Data Sheet, Feb. 2003

C515C

8-Bit Single-Chip Microcontroller

Microcontrollers

Never stop thinking.

Edition 2003-02

Published by Infineon Technologies AG,

St.-Martin-Strasse 53,

81669 München, Germany

© Infineon Technologies AG 2003.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as a guarantee of

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide

(www.infineon.com).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Data Sheet, Feb. 2003

C515C

8-Bit Single-Chip Microcontroller

Microcontrollers

Never stop thinking.

C515C Data Sheet

Revision History: 2003-02

Previous Version: 2000-08

Page Subjects (major changes since last revision)

Enhanced Hooks Technology™ is a trademark of Infineon Technologies.

We Listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continuously improve the quality of this document.

Please send your proposal (including a reference to this document) to:

mcdocu.comments@infineon.com

Features

• Full upward compatibility with SAB 80C515A

• On-chip program memory (with optional memory protection)

– C515C-8R 64 Kbytes on-chip ROM

– C515C-8E 64 Kbytes on-chip OTP

– alternatively up to 64 Kbytes external program memory

• 256 bytes on-chip RAM

• 2 Kbytes of on-chip XRAM

• Up to 64 Kbytes external data memory

• Superset of the 8051 architecture with 8 datapointers

• Up to 10 MHz external operating frequency (1

external clock)

• On-chip emulation support logic (Enhanced Hooks Technology)

• Current optimized oscillator circuit and EMI optimized design

µs instruction cycle time at 6 MHz

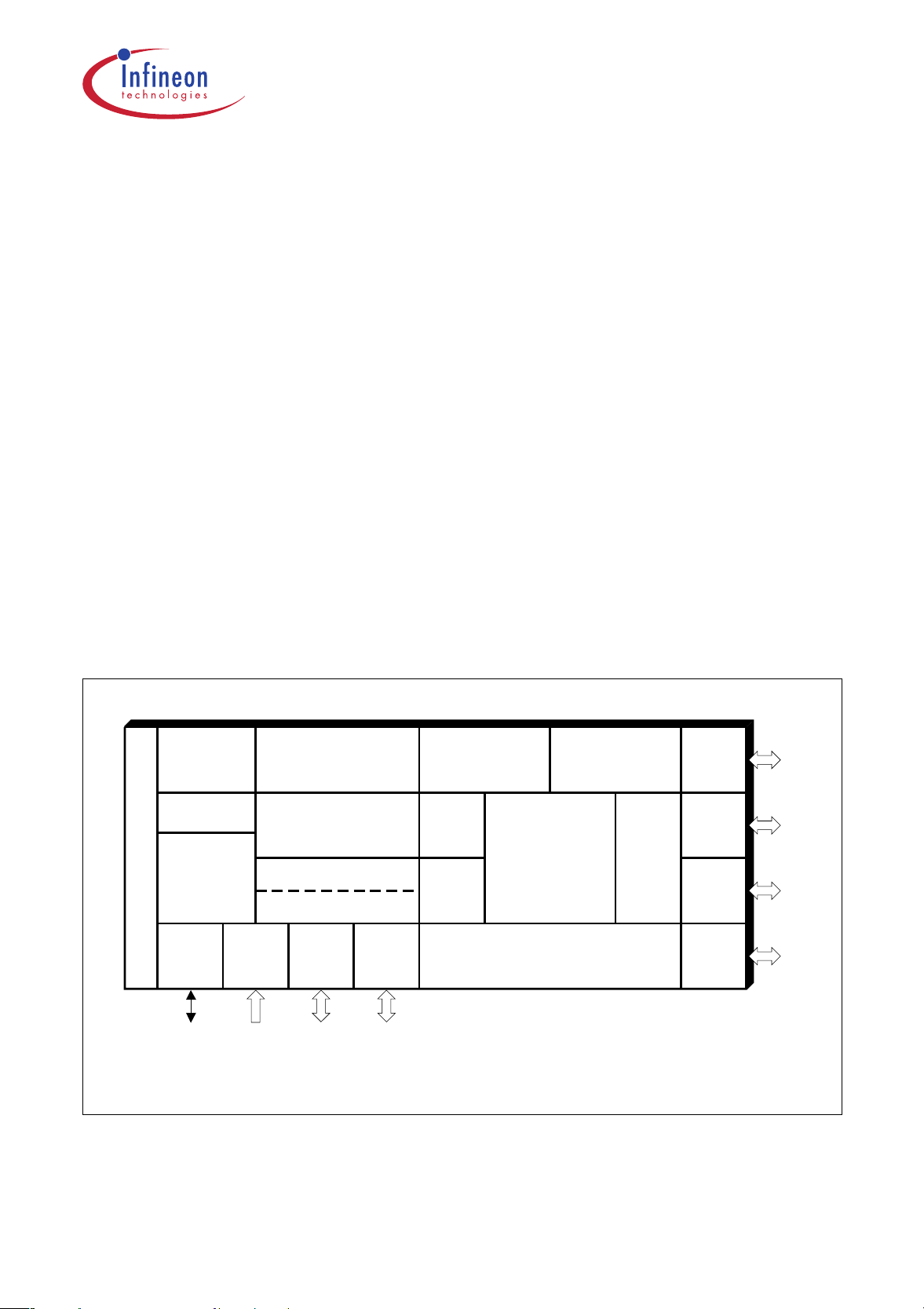

C515C8-Bit Single-Chip Microcontroller

(further features are on next page)

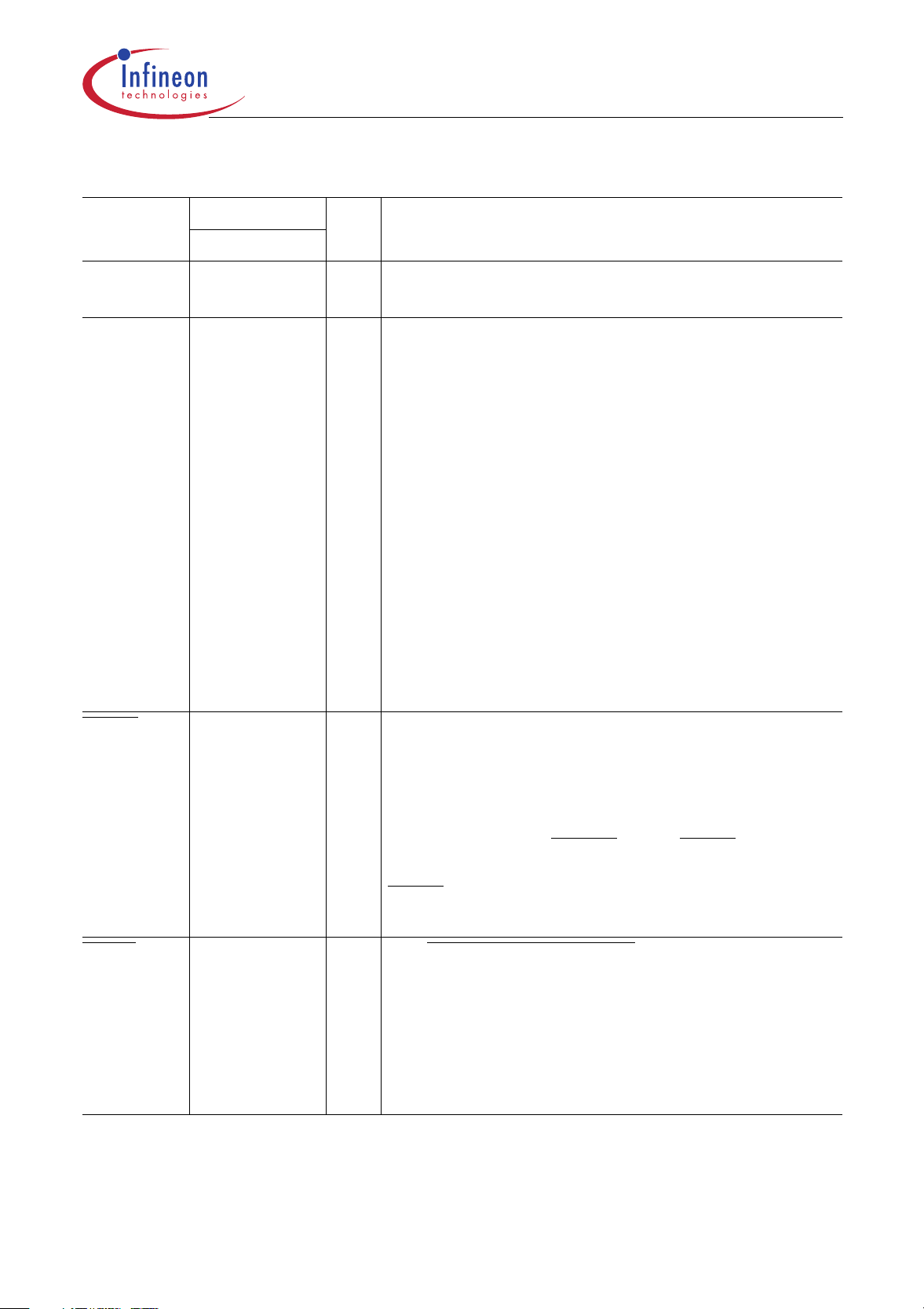

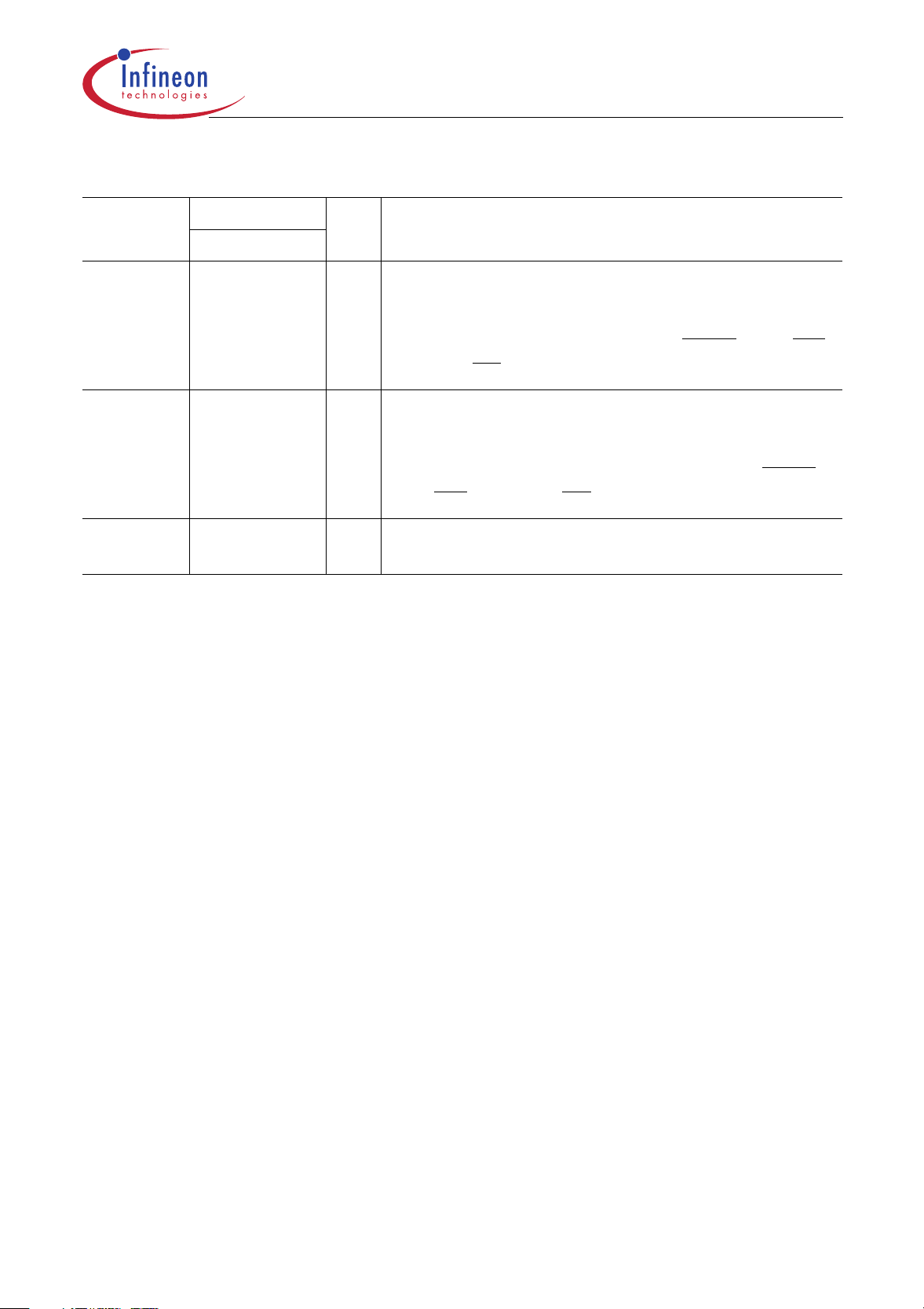

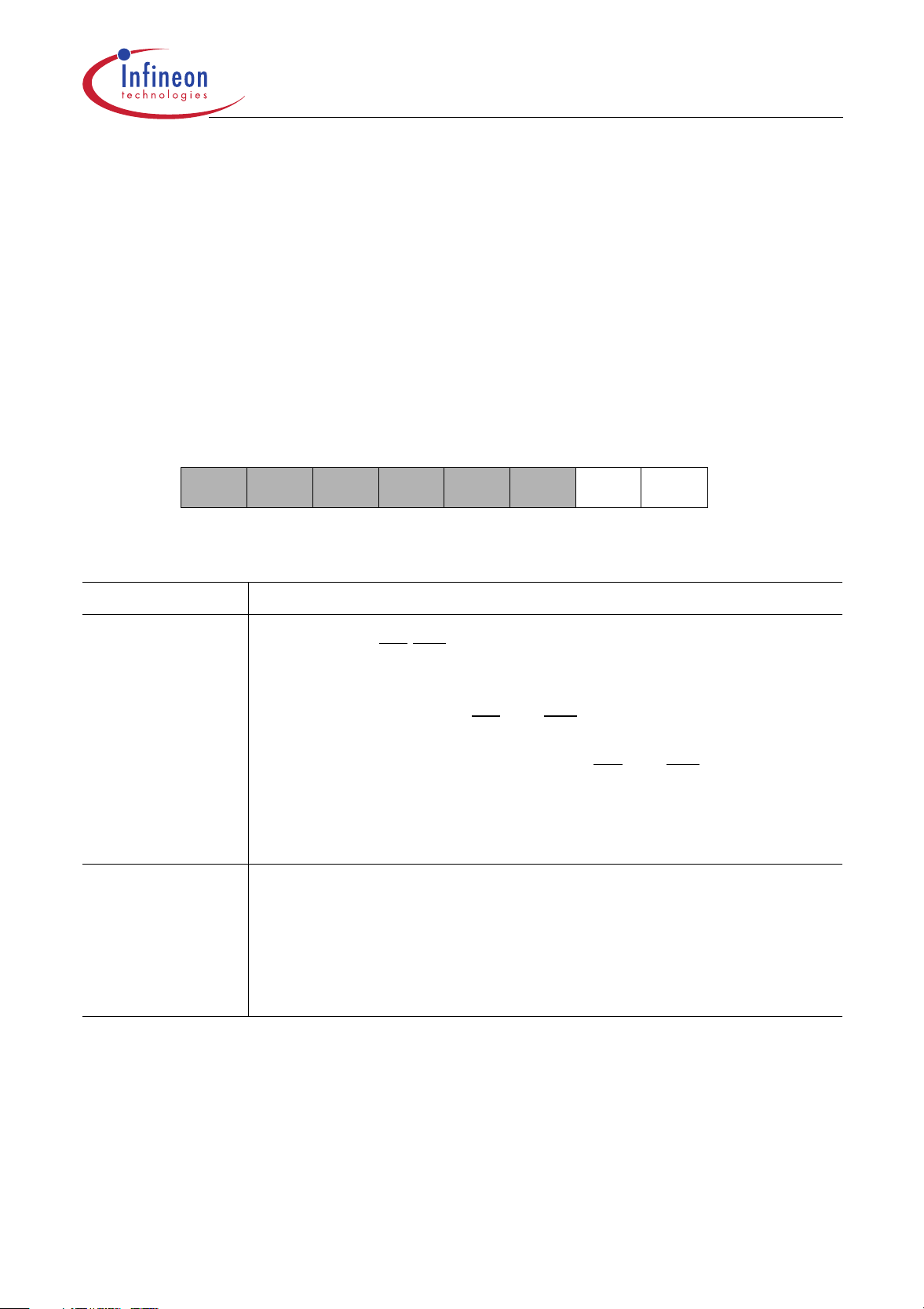

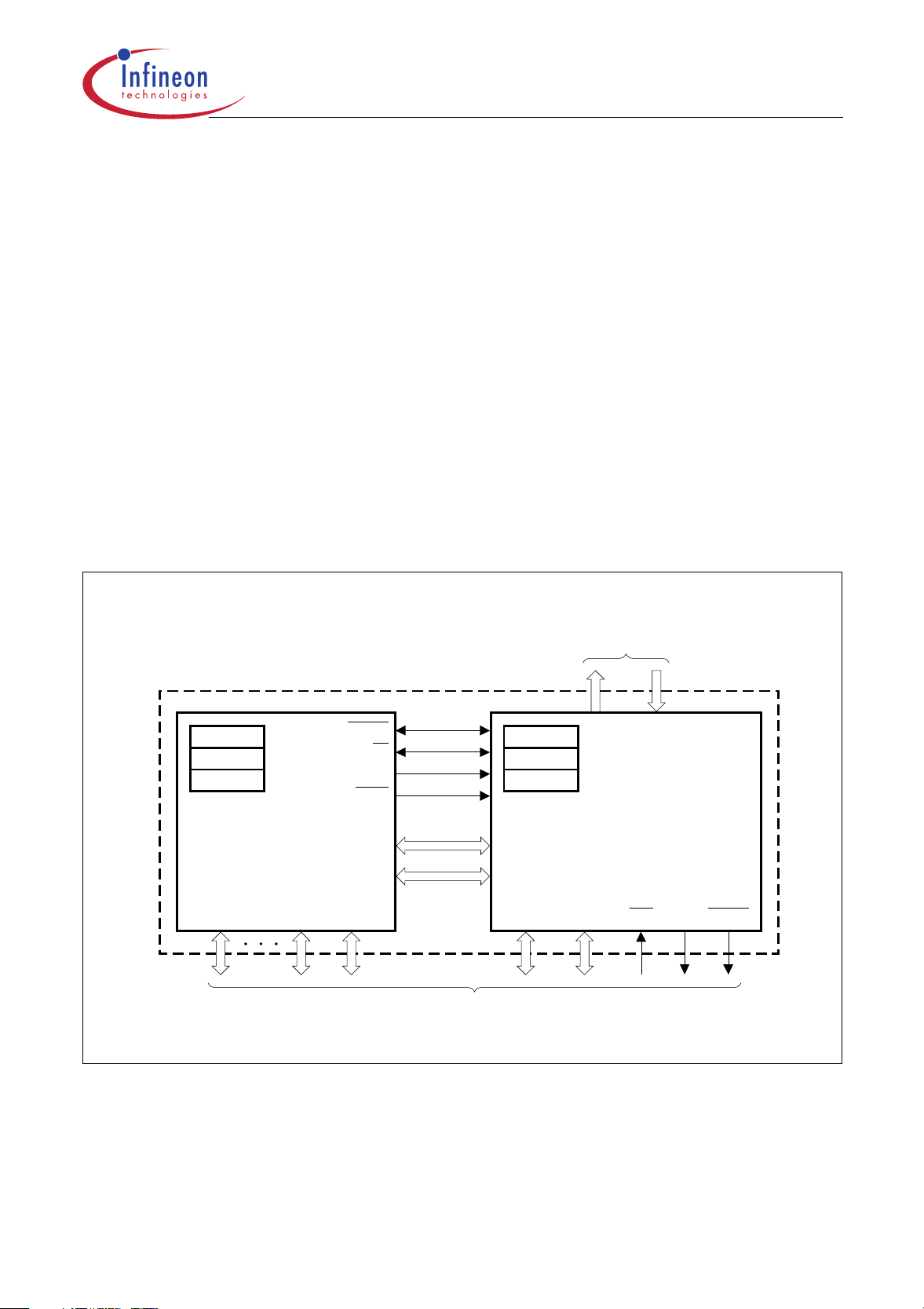

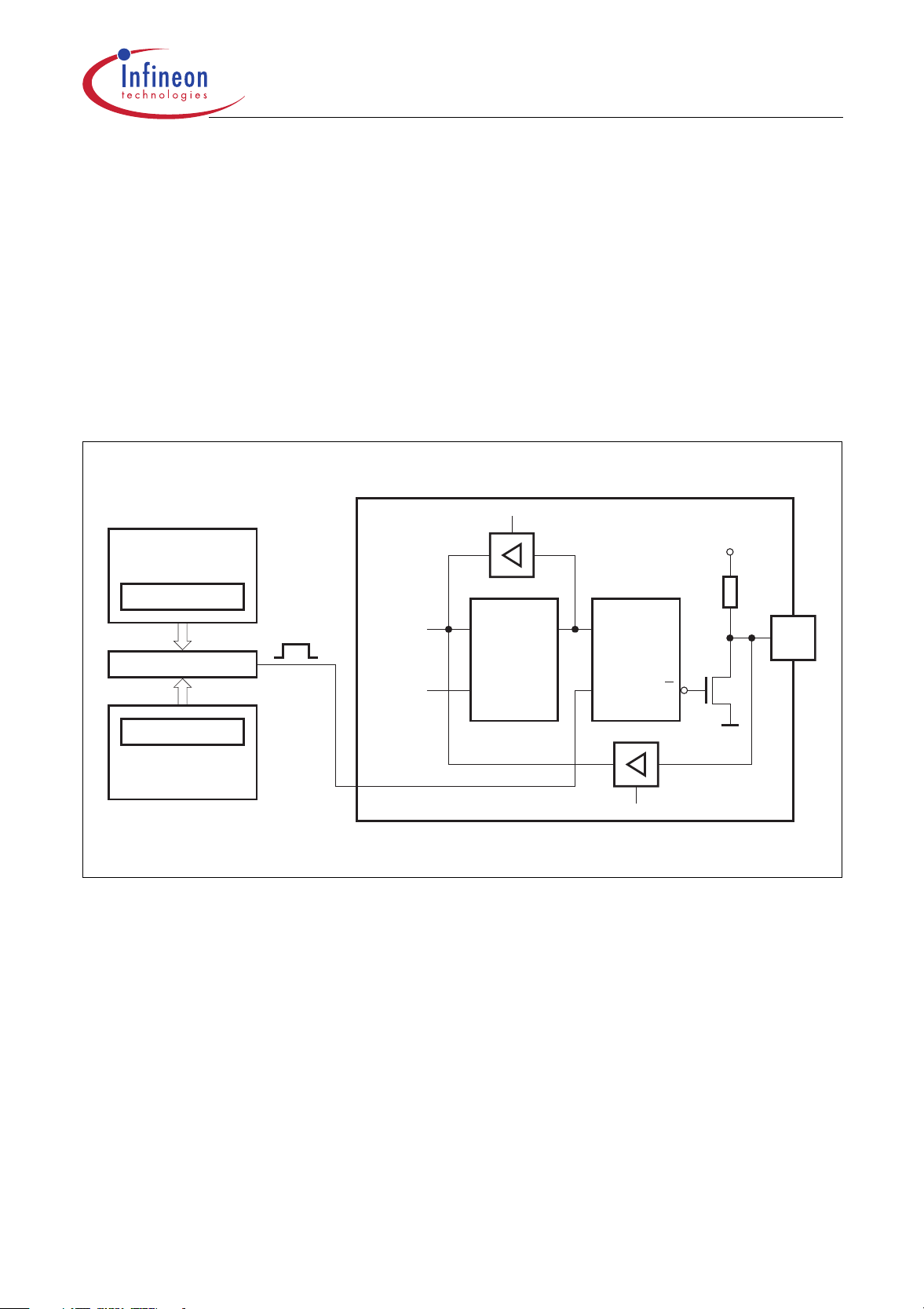

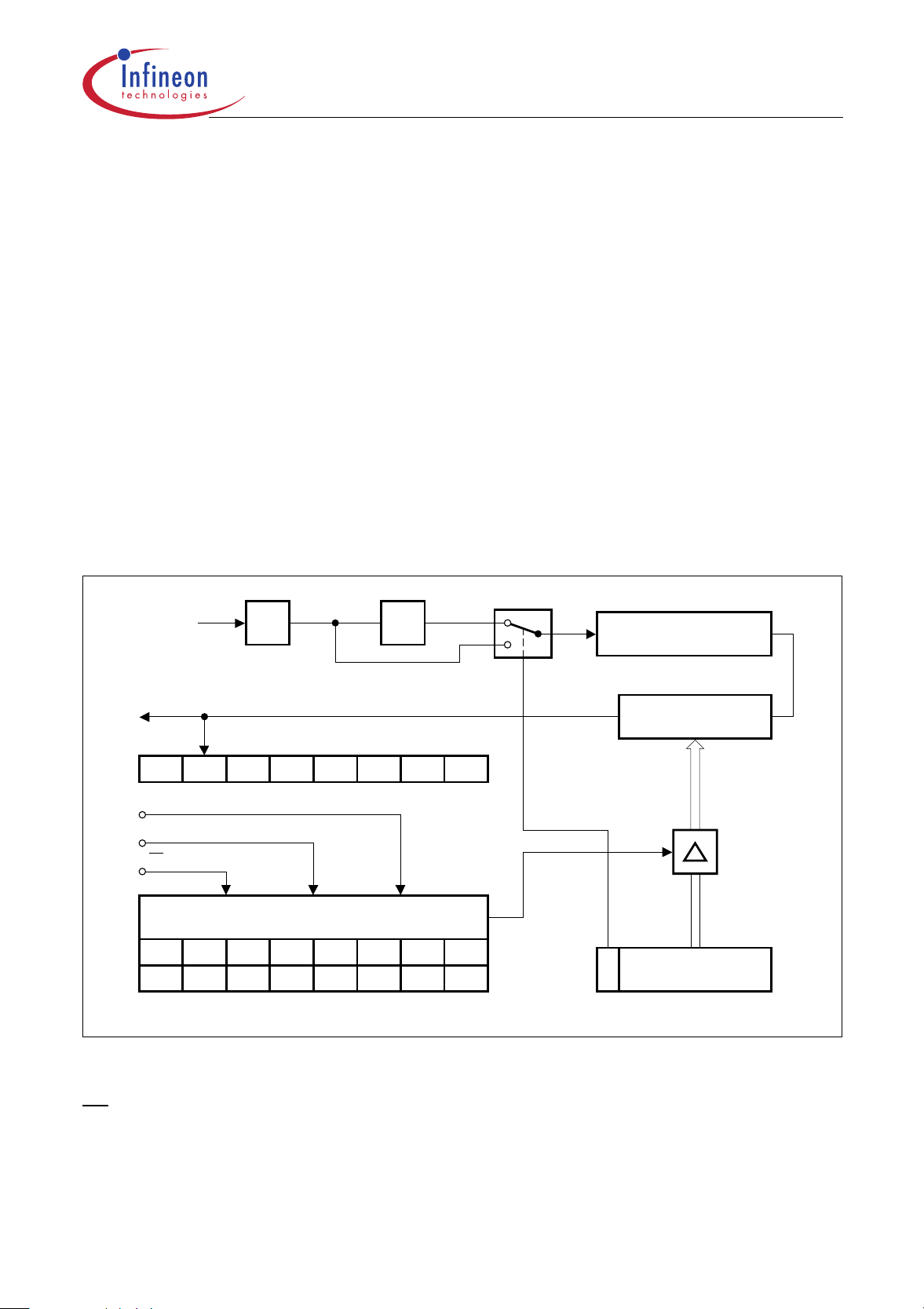

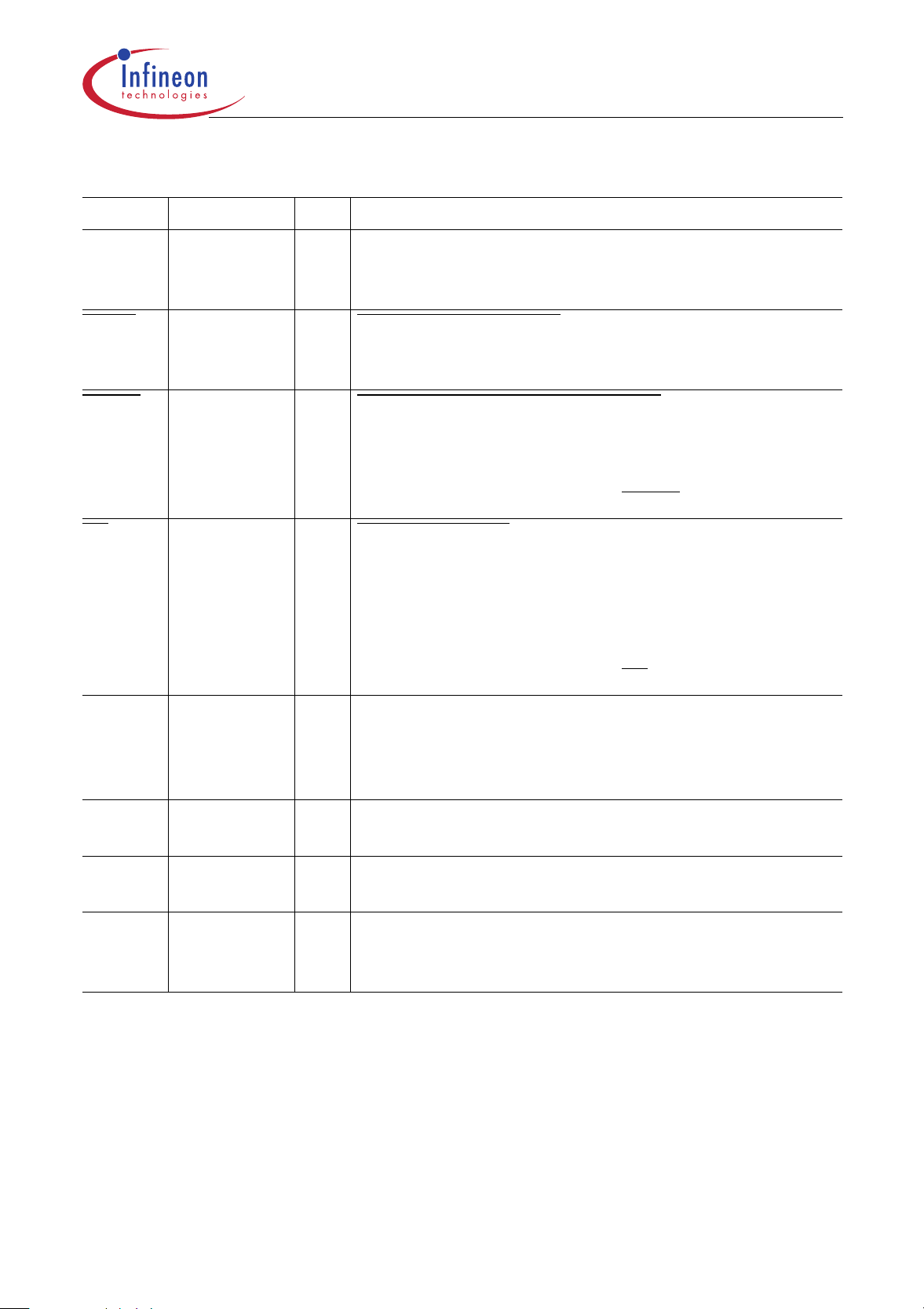

SSC (SPI)

