Silicon Switching Diode

• For high-speed switching applications

BAS16...

BAS16

BAS16W

BAS16-02L

BAS16-02V

BAS16U

BAS16-07L4BAS16S

BAS16-02W

BAS16-03W

"

!

#$

,

, , !

!

!"

,

,

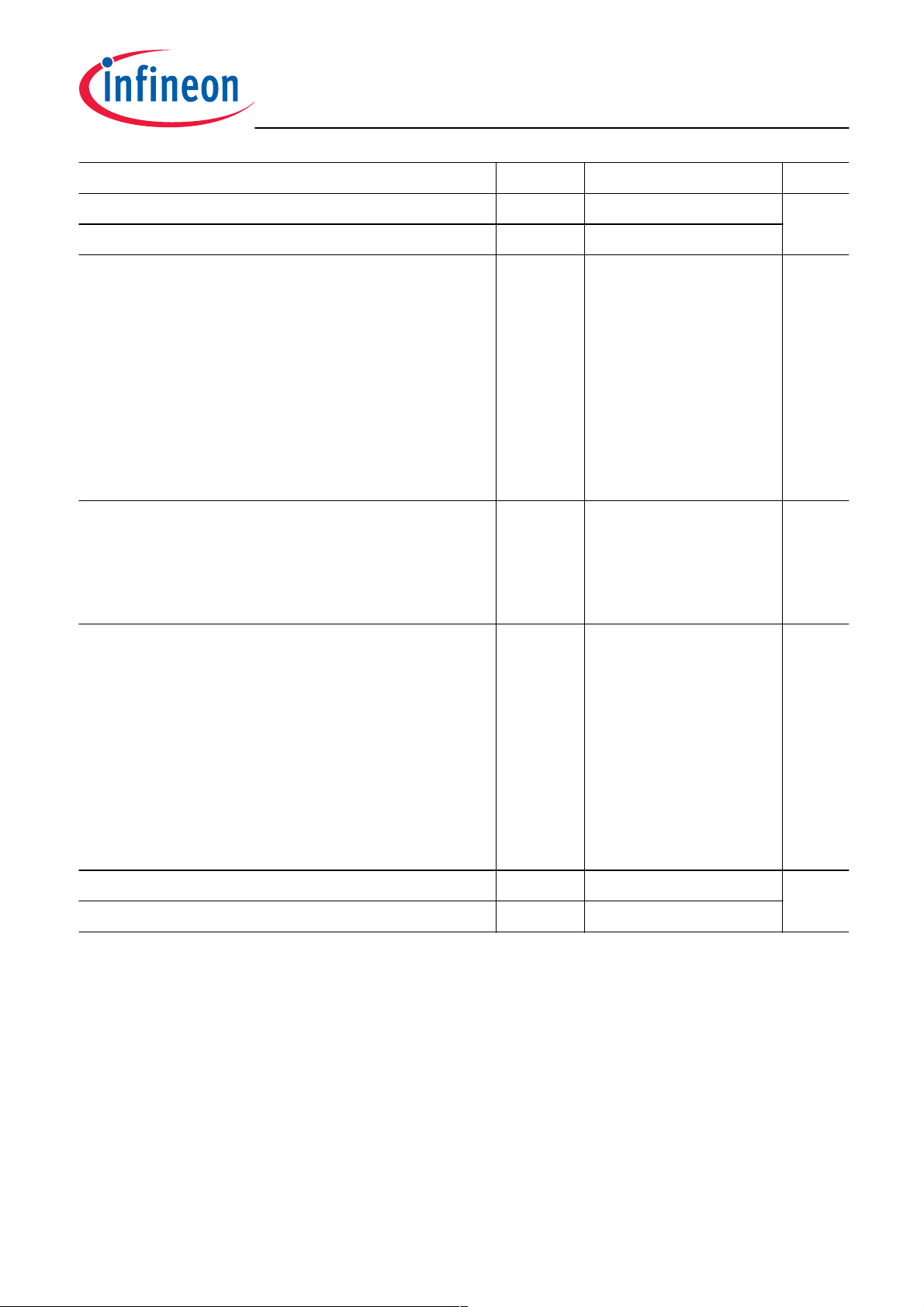

Type Package Configuration Marking

BAS16

BAS16-02L*

BAS16-02V

BAS16-02W

BAS16-03W

BAS16-07L4*

BAS16S

BAS16U

SOT23

TSLP-2-1

SC79

SCD80

SOD323

TSLP-4-4

SOT363

SC74

single

single, leadless

single

single

single

parallel pair, leadless

parallel triple

parallel triple

A6s

A6

6

A6

B

6A

A6s

A6s

BAS16W

* Preliminary Data

SOT323

single

1

A6s

2005-11-08

Maximum Ratings at TA = 25°C, unless otherwise specified

g

BAS16...

