Page 1

User Guide Please read the Important Notice and Warnings at the end of this document Revision 1.3

www.infineon.com 2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

About this document

Scope and purpose

This Board User Manual provides a short introduction into the Battery Switch 24V - System Demonstrator and

its application.

Intended audience

Electrical engineers who are qualified and familiar with the challenges of handling high current circuits.

Page 2

User Guide 2 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Important notice

Important notice

The Evaluation Boards and Reference Boards as well as the information in this document are solely intended to

support designers of applications in evaluating the use of products from Infineon Technologies for their

intended applications.

Environmental conditions have been considered in the design of the Evaluation Boards, Reference Boards and

the like provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards has

been tested by Infineon Technologies only as described in this document. The design is not qualified in terms of

safety requirements, manufacturing and operation over the entire operating temperature range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the same

procedures as regular products regarding returned material analysis (RMA), process change notification (PCN)

and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production. The

Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards (including but

not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other requirements of the

country in which they are operated by the customer. The customer shall ensure that all Evaluation Boards and

Reference Boards will be handled in a way which is compliant with the relevant requirements and standards of

the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and managed

according to the terms and conditions set forth in this document and in other related documentation supplied

with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the Evaluation

Boards and Reference Boards for the intended application, and to evaluate the completeness and correctness

of the information provided in this document with respect to such application.

The customer accepts that the Evaluation Boards and Reference Boards are not intended to be used in lifeendangering applications such as medical, nuclear, military, life-critical or other applications, where failure

of the Evaluation Boards and Reference Boards, or any results from the use thereof, can reasonably be

expected to result in personal injury.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is" and

Infineon Technologies disclaims any warranties, express or implied, including but not limited to warranties of

non-infringement of third party rights and implied warranties of fitness for any purpose, or for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation Boards

and Reference Boards and/or from any information provided in this document. The customer is obliged to

defend, indemnify and hold Infineon Technologies harmless from and against any claims or damages arising

out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided herein at

any time without further notice.

Page 3

User Guide 3 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Table of contents

Table of contents

About this document ....................................................................................................................... 1

Important notice ............................................................................................................................ 2

Table of contents ............................................................................................................................ 3

1 Overview ...................................................................................................................... 4

2 Connecting the Switch ................................................................................................... 6

2.1 Overview .................................................................................................................................................. 6

2.2 Control ..................................................................................................................................................... 7

2.2.1 Pin Assignment ................................................................................................................................... 7

2.2.2 Input Voltage Range ........................................................................................................................... 8

2.2.3 Control with bistable relay adaptor .................................................................................................. 9

3 Operating Range ........................................................................................................... 10

3.1 Voltage Range ........................................................................................................................................ 10

3.2 Current Rating ....................................................................................................................................... 10

4 Thermal Behavior ......................................................................................................... 11

5 Switching Behaviour ..................................................................................................... 12

6 Mechanical Dimensions ................................................................................................. 13

7 Schematics .................................................................................................................. 14

8 PCB Description ............................................................................................................ 17

8.1 PCB Technology .................................................................................................................................... 17

8.2 PCB Layout ............................................................................................................................................ 18

9 Bill Of Materials ............................................................................................................ 19

Revision History ............................................................................................................................ 20

Page 4

User Guide 4 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Overview

1 Overview

The Battery Switch 24V - System Demonstrator shows a semiconductor based solution of a 24 V battery master

switch for trucks.

Note: This demonstrator focus lies solely on the switching element and the demonstration of the current

carrying and short circuit handling capabilities.

The demonstrator consists of eight low ohmic MOSFETs connected in parallel and mounted on a structured

copper IMS (insolated metal substrate) board together with a gate driver circuit to switch those MOSFETs on

and off. In order to protect the MOSFETs against excessive overvoltage there are four transient voltage

suppressor diodes implemented at the bottom side of the board.

Table 1 Main Components

Component

Type

Comment

MOSFETs (8x)

IPLU300N04S4-R8

300 A, 40 V, 0.53 mOhm typ.

TVS Diodes (4x)

SMDJ33A

33 V

Gate Driver

AUIR3242S

Normally on (default)

AUIR3241S

Normally off (optional)

Thanks to the low ohmic MOSFETs the on state resistance of the whole switch is less than 160 uΩ from terminal

to terminal. The eight parallel MOSFETs account for typically 67 uΩ at room temperature. At 120°C board

temperature and 500 A current this value will increase to roughly 100 uΩ.

Please note that the Battery Switch 24V - System Demonstrator is a unidirectional switch. This means that it will

interrupt current flowing from the battery to the load but not current flowing into the battery. The reason for

this is the intrinsic body diode of the power MOSFETs as shown in Figure 1. Therefore charging through the

MOSFETs should be avoided or at least limited to currents below 20 A when the switch is deactivated (off).

