Page 1

Design and Installation Manual for

®

Quick4

Chambers in Minnesota

Angle Inlet

Pinecreek

Pencer

Skime

Four Town

Tabor

Eldred

Averill

High Landing

Beaulieu

Richwood

Lake Itasca

Two Inlets

Pinewood

Ponemah

Clementson

Indus

Loman

Ray

Waskish

Saum

Margie

Crane Lake

Nett Lake

Zim

Alborn

Britt

Embarrass

Arnold

INTRODUCTION 2

PRODUCTS 4

SYSTEM SIZING 8

CHAMBER

CONFIGURATIONS 11

QUICK4 INSTALLATION

TRENCH SYSTEMS 15

SEEPAGE BEDS 18

AT-GRADE SYSTEMS 20

MOUND SYSTEMS 23

QUICK4 PLUS INSTALLATION

TRENCH SYSTEMS 26

PRESSURE SYSTEMS 30

Brushvale

Lawndale

35

Saint Paul

35

Holyoke

90

Leader

Malmo

Pine Center

Collis

94

90

Day

Minneapolis

35

wq-wwists4-57c

DECEMBER 2009

Page 2

INTRODUCTION

The purpose of this manual is to provide minimum specifications for design and installation of Quick4®and Quick4 Plus

chambers approved for use in Minnesota in conformance with the Minnesota Pollution Control Agency (MPCA), design

standards for individual subsurface sewage treatment systems. Each revised version of this design and installation manual

supersedes the previous version. Please contact us or visit our website for more information regarding the most recent

version of this design and installation manual.

For more detailed design and installation information, please contact Infiltrator Systems at 1-800-221-4436.

Quick4 Equalizer®24 LP Chambers

The Quick4 Equalizer 24 LP chamber was designed for shallow

placement applications and can be installed in an 18-inch-wide

or 24-inch-wide trench. The Low Profile End Cap offers a simple

overlap design for easy installation.

Quick4 Equalizer 24 Low Profile (LP)

Nominal Chamber Specifications

Size (W x L x H) 16" x 48" x 8"

Effective Length 48"

Invert Elevation 2", 6”

LOW PROFILE

END CAP

QUICK4 EQUALIZER 24

LOW PROFILE CHAMBER

Quick4 Equalizer 24 Chambers

The Quick4 Equalizer 24 chambers can be installed in an

18-inch-wide or 24-inch-wide trench. The chamber offers

advanced contouring capability with its Contour Swivel

Connection

™

. The MultiPortTMEnd Cap with its six molded-in high

and low inlets allows for maximum piping flexibility.

Quick4 Equalizer 24

Nominal Chamber Specifications

Size (W x L x H) 16" x 48" x 12"

Effective Length 48"

Invert Elevation 6"

Quick4 Equalizer 36 Chambers

The patented Quick4 Equalizer 36 chamber can be installed in a

24-inch-wide trench. The chamber offers advanced contouring

capability with its Contour Swivel Connection. The MultiPort End

Cap with its six molded-in high and low inlets allows for

maximum piping flexibility.

Quick4 Equalizer 36

Nominal Chamber Specifications

Size (W x L x H) 22" x 48" x 12"

Effective Length 48"

Invert Elevation 6"

MULTIPORT

END CAP

MULTIPORT

END CAP

QUICK4 EQUALIZER 24

CHAMBER

QUICK4 EQUALIZER 36

CHAMBER

Page 2 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 3

INTRODUCTION

Quick4 PlusTMStandard LP Chambers

The Quick4 Plus Standard Low Profile (LP) chamber can be installed in

a 36-inch-wide trench. This chamber is 4 inches shorter than other

standard model chambers allowing for shallower installation. The

Quick4 Plus All-in-One and the Quick4 Plus Endcaps are available with

this chamber, providing increased flexibility in system configurations.

Quick4 Plus Standard Low Profile (LP)

Nominal Chamber Specifications

Size (W x L x H) 34" x 48" x 8"

Effective Length 48"

Invert Elevation 0.6”, 3.3”, 7.3”, 9.0”

Quick4 Plus Standard Chambers

The Quick4 Plus Standard chamber can be installed in a 36-inch-wide

trench. This chamber offers superior strength through its center

structural column. The Quick4 Plus All-in-One and the Quick4 Plus

Endcaps are available with this chamber, providing increased flexibility

in system configurations.

QUICK4 PLUS

ENDCAP

QUICK4 PLUS STANDARD

LP CHAMBER

Quick4 Plus Standard

Nominal Chamber Specifications

Size (W x L x H) 34" x 48" x 12"

Effective Length 48"

Invert Elevation 0.6”, 3.3”, 7.3”, 9.0”

Quick4 Standard Chambers

The Quick4 Standard chamber can be installed in a 36-inch-wide

trench and offers advanced contouring capability with its Contour

Swivel Connection. The MultiPort End Cap has eight molded-in high and

low inlets allowing for maximum piping flexibility. There are a variety

of system inletting options to choose from.

Quick4 Plus Standard

Nominal Chamber Specifications

Size (W x L x H) 34" x 48" x 12"

Effective Length 48"

Invert Elevation 8 ”

Quick4 High Capacity Chambers

The Quick4 High Capacity chamber can be installed in a 36-inch-wide

trench. The MultiPort End Cap has eight molded-in high and low inlets

to allow piping to enter or exit from multiple directions.

QUICK4 ALL-IN-ONE

ENDCAP

MULTIPORT

END CAP

QUICK4 PLUS STANDARD

CHAMBER

QUICK4 STANDARD

CHAMBER

Quick4 Plus High Capacity

Nominal Chamber Specifications

Size (W x L x H) 34" x 48" x 16"

Effective Length 48"

Invert Elevation 11.5”

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 3

QUICK4 HIGH CAPACITY

CHAMBER

Page 4

PRODUCTS

(EFFECTIVE LENGTH)

48"

9" AVG.

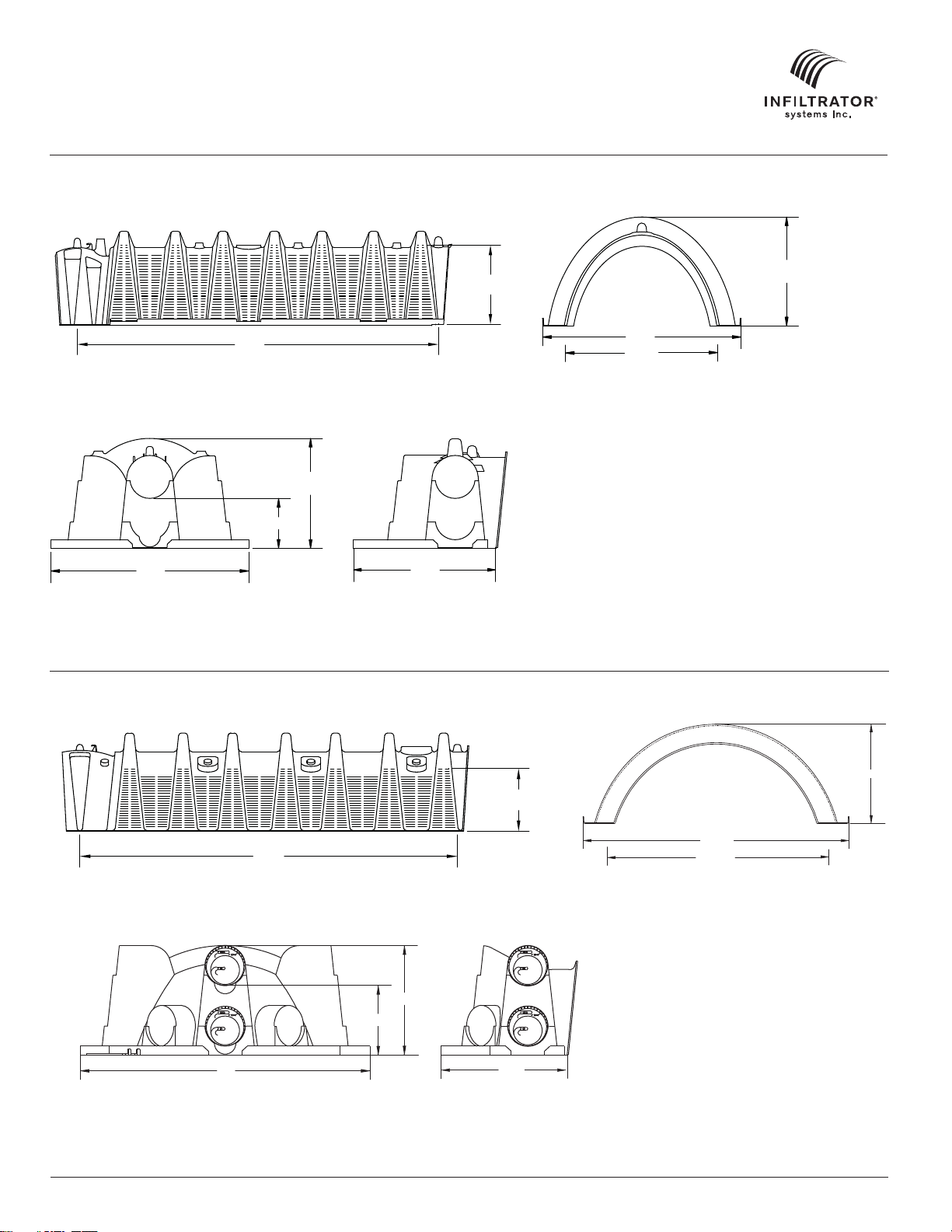

Quick4 Equalizer 24 Low Profile (LP) Chambers

SIDE AND END VIEWS

(not to scale)

48"

EFFECTIVE LENGTH

6" AVG.

