Data Sheet, V2.0, May 2001

C164CI/SI

C164CL/SL

16-Bit Single-Chip Microcontroller

Microcontrollers

Never stop thinking.

Edition 2001-05

Published by Infineon Technologies AG,

St.-Martin-Strasse 53,

D-81541 München, Germany

© Infineon Technologies AG 2001.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted

characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement, regarding

circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your nearest

Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide.

Warnings

Due to technical requirements components may contain dangerous substances. For information on the types in

question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written

approval of Infineon Technologies, if a failure of such components can reasonably be expected to cause the failure

of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support

devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain

and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may

be endangered.

Data Sheet, V2.0, May 2001

C164CI/SI

C164CL/SL

16-Bit Single-Chip Microcontroller

Microcontrollers

Never stop thinking.

C164CI

Revision History: 2001-05 V2.0

Previous Version: 1999-08

1998-02 (Preliminary)

04.97 (Advance Information)

Page Subjects (major changes since last revision)

1)

All Converted to Infineon layout

1 Operating frequency up to 25 MHz

1 et al. References to Flash removed

1 Timer Unit with three timers

1, 12, 73 On-chip XRAM described

2 Derivative table updated

10 Supply voltage is 5 V

21 Functionality of reduced CAPCOM6 corrected

22f Timer description improved

29, 30 Sections “Oscillator Watchdog” and “Power Management” added

37 POCON reset values adjusted

41 to 73 Parameter section reworked

1)

These changes refer to the last two versions. Version 1998-02 covers OTP and ROM derivatives, while version

1999-08 ist the most recent one.

Controller Area Network (CAN): License of Robert Bosch GmbH

We Listen to Your Comments

Any information within this document that you feel is wrong, unclear or missing at all?

Your feedback will help us to continuously improve the quality of this document.

Please send your proposal (including a reference to this document) to:

mcdocu.comments@infineon.com

C164CI16-Bit Single-Chip Microcontroller

C166 Family

C164CI/SI, C164CL/SL

• High Performance 16-bit CPU with 4-Stage Pipeline

– 80 ns Instruction Cycle Time at 25 MHz CPU Clock

– 400 ns Multiplication (16 × 16 bit), 800 ns Division (32 / 16 bit)

– Enhanced Boolean Bit Manipulation Facilities

– Additional Instructions to Support HLL and Operating Systems

– Register-Based Design with Multiple Variable Register Banks

– Single-Cycle Context Switching Support

– 16 MBytes Total Linear Address Space for Code and Data

– 1024 Bytes On-Chip Special Function Register Area

• 16-Priority-Level Interrupt System with 32 Sources, Sample-Rate down to 40 ns

• 8-Channel Interrupt-Driven Single-Cycle Data Transfer Facilities via

Peripheral Event Controller (PEC)

• Clock Generation via on-chip PLL (factors 1:1.5/2/2.5/3/4/5),

via prescaler or via direct clock input

• On-Chip Memory Modules

– 2 KBytes On-Chip Internal RAM (IRAM)

– 2 KBytes On-Chip Extension RAM (XRAM)

– up to 64 KBytes On-Chip Program Mask ROM or OTP Memory

• On-Chip Peripheral Modules

– 8-Channel 10-bit A/D Converter with Programmable Conversion Time

down to 7.8 µs

– 8-Channel General Purpose Capture/Compare Unit (CAPCOM2)

– Capture/Compare Unit for flexible PWM Signal Generation (CAPCOM6)

(3/6 Capture/Compare Channels and 1 Compare Channel)

– Multi-Functional General Purpose Timer Unit with 3 Timers

– Two Serial Channels (Synchronous/Asynchronous and High-Speed-Synchronous)

– On-Chip CAN Interface (Rev. 2.0B active) with 15 Message Objects

(Full CAN/Basic CAN)

– On-Chip Real Time Clock

• Up to 4 MBytes External Address Space for Code and Data

– Programmable External Bus Characteristics for Different Address Ranges

– Multiplexed or Demultiplexed External Address/Data Buses with 8-Bit or 16-Bit

Data Bus Width

– Four Optional Programmable Chip-Select Signals

• Idle, Sleep, and Power Down Modes with Flexible Power Management

• Programmable Watchdog Timer and Oscillator Watchdog

• Up to 59 General Purpose I/O Lines,

partly with Selectable Input Thresholds and Hysteresis

Data Sheet 1 V2.0, 2001-05

C164CI/SI

C164CL/SL

• Supported by a Large Range of Development Tools like C-Compilers,

Macro-Assembler Packages, Emulators, Evaluation Boards, HLL-Debuggers,

Simulators, Logic Analyzer Disassemblers, Programming Boards

• On-Chip Bootstrap Loader

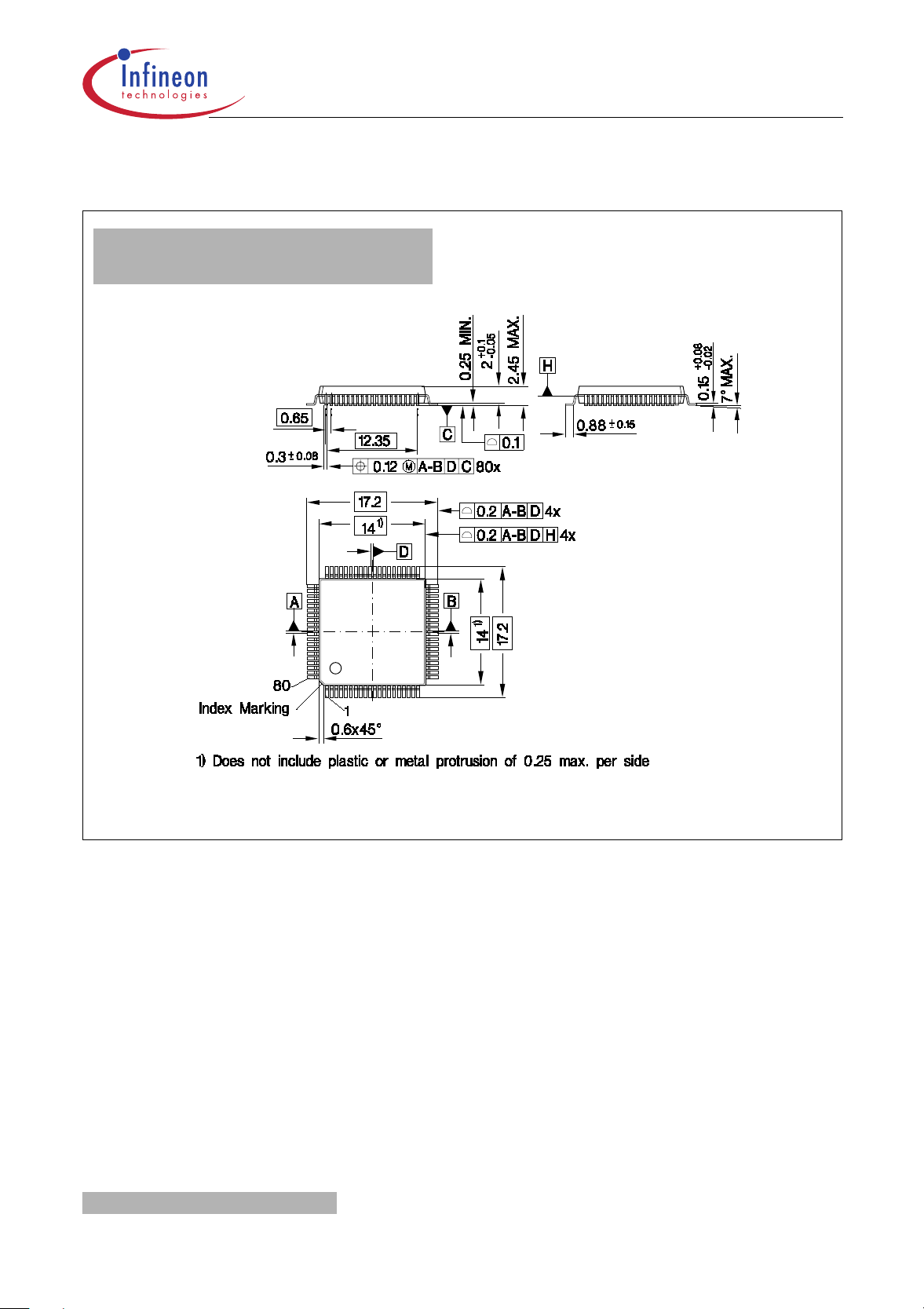

• 80-Pin MQFP Package, 0.65 mm pitch

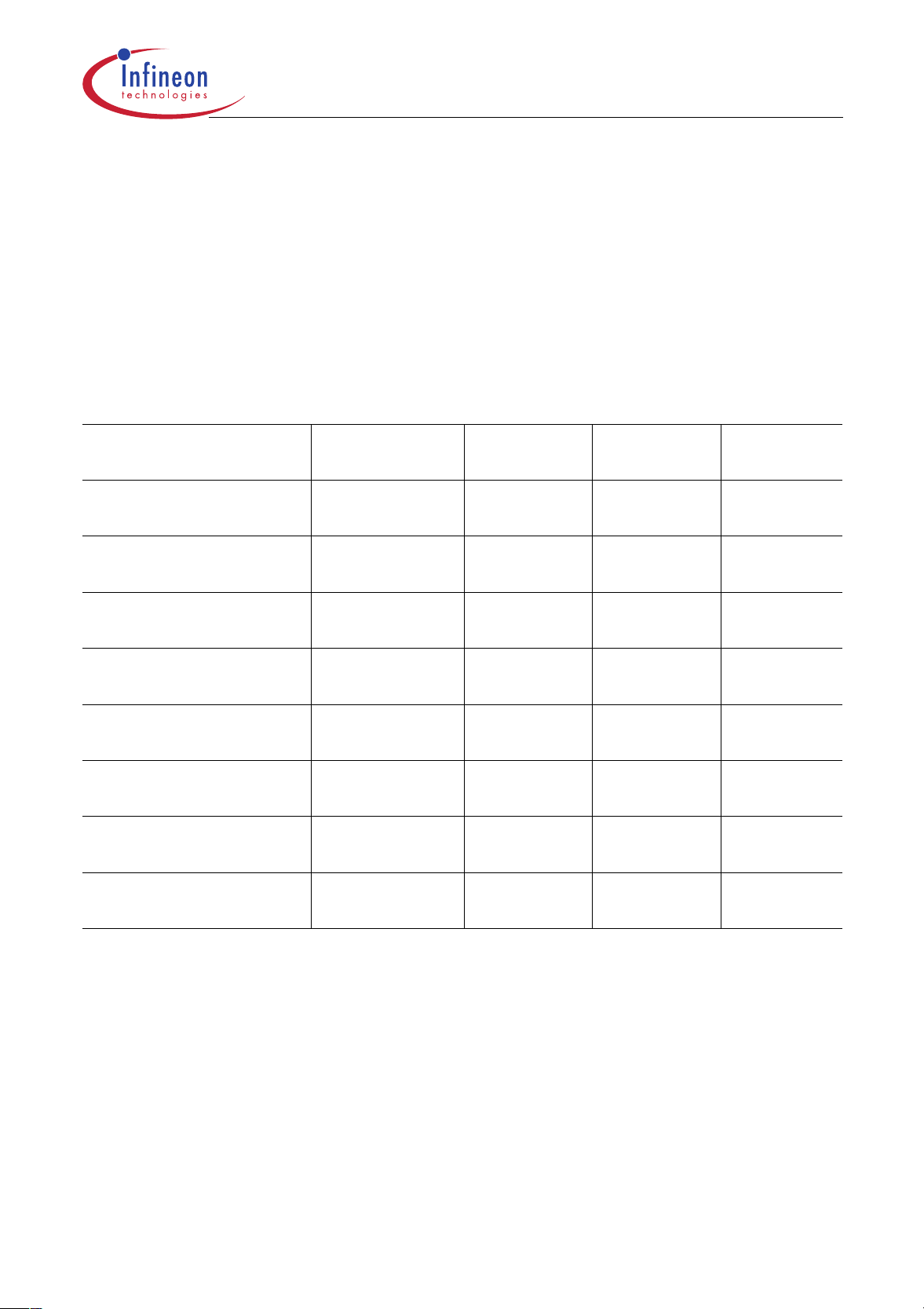

This document describes several derivatives of the C164 group. Table 1 enumerates

these derivatives and summarizes the differences. As this document refers to all of these

derivatives, some descriptions may not apply to a specific product.

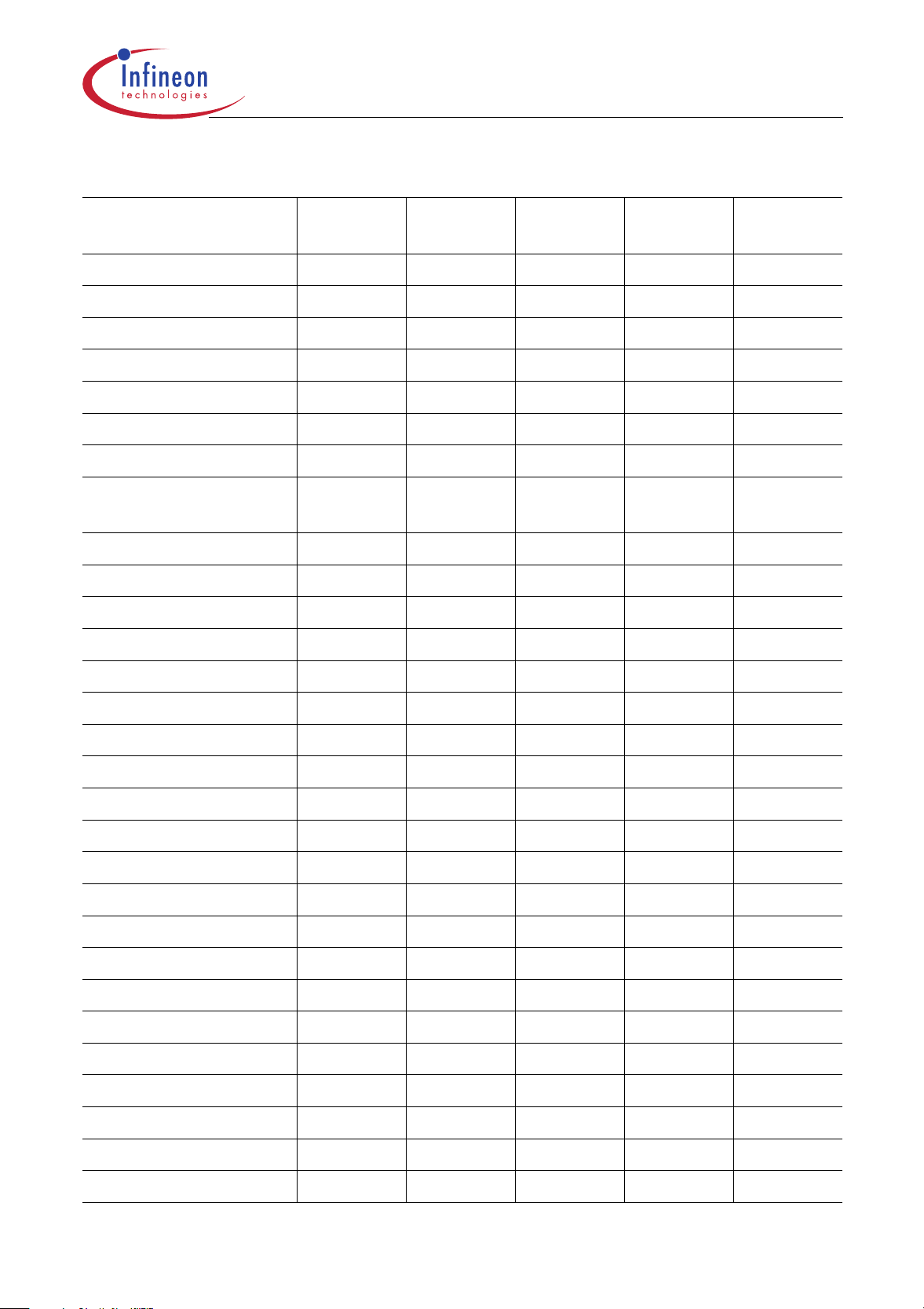

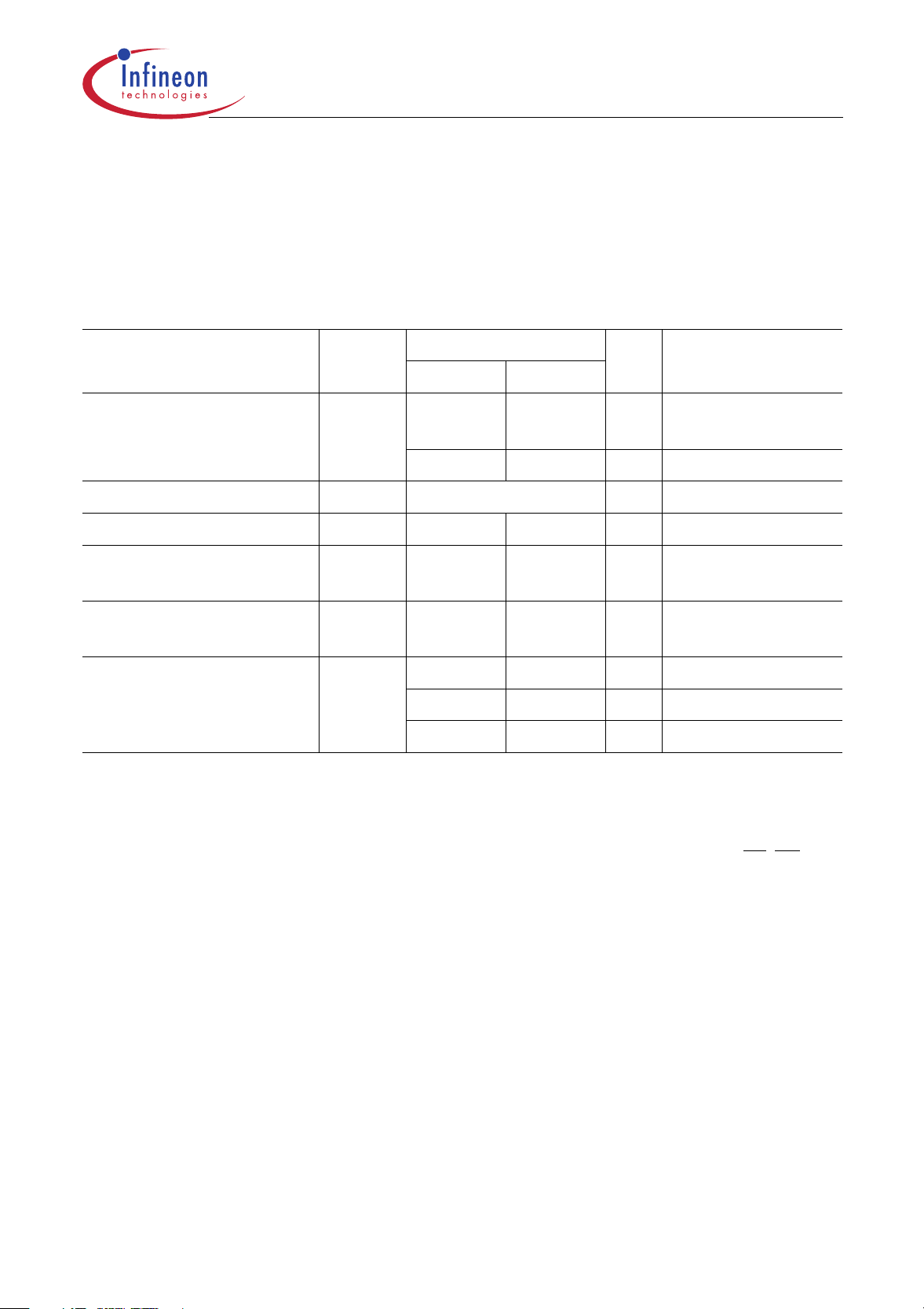

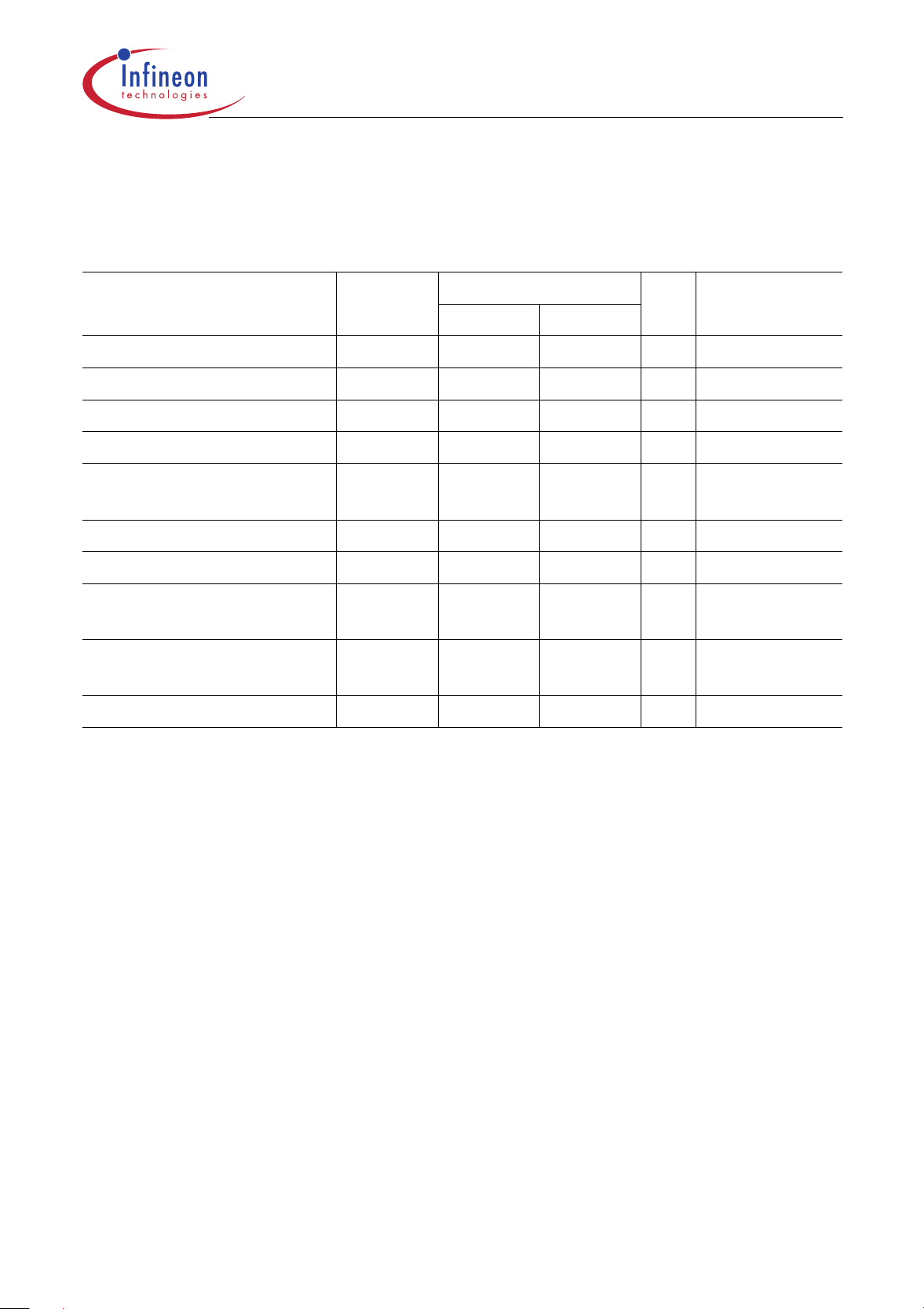

Table 1 C164CI Derivative Synopsis

Derivative

1)

Program

Memory

CAPCOM6 CAN Interf. Operating

Frequency

SAK-C164CI-8R[25]M

SAF-C164CI-8R[25]M

SAK-C164SI-8R[25]M

SAF-C164SI-8R[25]M

SAK-C164CL-8R[25]M

SAF-C164CL-8R[25]M

SAK-C164SL-8R[25]M

SAF-C164SL-8R[25]M

SAK-C164CL-6R[25]M

SAF-C164CL-6R[25]M

SAK-C164SL-6R[25]M

SAF-C164SL-6R[25]M

SAK-C164CI-L[25]M

SAF-C164CI-L[25]M

SAK-C164CI-8EM

64 KByte ROM Full function CAN1 20 MHz,

[25 MHz]

64 KByte ROM Full function --- 20 MHz,

[25 MHz]

64 KByte ROM Reduced fct. CAN1 20 MHz,

[25 MHz]

64 KByte ROM Reduced fct. --- 20 MHz,

[25 MHz]

48 KByte ROM Reduced fct. CAN1 20 MHz,

[25 MHz]

48 KByte ROM Reduced fct. --- 20 MHz,

[25 MHz]

--- Full function CAN1 20 MHz,

[25 MHz]

64 KByte OTP Full function CAN1 20 MHz

SAF-C164CI-8EM

1)

This Data Sheet is valid for ROM(less) devices starting with and including design step AB, and for OTP devices

starting with and including design step DA.