Figure 1 Unidirectional Switch due to MOSFET Body Diode

Page 5

User Guide 5 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Overview

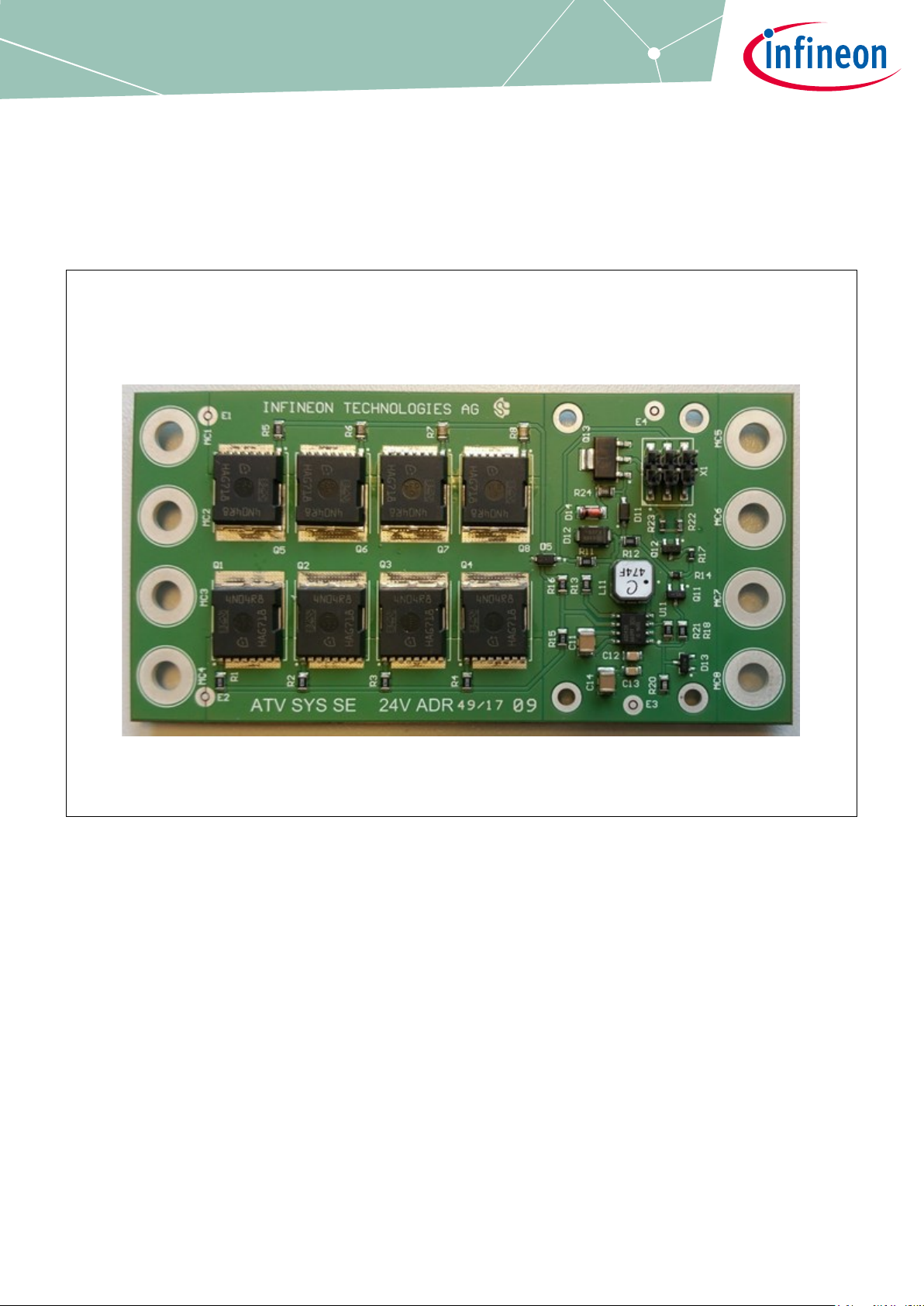

Figure 2 Battery Switch 24V - System Demonstrator Top View