Parameter

Diode reverse voltage V

Peak reverse voltage V

Forward current

BAS16

BAS16-02L, -07L4

BAS16-02V, -02W

BAS16-03W

BAS16S

BAS16U

BAS16W

Non-repetitive peak surge forward current

t = 1 µs, BAS16/ S/ U/ W/ -03W

t = 1 µs, BAS16-02L/ -02V/ -02W/ -07L4

t = 1 s

Symbol Value Unit

R

RM

I

F

80 V

85

mA

250

200

200

250

200

200

250

I

FSM

A

4.5

2.5

0.5

Total power dissipation

BAS16, T

BAS16-02L, -07L4, T

BAS16-02V, -02W, T

BAS16-03W, T

BAS16S, T

BAS16U, T

BAS16W, T

≤ 54 °C

S

S

≤ 85 °C

S

≤ 113 °C

S

≤ 119 °C

S

≤ 130 °C

S

≤ 120 °C

S

≤ 116 °C

Junction temperature T

Storage temperature T

P

tot

j

st

370

250

250

250

250

250

250

150 °C

-65 ... 150

mW

2

2005-11-08

Thermal Resistance

BAS16...

Parameter

Junction - soldering point1)

Symbol Value Unit

R

thJS

BAS16, BAS16S

BAS16-02L, -07L4

BAS16-02V, -02W

BAS16-03W

BAS16U

BAS16W

Electrical Characteristics at TA = 25°C, unless otherwise specified

Parameter

Symbol Values Unit

min. typ. max.

DC Characteristics

Breakdown voltage

I

= 100 µA

(BR)

Reverse current

V

= 75 V

R

V

= 25 V, TA = 150 °C

R

V

= 75 V, TA = 150 °C

R

V

I

R

(BR)

85 - - V

-

-

-

≤ 260

≤ 80

≤ 120

≤ 135

≤ 150

≤ 125

-

-

-

0.1

30

50

K/W

µA

Forward voltage

I

= 1 mA

F

I

= 10 mA

F

I

= 50 mA

F

I

= 100 mA

F

I

= 150 mA

F

Forward recovery voltage

I

= 10 mA, tP = 20 ns

F

1

For calculation of R

please refer to Application Note Thermal Resistance

thJA

V

V

F

-

-

-

-

-

fr

- - 1.75 V

-

-

-

-

-

715

855

1000

1200

1250

mV

3

2005-11-08

Electrical Characteristics at TA = 25°C, unless otherwise specified

Parameter

Symbol Values Unit

min. typ. max.