For simplicity all versions are referred to by the term C164CI throughout this document.

Data Sheet 2 V2.0, 2001-05

C164CI/SI

C164CL/SL

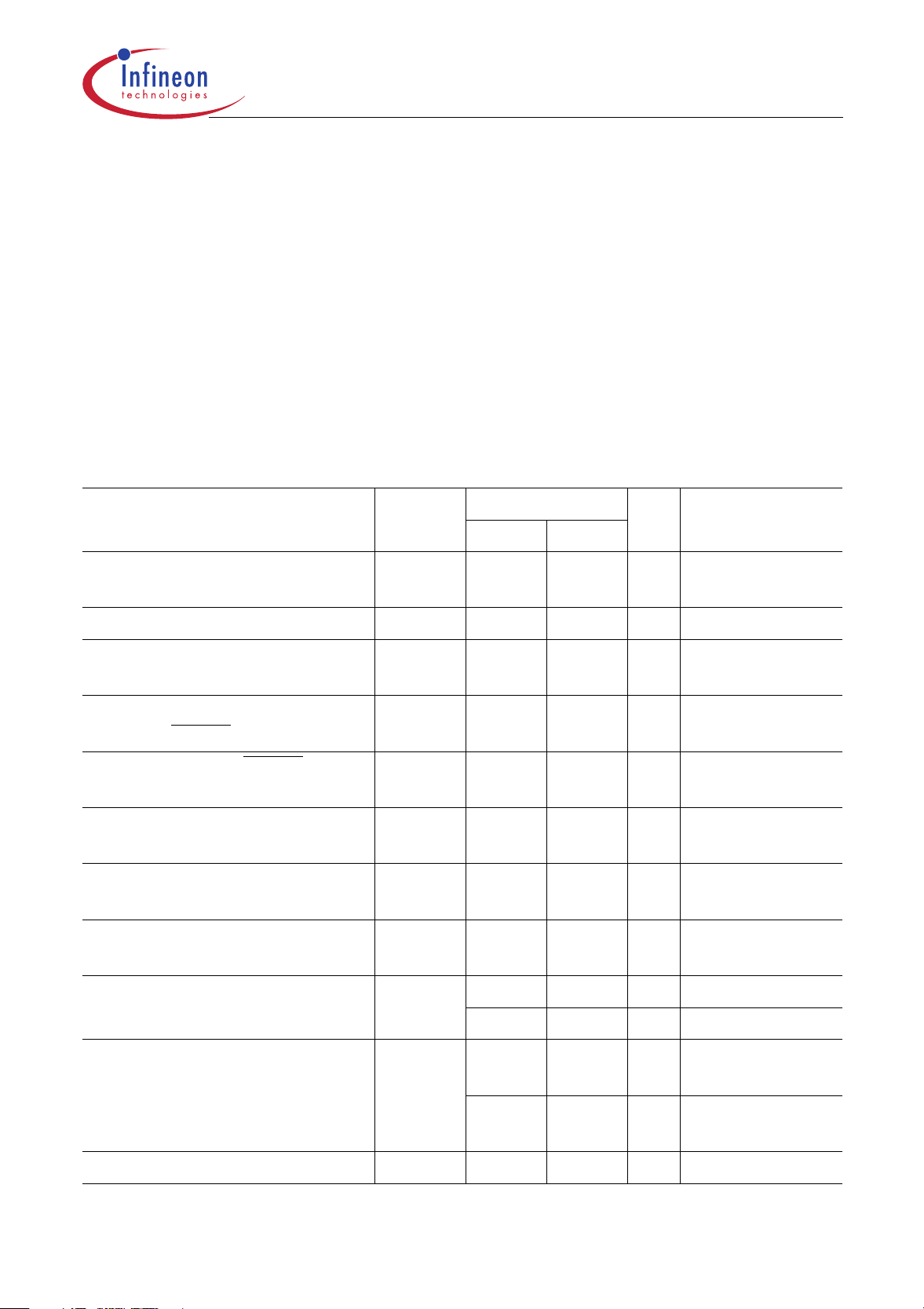

Ordering Information

The ordering code for Infineon microcontrollers provides an exact reference to the

required product. This ordering code identifies:

• the derivative itself, i.e. its function set, the temperature range, and the supply voltage

• the package and the type of delivery.

For the available ordering codes for the C164CI please refer to the “Product Catalog

Microcontrollers”, which summarizes all available microcontroller variants.

Note: The ordering codes for Mask-ROM versions are defined for each product after

verification of the respective ROM code.

Introduction

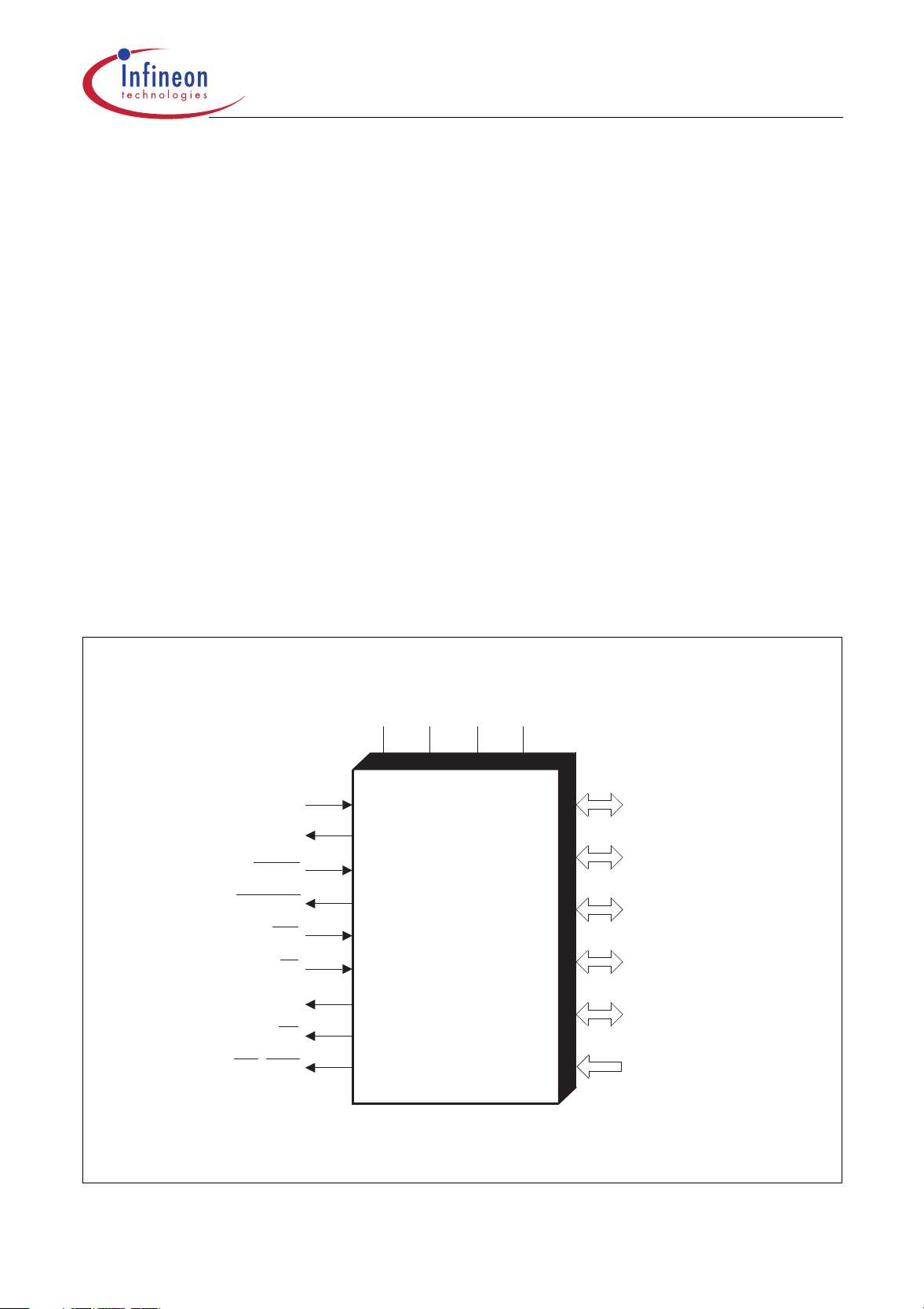

The C164CI derivatives of the Infineon C166 Family of full featured single-chip CMOS

microcontrollers are especially suited for cost sensitive applications. They combine high

CPU performance (up to 12.5 million instructions per second) with high peripheral

functionality and enhanced IO-capabilities. They also provide clock generation via PLL

and various on-chip memory modules such as program ROM or OTP, internal RAM, and

extension RAM.