LOW PROFILE END CAP

(Not to scale)

14” ID

FRONT VIEW

Quick4 Equalizer 24 Chambers

SIDE AND END VIEWS

(not to scale)

MULTIPORT END CAP

(Not to scale)

11"

0.76'

16"

FRONT VIEW

6"

OUTLET*

SIDE VIEW

11"

16"

14" ID

14"

1.12' INLET*

SIDE VIEW

* Installed lengths

Page 4 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 5

PRODUCTS

Quick4 Equalizer 36 Chambers

SIDE AND END VIEWS

(Not to scale)

(EFFECTIVE LENGTH)

48"

MULTIPORT END CAP

(Not to scale)

12"

6"

22"

FRONT VIEW SIDE VIEW

Quick4 Standard Chambers

SIDE AND END VIEWS

(Not to scale)

10" AVG.

12"

22"

19" ID

16"

12"

7" AVG.

34"

(EFFECTIVE LENGTH)

48"

MULTIPORT END CAP

(Not to scale)

12"

8"

34"

Front Side

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 5

16"

29" ID

Page 6

PRODUCTS

Quick4 Plus Standard Low Profile (LP) Chambers

SIDE AND END VIEWS

(Not to scale)

48"

EFFECTIVE LENGTH

Quick4 Plus Standard Chambers

SIDE AND END VIEWS

(Not to scale)

48"

EFFECTIVE LENGTH

Quick4 Plus All-in-One End Cap

SIDE AND END VIEWS

(Not to scale)

6" AVG.

8"

34"

30" ID

Inlet

12"

8" AVG.

34"

30" ID

Inlet

10.4"

17.8"

Front Side

Quick4 Plus End Cap

SIDE AND END VIEWS

(Not to scale)

17.8"

Front Side

Page 6 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

4.5"

Page 7

PRODUCTS

7

3

Quick4 Invert Adapter

SIDE AND END VIEWS

(Not to scale)

4"

Front

QUICK4 PLUS

ALL-IN-ONE ENDCAP

9"

Side

QUICK4 INVERT A

6.

Quick4 High Capacity Chambers

SIDE AND END VIEWS

(Not to scale)

16"

12" AVG.

34"

(EFFECTIVE LENGTH)

MULTIPORT END CAP

(Not to scale)

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 7

48"

34"

FRONT VIEW

19"

16"

11.5"

0.98'

OUTLET*

1.43' INLET*

SIDE VIEW

29" ID

Page 8

SYSTEM SIZING

Chamber Ratings

For trench applications, the following shall be the basis for establishing equivalency for nominal chamber width to stone and pipe

trench width.

• A 16-inch-wide chamber is equivalent to an 18-inch-wide stone and pipe trench

• A 22-inch-wide chamber is equivalent to an 24-inch-wide stone and pipe trench

• A 34-inch-wide chamber is equivalent to an 36-inch-wide stone and pipe trench

Note: The 34-inch-wide Quick4 High Capacity chamber is eligible for a bottom area reduction under Section 7080.2210, Subpart 3(B).

TABLE 1: TRENCH SIZING FOR CLASSIFICATION I DWELLINGS1AND EFFLUENT TREATMENT LEVEL C

QUICK4 STANDARD, QUICK4 PLUS STANDARD, AND QUICK4 PLUS STANDARD LOW PROFILE (LP) CHAMBERS

SIZING CREDIT PER CHAMBER = 12 SF OR 3 SF/LF

Soil Loading

Rate

2

(gpd/sf)

Number of

Chambers

2 3 4 5

Linear Feet

Number of

Chambers

1.20 21 84 32 128 42 168 52 208

0.78 32 128 48 192 65 260 81 324

0.60 42 168 63 252 84 336 105 420

Number of Bedrooms

Linear Feet

Number of

Chambers

Linear Feet

Number of

Chambers

Linear Feet

0.50 50 200 75 300 100 400 125 500

0.45 56 224 84 336 112 448 139 556

0.24 105 420 157 628 209 836 261 1044

Notes:

1. Sizing for Classification II and III dwellings shall use design flows in Table IV of Section 7080.1850.

2. Soil loading rates and corresponding soil texture groups are based on Table IX and IXa of Section 7080.2150.

3. Rapidly permeable soil textures require conformance with Section 7080.2260, including, but not limited to pressure distribution of effluent.

TABLE 2: TRENCH SIZING FOR CLASSIFICATION I DWELLINGS1AND EFFLUENT TREATMENT LEVEL C

QUICK4 HIGH CAPACITY CHAMBER AT A 20% BOTTOM REDUCTION

SIZING CREDIT PER CHAMBER = 15 SF OR 3.75 SF/LF

Soil Loading

Rate

3

(gpd/sf)

1.20 19

Number of

Chambers

5

2 3 4 5

Linear Feet

Number of

Chambers

76 25 100 34 136 42 168

Number of Bedrooms

Linear Feet

2

Number of

Chambers

Linear Feet

Number of

Chambers

Linear Feet

0.78 26 104 39 156 52 208 65 260

0.60 34 136 50 200 67 268 84 336

0.50 40 160 60 240 80 320 100 400

0.45 45 180 67 268 89 356 112 448

0.24 84 336 125 500 167 668 209 836

Notes:

1. Sizing for Classification II and III dwellings shall use design flows in Table IV of Section 7080.1850.

2. As allowed under Section 7080.2210, Subpart 3(B), a bottom area reduction of 20% has been included in the trench sizing calculation.

3. Soil loading rates and corresponding soil texture groups are based on Table IX and IXa of Section 7080.2150.

4. Rapidly permeable soil textures require conformance with Section 7080.2260, including, but not limited to pressure distribution of effluent.

5. Minimum trench length or number of chambers required by Infiltrator.

6. The drop between the drop box and end cap inlet invert must be equal to or greater than 0.5 inches.

7. The 20% bottom area reduction is only applicable to Infiltrator’s High Capacity chamber models used in trenches.

Page 8 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 9

SYSTEM SIZING

TABLE 3: AT-GRADE SIZING

Infiltrator Chamber Model

Quick4 Plus Standard Low Profile (LP)

Quick4 Standard

Quick4 Plus Standard

Number of Chambers Spanning At-Grade

Distribution Media Width

1 3

2 6

3 9

4 12

5 15

1 3

2 6

3 9

4 12

5 15

1 3

2 6

3 9

4 12

5 15

At-Grade Design Distribution Media Width (ft)

Notes:

1. At-grade shall be designed by bottom area only.

2. At-grade designs may be utilized when the upper 12 inches of the absorption area contains original soil with a loading rate of 0.45 gallons per day

per square foot or greater, as provided in 7080.2150, Subpart 3(E).

3. At-grade systems may only be installed on slopes less than or equal to 25 percent.

4. For slopes greater than one percent, the design absorption area excludes the area upslope from the top distribution line.

5. The maximum allowable at-grade bed width is 15 feet.

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 9

Page 10

SYSTEM SIZING

TABLE 5: MOUND SIZING

Infiltrator Chamber Model

Quick4 Plus Standard Low Profile (LP)

Quick4 Standard

Quick4 Plus Standard

Notes:

1. Mounds shall be sized by bottom area only.

2. The size of the mound shall be calculated by dividing the design flow by 1.2 gallons per day per square foot.

3. The maximum allowable width for mound distribution media beds is 9 feet.

TABLE 6: SEEPAGE BED SIZING

Infiltrator Chamber Model Number of Chambers Spanning Width Bed Design Width (ft)

Number of Chambers Spanning Mound

Distribution Media Width

1 3

2 6

3 9

1 3

2 6

3 9

1 3

2 6

3 9

Mound Design Distribution Media Width (ft)

Quick4 Plus Standard Low Profile (LP)

Quick4 Standard

Quick4 Plus Standard

Quick4 High Capacity

Notes:

1. When a seepage bed is specified with a design width less than or equal to 12 feet, gravity distribution may be utilized.