Interface

Oscillator

Watchdog

Power

Save Modes

Idle/

Power down

Slow down

On-Chip Emulation Support Module

Port 7 Port 6 Port 5 Port 4

I/O I/O I/OAnalog/

Digital

Input

Full-CAN

Controller

10 Bit ADC

(8 inputs)

Timer 2

Capture/Compare Unit

XRAM

2k x 8

T0

CPU

8 Datapointer

T1

Program Memory

C515C-8R : 64k x 8 ROM

C515C-8E : 64k x 8 OTP

RAM

256 x 8

USART

Port 0

Port 1

Bit8

Port 2

Port 3

I/O

I/O

I/O

I/O

MCA03646

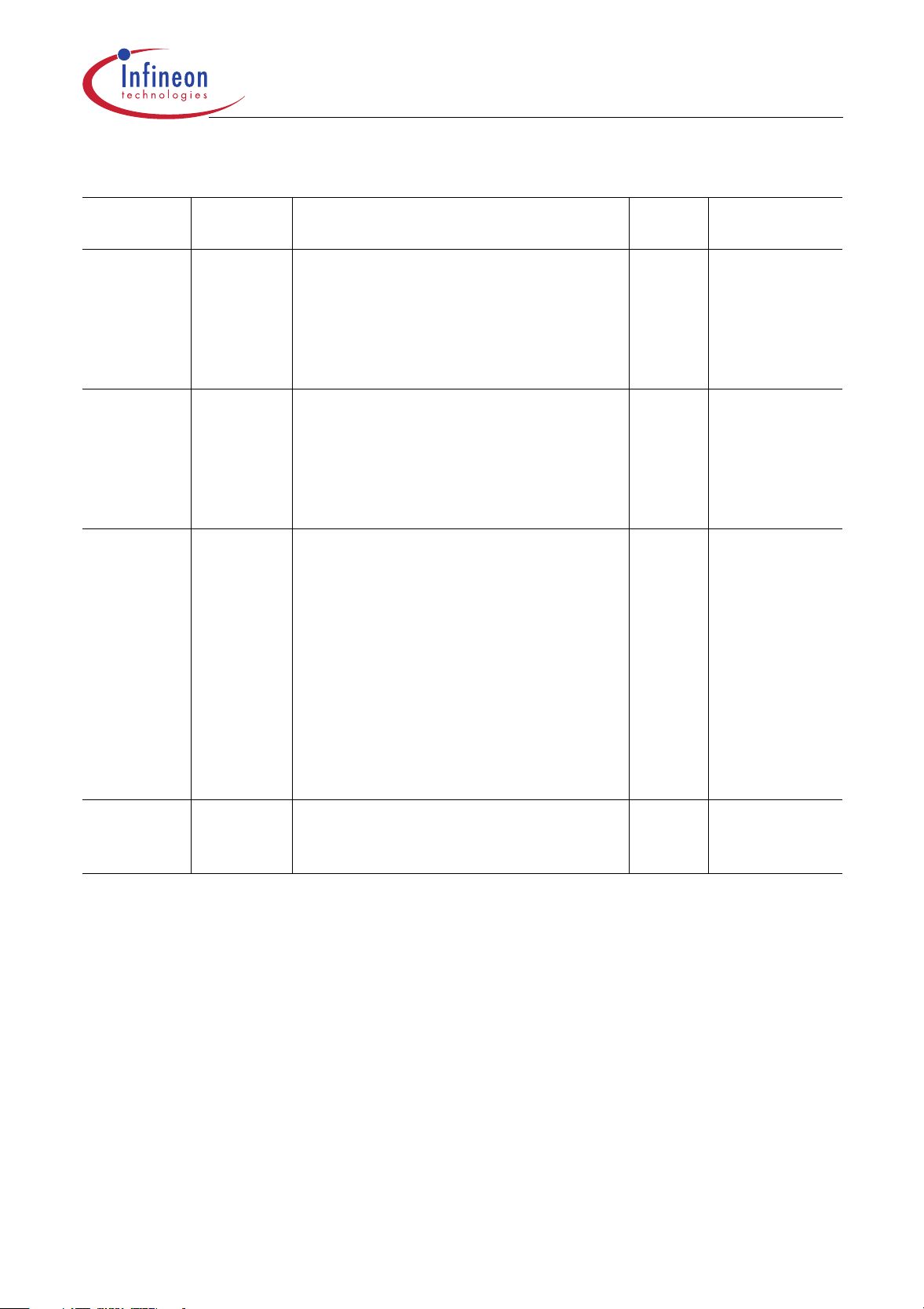

Figure 1 C515C Functional Units

Data Sheet 1 2003-02

• Eight ports: 48 + 1 digital I/O lines, 8 analog inputs

– Quasi-bidirectional port structure (8051 compatible)

– Port 5 selectable for bidirectional port structure (CMOS voltage levels)

• Full-CAN controller on-chip

– 256 register/data bytes are located in external data memory area

– max. 1 MBaud at 8 - 10 MHz operating frequency

• Three 16-bit timer/counters

– Timer 2 can be used for compare/capture functions

• 10-bit A/D converter with multiplexed inputs and built-in self calibration

• Full duplex serial interface with programmable baudrate generator (USART)

• SSC synchronous serial interface (SPI compatible)

– Master and slave capable

– Programmable clock polarity/clock-edge to data phase relation

– LSB/MSB first selectable

– 2.5 MHz transfer rate at 10 MHz operating frequency

• Seventeen interrupt vectors, at four priority levels selectable

• Extended watchdog facilities

– 15-bit programmable watchdog timer

– Oscillator watchdog

• Power saving modes

–Slow-down mode

– Idle mode (can be combined with slow-down mode)

– Software power-down mode with wake-up capability through INT0

or RXDC pin

– Hardware power-down mode

• CPU running condition output pin

• ALE can be switched off

• Multiple separate

V

DD/VSS

pin pairs

• P-MQFP-80-1 package

• Temperature Ranges:

SAB-C515C versions:

SAF-C515C versions:

SAH-C515C versions:

Note: Versions for extended temperature range -40

T

= 0 to 70 °C

A

T

= -40 to 85 °C

A

T

= -40 to 110 °C

A

°C to 110 °C (SAH-C515C) are

available on request.

C515C

The C515C is an enhanced, upgraded version of the SAB 80C515A 8-bit microcontroller

which additionally provides a full CAN interface, a SPI compatible synchronous serial

interface, extended power save provisions, additional on-chip RAM, 64K of on-chip

program memory, two new external interrupts and RFI related improvements. With a

maximum external clock rate of 10 MHz it achieves a 600 ns instruction cycle time (1

µs

at 6 MHz).

Data Sheet 2 2003-02

C515C

The C515C-8R contains a non-volatile 64 Kbytes read-only program memory. The

C515C-L is identical to the C515C-8R, except that it lacks the on-chip program memory.

The C515C-8E is the OTP version in the C515C microcontroller with an on-chip

64 Kbytes one-time programmable (OTP) program memory. The C515C is mounted in

a P-MQFP-80-1 package.

If compared to the C515C-8R and C515C-L, the C515C-8E OTP version additionally

provides two features:

• The wake-up from software power down mode can, additionally to the external pin

P3.2/INT0

P4.7/RXDC.

• For power consumption reasons the on-chip CAN controller can be switched off.

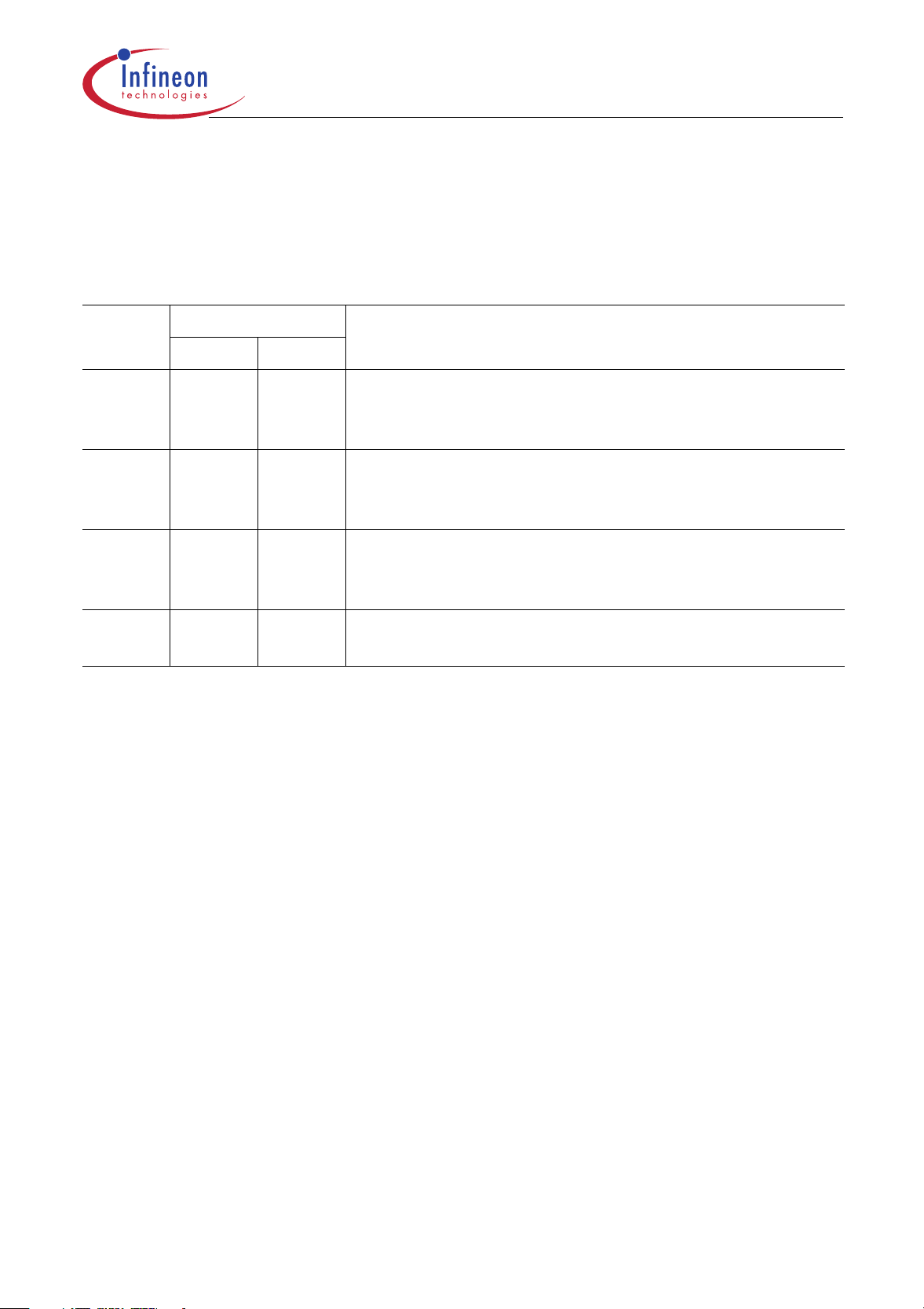

Table 1 Differences in Internal Program Memory of the C505 MCUs

Device Internal Program Memory

wake-up capability, also be triggered alternatively by a second pin

ROM OTP

C515C-LM

––

C515C-8RM 64 Kbytes –

C515C-8EM – 64 Kbytes

Note: The term C515C refers to all versions described within this document unless

otherwise noted.

Ordering Information

The ordering code for Infineon Technologies’ microcontrollers provides an exact

reference to the required product. This ordering code identifies:

• The derivative itself, i.e. its function set

• The specified temperature rage

• The package and the type of delivery

For the available ordering codes for the C515C please refer to the “Product information

Microcontrollers”, which summarizes all available microcontroller variants.

Note: The ordering codes for the Mask-ROM versions are defined for each product after

verification of the respective ROM code.