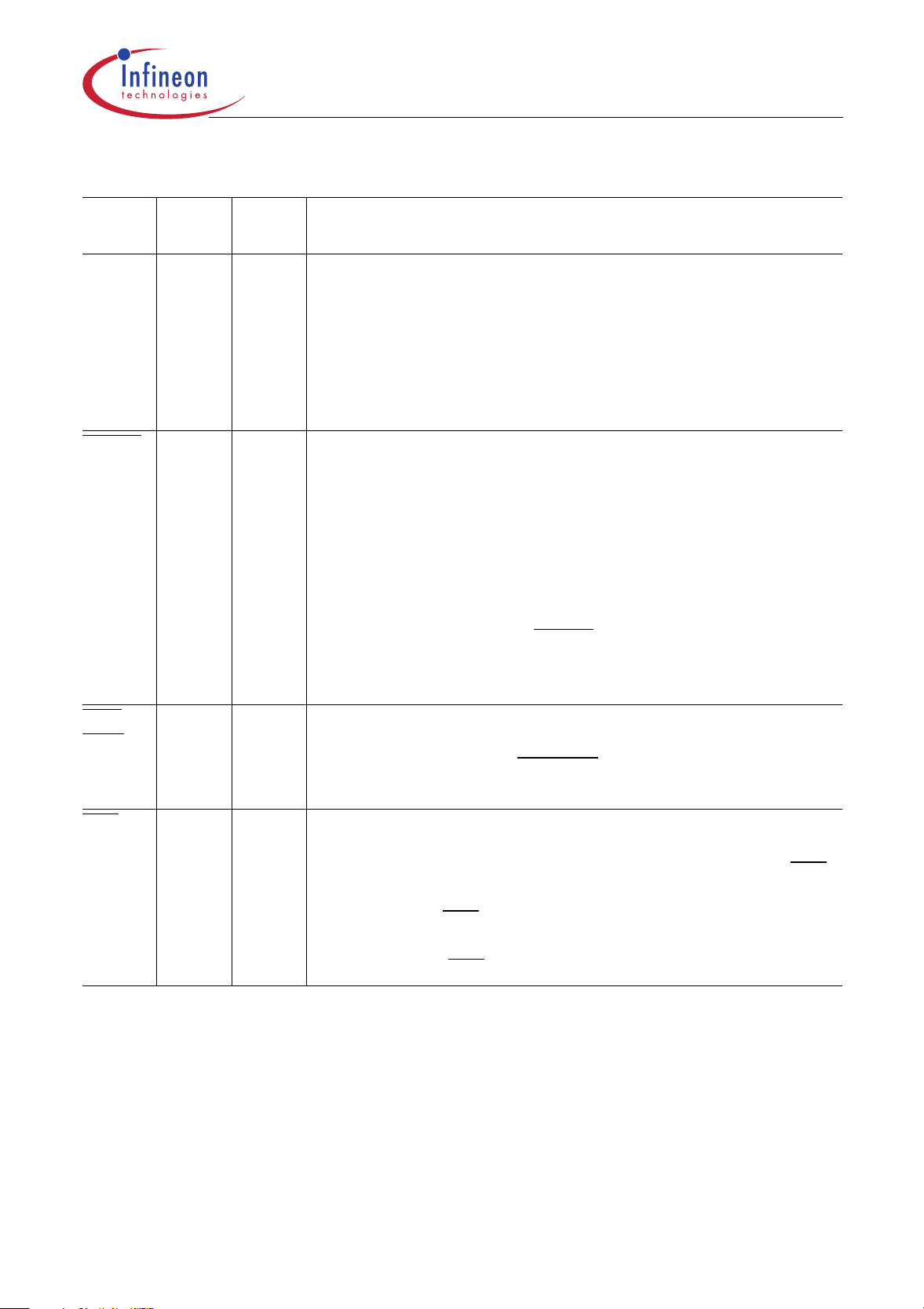

XTAL1

XTAL2

RSTIN

RSTOUT

NMI

EA

ALE

RD

WR/WRL

V

AREFVAGND

C164CI

V

DDVSS

Port 0

16 Bit

Port 1

16 Bit

Port 3

9 Bit

Port 4

6 Bit

Port 8

4 Bit

Port 5

8 Bit

MCL04869

Figure 1 Logic Symbol

Data Sheet 3 V2.0, 2001-05

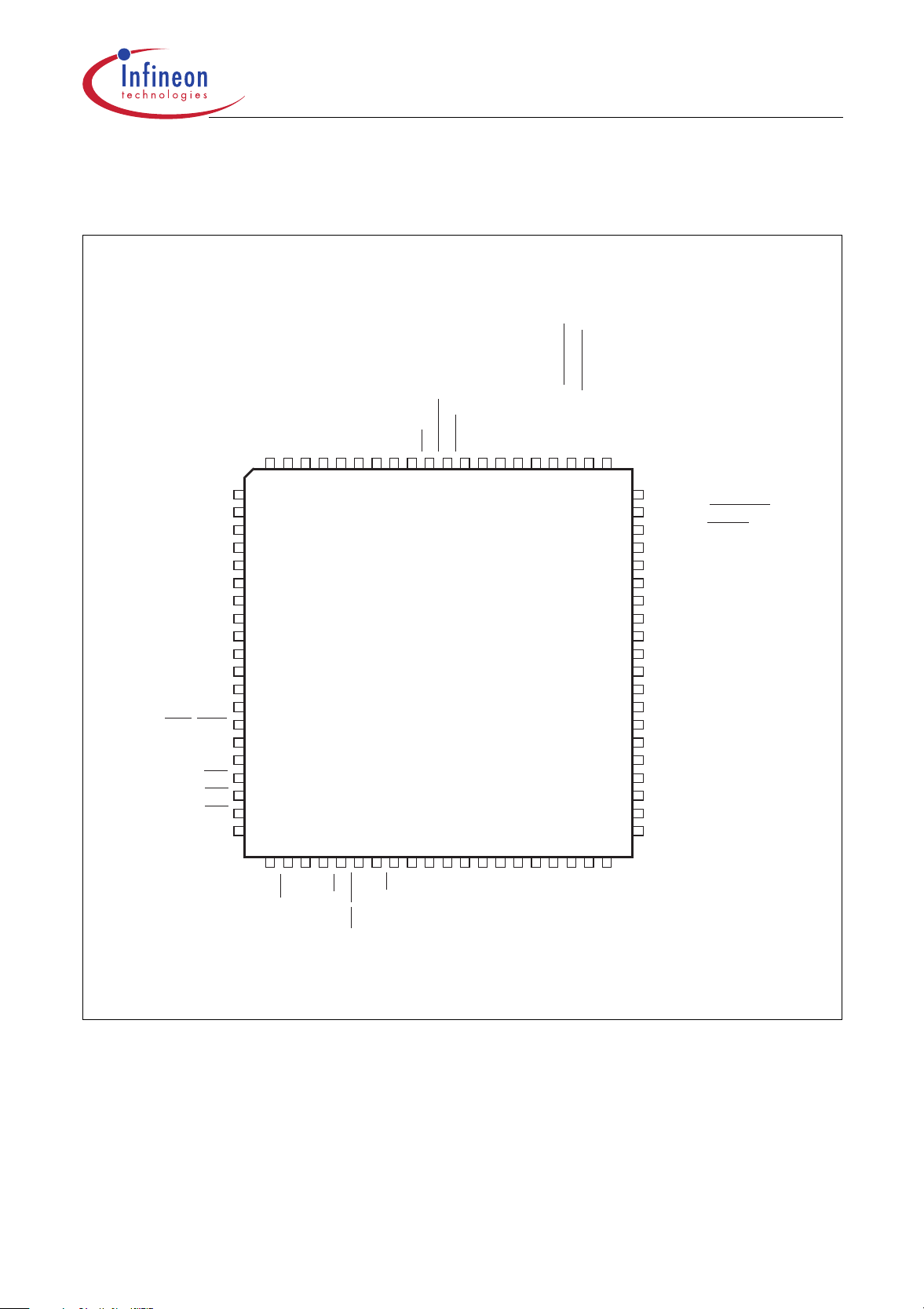

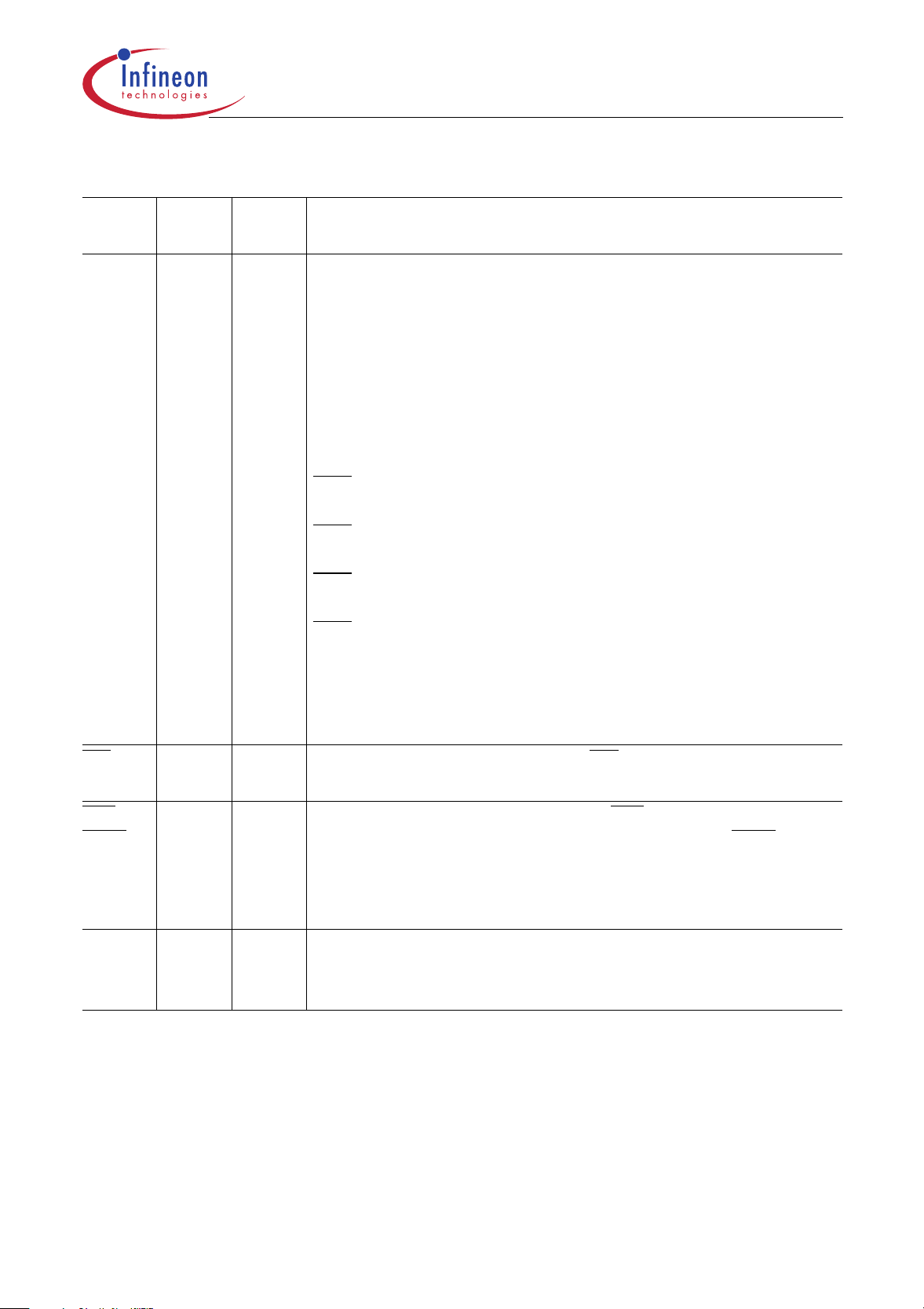

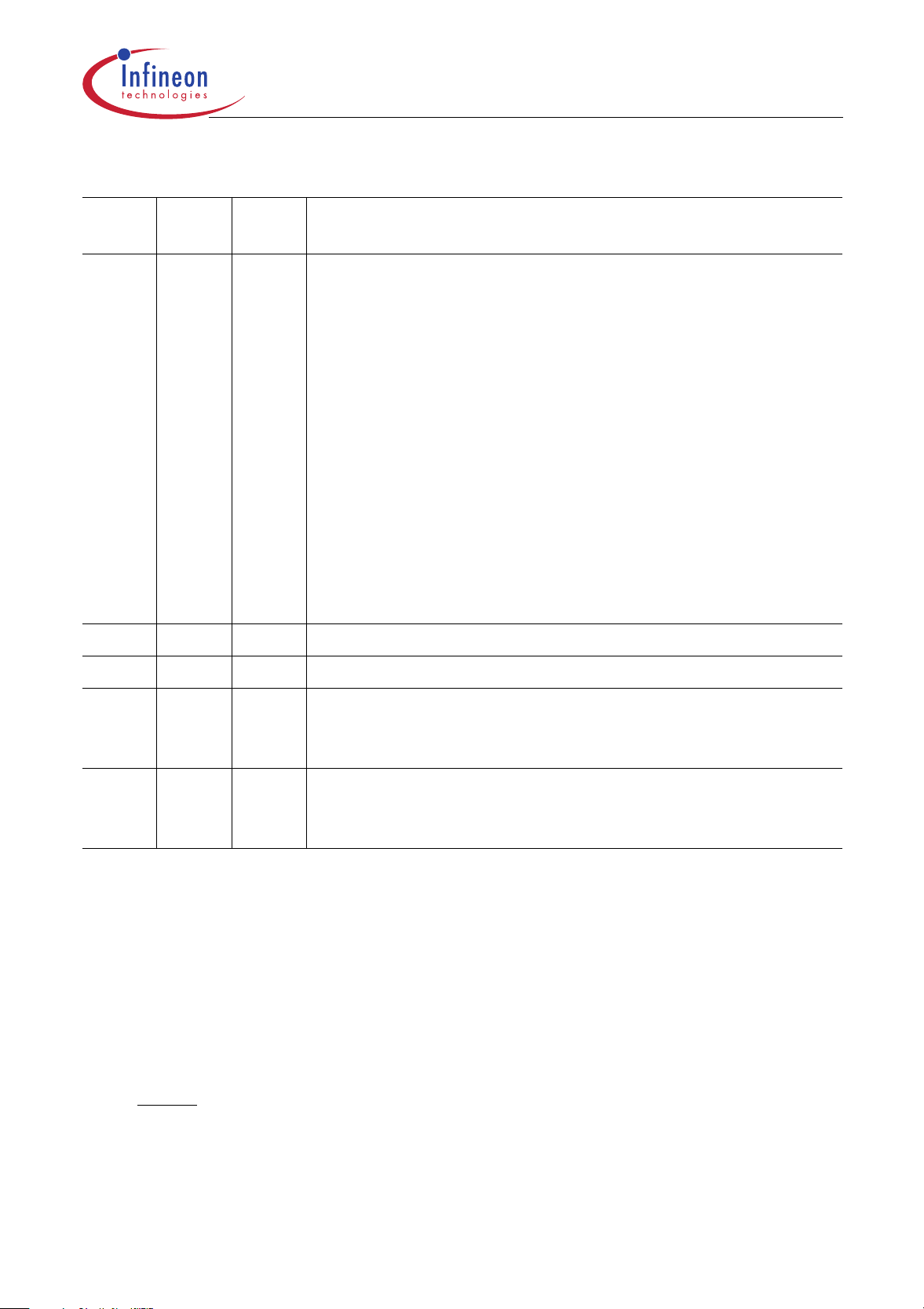

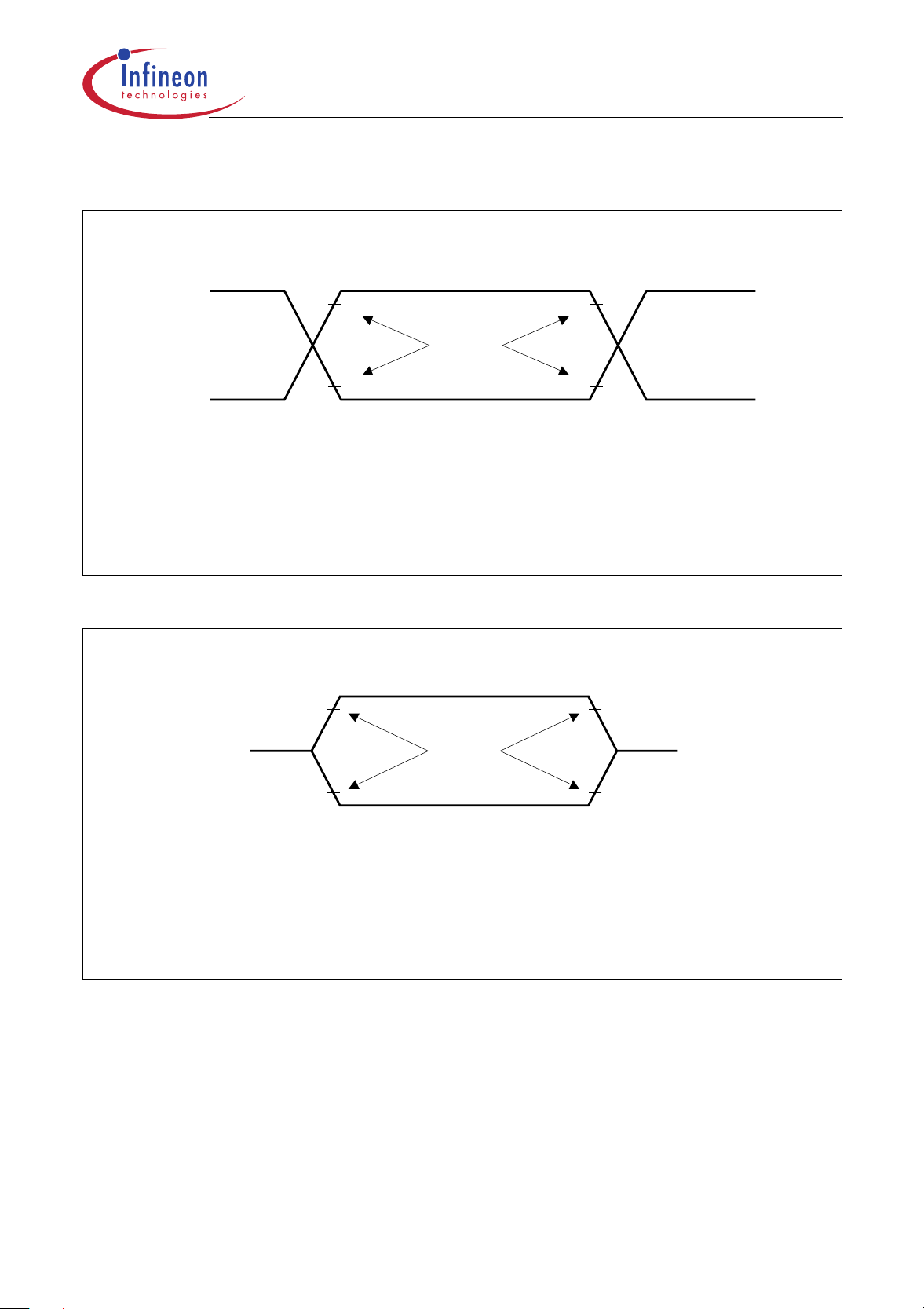

Pin Configuration

(top view)

D

N

G

A

P5.3/AN3

V

P5.0/AN0

P5.2/AN2

P5.1/AN1

/*

/*

/*

/*

C16IO

P8.1/CC17IO

P8.3/CC19IO

P8.2/CC18IO

P8.0/C

I

NM

T

P1H.7/A15/CC27IO

RSTOU

RSTIN

P1H.6/A14/CC26IO

/EX2IN

/EX1IN

S2

S1

6PO

CC

CC6PO

D

P1H.3/A11/EXIN/T7IN

P1H.5/A13/CC25IO

P1H.4/A12/CC24IO

D

P1H.2/A10/

V

P1H.1/A9/

C164CI/SI

C164CL/SL

V

P5.4/AN4/T2EUD 2

P5.5/AN5/T4EUD

P5.6/AN6/T2IN

P5.7/AN7/T4IN

P3.4/T3EUD

P3.11/RxD0

P3.12/BHE/WRH

P3.13/SCLK

P3.15/CLKOUT/FOUT

P4.0/A16/CS3

P4.1/A17/CS2

P4.2/A18/CS1

AREF

V

V

P3.6/T3IN

P3.8/MRST

P3.9/MTSR

P3.10/TxD0

V

SS

DD

SS

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

80

21

V

797877

23

24

22

D

D

*/P4.5/A20

*/P4.6/A21

P4.3/A19/CS0

76

25

RD

75

26

RL

R/W

W

74

27

ALE

737271

C164CI

30

29

28

Vpp/EA

P0L.1/AD1

P0L.0/AD0

70

68

69

33

31

32

P0L.2/AD2

P0L.4/AD4

P0L.3/AD3

676665

34

36

35

P0L.5/AD5

P0L.7/AD7

P0L.6/AD6

646362

37

38

39

61

40

V

P0H.0/AD8

P0H.1/AD9

P0H.2/AD10

V

60

SS

P1H.0/A8/CC6POS0/EX0IN

59

58

P1L.7/A7/CTRAP

P1L.6/A6/COUT6357

V

56

SS

XTAL155

XTAL254

V

53

DD

P1L.5/A5/COUT6252

P1L.4/A4/CC6251

P1L.3/A3/COUT61

50

P1L.2/A2/CC6149

P1L.1/A1/COUT6048

P1L.0/A0/CC60

47

P0H.7/AD1546

P0H.6/AD1445

P0H.5/AD13

44

43

P0H.4/AD12

P0H.3/AD1142

V

41

SS

D

D

MCP04870

Figure 2

*) The marked pins of Port 4 and Port 8 can have CAN interface lines assigned to them.

Table 2 on the pages below lists the possible assignments.

The marked input signals are available only in devices with a full-function CAPCOM6.

They are not available in devices with a reduced-function CAPCOM6.

Data Sheet 4 V2.0, 2001-05

Table 2 Pin Definitions and Functions

C164CI/SI

C164CL/SL

Symbol Pin

No.

P5

P5.0

P5.1

P5.2

P5.3

P5.4

P5.5

P5.6

P5.7

P3

P3.4

P3.6

P3.8

P3.9

P3.10

P3.11

P3.12

P3.13

P3.15

76

77

78

79

2

3

4

5

8

9

10

11

12

13

14

15

16

Input

Outp.

I

I

I

I

I

I

I

I

I

IO

I

I

I/O

I/O

O

I/O

O

O

I/O

O

O

Function

Port 5 is an 8-bit input-only port with Schmitt-Trigger charact.

The pins of Port 5 also serve as analog input channels for the

A/D converter, or they serve as timer inputs:

AN0

AN1

AN2

AN3

AN4, T2EUD GPT1 Timer T2 Ext. Up/Down Ctrl. Inp.

AN5, T4EUD GPT1 Timer T4 Ext. Up/Down Ctrl. Inp.

AN6, T2IN GPT1 Timer T2 Input for

Count/Gate/Reload/Capture

AN7, T4IN GPT1 Timer T4 Input for

Count/Gate/Reload/Capture

Port 3 is a 9-bit bidirectional I/O port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state. Port 3 outputs can be configured as push/

pull or open drain drivers. The input threshold of Port 3 is

selectable (TTL or special).

The following Port 3 pins also serve for alternate functions:

T3EUD GPT1 Timer T3 External Up/Down Control Input

T3IN GPT1 Timer T3 Count/Gate Input

MRST SSC Master-Receive/Slave-Transmit Inp./Outp.

MTSR SSC Master-Transmit/Slave-Receive Outp./Inp.

TxD0 ASC0 Clock/Data Output (Async./Sync.)

RxD0 ASC0 Data Input (Async.) or Inp./Outp. (Sync.)

BHE

WRH

SCLK SSC Master Clock Output / Slave Clock Input.

CLKOUT System Clock Output (= CPU Clock),

FOUT Programmable Frequency Output

External Memory High Byte Enable Signal,

External Memory High Byte Write Strobe

Data Sheet 5 V2.0, 2001-05

Table 2 Pin Definitions and Functions (cont’d)

C164CI/SI

C164CL/SL

Symbol Pin

No.

P4

P4.0

P4.1

P4.2

P4.3

P4.5

P4.6

17

18

19

22

23

24

Input

Outp.

IO

O

O

O

O

O

O

O

O

O

I

O

O

Function

Port 4 is a 6-bit bidirectional I/O port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state. Port 4 outputs can be configured as push/

pull or open drain drivers. The input threshold of Port 4 is

selectable (TTL or special).

Port 4 can be used to output the segment address lines, the

optional chip select lines, and for serial interface lines:

1)

A16 Least Significant Segment Address Line,

CS3 Chip Select 3 Output

A17 Segment Address Line,

CS2

Chip Select 2 Output

A18 Segment Address Line,

CS1

Chip Select 1 Output

A19 Segment Address Line,

CS0

Chip Select 0 Output

A20 Segment Address Line,

CAN1_RxD CAN 1 Receive Data Input

A21 Most Significant Segment Address Line,

CAN1_TxD CAN 1 Transmit Data Output

RD

25 O External Memory Read Strobe. RD is activated for every

external instruction or data read access.

WR

WRL

/

26 O External Memory Write Strobe. In WR-mode this pin is

activated for every external data write access. In WRL

-mode

this pin is activated for low byte data write accesses on a

16-bit bus, and for every data write access on an 8-bit bus.

See WRCFG in register SYSCON for mode selection.

ALE 27 O Address Latch Enable Output. Can be used for latching the

address into external memory or an address latch in the

multiplexed bus modes.

Data Sheet 6 V2.0, 2001-05

Table 2 Pin Definitions and Functions (cont’d)

C164CI/SI

C164CL/SL

Symbol Pin

No.

EA/V

28 I External Access Enable pin.

PP

PORT0

P0L.0-7

2936

P0H.0-7

37-39,

42-46

Input

Function

Outp.

A low level at this pin during and after Reset forces the

C164CI to latch the configuration from PORT0 and pin RD

and to begin instruction execution out of external memory.

A high level forces the C164CI to latch the configuration

from pins RD

and ALE, and to begin instruction execution out

of the internal program memory.

“ROMless” versions must have this pin tied to ‘0’.

Note: This pin also accepts the programming voltage for the

OTP derivatives.

IO PORT0 consists of the two 8-bit bidirectional I/O ports P0L

and P0H. It is bit-wise programmable for input or output via

direction bits. For a pin configured as input, the output driver

is put into high-impedance state.

In case of an external bus configuration, PORT0 serves as

the address (A) and address/data (AD) bus in multiplexed

bus modes and as the data (D) bus in demultiplexed bus

modes.

Demultiplexed bus modes:

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: D0 – D7 D0 – D7

P0H.0 – P0H.7: I/O D8 – D15

Multiplexed bus modes:

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: AD0 – AD7 AD0 – AD7

P0H.0 – P0H.7: A8 – A15 AD8 – AD15

,

Data Sheet 7 V2.0, 2001-05

Table 2 Pin Definitions and Functions (cont’d)

C164CI/SI

C164CL/SL

Symbol Pin

No.

PORT1

P1L.0-7

P1H.0-7

P1L.0

P1L.1

P1L.2

P1L.3

P1L.4

P1L.5

P1L.6

P1L.7

P1H.0

P1H.1

P1H.2

P1H.3

P1H.4

P1H.5

P1H.6

P1H.7

47-52,

57-59

59,

62-68

47

48

49

50

51

52

57

58

59

62

63

64

65

66

67

68

Input

Outp.

IO

I/O

O

I/O

O

I/O

O

O

I

I

I

I

I

I

I

I

I/O

I/O

I/O

I/O

Function

PORT1 consists of the two 8-bit bidirectional I/O ports P1L

and P1H. It is bit-wise programmable for input or output via

direction bits. For a pin configured as input, the output driver

is put into high-impedance state. PORT1 is used as the

16-bit address bus (A) in demultiplexed bus modes and also

after switching from a demultiplexed bus mode to a

multiplexed bus mode.

The following PORT1 pins also serve for alt. functions:

CC60 CAPCOM6: Input / Output of Channel 0

COUT60 CAPCOM6: Output of Channel 0

CC61 CAPCOM6: Input / Output of Channel 1

COUT61 CAPCOM6: Output of Channel 1

CC62 CAPCOM6: Input / Output of Channel 2

COUT62 CAPCOM6: Output of Channel 2

COUT63 Output of 10-bit Compare Channel

CTRAP

CTRAP

level on this pin switches the compare outputs of the

CAPCOM6 unit to the logic level defined by software.

CC6POS0

EX0IN Fast External Interrupt 0 Input

CC6POS1

EX1IN Fast External Interrupt 1 Input

CC6POS2

EX2IN Fast External Interrupt 2 Input

EX3IN Fast External Interrupt 3 Input,

T7IN CAPCOM2: Timer T7 Count Input

CC24IO CAPCOM2: CC24 Capture Inp./Compare Outp.

CC25IO CAPCOM2: CC25 Capture Inp./Compare Outp.

CC26IO CAPCOM2: CC26 Capture Inp./Compare Outp.

CC27IO CAPCOM2: CC27 Capture Inp./Compare Outp.

CAPCOM6: Trap Input

is an input pin with an internal pullup resistor. A low

CAPCOM6: Position 0 Input, **)

CAPCOM6: Position 1 Input, **)

CAPCOM6: Position 2 Input, **)

Note: The marked (**) input signals are available only in

devices with a full function CAPCOM6.

Data Sheet 8 V2.0, 2001-05

Table 2 Pin Definitions and Functions (cont’d)

C164CI/SI

C164CL/SL

Symbol Pin

No.

XTAL2

XTAL15455

RSTIN

69 I/O Reset Input with Schmitt-Trigger characteristics. A low level

Input

Outp.

O

I

Function

XTAL2: Output of the oscillator amplifier circuit.

XTAL1: Input to the oscillator amplifier and input to

the internal clock generator

To clock the device from an external source, drive XTAL1,

while leaving XTAL2 unconnected. Minimum and maximum

high/low and rise/fall times specified in the AC

Characteristics must be observed.

at this pin while the oscillator is running resets the C164CI.

An internal pullup resistor permits power-on reset using only

V

a capacitor connected to

A spike filter suppresses input pulses <10 ns. Input pulses

>100 ns safely pass the filter. The minimum duration for a

safe recognition should be 100 ns + 2 CPU clock cycles.

In bidirectional reset mode (enabled by setting bit BDRSTEN

in register SYSCON) the RSTIN

for the duration of the internal reset sequence upon any reset

(HW, SW, WDT). See note below this table.

.

SS

line is internally pulled low

RST

OUT

NMI

70 O Internal Reset Indication Output. This pin is set to a low level

when the part is executing either a hardware-, a software- or

a watchdog timer reset. RSTOUT

(end of initialization) instruction is executed.

71 I Non-Maskable Interrupt Input. A high to low transition at this

pin causes the CPU to vector to the NMI trap routine. When

the PWRDN (power down) instruction is executed, the NMI

pin must be low in order to force the C164CI to go into power

down mode. If NMI

part will continue to run in normal mode.

If not used, pin NMI

is high, when PWRDN is executed, the

should be pulled high externally.

remains low until the EINIT

Data Sheet 9 V2.0, 2001-05

Table 2 Pin Definitions and Functions (cont’d)

C164CI/SI

C164CL/SL

Symbol Pin

No.

P8

P8.0

P8.1

P8.2

P8.3

V

AREF

72

73

74

75

1 – Reference voltage for the A/D converter.

Input

Outp.

IO

I/O

I

I/O

O

I/O

I

I/O

O

Function

Port 8 is a 4-bit bidirectional I/O port. It is bit-wise

programmable for input or output via direction bits. For a pin

configured as input, the output driver is put into highimpedance state. Port 8 outputs can be configured as push/

pull or open drain drivers. The input threshold of Port 8 is

selectable (TTL or special). Port 8 pins provide inputs/

outputs for CAPCOM2 and serial interface lines.

1)

CC16IO CAPCOM2: CC16 Capture Inp./Compare Outp.,

CAN1_RxD CAN 1 Receive Data Input

CC17IO CAPCOM2: CC17 Capture Inp./Compare Outp.,

CAN1_TxD CAN 1 Transmit Data Output

CC18IO CAPCOM2: CC18 Capture Inp./Compare Outp.,

CAN1_RxD CAN 1 Receive Data Input

CC19IO CAPCOM2: CC19 Capture Inp./Compare Outp.,

CAN1_TxD CAN 1 Transmit Data Output

V

AGND

V

DD

V

SS

80 – Reference ground for the A/D converter.

7, 21,

40, 53,

61

6, 20,

– Digital Supply Voltage:

+5 V during normal operation and idle mode.

≥2.5 V during power down mode.

– Digital Ground.

41, 56,

60

1)

The CAN interface lines are assigned to ports P4 and P8 under software control. Within the CAN module

several assignments can be selected.

Note: The following behavioural differences must be observed when the bidirectional

reset is active:

• Bit BDRSTEN in register SYSCON cannot be changed after EINIT and is cleared

automatically after a reset.

• The reset indication flags always indicate a long hardware reset.

• The PORT0 configuration is treated as if it were a hardware reset. In particular, the

bootstrap loader may be activated when P0L.4 is low.

• Pin RSTIN

may only be connected to external reset devices with an open drain output

driver.

• A short hardware reset is extended to the duration of the internal reset sequence.

Data Sheet 10 V2.0, 2001-05

C164CI/SI

C164CL/SL

Functional Description

The architecture of the C164CI combines advantages of both RISC and CISC

processors and of advanced peripheral subsystems in a very well-balanced way. In

addition the on-chip memory blocks allow the design of compact systems with maximum

performance.