2. Seepage bed design greater than 12 feet and up to 25 feet in width require pressure distribution.

TABLE 7: ABSORPTION AREA FOR QUICK4 CHAMBER END CAPS

4 12

8 24

4 12

8 24

4 12

8 24

4 12

8 24

Infiltrator Chamber Model End Cap Model Area Credit

Quick4 Equalizer 24 Low Profile (LP) MultiPort End Cap 0.87 sf/pair

Quick4 Equalizer 24 MultiPort End Cap 2.33 sf/pair

Quick4 Equalizer 36 MultiPort End Cap 3.25 sf/pair

Quick4 Plus Standard Low Profile (LP) Quick4 Plus Endcap 0.56 sf/end cap

Quick4 Plus All-in-One Endcap installed

mid-line with chambers

Quick4 Plus All-in-One Endcap installed

at end of chamber line

1.29 sf/end cap

1.65 sf/end cap

Quick4 Standard MultiPort End Cap 4.62 sf/pair

Quick4 Plus Standard Quick4 Plus Endcap 0.56 sf/end cap

Quick4 Plus All-in-One Endcap installed

mid-line with chambers

Quick4 Plus All-in-One Endcap installed

mid-line with chambers

1.29 sf/end cap

1.65 sf/end cap

Quick4 High Capacity MultiPort End Cap 6.02 sf/pair

Notes:

1. End caps provide additional bottom absorption area.

2. End caps may be cumulatively included as part of the total design area for trench, seepage bed, mound, and at-grade system design when the

design absorption area cannot be reasonably attained with additional chambers, and approved by the local permitting authority.

Page 10 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 11

CHAMBER CONFIGURATIONS

Trench Systems

CROSS SECTION

(not to scale)

PLAN VIEW

(not to scale)

MOUND FOR PROPER

DRAINAGE

INFILTRATOR

CHAMBER

INFILTRATOR TW-SERIES TANK

AVAILABLE IN 900, 1050, 1250 & 1500 GAL.

TOPSOIL

NATIVE SOIL BACKFILL

34"

36"

TRENCH WIDTH

ESTABLISH VEGETATIVE

COVER

12" MIN

8"

QUICK4 PLUS STANDARD OR

QUICK4 PLUS STANDARD LP CHAMBER (TYP.)

PLAN VIEW

(not to scale)

PER CODE

INFILTRATOR TW-SERIES SEPTIC TANK

AVAILABLE IN 900, 1050, 1250 & 1500 GAL.

LENGTH PER DESIGN

SCHEMATIC LAYOUT ONLY, TRENCH LENGTH AND NUMBER OF

TRENCHES WILL VARY PER DESIGN

DROP BOX

QUICK4 PLUS ALL-IN-ONE ENDCAP (TYP.)

4" PVC PIPE (TYP)

CENTER-TO-CENTER

SPACING PER CODE

INFILTRATOR CHAMBER (TYP)

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 11

Page 12

CHAMBER CONFIGURATIONS

At-Grade Systems

CROSS SECTION: SLOPE < 1%

(not to scale)

6" TOPSOIL (TYP)

QUICK4 CHAMBER

ESTABLISH

VEGETATIVE

COVER

BACKHOE TEETH. SOIL CLODS LARGE ENOUGH TO

PREVENT CHAMBERS FROM LAYING LEVEL ONTO THE

GROUND. SURFACE SHOULD BE BROKEN UP. USE A

RAKE OR SHOVEL TO BREAK UP SUCH SOIL CLODS AS

TO MINIMIZE FOOT TRAFFIC ON THE ABSORPTION AREA.

NATIVE SOIL SHALL BE SCARIFIED WITH

CROSS SECTION: SLOPE > 1%

(not to scale)

4 (TYP)

1

10:1 SLOPE (TYP.)

4" VERTICAL INSPECTION PIPE

NATIVE SOIL

12" MIN. COVER

PRESSURE PIPE PER

DESIGN (TYP)

LOAMY TO SANDY FILL

PER CODE, MIN 6"

ABOVE CHAMBERS

PLAN VIEW

(not to scale)

PRESSURE PIPE

PER DESIGN

INFILTRATOR TW-SERIES SEPTIC TANK

AVAILABLE IN 900, 1050, 1250 & 1500 GAL.

INFILTRATOR TW-375

PUMP TANK

UNIFORMITY IN PRESSURE

DISTRIBUTION ESTABLISHED BY USE

OF PRESSURE VALVES OR VARYING

ORIFICE SIZE WITHIN EACH LATERAL

INFILTRATOR CHAMBER (TYP)

PER DESIGN

Notes:

1. Chamber At-grades on both level and sloping sites require pressure distribution pipes in each row of chambers.

2. The overall Contour Loading Rate for the system must be maintained.

Page 12 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 13

CHAMBER CONFIGURATIONS

Mound Systems

CROSS SECTION

(not to scale)

MOUND SHALL BE FILLED TO

THE TOP OF THE CHAMBER

INFILTRATOR QUICK4 STANDARD,

QUICK4 PLUS STANDARD or

QUICK 4 PLUS STANDARD LP

CHAMBER (typical)

1

LOUVER HEIGHT

3 (TYP.)

10:1 SLOPE (TYP.)

6" MIN. TOPSOIL

4" VERTICAL INSPECTION PIPE

6" MIN. COVER

SANDY TO LOAMY

SOIL FILL

PRESSURIZED PIPE

ESTABLISH

VEGETATIVE COVER

NATIVE SOIL ROUGHENED PER CODE

MOUND LENGTH IS 1:1 WITH A ROCK MOUND

PLAN VIEW

(not to scale)

INFILTRATOR TW-SERIES SEPTIC TANK

AVAILABLE IN 900, 1050, 1250 & 1500 GAL.

3"

SAND LAYER

DEPTH PER DESIGN

(12" MIN.)

INFILTRATOR TW-375

PUMP TANK

NATIVE SOIL

9'

TO LIMITING ZONE

PRESSURE PIPE

3"

3' MIN.

PER DESIGN

INFILTRATOR QUICK4 CHAMBERS (TYP)

PER DESIGN

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 13

Page 14

CHAMBER CONFIGURATIONS

Seepage Bed Systems (Gravity)

CROSS SECTION

(not to scale)

VERTICAL INSPECTION PIPE

QUICK4

CHAMBER (TYP)

12" MIN. COVER

PLAN VIEW

(not to scale)

INFILTRATOR TW-SERIES SEPTIC TANK

AVAILABLE IN 900, 1050, 1250 & 1500 GAL.

DROP BOX(TYP)

4" PVC PIPE (TYP)

INFILTRATOR CHAMBER (TYP)

Page 14 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 15

QUICK4 CHAMBERS INSTALLATION

Trench Systems

Before You Begin

Quick4 Chambers may only be installed according to State

and/or local regulations. If unsure of the installation

requirements for a particular site, contact the local unit of

government.

All systems require a design, which includes a thorough site

and soil evaluation of system sizing and the issuance of a

local permit to construct the system. The system installer

must schedule required regulatory inspections.

Materials and Equipment Needed

Quick4 Chambers

End Caps

PVC Pipe and Couplings

Backhoe

Laser, Transit, or Level

Shovel and Rake

Tape Measure

Utility Knife

These guidelines for construction machinery must be

followed during installation:

Avoid direct contact with chambers when using

construction equipment. Chambers require a 12-inch

minimum of compacted cover to support a wheel

load rating of 16,000 lbs/axle or equivalent to an

H-10 AASHTO load rating.

Only drive across the trenches when necessary.

Never drive down the length of the trenches.

To avoid additional soil compaction, do not drive

vehicles over the completed system.

Hole Saw*

2-inch Drywall Screws*

Screw Gun*

Small Valve-Cover Box*

4-inch Cap for

Inspection Port*

* Optional

Excavating and Preparing the Site

Note: As is the case with conventional systems, do not install

the systems in wet conditions or in overly moist soils, as this

causes machinery to smear the soil.

Note: Raking to eliminate smearing is not necessary in

sandy soils. In fine textured soils (silts and clays), avoid

walking in the trench to prevent compaction and loss of

soil structure.

5. Verify that the bottom of the system is level using a level,

transit, or laser.

Preparing the MultiPort End Cap

1. With a utility knife start

the tear-out seal at the

appropriate diameter for

the inlet pipe. The seal

allows for a tight fit for

3-inch, 4-inch SDR35,

and 4-inch Schedule 40

pipe.

2. Pull the tab on the

tear-out seal to create an

opening on the end cap.

3. Snap off the molded

splash plate located on the

bottom front of the end cap.

4. Install splash plate into

the appropriate slots below

the inlet to prevent bottom

erosion of the system.

5. Insert the inlet pipe into

the end cap at the beginning of the chamber line.

The pipe will go in several

inches before reaching a

stop. (Screws optional.)

1

Start tear-out seal.

4

Install splash plate.

1. Stake out the location of all chamber lines. Set the

elevations of the tank, pipe, and system bottom.

2. Install sedimentation and erosion control measures.

Temporary drainage swales/berms may be installed to protect

the site during rainfall events.

3. Excavate and level the trenches with proper center-to-center

sep aration. Verify that the bottom of the system is level and that

it is at least 3 feet abov e the limiting layer.

Note: Over excavate the trench width in areas where the

chamber line will contour.

4. Rake the bottom and sides if smearing has occurred while

excavating. Remove any large stones and other debris. Do not

use the bucket teeth to rake the trench bottom. Minimize or

avoid walking in the trench to prevent compaction, loss of soil

structure, and the subsequent reduction in the soil’s infiltrative

capacity.

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 15

Preparing the Low Profile End Cap

1. With a hole saw, drill an opening appropriate for the pipe

diameter being used (normally 3 to 4 inches) on the front of the

end cap.

2. Snap off the molded splash plate located on the bottom front

of the end cap.

3. Install splash plate into the appropriate slots below the inlet

to prevent trench bottom erosion.