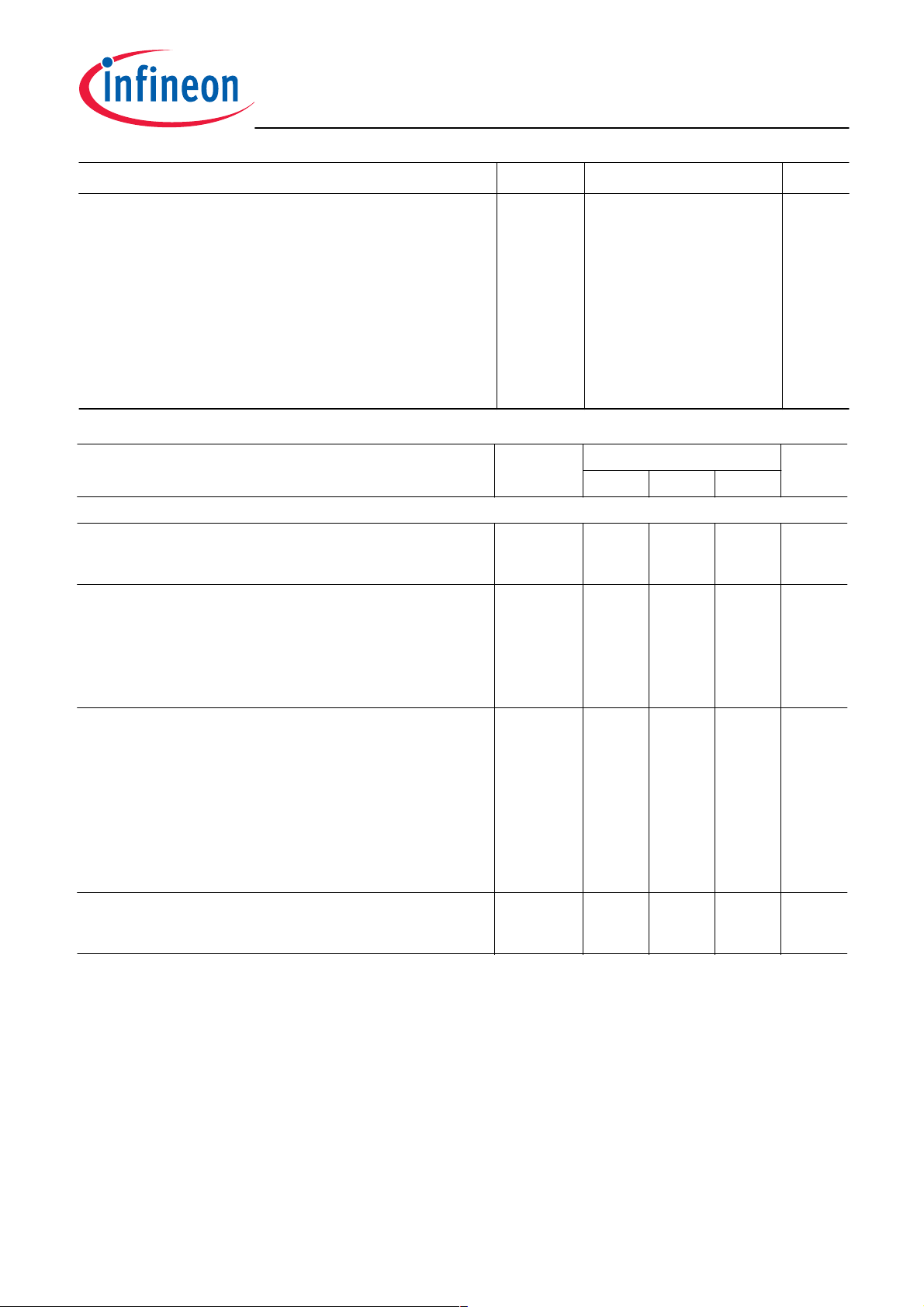

AC Characteristics

BAS16...

Diode capacitance

V

= 0 V, f = 1 MHz

R

Reverse recovery time

I

= 10 mA, IR = 10 mA, measured at IR = 1mA ,

F

R

= 100 Ω

L

C

t

T

rr

Test circuit for reverse recovery time

D.U.T.

Pulse generator: tp = 100ns, D = 0.05, tr = 0.6ns,

R

Ι

F

Oscillograph

Oscillograph: R = 50Ω, t

EHN00017

- - 2 pF

- - 4 ns

= 50Ω

i

= 0.35ns, C = 0.05pF

r

4

2005-11-08

BAS16...