Data Sheet 3 2003-02

C515C

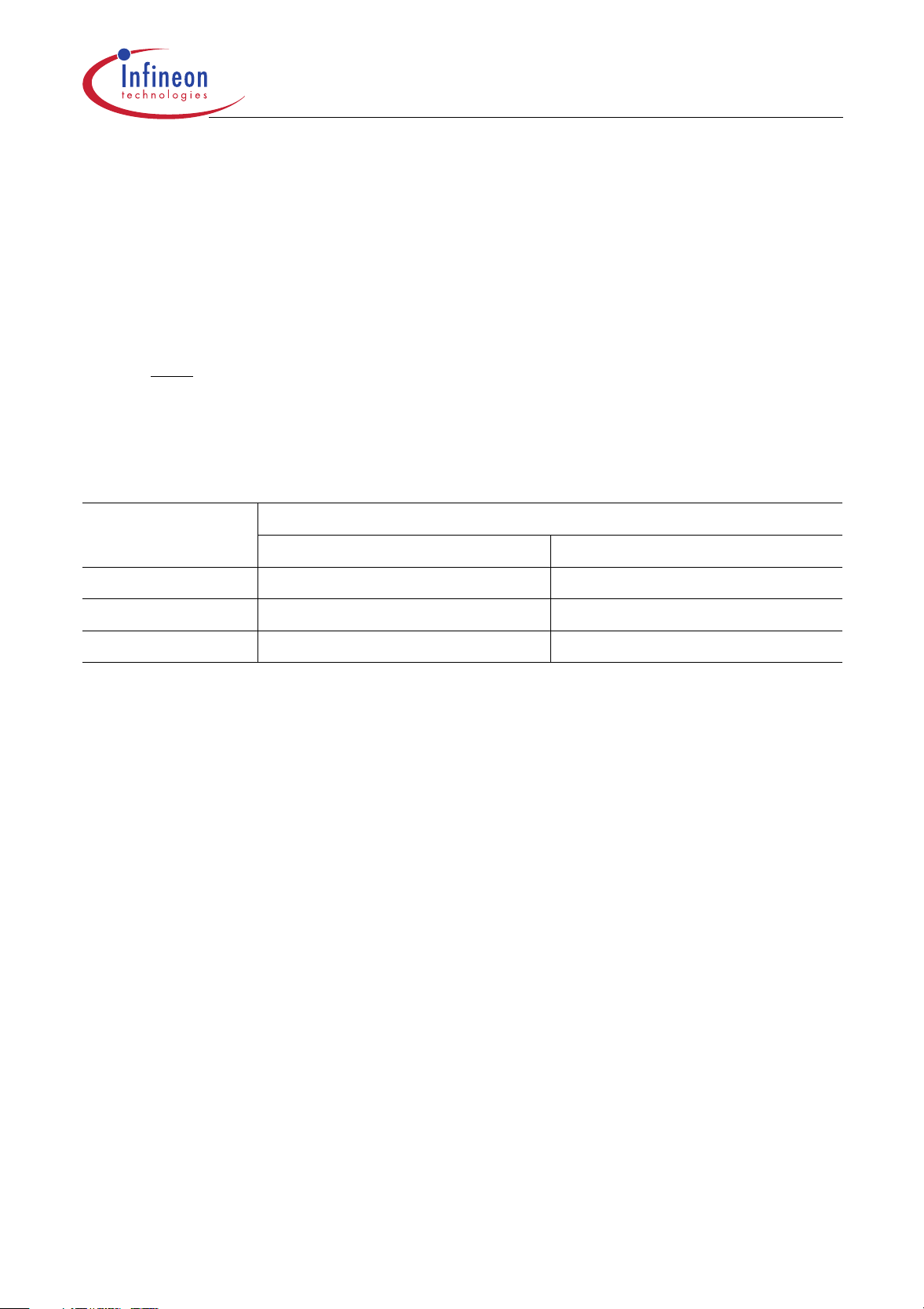

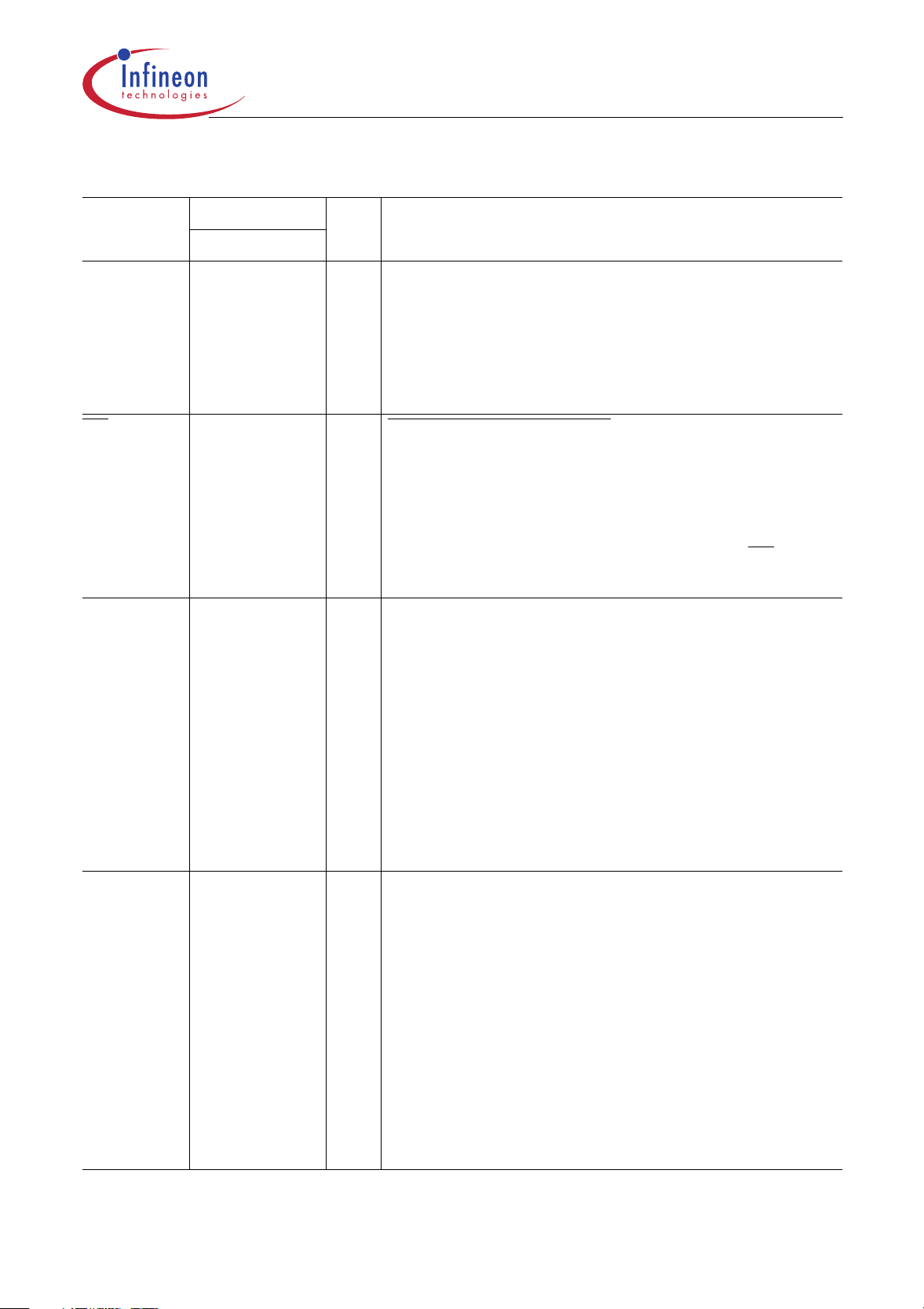

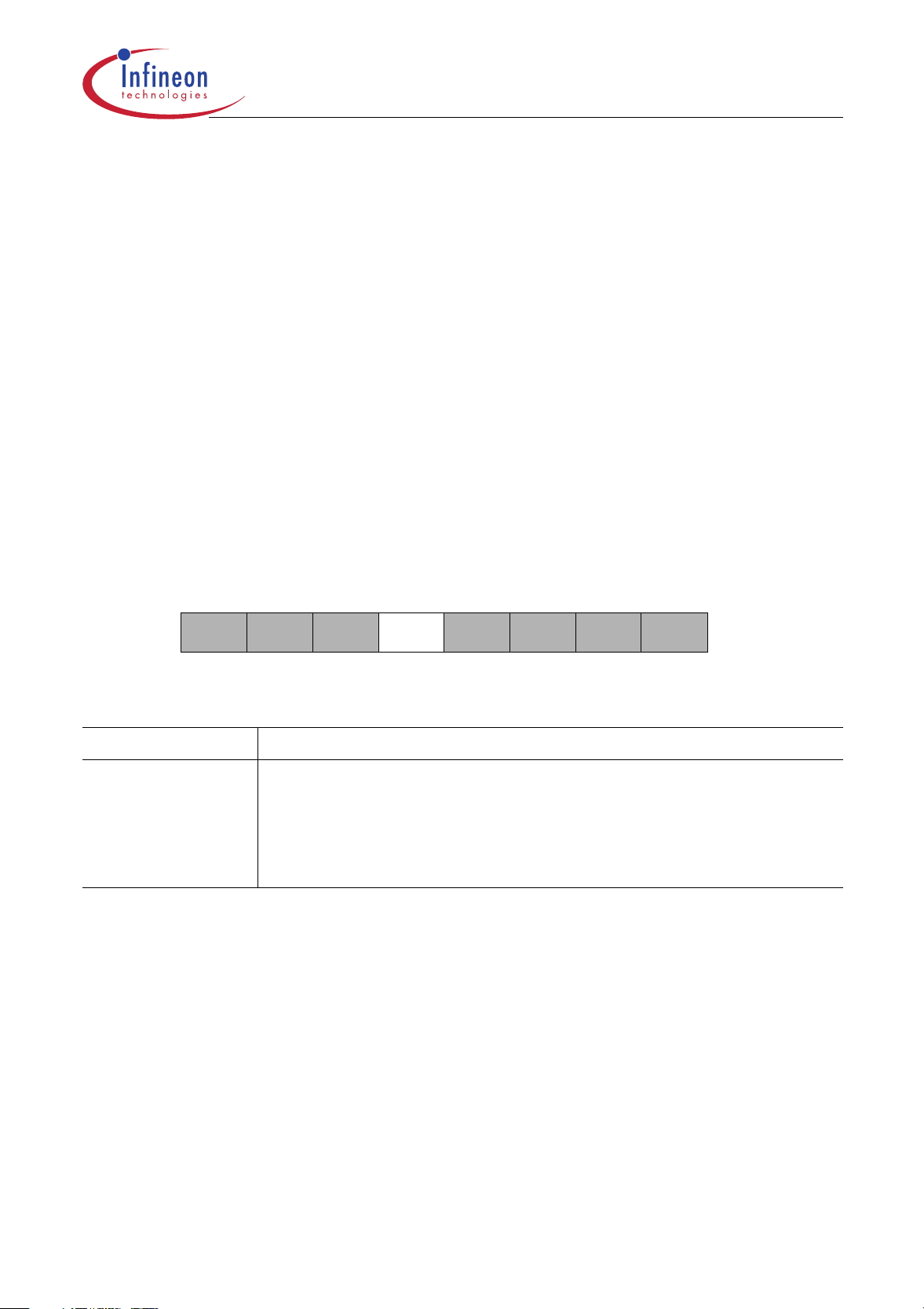

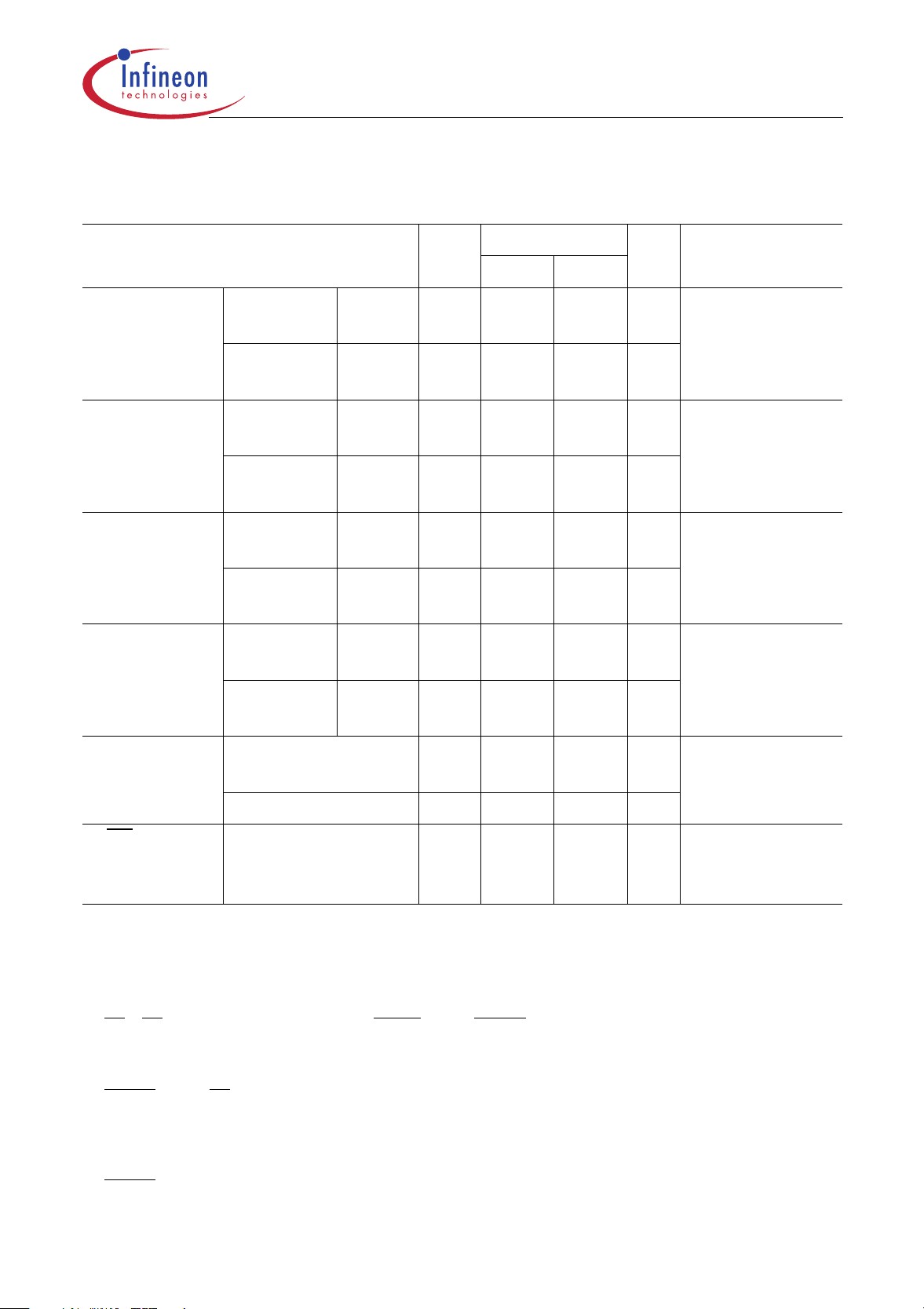

XTAL1

XTAL2

ALE

PSEN

EA

RESET

PE/SWD

HWPD

CPUR

V

SSE1

V

DDE1

V

SSE2

V

DDE2

V

C515C

V

AREFAGND

Port 0

8 Bit Digital I/O

Port 1

8 Bit Digital I/O

Port 2

8 Bit Digital I/O

Port 3

8 Bit Digital I/O

Port 4

8 Bit Digital I/O

Port 5

8 Bit Digital I/O

Port 6

8 Bit Analog/

Digital Inputs

Port 7

1 Bit Digital I/O

V

SS1

V

DD1

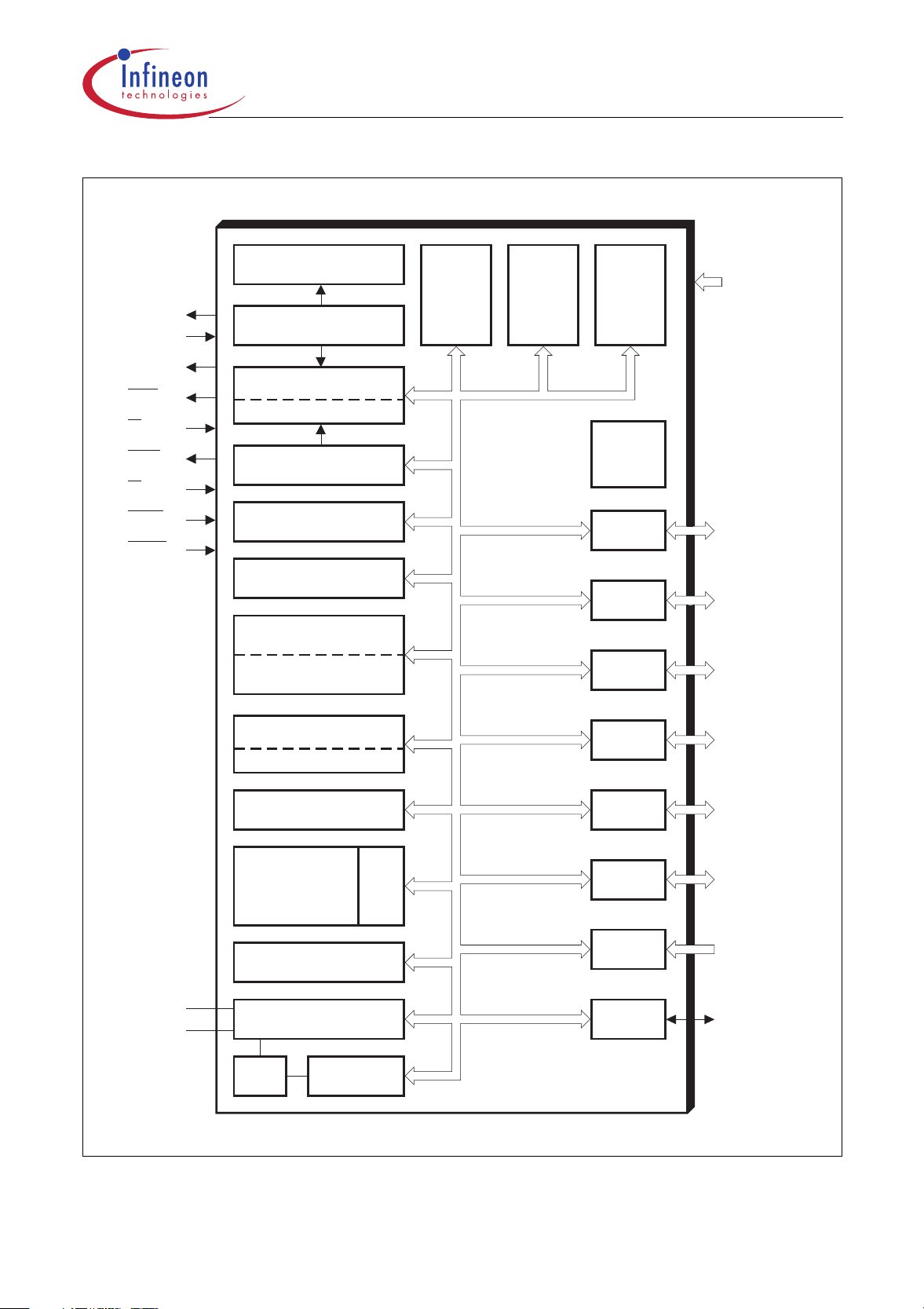

Figure 2 Logic Symbol

V

SSCLK

V

DDCLK

V

SSEXT

V

DDEXT

MCL02714

Data Sheet 4 2003-02

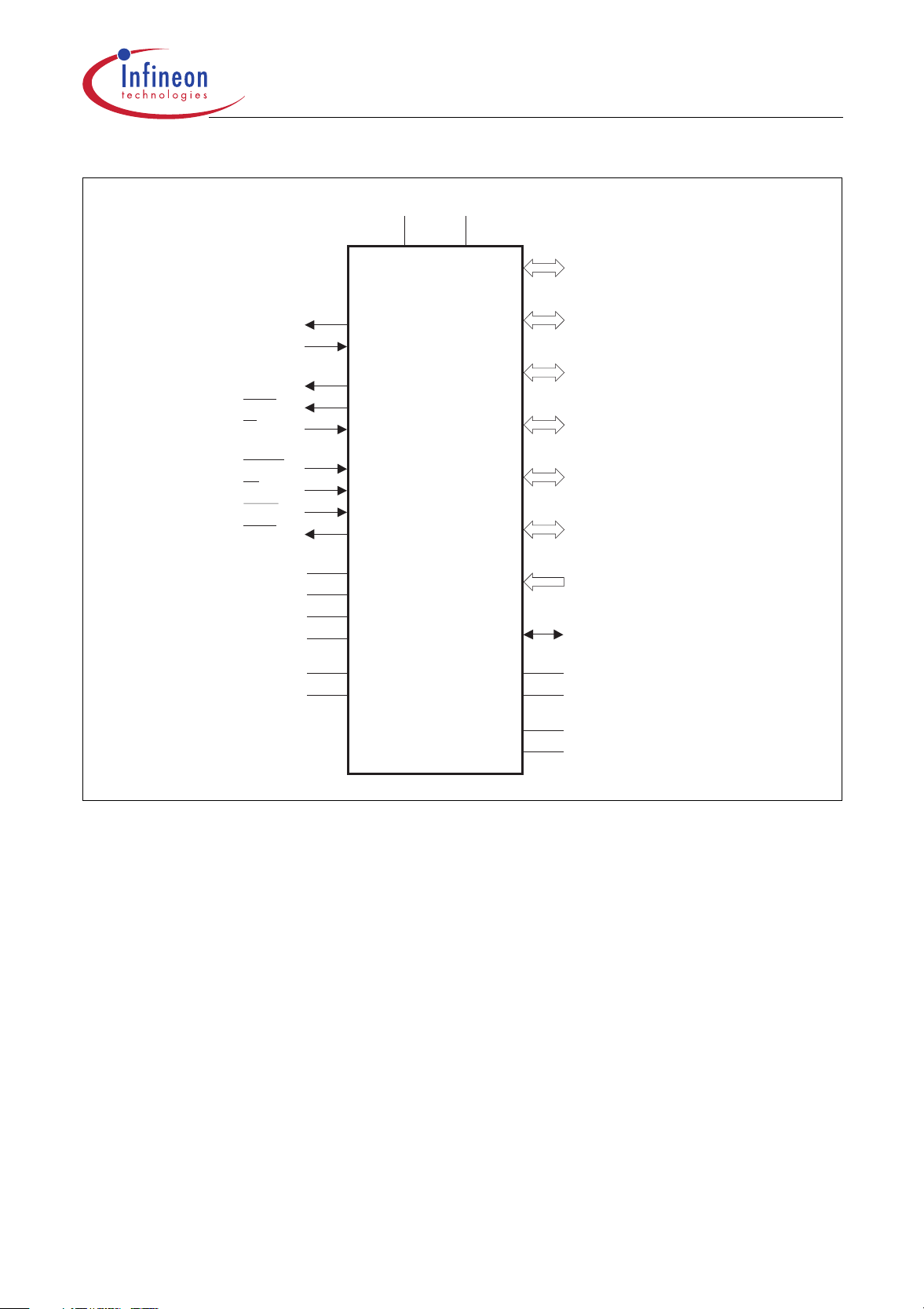

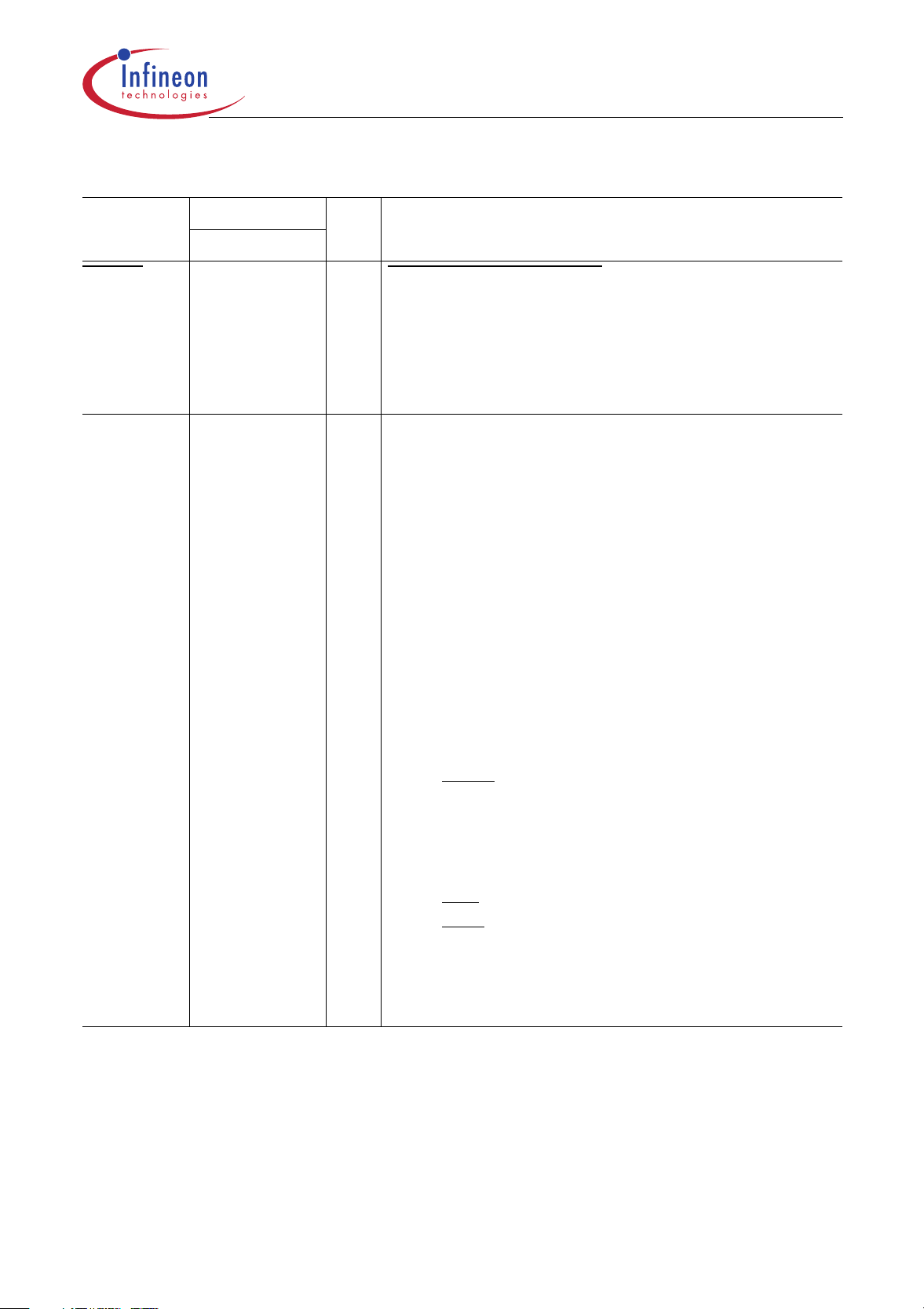

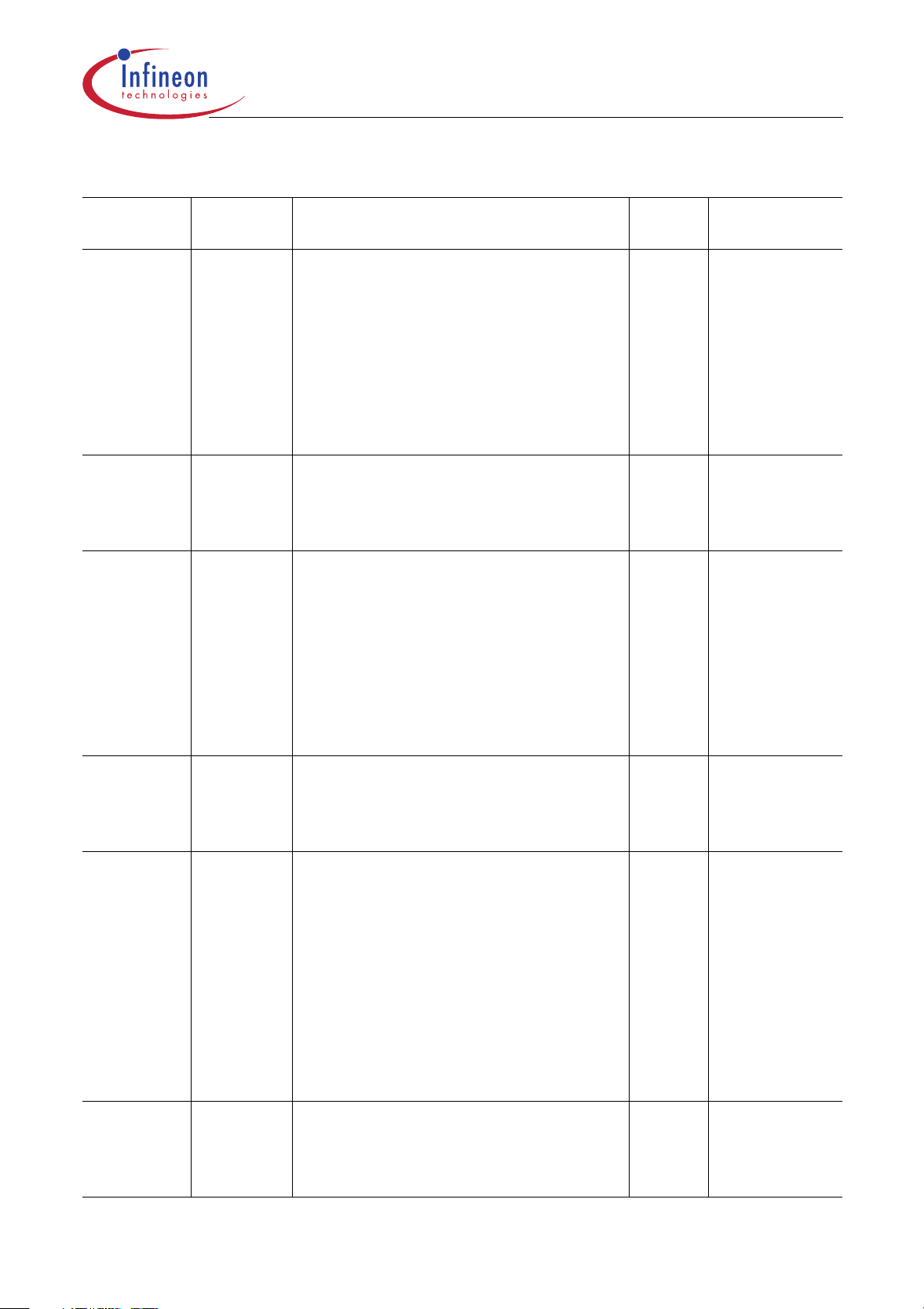

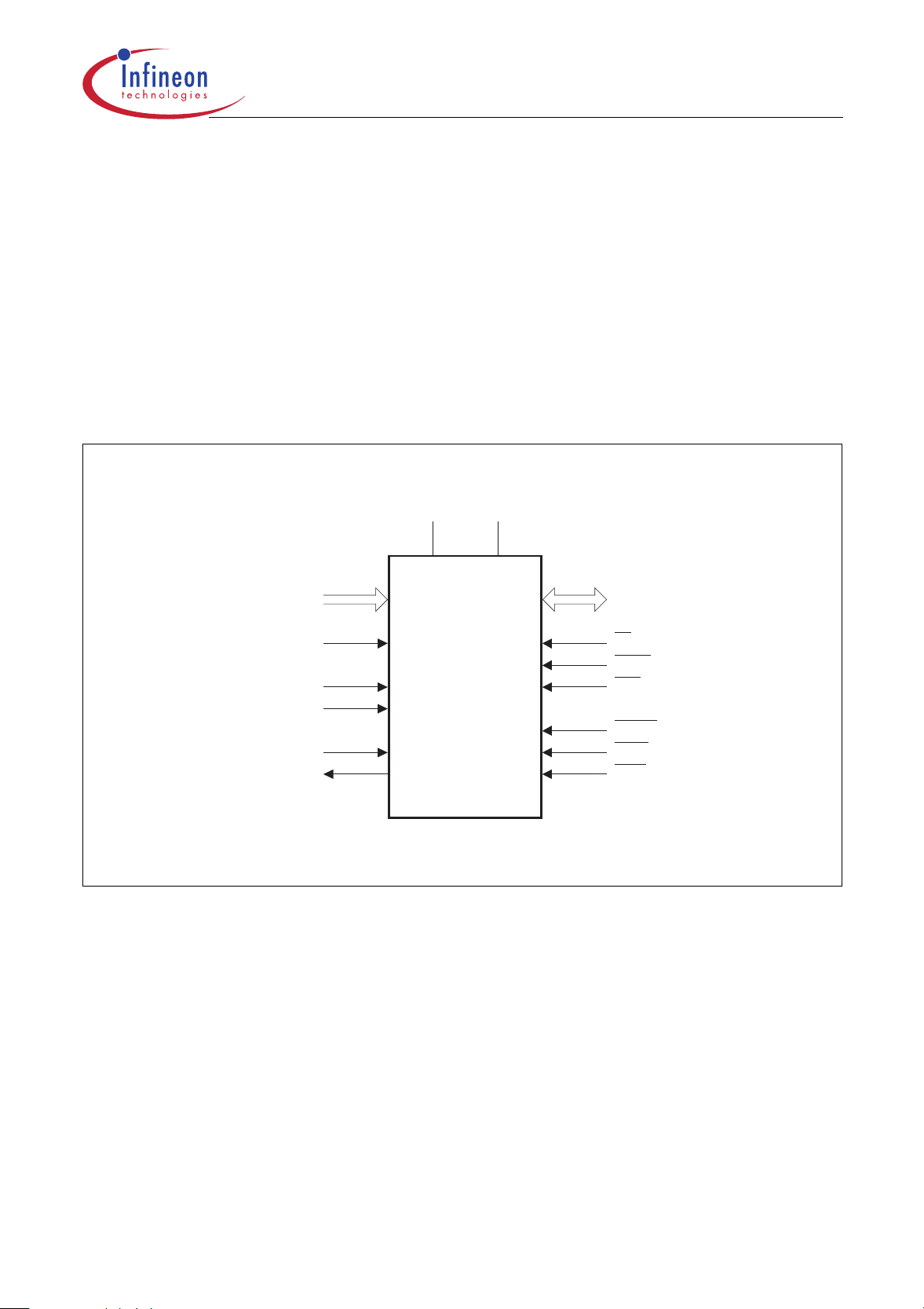

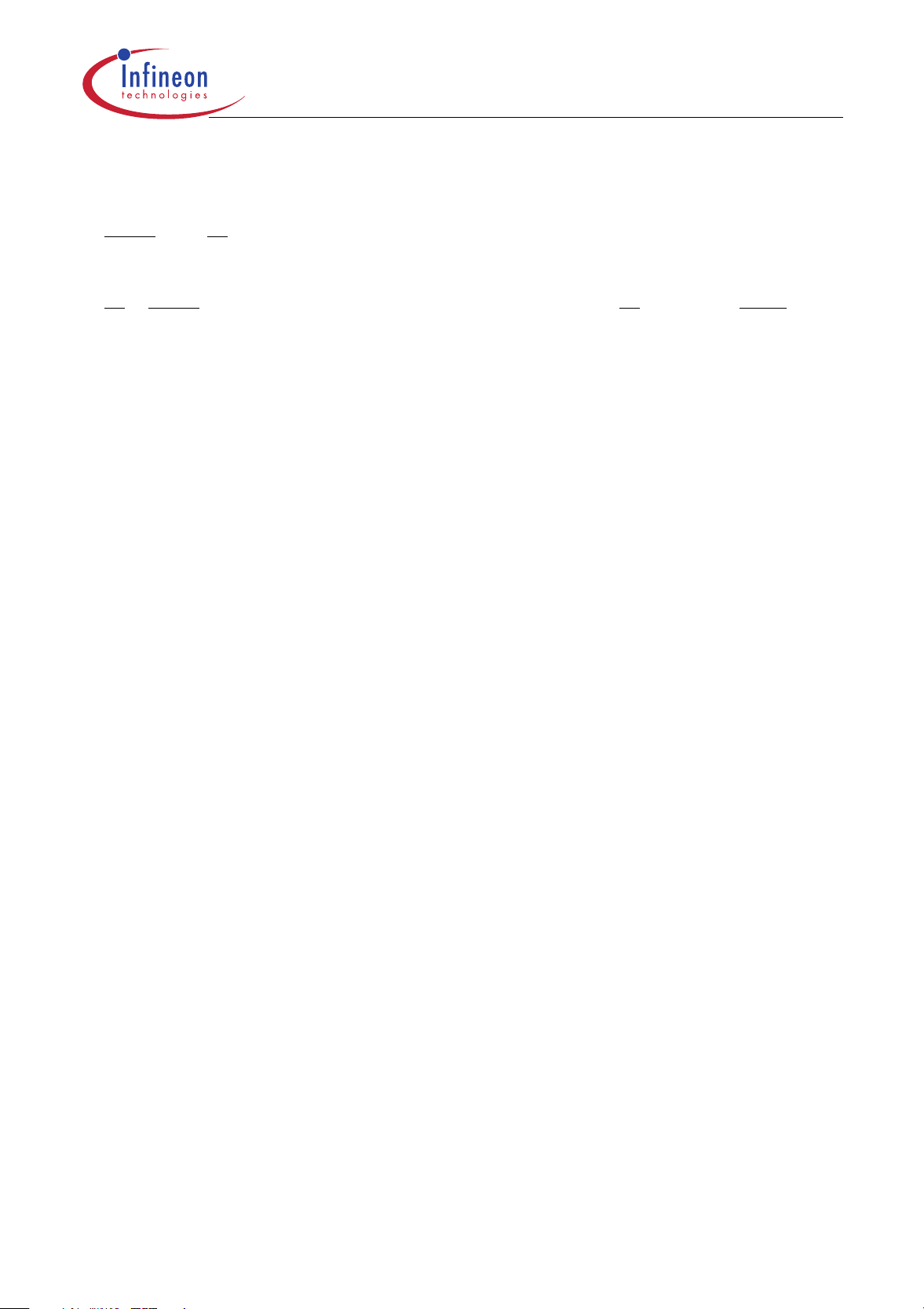

C515C

DDEXT

P0.7/AD7

P5.7

P0.6/AD6

P0.5/AD5

P0.4/AD4

P0.3/AD3

P0.2/AD2

SSEXT

P0.1/AD1

P0.0/AD0EAALE

V

V

PSEN

CPUR

P2.7/A15

P2.6/A14

P2.5/A13

P2.4/A12

P2.3/A11

4142434445464748495051525354555657585960

P5.6

P5.5

P5.4

P5.3

P5.2

P5.1

P5.0

V

DDE2

HWPD

V

SSE2

N.C.

P4.0/ADST

P4.1/SCLK

P4.2/SRI

PE/SWD

P4.3/STO

P4.4/SLS

P4.5/INT8

P4.6/TXDC

P4.7/RXDC

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

12

345

4061

39

38

37

36

35

34

33

32

C515C

31

30

29

28

27

26

25

24

23

22

21

6

7

8

9

10

11

12

13 14 15

16

17

18

19

20

P2.2/A10

P2.1/A9

P2.0/A8

XTAL1

XTAL2

V

SSE1

V

SS1

V

DD1

V

DDE1

P1.0/INT3/CC0

P1.1/INT4/CC1

P1.2/INT5/CC2

P1.3/INT6/CC3

P1.4/INT2

P1.5/T2EX

P1.6/CLKOUT

P1.7/T2

P7.0/INT7

P3.7/RD

P3.6/WR

N.C.

AREF

V

RESET

AGND

V

P6.7/AIN7

P6.5/AIN5

P6.6/AIN6

P6.3/AIN3

P6.4/AIN4

P6.2/AIN2

SSCLK

DDCLK

V

V

P6.0/AIN0

P6.1/AIN1

P3.1/TXD

P3.0/RXD

P3.2/INT0

P3.3/INT1

P3.4/T0

P3.5/T1

MCP02715

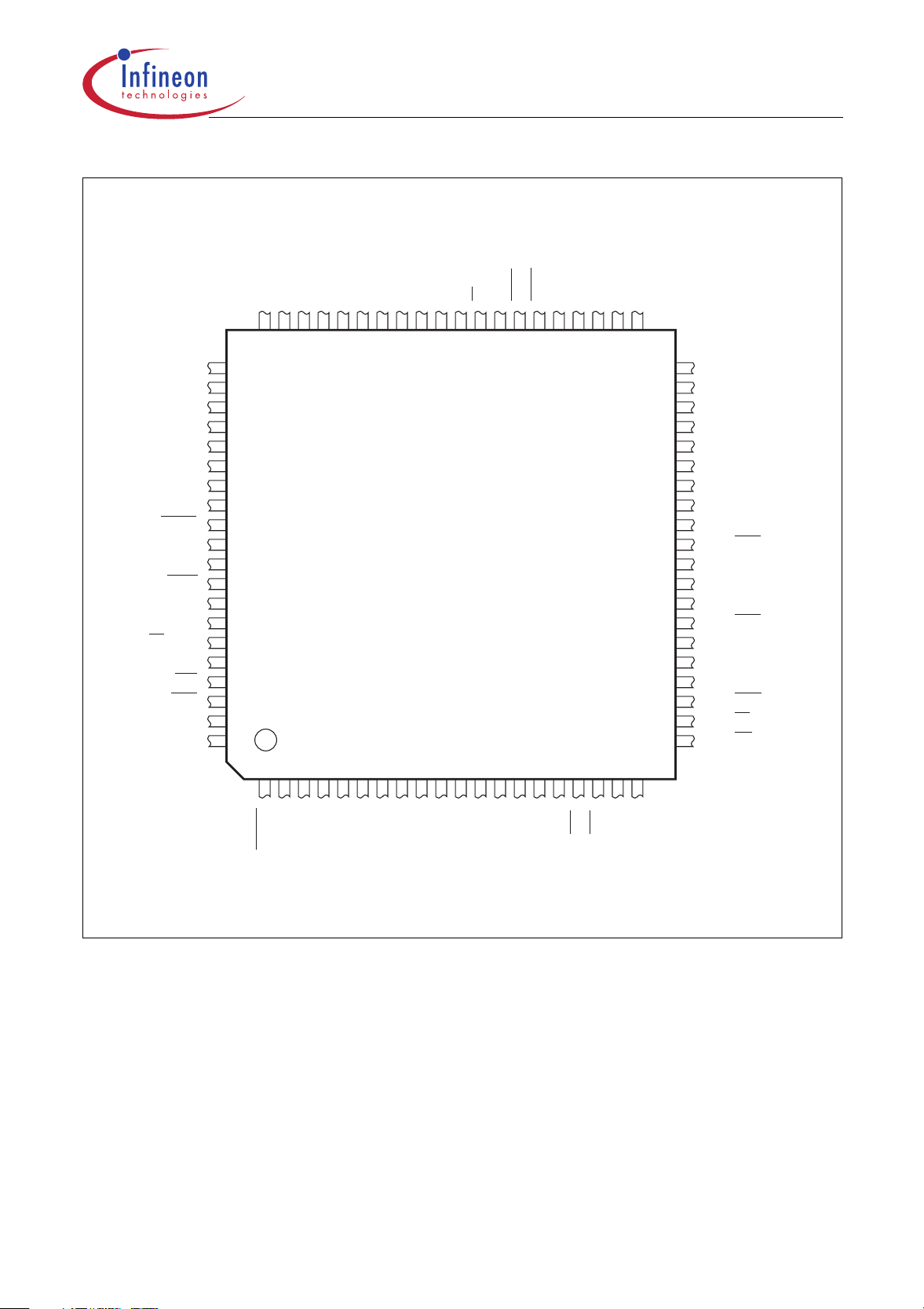

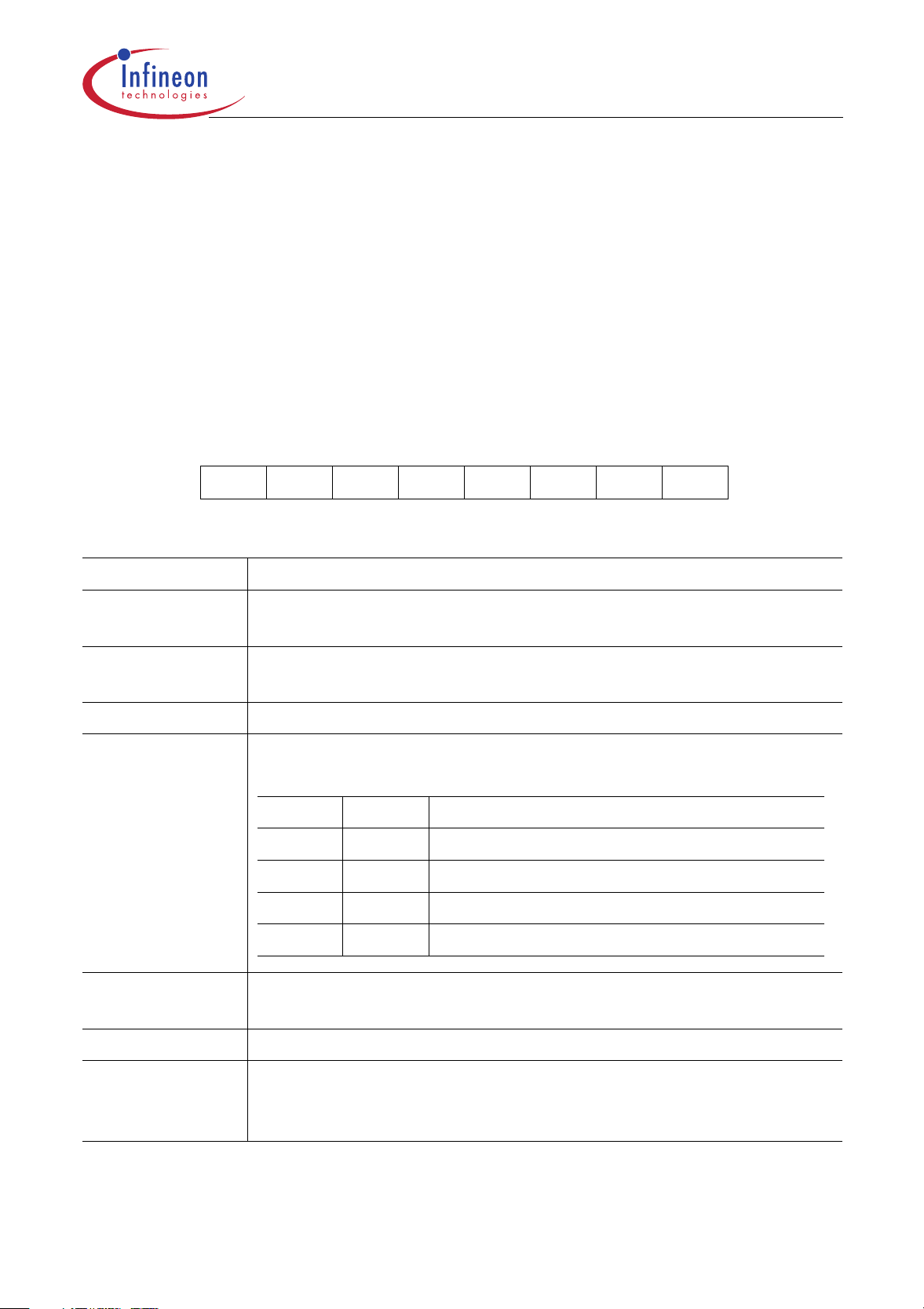

Figure 3 C515C Pin Configuration P-MQFP-80-1 (top view)