5

Insert inlet pipe.

Page 16

QUICK4 CHAMBERS INSTALLATION

Installing the System

For installing the Quick4 Equalizer Low Profile (LP) Chamber,

see Installing the System with Q4 EQ24 LP section.

1. Check the inlet pipe to be sure it is level or has the

prescribed slope. It may be firmly supported on a solid base

of unexcavated soil (not required).

Note: If possible, avoid walking in the trench to minimize disturbance of the soil structure and loss of infiltrative capacity.

Rake any areas where foot traffic has occured in the trench.

2. Place the inlet end of the

first chamber over the back

edge of the end cap so that

the chamber overlaps the

end cap when in place.

3. Lift and place the end of

the next chamber onto the

previous chamber by holding it at a 45-degree angle.

Line up the chamber end

between the connector

hook and locking pin at

the top of the first chamber. Lower it to the ground

to connect the chambers.

Note: When the chamber

end is placed between

the connector hook and

locking pin at a 45-degree

angle, the pin will be

visible from the back

side of the chamber.

Note: The connector hook

serves as a guide to insure

proper connection and

does not add structural

integrity to the chamber joint. Broken hooks will not affect the

structure nor void the warranty.

4. Swivel the chamber on the pin to the proper direction for

the trench layout.

Note: The Quick4 Standard chamber and Quick4 High

Capacity chamber allow 10º of swivel in either direction at

each joint. The Quick4 Equalizer 36 and Quick4 Equalizer 24

allow for 15º of swivel.

Note: If installing the Quick4 High Capacity chamber with the

20% bottom area reduction allowed in the product registration, make sure to provide at least 0.5-inches of fall from the

drop box outlet to the end cap inlet to allow full use of the 12inch sidewall profile (see drawing).

2

Place first chamber onto end cap.

3

Connect the chambers.

5. Continue connecting the

chambers until the chamber

line is completed.

Note: As chambers are

installed, verify they are level.

6. The last chamber in the

trench requires an end cap.

Lift the end cap at a 45degree angle and insert the

connector hook through the

opening on the top of the

end cap. Applying firm

6

Attach end cap to chamber.

pressure, lower the end cap

to the ground to snap it into place. Do not remove the

tear-out seal.

7. To ensure structural stability, fill the sidewall area by pulling

soil from the sides of the trench with a shovel. Start at the

joints where the chambers connect. Continue backfilling the

entire sidewall area, making sure the fill covers the louvers.

8. Pack down the fill by walking along the edges of the

chambers.

9. Proceed to the next chamber line and begin with Step 1.

Installing the System with Q4 EQ24 LP

1. Place the first chamber in the trench.

2. Place the back edge of the end cap over the inlet end of

the first chamber. Be sure to line up the locking pins on the

top of both the chamber and end cap.

Optional: Fasten the end cap to the chamber with a screw at

the top of the end cap.

3. Insert the inlet pipe 2.5 inches into the opening on the front

of the end cap.

4. Lift and place the end of

the next chamber onto the

previous chamber by holding it at a 45-degree angle.

Line up the chamber end

between the connector

hook and locking pin at the

top of the first chamber.

Lower the chamber to the

ground to connect the

chambers.

Note: When the chamber end is placed between the

connector hook and locking pin at a 45-degree angle, the

pin will be visible from the back side of the chamber.

Note: The connector hook serves as a guide to ensure

proper connection and does not add structural integrity to

the chamber joint. Broken hooks will not affect the structure

or void the warranty.

5. For a trench layout, swivel the chamber on the pin to

achieve the proper direction for the chamber line.

6. Continue connecting the chambers until the trench is

completed.

4

Connect chambers.

Page 16 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 17

QUICK4 CHAMBERS INSTALLATION

Attaching the Q4 EQ24 LP End Caps

1. Lift the end cap at a

45-degree angle and align

the connector hook on the

top of the chamber with

the raised slot on the top

of the end cap. Lower the

end cap to the ground

and into place.

Note: Place a few shovels

of soil around the end cap

to secure it during backfill.

1

Attach end cap to last chamber.

Installing Inspection Ports

1. With a hole saw, drill the pre-marked area in the top of the

chamber to create a 4-inch opening.

2. Set a cut piece of pipe of the appropriate length into

the corresponding chamber’s inspection port sleeve.

Note: The sleeve will accommodate a 4-inch Schedule 40 pipe.

3. Use two screws to fasten

the pipe to the sleeve

around the inspection port.

4. Attach a threaded cap or

cleanout assembly onto the

protruding pipe at the

appropriate height.

5. A small valve cover box

may be used if inspection

port is below the desired

grade.

3

Fasten the pipe.

Covering the System

Before backfilling, the system must be inspected by the

local unit of governmentʼs SSTS Inspector as per local

ordinance requirements. Create an as-built drawing at

this time for future records.

1. Apply the backfill

material along the sides

of the chambers and walk

the soil in.

1

Walk the soil in.

2. Continue backfilling the

soil to the top of chambers.

Note: When backfilling a

wide excavation or soil

substitution system use a

dozer, small box blade or a

tracked Bobcat machine.

2

Backfill the soil.

INSPECTION PORT DETAIL (Not to scale)

SMALL VALVE COVER

BOX OR IRRIGATION

VALVE BOX AT GRADE

COMPACT SOIL BASE

TO SUPPORT BOX

USE HOLE SAW TO CUT

OUT PRE-MARKED CIRCLE.

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 17

ATTACH CAP OR THREADED

CLEANOUT ASSEMBLY.

4" PVC PIPE

CUT TO FIT

REST 4" PVC PIPE ON TOP

OF INSPECTION PORT

SEAT. SECURE IN PLACE

WITH A DRYWALL SCREW.

Page 18

QUICK4 CHAMBERS INSTALLATION

Seepage Bed Systems

Before You Begin

This document provides septic installation instructions for

Quick4 chambers in bed systems. These chambers may

only be installed according to state and local regulations. If unsure of the installation requirements, contact

the local unit of government.

All systems require a design, which includes a thorough

site and soil evaluation, system sizing, and the issuance

of a local permit to construct the system.

Materials and Equipment Needed

Quick4 Chambers

End Caps

Backhoe/Bulldozer

4-inch PVC Pipe and

Couplings

Laser, Transit, or Level

These guidelines for construction machinery must be

followed during installation:

Avoid direct contact with chambers when using

construction equipment. Chambers require a 12-inch

minimum of compacted cover to support a wheel load

rating of 16,000 lbs/axle or equivalent to an H-10

AASHTO load rating.

Only drive across the bed when necessary. Never

drive down the length of the bed system.

Prior to compaction and during backfill, only use

tracked vehicles. Always keep 6 inches of soil between

tracks and chambers.

Shovel and Rake

Tape Measure

Utility Knife

Hole Saw/Router Bit*

D-Box*

* Optional

2. Excavate and level the designated area. Be sure to excavate

at least one extra foot around perimeter to allow for proper fit

and ease installation.

3. If required, be sure to dig through any restrictive layer to

the more suitable soils. Remove any debris from the bed walls.

Prepare the chamber bed’s sub grade soil as outlined in the

designer’s plans.

4. Rake the bottom and sides if smearing has occurred while

excavating. Verify the bottom of the bed is level using a transit, laser or level. Minimize or avoid walking on the bottom of

the bed to prevent compaction, loss of soil structure and the

subsequent reduction in the soil’s infiltrative capacity.

5. If pressure distribution is required, refer to the “Pressure

Pipe Design Options” instructions provided in the Mound

Systems section.

Preparing the End Caps

1. With a utility knife start the

tear-out seal at the appropriate diameter for the inlet

pipe. The seal allows for a

tight fit for 3-inch, 4-inch

SDR35 and 4-inch SCH40

pipe. A 2-inch line can be

installed by using an

appropriately sized hole

saw to cut an opening in

the end cap.

Note: Pipe size may vary

according to state/county regulations

or designer specifications.

1

Start tear-out seal.

TYPICAL BED SYSTEM (plan view)

CHAMBER SPACING

PER CODE

34"

REAR (LOOP)

MANIFOLD (OPTIONAL)

QUICK4 CHAMBER

QUICK4 MULTIPORT

LENGTH VARIES PER DESIGN

END CAPS (TYP.)

SEPTIC

TANK

D-BOX

Excavating and Preparing the Site

Note: It is not recommended to install systems in wet conditions or in overly moist soils, as this causes machinery to

smear the soil interface which can affect system performance.

1. Stake out the location of the bed and set the elevations of

the tanks, pump chamber (if required), pre-treatment devices

(if required), piping, and bed bottom. Install sedimentation

and erosion control barriers as necessary.

2. Pull the tab on the tear-out

seal to create an opening on

the end cap.

3. Snap off the molded

splash plate located on the

bottom front of the end cap.

4. Install splash plate into

the appropriate slots below

the inlet to prevent trench

bottom erosion.

2

Pull tab on tear-out seal.

5. Construct a manifold to

inlet each row of chambers.

A d-box may be used if

required by code or

designer preference.

Note: It is sometimes easier

to install the chamber bed

before constructing the

manifold. If installing the

chambers first in a gravity

fed system, it is critical to

4

Install splash plate.

ensure there is proper fall

from the tank to accommodate a manifold.