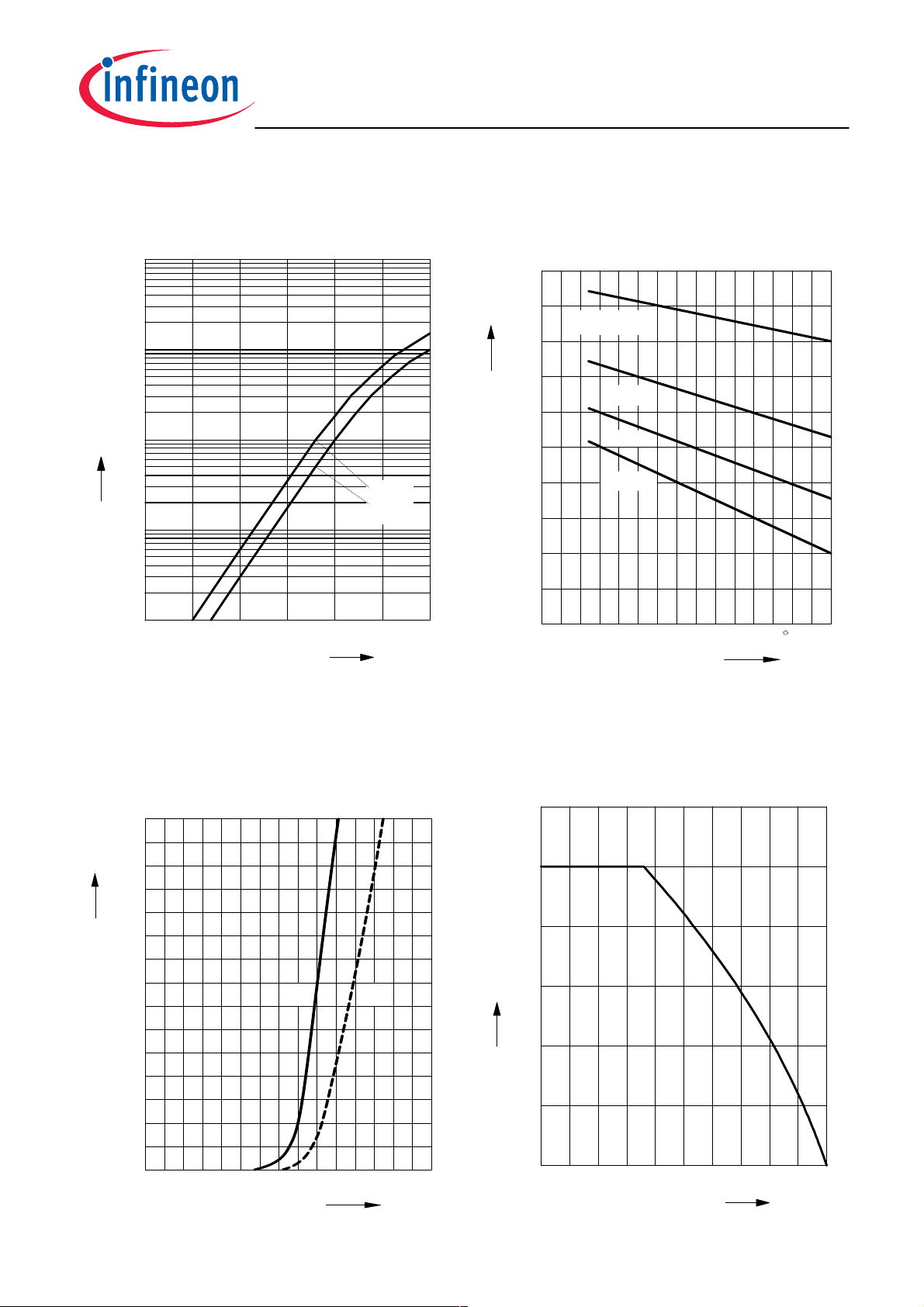

Reverse current IR = ƒ (TA)

V

= Parameter

R

5

10

nA

4

10

R

I

3

10

2

10

1

10

0 25 50 75 100

70 V

25 V

°C

Forward Voltage VF = ƒ (TA)

I

= Parameter

F

BAS 16 EHB00025

1.0

V

V

F

0.5

150

T

A

Ι

= 100 mA

F

10 mA

1 mA

0.1 mA

0

0 50 100 150

C

T

A

Forward current IF = ƒ (VF)

T

= 25°C

A

150

Ι

F

mA

100

50

0

0

0.5 1.0 V 1.5

Forward current IF = ƒ (TS)

BAS16

EHB00023BAS 16

maxtyp

V

F

300

mA

200

F

I

150

100

50

0

0 15 30 45 60 75 90 105 120

°C

150

T

S

5

2005-11-08

BAS16...

