer reaches the

compare value in channel 1, the next multi-channel state is switched by triggering the

shadow transfer of bit field MCMP (if enabled in bit field SWEN). This trigger event can

be combined with several conditions which are necessary to implement a noise filtering

(correct Hall event) and to synchronize the next multi-channel state to the modulation

sources (avoiding spi kes on the output line s). This compar e function of channel 1 can be

used as a phase delay for the position input to the output switching which is necessary

if a sensorless back -EMF tec hniqu e is us ed ins tead of Hall senso rs. The com pare v alue

in channel 2 can be used as a time-out trigger (interrupt) indicating that the motors

destination spee d is far below the d esired value w hich can be ca used by a abnormal load

change. In this mode the modulation of T12 has to be disabled (T12MODENx = ’0’).

ch0

act. speedCC60

phase delayCC61

timeoutCC62

capture

event resets

T12

gets

captured

value for

act. speed

ch2

for timeout

ch1

compare

for phase delay

compare

CCPOS0

CCPOS1

CCPOS2

CC6x

COUT6y

111

001

1

0

00

11 0

00

0

11

Figure 0-2 Timer T12 Brushless-DC Mode (MSEL6x = 1000)

Data Sheet 51 V 1.0, 2003-05

C868

A/D Converter

The C868 includes a high performance / high speed 8-bit A/D-Converter (ADC) with 5

analog input chann els . It op era tes with a s uc ce ss ive ap prox im ati on t ech ni que and u se s

self calibration mechanisms fo r reduction and compensation of offset and line arity errors.

The A/D converter provides the following features:

– 5 multiplexed input channels, which can also be used as digital inputs

– 8-bit resolution with TUE of +/- 2 LSB8.

– Single or continuous conversion mode

– Start of conversion by software and hardware

– Interrupt request generation after each conversion

– Using successive approximation conversion technique via a capacitor array

– Powerdow n in normal, idle and slow-down modes

The ADC supports two conversion modes - single and continuous conversions. For

each mode, there are two wa ys in whi ch conv ersion ca n be st arted - by softw are and by

the T13PM signal from the CCU module.

Writing a ‘0’ to bit CCU_ADEX select conversion control by ADST. Writing a ’1’ to bit

field ADST starts conversion on the channel that is specified by ADCH. In single

conversion mode, bit field ADM is cleared to ’0’. This is the default mode selected after

hardware re set. When a conve rsion is started , the channel spec ified is sample d. The

busy flag ADBSY is set and ADST is cleared. When the conversion is completed, the

interrupt request signal ADCIRQ is asserted possitively for 2 clocks and the 8-bit result

together with the number of the converted channel is transferred to the result register

ADDATH.

In continuous conversion mode, bit field ADM is set to ’1’. In this mode, the ADC

repeatedly converts the channel specified by ADCH. Bit ADST is cleared at the

beginning of the first conversion. The busy flag ADBSY is asserted until the last

conversion is completed. At the end of each conversion, the interrupt request signal

ADCIRQ will be activated. To stop conversion, ADM has to be reset by software. If the

channel number ADCH is changed while continuous conversion is in progress, the new

channel specified will be sampled in the conversions that follow.

A new request to start conversion will be allowed only after the completion of any

conversion that is in progress.

Writing a ‘1’ to bit CCU_ADEX select conversion control by T13PM trigger signal from

the CCU module.

Note: Caution must be taken when changing conversion start source. To change

conversion source from software to hardware trigger, it is best to let remaining

software conversion to complete before changing. To chan ge co nv ersi on sourc e

from hardware trigger to software, it is best to change source first, let any

Data Sheet 52 V 1.0, 2003-05

C868

remaining hardware conversion to complete before beginning a software

conversion.

Conversion and sample time control

The conversion and sa mple times a re programmed v ia the bit field s ADCTC and ADSTC

respectively of the register ADCON1. Bit field ADCTC (conversion time c ont rol) selects

the internal ADC clock - adc_clk. Bit field ADSTC (sample time control) selects the

sample time.

The total A/D conversion time is given by:

= 2/f