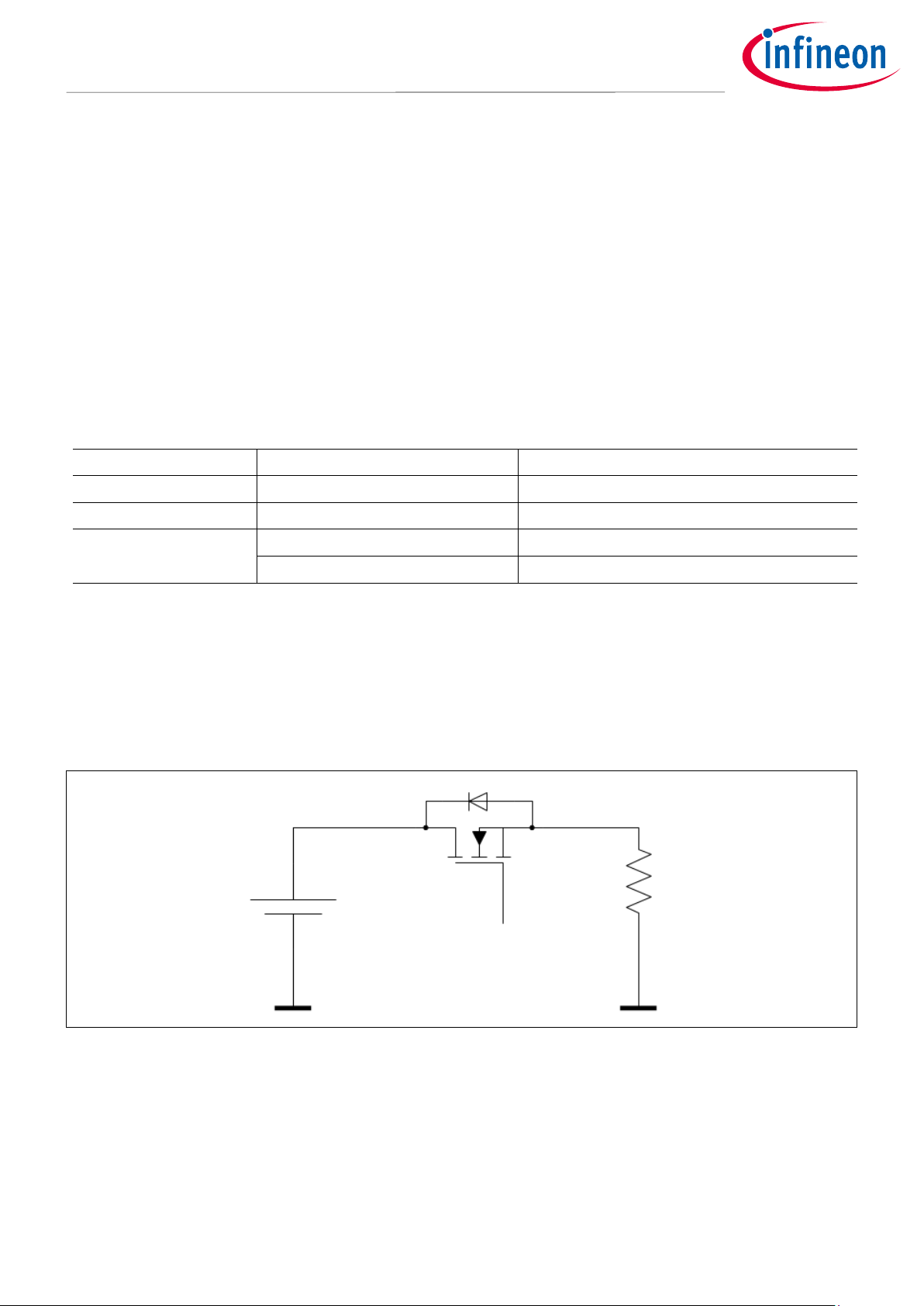

Figure 3 Battery Switch 24V - System Demonstrator Bottom View

Page 6

User Guide 6 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Connecting the Switch