Data Sheet 5 2003-02

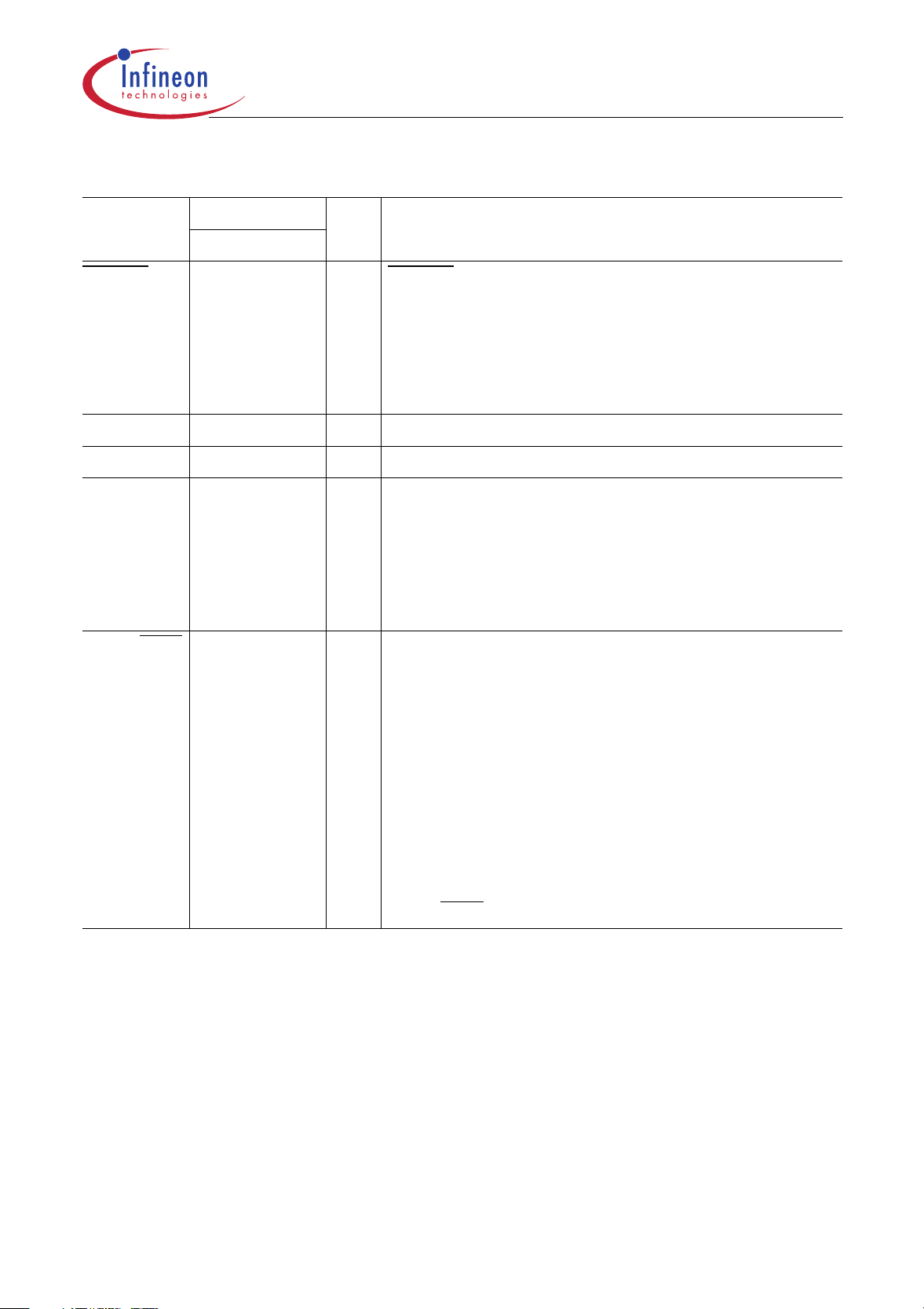

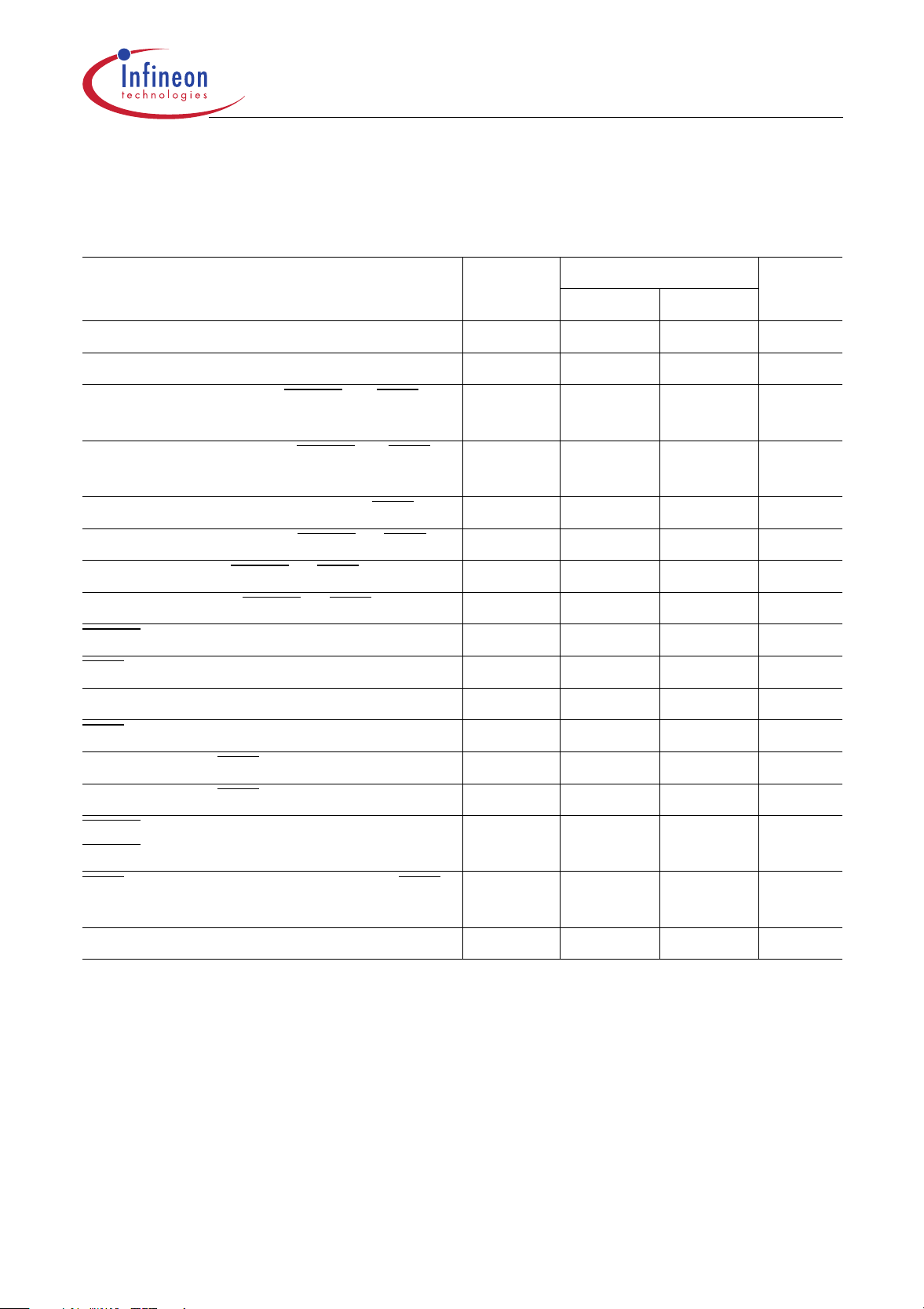

Table 2 Pin Definitions and Functions

Symbol Pin Number I/O

1)

Function

P-MQFP-80-1

C515C

RESET

1IRESET

A low level on this pin for the duration of two

machine cycles while the oscillator is running resets

the C515C. A small internal pullup resistor permits

power-on reset using only a capacitor connected to

V

.

SS

V

AREF

V

AGND

3–Reference voltage for the A/D converter

4–Reference ground for the A/D converter

P6.0-P6.7 12-5 I Port 6

is an 8-bit unidirectional input port to the

A/D converter. Port pins can be used for digital

input, if voltage levels simultaneously meet the

specifications high/low input voltages and for the

eight multiplexed analog inputs.

P7.0 / INT7

23 I/O Port 7

is an 1-bit quasi-bidirectional I/O port with internal

pull-up resistor. When a 1 is written to P7.0 it is

pulled high by an internal pull-up resistor, and in that

state can be used as input. As input, P7.0 being

externally pulled low will source current (

DC characteristics) because of the internal pull-up

resistor. If P7.0 is used as interrupt input, its output

latch must be programmed to a one (1). The

secondary function is assigned to the port 7 pin as

follows:

P7.0 INT7

, Interrupt 7 input

I

, in the

IL

Data Sheet 6 2003-02

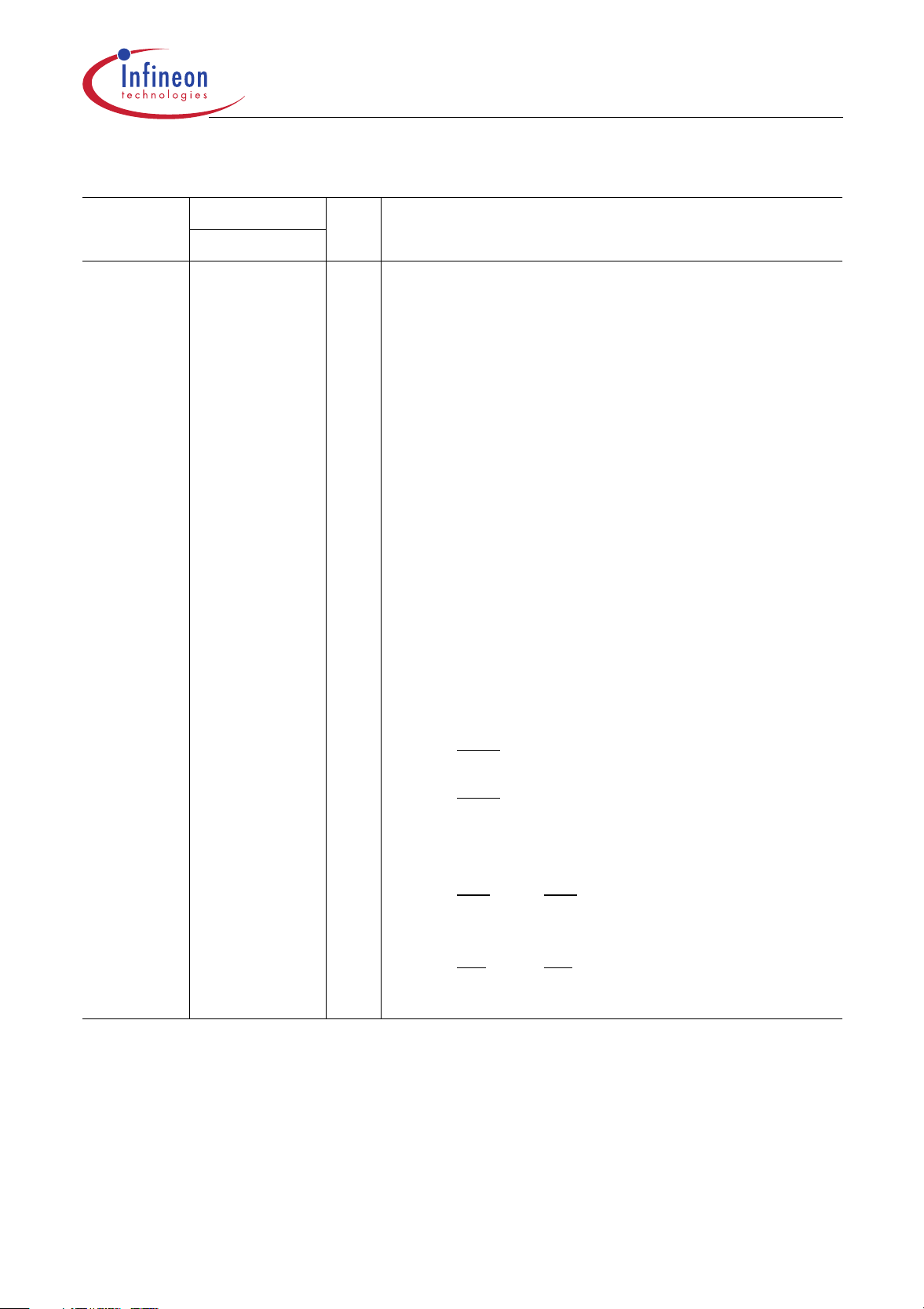

Table 2 Pin Definitions and Functions (cont’d)

1)

Symbol Pin Number I/O

Function

P-MQFP-80-1

C515C

P3.0-P3.7 15-22

15

16

17

18

19

20

21

22

I/O Port 3

is an 8-bit quasi-bidirectional I/O port with internal

pullup resistors. Port 3 pins that have 1's written to

them are pulled high by the internal pullup resistors,

and in that state can be used as inputs. As inputs,

port 3 pins being externally pulled low will source

current (

the internal pullup resistors. Port 3 also contains the

interrupt, timer, serial port and external memory

strobe pins that are used by various options. The

output latch corresponding to a secondary function

must be programmed to a one (1) for that function to

operate. The secondary functions are assigned to

the pins of port 3, as follows:

P3.0 RXD Receiver data input (asynch.) or

P3.1 TXD Transmitter data output (asynch.)

P3.2 INT0

P3.3 INT1

P3.4 T0 Timer 0 counter input

P3.5 T1 Timer 1 counter input

P3.6 WR

P3.7 RD

I

, in the DC characteristics) because of

IL

data input/output (synch.) of

serial interface

or clock output (synch.) of serial

interface

External interrupt 0 input / timer 0

gate control input

External interrupt 1 input / timer 1

gate control input

WR control output; latches the

data byte from port 0 into the

external data memory

RD control output; enables the

external data memory

Data Sheet 7 2003-02

Table 2 Pin Definitions and Functions (cont’d)

Symbol Pin Number I/O

1)

Function

P-MQFP-80-1

C515C

P1.0 - P1.7 31-24

31

30

29

28

27

26

25

24

I/O Port 1

is an 8-bit quasi-bidirectional I/O port with internal

pullup resistors. Port 1 pins that have 1's written to

them are pulled high by the internal pullup resistors,

and in that state can be used as inputs. As inputs,

port 1 pins being externally pulled low will source

current (

the internal pullup resistors. The port is used for the

low-order address byte during program verification.

Port 1 also contains the interrupt, timer, clock,

capture and compare pins that are used by various

options. The output latch corresponding to a

secondary function must be programmed to a one

(1) for that function to operate (except when used for

the compare functions). The secondary functions

are assigned to the port 1 pins as follows:

P1.0 INT3

P1.1 INT4 CC1 Interrupt 4 input / compare 1

P1.2 INT5 CC2 Interrupt 5 input / compare 2

P1.3 INT6 CC3 Interrupt 6 input / compare 3

P1.4 INT2

P1.5 T2EX Timer 2 external reload / trigger

P1.6 CLKOUT System clock output

P1.7 T2 Counter 2 input

I

, in the DC characteristics) because of

IL

CC0 Interrupt 3 input / compare 0

output / capture 0 input

output / capture 1 input

output / capture 2 input

output / capture 3 input

Interrupt 2 input

input

XTAL2 36 I XTAL2

Input to the inverting oscillator amplifier and input to

the internal clock generator circuits.

To drive the device from an external clock source,

XTAL2 should be driven, while XTAL1 is left

unconnected. Minimum and maximum high and low

times as well as rise/fall times specified in the AC

characteristics must be observed.

Data Sheet 8 2003-02

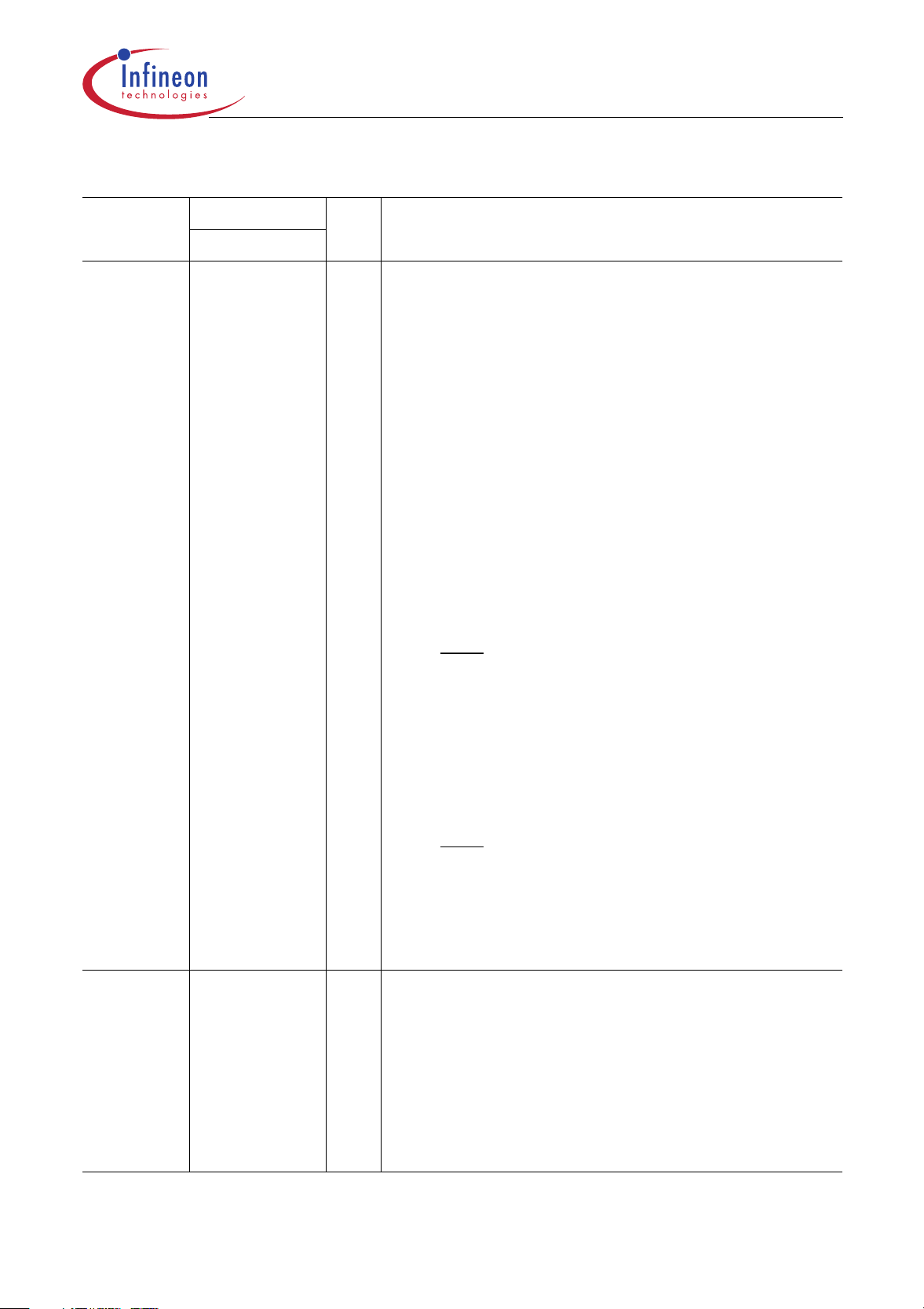

Table 2 Pin Definitions and Functions (cont’d)

1)

Symbol Pin Number I/O

Function

P-MQFP-80-1

XTAL1 37 O XTAL1

Output of the inverting oscillator amplifier.

P2.0-P2.7 38-45 I/O Port 2

is an 8-bit quasi-bidirectional I/O port with internal

pullup resistors. Port 2 pins that have 1's written to

them are pulled high by the internal pullup resistors,

and in that state can be used as inputs. As inputs,

port 2 pins being externally pulled low will source

current (

I

, in the DC characteristics) because of

IL

the internal pullup resistors.

Port 2 emits the high-order address byte during

fetches from external program memory and during

accesses to external data memory that use 16-bit

addresses (MOVX @DPTR). In this application it

uses strong internal pullup resistors when issuing

1's. During accesses to external data memory that

use 8-bit addresses (MOVX @Ri), port 2 issues the

contents of the P2 special function register.

C515C

CPUR

PSEN

46 O CPU Running Condition

This output pin is at low level when the CPU is

running and program fetches or data accesses in

the external data memory area are executed. In idle

mode, hardware and software power down mode,

and with an active RESET

signal CPUR is set to

high level.

CPUR

can be typically used for switching external

memory devices into power saving modes.

47 O The Program Store Enable

output is a control signal that enables the external

program memory to the bus during external fetch

operations. It is activated every six oscillator

periods, except during external data memory

accesses. The signal remains high during internal

program execution.

Data Sheet 9 2003-02

Table 2 Pin Definitions and Functions (cont’d)

1)

Symbol Pin Number I/O

Function

P-MQFP-80-1

ALE 48 O The Address Latch Enable

output is used for latching the address into external

memory during normal operation. It is activated

every six oscillator periods, except during an

external data memory access. ALE can be switched

off when the program is executed internally.

C515C

EA

49 I External Access Enable

When held high, the C515C executes instructions

always from the internal ROM. When held low, the

C515C fetches all instructions from external

program memory.

Note: For the ROM protection version EA

P0.0-P0.7 52-59 I/O Port 0

is an 8-bit open-drain bidirectional I/O port.

Port 0 pins that have 1's written to them float, and in

that state can be used as high-impedance inputs.

Port 0 is also the multiplexed low-order address and

data bus during accesses to external program and

data memory. In this application it uses strong

internal pullup resistors when issuing 1's.

Port 0 also outputs the code bytes during program

verification in the C515C. External pullup resistors

are required during program verification.

pin is

latched during reset.

P5.0-P5.7 67-60 I/O Port 5

is an 8-bit quasi-bidirectional I/O port with internal

pullup resistors. Port 5 pins that have 1's written to

them are pulled high by the internal pullup resistors,

and in that state can be used as inputs. As inputs,

port 5 pins being externally pulled low will source

current (

I

, in the DC characteristics) because of

IL

the internal pullup resistors.

Port 5 can also be switched into a bidirectional

mode, in which CMOS levels are provided. In this

bidirectional mode, each port 5 pin can be

programmed individually as input or output.

Data Sheet 10 2003-02

Table 2 Pin Definitions and Functions (cont’d)

1)

Symbol Pin Number I/O

Function

P-MQFP-80-1

C515C

HWPD

69 I Hardware Power Down

P4.0-P4.7 72-74, 76-80

72

73

74

76

77

78

79

80

A low level on this pin for the duration of one

machine cycle while the oscillator is running resets

the C515C.

A low level for a longer period will force the part to

power down mode with the pins floating.

I/O Port 4

is an 8-bit quasi-bidirectional I/O port with internal

pull-up resistors. Port 4 pins that have 1’s written to

them are pulled high by the internal pull-up resistors,

and in that state can be used as inputs. As inputs,

port 4 pins being externally pulled low will source

current (

the internal pull-up resistors.

P4 also contains the external A/D converter control

pin, the SSC pins, the CAN controller input/output

lines, and the external interrupt 8 input. The output

latch corresponding to a secondary function must

be programmed to a one (1) for that function to

operate. The alternate functions are assigned to

port 4 as follows:

P4.0 ADST

P4.1 SCLK SSC Master Clock Output /

P4.2 SRI SSC Receive Input

P4.3 STO SSC Transmit Output

P4.4 SLS

P4.5 INT8

P4.6 TXDC Transmitter output of the CAN

P4.7 RXDC Receiver input of the CAN controller

I

, in the DC characteristics) because of

IL

External A/D converter start pin

SSC Slave Clock Input

Slave Select Input

External interrupt 8 input

controller

Data Sheet 11 2003-02

Table 2 Pin Definitions and Functions (cont’d)

1)

Symbol Pin Number I/O

Function

P-MQFP-80-1

PE

/SWD 75 I Power saving mode enable / Start watchdog

timer

A low level on this pin allows the software to enter

the power down, idle and slow down mode. In case

the low level is also seen during reset, the watchdog

timer function is off on default.

Use of the software controlled power saving modes

is blocked, when this pin is held on high level. A high

level during reset performs an automatic start of the

watchdog timer immediately after reset. When left

unconnected this pin is pulled high by a weak

internal pull-up resistor.

C515C

V

SSCLK

V

DDCLK

V

DDE1

V

DDE2

V

SSE1

V

SSE2

V

DD1

V

SS1

13 – Ground (0 V) for on-chip oscillator

This pin is used for ground connection of the on-chip

oscillator circuit.

14 – Supply voltage for on-chip oscillator

This pin is used for power supply of the on-chip

oscillator circuit.

32

68

– Supply voltage for I/O ports

These pins are used for power supply of the I/O

ports during normal, idle, and power down mode.

35

70

– Ground (0 V) for I/O ports

These pins are used for ground connections of the

I/O ports during normal, idle, and power down

mode.

33 – Supply voltage for internal logic

This pins is used for the power supply of the internal

logic circuits during normal, idle, and power down

mode.

34 – Ground (0 V) for internal logic

This pin is used for the ground connection of the

internal logic circuits during normal, idle, and power

down mode.

Data Sheet 12 2003-02

Table 2 Pin Definitions and Functions (cont’d)

Symbol Pin Number I/O

1)

Function

P-MQFP-80-1

C515C

V

DDEXT

50 – Supply voltage for external access pins

This pin is used for power supply of the I/O ports and

control signals which are used during external

accesses (for Port 0, Port 2, ALE, PSEN

V

SSEXT

and P3.7/RD

51 – Ground (0 V) for external access pins

).

This pin is used for the ground connection of the I/O

ports and control signals which are used during

external accesses (for Port 0, Port 2, ALE, PSEN

P3.6/WR

, and P3.7/RD).

N.C. 2, 71 – Not connected

These pins should not be connected.

1)