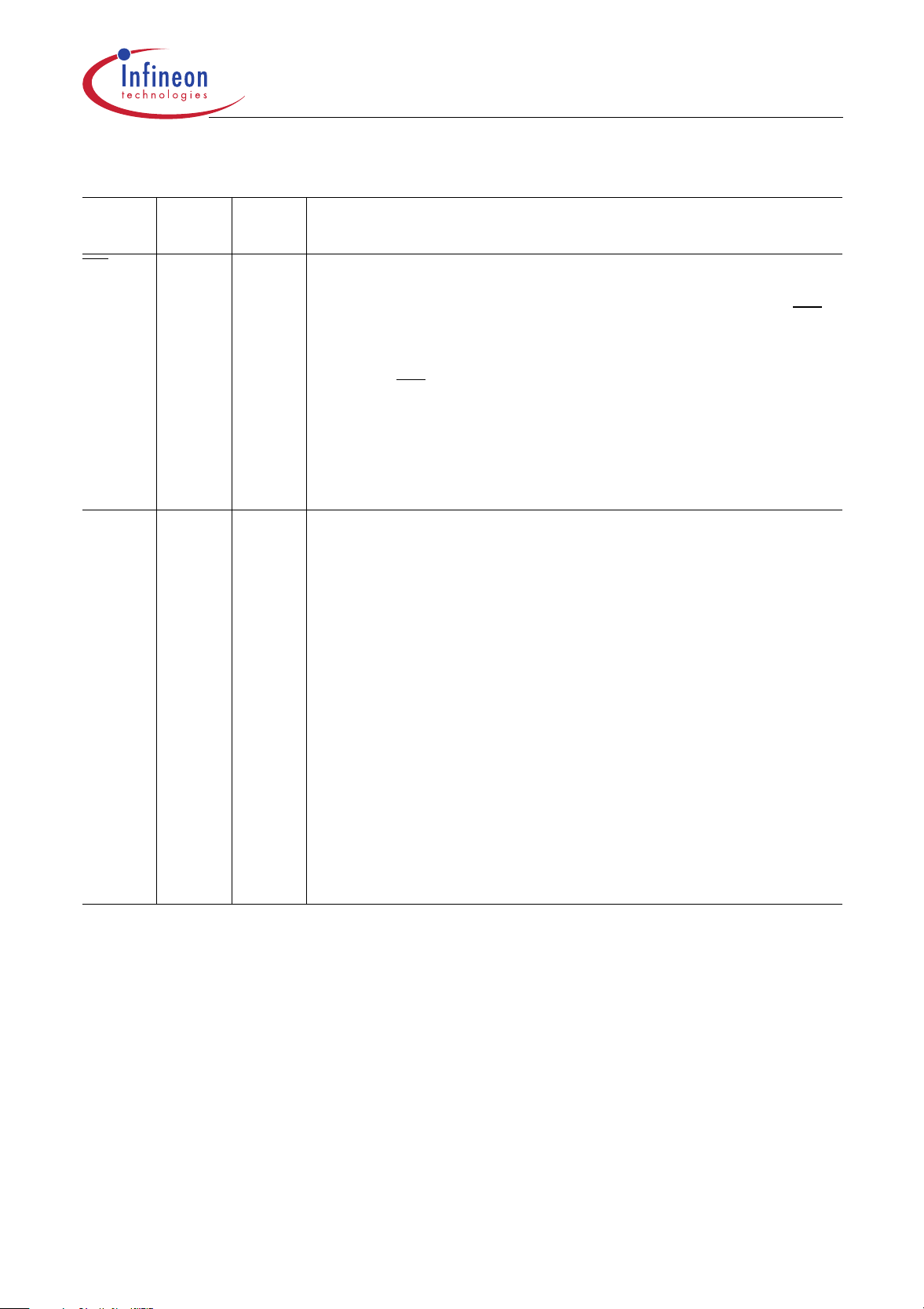

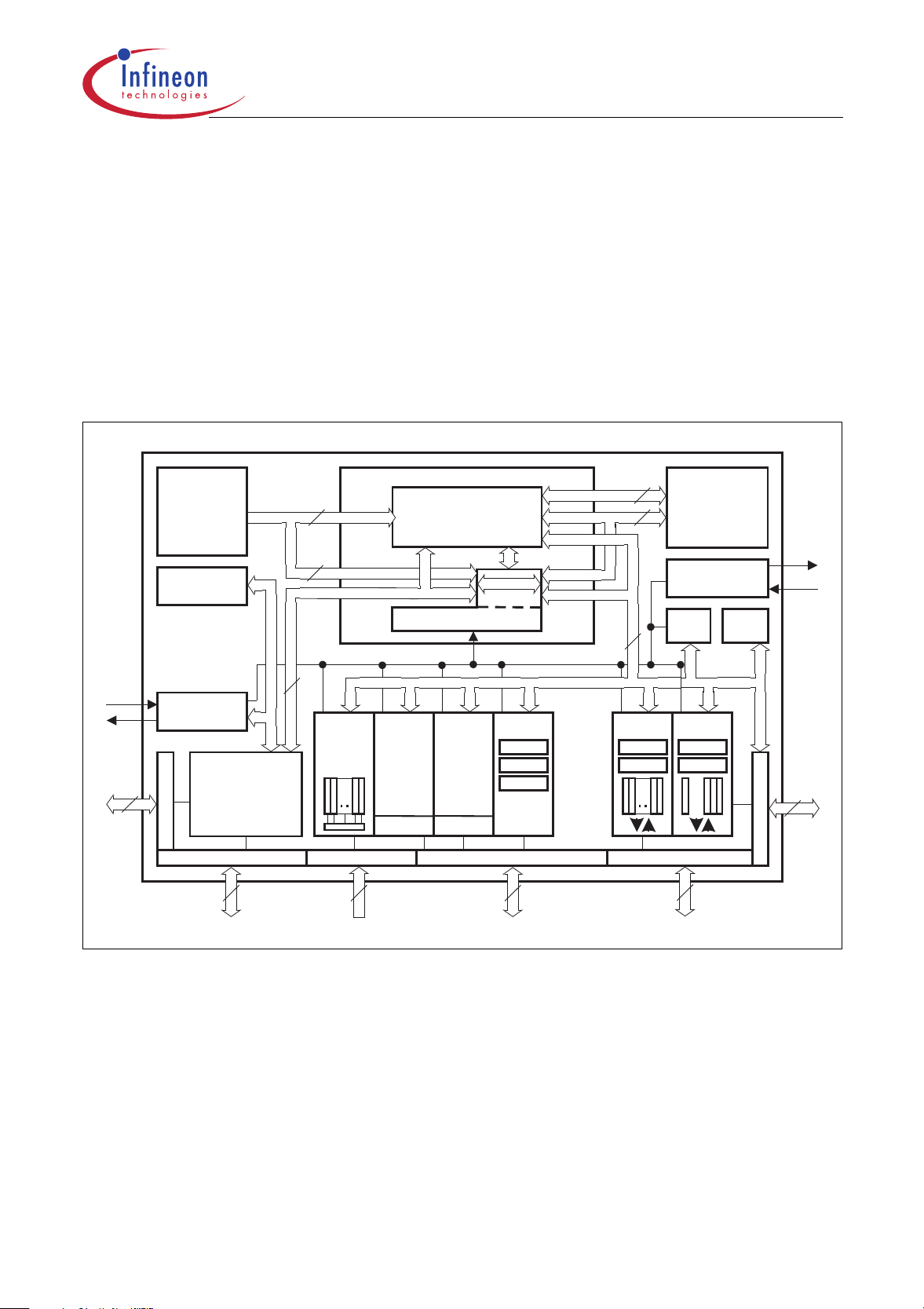

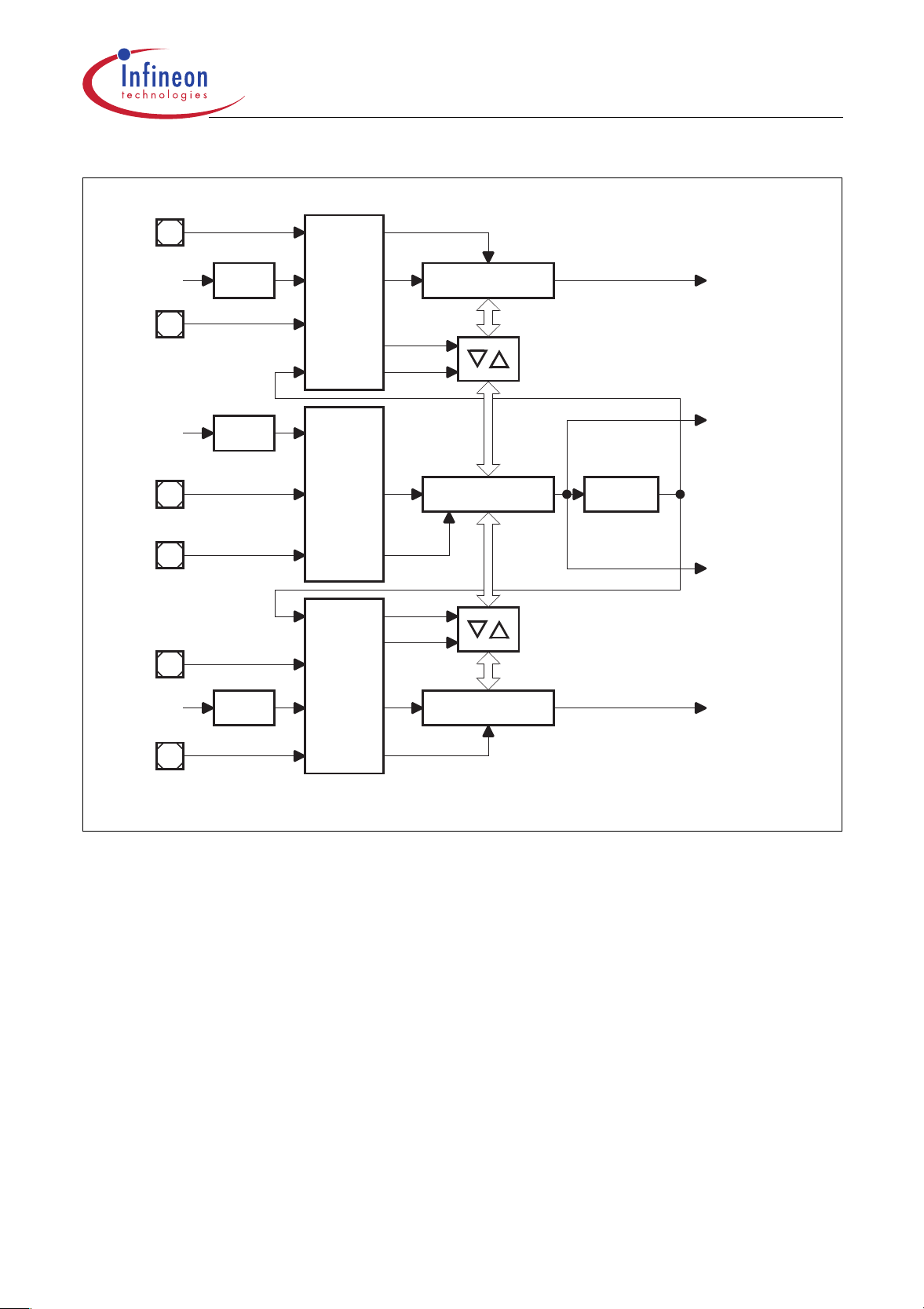

The following block diagram gives an overview of the different on-chip components and

of the advanced, high bandwidth internal bus structure of the C164CI.

Note: All time specifications refer to a CPU clock of 25 MHz

(see definition in the AC Characteristics section).

6

ProgMem

ROM: 48/64

OTP: 64

KByte

XRAM

2 KByte

CAN

Rev 2.0B active

EBC

XBUS Control

rt 4

o

External Bus

P

Control

Port 0

32

Instr. / Data

16

)

x

u

m

e

it D

-B

16

6

(1

S

U

B

X

ip

h

-C

n

O

16 8

ADC

10-Bit

8

Channels

Port 5 Port 3

External Instr. / Data

Interrupt Controller

ASC0

(USART)

BRGen

C166-Core

CPU

SSC

(SPI)

BRGen

PEC

16-Level

Priority

GPT1

T2

T3

T4

9

Interrupt Bus

Peripheral Data Bus

Data

Data

16

CCOM2

16

rt

o

l P

16

a

u

D

RTC WDT

CCOM6

T7

T8

Port 8

IRAM

Internal

RAM

2 KByte

Osc / PLL

T12

T13

4

MCB04323_4ci

rt 1

o

P

XTAL

16

Figure 3 Block Diagram

The program memory, the internal RAM (IRAM) and the set of generic peripherals are

connected to the CPU via separate buses. A fourth bus, the XBUS, connects external

resources as well as additional on-chip resoures, the X-Peripherals (see Figure 3).

The XBUS resources (XRAM, CAN) of the C164CI can be enabled or disabled during

initialization by setting the general X-Peripheral enable bit XPEN (SYSCON.2). Modules

that are disabled consume neither address space nor port pins.

Data Sheet 11 V2.0, 2001-05

C164CI/SI

C164CL/SL

Memory Organization

The memory space of the C164CI is configured in a Von Neumann architecture which

means that code memory, data memory, registers and I/O ports are organized within the

same linear address space which includes 16 MBytes. The entire memory space can be

accessed bytewise or wordwise. Particular portions of the on-chip memory have

additionally been made directly bitaddressable.

The C164CI incorporates 64 KBytes of on-chip OTP memory or 64/48 KBytes of on-chip

mask-programmable ROM (not in the ROM-less derivative, of course) for code or

constant data. The lower 32 KBytes of the on-chip ROM/OTP can be mapped either to

segment 0 or segment 1.

The OTP memory can be programmed by the CPU itself (in system, e.g. during booting)

or directly via an external interface (e.g. before assembly). The programming time is

V

approx. 100 µs per word. An external programming voltage

supplied for this purpose (via pin EA

/VPP).

=11.5V must be

PP

2 KBytes of on-chip Internal RAM (IRAM) are provided as a storage for user defined

variables, for the system stack, general purpose register banks and even for code. A

register bank can consist of up to 16 wordwide (R0 to R15) and/or bytewide (RL0, RH0,

…, RL7, RH7) so-called General Purpose Registers (GPRs).

1024 bytes (2 × 512 bytes) of the address space are reserved for the Special Function

Register areas (SFR space and ESFR space). SFRs are wordwide registers which are

used for controlling and monitoring functions of the different on-chip units. Unused SFR

addresses are reserved for future members of the C166 Family.

2 KBytes of on-chip Extension RAM (XRAM) are provided to store user data, user

stacks, or code. The XRAM is accessed like external memory and therefore cannot be

used for the system stack or for register banks and is not bitaddressable. The XRAM

permits 16-bit accesses with maximum speed.

In order to meet the needs of designs where more memory is required than is provided

on chip, up to 4 MBytes of external RAM and/or ROM can be connected to the

microcontroller.

Data Sheet 12 V2.0, 2001-05

C164CI/SI

C164CL/SL

External Bus Controller

All of the external memory accesses are performed by a particular on-chip External Bus

Controller (EBC). It can be programmed either to Single Chip Mode when no external

memory is required, or to one of four different external memory access modes, which are

as follows:

– 16-/18-/20-/22-bit Addresses, 16-bit Data, Demultiplexed

– 16-/18-/20-/22-bit Addresses, 16-bit Data, Multiplexed

– 16-/18-/20-/22-bit Addresses, 8-bit Data, Multiplexed

– 16-/18-/20-/22-bit Addresses, 8-bit Data, Demultiplexed

In the demultiplexed bus modes, addresses are output on PORT1 and data is input/

output on PORT0 or P0L, respectively. In the multiplexed bus modes both addresses

and data use PORT0 for input/output.

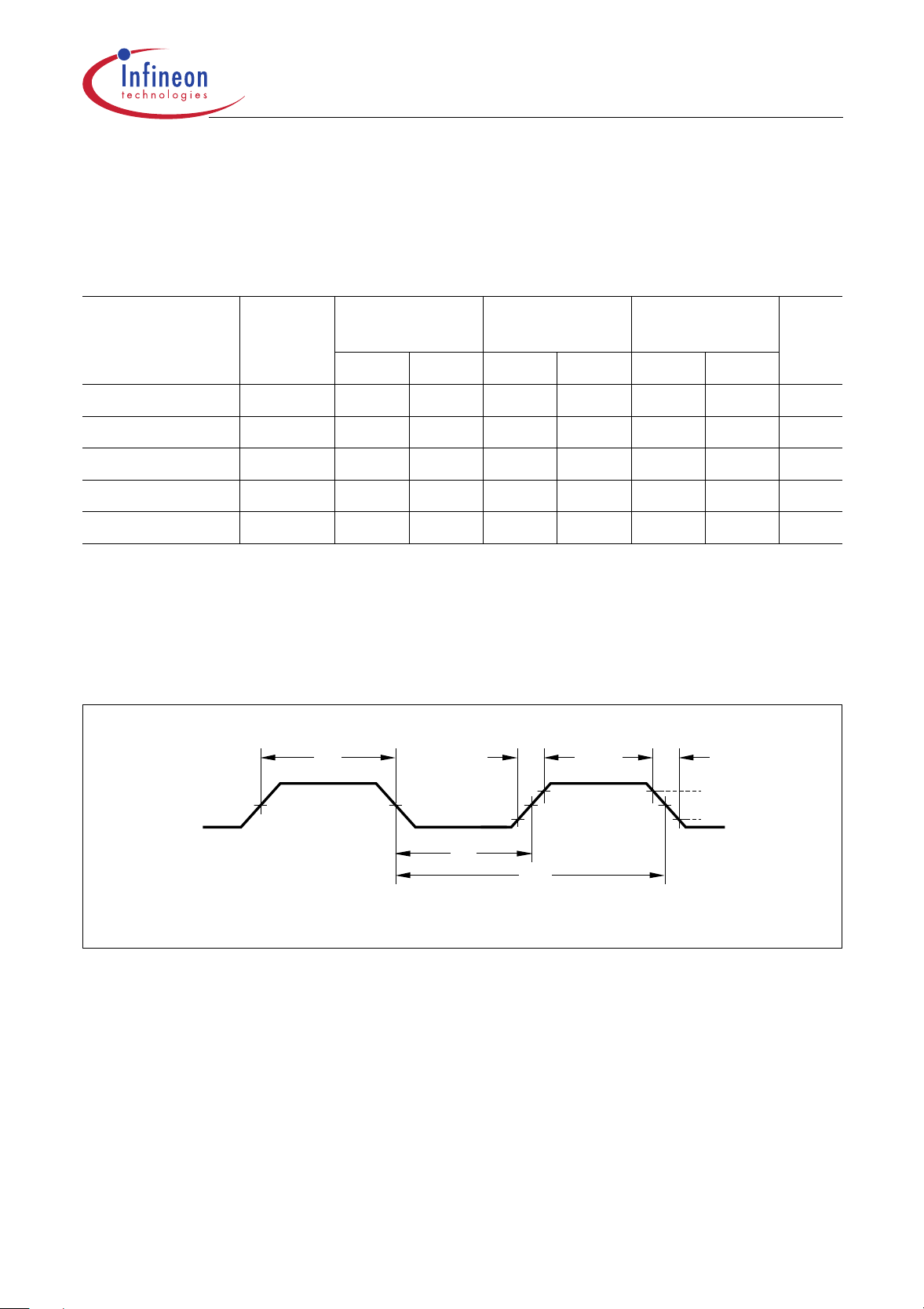

Important timing characteristics of the external bus interface (Memory Cycle Time,

Memory Tri-State Time, Length of ALE and Read Write Delay) have been made

programmable to allow the user the adaption of a wide range of different types of

memories and external peripherals.

In addition, up to 4 independent address windows may be defined (via register pairs

ADDRSELx / BUSCONx) which control the access to different resources with different

bus characteristics. These address windows are arranged hierarchically where

BUSCON4 overrides BUSCON3 and BUSCON2 overrides BUSCON1. All accesses to

locations not covered by these 4 address windows are controlled by BUSCON0.

Up to 4 external CS

external glue logic. The C164CI offers the possibility to switch the CS

unlatched mode. In this mode the internal filter logic is switched off and the CS

are directly generated from the address. The unlatched CS

CSCFG (SYSCON.6).

For applications which require less than 4 MBytes of external memory space, this

address space can be restricted to 1 MByte, 256 KByte, or to 64 KByte. In this case

Port 4 outputs four, two, or no address lines at all. It outputs all 6 address lines, if an

address space of 4 MBytes is used.

Note: When the on-chip CAN Module is used with the interface lines assigned to Port 4,

the CAN lines override the segment address lines and the segment address

output on Port 4 is therefore limited to 4 bits i.e. address lines A19 … A16.

signals (3 windows plus default) can be generated in order to save

outputs to an

signals

mode is enabled by setting

Data Sheet 13 V2.0, 2001-05

C164CI/SI

C164CL/SL

Central Processing Unit (CPU)

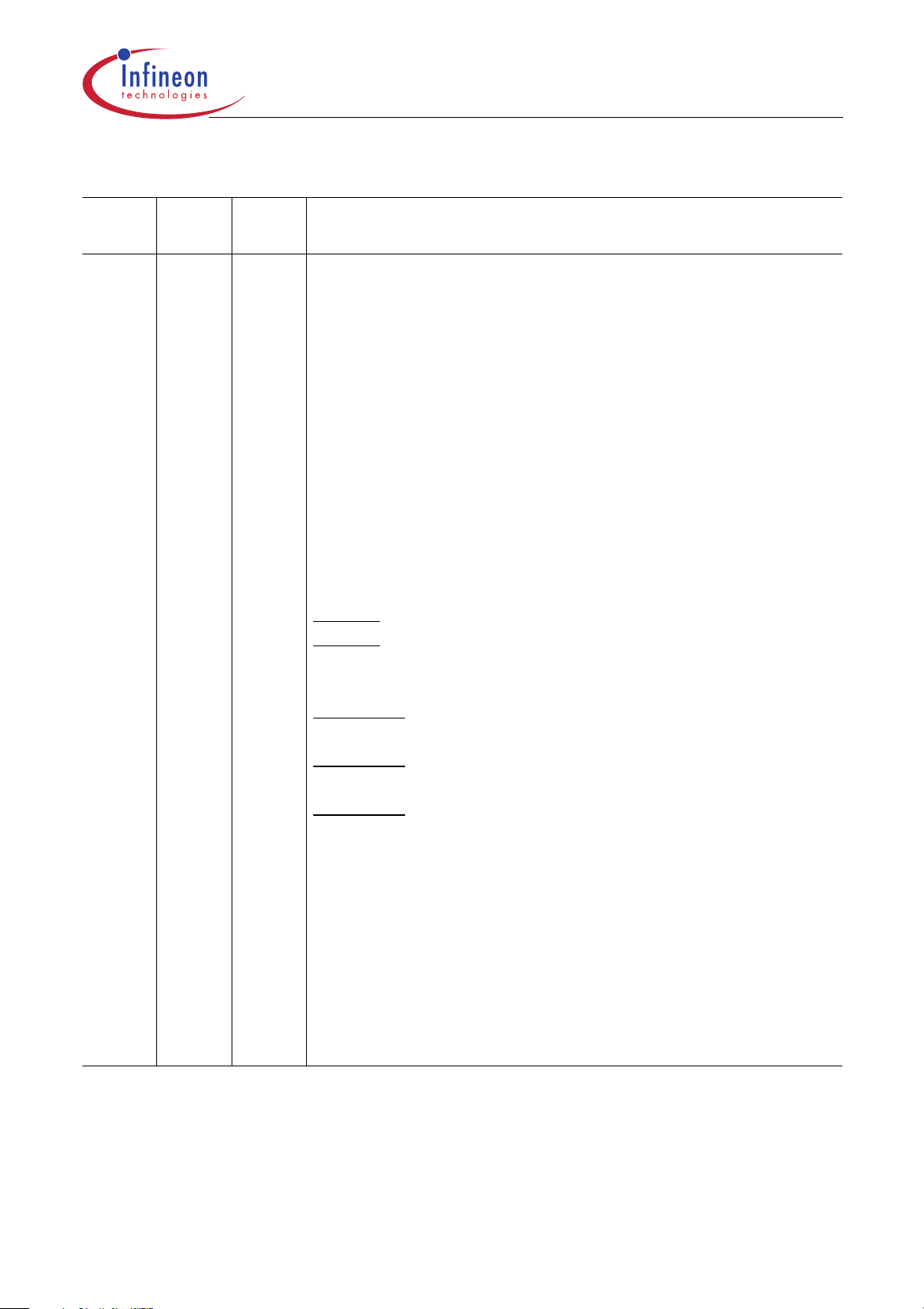

The main core of the CPU consists of a 4-stage instruction pipeline, a 16-bit arithmetic

and logic unit (ALU) and dedicated SFRs. Additional hardware has been spent for a

separate multiply and divide unit, a bit-mask generator and a barrel shifter.