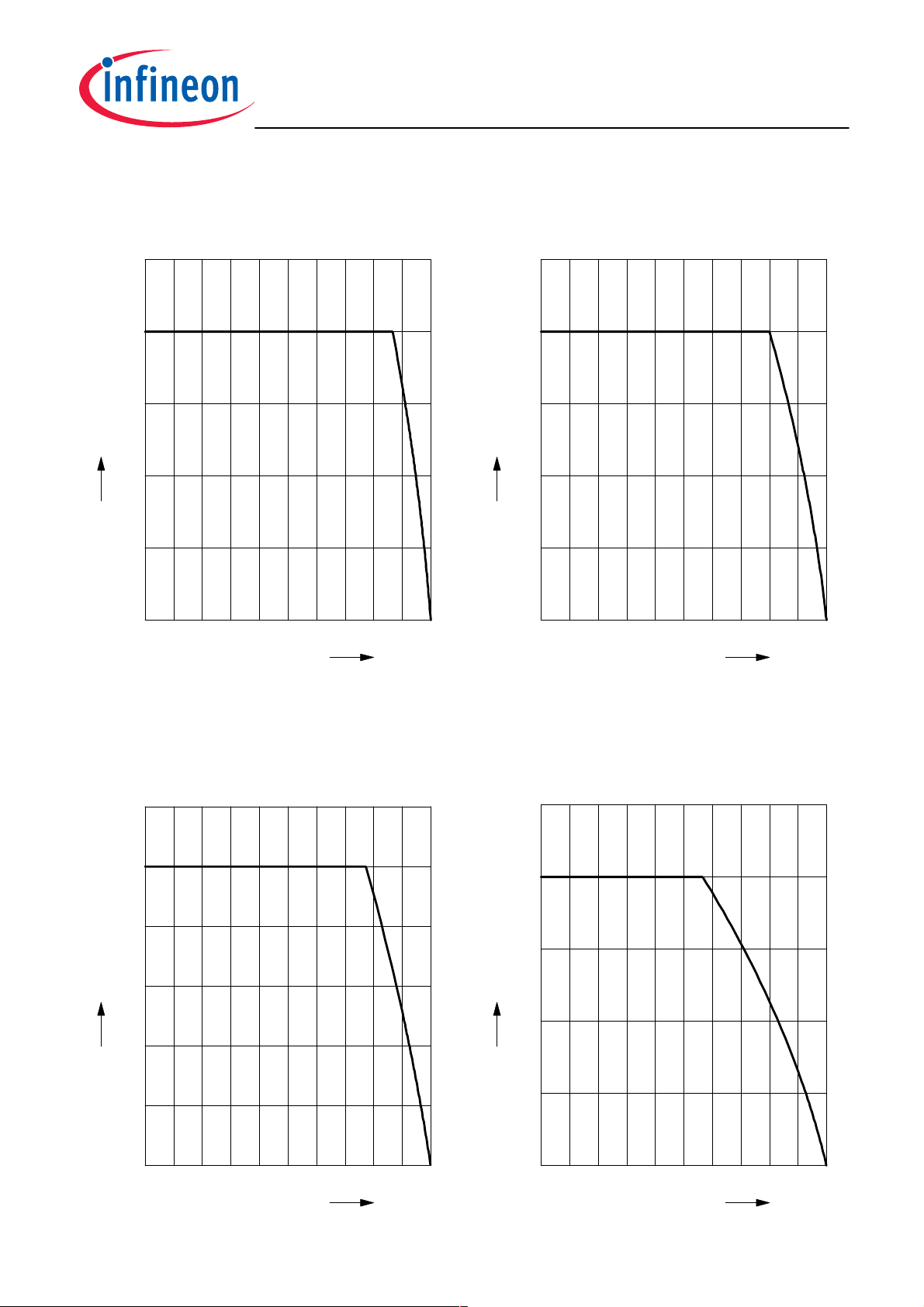

Forward current IF = ƒ (TS)

BAS16-02L, -07L4

250

mA

F

I

150

100

50

0

0 15 30 45 60 75 90 105 120

°C

Forward current IF = ƒ (TS)

BAS16-02V, -02W

250

mA

F

I

150

100

50

150

T

S

0

0 15 30 45 60 75 90 105 120

°C

150

T

S

Forward current IF = ƒ (TS)

BAS16-03W

300

mA

200

F

I

150

100

50

0

0 15 30 45 60 75 90 105 120

°C

Forward current IF = ƒ (TS)

BAS16S

250

mA

F

I

150

100

50

150

T

S

0

0 15 30 45 60 75 90 105 120

°C

T

150

S

6

2005-11-08

BAS16...

Forward current IF = ƒ (TS)

BAS16U

250

mA

200

175

F

I

150

125

100

75

50

25

0

0 15 30 45 60 75 90 105 120

T

°C

Forward current IF = ƒ (TS)