I = Input; O = Output

, P3.6/WR,

,

Data Sheet 13 2003-02

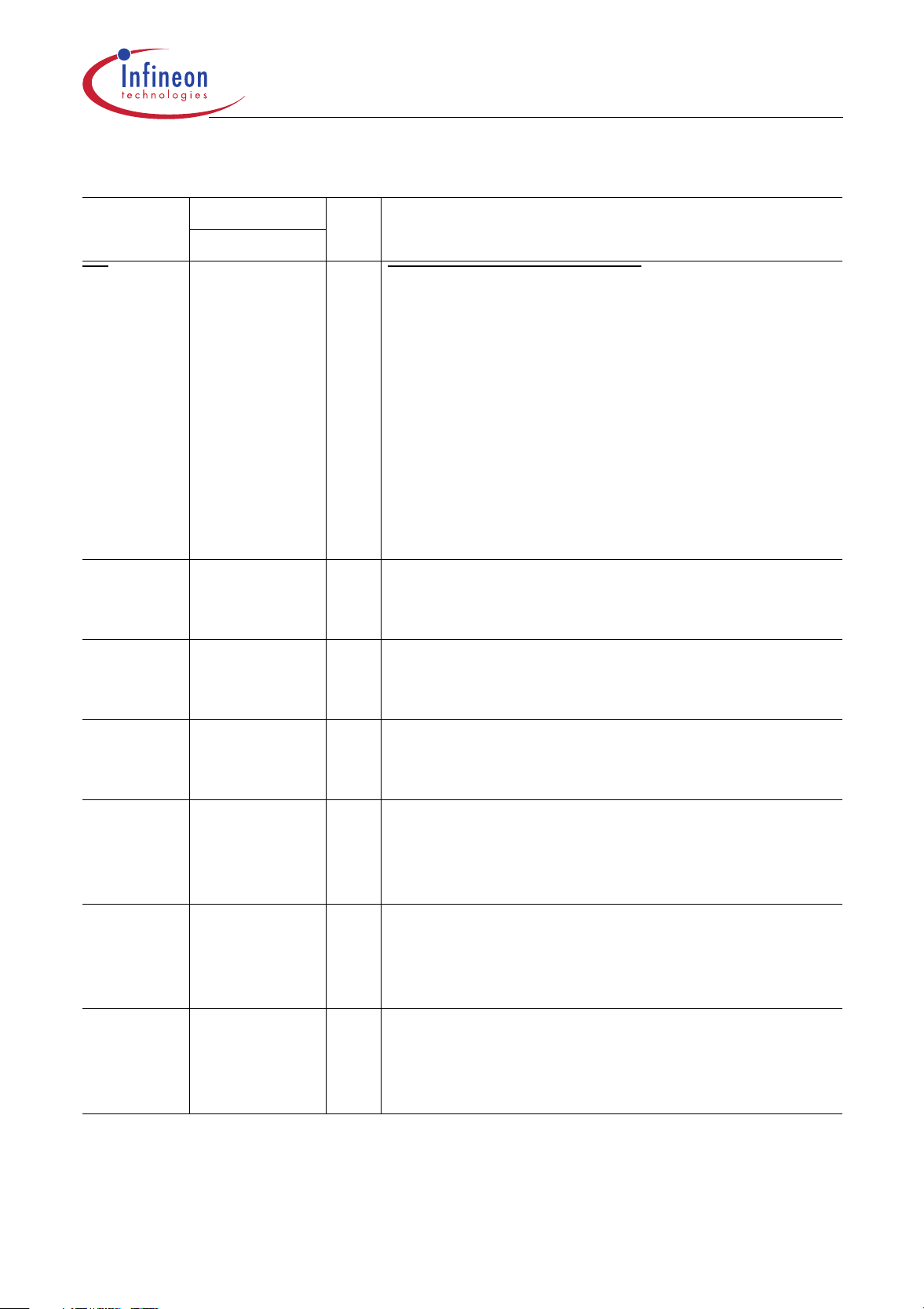

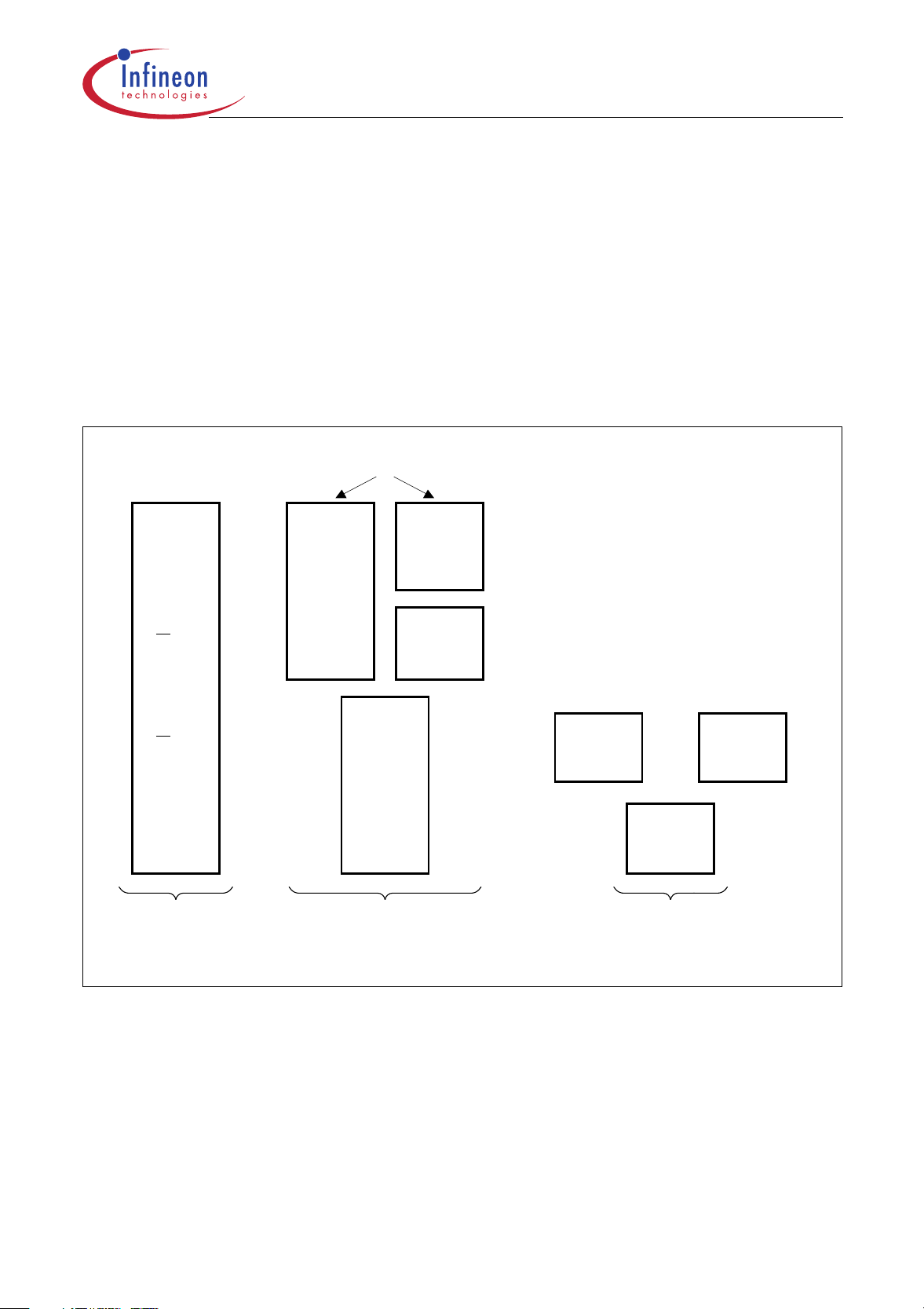

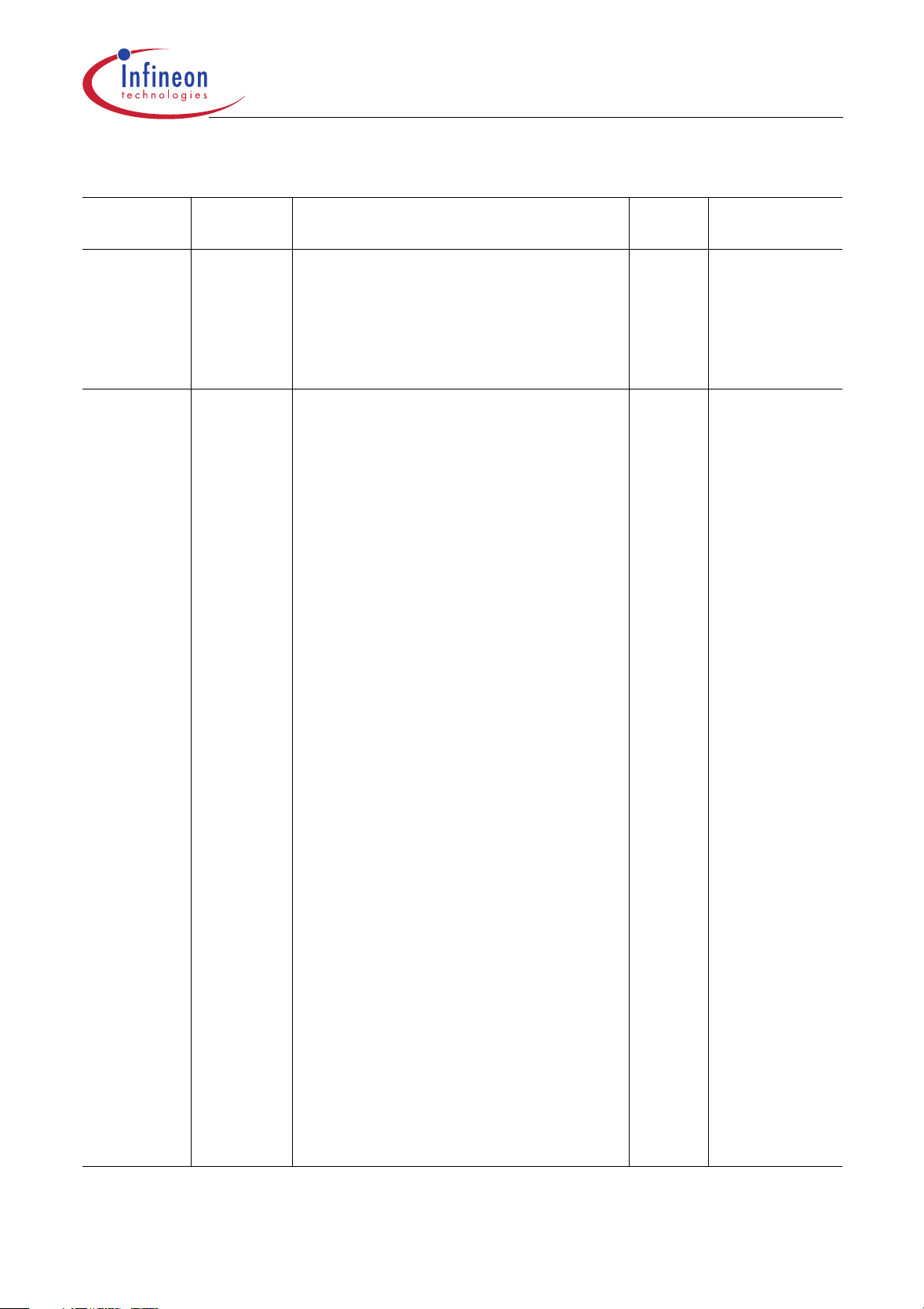

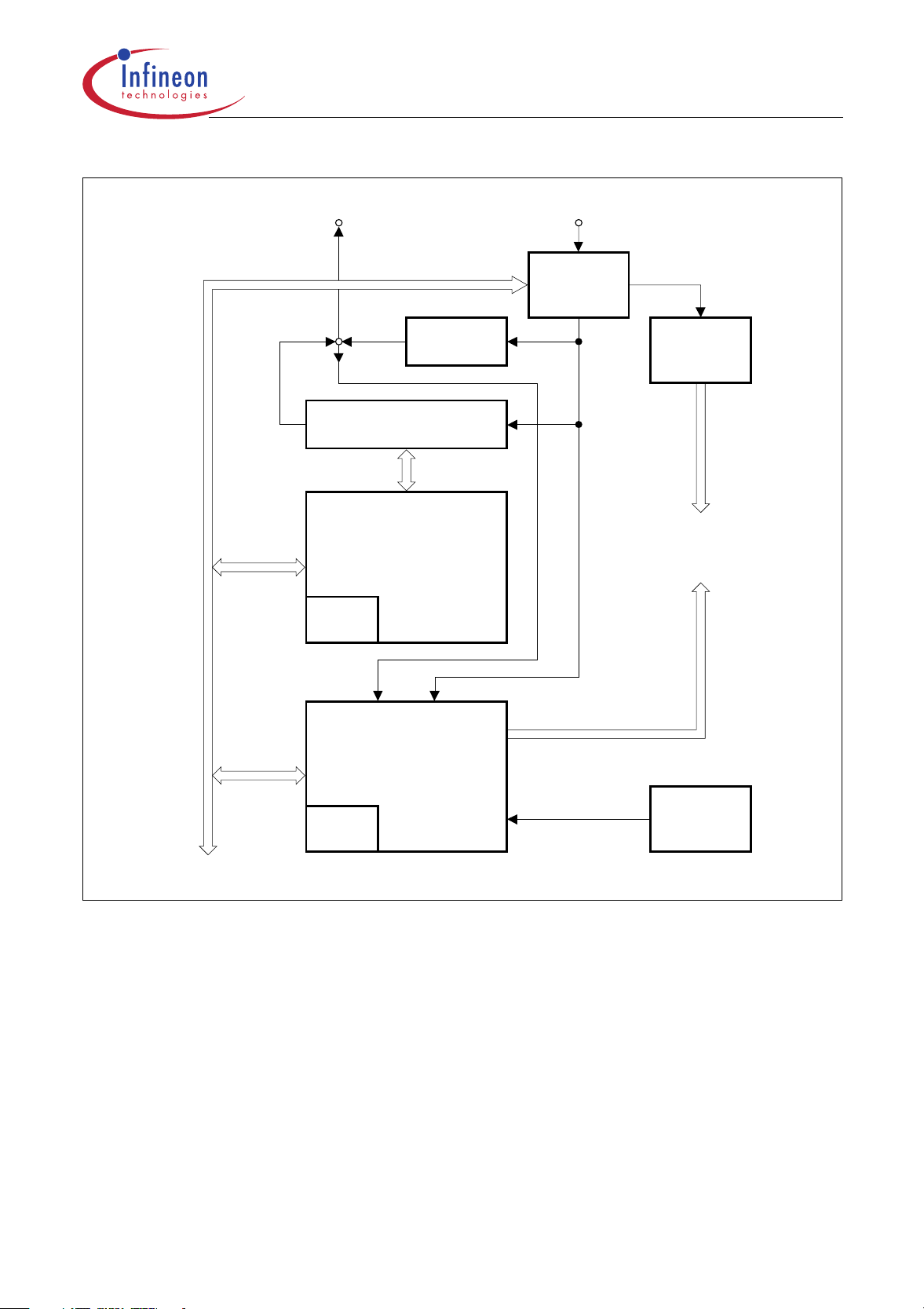

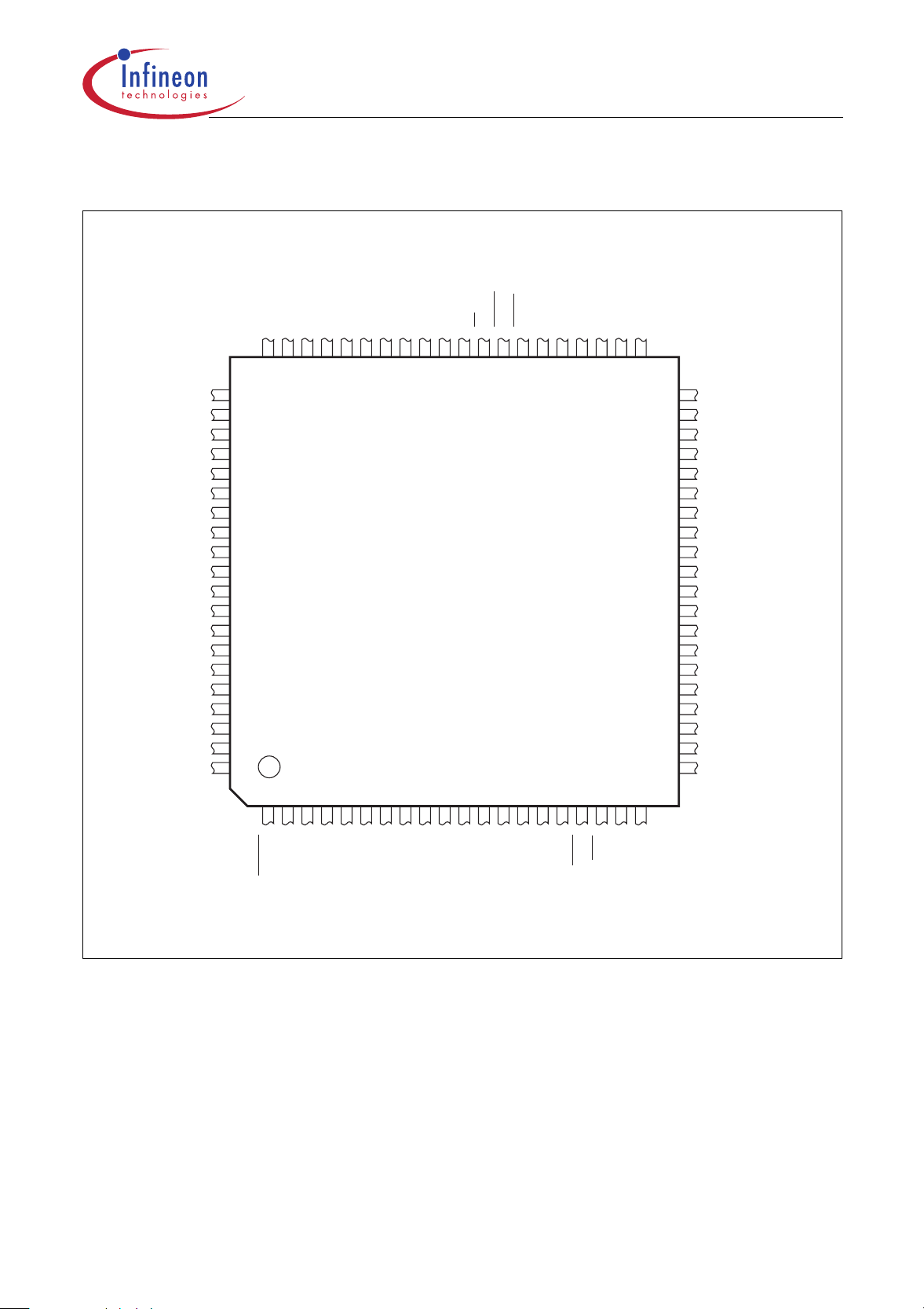

C515C

XTAL1

XTAL2

ALE

PSEN

EA

CPUR

PE/SWD

HWPD

RESET

Oscillator Watchdog

OSC & Timing

CPU

8 Datapointers

Programmable

Watchdog Timer

Timer 0

Timer 1

Timer 2

Capture

Compare Unit

XRAM

2k x 8 256 x 8

RAM ROM/OTP

64k x 8

Emulation

Support

Logic

Port 0

Port 1

Port 2

Multiple

V

V

/

DD SS

Lines

Port 0

8 Bit Digital I/O

Port 1

8 Bit Digital I/O

Port 2

8 Bit Digital I/O

USART

Baud Rate Generator

SSC (SPI) Interface

Full-CAN

Controller

256 Byte

Reg./Data

Interrupt Unit

V

AREF

V

AGND

A/D Converter

S & H

10 Bit

MUX

Figure 4 Block Diagram of the C515C

Port 3

Port 4

Port 5

Port 6

Port 7

C515C

Port 3

8 Bit Digital I/O

Port 4

8 Bit Digital I/O

Port 5

8 Bit Digital I/O

Port 6

8 Bit Analog/

Digital Inputs

Port 7

1 Bit Digital I/O

MCB03647

Data Sheet 14 2003-02

C515C

CPU

The C515C is efficient both as a controller and as an arithmetic processor. It has

extensive facilities for binary and BCD arithmetic and excels in its bit-handling

capabilities. Efficient use of program memory results from an instruction set consisting

of 44% one-byte, 41% two-byte, and 15% three-byte instructions. With a 6 MHz crystal,

58% of the instructions are executed in 1

PSW

Special Function Register (D0

Bit No. MSB LSB

µs (10 MHz: 600 ns).

) Reset Value: 00

H

H

D7

H

CY AC F0 RS1 RS0 OV F1 PD0

D6

H

D5

H

D4

H

Bit Function

CY Carry Flag

Used by arithmetic instruction.

AC Auxiliary Carry Flag

Used by instructions which execute BCD operations.

F0 General Purpose Flag

RS1

RS0

Register Bank select control bits

These bits are used to select one of the four register banks.

RS1 RS0 Function

0 0 Bank 0 selected, data address 00

0 1 Bank 1 selected, data address 08H-0F

1 0 Bank 2 selected, data address 10H-17

1 1 Bank 3 selected, data address 18H-1F

D3

H

D2

H

D1

H

D0

H

H

PSW

-07

H

H

H

H

H

OV Overflow Flag

Used by arithmetic instruction.

F1 General Purpose Flag

PParity Flag

Set/cleared by hardware after each instruction to indicate an

odd/even number of “one” bits in the accumulator, i.e. even parity.

Data Sheet 15 2003-02

C515C

Memory Organization

The C515C CPU manipulates data and operands in the following five address spaces:

• up to 64 Kbytes of internal/external program memory

• up to 64 Kbytes of external data memory

• 256 bytes of internal data memory

• 256 bytes CAN controller registers / data memory

• 2 Kbytes of internal XRAM data memory

• a 128 byte special function register area

Figure 5 illustrates the memory address spaces of the C515C.

Alternatively

FFFF

Internal

(EA = 1)

External

(EA = 0)

0000

"Code Space"

FFFF

F800

F7FF

F700

H

H

H

H

Indirect

Address

Internal

RAM

FF

H

80

H

Internal

RAM

Direct

Address

Special

Function

Register

7F

H

00

H

FF

H

80

H

MCD02717

H

Internal

XRAM

External

Data

Memory

External

H

"Data Space" "Internal Data Space"

(2 KByte)

Int. CAN

Controller

(256 Byte)

F6FF

H

0000

H

Figure 5 C515C Memory Map

Data Sheet 16 2003-02

C515C

Control of XRAM/CAN Controller Access

The XRAM in the C515C is a memory area that is logically located at the upper end of

the external memory space, but is integrated on the chip. Because the XRAM and the

CAN controller is used in the same way as external data memory the same instruction

types (MOVX) must be used for accessing the XRAM. Two bits in SFR SYSCON,

XMAP0 and XMAP1, control the accesses to the XRAM and the CAN controller.

SYSCON

Special Function Register (B1

Bit No. MSB LSB

76543210

) C515C-8R Reset Value: X010XX01

H

C515C-8E Reset Value: X010X001

B

B

B1

H

–PMOD

The function of the shaded bits is not described in this section.

EALE RMAP –

CSWO XMAP1

XMAP0

SYSCON

Bit Function

XMAP1 XRAM/CAN controller visible access control

Control bit for RD

/WR signals during XRAM/CAN Controller

accesses. If addresses are outside the XRAM/CAN controller

address range or if XRAM is disabled, this bit has no effect.

XMAP1 = 0: The signals RD

and WR are not activated during

accesses to the XRAM/CAN Controller

XMAP1 = 1: Ports 0, 2 and the signals RD

and WR are activated

during accesses to XRAM/CAN Controller. In this

mode, address and data information during

XRAM/CAN Controller accesses are visible externally.

XMAP0 Global XRAM/CAN controller access enable/disable control

XMAP0 = 0: The access to XRAM and CAN controller is enabled.

XMAP0 = 1: The access to XRAM and CAN controller is disabled

(default after reset). All MOVX accesses are

performed via the external bus. Further, this bit is

hardware protected.

Bit XMAP0 is hardware protected. If it is reset once (XRAM/CAN controller access

enabled) it cannot be set by software. Only a reset operation will set the XMAP0 bit

again.

Data Sheet 17 2003-02

C515C

The XRAM/CAN controller can be accessed by read/write instructions (MOVX A,DPTR,

MOVX @DPTR,A), which use the 16-bit DPTR for indirect addressing. For accessing the

XRAM or CAN controller, the effective address stored in DPTR must be in the range of

F700

The XRAM can be also accessed by read/write instructions (MOVX A,@Ri, MOVX

@Ri,A), which use only an 8-bit address (indirect addressing with registers R0 or R1).

Therefore, a special page register XPAGE which provides the upper address information

(A8-A15) during 8-bit XRAM accesses. The behaviour of Port 0 and P2 during a MOVX

access depends on the control bits XMAP0 and XMAP1 in register SYSCON and on the

state of pin

to FFFFH.

H

EA. Table 3 lists the various operating conditions.

Data Sheet 18 2003-02

C515C

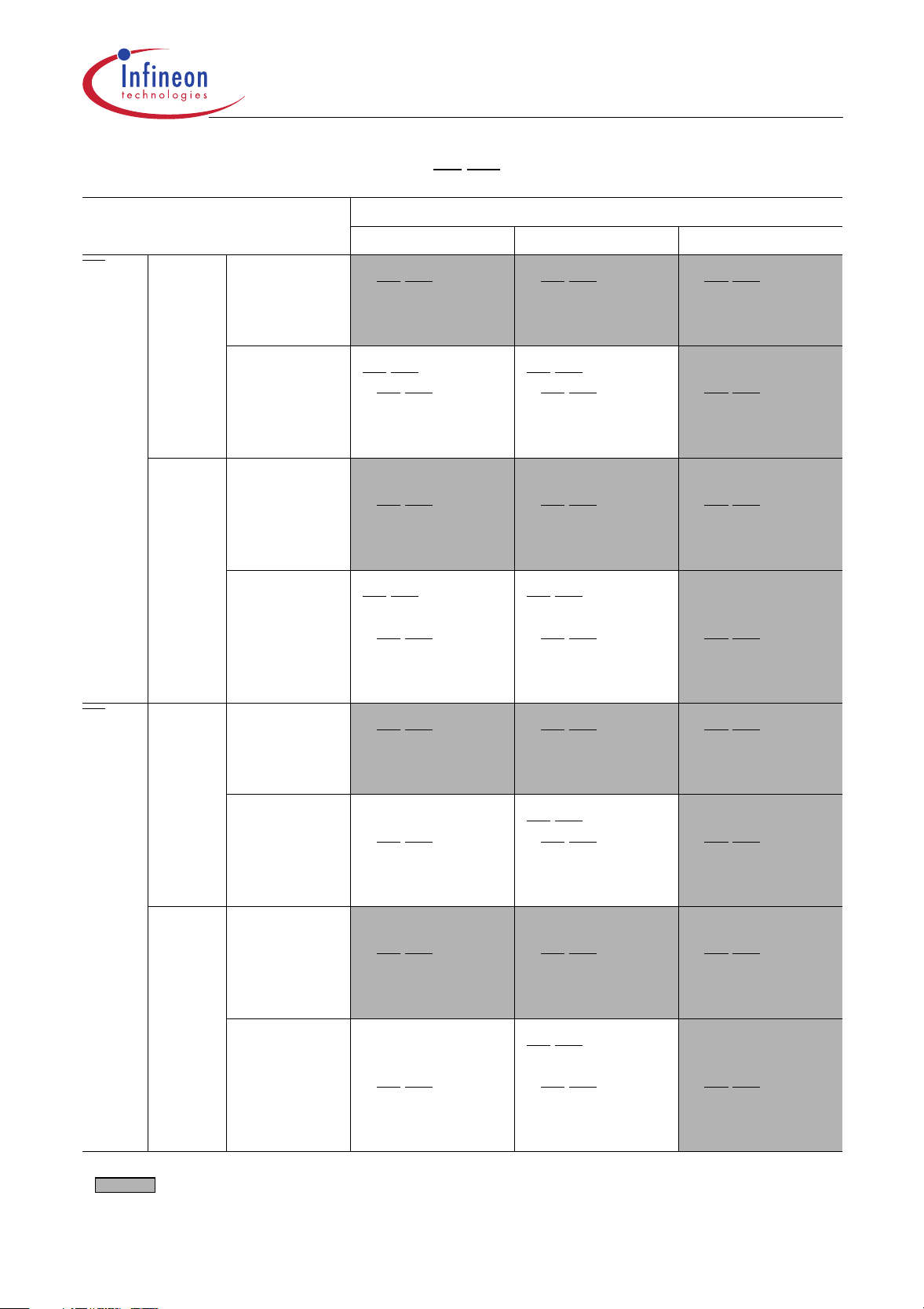

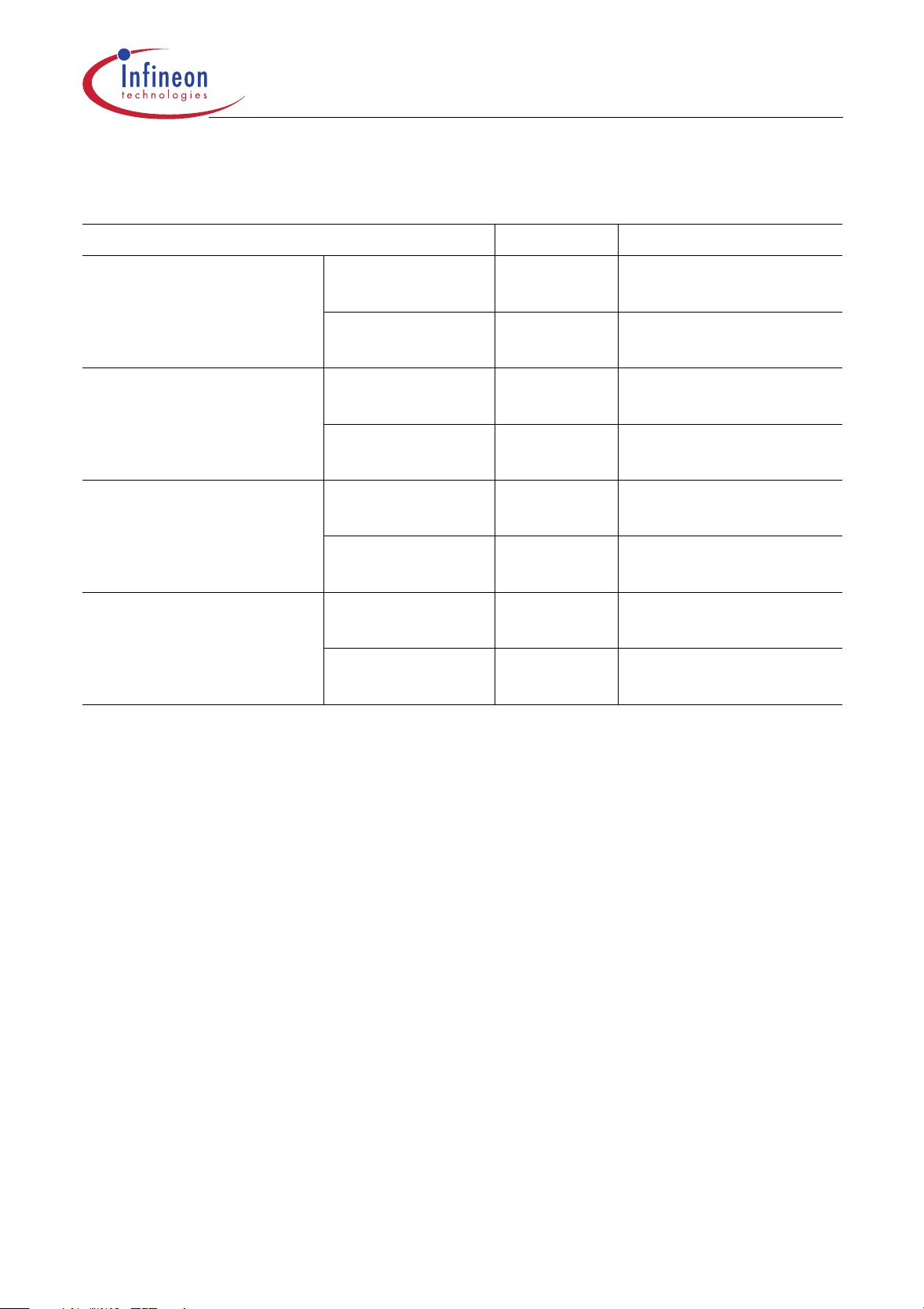

Table 3 Behaviour of P0/P2 and RD

00 10 X1

EA

= 0 MOVX

@DPTR

MOVX

@ Ri

DPTR

<

XRAM/CAN

address range

DPTR

≥

XRAMCAN

address range

XPAGE

<

XRAMCAN

addr. page

range

XPAGE

≥

XRAMCAN

addr. page

range

a) P0/P2→Bus

b) RD

/WR active

c) ext.memory

is used

a) P0/P2

(RD

b) RD

c) XRAM is used

a) P0→Bus

P2

b) RD

c) ext.memory

is used

a) P0

(RD

P2

b) RD

c) XRAM is used

→Bus

/WR-Data)

/WR inactive

→I/O

/WR active

→Bus

/WR-Data)

→I/O

/WR inactive

/WR During MOVX Accesses

XMAP1, XMAP0

a) P0/P2→Bus

b) RD

/WR active

c) ext.memory

is used

a) P0/P2

(RD

b) RD

c) XRAM is used

a) P0→Bus

P2

b) RD

c) ext.memory

is used

a) P0

(RD

P2

b) RD

c) XRAM is used

→Bus

/WR-Data)

/WR active

→I/O

/WR active

→Bus

/WR-Data only)

→I/O

/WR active

a) P0/P2→Bus

b) RD

c) ext.memory

is used

a) P0/P2→Bus

b) RD

c) ext.memory

is used

a) P0→Bus

P2

→I/O

b) RD

c) ext.memory

is used

a) P0→Bus

P2

→I/O

b) RD

c) ext.memory

is used

/WR active

/WR active

/WR active

/WR active

EA

= 1 MOVX

@DPTR

MOVX

@ Ri

DPTR

<

XRAM/CAN

address range

DPTR

≥

XRAMCAN

address range

XPAGE

<

XRAMCAN

addr. page

range

XPAGE

≥

XRAMCAN

addr. page

range

a) P0/P2→Bus

b) RD

/WR active

c) ext.memory

is used

a) P0/P2

b) RD/WR inactive

c) XRAM is used

a) P0→Bus

P2

b) RD

c) ext.memory

is used

a) P2

P0/P2

b) RD

c) XRAM is used

→Ι/0

→I/O

/WR active

→I/O

→I/O

/WR inactive

a) P0/P2→Bus

b) RD

/WR active

c) ext.memory

is used

a) P0/P2

(RD

b) RD

c) XRAM is used

a) P0→Bus

P2

b) RD

c) ext.memory is

used

a) P0

(RD

P2

b) RD

c) XRAM is used

→Bus

/WR-Data)

/WR active

→I/O

/WR active

→Bus

/WR-Data)