2 Connecting the Switch

2.1 Overview

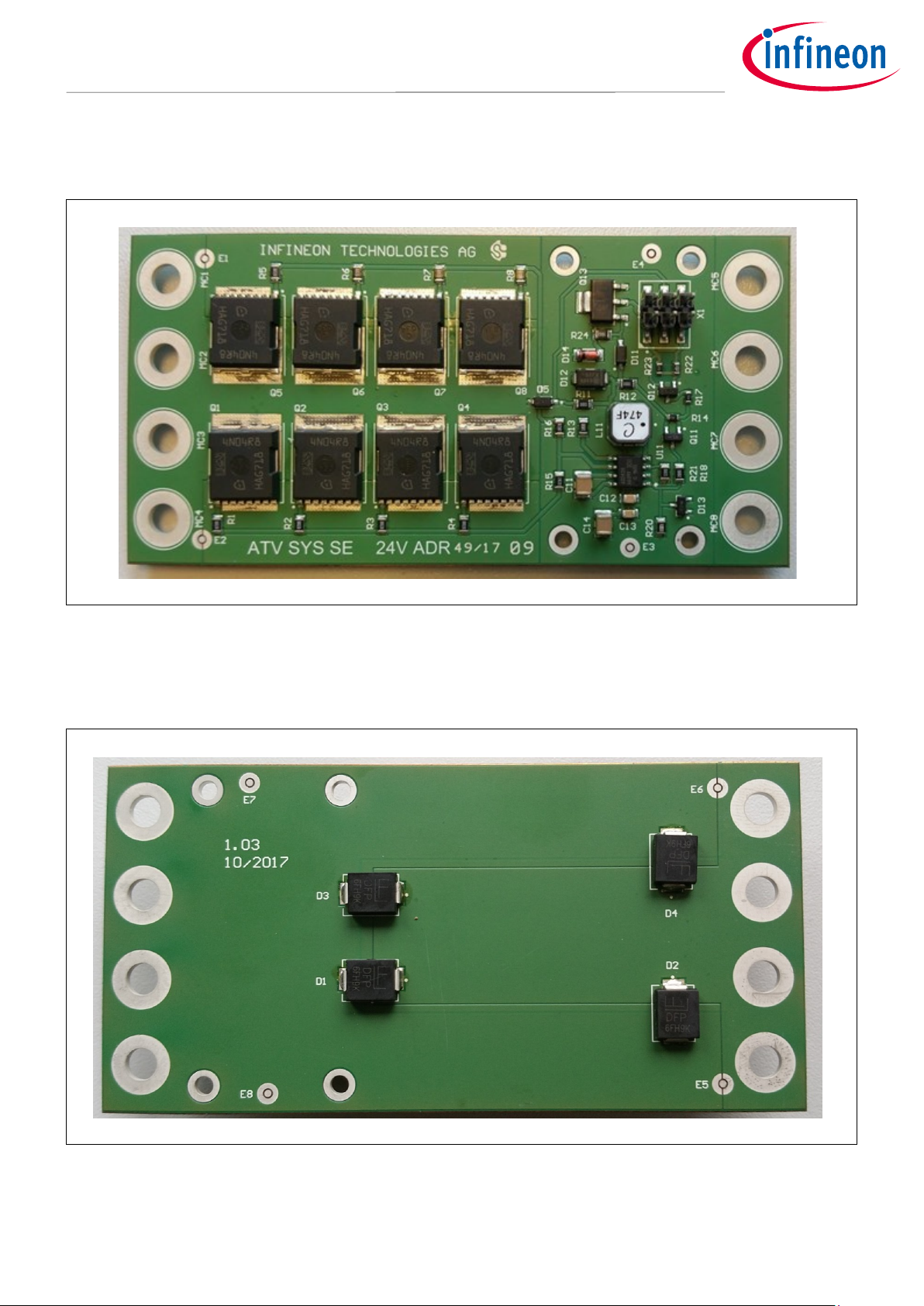

Figure 4 Basic Connection Diagram

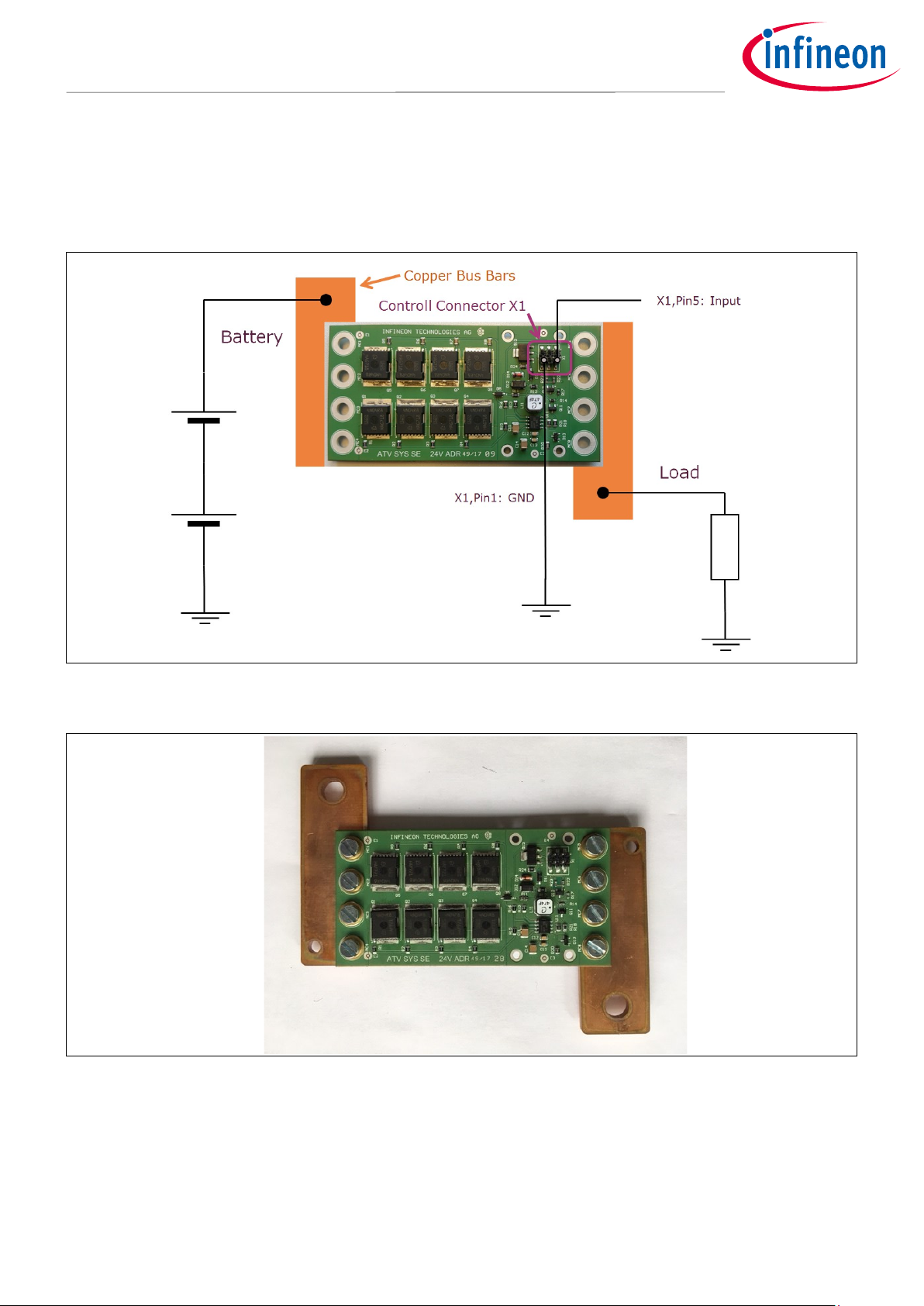

Figure 5 Connecting the Bus Bars with M4 Screws

The switch shall be connected between battery and load as pictured in Figure 4. It is recommended to use

copper bus bars to provide a low ohmic current path. To ensure proper contact to the PCB please use copper

washers between the PCB and the bus bar (Figure 6).

Mechanical dimensions of the board and the mounting holes can be found in chapter 6 Mechanical Dimensions

Page 7

User Guide 7 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Connecting the Switch