Based on these hardware provisions, most of the C164CI’s instructions can be executed

in just one machine cycle which requires 2 CPU clocks (4 TCL). For example, shift and

rotate instructions are always processed during one machine cycle independent of the

number of bits to be shifted. All multiple-cycle instructions have been optimized so that

they can be executed very fast as well: branches in 2 cycles, a 16 × 16 bit multiplication

in 5 cycles and a 32-/16-bit division in 10 cycles. Another pipeline optimization, the socalled ‘Jump Cache’, reduces the execution time of repeatedly performed jumps in a loop

from 2 cycles to 1 cycle.

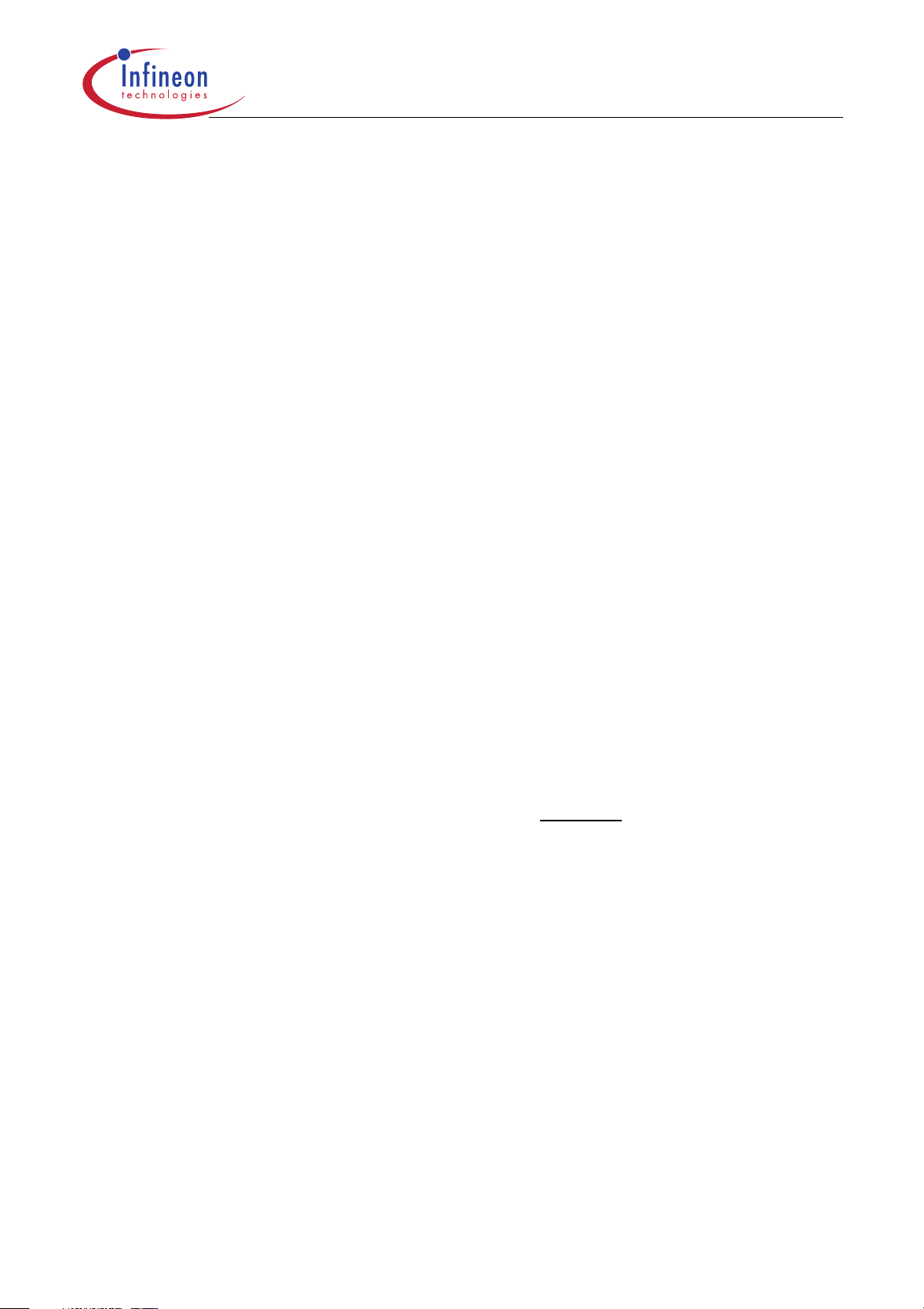

ROM

32

CPU

SP

STKOV

STKUN

Exec. Unit

Instr. Ptr.

Instr. Reg.

4-Stage

Pipeline

PSW

SYSCON

BUSCON 0

BUSCON 1

BUSCON 2

BUSCON 3

BUSCON 4 ADDRSEL 4

Data Page Ptr. Code Seg. Ptr.

MDH

MDL

Mul/Div-HW

Bit-Mask Gen

ALU

(16-bit)

Barrel - Shifter

Context Ptr.

ADDRSEL 1

ADDRSEL 2

ADDRSEL 3

R15

General

Purpose

Registers

R0

16

Internal

RAM

R15

R0

16

MCB02147

Figure 4 CPU Block Diagram

Data Sheet 14 V2.0, 2001-05

C164CI/SI

C164CL/SL

The CPU has a register context consisting of up to 16 wordwide GPRs at its disposal.

These 16 GPRs are physically allocated within the on-chip RAM area. A Context Pointer

(CP) register determines the base address of the active register bank to be accessed by

the CPU at any time. The number of register banks is only restricted by the available

internal RAM space. For easy parameter passing, a register bank may overlap others.

A system stack of up to 1024 words is provided as a storage for temporary data. The

system stack is allocated in the on-chip RAM area, and it is accessed by the CPU via the

stack pointer (SP) register. Two separate SFRs, STKOV and STKUN, are implicitly

compared against the stack pointer value upon each stack access for the detection of a

stack overflow or underflow.

The high performance offered by the hardware implementation of the CPU can efficiently

be utilized by a programmer via the highly efficient C164CI instruction set which includes

the following instruction classes:

– Arithmetic Instructions

– Logical Instructions

– Boolean Bit Manipulation Instructions

– Compare and Loop Control Instructions

– Shift and Rotate Instructions

– Prioritize Instruction

– Data Movement Instructions

– System Stack Instructions

– Jump and Call Instructions

– Return Instructions

– System Control Instructions

– Miscellaneous Instructions

The basic instruction length is either 2 or 4 bytes. Possible operand types are bits, bytes

and words. A variety of direct, indirect or immediate addressing modes are provided to

specify the required operands.

Data Sheet 15 V2.0, 2001-05

C164CI/SI

C164CL/SL

Interrupt System

With an interrupt response time within a range from just 5 to 12 CPU clocks (in case of

internal program execution), the C164CI is capable of reacting very fast to the

occurrence of non-deterministic events.

The architecture of the C164CI supports several mechanisms for fast and flexible

response to service requests that can be generated from various sources internal or

external to the microcontroller. Any of these interrupt requests can be programmed to

being serviced by the Interrupt Controller or by the Peripheral Event Controller (PEC).

In contrast to a standard interrupt service where the current program execution is

suspended and a branch to the interrupt vector table is performed, just one cycle is

‘stolen’ from the current CPU activity to perform a PEC service. A PEC service implies a

single byte or word data transfer between any two memory locations with an additional

increment of either the PEC source or the destination pointer. An individual PEC transfer

counter is implicity decremented for each PEC service except when performing in the

continuous transfer mode. When this counter reaches zero, a standard interrupt is

performed to the corresponding source related vector location. PEC services are very

well suited, for example, for supporting the transmission or reception of blocks of data.

The C164CI has 8 PEC channels each of which offers such fast interrupt-driven data

transfer capabilities.

A separate control register which contains an interrupt request flag, an interrupt enable

flag and an interrupt priority bitfield exists for each of the possible interrupt sources. Via

its related register, each source can be programmed to one of sixteen interrupt priority

levels. Once having been accepted by the CPU, an interrupt service can only be

interrupted by a higher prioritized service request. For the standard interrupt processing,

each of the possible interrupt sources has a dedicated vector location.

Fast external interrupt inputs are provided to service external interrupts with high

precision requirements. These fast interrupt inputs feature programmable edge

detection (rising edge, falling edge or both edges).

Software interrupts are supported by means of the ‘TRAP’ instruction in combination with

an individual trap (interrupt) number.

Table 3 shows all of the possible C164CI interrupt sources and the corresponding

hardware-related interrupt flags, vectors, vector locations and trap (interrupt) numbers.

Note: Interrupt nodes which are not used by associated peripherals, may be used to

generate software controlled interrupt requests by setting the respective interrupt

request bit (xIR).

Data Sheet 16 V2.0, 2001-05

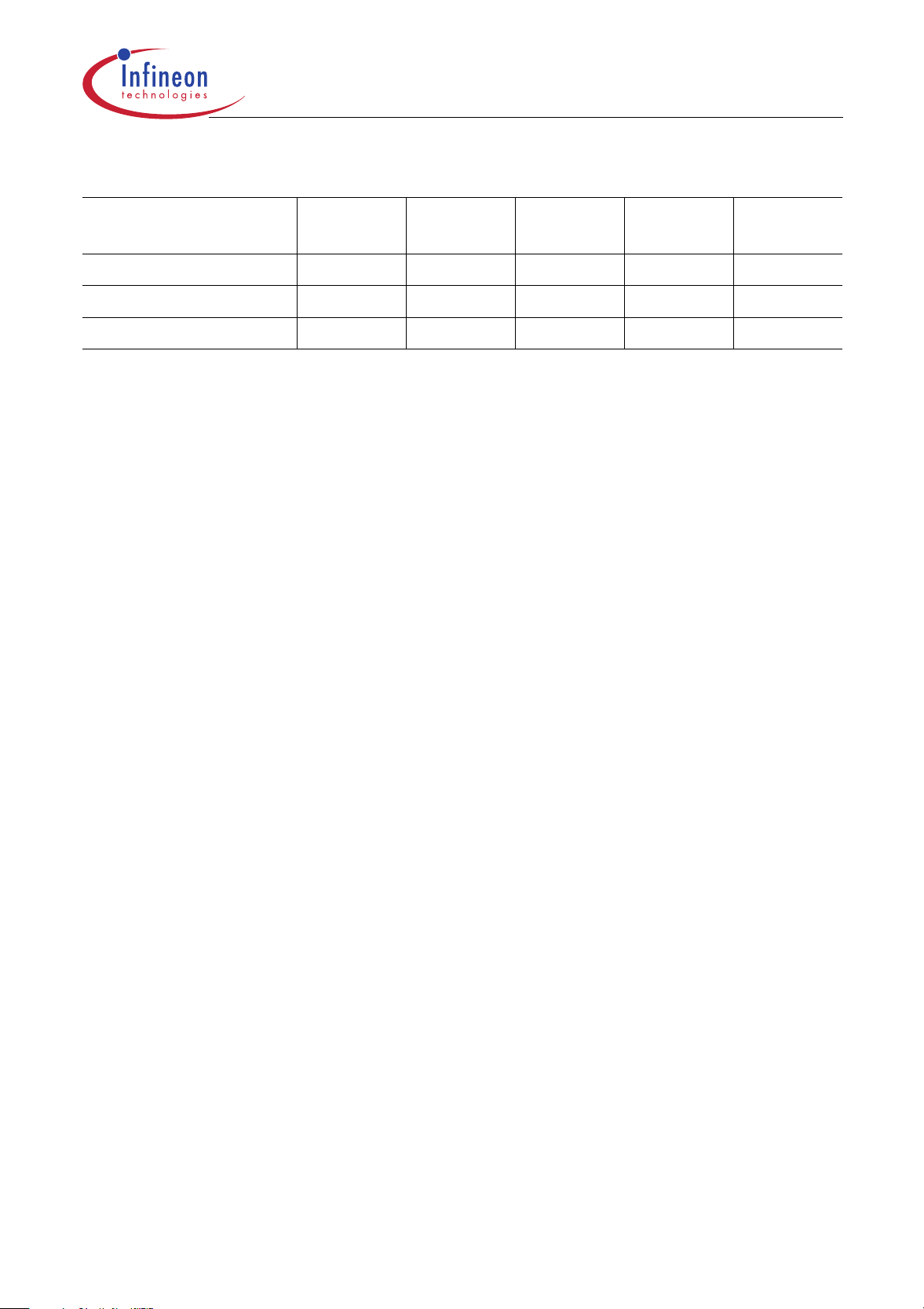

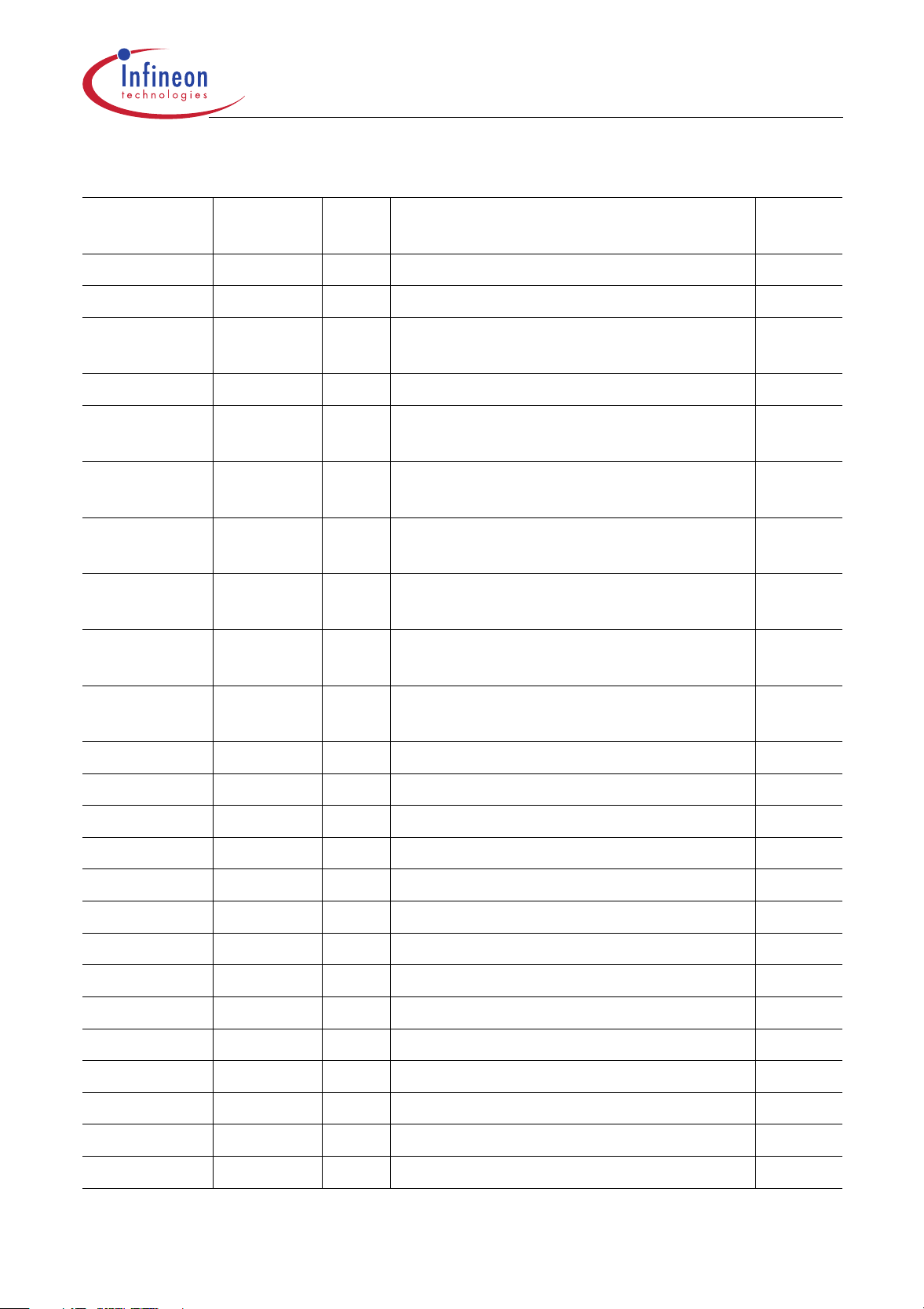

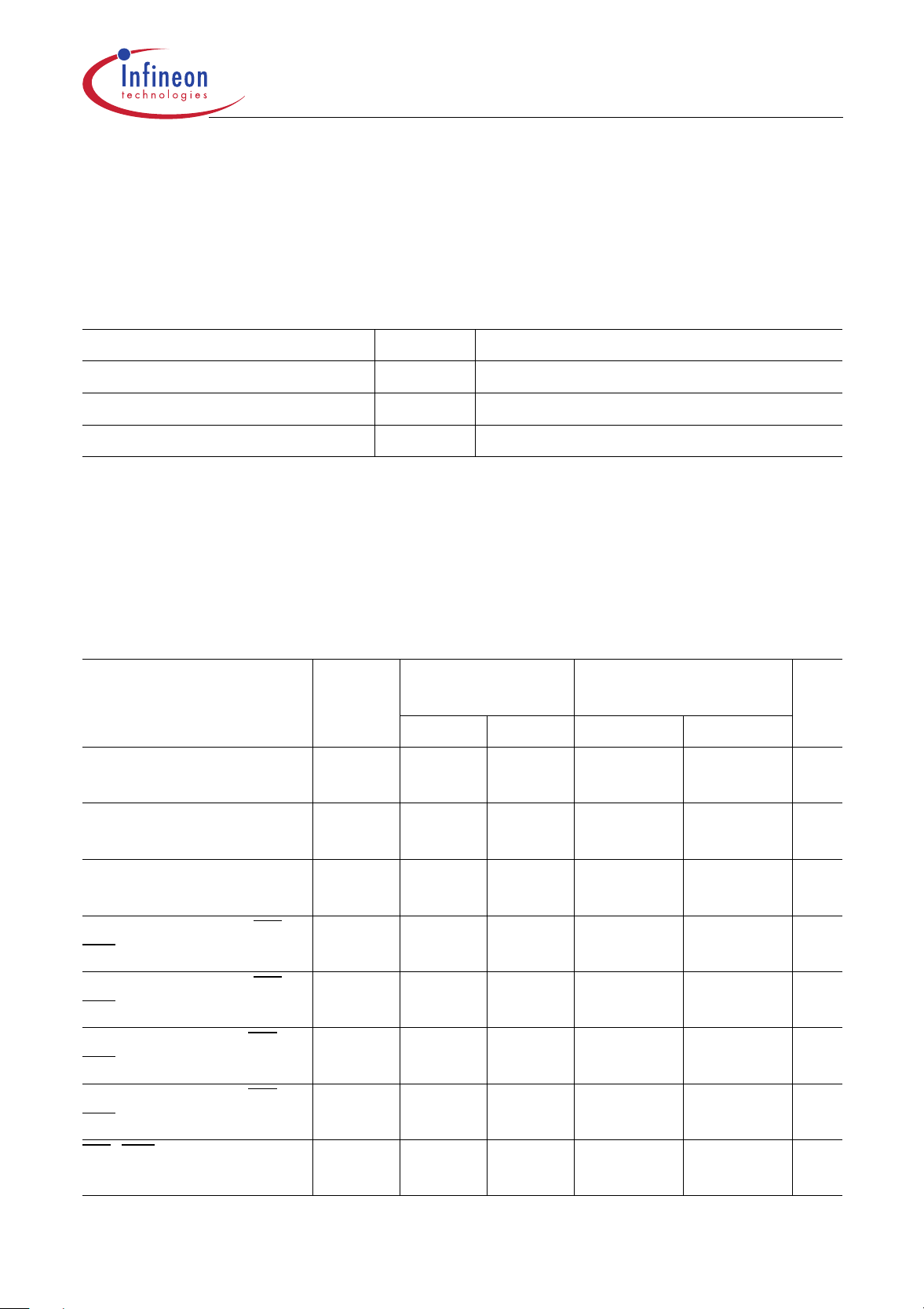

Table 3 C164CI Interrupt Nodes

C164CI/SI

C164CL/SL

Source of Interrupt or

PEC Service Request

Request

Flag

Enable

Flag

Interrupt

Vector

Vector

Location

Fast External Interrupt 0 CC8IR CC8IE CC8INT 00’0060

Fast External Interrupt 1 CC9IR CC9IE CC9INT 00’0064

Fast External Interrupt 2 CC10IR CC10IE CC10INT 00’0068

Fast External Interrupt 3 CC11IR CC11IE CC11INT 00’006C

GPT1 Timer 2 T2IR T2IE T2INT 00’0088

GPT1 Timer 3 T3IR T3IE T3INT 00’008C

GPT1 Timer 4 T4IR T4IE T4INT 00’0090

A/D Conversion

ADCIR ADCIE ADCINT 00’00A0

Complete

A/D Overrun Error ADEIR ADEIE ADEINT 00’00A4

ASC0 Transmit S0TIR S0TIE S0TINT 00’00A8

ASC0 Transmit Buffer S0TBIR S0TBIE S0TBINT 00’011C

ASC0 Receive S0RIR S0RIE S0RINT 00’00AC

H

H

H

H

H

H

H

H

H

H

H

H

Trap

Number

18

H

19

H

1A

H

1B

H

22

H

23

H

24

H

28

H

29

H

2A

H

47

H

2B

H

ASC0 Error S0EIR S0EIE S0EINT 00’00B0

SSC Transmit SCTIR SCTIE SCTINT 00’00B4

SSC Receive SCRIR SCRIE SCRINT 00’00B8

SSC Error SCEIR SCEIE SCEINT 00’00BC

CAPCOM Register 16 CC16IR CC16IE CC16INT 00’00C0

CAPCOM Register 17 CC17IR CC17IE CC17INT 00’00C4

CAPCOM Register 18 CC18IR CC18IE CC18INT 00’00C8

CAPCOM Register 19 CC19IR CC19IE CC19INT 00’00CC

CAPCOM Register 24 CC24IR CC24IE CC24INT 00’00E0

CAPCOM Register 25 CC25IR CC25IE CC25INT 00’00E4

CAPCOM Register 26 CC26IR CC26IE CC26INT 00’00E8

CAPCOM Register 27 CC27IR CC27IE CC27INT 00’00EC

CAPCOM Timer 7 T7IR T7IE T7INT 00’00F4

CAPCOM Timer 8 T8IR T8IE T8INT 00’00F8

CAPCOM6 Interrupt CC6IR CC6IE CC6INT 00’00FC

2C

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

2D

2E

2F

30

31

32

33

38

39

3A

3B

3D

3E

3F

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

CAN Interface 1 XP0IR XP0IE XP0INT 00’0100

PLL/OWD and RTC XP3IR XP3IE XP3INT 00’010C

Data Sheet 17 V2.0, 2001-05

40

H

H

43

H

H

Table 3 C164CI Interrupt Nodes (cont’d)

C164CI/SI

C164CL/SL

Source of Interrupt or

PEC Service Request

Request

Flag

Enable

Flag

Interrupt

Vector

Vector

Location

CAPCOM 6 Timer 12 T12IR T12IE T12INT 00’0134

CAPCOM 6 Timer 13 T13IR T13IE T13INT 00’0138

CAPCOM 6 Emergency CC6EIR CC6EIE CC6EINT 00’013C

H

H

H

Trap

Number

4D

H

4E

H

4F

H

Data Sheet 18 V2.0, 2001-05

C164CI/SI

C164CL/SL

The C164CI also provides an excellent mechanism to identify and to process exceptions

or error conditions that arise during run-time, so-called ‘Hardware Traps’. Hardware

traps cause immediate non-maskable system reaction which is similar to a standard

interrupt service (branching to a dedicated vector table location). The occurence of a

hardware trap is additionally signified by an individual bit in the trap flag register (TFR).