→I/O

/WR active

a) P0/P2→Bus

b) RD

/WR active

c) ext.memory

is used

a) P0/P2→Bus

b) RD

/WR active

c) ext.memory

is used

a) P0→Bus

P2

→I/O

b) RD

/WR active

c) ext.memory

is used

a) P0→Bus

P2

→I/O

b) RD

/WR active

c) ext.memory

is used

modes compatible to 8051/C501 family

Data Sheet 19 2003-02

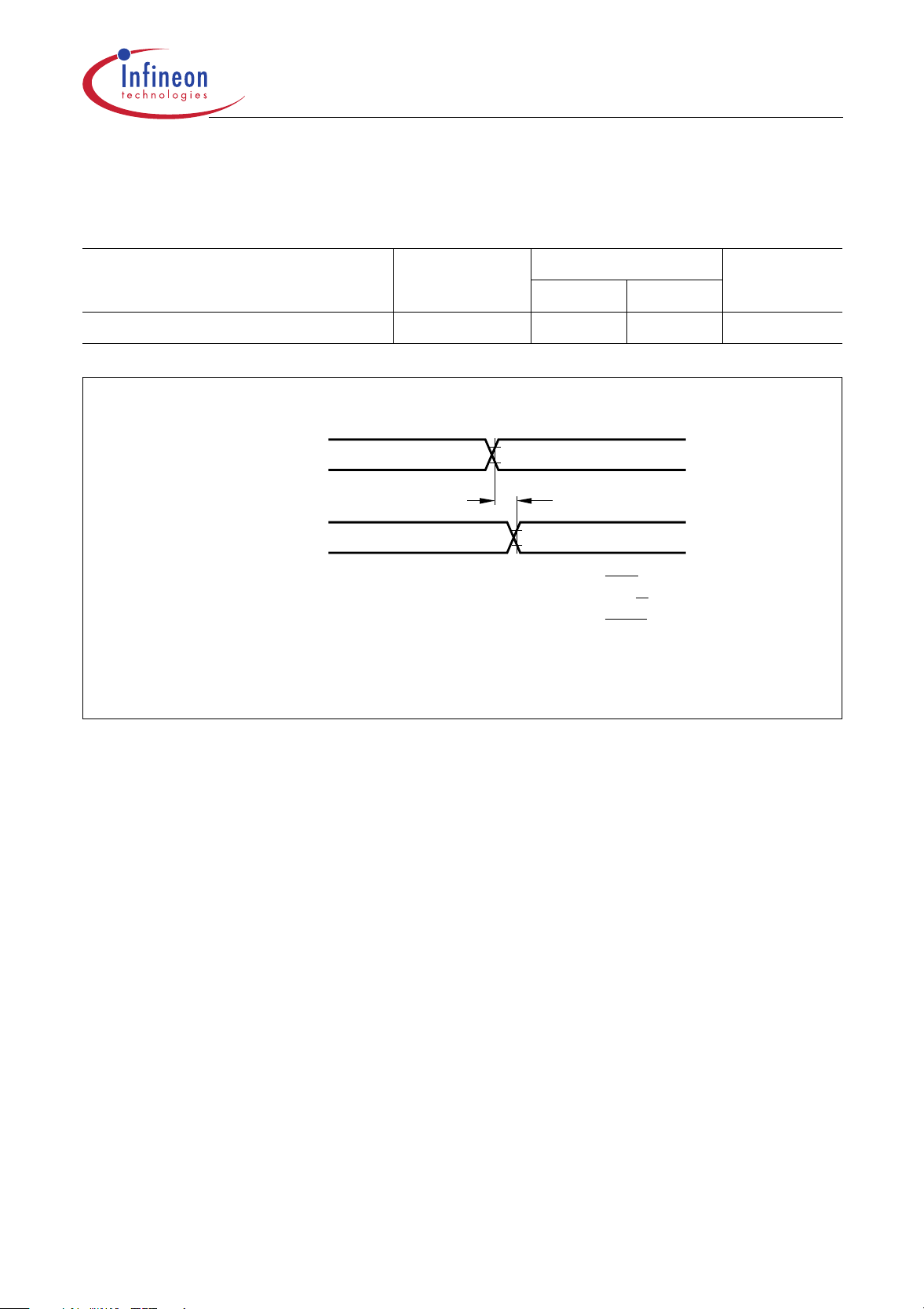

Reset and System Clock

C515C

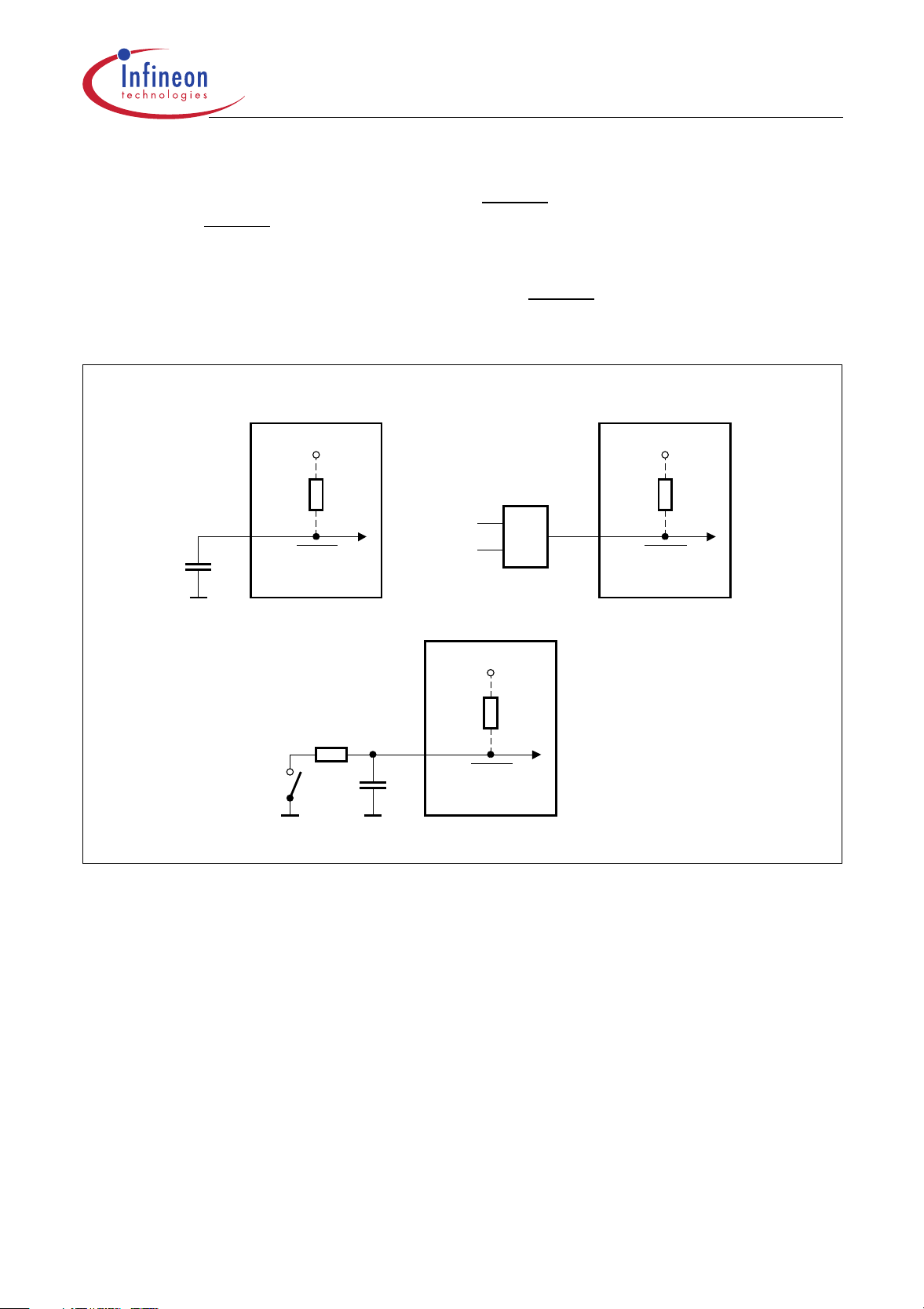

The reset input is an active low input at pin RESET

internally, the RESET

pin must be held low for at least two machine cycles (12 oscillator

periods) while the oscillator is running. A pullup resistor is internally connected to

. Since the reset is synchronized

V

to

DD

allow a power-up reset with an external capacitor only. An automatic reset can be

V

obtained when

is applied by connecting the RESET pin to VSS via a capacitor.

DD

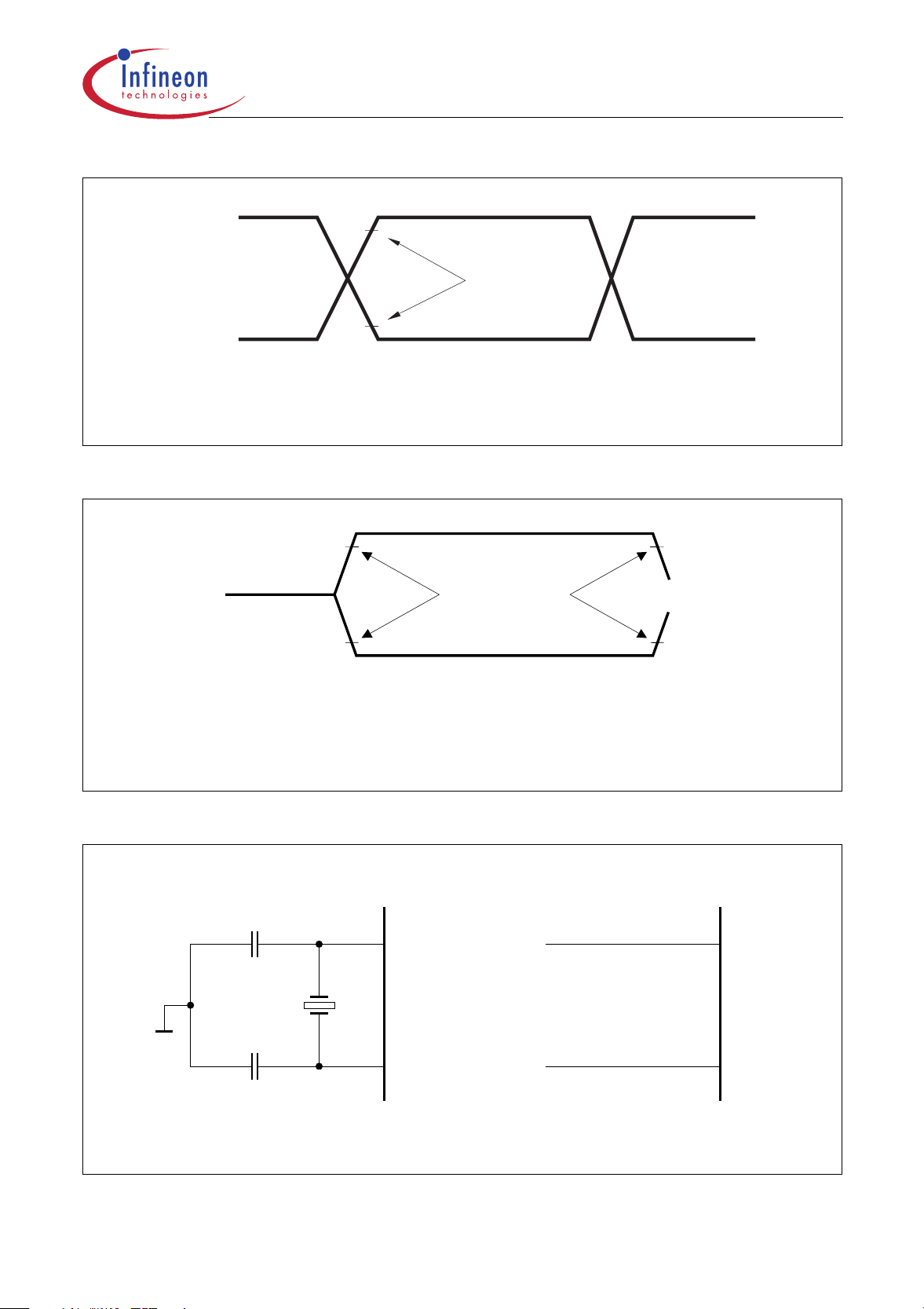

Figure 6 shows the possible reset circuitries.

b)a)

&

+

RESET

C515C

RESET

C515C

c)

+

RESET

C515C

MCS02721

Figure 6 Reset Circuitries

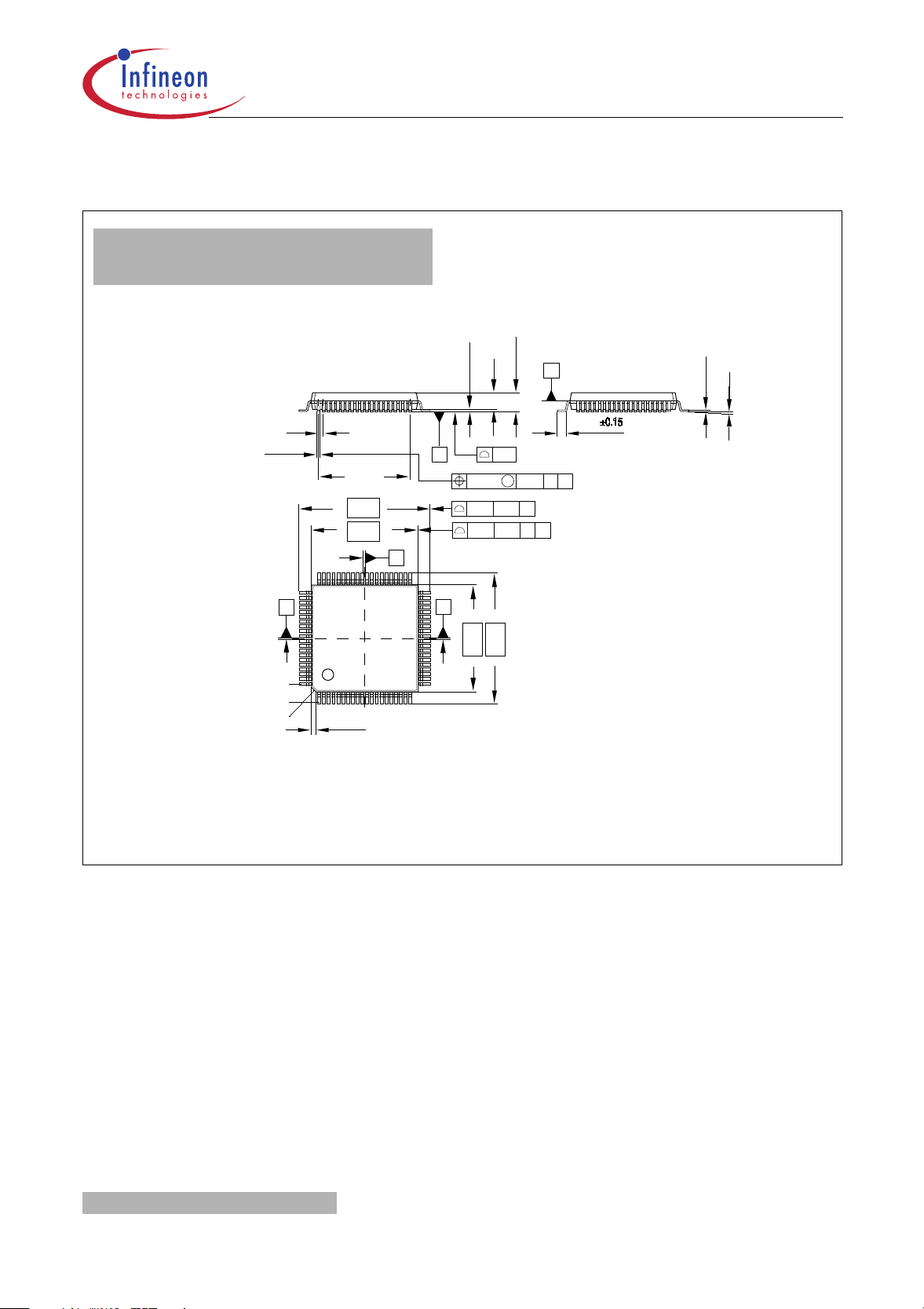

Figure 7 shows the recommended oscillator circiutries for crystal and external clock

operation.

Data Sheet 20 2003-02

C515C

Crystal/Resonator Oscillator Mode Driving from External Source

C

2 - 10 MHz

C

Crystal Mode :

XTAL1

XTAL2 XTAL2

C = 20 pF ± 10 pF (incl. stray capacitance)

:Resonator Mode

= depends on selected ceramic resonatorC

N.C.

External Oscillator

Signal

XTAL1

MCT02765

Figure 7 Recommended Oscillator Circuitries

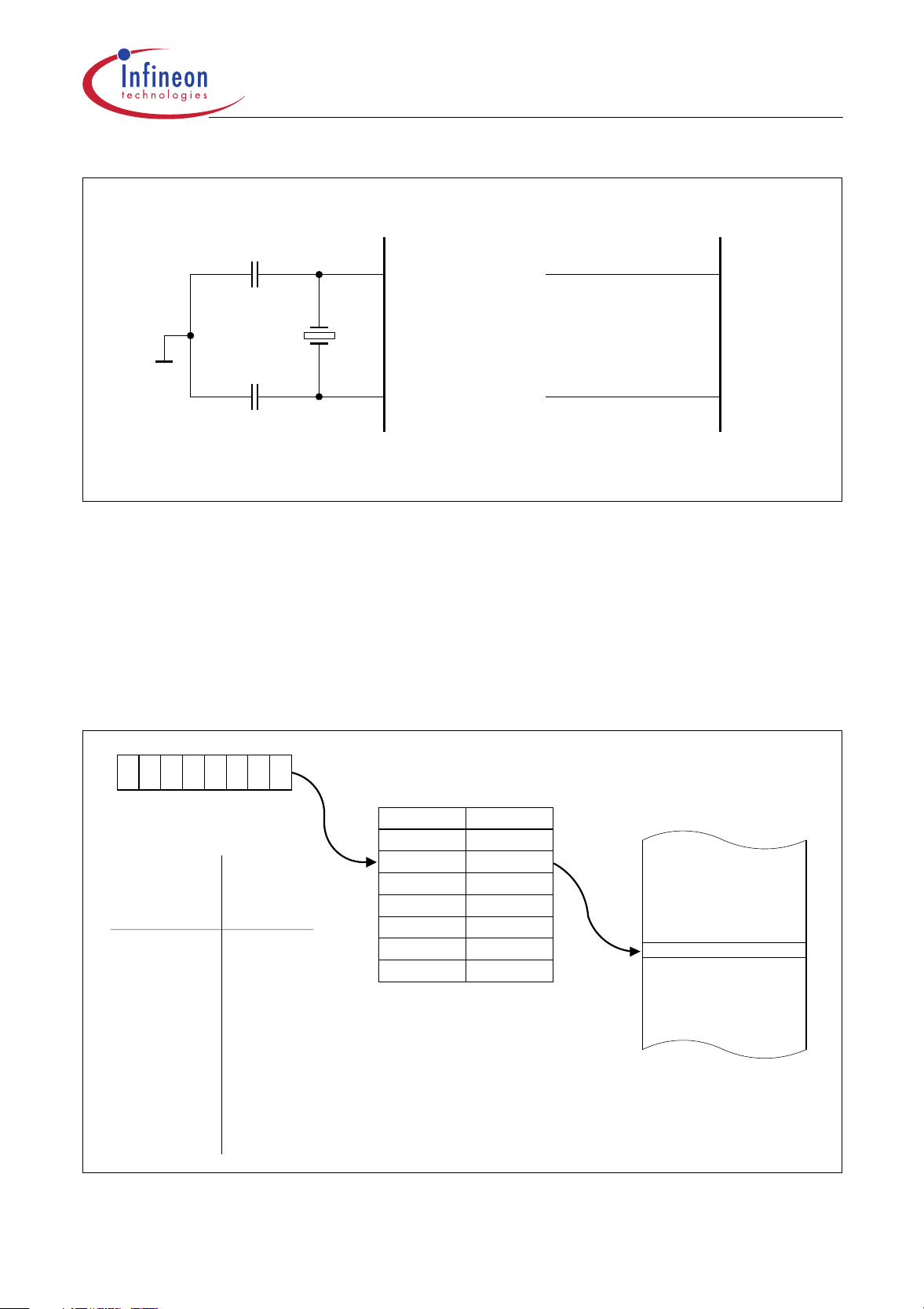

Multiple Datapointers

As a functional enhancement to the standard 8051 architecture, the C515C contains

eight 16-bit datapointers instead of only one datapointer. The instruction set uses just

one of these datapointers at a time. The selection of the actual datapointer is done in the

special function register DPSEL. Figure 8 illustrates the datapointer addressing

mechanism.

Datapointer

DPTR 0000

.0.1.2

DPTR7

DPTR0

DPH(83 ) DPL(82 )

HH

External Data Memory

MCD00779

-----

DPSEL(92 )

DPSEL Selected

.2 .1 .0

0 0 1 DPTR 1

0 1 0 DPTR 2

0 1 1 DPTR 3

1 0 0 DPTR 4

1 0 1 DPTR 5

1 1 0 DPTR 6

1 1 1 DPTR 7

H

Figure 8 External Data Memory Addressing using Multiple Datapointers

Data Sheet 21 2003-02

C515C

Enhanced Hooks Emulation Concept

The Enhanced Hooks Emulation Concept of the C500 microcontroller family is a new,

innovative way to control the execution of C500 MCUs and to gain extensive information

on the internal operation of the controllers. Emulation of on-chip ROM based programs

is possible, too.

Each production chip has built-in logic for the support of the Enhanced Hooks Emulation

Concept. Therefore, no costly bond-out chips are necessary for emulation. This also

ensure that emulation and production chips are identical.

The Enhanced Hooks Technology, which requires embedded logic in the C500 allows

the C500 together with an EH-IC to function similar to a bond-out chip. This simplifies the

design and reduces costs of an ICE-system. ICE-systems using an EH-IC and a

compatible C500 are able to emulate all operating modes of the different versions of the

C500 microcontrollers. This includes emulation of ROM, ROM with code rollover and

ROMless modes of operation. It is also able to operate in single step mode and to read

the SFRs after a break.

SYSCON

PCON

TCON

Optional

I/O Ports

ICE-System Interface

to Emulation Hardware

RESET

EA

ALE

PSEN

C500

0

MCU Interface Circuit

Port 3 Port 1

Port

Port

2

Target System Interface

RSYSCON

RPCON

RTCON

Enhanced Hooks

RPort 0RPort 2

EH-IC

TEA TALE TPSEN

MCS03280

Figure 9 Basic C500 MCU Enhanced Hooks Concept Configuration

Port 0, port 2 and some of the control lines of the C500 based MCU are used by

Enhanced Hooks Emulation Concept to control the operation of the device during

emulation and to transfer informations about the program execution and data transfer

between the external emulation hardware (ICE-system) and the C500 MCU.

Data Sheet 22 2003-02

C515C

Special Function Registers

The registers, except the program counter and the four general purpose register banks,

reside in the special function register area. The special function register area consists of

two portions: the standard special function register area and the mapped special function

register area. Two special function registers of the C515C (PCON1 and DIR5) are

located in the mapped special function register area. For accessing the mapped special

function register area, bit RMAP in special function register SYSCON must be set. All

other special function registers are located in the standard special function register area

which is accessed when RMAP is cleared (“0”). As long as bit RMAP is set, mapped

special function register area can be accessed. This bit is not cleared by hardware

automatically. Thus, when non-mapped/mapped registers are to be accessed, the bit

RMAP must be cleared/set by software, respectively each.

SYSCON

Special Function Register (B1

) C515C-8R Reset Value: X010XX01

H

C515C-8E Reset Value: X010X001

B

B

Bit No. MSB LSB

76543210

B1

H

–PMOD

The function of the shaded bits is not described in this section.

EALE RMAP –

CSWO XMAP1

XMAP0

SYSCON

Bit Function

RMAP Special function register map bit

RMAP = 0: The access to the non-mapped (standard) special

function register area is enabled (reset value).

RMAP = 1: The access to the mapped special function register

area is enabled.

The 59 special function registers (SFRs) in the standard and mapped SFR area include

pointers and registers that provide an interface between the CPU and the other on-chip

peripherals. The SFRs of the C515C are listed in Table 4 and Table 5. In Table 4 they

are organized in groups which refer to the functional blocks of the C515C. The CANSFRs are also included in Table 4. Table 5 illustrates the contents of the SFRs in

numeric order of their addresses. Table 6 list the CAN-SFRs in numeric order of their

addresses.

Data Sheet 23 2003-02

C515C

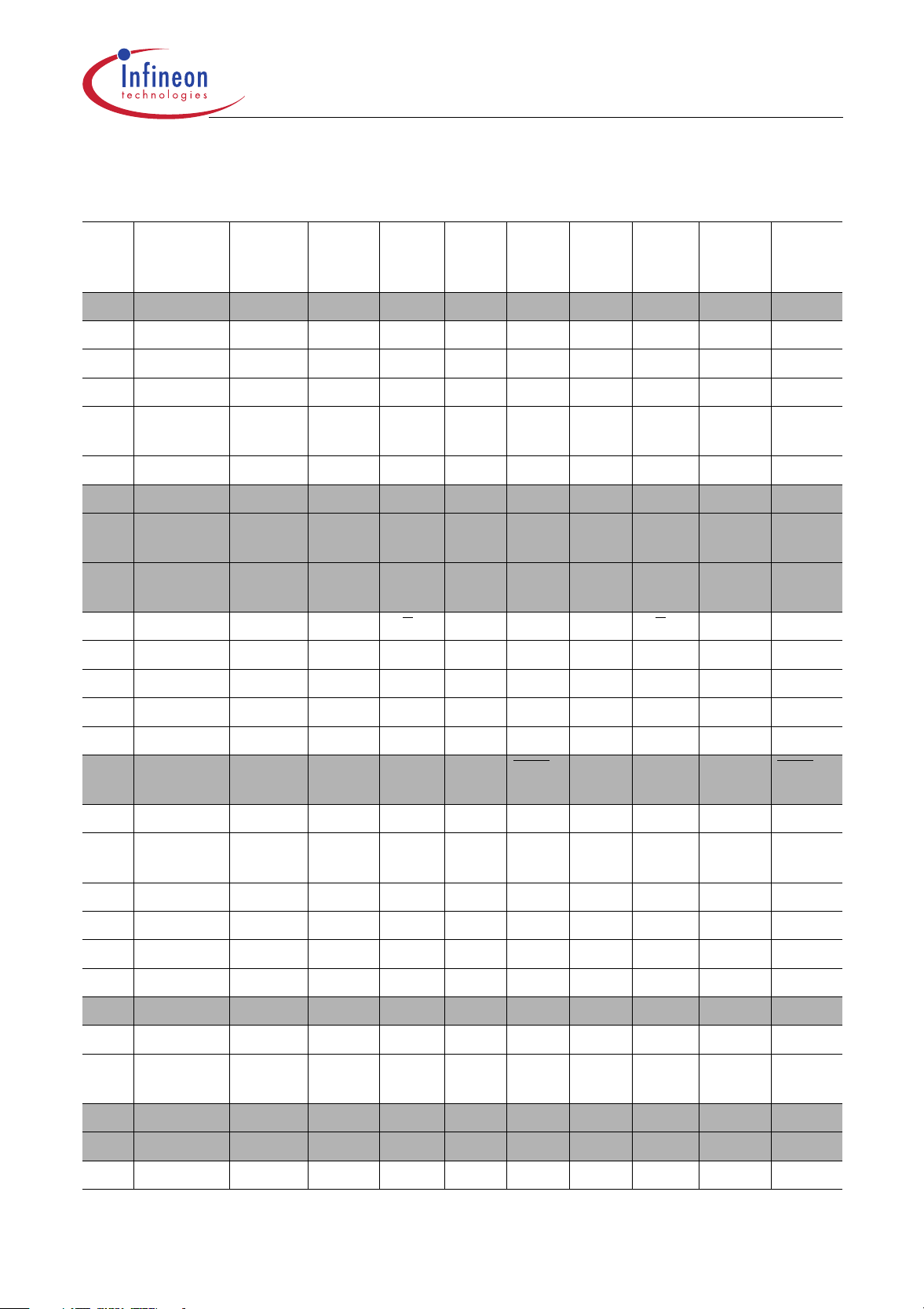

Table 4 Special Function Registers - Functional Block

Block Symbol Name Addr Contents after

Reset

CPU ACC

B

DPH

DPL

DPSEL

PSW

SP

SYSCON

A/DConverter

ADCON0

ADCON1

ADDATH

ADDATL

Interrupt

System

IEN0

IEN1

1)

1)

IEN2

1)

IP0

IP1

TCON

T2CON

SCON

1)

1)

1)

IRCON

XRAM XPAGE

SYSCON

Ports P0

P1

P2

P3

P4

P5

DIR5

P6

P7

SYSCON

Watchdog WDTREL

1)

IEN0

1)

IEN1

1)

IP0

Accumulator

B-Register

Data Pointer, High Byte

Data Pointer, Low Byte

Data Pointer Select Register

Program Status Word Register

Stack Pointer

1)

System Control Register C515C-8R

C515C-8E

1)

A/D Converter Control Register 0

A/D Converter Control Register 1

A/D Converter Data Register High Byte

A/D Converter Data Register Low Byte

Interrupt Enable Register 0

Interrupt Enable Register 1

Interrupt Enable Register 2

Interrupt Priority Register 0

Interrupt Priority Register 1

Timer Control Register

Timer 2 Control Register

Serial Channel Control Register

Interrupt Request Control Register

Page Address Register for Extended

on-chip XRAM and CAN Controller

1)

System Control Register C515C-8R

C515C-8E

Port 0

Port 1

Port 2

Port 3

Port 4

Port 5

Port 5 Direction Register

Port 6, Analog/Digital Input

Port 7

1)

System Control Register C515C-8R

C515C-8E

Watchdog Timer Reload Register

Interrupt Enable Register 0

Interrupt Enable Register 1

Interrupt Priority Register 0

E0

F0

83

82

92

D0

81

B1

B1

D8

DC

D9

DA

A8

B8

9A

A9

B9

88

C8

98

C0

91

B1

B1

80

90

A0

B0

E8

F8

F8

DB

FA

B1

86

A8

B8

A9

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

2)

2)

2)

2)

H

H

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)4)

H

2)

2)

00

H

00

H

00

H

00

H

XXXXX000

00

H

07

H

X010XX01

X010X001

00

H

0XXXX000

00

H

00XXXXXX

00

H

00

H

XX00X00X

00

H

0X000000

00

H

00

H

00

H

00

H

00

H

X010XX01

X010X001

FF

H

FF

H

FF

H

FF

H

FF

H

FF

H

FF

H

–

XXXXXXX1

X010XX01

X010X001

00

H

00

H

00

H

00

H

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

3)

B

Data Sheet 24 2003-02

C515C

Table 4 Special Function Registers - Functional Block (cont’d)

Block Symbol Name Addr Contents after

Reset

Serial

Channel

CAN

Controller

ADCON0

PCON

1)

SBUF

SCON

SRELL

SRELH

CR

SR

IR

BTR0

BTR1

GMS0

GMS1

UGML0

UGML1

LGML0

LGML1

UMLM0

UMLM1

LMLM0

LMLM1

MCR0

MCR1

UAR0

UAR1

LAR0

LAR1

MCFG

DB0n

DB1n

DB2n

DB3n

DB4n

DB5n

DB6n

DB7n

1)

A/D Converter Control Register 0

Power Control Register

Serial Channel Buffer Register

Serial Channel Control Register

Serial Channel Reload Register, low byte

Serial Channel Reload Register, high byte

Control Register

Status Register

Interrupt Register

Bit Timing Register Low

Bit Timing Register High

Global Mask Short Register Low

Global Mask Short Register High

Upper Global Mask Long Register Low

Upper Global Mask Long Register High

Lower Global Mask Long Register Low

Lower Global Mask Long Register High

Upper Mask of Last Message Register

Low

Upper Mask of Last Message Register

High

Lower Mask of Last Message Register

Low

Lower Mask of Last Message Register

High

Message Object Registers:

Message Control Register Low

Message Control Register High

Upper Arbitration Register Low

Upper Arbitration Register High

Lower Arbitration Register Low

Lower Arbitration Register High

Message Configuration Register

Message Data Byte 0

Message Data Byte 1

Message Data Byte 2

Message Data Byte 3

Message Data Byte 4

Message Data Byte 5

Message Data Byte 6

Message Data Byte 7

D8

H

87

H

99

H

98

H

AA

H

BA

H

F700

F701

F702

F704

F705

F706

F707

F708

F709

F70A

F70B

F70C

F70D

F70E

F70F

F7n0

F7n1

F7n2

F7n3

F7n4

F7n5

F7n6

F7n7

F7n8

F7n9

F7nA

F7nB

F7nC

F7nD

F7nE

2)

2)

00

00

XX

00

D9

XXXXXX11

101

H

XX

H

XX

H

UU

H

0UUUUUUU

H

UU

H

UUU11111

H

UU

H

UU

H

UU

H

UUUUU000

H

UU

H

UU

H

UU

H

UUUUU000

H

5)

UU

H

5)

UU

H

5)

UU

H

5)

UU

H

5)

UU

H

5)

UUUUU000

H

5)

UUUUUU00

H

5)

XX

H

5)

XX

H

5)

XX

H

5)

XX

H

5)

XX

H

5)

XX

H

5)

XX

H

5)

XX

H

H

H

3)

H

H

H

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

6)

H

3)

B

B

6)

B

6)

B

6)

B

6)

B

6)

B

6)

Data Sheet 25 2003-02

C515C

Table 4 Special Function Registers - Functional Block (cont’d)

Block Symbol Name Addr Contents after

Reset

SSC

Interface

Timer 0/

Timer 1

Compare/

Capture Unit/

Timer 2

Power Save

Modes

SSCCON

STB

SRB

SCF

SCIEN

SSCMOD

TCON

TH0

TH1

TL0

TL1

TMOD

CCEN

CCH1

CCH2

CCH3

CCL1

CCL2

CCL3

CRCH

CRCL

TH2

TL2

T2CON

PCON

1)

PCON1

SSC Control Register

SSC Transmit Buffer

SSC Receive Register

SSC Flag Register

SSC Interrupt Enable Register

SSC Mode Test Register

Timer 0/1 Control Register

Timer 0, High Byte

Timer 1, High Byte

Timer 0, Low Byte

Timer 1, Low Byte

Timer Mode Register

Comp./Capture Enable Reg.