Figure 6 Copper washers between PCB and bus bar

2.2 Control

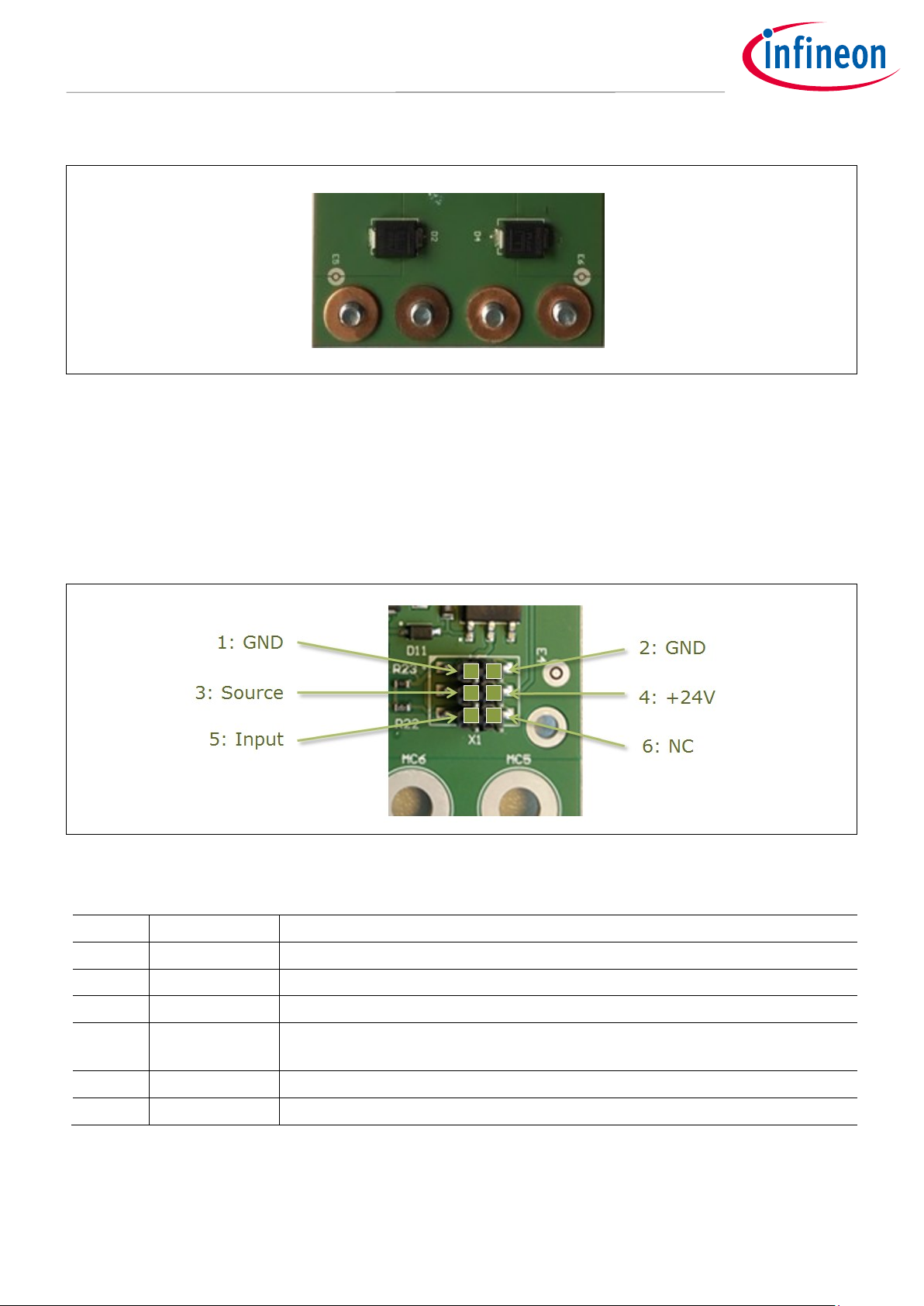

2.2.1 Pin Assignment

The switch can be controlled by a logic level signal on pin 5 (Input) of the header connector X1.

This connector is a standard 6-pin dual row 2.54 mm header (Samtec TSM-103-01-T-DV).

Figure 7 Controll Connector X1 Pin Assignment

Table 2 X1 Pin Description

Pin

Name

Function

1

GND

Ground

2

GND

Ground

3

Source

Voltage at the output of the switch

4

+24 V

Voltage at the battery terminal of the switch, protected via diode against

reverse polarity. Can be used to power own circuitry3

5

Input

Control signal for switch

6

NC

Not connected

Page 8

User Guide 8 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Connecting the Switch

2.2.2 Input Voltage Range

The input will accept a very wide input voltage range. Therefore it is possible to drive the switch with 5 V logic

as well as directly from the 24 V battery. The switching threshold is at approximately 0.8 V.

With increasing input voltage the input current will increase. It is mainly determined by the base resistor of the

npn transistor at the input stage (see Figure 8).

Please note that the input should be properly biased by an external pull-down resistor. If the input is left

floating it may react on disturbances like EMC or simply on touching it.

Figure 8 Input Stage

Depending on the driver IC used the switching logic differs. The AUIR3241S is a “normally off” driver, i.e. the

switch is open when the input signal is low and closed when the input signal is high.

For the AUIR3242S the input logic is reversed. That means the switch will be conducting as long as the input

signal is low and be opened when a high signal is applied. The advantage of the “normally on” driver

AUIR3242S is the low quiescent current in “on” condition.

Logic Table

Input Signal

Switch Status for AUIR3242

(default)

Switch Status for AUIR3241

Low

Closed

Open

High

Open

Closed

Page 9

User Guide 9 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Connecting the Switch

2.2.3 Control with bistable relay adaptor

In order to emulate the behavior of a latching (bistable) power relay the switch can be controlled using an

adptor board with a small bistable relay to drive the input. The adapter board is placed onto the connector X1

as shown in Figure 9.

Figure 9 Mounting of bi-stable relay adaptor board

Figure 10 Schematics of adaptor board

Page 10

User Guide 10 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Operating Range

3 Operating Range

3.1 Voltage Range

Figure 11 shows the different operating ranges of the switch. The nominal operating voltage range is from 16 V

to 36V.

Figure 11 Operating Voltage Range

3.2 Current Rating

The switch is designed to handle peak currents up to 1800 A. However, due to the on-state resistance of the

switch (160 uΩ typ. at 120°C) high currents will lead to significant power dissipation and a temperature increase

in the MOSFETs. These can handle a maximum junction temperature of 175 °C. Therefore the maximum

allowable duration for high currents is limited depending on the cooling conditions. The values in Table 3 are

estimated for the board exposed to a small air flow of approximately 50 cm / min. and a start temperature of 25

°C.