Except when another higher prioritized trap service is in progress, a hardware trap will

interrupt any actual program execution. In turn, hardware trap services can normally not

be interrupted by standard or PEC interrupts.

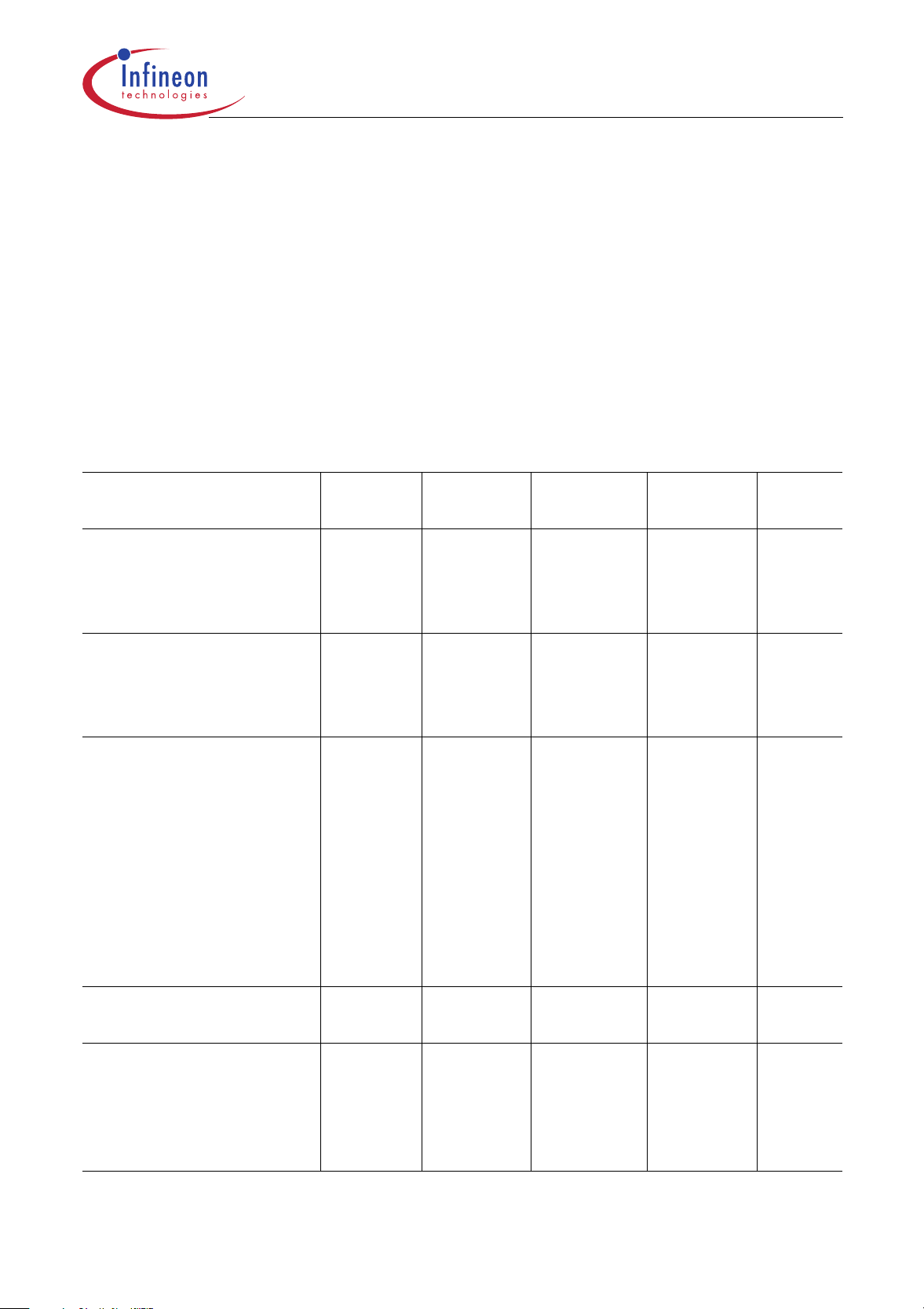

Table 4 shows all of the possible exceptions or error conditions that can arise during run-

time:

Table 4 Hardware Trap Summary

Exception Condition Trap

Flag

Reset Functions:

–

– Hardware Reset

– Software Reset

– W-dog Timer Overflow

Class A Hardware Traps:

– Non-Maskable Interrupt

– Stack Overflow

– Stack Underflow

NMI

STKOF

STKUF

Class B Hardware Traps:

– Undefined Opcode

– Protected Instruction

UNDOPC

PRTFLT

Fault

– Illegal Word Operand

ILLOPA

Access

– Illegal Instruction

ILLINA

Access

– Illegal External Bus

ILLBUS

Access

Trap

Vector

RESET

RESET

RESET

NMITRAP

STOTRAP

STUTRAP

BTRAP

BTRAP

BTRAP

BTRAP

BTRAP

Vector

Location

00’0000

00’0000

00’0000

00’0008

00’0010

00’0018

00’0028

00’0028

00’0028

00’0028

00’0028

H

H

H

H

H

H

H

H

H

H

H

Trap

Number

00

H

00

H

00

H

02

H

04

H

06

H

0A

H

0A

H

0A

H

0A

H

0A

H

Trap

Priority

III

III

III

II

II

II

I

I

I

I

I

Reserved –– [2C

3CH]

Software Traps

– TRAP Instruction

–– Any

[00’0000

00’01FCH]

–

H

–

H

[0BH –

0FH]

Any

–

[00

H

7FH]

–

Current

CPU

Priority

in steps

of 4

H

Data Sheet 19 V2.0, 2001-05

C164CI/SI

C164CL/SL

The Capture/Compare Unit CAPCOM2

The general purpose CAPCOM2 unit supports generation and control of timing

sequences on up to 8 channels with a maximum resolution of 16 TCL. The CAPCOM

units are typically used to handle high speed I/O tasks such as pulse and waveform

generation, pulse width modulation (PMW), Digital to Analog (D/A) conversion, software

timing, or time recording relative to external events.

Two 16-bit timers (T7/T8) with reload registers provide two independent time bases for

the capture/compare register array.

Each dual purpose capture/compare register, which may be individually allocated to

either CAPCOM timer and programmed for capture or compare function, has one port

pin associated with it which serves as an input pin for triggering the capture function, or

as an output pin to indicate the occurrence of a compare event.

When a capture/compare register has been selected for capture mode, the current

contents of the allocated timer will be latched (‘capture’d) into the capture/compare

register in response to an external event at the port pin which is associated with this

register. In addition, a specific interrupt request for this capture/compare register is

generated. Either a positive, a negative, or both a positive and a negative external signal

transition at the pin can be selected as the triggering event. The contents of all registers

which have been selected for one of the five compare modes are continuously compared

with the contents of the allocated timers. When a match occurs between the timer value

and the value in a capture/compare register, specific actions will be taken based on the

selected compare mode.

Table 5 Compare Modes (CAPCOM2)

Compare Modes Function

Mode 0 Interrupt-only compare mode;

several compare interrupts per timer period are possible

Mode 1 Pin toggles on each compare match;

several compare events per timer period are possible

Mode 2 Interrupt-only compare mode;

only one compare interrupt per timer period is generated

Mode 3 Pin set ‘1’ on match; pin reset ‘0’ on compare time overflow;

only one compare event per timer period is generated

Double

Register Mode

Two registers operate on one pin; pin toggles on each compare

match;

several compare events per timer period are possible.

Registers CC16 & CC24 ➞ pin CC16IO

Registers CC17 & CC25 ➞ pin CC17IO

Registers CC18 & CC26 ➞ pin CC18IO

Registers CC19 & CC27 ➞ pin CC19IO

Data Sheet 20 V2.0, 2001-05

C164CI/SI

C164CL/SL

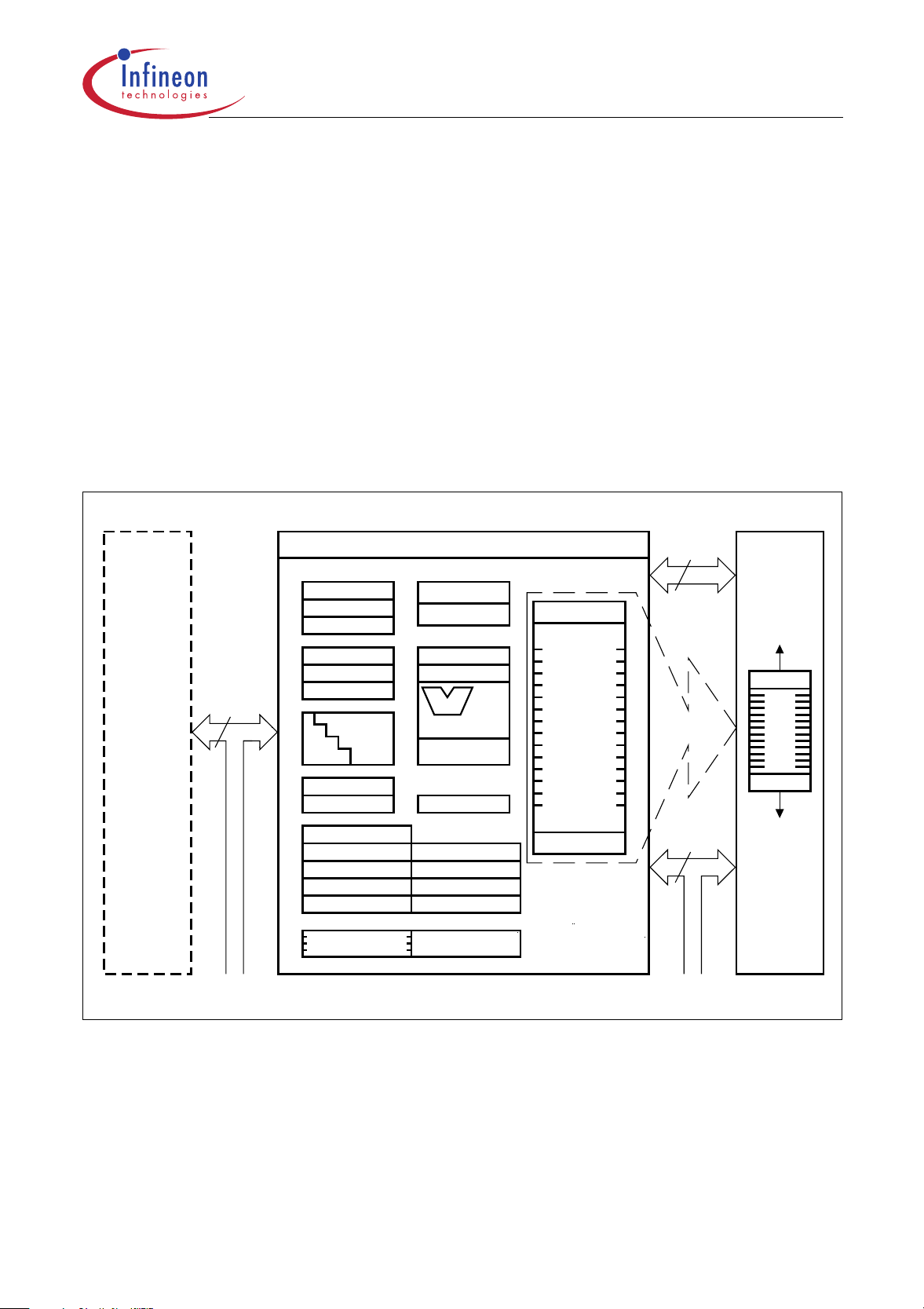

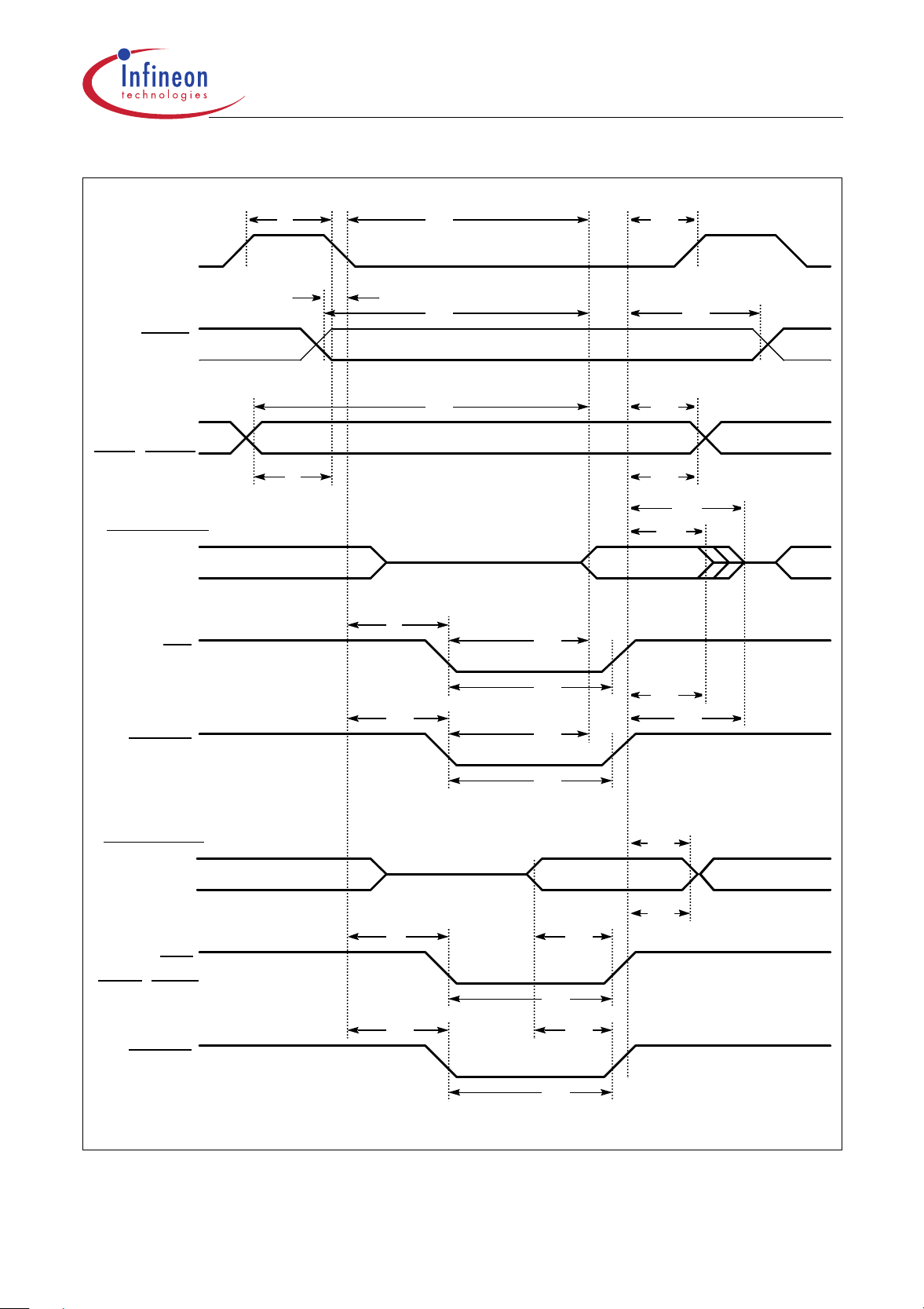

The Capture/Compare Unit CAPCOM6

The CAPCOM6 unit supports generation and control of timing sequences on up to three

16-bit capture/compare channels plus one 10-bit compare channel.

In compare mode the CAPCOM6 unit provides two output signals per channel which

have inverted polarity and non-overlapping pulse transitions. The compare channel can

generate a single PWM output signal and is further used to modulate the capture/

compare output signals.

In capture mode the contents of compare timer 12 is stored in the capture registers upon

a signal transition at pins CCx.

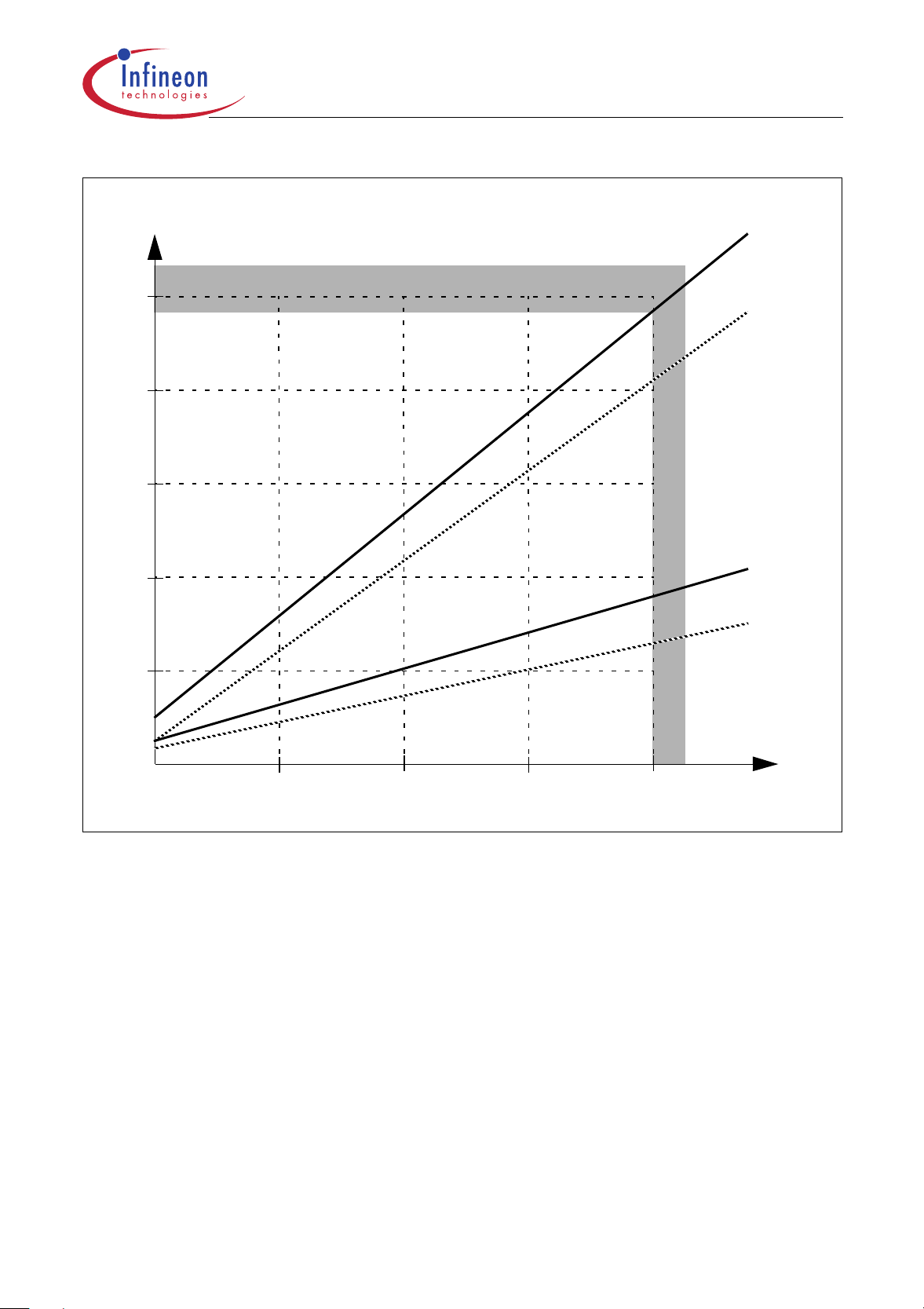

Compare timers T12 (16-bit) and T13 (10-bit) are free running timers which are clocked

by the prescaled CPU clock.

f

f

CPU

CPU

Period Register

T12P

Offset Register

T12OF

Compare

Timer T12

Prescaler

Prescaler

16-Bit

Control Register

CTCON

Compare

Timer T13

10-Bit

Period Register

T13P

Mode

Select Register

CC6MSEL

CC Channel 0

CC60

CC Channel 1

Control

CC61

CC Channel 2

CC62

Compare Register

CMP13

Trap Register

Port

Control

Logic

Block

Commutation

Control

CC6MCON.H

CTRAP

CC60

COUT60

CC61

COUT61

CC62

COUT62

COUT63

CC6POS0

CC6POS1

CC6POS2

The timer registers (T12, T13) are not directly accessible.