Page 18 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 19

QUICK4 CHAMBERS INSTALLATION

6. Once piping network is complete, insert pipe into the end

cap at the beginning of each row of the bed.

7. Attach a closed end cap onto the outlet end of the chamber.

Do not create an opening on the closed or outlet end cap.

Installing the Bed System

1. Construct the chamber bed

by joining chambers. Place

the inlet end of the first chamber over the back edge of the

end cap.

2. Lift and place the end of

the next chamber on to the

previous chamber by holding it at a 90-degree angle.

Line up the chamber end

between the connector hook

and locking pin at the top of

the first chamber. Lower to

the ground to connect the

chambers.

Note: When the chamber

end is placed between the

connector hook and locking

pin at a 90-degree angle, the

pin will be visible from the

back side of the chamber.

Note: The connector hook

serves as a guide to ensure

proper connection and does

not add structural integrity to the chamber joint. Broken hooks

will not affect the structure nor void the warranty.

3. Continue connecting the chambers until the first row is

completed.

4. Check the first row of chambers to be sure that it is level.

5. Continue connecting chambers until the bed is complete.

As the chambers are installed, verify that they are level,

straight and maintain the required separation distance

between each row of chambers.

Note: After installing chambers edge to edge or with up to 6" of

spacing, it is important to properly backfill per current installation instructions so as to not compromise the integrity of the

product.

6. The last chamber in the row requires an end cap. Lift the

end cap at a 45-degree angle and insert the connector hook

through the opening on the top of the end cap. Applying firm

pressure, lower the end cap to the ground to snap it into place.

Do not remove the tear out seal if ends are not to be connected.

Repeat this step for each row in the bed.

Note: Looping the outlet end of the bed may be required or

specified by design. Infiltrator Systems recommends creating a

hole in the end cap at the specified invert height.

7. Insert the loop manifold through the end cap and

determine that the manifold is level before backfilling.

1

Place first chamber onto end cap.

2

Connect the chambers.

8. Bed systems require at least one vertical inspection pipe.

Refer to the “Installing Inspection Ports” instructions provided

in the Trench Systems section.

9. To ensure structural stability, fill the sidewall area by pulling

soil in from the sides of the bed with a shovel or by placing fill

material with a backhoe or excavator bucket.

10. Continue to carefully anchor chambers by ladling fill material between the chamber rows making sure not to dislodge the

units. Be sure the fill extends above the louvers a minimum of

two inches.

Note: Only drive over the system with a tracked v ehicle.

Note: Do not to drive over the chambers until a minimum of

12" of fill is placed above the chambers. For rows not accessible from the edge of the bed, wait until a majority of the chambers are covered with 6" of fill before stabilizing middle rows

(for tracked vehicles only).

11. Pack down the fill by walking along the sidewalls of the

chambers as this helps to give better structural support. In wet

conditions, silty or clay soils, do not walk in the sidewalls.

Covering the System

Before backfilling, the system must be inspected by the

local unit of governts SSTS inspector as per local ordinance

requirements.

1. Backfill the chamber sys-

tem by pushing or ladling

the fill material onto the units

with a backhoe or bulldozer.

Be sure to avoid having

large rocks in backfill.

Note: For large bed systems

that cannot be filled from the

sides, use a light tracked

vehicle making sure to maintain a minimum of cover of 6"

between the chambers and tracks at all times.

2. Do not drive wheeled vehicles across the system when

applying cover material.

Note: Chambers can be installed with a minimum of 6 inches of

cover using light tracked vehicles. A maximum of 4 feet of cover is

allowed for bed systems.

3. Leave several inches of soil above the required amount for

settling and to divert runoff water from the system.

4. After the system is covered, the site should be seeded or

sodded to prevent erosion.

TYPICAL STANDARD BED SYSTEM (front view)

QUICK4

CHAMBER (TYP)

Note: All Infiltrator chambers currently registered for use in

Minnesota are allowed for use in bed systems.

1

VERTICAL INSPECTION PIPE

Ladle the fill.

12" MIN. COVER

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 19

Page 20

QUICK4 CHAMBERS INSTALLATION

At-Grade Systems

Before You Begin

Quick4 chambers can only be installed according to

state or county regulations. Contact your local unit of

government for specific requirements.

Materials and Equipment Needed

Quick4 Chambers and End Caps

Pressure Lateral Pipe and Fittings

Sand and Specified Fill Material

Plastic Pipe straps, all weather, 120 lb. tensile

strength (nylon prohibited)

Utility Knife or Hole Saw

Backhoe/Bulldozer/Skid-Steer

Glue

Rake

2" Drywall Screws*

Garden Hose*

Chisel Plow*

Paving Block*

* Optional

These guidelines for construction machinery

must be followed during installation:

Avoid direct contact with chambers when using

construction equipment. Chambers require a 12inch minimum of compacted cover to support a

wheel load rating of 16,000 lbs/axle or equivalent to

an H-10 AASHTO load rating.

Only drive across sand mound when necessary.

Never drive wheeled machinery over chambers.

Avoid stones larger than 3 inches in diameter in

backfill. Remove stones this size or larger that are

in contact with chambers.

Preparing the Site

1. Review approved system design to determine the height

of the seasonal high water table or other limiting factors.

2. Stake out the site for At-grade system placement.

3. Install sedimentation and erosion control measures.

4. Cut trees flush to the ground, remove surface boulders

that can be easily rolled off, and remove vegetation per

code requirements.

5. The original At-Grade absorption area must be scarified

by backhoe teeth, moldboard, or chisel plow.

Installing Chambers and End Caps

1. To allow pressure laterals to drain after each dose, drill a

hole in the bottom of the pipe at the end of the pressure

line. Place the snap-off splash plate, gravel or a paving

block at the bottom of the trench to protect the infiltrative

surface from erosion.

2. With a hole saw, drill out

the appropriate diameter

hole in the end cap to

accommodate the

pressure lateral pipe.

3. Each chamber row shall

require a pressure distribution pipe.

4. Insert the pressure lateral

pipe into the end cap’s

drilled opening and slide it

into the manifold pipe.

Glue the pressure lateral

pipe to the manifold pipe.

5. With the pressure lateral

pipe through the end cap,

place the inlet end of the

first chamber over the

back edge of the end cap.

6. Secure the pressure lateral pipe to the top of the

first chamber with a plastic

pipe strap at the outlet end

of the unit. Slide the strap

up through a slot in the

chamber top, down

through the other slot, and

cinch the two ends around

the pipe.

7. Lift and place the next

chamber onto the previous

one at a 90-degree angle.

Line up the chamber end

between the connector

hook and locking pin at

the top of the first

chamber. Lower it to the

ground to engage the

interlocks. Make sure that

the connected chambers

are level with the absorption surface area.

8. Secure the lateral pipe

to the top of the next

chamber once in place.

Follow the same method

in Step 6.

9. Continue interlocking chambers and securing the pipe

until the row is completed.

10. Before attaching the final end cap, remove the tongue

of the connector hook on the last chamber with a pair of

pliers.

1

2

4

6

Page 20 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 21

QUICK4 CHAMBERS INSTALLATION

11. Insert the pressure

lateral pipe through the

hole in the final end cap

and slide the end cap

towards the last chamber.

Lift the end cap over the

modified connector hook

and push straight down

to secure it to the chamber.

Note: If cleanout exten-

11

sions are required, use a

hole saw to cut a hole in the end cap at the proper elevation

so that the lateral pipe can extend. For clean-out access, a

90-degree long sweep or 45-degree bend elbow that

extends to the soilʼs surface can be attached to the lateral

pipe.

12. If installing multiple rows of chambers on a slope each

row must be installed along the slope and covered with

geotextile to prevent soil intrusion into the up slope sidewall.