Table 3 Current Carrying Capability Estimation

Current

Power Dissipation

Duration

300 A

~ 15 W

Continuous

500 A

~ 40 W

~ 10 min.

700 A

~ 80 W

~ 5 min.

1500 A

~ 360 W

~ 15 s

1800 A

~ 520 W

~ 10 s

Page 11

User Guide 11 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Thermal Behavior

4 Thermal Behavior

Figure 12 Temperature increase at high currents

Even if the on state resistance of the MOSFETs is very small, high currents will lead to power dissipation and

therefore to a temperature increase. The maximum permissible junction temperature of the MOSFETs is 175 °C.

Depending on the cooling conditions there is a limit on how long the switch can withstand the current. Figure

12 shows the temperature curve for a current of 500 A at room temperature and very light airflow around the

board.

Page 12

User Guide 12 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Switching Behaviour

5 Switching Behaviour

In contrast to relays MOSFETs are switching much faster and cleaner. There is no bouncing of contacts and no

arcing. Switching just takes microseconds instead of several milliseconds. The following oscilloscope pictures

show the switching behavior of the Battery Switch 24V - System Demonstrator with the “normally on”

AUIR3242S driver. Please note that the magenta curve shows the drain source voltage across the MOSFETs, so a

small voltage means the switch is on (conducting) and a high voltage means the switch is off (blocking). The

delay between the input signal and the output is caused by the input circuitry.

Figure 13 Switch Timing – On and Off

In the oscilloscope plots it can be seen that after switching off V_DS reaches 40 V. The reason for this is the load

inductance. When the current flow is interrupted it induces a voltage that pulls the output below ground

potential. As a result V_DS rises. When V_DS reaches the threshold of the transient voltage suppressor (TVS)

diodes these start to conduct and to dissipate a part of the energy stored in the inductance. Another part of the

energy will be taken over by the MOSFETs due to the avalanche effect, which sets in at a V_DS of about 40 V.

Note: The amount of switching energy that can be dissipated by the TVS diodes and the MOSFETs is

limited. In our lab the Battery Switch 24V - System Demonstrator has been tested successfully with

cable inductances of up to 12 µH and currents up to 1600 A. The switch survived energies up to 20

Joule. However, this can just be seen as an indicator but not as a guarantee of which performance

to expect. Since the load inductance is dependent on the specific system setup like cable length, diameter, -routing etc. the suitability of the switch has to be verified for each setup separately.

Page 13

User Guide 13 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Mechanical Dimensions

6 Mechanical Dimensions

Figure 14 Board Dimensions [mm]

Figure 15 Side View

Page 14

User Guide 14 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Schematics

7 Schematics

Figure 16 Top Level Schematics

Page 15

User Guide 15 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Schematics

Figure 17 MOSFET Driver Circuit

Page 16

User Guide 16 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Schematics

Figure 18 Power Stage

Page 17

User Guide 17 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

PCB Description

8 PCB Description

8.1 PCB Technology

The Printed Circuit Board used for the shown Battery Switch 24V - System Demonstrator is a product idea of

Schweizer Electronic AG. The deployment of the Inlay Board 2.0 technology assures highest current carrying

capability in conjunction with lowest thermal resistance. A superior thermal connection between the MOSFETs

and the integrated power rail of the PCB allows to conduct a permanent current of up to 500 A and a shortcircuit current of up to 1800 A.

Table 4 Feature Set of Metal Core Board (Non-Isolated Version)

Feature

Value

Size

100.0 mm x 50.0 mm

Thickness

1,3 mm

Electrical resistance

60 µΩ

Thermal resistance (non-isolated version)

0.1 K/W

Thermal resistance (isolated version)

~ 0.2 K/W

No. of copper-filled laser vias per MOSFET

300

Figure 19 PCB Stackup

The core of the PCB is a copper plate of 1.0 mm thickness which represents the power rail for the switch. This

copper plate is structured by an isolation gap of 500 µm width. By means of a lamination process the isolation

gap is filled with the resin from Prepreg material. This represents a safe isolation space between battery and

load potential. The outer layers are consisting of 35 µm copper foils, after plating 70 µm. To ensure both a lowohmic electrical connection from the MOSFETs to the current rail and a good heat flow to a potentially used

heatsink, the PCB is provided with hundreds of copper-filled microvias in the soldering area of the MOSFET and

on the back-side of the PCB. The high filling factor with dimple depths lower than 25µm allows the designer to

have the MOSFETs soldered on top of the via field without facing the risk of solder voids. During assembly it has

to be made sure that solder profiles will be used which are appropriate for power PCBs with a large thermal

mass. The MOSFETs are placed on the PCB so that the MOSFETs, once they are turned on, connect the two

isolated parts of the PCB.