The period and offset registers are loading a value into the timer registers.

The shaded blocks are available in the full function module only.

MCB04109

Figure 5 CAPCOM6 Block Diagram

For motor control applications both subunits may generate versatile multichannel PWM

signals which are basically either controlled by compare timer 12 or by a typical hall

sensor pattern at the interrupt inputs (block commutation).

Note: Multichannel signal generation is provided only in devices with a full CAPCOM6.

Data Sheet 21 V2.0, 2001-05

C164CI/SI

C164CL/SL

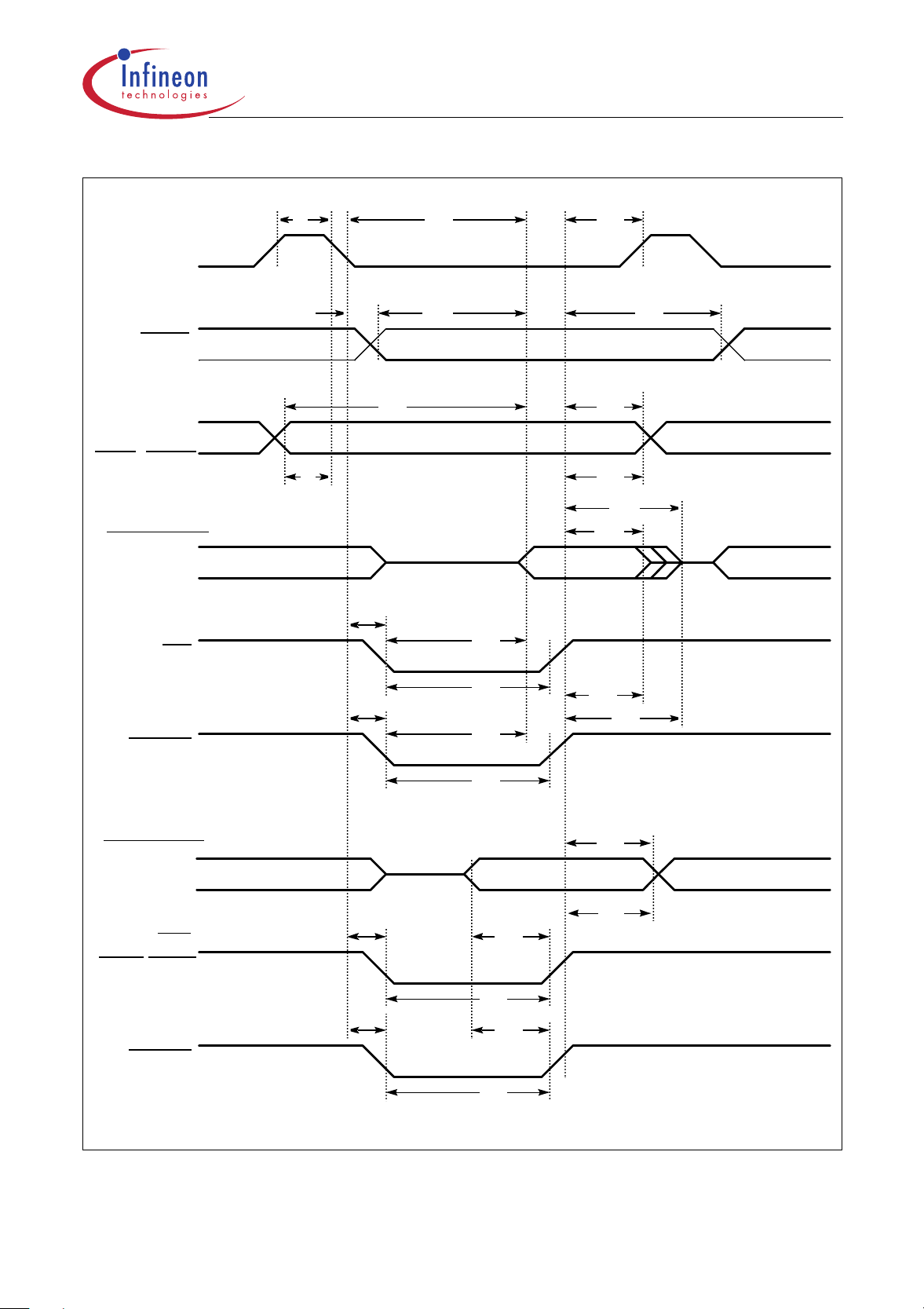

General Purpose Timer (GPT) Unit

The GPT unit represents a very flexible multifunctional timer/counter structure which

may be used for many different time related tasks such as event timing and counting,

pulse width and duty cycle measurements, pulse generation, or pulse multiplication.

The GPT unit incorporates three 16-bit timers. Each timer may operate independently in

a number of different modes, or may be concatenated with another timer.

Each of the three timers T2, T3, T4 of module GPT1 can be configured individually for

one of four basic modes of operation, which are Timer, Gated Timer, Counter, and

Incremental Interface Mode. In Timer Mode, the input clock for a timer is derived from

the CPU clock, divided by a programmable prescaler, while Counter Mode allows a timer

to be clocked in reference to external events.

Pulse width or duty cycle measurement is supported in Gated Timer Mode, where the

operation of a timer is controlled by the ‘gate’ level on an external input pin. For these

purposes, each timer has one associated port pin (TxIN) which serves as gate or clock

input. The maximum resolution of the timers in module GPT1 is 16 TCL.

The count direction (up/down) for each timer is programmable by software or may

additionally be altered dynamically by an external signal on a port pin (TxEUD) to

facilitate e.g. position tracking.

In Incremental Interface Mode the GPT1 timers (T2, T3, T4) can be directly connected

to the incremental position sensor signals A and B via their respective inputs TxIN and

TxEUD. Direction and count signals are internally derived from these two input signals,

so the contents of the respective timer Tx corresponds to the sensor position. The third

position sensor signal TOP0 can be connected to an interrupt input.

Timer T3 has an output toggle latch (T3OTL) which changes its state on each timer overflow/underflow. The state of this latch may be used internally to clock timers T2 and T4

for measuring long time periods with high resolution.

In addition to their basic operating modes, timers T2 and T4 may be configured as reload

or capture registers for timer T3. When used as capture or reload registers, timers T2

and T4 are stopped. The contents of timer T3 is captured into T2 or T4 in response to a

signal at their associated input pins (TxIN). Timer T3 is reloaded with the contents of T2

or T4 triggered either by an external signal or by a selectable state transition of its toggle

latch T3OTL.

Data Sheet 22 V2.0, 2001-05

C164CI/SI

C164CL/SL

T2EUD

T2IN

T3IN

T3EUD

T4IN

T4EUD

CPU

CPU

CPU

U/D

Interrupt

2n : 1f

2n : 1f

2n : 1f

T2

Mode

Control

T3

Mode

Control

T4

Mode

Control

GPT1 Timer T2

Reload

Capture

Toggle FF

GPT1 Timer T3 T3OTL

U/D

Capture

Reload

GPT1 Timer T4

U/D

Request

(T2IR)

Interrupt

Request

(T3IR)

Other

Timers

Interrupt

Request

(T4IR)

Mct04825_4.vsd

n = 3 … 10

Figure 6 Block Diagram of GPT1

Data Sheet 23 V2.0, 2001-05

C164CI/SI

C164CL/SL

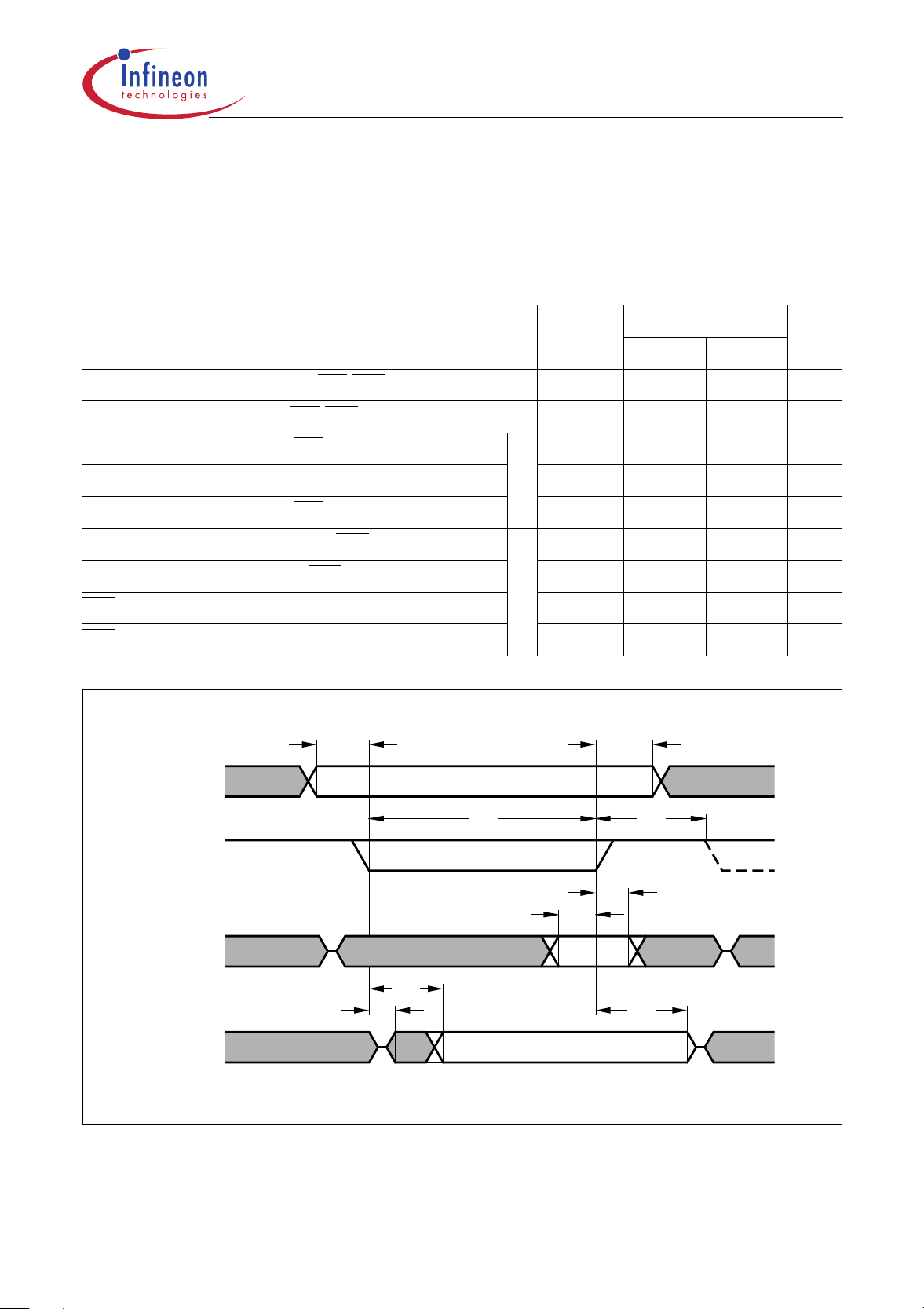

Real Time Clock

The Real Time Clock (RTC) module of the C164CI consists of a chain of 3 divider blocks,

a fixed 8:1 divider, the reloadable 16-bit timer T14, and the 32-bit RTC timer (accessible

via registers RTCH and RTCL). The RTC module is directly clocked with the on-chip

f

oscillator frequency divided by 32 via a separate clock driver (

RTC

= f

therefore independent from the selected clock generation mode of the C164CI. All timers

count up.

The RTC module can be used for different purposes:

• System clock to determine the current time and date

• Cyclic time based interrupt

• 48-bit timer for long term measurements

/32) and is

OSC

T14REL

Reload

f

T14 8:1

RTCLRTCH

RTC

Interrupt

Request

MCD04432

Figure 7 RTC Block Diagram

Note: The registers associated with the RTC are not affected by a reset in order to

maintain the correct system time even when intermediate resets are executed.

Data Sheet 24 V2.0, 2001-05

C164CI/SI

C164CL/SL

A/D Converter

For analog signal measurement, a 10-bit A/D converter with 8 multiplexed input channels

and a sample and hold circuit has been integrated on-chip. It uses the method of

successive approximation. The sample time (for loading the capacitors) and the

conversion time is programmable and can so be adjusted to the external circuitry.

Overrun error detection/protection is provided for the conversion result register

(ADDAT): either an interrupt request will be generated when the result of a previous

conversion has not been read from the result register at the time the next conversion is

complete, or the next conversion is suspended in such a case until the previous result

has been read.

For applications which require less than 8 analog input channels, the remaining channel

inputs can be used as digital input port pins.

The A/D converter of the C164CI supports four different conversion modes. In the

standard Single Channel conversion mode, the analog level on a specified channel is

sampled once and converted to a digital result. In the Single Channel Continuous mode,

the analog level on a specified channel is repeatedly sampled and converted without

software intervention. In the Auto Scan mode, the analog levels on a prespecified

number of channels (standard or extension) are sequentially sampled and converted. In

the Auto Scan Continuous mode, the number of prespecified channels is repeatedly

sampled and converted. In addition, the conversion of a specific channel can be inserted

(injected) into a running sequence without disturbing this sequence. This is called

Channel Injection Mode.

The Peripheral Event Controller (PEC) may be used to automatically store the

conversion results into a table in memory for later evaluation, without requiring the

overhead of entering and exiting interrupt routines for each data transfer.

After each reset and also during normal operation the ADC automatically performs

calibration cycles. This automatic self-calibration constantly adjusts the converter to

changing operating conditions (e.g. temperature) and compensates process variations.

These calibration cycles are part of the conversion cycle, so they do not affect the normal

operation of the A/D converter.

In order to decouple analog inputs from digital noise and to avoid input trigger noise

those pins used for analog input can be disconnected from the digital IO or input stages

under software control. This can be selected for each pin separately via register P5DIDIS

(Port 5 Digital Input Disable).

Data Sheet 25 V2.0, 2001-05

C164CI/SI

C164CL/SL

Serial Channels

Serial communication with other microcontrollers, processors, terminals or external

peripheral components is provided by two serial interfaces with different functionality, an

Asynchronous/Synchronous Serial Channel (ASC0) and a High-Speed Synchronous

Serial Channel (SSC).

The ASC0 is upward compatible with the serial ports of the Infineon 8-bit microcontroller

families and supports full-duplex asynchronous communication at up to 781 Kbit/s and

half-duplex synchronous communication at up to 3.1 Mbit/s (@ 25 MHz CPU clock).

A dedicated baud rate generator allows to set up all standard baud rates without

oscillator tuning. For transmission, reception and error handling 4 separate interrupt

vectors are provided. In asynchronous mode, 8- or 9-bit data frames are transmitted or

received, preceded by a start bit and terminated by one or two stop bits. For

multiprocessor communication, a mechanism to distinguish address from data bytes has

been included (8-bit data plus wake up bit mode).

In synchronous mode, the ASC0 transmits or receives bytes (8 bits) synchronously to a

shift clock which is generated by the ASC0. The ASC0 always shifts the LSB first. A loop

back option is available for testing purposes.

A number of optional hardware error detection capabilities has been included to increase

the reliability of data transfers. A parity bit can automatically be generated on

transmission or be checked on reception. Framing error detection allows to recognize

data frames with missing stop bits. An overrun error will be generated, if the last

character received has not been read out of the receive buffer register at the time the

reception of a new character is complete.

The SSC supports full-duplex synchronous communication at up to 6.25 Mbit/s

(@ 25 MHz CPU clock). It may be configured so it interfaces with serially linked

peripheral components. A dedicated baud rate generator allows to set up all standard

baud rates without oscillator tuning. For transmission, reception and error handling

3 separate interrupt vectors are provided.

The SSC transmits or receives characters of 2 … 16 bits length synchronously to a shift

clock which can be generated by the SSC (master mode) or by an external master (slave

mode). The SSC can start shifting with the LSB or with the MSB and allows the selection

of shifting and latching clock edges as well as the clock polarity.

A number of optional hardware error detection capabilities has been included to increase

the reliability of data transfers. Transmit and receive error supervise the correct handling

of the data buffer. Phase and baudrate error detect incorrect serial data.

Data Sheet 26 V2.0, 2001-05

C164CI/SI

C164CL/SL

CAN-Module

The integrated CAN-Module handles the completely autonomous transmission and

reception of CAN frames in accordance with the CAN specification V2.0 part B (active),

i.e. the on-chip CAN-Modules can receive and transmit standard frames with 11-bit

identifiers as well as extended frames with 29-bit identifiers.

The module provides Full CAN functionality on up to 15 message objects. Message

object 15 may be configured for Basic CAN functionality. Both modes provide separate

masks for acceptance filtering which allows to accept a number of identifiers in Full CAN

mode and also allows to disregard a number of identifiers in Basic CAN mode. All

message objects can be updated independent from the other objects and are equipped

for the maximum message length of 8 bytes.

The bit timing is derived from the XCLK and is programmable up to a data rate of 1 Mbit/

s. Each CAN-Module uses two pins of Port 4 or Port 8 to interface to an external bus

transceiver. The interface pins are assigned via software.

Note: When the CAN interface is assigned to Port 4, the respective segment address

lines on Port 4 cannot be used. This will limit the external address space.

Watchdog Timer

The Watchdog Timer represents one of the fail-safe mechanisms which have been

implemented to prevent the controller from malfunctioning for longer periods of time.

The Watchdog Timer is always enabled after a reset of the chip, and can only be

disabled in the time interval until the EINIT (end of initialization) instruction has been

executed. Thus, the chip’s start-up procedure is always monitored. The software has to

be designed to service the Watchdog Timer before it overflows. If, due to hardware or

software related failures, the software fails to do so, the Watchdog Timer overflows and

generates an internal hardware reset and pulls the RSTOUT

external hardware components to be reset.

The Watchdog Timer is a 16-bit timer, clocked with the system clock divided by 2/4/128/

256. The high byte of the Watchdog Timer register can be set to a prespecified reload

value (stored in WDTREL) in order to allow further variation of the monitored time

interval. Each time it is serviced by the application software, the high byte of the

Watchdog Timer is reloaded. Thus, time intervals between 20 µs and 336 ms can be

monitored (@ 25 MHz).

The default Watchdog Timer interval after reset is 5.24 ms (@ 25 MHz).

pin low in order to allow

Data Sheet 27 V2.0, 2001-05

C164CI/SI

C164CL/SL

Parallel Ports

The C164CI provides up to 59 I/O lines which are organized into five input/output ports

and one input port. All port lines are bit-addressable, and all input/output lines are

individually (bit-wise) programmable as inputs or outputs via direction registers. The I/O

ports are true bidirectional ports which are switched to high impedance state when

configured as inputs. The output drivers of three I/O ports can be configured (pin by pin)

for push/pull operation or open-drain operation via control registers. During the internal

reset, all port pins are configured as inputs.

The input threshold of Port 3, Port 4, and Port 8 is selectable (TTL or CMOS like), where

the special CMOS like input threshold reduces noise sensitivity due to the input

hysteresis. The input threshold may be selected individually for each byte of the

respective ports.

All port lines have programmable alternate input or output functions associated with

them. All port lines that are not used for these alternate functions may be used as general

purpose IO lines.

PORT0 and PORT1 may be used as address and data lines when accessing external

memory, while Port 4 outputs the additional segment address bits A21/19/17 … A16 and

the optional chip select signals in systems where segmentation is enabled to access

more than 64 KBytes of memory.

Ports P1L, P1H, and P8 are associated with the capture inputs or compare outputs of

the CAPCOM units and/or serve as external interrupt inputs.

Port 3 includes alternate functions of timers, serial interfaces, the optional bus control

signal BHE

frequency output FOUT).

Port 5 is used for the analog input channels to the A/D converter or timer control signals.

The edge characteristics (transition time) and driver characteristics (output current) of

the C164CI’s port drivers can be selected via the Port Output Control registers

(POCONx).

/WRH, and the system clock output CLKOUT (or the programmable

Data Sheet 28 V2.0, 2001-05

C164CI/SI

C164CL/SL

Oscillator Watchdog

The Oscillator Watchdog (OWD) monitors the clock signal generated by the on-chip

oscillator (either with a crystal or via external clock drive). For this operation the PLL

provides a clock signal which is used to supervise transitions on the oscillator clock. This

PLL clock is independent from the XTAL1 clock. When the expected oscillator clock

transitions are missing the OWD activates the PLL Unlock/OWD interrupt node and

supplies the CPU with the PLL clock signal. Under these circumstances the PLL will

oscillate with its basic frequency.

f

In direct drive mode the PLL base frequency is used directly (

In prescaler mode the PLL base frequency is divided by 2 (

f

CPU

Note: The CPU clock source is only switched back to the oscillator clock after a

hardware reset.

The oscillator watchdog can be disabled by setting bit OWDDIS in register SYSCON.

In this case (OWDDIS = ‘1’) the PLL remains idle and provides no clock signal, while the

CPU clock signal is derived directly from the oscillator clock or via prescaler or SDD. Also

no interrupt request will be generated in case of a missing oscillator clock.

= 2 … 5 MHz).

CPU

= 1 … 2.5 MHz).

Note: At the end of a reset bit OWDDIS reflects the inverted level of pin RD

Thus the oscillator watchdog may also be disabled via hardware by (externally)

pulling the RD

line low upon a reset, similar to the standard reset configuration via

PORT0.

at that time.

Data Sheet 29 V2.0, 2001-05

C164CI/SI

C164CL/SL

Power Management

The C164CI provides several means to control the power it consumes either at a given

time or averaged over a certain timespan. Three mechanisms can be used (partly in

parallel):

• Power Saving Modes switch the C164CI into a special operating mode (control via

instructions).

Idle Mode stops the CPU while the peripherals can continue to operate.

Sleep Mode and Power Down Mode stop all clock signals and all operation (RTC may

optionally continue running). Sleep Mode can be terminated by external interrupt

signals.

• Clock Generation Management controls the distribution and the frequency of

internal and external clock signals (control via register SYSCON2).

f

Slow Down Mode lets the C164CI run at a CPU clock frequency of

for prescaler operation) which drastically reduces the consumed power. The PLL can

be optionally disabled while operating in Slow Down Mode.