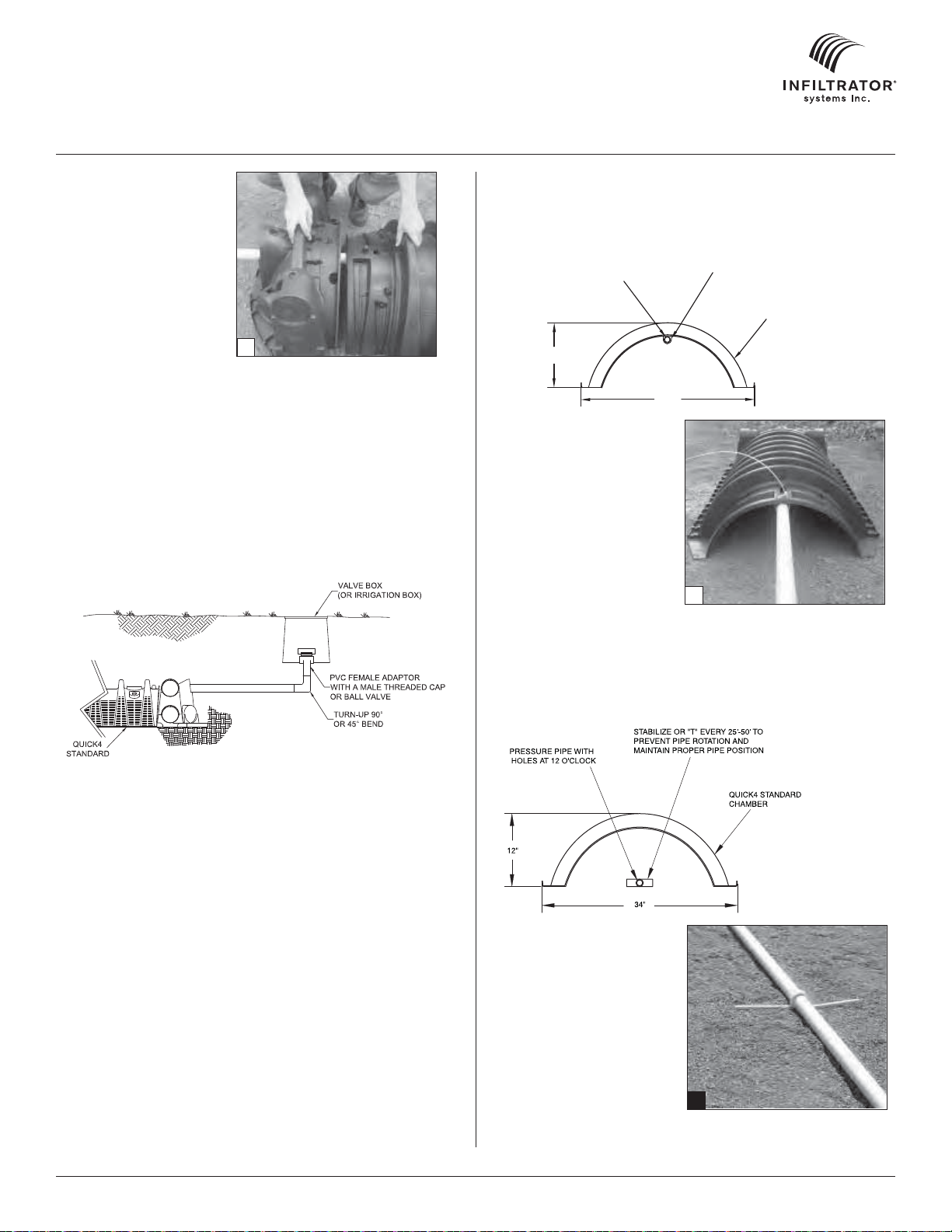

ACCESS FOR DRAINFIELD MAINTENANCE AND FLUSHING

Pressure Pipe Design Options

METHOD A: TOP PLACEMENT

ALL WEATHER PLASTIC PIPE STRAP

WITH 120 POUNDS TENSILE STRENGTH

PRESSURE PIPE WITH

HOLES AT 12 O’CLOCK

12"

Advantages of Method A

• Pipe and orifice placed

closer to the chamber

dome offer improved

distribution.

• Pipe positioned at the

top of the chamber

places it well above

effluent.

• Plastic pipe hanger

easily secures pipe

in place.

• If necessary, trim excess plastic pipe strap before connecting chambers.

AT EVERY CHAMBER CONNECTION

QUICK4 STANDARD

34"

A

METHOD B: BOTTOM PLACEMENT

Advantages of Method B

• Pipe resting on the

mound distribution media

bed allows easy installation and maintenance.

• Glue “T’s” or PVC Jhooks to keep pipe level.

• System promotes efficient

pressure checks.

• Pipe resting on the trench

bottom allows easier

B

inspection if monitoring

ports are installed.

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 21

Page 22

QUICK4 CHAMBERS INSTALLATION

Covering the System

Before backfilling, the system must be in spected by the

local unit of governmentʼs SSTS Inspector as per local

ordinance requirements. System should be installed as

per design.

1. For sites sloping greater than 1%, a geotextile fabric of

at least 3-feet in width shall be placed over the upslope

sidewall and chamber top to prevent intrusion of fill. A

getextile fabric spanning the width of the dispersal area

and covering each chamber row may be used.

2. Place a 2-foot high pile of berm material around the

perimeter of the At-Grade and directly against the outer

rows of chambers for stabilization.

3. Ladle clean sand between the chamber rows to the top

sidewall louver to prevent chamber movement before final

backfill. Firm the soil between the chamber rows by walking

it in.

4. Push the berm material between and over the

chamber rows with a tracked vehicle from the upslope side.

Keep a minimum 12-inches of densified cover over the

system.

Note: NO wheeled machinery is allowed on chambers in AtGrades. Tracked vehicles may be used.

5. After the system is covered, the site shall be seeded or

sodded per 7080.2150 Subp 3.J. to prevent erosion.

Note: If the system is for new home construction, it is important

to place marking stakes along the boundary of the

system. This will notify contractors of the site location so they will

not cross it with equipment or vehicles.

Page 22 January 2006 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 23

QUICK4 CHAMBERS INSTALLATION

Mound Systems

Before You Begin

Quick4 chambers can only be installed according to

state or county regulations. Contact your local unit of

government for specific requirements.

All systems require a design, which includes a thorough

site and soil evaluation of system sizing and the issuance of

a local permit to construct the system. The system installer

must schedule required regulatory inspections

Materials and Equipment Needed

Quick4 Chambers and End Caps

Pressure Lateral Pipe and Fittings

Sand and Specified Fill Material

Plastic Pipe straps, all weather, 120 lb. tensile

strength (nylon prohibited)

Utility Knife or Hole Saw

Backhoe/Bulldozer/Skid-Steer

Glue

Rake

2" Drywall Screws*

Garden Hose*

Chisel Plow*

Paving Block*

* Optional

These guidelines for construction machinery

must be followed during installation:

Avoid direct contact with chambers when using

construction equipment. Chambers require a 12inch minimum of compacted cover to support a

wheel load rating of 16,000 lbs/axle or equivalent to

an H-10 AASHTO load rating.

Only drive across sand mound when necessary.

Never drive wheeled machinery over chambers.

Avoid stones larger than 3 inches in diameter in

backfill. Remove stones this size or larger that are

in contact with chambers.

Preparing the Site

1. Review approved system design to determine the height

of the seasonal high water table or other limiting factors.

2. Calculate the number of sand lifts necessary. Lifts should

measure 6 to 12 inches in height.

3. Confirm that the sand used to build the mound meets

Minnesota design standards. Sand must meet requirements

of Chapter 7080.2220, subpart.3. (C).

4. Stake out the site for mound placement.

5. Install sedimentation and erosion control measures.

6. Cut trees flush to the ground, remove surface boulders

that can be easily rolled off, and remove vegetation per

code requirements.

7. The original soil mound absorption area must be roughened by backhoe teeth, moldboard, or chisel plow. The soil

must be roughened to a depth of eight inches.

Placing the Sand

1. After placement of six

inches of clean sand, use

a crawler or track-type

tractor to evenly spread a

one-foot lift of specified fill

material over required

area.

Note: Firming up the fill is

critical to prevent settling

and will not have a significant effect on permeability

of clean, sandy fill.

2. To firm up the fill, a crawler or track-type tractor can be

driven over the entire bed. After first tracks are made

across the bed, move across the bed at increments equal

to the width of the wheels/ tracks.

3. Place consecutive lifts following Steps 1 and 2 until

design elevation is achieved (desired elevation is the infiltrative surface). Lifts should not exceed a 12 inch height.

4. Lightly drag a landscape rake over the final infiltrative

surface to scarify the top

elevation to be sure it is level and has the correct depth of

clean sand in accordance with the approved system

design.