Comp./Capture Reg. 1, High Byte

Comp./Capture Reg. 2, High Byte

Comp./Capture Reg. 3, High Byte

Comp./Capture Reg. 1, Low Byte

Comp./Capture Reg. 2, Low Byte

Comp./Capture Reg. 3, Low Byte

Com./Rel./Capt. Reg. High Byte

Com./Rel./Capt. Reg. Low Byte

Timer 2, High Byte

Timer 2, Low Byte

Timer 2 Control Register

Power Control Register

Power Control Register 1 C515C-8R

C515C-8E

1)

This special function register is listed repeatedly since some bits of it also belong to other functional blocks.

2)

Bit-addressable special function registers

3)

“X” means that the value is undefined and the location is reserved.

4)

This SFR is a mapped SFR. For accessing this SFR, bit PDIR in SFR IP1 must be set.

5)

The notation “n” in the message object address definition defines the number of the related message object.

6)

“X” means that the value is undefined and the location is reserved. “U” means that the value is unchanged by

a reset operation. “U” values are undefined (as “X”) after a power-on reset operation.

7)

SFR is located in the mapped SFR area. For accessing this SFR, bit RMAP in SFR SYSCON must be set.

93

94

95

AB

AC

96

88

8C

8D

8A

8B

89

C1

C3

C5

C7

C2

C4

C6

CB

CA

CD

CC

C8

87

88

88

2)

H

H

H

H

H

H

2)

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

2)

H

H

7)

H

7)

H

2)

07

H

3)

XX

H

3)

XX

H

XXXXXX00

XXXXXX00

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

00

H

0XXXXXXX

0XX0XXXX

3)

B

3)

B

3)

B

3)

B

Data Sheet 26 2003-02

Table 5 Contents of the SFRs, SFRs in Numeric Order

of their Addresses

C515C

Addr. Register Content

after

1)

Reset

2)

80

81

82

83

86

87

88

88

88

89

8A

8B

8C

8D

90

P0 FF

H

SP 07

H

DPL 00

H

DPH 00

H

WDTREL 00

H

PCON 00

H

2)

TCON 00

H

3)

PCON1

H

3)

PCON1

H

TMOD 00

H

TL0 00

H

TL1 00

H

TH0 00

H

TH1 00

H

2)

P1 FF

H

H

H

H

H

H

H

H

4)

0XXXXXXX

B

5)

0XX0XXXX

B

H

H

H

H

H

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

WDT

.6 .5 .4 .3 .2 .1 .0

PSEL

SMOD PDS IDLS SD GF1 GF0 PDE IDLE

TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0

EWPD – – – – – – –

EWPD – – WS – – – –

GATE C/T M1 M0 GATE C/T M1 M0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

T2 CLK-

T2EX INT2 INT6 INT5 INT4 INT3

OUT

91

92

93

94

95

96

98

99

9A

A0

A8

A9

XPAGE 00

H

DPSEL XXXX-

H

SSCCON 07

H

STB XX

H

SRB XX

H

SSCMOD 00

H

2)

SCON 00

H

SBUF XX

H

IEN2 X00X-

H

2)

P2 FF

H

2)

IEN0 00

H

IP0 00

H

H

X000

H

H

H

H

H

H

X00X

H

H

H

.7 .6 .5 .4 .3 .2 .1 .0

– ––––.2.1 .0

B

SCEN TEN MSTR CPOL CPHA BRS2 BRS1 BRS0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

LOOPB TRIO 0 0 0 0 0 LSBSM

SM0 SM1 SM2 REN TB8 RB8 TI RI

.7 .6 .5 .4 .3 .2 .1 .0

– – EX8 EX7 – ESSC ECAN –

B

.7 .6 .5 .4 .3 .2 .1 .0

EAL WDT ET2 ES ET1 EX1 ET0 EX0

OWDS WDTS .5 .4 .3 .2 .1 .0

Data Sheet 27 2003-02

Table 5 Contents of the SFRs, SFRs in Numeric Order

of their Addresses (cont’d)

C515C

Addr. Register Content

after

1)

Reset

AA

AB

AC

B0

B1

B1

B8

B9

BA

C0

C1

SRELL D9

H

SCF XXXX-

H

SCIEN XXXX-

H

2)

P3 FF

H

SYSCON4)X010-

H

SYSCON5)X010-

H

2)

IEN1 00

H

IP1 0X00-

H

SRELH XXXX-

H

2)

IRCON 00

H

CCEN 00

H

H

XX00

XX00

H

XX01

X001

H

0000

XX11

H

H

B

B

B

B

B

B

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

.7 .6 .5 .4 .3 .2 .1 .0

– ––––– WCOLTC

– ––––– WCENTCEN

RD WR T1 T0 INT1 INT0 TxD RxD

– PMOD EALE RMAP – – XMAP1 XMAP0

– PMOD EALE RMAP – CSWO XMAP1 XMAP0

EXEN2 SWDT EX6 EX5 EX4 EX3 EX2 EADC

PDIR – .5 .4 .3 .2 .1 .0

– ––––– .1 .0

EXF2 TF2 IEX6 IEX5 IEX4 IEX3 IEX2 IADC

COCAH3COCAL3COCAH2COCAL2COCAH1COCAL1COCAH0COCA

L0

C2

C3

C4

C5

C6

C7

C8

CA

CB

CC

CD

CCL1 00

H

CCH1 00

H

CCL2 00

H

CCH2 00

H

CCL3 00

H

CCH3 00

H

2)

T2CON 00

H

CRCL 00

H

CRCH 00

H

TL2 00

H

TH2 00

H

H

H

H

H

H

H

H

H

H

H

H

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

T2PS I3FR I2FR T2R1 T2R0 T2CM T2I1 T2I0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

Data Sheet 28 2003-02

Table 5 Contents of the SFRs, SFRs in Numeric Order

of their Addresses (cont’d)

C515C

Addr. Register Content

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

after

1)

Reset

2)

D0

D8

D9

DA

DB

DC

E0

E8

F0

F8

F8

FA

FC

FD

FE

1)

2)

3)

4)

5)

6)

7)

8)

9)

PSW 00

H

2)

ADCON0 00

H

ADDATH 00

H

ADDATL 00XX-

H

H

H

H

XXXX

P6 – .7 .6 .5 .4 .3 .2 .1 .0

H

ADCON1 0XXX-

H

X000

2)

ACC 00

H

2)

P4 FF

H

2)

B 00

H

2)

P5 FF

H

2)

H

H

6)

DIR5

P7 XXXX-

FF

H

H

H

H

H

XXX1

7)8)

VR0

H

7)8)

VR1

H

7)8)

VR2

H

C5

95

02

H

H

9)

H

CY AC F0 RS1 RS0 OV F1 P

BD CLK ADEX BSY ADM MX2 MX1 MX0

.9 .8 .7 .6 .5 .4 .3 .2

.1 .0–––– – –

B

ADCL – – – 0 MX2 MX1 MX0

B

.7 .6 .5 .4 .3 .2 .1 .0

RXDC TXDC INT8 SLS STO SRI SCLK ADST

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

– ––––– – INT7

B

1 1 0001 0 1

1 0 0101 0 1

0 0 0000 1 0

“X” means that the value is undefined and the location is reserved.

Bit-addressable special function registers

SFR is located in the mapped SFR area. For accessing this SFR, bit RMAP in SFR SYSCON must be set.

This SFR is available in the C515C-8R and C515C-L.

This SFR is available in the C515C-8E.

This SFR is a mapped SFR. For accessing this SFR, bit PDIR in SFR IP1 must be set.

This SFR is a mapped SFR. For accessing this SFR, bit RMAP in SFR SYSCON must be set.

These SFRs are read-only registers (C515C-8E only).

The content of this SFR varies with the actual step of the C515C-8E (e.g. 01H for the first step).

Data Sheet 29 2003-02

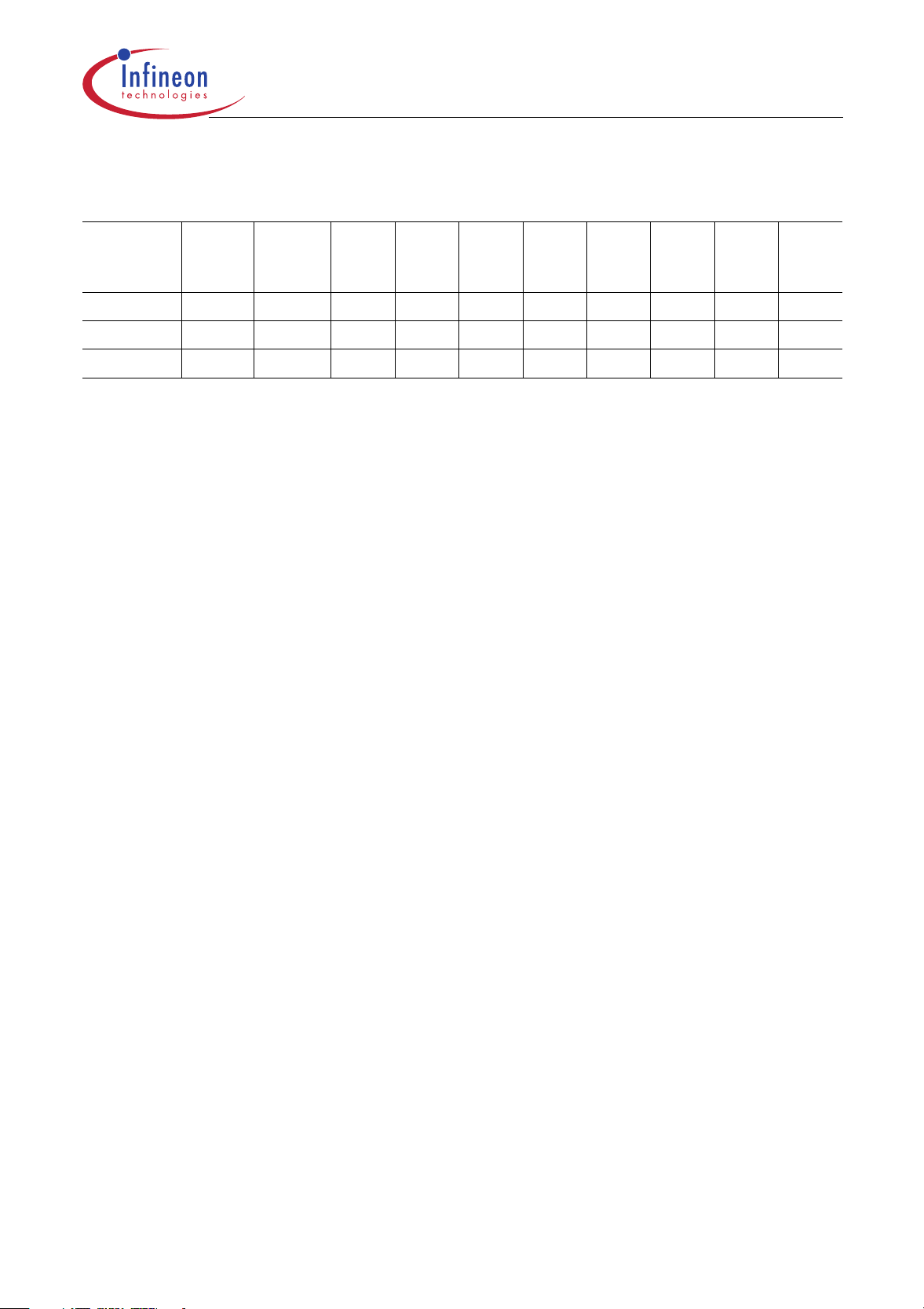

Table 6 Contents of the CAN Registers in Numeric Order

of their Addresses

C515C

Addr.

n = 1 to F

F700

H

F701

H

F702

H

F704

H

F705

H

F706

H

F707

H

F708

H

F709

H

F70A

H

F70B

H

F70C

H

F70D

H

F70E

H

F70F

H

F7n0

H

F7n1

H

Regis-

1)

ter

H

CR 01

SR XX

IR XX

BTR0 UU

BTR1 0UUU.

GMS0 UU

GMS1 UUU1.

UGML0 UU

UGML1 UU

LGML0 UU

LGML1 UUUU.

UMLM0 UU

UMLM1 UU

LMLM0 UU

LMLM1 UUUU.

MCR0 UU

MCR1 UU

Content

after

2)

Reset

H

H

H

H

UUUU

1111

U000

U000

B

H

B

H

H

H

B

H

H

H

B

H

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

TEST CCE 0 0 EIE SIE IE INIT

BOFF EWRN – RXOK TXOK LEC2 LEC1 LEC0

INTID

SJW BRP

0TSEG2 TSEG1

ID28-21

ID20-18 11111

ID28-21

ID20-13

ID12-5

ID4-0 000

ID28-21

ID20-18 ID17-13

ID12-5

ID4-0 000

MSGVAL TXIE RXIE INTPND

RMTPND TXRQ MSGLST

NEWDAT

CPUUPD

F7n2

F7n3

F7n4

F7n5

F7n6

F7n7

F7n8

F7n9

F7nA

F7nB

H

H

H

H

H

H

H

H

H

H

UAR0 UU

UAR1 UU

LAR0 UU

H

H

H

LAR1 UUUU.

U000

MCFG UUUU.

UU00

DB0n XX

DB1n XX

DB2n XX

DB3n XX

DB4n XX

H

H

H

H

H

ID28-21

ID20-18 ID17-13

ID12-5

ID4-0 000

B

DLC DIR XTD 0 0

B

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

Data Sheet 30 2003-02

Table 6 Contents of the CAN Registers in Numeric Order

of their Addresses (cont’d)

C515C

Addr.

n = 1 to F

F7nC

H

F7nD

H

F7nE

H

1)

The notation “n” in the address definition defines the number of the related message object.

2)

“X” means that the value is undefined and the location is reserved. “U” means that the value is

Regis-

1)

ter

H

DB5n XX

DB6n XX

DB7n XX

Content

after

2)

Reset

H

H

H

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

.7 .6 .5 .4 .3 .2 .1 .0

unchanged by a reset operation. “U” values are undefined (as “X”) after a power-on reset operation.

Data Sheet 31 2003-02

C515C

Digital I/O Ports

The C515C allows for digital I/O on 49 lines grouped into 6 bidirectional 8-bit ports and

one 1-bit port. Each port bit consists of a latch, an output driver and an input buffer. Read

and write accesses to the I/O ports P0 through P7 are performed via their corresponding

special function registers P0 to P7. The port structure of port 5 of the C515C is especially

designed to operate either as a quasi-bidirectional port structure, compatible to the

standard 8051-Family, or as a genuine bidirectional port structure. This port operating

mode can be selected by software (setting or clearing the bit PMOD in the SFR

SYSCON).

The output drivers of port 0 and 2 and the input buffers of port 0 are also used for

accessing external memory. In this application, port 0 outputs the low byte of the external

memory address, time-multiplexed with the byte being written or read. Port 2 outputs the

high byte of the external memory address when the address is 16 bits wide. Otherwise,

the port 2 pins continue emitting the P2 SFR contents.

Analog Input Ports

Ports 6 is available as input port only and provides two functions. When used as digital

inputs, the corresponding SFR P6 contains the digital value applied to the port 6 lines.

When used for analog inputs the desired analog channel is selected by a three-bit field

in SFR ADCON0 or SFR ADCON1. Of course, it makes no sense to output a value to

these input-only ports by writing to the SFR P6. This will have no effect.

If a digital value is to be read, the voltage levels are to be held within the input voltage

specifications (

V

IL/VIH

). Since P6 is not bit-addressable, all input lines of P6 are read at

the same time by byte instructions.

Nevertheless, it is possible to use port 6 simultaneously for analog and digital input.

However, care must be taken that all bits of P6 that have an undetermined value caused

by their analog function are masked.

Data Sheet 32 2003-02

C515C

Port Structure Selection of Port 5

After a reset operation of the C515C, the quasi-bidirectional 8051-compatible port

structure is selected. For selection of the bidirectional (CMOS) port 5 structure the bit

PMOD of SFR SYSCON must be set. Because each port 5 pin can be programmed as

an input or an output, additionally, after the selection of the bidirectional mode the

direction register DIR5 of port 5 must be written. This direction register is mapped to the

port 5 register. This means, the port register address is equal to its direction register

address. Figure 10 illustrates the port and direction register configuration.

Int. Bus, Bit 7

Write to IP 1

Instruction sequence for the programming of the direction registers:

ORL IP1, #80H ; Set bit PDIR

D

RQ

Write port x direction register with value YYH;#OYYHDIRx,MOV

Q

PDIR

Delay:

2.5 Machine Cycles

Figure 10 Port Register, Direction Register

Enable

Enable

Write to Port

Port Register

Direction Register

Read Port

Internal

Bus

MCS02649

Data Sheet 33 2003-02

C515C

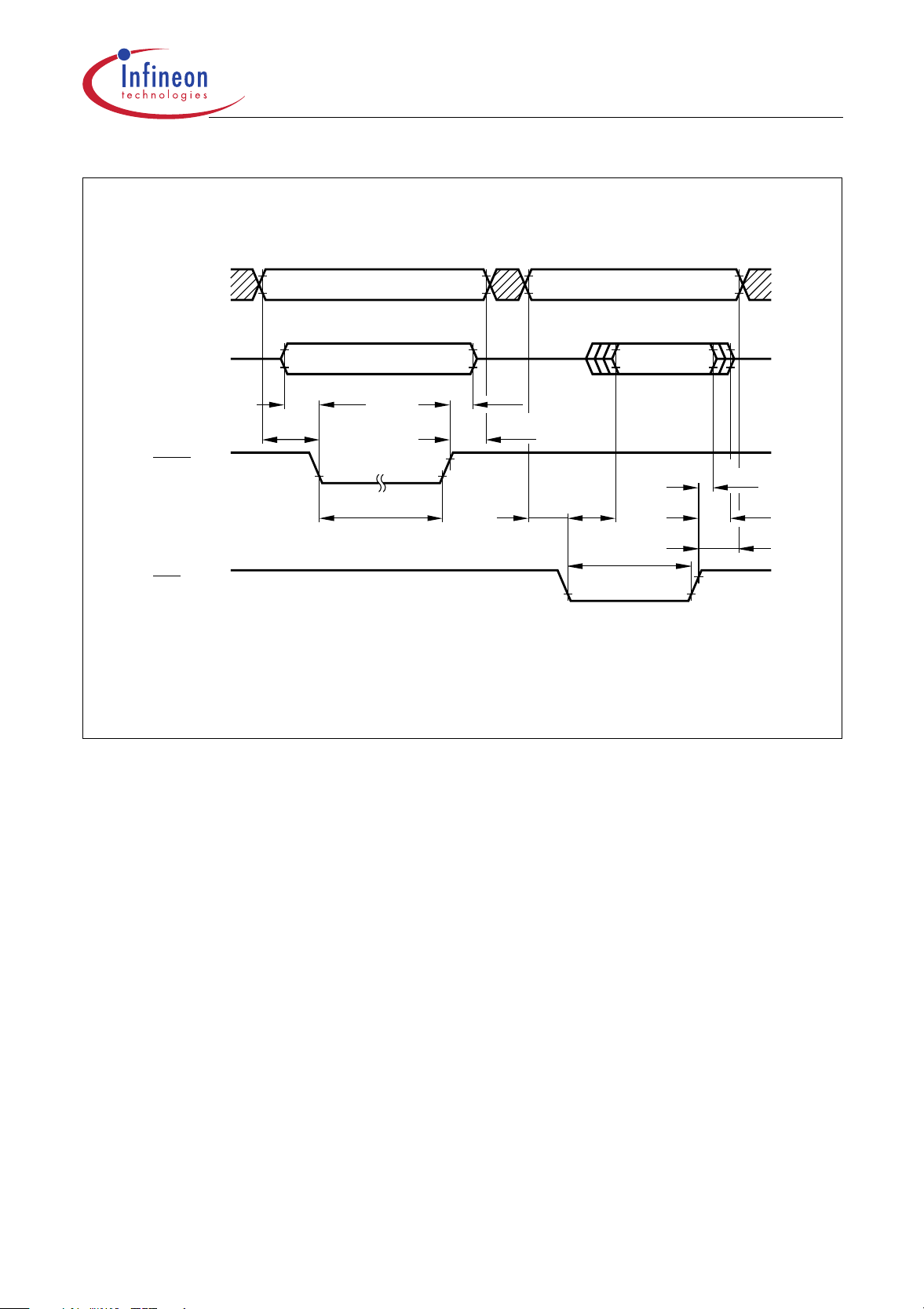

Timer / Counter 0 and 1

Timer / Counter 0 and 1 can be used in four operating modes as listed in Table 7:

Table 7 Timer/Counter 0 and 1 Operating Modes

Mode Description TMOD Timer/Counter Input Clock

M1 M0 internal external (max)

f

0 8-bit timer/counter with a

00

divide-by-32 prescaler

1 16-bit timer/counter 0 1

/6 × 32 f

OSC

f

/6 f

OSC

OSC

OSC

/12 × 32

/12

2 8-bit timer/counter with 8-bit

10

autoreload

3 Timer/counter 0 used as

11

one 8-bit timer/counter and

one 8-bit timer / Timer 1

stops

In the “timer” function (C/

Therefore the count rate is

T = ‘0’) the register is incremented every machine cycle.

f

/6.

OSC

In the “counter” function the register is incremented in response to a 1-to-0 transition at

its corresponding external input pin (P3.4/T0, P3.5/T1). Since it takes two machine

f

cycles to detect a falling edge the max. count rate is

INT1 (P3.2, P3.3) can be programmed to function as a gate to facilitate pulse width

/12. External inputs INT0 and

OSC

measurements. Figure 11 illustrates the input clock logic.

P3.4/T0

P3.5/T1

OSC

÷

6

C/T = 0

C/T = 1

Control

f

/6

OSC

Timer 0/1

Input Clock

Gate

(TMOD)

P3.2/INT0

P3.3/INT1

=1

TR0

TR1

_

<

1

&

MCS03117

Figure 11 Timer/Counter 0 and 1 Input Clock Logic

Data Sheet 34 2003-02

C515C

Timer / Counter 2 with Compare/Capture/Reload

The timer 2 of the C515C provides additional compare/capture/reload features, which

allow the selection of the following operating modes:

• Compare: up to 4 PWM signals with 16-bit/600 ns resolution

• Capture: up to 4 high speed capture inputs with 600 ns resolution

• Reload: modulation of timer 2 cycle time

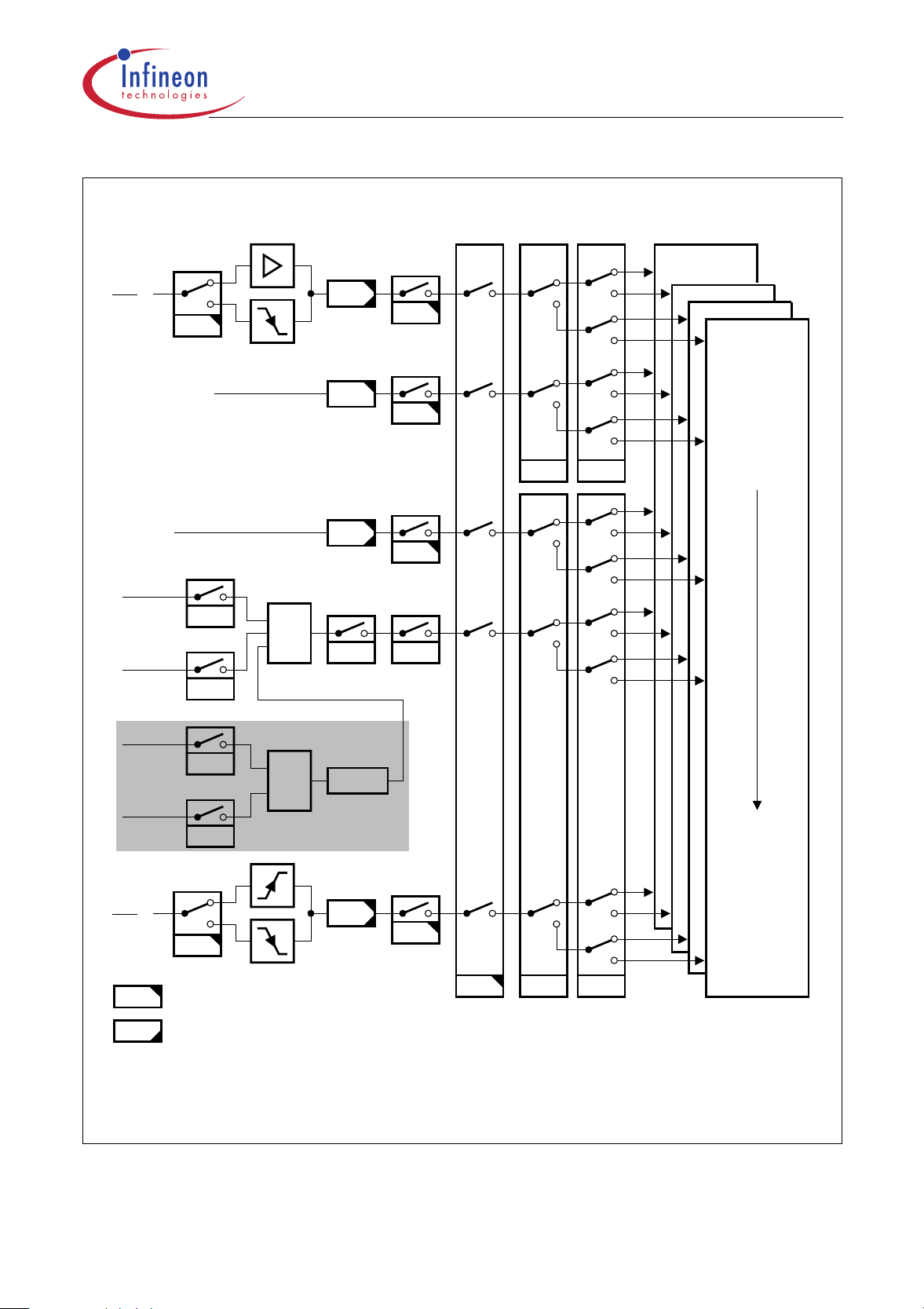

The block diagram in Figure 12 shows the general configuration of timer 2 with the

additional compare/capture/reload registers. The I/O pins which can used for timer 2

control are located as multifunctional port functions at port 1.

P1.5/

T2EX

P1.7/

T2

OSC

Sync.

T2I0

T2I1

Sync.

&

÷6

f

OSC

÷12

T2PS

Bit16 16 Bit 16 Bit 16 Bit

Comparator

Comparator

Comparator

EXEN2

Reload

EXF2

Reload

Timer 2

TH2TL2

Compare

Comparator

Capture

_

<

1

TF2

Input/

Output

Control

Interrupt

Request

P1.0/

INT3/

CC0

P1.1/

INT4/

CC1

P1.2/

INT5/

CC2

P1.2/

INT6/

CCL3/CCH3

CCL2/CCH2

CCL1/CCH1

CRCL/CRCH

CC3

MCB02730

Figure 12 Timer 2 Block Diagram

Data Sheet 35 2003-02

C515C

Timer 2 Operating Modes

The timer 2, which is a 16-bit-wide register, can operate as timer, event counter, or gated

timer. A roll-over of the count value in TL2/TH2 from all 1’s to all 0’s sets the timer

overflow flag TF2 in SFR IRCON, which can generate an interrupt. The bits in register

T2CON are used to control the timer 2 operation.

Timer Mode: In timer function, the count rate is derived from the oscillator frequency. A

prescaler offers the possibility of selecting a count rate of 1/6 or 1/12 of the oscillator

frequency.