BAS16W

300

mA

200

F

I

150

100

50

150

0

0 15 30 45 60 75 90 105 120

S

°C

150

T

S

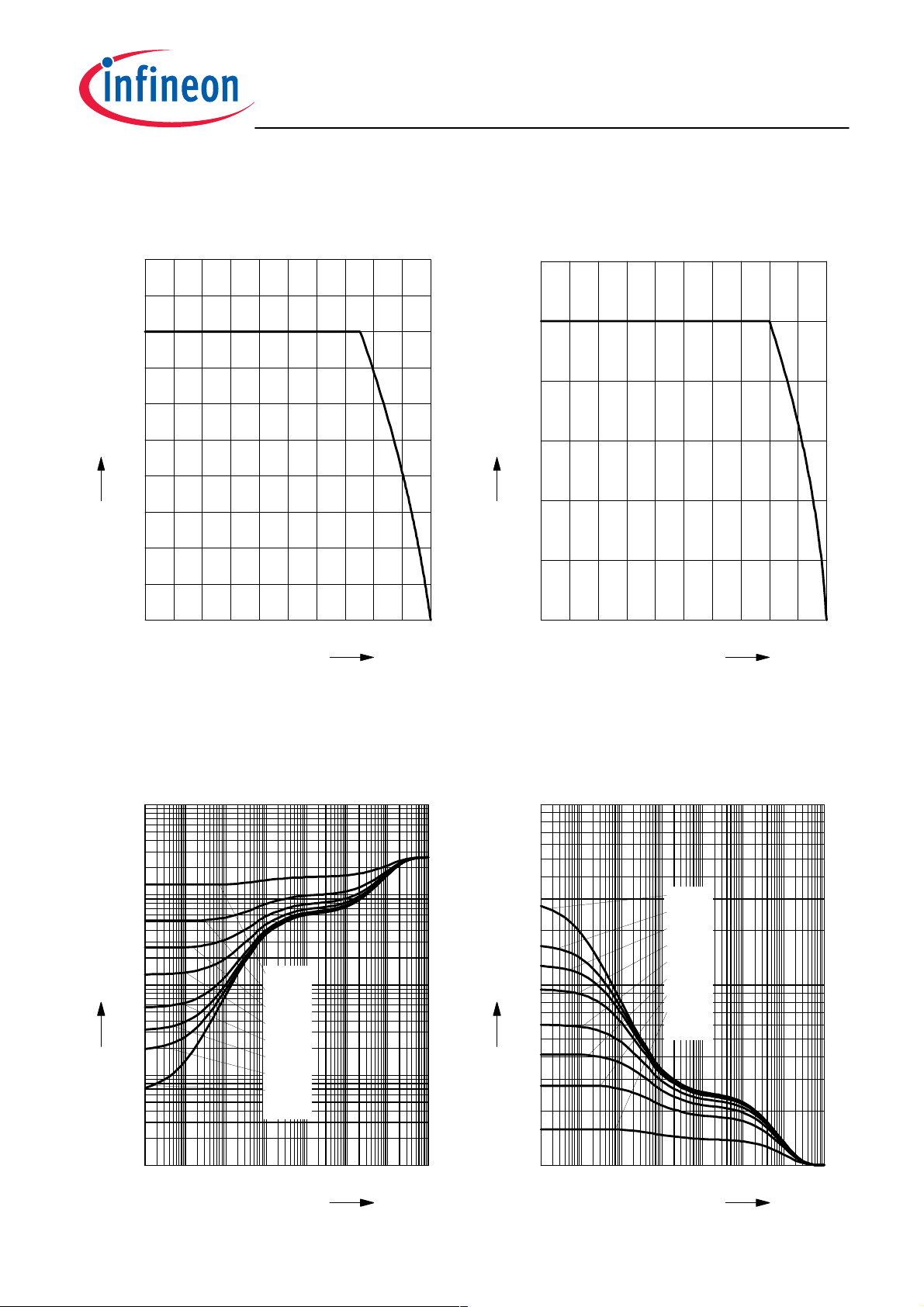

Permissible Puls Load R

BAS16

3

10

K/W

2

10

thJS

R

10

10

10

-1

1

0

10

-7

-6

10

10

0.5

0.2

0.1

0.05

0.02

0.01

0.005

D = 0

-5

-4

10

thJS

10

= ƒ (tp)

-3

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16

2

10

FDC

/I

Fmax

I

1

10

0

-2

s

t

0

10

p

10

10

-7

-6

10

10

D = 0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

-5

-4

-3

10

10

10

-2

t

0

s

10

p

7

2005-11-08

BAS16...

Permissible Puls Load R

BAS16-02L, -07L4

2

10

K/W

thJS

R

10

0.5

0.2

0.1

0.05

0.02

0.01

0.005

D = 0

-4

-3

10

10

10

1

0

10

-6

-5

10

thJS

10

= ƒ (tp)

-2

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16-02L, -07L4

2

10

-

FDC

/ I

10

D = 0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

-4

10

-3

10

-2

s

t

0

10

p

Fmax

I

1

10

0

-1

1

s

10

t

p

10

10

-6

10

-5

Permissible Puls Load R

BAS16-02V, -02W

3

10

K / W

2

10

thJS

R

1

10

0

10

-6

10

10

-5

10

-4

10

thJS

-3

= ƒ (tp)

D=0.5

0.2

0.1

0.05

0.02

0.01

0.005

0

-2

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16-02V, -02W

2

10

10

-4

D=0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

10

-3

10

-2

s

t

0

10

p

FDC

/ I

Fmax

I

1

10

0

10

s

t

0

10

p

10

-6

10

-5

8

2005-11-08

BAS16...

Permissible Puls Load R

BAS16-03W

3

10

K/W

2

10

thJS

R

1

10

0

10

-6

10

10

-5

10

-4

10

thJS

D=0.5

0.2

0.1

0.05

0.02

0.01

0.005

0

-3

= ƒ (tp)

-2

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16-03W

2

10

10

D=0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

-3

10

-2

s

t

0

10

p

FDC

/ I

Fmax

I

1

10

0

s

t

0

10

p

10

10

-6

10

-5

-4

10

Permissible Puls Load R

BAS16S

3

10

K/W

2

10

thJS

R

1

10

0

10

-6

10

10

-5

10

-4

10

thJS

D=0.5

0.2

0.1

0.05

0.02

0.01

0.005

0

-3

= ƒ (tp)

-2

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16S

2

10

-

FDC

/ I

Fmax

I

1

10

0

s

t

0

10

p

10

10

-6

10

-5

-4

10

10

D = 0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

-3

10

-2

s

t

0

10

p

9

2005-11-08

BAS16...