1

1

⁄2 inch of the sand. Check bed

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 23

Page 24

QUICK4 CHAMBERS INSTALLATION

Installing Chambers and End Caps

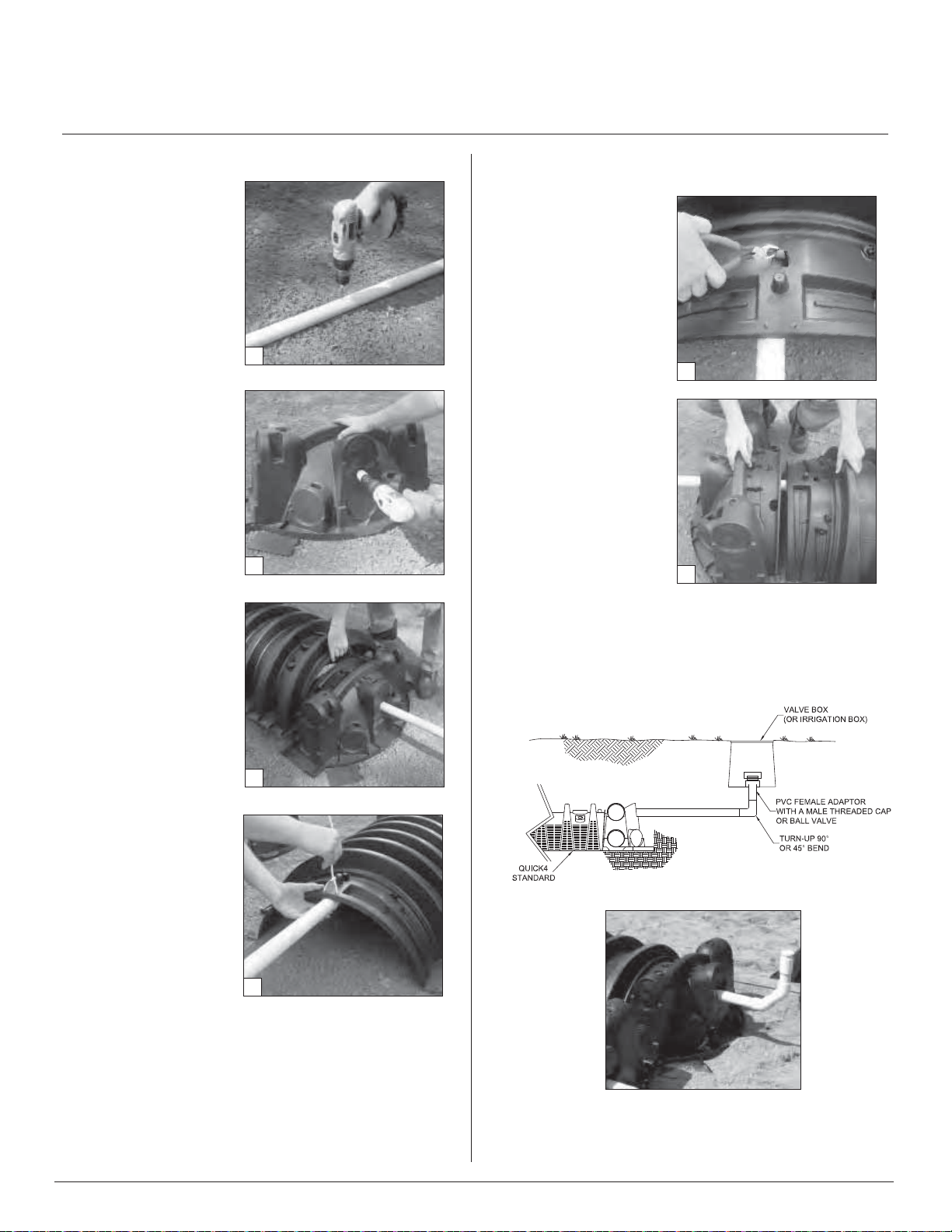

1. To allow pressure laterals

to drain after each dose,

drill a hole in the bottom of

the pipe at the end of the

pressure line. Place the

snap-off splash plate,

gravel or a paving block at

the bottom of the trench to

protect the infiltrative surface from erosion.

2. With a hole saw, drill out

the appropriate diameter

hole to accommodate the

pressure lateral pipe.

3. Insert the pressure lateral

pipe into the end cap’s

drilled opening and slide it

into the manifold pipe.

Glue the pressure lateral

pipe to the manifold pipe.

4. With the pressure lateral

pipe through the end cap,

place the inlet end of the

first chamber over the

back edge of the end cap.

5. Secure the pressure lateral pipe to the top of the

first chamber with a plastic

pipe strap at the outlet

end of the unit. Slide the

strap up through a slot in

the chamber top, down

through the other slot, and

cinch the two ends around

the pipe.

6. Lift and place the next

chamber onto the previous one at a 90-degree

angle. Line up the chamber end between the connector hook and locking

pin at the top of the first

chamber. Lower it to the

ground to engage the

interlocks.

7. Secure the lateral pipe

to the top of the next

chamber once in place. Follow the same method in Step 5.

8. Continue interlocking chambers and securing the pipe

until the row is completed.

1

2

4

5

9. Before attaching the final end cap, remove the tongue of

the connector hook on the last chamber with a pair of pliers.

10. Insert the pressure

lateral pipe through the

hole in the final end cap

and slide the end cap

towards the last chamber.

Lift the end cap over the

modified connector hook

and push straight down to

secure it to the chamber.

Note: If cleanout exten-

9

sions are required, use a

hole saw to cut a hole in

the end cap at the proper

elevation so that the lateral

pipe can extend. For

clean-out access, a

90-degree elbow that

extends to the soilʼs

surface can be attached

to the lateral pipe.

11. If installing multiple

rows of chambers, follow

10

Steps 1-9 to lay the next

row of chambers parallel to the first. Keep a minimum separation distance between each row of

chambers as required by regulation.

ACCESS FOR DRAINFIELD MAINTENANCE AND FLUSHING

Page 24 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 25

QUICK4 CHAMBERS INSTALLATION

Pressure Pipe Design Options

METHOD A: TOP PLACEMENT

ALL WEATHER PLASTIC PIPE STRAP

WITH 120 POUNDS TENSILE STRENGTH

PRESSURE PIPE WITH

HOLES AT 12 O’CLOCK

12"

Advantages of Method A

• Pipe and orifice placed

closer to the chamber

dome offer improved

distribution.

• Pipe positioned at the

top of the chamber

places it well above

effluent.

• Plastic pipe hanger

easily secures pipe

in place.

• If necessary, trim excess plastic pipe strap before connecting chambers.

AT EVERY CHAMBER CONNECTION

QUICK4 STANDARD

34"

A

Covering the System

Before backfilling, the system must be in spected by the

local unit of governmentʼs SSTS Inspector as per local

ordinance requirements. System should be installed as

per design.

1. Place a 2-foot high pile of berm material around the

perimeter of the sand mound and directly against the outer

rows of chambers for stabilization.

2. Ladle clean sand between the chamber rows to the top

sidewall louver to prevent chamber movement before final

backfill. Firm the soil between the chamber rows by walking

it in.

3. Push the berm material between and over the

chamber rows with a tracked vehicle from the upslope side.

Keep a minimum 12-inches of densified cover over the

system.

Note: NO wheeled machinery is allowed on chambers in mounds.

Tracked vehicles may be used.

4. After the system is covered, the site shall be seeded or

sodded per 7080.2150 Subp 3.J. to prevent erosion.

Note: If the system is for new home construction, it is important

to place marking stakes along the boundary of the

system. This will notify contractors of the site location so they will

not cross it with equipment or vehicles.

METHOD B: BOTTOM PLACEMENT

Advantages of Method B

• Pipe resting on the

mound distribution media

bed allows easy installation and maintenance.

• Glue “T’s” or PVC Jhooks to keep pipe level.

• System promotes efficient

pressure checks.

• Pipe resting on the trench

bottom allows easier

B

inspection if monitoring

ports are installed.

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 25

Page 26

QUICK4 PLUS CHAMBERS INSTALLATION

Trench Systems

Before You Begin

Quick4 Plus Chambers may only be installed according to

State and/or local regulations. If unsure of the installation

requirements for a particular site, contact the local unit of

government.

All systems require a design, which includes a thorough site

and soil evaluation of system sizing and the issuance of a

local permit to construct the system. The system installer must

schedule required regulatory inspections.

Materials and Equipment Needed

Quick4 Plus Chambers

Quick4 Plus Endcaps

Quick4 Plus All-in-One

Endcaps

PVC Pipe and Couplings

Backhoe

Laser, Transit or Level

Tape measure

These guidelines for construction machinery must be

followed during installation:

Avoid direct contact with chambers when using construction

equipment. Chambers require a 12-inch minimum of compacted cover to support a wheel load rating of 16,000 lbs/axle or

equivalent to an H-10 AASHTO load rating.

Only drive across the trenches when necessary. Never drive

wheeled machinery over chambers.

Avoid stones larger than 3 inches in diameter in backfill.

Remove stones this size or larger that are in contact with

chambers.

Shovel and Rake

Utility Knife

1 1/4-inch Drywall Screws*

Screw Gun*

Small Valve-cover Box*

4-inch Cap Inspection Port

* Optional

Preparing the End Cap

Note: Quick4 Plus and Quick4 Plus All-in-One Endcaps are avaliable for

use with the Quick4 Plus chambers on either end of the trench, depending upon installer’s preference and configuration requirements.

1. With a hole saw drill an

opening appropriate for pipe

diameter being used (normally

3 - 4 inches) on front or side

of end cap using center point

marking (see illustration

below) as a guide.

2. Snap off the molded splash

plate located on the bottom

front of the end cap.

3. Install splash plate into the

appropriate slots below the

inlet to prevent trench bottom

erosion.

1" PRESSURE

LATERAL (TYP.)

2" PRESSURE

LATERAL (TYP.)

Installing the Quick4 Plus All-in-One Periscope

Note: Available for use with Quick4 Plus All-in-One Endcap only.

Invert options based on system design.

1. With a hole saw drill the

pre-marked area on top of

the Quick4 Plus All-in-One

Endcap.

1

Drill end cap.

TOP 9" INVERT (INLET OR OUTLET)

END OR SIDE 3.3" INVERT

(GRAVITY INLET OR OUTLET)

END OR SIDE 0.5” INVERT

(FOR MID-LINE CONNECTION

OR LOOPED ENDS)

Excavating and Preparing the Site

Note: As is the case with conventional systems, do not install the

systems in wet conditions or in overly moist soils, as this causes

machinery to smear the soil.

1. Stake out location of all trenches and lines. Set elevations of

the tank, pipe, and trench bottom.

2. Install sedimentation and erosion control measures.

Temporary drainage swales/berms may be installed to protect

the site during rainfall events.