Gated Timer Mode: In gated timer function, the external input pin T2 (P1.7) functions as

a gate to the input of timer 2. If T2 is high, the internal clock input is gated to the timer.

T2 = 0 stops the counting procedure. This facilitates pulse width measurements. The

external gate signal is sampled once every machine cycle.

Event Counter Mode: In the event counter function. the timer 2 is incremented in

response to a 1-to-0 transition at its corresponding external input pin T2 (P1.7). In this

function, the external input is sampled every machine cycle. Since it takes two machine

cycles (12 oscillator periods) to recognize a 1-to-0 transition, the maximum count rate is

1/12 of the oscillator frequency. There are no restrictions on the duty cycle of the external

input signal, but to ensure that a given level is sampled at least once before it changes,

it must be held for at least one full machine cycle.

Reload of Timer 2: Two reload modes are selectable:

In mode 0, when timer 2 rolls over from all 1’s to all 0’s, it not only sets TF2 but also

causes the timer 2 registers to be loaded with the 16-bit value in the CRC register, which

is preset by software.

In mode 1, a 16-bit reload from the CRC register is caused by a negative transition at the

corresponding input pin P1.5/T2EX. This transition will also set flag EXF2 if bit EXEN2

in SFR IEN1 has been set.

Data Sheet 36 2003-02

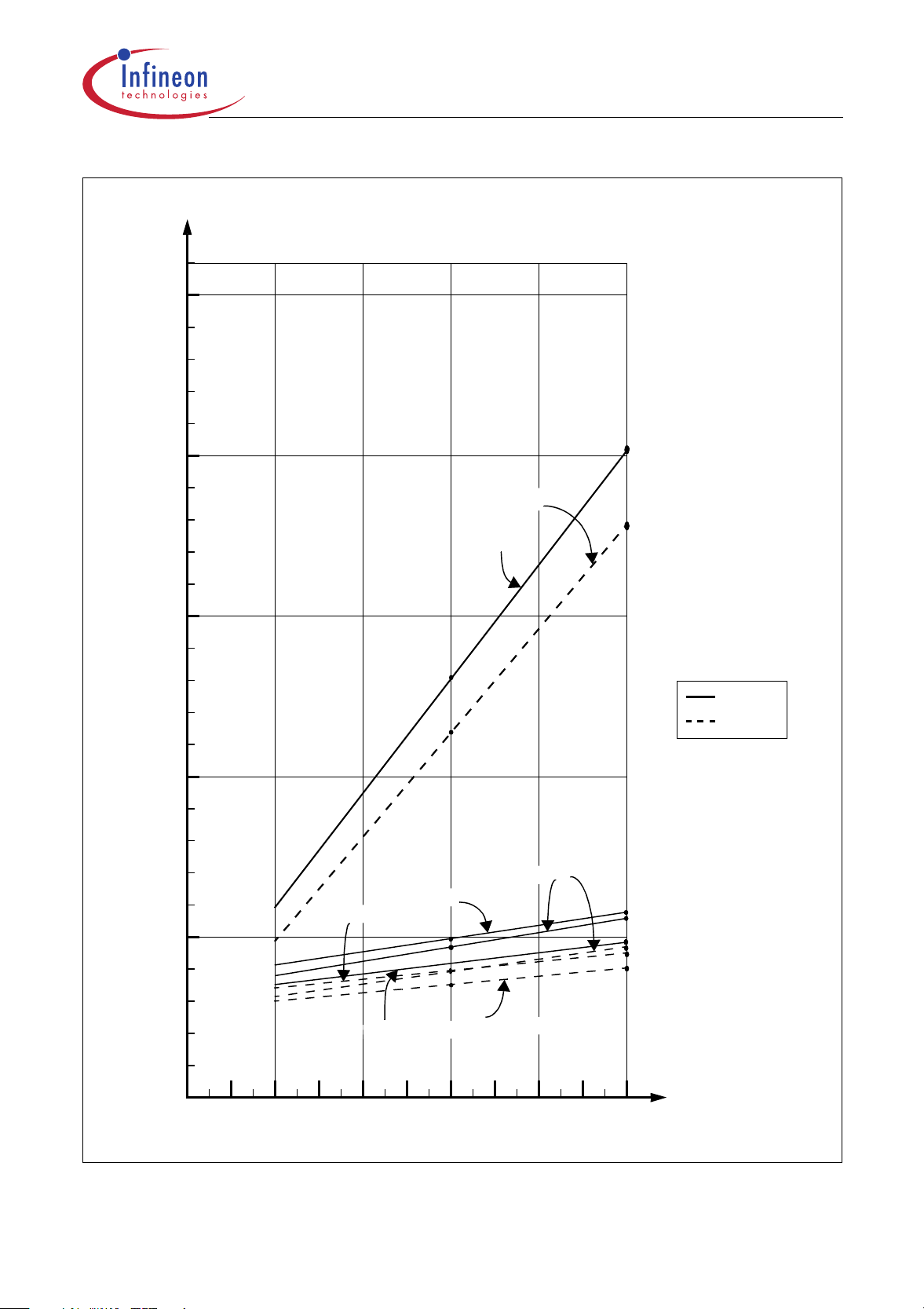

C515C

Timer 2 Compare Modes

The compare function of a timer/register combination operates as follows: the 16-bit

value stored in a compare or compare/capture register is compared with the contents of

the timer register; if the count value in the timer register matches the stored value, an

appropriate output signal is generated at a corresponding port pin and an interrupt can

be generated.

Compare Mode 0

In compare mode 0, upon matching the timer and compare register contents, the output

signal changes from low to high. lt goes back to a low level on timer overflow. As long as

compare mode 0 is enabled, the appropriate output pin is controlled by the timer circuit

only and writing to the port will have no effect. Figure 13 shows a functional diagram of

a port circuit when used in compare mode 0. The port latch is directly controlled by the

timer overflow and compare match signals. The input line from the internal bus and the

write-to-latch line of the port latch are disconnected when compare mode 0 is enabled.

Port Circuit

Compare Register

Circuit

Compare Reg.

16 Bit

Comparator

Bit16

Timer Register

Timer Circuit

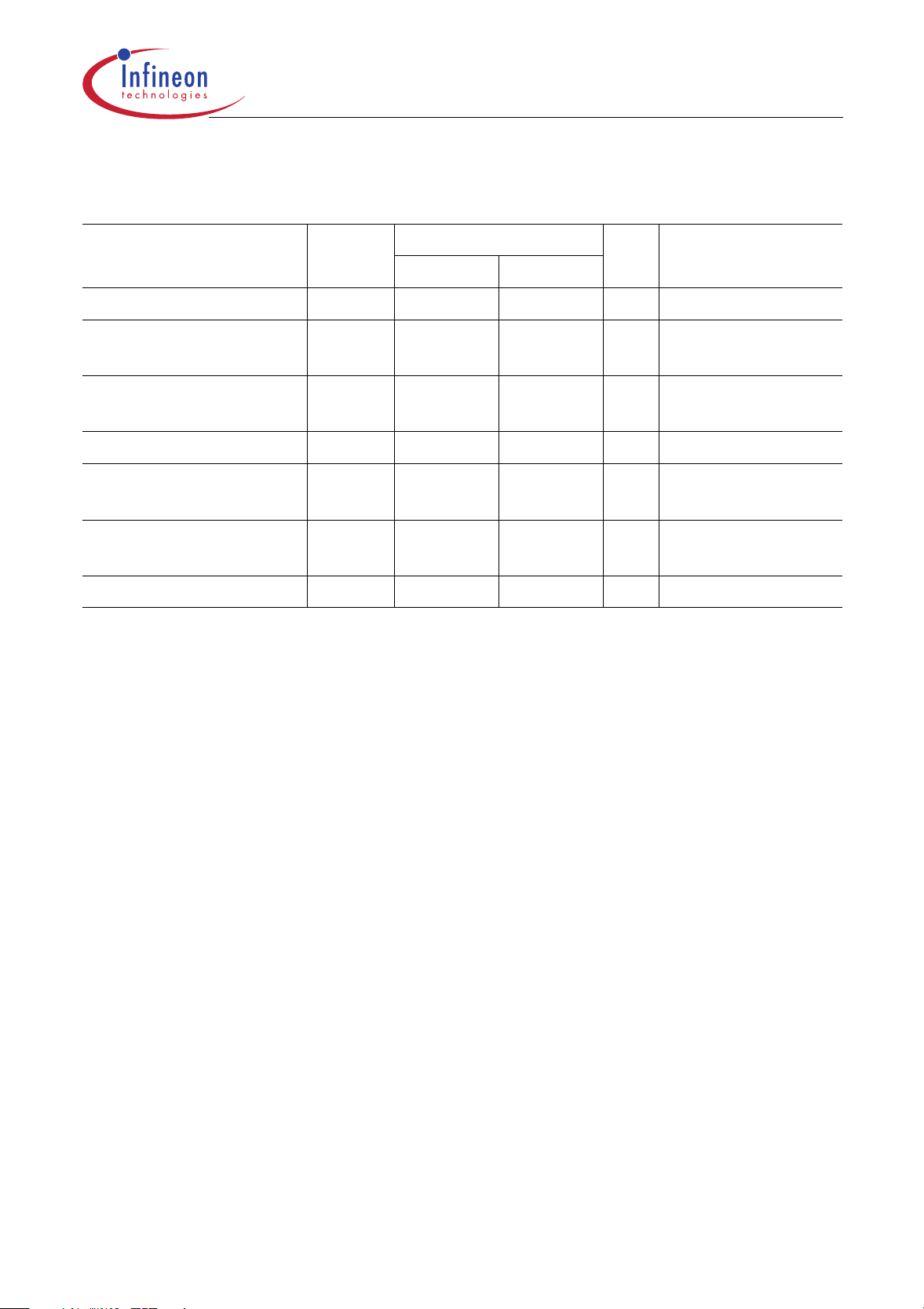

Compare

Match

Timer

Overflow

Internal

Bus

Write to

Latch

Figure 13 Port Latch in Compare Mode 0

S

D

Latch

CLK

R

Read Latch

Q

Port

Q

Read Pin

V

DD

Port

Pin

MCS02661

Data Sheet 37 2003-02

C515C

Compare Mode 1

If compare mode 1 is enabled and the software writes to the appropriate output latch at

the port, the new value will not appear at the output pin until the next compare match

occurs. Thus, it can be choosen whether the output signal has to make a new transition

(1-to-0 or 0-to-1, depending on the actual pin-level) or should keep its old value at the

time when the timer value matches the stored compare value.

In compare mode 1 (see Figure 14) the port circuit consists of two separate latches. One

latch (which acts as a “shadow latch”) can be written under software control, but its value

will only be transferred to the port latch (and thus to the port pin) when a compare match

occurs.

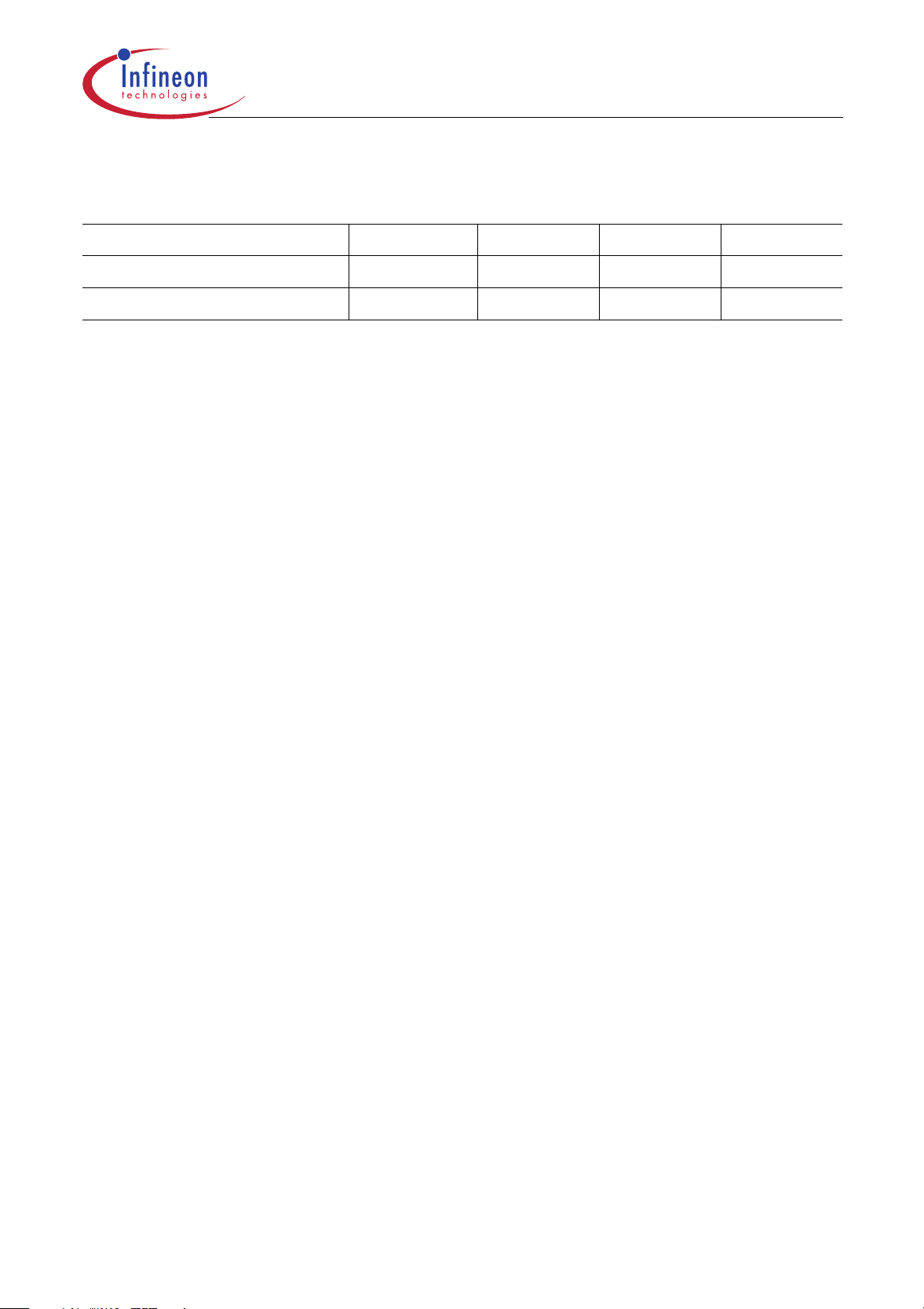

Port Circuit

Read Latch

Compare Register

Circuit

Compare Reg.

16 Bit

Comparator

16 Bit

Timer Register

Timer Circuit

Compare

Match

Internal

Bus

Write to

Latch

D

Shadow

Latch

CLK

Q

Figure 14 Compare Function in Compare Mode 1

D

Port

Latch

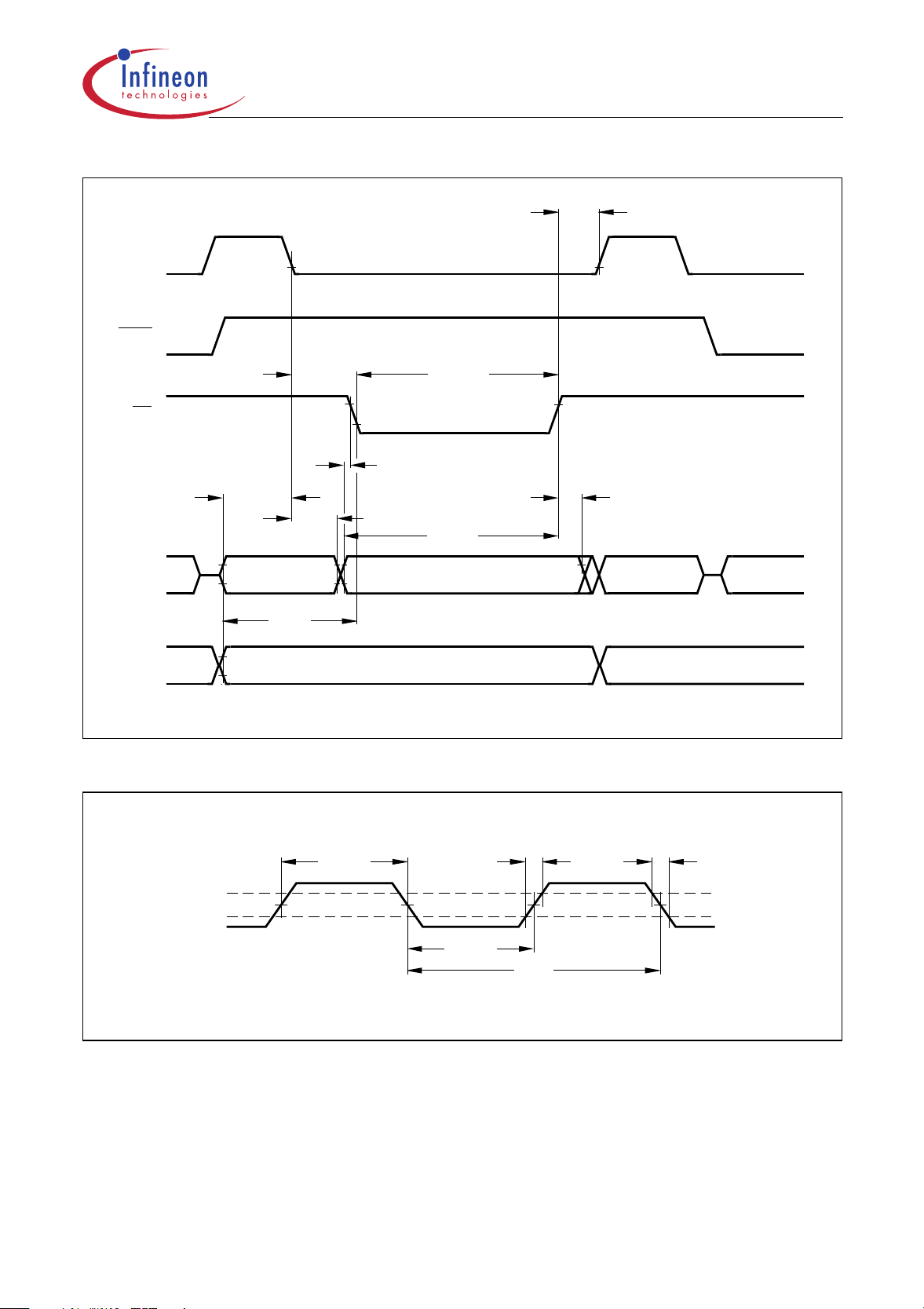

Read Pin

Q

QCLK

V

DD

Port

Pin

MCS02662

Data Sheet 38 2003-02

C515C

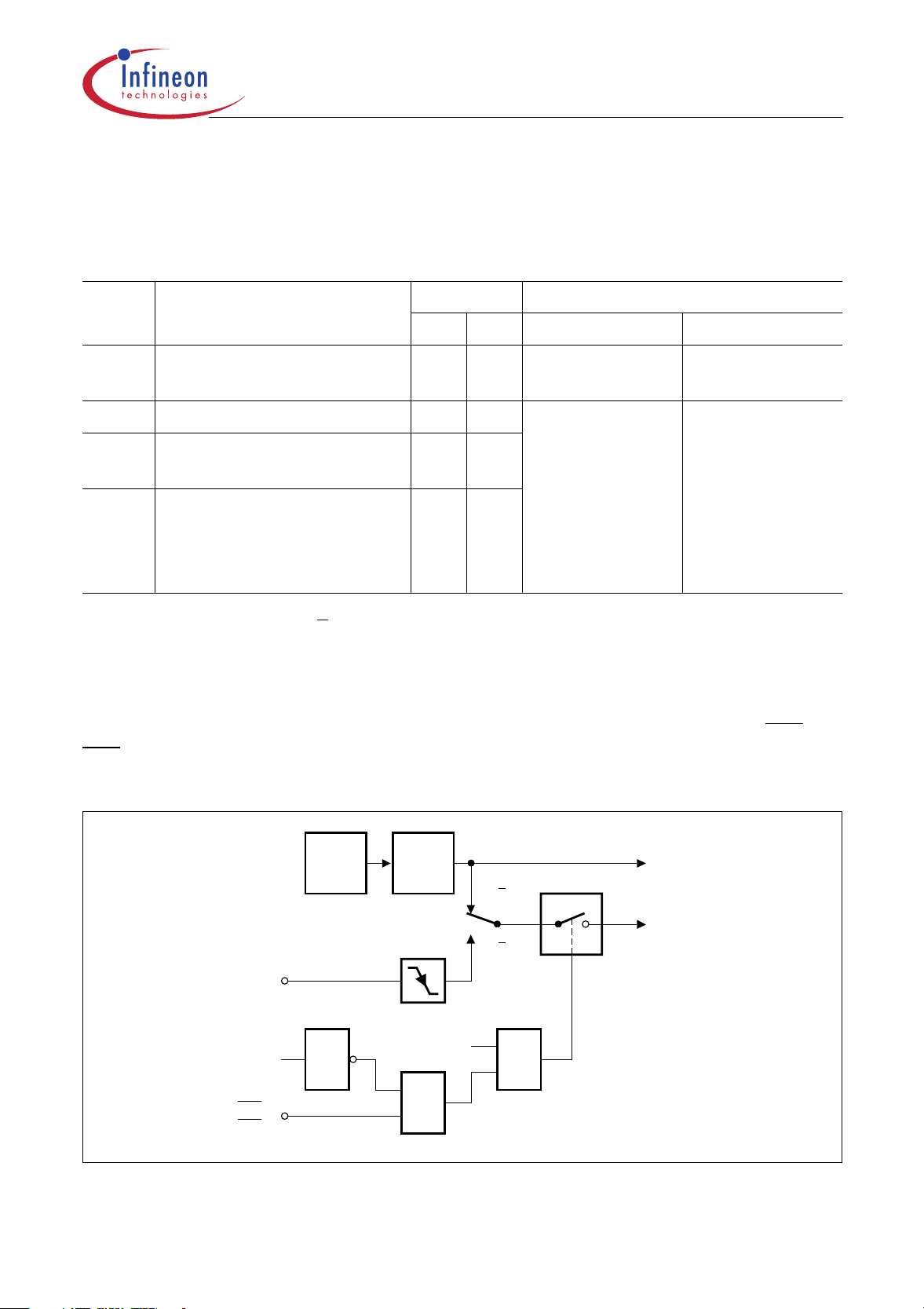

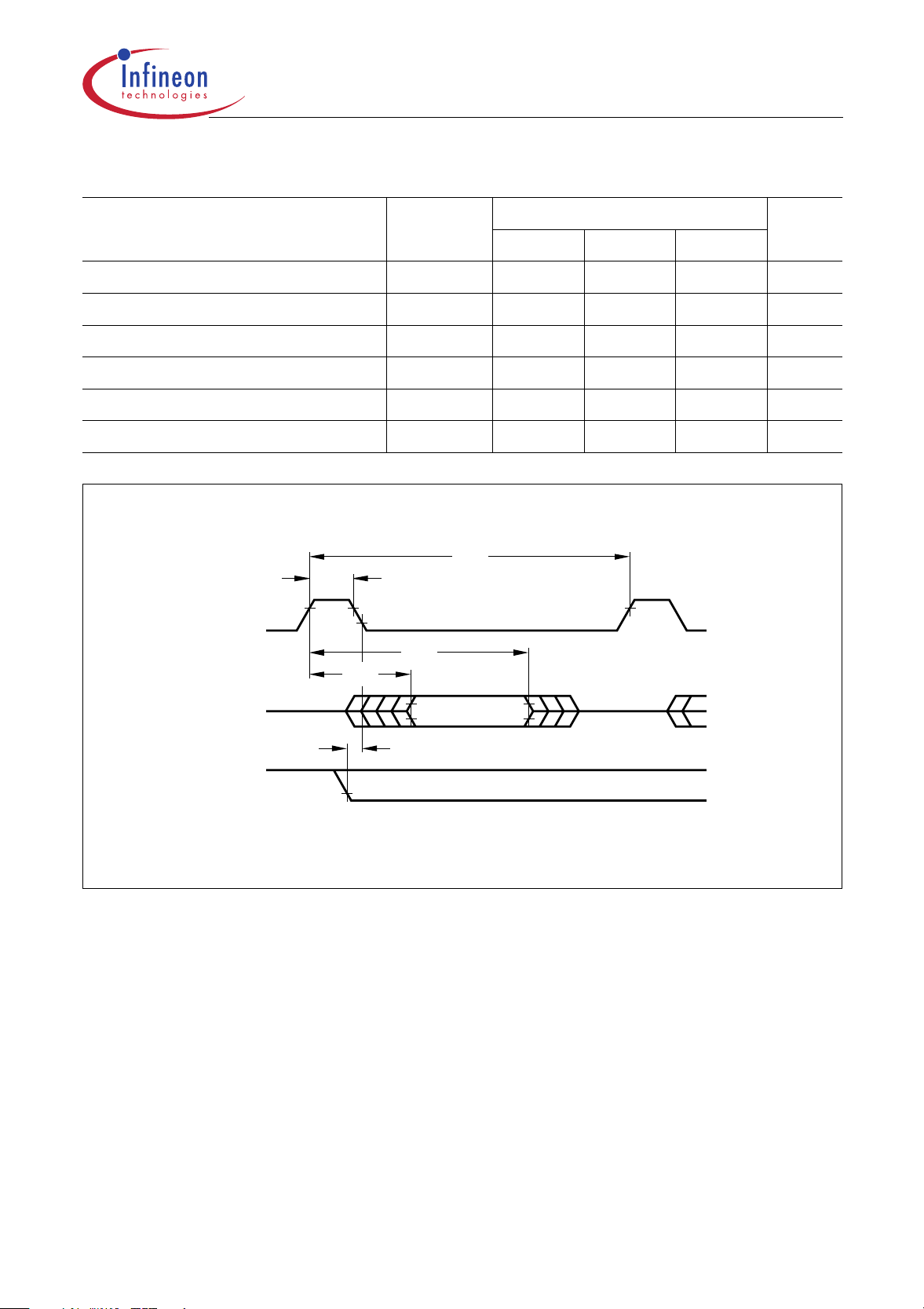

Serial Interface (USART)

The serial port is full duplex and can operate in four modes (one synchronous mode,

three asynchronous modes) as illustrated in Table 8.

Table 8 USART Operating Modes

SCON Description

Mode

SM0 SM1

000Shift register mode, fixed baud rate

Serial data enters and exits through R

the shift clock; 8-bit are transmitted/received (LSB first)

1018-bit UART, variable baud rate

10 bits are transmitted (through T

R

×D)

×D; T×D outputs

×D) or received (at

2109-bit UART, fixed baud rate

11 bits are transmitted (through T

×D)

R

×D) or received (at

3119-bit UART, variable baud rate

Like mode 2

For clarification some terms regarding the difference between “baud rate clock” and

“baud rate” should be mentioned. In the asynchronous modes the serial interfaces

require a clock rate which is 16 times the baud rate for internal synchronization.

Therefore, the baud rate generators/timers have to provide a “baud rate clock” (output

signal in Figure 15 to the serial interface which - there divided by 16 - results in the

actual “baud rate”. Further, the abbreviation

f

refers to the oscillator frequency

OSC

(crystal or external clock operation).

The variable baud rates for modes 1 and 3 of the serial interface can be derived either

from timer 1 or from a dedicated baud rate generator (see Figure 15).

Data Sheet 39 2003-02

Timer 1

Overflow

f

OSC

Baud

Rate

Generator

(SRELH

SRELL)

6÷÷

ADCON0.7

(BD)

0

1

Mode 2

Mode 0

Mode 1

Mode 3

SCON.7

SCON.6

(SM0/

SM1)

Only one mode

can be selected

C515C

PCON.7

2

(SMOD)

0

1

Baud

Rate

Clock

Note: The switch configuration shows the reset state.

MCS02733

Figure 15 Block Diagram of Baud Rate Generation for the Serial Interface

Table 9 below lists the values/formulas for the baud rate calculation of the serial

interface with its dependencies of the control bits BD and SMOD.

Table 9 Serial Interface - Baud Rate Dependencies

Serial Interface

Operating Modes

Active Control

Bits

Baud Rate Calculation

BD SMOD

Mode 0 (Shift

––

f

OSC

/ 6

Register)

Mode 1 (8-bit UART)

Mode 3 (9-bit UART)

0 X Controlled by timer 1 overflow:

SMOD

(2

× timer 1 overflow rate) / 32

1 X Controlled by baud rate generator

(2

(32

SMOD

× f

OSC

) /

× baud rate generator overflow rate)

f

Mode 2 (9-bit UART) – 0

1

Data Sheet 40 2003-02

OSC

f

OSC

/ 32

/ 16

C515C

SSC Interface

The C515C microcontroller provides a Synchronous Serial Channel unit, the SSC. This

interface is compatible to the popular SPI serial bus interface. Figure 16 shows the block

diagram of the SSC. The central element of the SSC is an 8-bit shift register. The input

and the output of this shift register are each connected via a control logic to the pin P4.2

/ SRI (SSC Receiver In) and P4.3 / STO (SSC Transmitter Out). This shift register can

be written to (SFR STB) and can be read through the Receive Buffer Register SRB.

f

OSC

Clock Divider

Clock Selection

Receive Buffer Register

Interrupt

SCIEN

Int. Enable Reg.

SSCCON SCF

Control Register Status Register

Control Logic

Shift Register

SRB

STB

Pin

Control

Logic

Internal Bus

P4.1/SCLK

P4.2/SRI

P4.3/STO

P4.4/SLS

MCB02735

Figure 16 SSC Block Diagram

The SSC has implemented a clock control circuit, which can generate the clock via a

baud rate generator in the master mode, or receive the transfer clock in the slave mode.

The clock signal is fully programmable for clock polarity and phase. The pin used for the

clock signal is P4.1 / SCLK. When operating in slave mode, a slave select input is

provided which enables the SSC interface and also will control the transmitter output.

The pin used for this is P4.4 / SLS

.

The SSC control block is responsible for controlling the different modes and operation of

the SSC, checking the status, and generating the respective status and interrupt signals.

Data Sheet 41 2003-02

C515C

CAN Controller

The on-chip CAN controller is the functional heart which provides all resources that are

required to run the standard CAN protocol (11-bit identifiers) as well as the extended

CAN protocol (29-bit identifiers). It provides a sophisticated object layer to relieve the

CPU of as much overhead as possible when controlling many different message objects

(up to 15). This includes bus arbitration, resending of garbled messages, error handling,

interrupt generation, etc. In order to implement the physical layer, external components

have to be connected to the C515C.

The internal bus interface connects the on-chip CAN controller to the internal bus of the

microcontroller. The registers and data locations of the CAN interface are mapped to a

specific 256 bytes wide address range of the external data memory area (F700

F7FF