Permissible Puls Load R

BAS16U

3

10

K/W

2

10

thJS

R

1

10

0

10

-6

10

10

-5

10

-4

10

thJS

D=0.5

0.2

0.1

0.05

0.02

0.01

0.005

0

-3

= ƒ (tp)

-2

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16U

2

10

FDC

/ I

Fmax

I

1

10

0

s

t

0

10

p

10

10

-6

10

-5

10

D=0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

-4

10

-3

10

-2

s

t

0

10

p

Permissible Puls Load R

BAS16W

3

10

K/W

2

10

thJS

R

1

10

0

10

-6

10

10

-5

10

-4

10

thJS

0.5

0.2

0.1

0.05

0.02

0.01

0.005

D = 0

-3

= ƒ (tp)

-2

10

Permissible Pulse Load

I

Fmax

/ I

FDC

= ƒ (tp)

BAS16W

2

10

-

FDC

/ I

Fmax

I

1

10

0

s

t

0

10

p

10

10

-6

10

-5

-4

10

10

D = 0

0.005

0.01

0.02

0.05

0.1

0.2

0.5

-3

10

-2

s

t

0

10

p

10

2005-11-08

Package Outline

Foot Print

Pin 1

marking

±0.2

2.9

(2.25)

1.9

Package SC74

B

(0.35)

546

321

+0.1

0.35

-0.05

0.95

0.2

M

0.5

BAS16...

1.1 MAX.

+0.1

0.15

-0.06

±0.1

±0.1

2.5

0.25

6x

B

10˚ MAX.

0.1 MAX.

M

A0.2

±0.1

1.6

10˚ MAX.

A

Marking Layout

Laser

marking

Standard Packing

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

1.9

0.95

Manufacturer

Date code (Year/Month)

Type code

2.9

Pin 1

marking

2005, June

BCW66H

Example

Pin 1

marking

4

3.15

2.7

11

0.2

8

1.15

2005-11-08

Package Outline

Foot Print

Package SC79

±0.1

0.8

2

Cathode

marking

1

0.3

±0.05

±0.1

1.6

0.55

MAX.

˚

10

±0.04

M

A0.2

0.13

+0.05

-0.03

A

MAX.

˚

10

±0.1

1.2

±0.05

0.2

BAS16...

Marking Layout

Standard Packing

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

1.35

Date code

Type code

Laser marking

0.35

0.35

2003, July

BAR63-02V

Cathode marking

Example

Cathode

marking

4

1.96

1.33

8

0.4

0.93

12

0.2

0.66

2005-11-08

Package Outline

Foot Print

Cathode

marking

Package SCD80

0.2MA

±0.1

0.8

2

MAX.

˚

±0.1

10

1.7

1

±0.05

0.3

0.7

0.13

±0.1

+0.05

-0.03

˚

±1.5

˚

7

BAS16...

A

±0.1

1.3

±0.05

0.2

Marking Layout

Standard Packing

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

1.45

Date code

Type code

Laser marking

0.35

0.35

2003, July

BAR63-02W

Cathode marking

Example

Cathode

marking

4

1.45

8

2.5

0.4

0.9

13

0.2

0.7

2005-11-08

BAS16...

Data Code marking for discrete packages with

one digit (SCD80, SC79) CES-Code

Month 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014

01apAPapAPapAP

02bqBQbqBQbqBQ

03crCRcrCRcrCR

04 d s D S d s D S d s D S

05etETetETetET

06fuFUfuFUfuFU

07gvGVgvGVgvGV

08hxHXhxHXhxHX

09j yJYj yJYj y JY

10kzKZkzKZkzKZ

11l 2L4 l 2L4 l 2L4

12n3N5n3N5n3N5

62

14

2005-11-08

Package Outline

Foot Print

Package SOD323

+0.2

1.25

-0.1

2

1

0.3

+0.1

-0.05

M

A

Cathode

marking

±0.2

2.5

0.25

0

±0.05

±0.15

0.45

0.9

+0.2

-0.1

0.15

+0.2

0.3

+0.1

-0.06

A

-0.1

1.7

+0.05

-0.2

BAS16...

Marking Layout

Standard Packing

Type code

Laser marking

0.80.8

1.7

0.6

BAR63-03W

Cathode marking

Example

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

Cathode

marking

4

8

2

2.9

0.65

0.2

1

1.35

15

2005-11-08

Package Outline

Foot Print

Package SOT23

±0.1

2.9

12

1)

+0.1

0.4

-0.05

1.9

0.25MBC

1) Lead width can be 0.6 max. in dambar area

B

3

C

0.95

0.8

0.15 MIN.

±0.15

2.4

0.2

±0.1

1

0.1 MAX.

10˚ MAX.