Figure 20 Cross Section

Page 18

User Guide 18 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

PCB Description

For higher logic content requirements compared to the presented switch demonstrator the Inlay Board 2.0

technology can optionally accommodate an area with four or more electrical layers next to the power rails.

8.2 PCB Layout

Figure 21 Top Layer

Figure 22 Middle Layer (1mm Cu)

Figure 23 Bottom Layer

Page 19

User Guide 19 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Bill Of Materials

9 Bill Of Materials

Table 5 BOM

Designator

Value

Description

D1, D2, D3, D4

SMDJ33A

Transient Voltage Suppression Diode, Uni-directional, 33V

D11

MMSZ5256BT1G

Zener Voltage Regulator, 500mW, 30V

D12

SZ1SMA5938BT3

Zener Voltage Regulator, 36V

D13

BZX84C5V1LTG

Zener Voltage Regulator, 5.1V

D14

LL4148

Small Signal Diode, 100V

D5

1N4148W-13-F

Surface Mount Fast Switching Diode

R13

1R

1R/150V/1%

C11, C14

1u/100V

Cap-1210-1u/100V/0.1/X7R

R15, R16

2.2R

2.2R/150V/1%

R14, R23

3.3k

3.3k/75V/1%

R11

5.6R

5.6R/150V/1%

R20

6.8k

6.8k/150V/1%

R22

6.8k

6.8k/75V/1%

R1 .. R8

8.2R

8.2R/150V/1%

R24

10k

10k/150V/1%

R18

12k

12k/150V/1%

R21

12R

12R/150V/1%

R17

22k

22k/75V/1%

C12

100n

Cap-0805-100n/100V/0.1/X7R

R12

100R

100R/150V/1%

C13

220n

Cap-0805-220n/50V/0.1/X7R

L11

470uH

Shielded Power Inductor

U11

AUIR3242S

Low Quiescent Current Back to Back MOSFET Driver

Q13

FZT753

100V PNP High Performance Transistor

Q1 .. Q8

IPLU300N04S4-R8

OptiMOS T2 N-Channel Enhancement Power-Transistor, 40 V

Q11

NSV1C200L

100V, 2.0 A, Low VCEsat PNP Transistor

Q12

NSV1C201L

100V, 3.0 A, Low VCEsat NPN Transistor

X1

TSM-103-01-T-DV

SMT .025" SQ Post Header, 2.54mm, 6 pin, vertical, double row

Page 20

User Guide 20 Revision 1.3

2020-09-11

Battery Switch 24V - System Demonstrator

User Guide

Revision History

Revision History

Major changes since the last revision

Page or Reference

Description of change

Figure 19

New picture

New Filename; new naming

Page 21

Trademarks of Infineon Technologies AG

µHVIC™, µIPM™, µPFC™, AU-ConvertIR™, AURIX™, C166™, CanPAK™, CIPOS™, CIPURSE™, CoolDP™, CoolGaN™, COOLiR™, CoolMOS™, CoolSET™, CoolSiC™,

DAVE™, DI-POL™, DirectFET™, DrBlade™, EasyPIM™, EconoBRIDGE™, EconoDUAL™, EconoPACK™, EconoPIM™, EiceDRIVER™, eupec™, FCOS™, GaNpowIR™,

HEXFET™, HITFET™, HybridPACK™, iMOTION™, IRAM™, ISOFACE™, IsoPACK™, LEDrivIR™, LITIX™, MIPAQ™, ModSTACK™, my-d™, NovalithIC™, OPTIGA™,

OptiMOS™, ORIGA™, PowIRaudio™, PowIRStage™, PrimePACK™, PrimeSTACK™, PROFET™, PRO-SIL™, RASIC™, REAL3™, SmartLEWIS™, SOLID FLASH™,

SPOC™, StrongIRFET™, SupIRBuck™, TEMPFET™, TRENCHSTOP™, TriCore™, UHVIC™, XHP™, XMC™

Trademarks updated November 2015

Other Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2020-09-11

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2020 Infineon Technologies AG.

All Rights Reserved.

IMPORTANT NOTICE

The information contained in this application note is

given as a hint for the implementation of the product

only and shall in no event be regarded as a

description or warranty of a certain functionality,

condition or quality of the product. Before

implementation of the product, the recipient of this

application note must verify any function and other

technical information given herein in the real

application. Infineon Technologies hereby disclaims

any and all warranties and liabilities of any kind

(including without limitation warranties of noninfringement of intellectual property rights of any

third party) with respect to any and all information

given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Loading...

Loading...