External circuitry can be controlled via the programmable frequency output FOUT.

• Peripheral Management permits temporary disabling of peripheral modules (control

via register SYSCON3).

Each peripheral can separately be disabled/enabled. A group control option disables

a major part of the peripheral set by setting one single bit.

/1 … 32 (half

OSC

The on-chip RTC supports intermittend operation of the C164CI by generating cyclic

wakeup signals. This offers full performance to quickly react on action requests while the

intermittend sleep phases greatly reduce the average power consumption of the system.

Data Sheet 30 V2.0, 2001-05

C164CI/SI

C164CL/SL

Instruction Set Summary

Table 6 lists the instructions of the C164CI in a condensed way.

The various addressing modes that can be used with a specific instruction, the operation

of the instructions, parameters for conditional execution of instructions, and the opcodes

for each instruction can be found in the “C166 Family Instruction Set Manual”.

This document also provides a detailled description of each instruction.

Table 6 Instruction Set Summary

Mnemonic Description Bytes

ADD(B) Add word (byte) operands 2 / 4

ADDC(B) Add word (byte) operands with Carry 2 / 4

SUB(B) Subtract word (byte) operands 2 / 4

SUBC(B) Subtract word (byte) operands with Carry 2 / 4

MUL(U) (Un)Signed multiply direct GPR by direct GPR (16-16-bit) 2

DIV(U) (Un)Signed divide register MDL by direct GPR (16-/16-bit) 2

DIVL(U) (Un)Signed long divide reg. MD by direct GPR (32-/16-bit) 2

CPL(B) Complement direct word (byte) GPR 2

NEG(B) Negate direct word (byte) GPR 2

AND(B) Bitwise AND, (word/byte operands) 2 / 4

OR(B) Bitwise OR, (word/byte operands) 2 / 4

XOR(B) Bitwise XOR, (word/byte operands) 2 / 4

BCLR Clear direct bit 2

BSET Set direct bit 2

BMOV(N) Move (negated) direct bit to direct bit 4

BAND, BOR,

BXOR

BCMP Compare direct bit to direct bit 4

BFLDH/L Bitwise modify masked high/low byte of bit-addressable

CMP(B) Compare word (byte) operands 2 / 4

AND/OR/XOR direct bit with direct bit 4

4

direct word memory with immediate data

CMPD1/2 Compare word data to GPR and decrement GPR by 1/2 2 / 4

CMPI1/2 Compare word data to GPR and increment GPR by 1/2 2 / 4

PRIOR Determine number of shift cycles to normalize direct

word GPR and store result in direct word GPR

SHL / SHR Shift left/right direct word GPR 2

ROL / ROR Rotate left/right direct word GPR 2

ASHR Arithmetic (sign bit) shift right direct word GPR 2

Data Sheet 31 V2.0, 2001-05

2

C164CI/SI

C164CL/SL

Table 6 Instruction Set Summary (cont’d)

Mnemonic Description Bytes

MOV(B) Move word (byte) data 2 / 4

MOVBS Move byte operand to word operand with sign extension 2 / 4

MOVBZ 2 / 4

JMPA, JMPI,

JMPR

JMPS Jump absolute to a code segment 4

J(N)B Jump relative if direct bit is (not) set 4

JBC Jump relative and clear bit if direct bit is set 4

JNBS Jump relative and set bit if direct bit is not set 4

CALLA, CALLI,

CALLR

CALLS Call absolute subroutine in any code segment 4

PCALL Push direct word register onto system stack and call

TRAP Call interrupt service routine via immediate trap number 2

PUSH, POP Push/pop direct word register onto/from system stack 2

SCXT Push direct word register onto system stack und update

RET Return from intra-segment subroutine 2

Move byte operand to word operand with zero extension

Jump absolute/indirect/relative if condition is met 4

Call absolute/indirect/relative subroutine if condition is met 4

4

absolute subroutine

4

register with word operand

RETS Return from inter-segment subroutine 2

RETP Return from intra-segment subroutine and pop direct

word register from system stack

RETI Return from interrupt service subroutine 2

SRST Software Reset 4

IDLE Enter Idle Mode 4

PWRDN Enter Power Down Mode (supposes NMI

SRVWDT Service Watchdog Timer 4

DISWDT Disable Watchdog Timer 4

EINIT Signify End-of-Initialization on RSTOUT

ATOMIC Begin ATOMIC sequence 2

EXTR Begin EXTended Register sequence 2

EXTP(R) Begin EXTended Page (and Register) sequence 2 / 4

EXTS(R) Begin EXTended Segment (and Register) sequence 2 / 4

NOP Null operation 2

-pin being low) 4

-pin 4

2

Data Sheet 32 V2.0, 2001-05

C164CI/SI

C164CL/SL

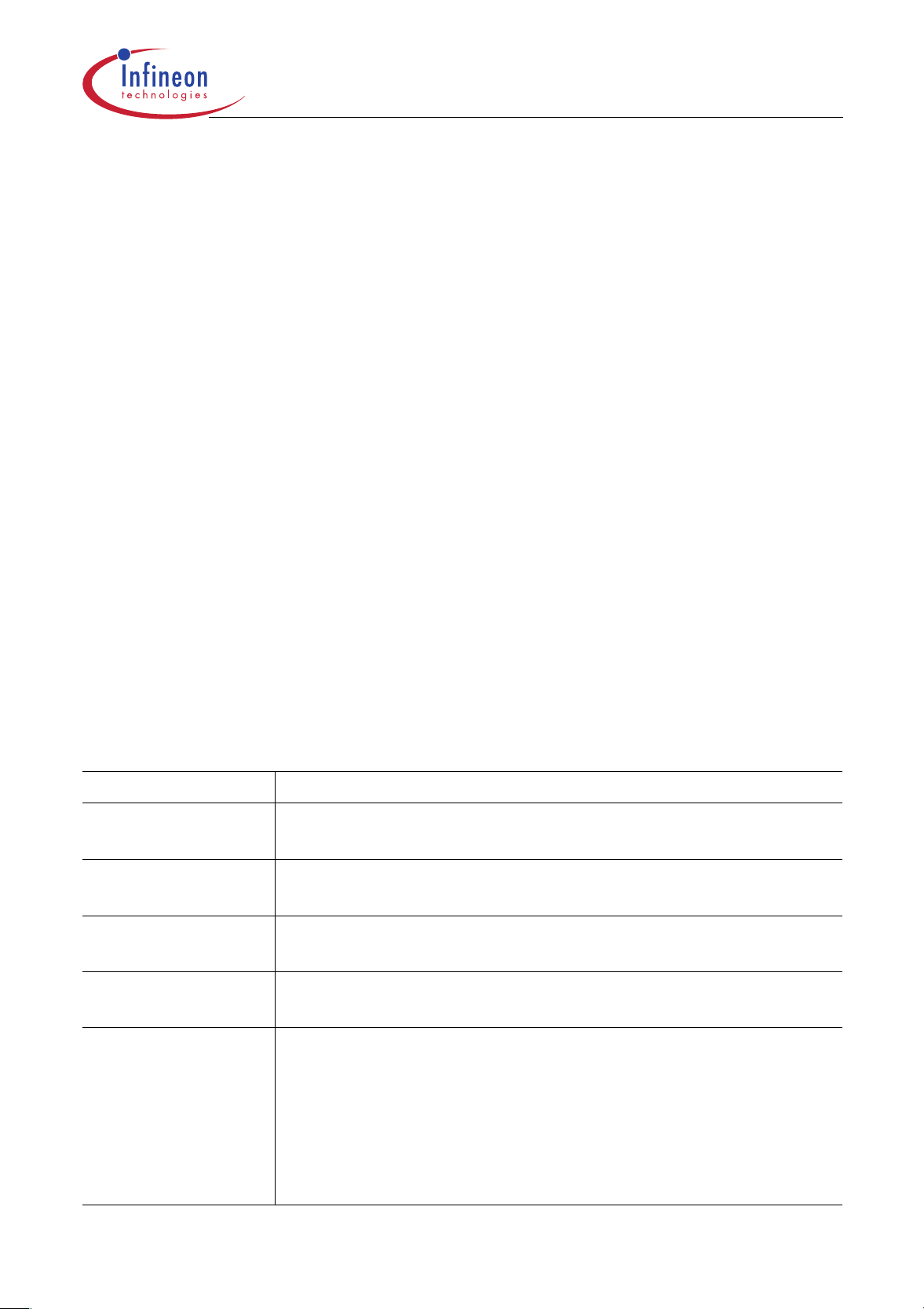

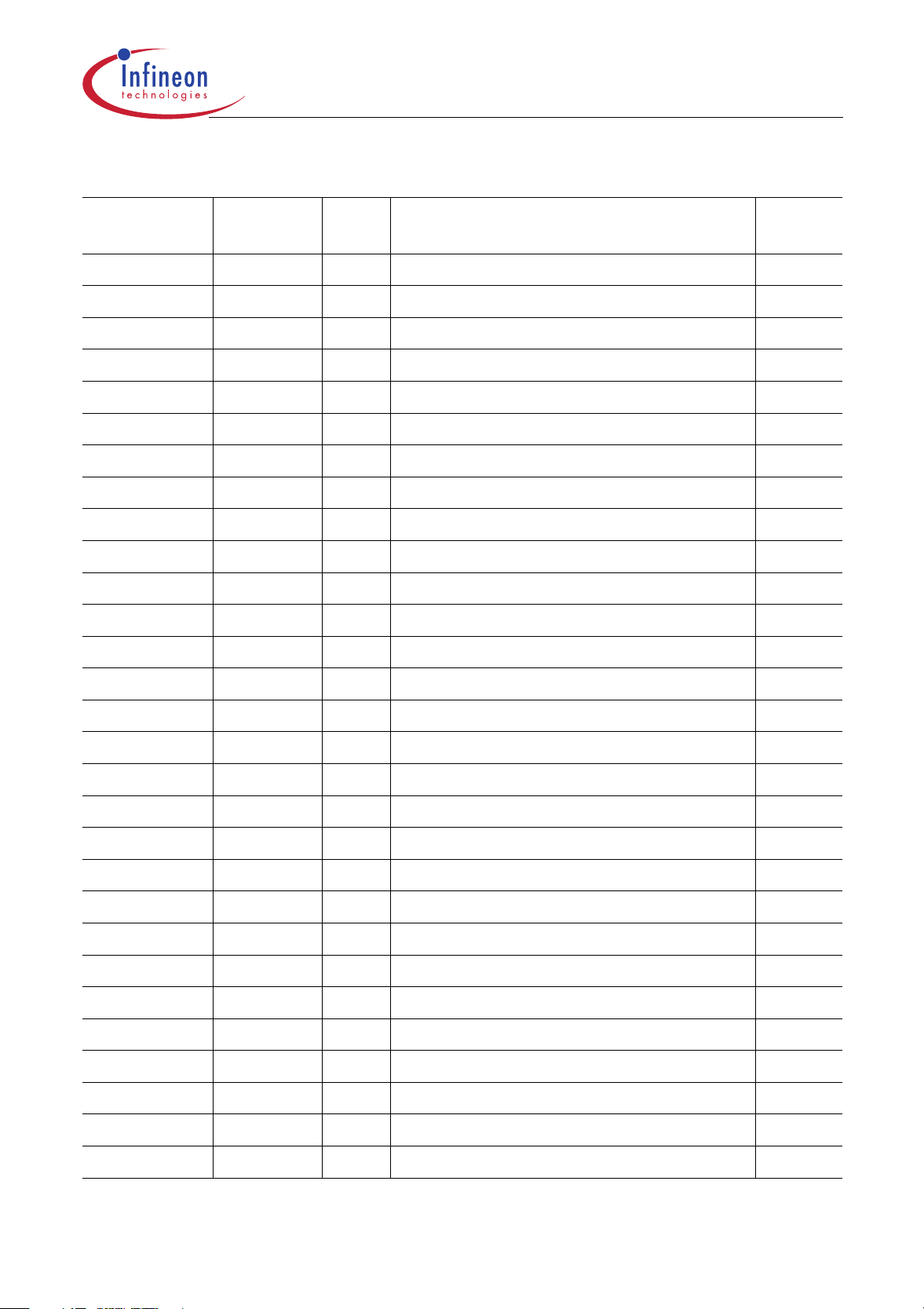

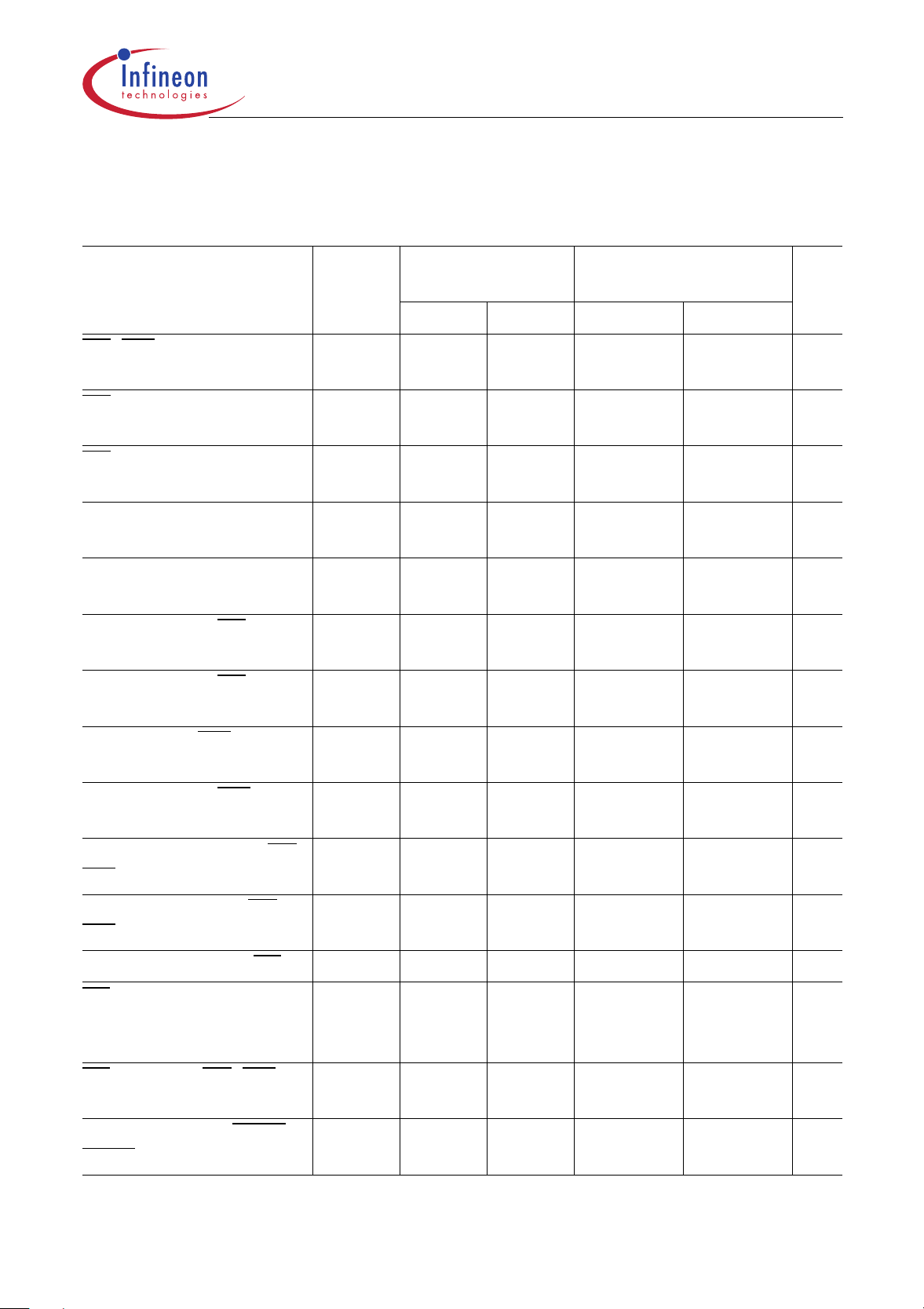

Special Function Registers Overview

Table 7 lists all SFRs which are implemented in the C164CI in alphabetical order.

Bit-addressable SFRs are marked with the letter “b” in column “Name”. SFRs within the

Extended SFR-Space (ESFRs) are marked with the letter “E” in column “Physical

Address”. Registers within on-chip X-peripherals are marked with the letter “X” in column

“Physical Address”.

An SFR can be specified via its individual mnemonic name. Depending on the selected

addressing mode, an SFR can be accessed via its physical address (using the Data

Page Pointers), or via its short 8-bit address (without using the Data Page Pointers).

Table 7 C164CI Registers, Ordered by Name

Name Physical

Address

ADCIC b FF98

ADCON b FFA0

ADDAT FEA0

ADDAT2 F0A0

ADDRSEL1 FE18

ADDRSEL2 FE1A

ADDRSEL3 FE1C

ADDRSEL4 FE1E

ADEIC b FF9A

BUSCON0 b FF0C

BUSCON1 b FF14

BUSCON2 b FF16

H

H

H

H

H

H

H

H

H

H

H

H

8-Bit

Addr.

CC

D0

50

E 50

0C

0D

0E

0F

CD

86

8A

8B

Description Reset

A/D Converter End of Conversion

H

Interrupt Control Register

A/D Converter Control Register 0000

H

A/D Converter Result Register 0000

H

A/D Converter 2 Result Register 0000

H

Address Select Register 1 0000

H

Address Select Register 2 0000

H

Address Select Register 3 0000

H

Address Select Register 4 0000

H

A/D Converter Overrun Error Interrupt

H

Control Register

Bus Configuration Register 0 0000

H

Bus Configuration Register 1 0000

H

Bus Configuration Register 2 0000

H

Value

0000

0000

H

H

H

H

H

H

H

H

H

H

H

H

BUSCON3 b FF18

BUSCON4 b FF1A

C1BTR EF04

C1CSR EF00

C1GMS EF06

C1LARn EFn4

C1LGML EF0A

C1LMLM EF0E

Data Sheet 33 V2.0, 2001-05

H

H

H

H

H

H

H

H

8C

8D

Bus Configuration Register 3 0000

H

Bus Configuration Register 4 0000

H

X --- CAN1 Bit Timing Register UUUU

X --- CAN1 Control / Status Register XX01

X --- CAN1 Global Mask Short UFUU

X --- CAN Lower Arbitration Register (msg. n) UUUU

X --- CAN Lower Global Mask Long UUUU

X --- CAN Lower Mask of Last Message UUUU

H

H

H

H

H

H

H

H

Table 7 C164CI Registers, Ordered by Name (cont’d)

C164CI/SI

C164CL/SL

Name Physical

Address

C1MCFGn EFn6

C1MCRn EFn0

C1PCIR EF02

C1UARn EFn2

C1UGML EF08

C1UMLM EF0C

CC10IC b FF8C

CC11IC b FF8E

CC16 FE60

CC16IC b F160

CC17 FE62

CC17IC b F162

H

H

H

H

H

H

H

H

H

H

H

H

8-Bit

Addr.

X --- CAN Message Configuration Register

Description Reset

Value

UU

(msg. n)

X --- CAN Message Control Register (msg. n) UUUU

X --- CAN1 Port Control / Interrupt Register XXXX

X --- CAN Upper Arbitration Register (msg. n) UUUU

X --- CAN Upper Global Mask Long UUUU

X --- CAN Upper Mask of Last Message UUUU

C6

C7

30

E B0

31

E B1

External Interrupt 2 Control Register 0000

H

External Interrupt 3 Control Register 0000

H

CAPCOM Register 16 0000

H

CAPCOM Reg. 16 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 17 0000

H

CAPCOM Reg. 17 Interrupt Ctrl. Reg. 0000

H

H

H

H

H

H

H

H

H

H

H

H

H

CC18 FE64

CC18IC b F164

CC19 FE66

CC19IC b F166

CC20 FE68

CC20IC b F168

CC21 FE6A

CC21IC b F16A

CC22 FE6C

H

H

H

H

H

H

H

H

H

32

E B2

33

E B3

34

E B4

35

E B5

36

CC22IC b F16CHE B6

CC23 FE6E

CC23IC b F16E

CC24 FE70

CC24IC b F170

CC25 FE72

H

H

H

H

H

37

E B7

38

E B8

39

CAPCOM Register 18 0000

H

CAPCOM Reg. 18 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 19 0000

H

CAPCOM Reg. 19 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 20 0000

H

CAPCOM Reg. 20 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 21 0000

H

CAPCOM Reg. 21 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 22 0000

H

CAPCOM Reg. 22 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 23 0000

H

CAPCOM Reg. 23 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 24 0000

H

CAPCOM Reg. 24 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 25 0000

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

CC25IC b F172

CC26 FE74

Data Sheet 34 V2.0, 2001-05

H

H

E B9

3A

CAPCOM Reg. 25 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 26 0000

H

H

H

Table 7 C164CI Registers, Ordered by Name (cont’d)

C164CI/SI

C164CL/SL

Name Physical

Address

CC26IC b F174

CC27 FE76

CC27IC b F176

CC28 FE78

CC28IC b F178

CC29 FE7A

CC29IC b F184

CC30 FE7C

H

H

H

H

H

H

H

H

8-Bit

Addr.

E BA

3B

E BB

3C

E BC

3D

E C2

3E

CC30IC b F18CHE C6

CC31 FE7E

CC31IC b F194

CC60 FE30

CC61 FE32

H

H

H

H

3F

E CA

18

19

Description Reset

CAPCOM Reg. 26 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 27 0000

H

CAPCOM Reg. 27 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 28 0000

H

CAPCOM Reg. 28 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 29 0000

H

CAPCOM Reg. 29 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 30 0000

H

CAPCOM Reg. 30 Interrupt Ctrl. Reg. 0000

H

CAPCOM Register 31 0000

H

CAPCOM Reg. 31 Interrupt Ctrl. Reg. 0000

H

CAPCOM 6 Register 0 0000

H

CAPCOM 6 Register 1 0000

H

Value

H

H

H

H

H

H

H

H

H

H

H

H

H

CC62 FE34

CC6EIC b F188

CC6CIC b F17E

CC6MCON b FF32

CC6MIC b FF36

CC6MSEL F036

CC8IC b FF88

CC9IC b FF8A

CCM4 b FF22

CCM5 b FF24

CCM6 b FF26

CCM7 b FF28

CMP13 FE36

CP FE10

H

H

H

H

H

H

H

H

H

H

H

H

H

H

1A

E C4

E BF

99

9B

E 1B

C4

C5

91

92

93

94

1B

08

CAPCOM 6 Register 2 0000

H

CAPCOM 6 Emergency Interrrupt

H