0.08...0.15

0...8˚

M

A

±0.1

1.3

10˚ MAX.

A

BAS16...

Marking Layout

12

Pin 1

s

Standard Packing

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

0.8 1.2

Manufacturer

Date code (Year/Month)

Type code

4

0.9

0.9 0.91.3

EH

Example

0.2

s

2003, July

37

BCW66

Pin 1

3.15

2.13

16

2.65

8

1.15

2005-11-08

Package Outline

Package SOT323

±0.2

2

0.3

+0.1

-0.05

3x

M

0.1

3

0.1 MAX.

0.1

0.9

BAS16...

±0.1

A

Foot Print

Marking Layout

12

0.650.65

0.6

1.6

0.8

0.65

0.65

±0.1

2.1

0.1 MIN.

M

0.2 A

0.15

+0.1

-0.05

±0.1

1.25

Pin 1

Standard Packing

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

Pin 1

Manufacturer

Date code (Year/Month)

Type code

4

2.15

2005, June

BCR108W

Example

0.2

8

2.3

1.1

17

2005-11-08

Package Outline

Package SOT363

±0.2

2

0.2

+0.1

-0.05

5 4

6x

M

0.1

0.1 MAX.

0.1

0.9

BAS16...

±0.1

A

Foot Print

Marking Layout

Pin 1

marking

1623

0.650.65

0.3

0.70.9

0.65

0.65

1.6

±0.1

2.1

0.1 MIN.

M

0.2 A

0.15

+0.1

-0.05

±0.1

1.25

Laser

marking

Standard Packing

Reel ø180 mm = 3.000 Pieces/Reel

Reel ø330 mm = 10.000 Pieces/Reel

Pin 1

marking

Manufacturer

Date code (Year/Month)

Type code

4

2.3

2.15

Pin 1

marking

8

2005, June

BCR108S

Example

0.2

1.1

18

2005-11-08

Package Outline

Package TSLP-2-1

BAS16...

Top view Bottom view

0.05 MAX.

2

1

Cathode

marking

1) Dimension applies to plated terminal

0.4

+0.1

0.5

±0.05

0.65

±0.035

±0.05

0.6

2

1

1)

Foot Print

For board assembly information please refer to Infineon website "Packages"

0.6

1

Copper Solder mask Stencil apertures

0.35

0.3

0.35

0.45

0.275

0.925

0.375

0.275

1)

±0.035

0.25

±0.05

1

Marking Layout

Standard Packing

Reel ø180 mm = 15.000 Pieces/Reel

Cathode

marking

Type code

Laser marking

0.76

BAS16-02L

Cathode marking

Example

4

1.16

8

0.5

19

2005-11-08

Package TSLP-4-4

Package Outline

Bottom viewTop view

+0.01

0.4

1)

±0.035

4x

0.05 MAX.

3

4

2

1

Pin 1 marking

1) Dimension applies to plated terminal

Foot Print

For board assembly information please refer to Infineon website "Packages"

0.8

0.25

±0.05

0.45

0.75

±0.05

0.78

2

1

0.8

±0.05

3

4

BAS16...

1)

±0.035

4x0.35

±0.05

1.2

Marking Layout

Standard Packing

1.2

0.3

0.3

0.2

Copper Solder mask

Type code

Laser marking

0.4

0.4

0.4

1.18

0.28

0.22

Stencil apertures

Example

0.38

0.42

0.38

0.28

BAR90-07L4

Pin 1 marking

Reel ø180 mm = 15.000 Pieces/Reel

Pin 1

marking

4

1.05

1.45

20

0.5

8

2005-11-08

BAS16...

Published by Infineon Technologies AG,

St.-Martin-Strasse 53,

81669 München

© Infineon Technologies AG 2005.

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be

considered as a guarantee of characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of

non-infringement, regarding circuits, descriptions and charts stated herein.

Information

For further information on technology, delivery terms and conditions and prices

please contact your nearest Infineon Technologies Office (www.Infineon.com).

Warnings

Due to technical requirements components may contain dangerous substances.

For information on the types in question please contact your nearest Infineon

Technologies Office.

Infineon Technologies Components may only be used in life-support devices or

systems with the express written approval of Infineon Technologies, if a failure of

such components can reasonably be expected to cause the failure of that life-support

device or system, or to affect the safety or effectiveness of that device or system.

Life support devices or systems are intended to be implanted in the human body, or

to support and/or maintain and sustain and/or protect human life. If they fail, it is

reasonable to assume that the health of the user or other persons may be endangered.

21

2005-11-08

Loading...

Loading...