3. Excavate and level 36" wide trenches with proper center-to-

2. Insert the Quick4 Plus

All-in-One Periscope into

the top of the Quick4 Plus

All-in-One Endcap.

center separation. Verify that trenches are level and are located

at least 3 feet above the limiting layer.

Note: Over excavate the trench width in areas where you are planning

to contour.

4. Rake the bottom and sides if smearing has occurred while

excavating. Remove any large stones and other debris. Do not

use the bucket teeth to rake the trench bottom. Minimize or

avoid walking in the trench to prevent compaction, loss of soil

structure, and the subsequent reduction in the soil’s infiltrative

capacity.

Note: Raking to eliminate smearing is not necessary in sandy soils. In

fine textured soils (silts and clays), avoid walking in the trench to

prevent compaction and loss of soil structure

.

5. Verify that each trench is level using a level, transit, or laser.

Page 26 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

1

Drill end cap.

2

Insert periscope.

Page 27

QUICK4 PLUS CHAMBERS INSTALLATION

3. Insert a 4” Schedule 40

PVC pipe into the Quick4

Periscope.

3

Insert pipe.

4. Rotate the Quick4 Plus

All-in-One Periscope to

desired angle. The Quick4

Periscope rotates 360

o

horizontally when installed

on the endcap.

4

Rotate periscope.

Installing the Quick4 Invert Adapter

Note: Available for use with Quick4 Plus All-in-One and the Quick4

Plus Endcaps. Invert options based on system design.

1. With a hole saw drill the

pre-marked area on the front

of either the Quick4 Plus

Endcap or the Quick4 Plus

All-in-One Endcap.

2. With a hole saw drill the

pre-marked area on front of

the Quick4 Invert Adaper.

4. Rotate invert adapter to

desired angle.

4

Rotate to desired angle.

5. Screw Quick4 Invert

Adapter into place at final

position.

5

Screw into place.

6. Insert a 4” Schedule 40

PVC pipe into the front of

the Quick4 Invert Adapter.

6

Insert pipe.

2

Drill invert adapter.

3. Insert the Quick4 Invert

Adapter into the front of the

end cap.

Installing the System

1. Check the header pipe to be sure it is level or has the

prescribed slope.

2. Set the invert height as specified in the design from the

bottom of the inlet.

3. Place the first chamber in the trench.

4. Place the back edge of the

end cap over the inlet end of

the first chamber. Be sure to

line up the locking pins on

the top of both the chamber

and end cap.

3

Insert invert adapter.

4

Place end cap inlet end.

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 27

Page 28

QUICK4 PLUS CHAMBERS INSTALLATION

5. Insert the inlet pipe 2.5

inches into the opening on

the front of the end cap.

5

Insert inlet pipe.

6. Lift and place the end of

the next chamber onto the

previous chamber by holding

it at a 45-degree angle. Line

up the chamber end between

the connector hook and locking pin at the top of the first

chamber. Lower the chamber

to the ground to connect the

chambers.

Note: When the chamber

end is placed between the

connector hook and locking

6

Connect chambers.

pin at a 45-degree angle, the pin will be visible from the back

side of the chamber.

Note: The connector hook serves as a guide to ensure proper

connection and does not add structural integrity to chamber

joint. Broken hooks will not affect the structure or void the warranty.

7. Swivel the chamber on the pin to achieve the proper direction

for the trench layout.

Note: The chamber allows up to 10-degree swivel in either direction at

each joint.

Note: If possible avoid walking in the trench to minimize disturbance of

the soil structure and loss of infiltrative capacity. Rake any areas where

foot traffic has occured in the trench.

8. Continue connecting chambers until the trench is completed.

Note: As chambers are installed, verify they are level.

9. The last chamber in the trench requires an end cap. Lift the

end cap at a 45-degree angle and align the connector hook on

the top of the chamber with the raised slot on the top of the end

cap. Lower the end cap to

the ground and into place.

Note: Place a few shovels of soil

around the end cap to secure it

during backfill.

10. To ensure structural

stability, fill the sidewall area

by pulling soil from the sides

of the trench with a shovel.

Start at the joints where the

chambers

9

Place end cap outlet end.

connect. Continue backfilling the entire sidewall area, making

sure the fill covers the louvers.

11. Pack down fill by walking along the edges of trench and

chambers.

Note: In wet or clay soils, do not walk in the sidewalls

.

12. Proceed to the next trench and begin with Step 1.

Installing Quick4 Plus All-in-One

Endcap as a Mid-line Connection

Note: See mid-line piping options on the back of this document.

1. With a hole saw drill an opening appropriate for the pipe

diameter being used (normally 3 to 4 inches) on the side or on

top of the Quick4 Plus All-in-One Endcap.

Note: Piping configurations are determined by the preference of the

installer or designer. Please review drawings below for the functional

benefits of each option.

2. Snap off the molded

splash plate located on the

bottom front of the end cap.

3. Install splash plate into the

appropriate slots below the

inlet to prevent trench bottom erosion.

4. Place the back edge of the

end cap over the inlet end of

the first chamber. Be sure to

line up the locking pins on

the top of both the chamber

All-in-One as mid-line connection.

and end cap.

Optional: Fasten the end cap to the chamber with a screw at the

top of the end cap.

5. Insert the connection pipe 2.5 inches into the opening on the

endcap.

6. Place the next chamber onto the endcap by holding it at a 45degree angle. Line up the chamber end between the connector

hook and locking pin at the top of the endcap. Lower the chamber to the ground to connect.

Repeat Steps 1 through 5 for additional trenches.

Installing Inspection Ports

Inspection ports may be installed on the chamber or the Quick4 Plus

All-in-One Endcap. The Quick4 Plus Endcap does not allow inspection

port construction.

Quick4 Plus All-in-One Inspection Port

1. With a hole saw drill the

pre-marked area in the top

of the Quick4 Plus All-inOne Endcap to create a

4-inch opening.

2. Set a cut piece of pipe of

the appropriate length into

the corresponding end cap’s

inspection port sleeve.

Note: The sleeve will accommodate up to a 4-inch Schedule 40

pipe.

All-in-One inspection port.

Page 28 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

Page 29

QUICK4 PLUS CHAMBERS INSTALLATION

3. Use two screws to fasten the pipe to the sleeve around the

inspection port.

4. Attach a threaded cap or cleanout assembly onto the

protuding pipe at the appropriate height.

5. A small valve cover box may be used if the inspection port is

below the desired grade.

Chamber Inspection Port

1. With a hole saw drill the

pre-marked area in the top of

the chamber to create a

2.5-inch opening.

2. Set a cut piece of pipe of

the appropriate length into

the corresponding chamber’s

inspection port sleeve.

Note: The sleeve will accommodate up to a 2.5-inch Schedule

40 pipe.

3. Use two screws to fasten

the pipe to the sleeve around

Chamber inspection port.

the inspection port.

4. Attach a threaded cap or cleanout assembly onto the

protuding pipe at the appropriate height.

5. A small valve cover box may be used if the inspection port is

below the desired grade.

Covering the System

Before backfilling, the system must be inspected by the

local unit of governmentʼs SSTS Inspector as per local

ordinance requirements. Create an as-built drawing at this

time for future records.

1. Backfill the trench by pushing fill material over the chambers

with a backhoe. Keep a minimum of 12 inches of densified cover

over the chambers before driving over the system.

Note: Do not drive over the system while backfilling in sand.

2. It is best to mound several inches of soil over the finished

grade to allow for settling. This also ensures that runoff water is

diverted away from the system.

3. After the system is covered, the site should be seeded or

sodded to prevent erosion.

Note: If the system is for new home construction, it is important to leave

marking stakes along the boundary of the system. This will notify

contractors of the system location so they will not cross it with

equipment or vehicles.

EXAMPLE: QUICK4 PLUS ALL-IN-ONE ENDCAP AS A MID-LINE CONNECTION

ORIGINAL GRADE

8"

QUICK4 PLUS

ALL-IN-ONE ENDCAP

ORIGINAL GRADE

ESTABLISH VEGETATIVE COVER

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 29

Page 30

QUICK4 PLUS CHAMBERS INSTALLATION

Pressure Systems

Before You Begin

Quick4 Plus chambers can only be installed according to

state and/or local regulations. Soil and site conditions must

be approved prior to installation. Conduct a thorough site

evaluation to determine proper sizing and siting of the

system before installation.

Materials and Equipment Needed

Quick4 Plus Chambers

Quick4 Plus All-in-One

or Q4 Plus Endcaps

PVC Pipe and Couplings

Backhoe

Laser, Transit or Level

Tape measure

Shovel and Rake

Utility Knife

1 1/4-inch Drywall Screws*

Screw Gun*

Small Valve-cover Box*

4-inch Cap Inspection Port

* Optional

These guidelines for construction machinery must be

followed during installation:

Avoid direct contact with chambers when using construction equipment. Chambers require a 12-inch minimum of

compacted cover to support a wheel load rating of 16,000

lbs/axle or equivalent to an H-10 AASHTO load rating.

Only drive across the trenches when necessary. Never

drive wheeled machinery over chambers.

Avoid stones larger than 3 inches in diameter in backfill.

Remove stones this size or larger that are in contact with

chambers.

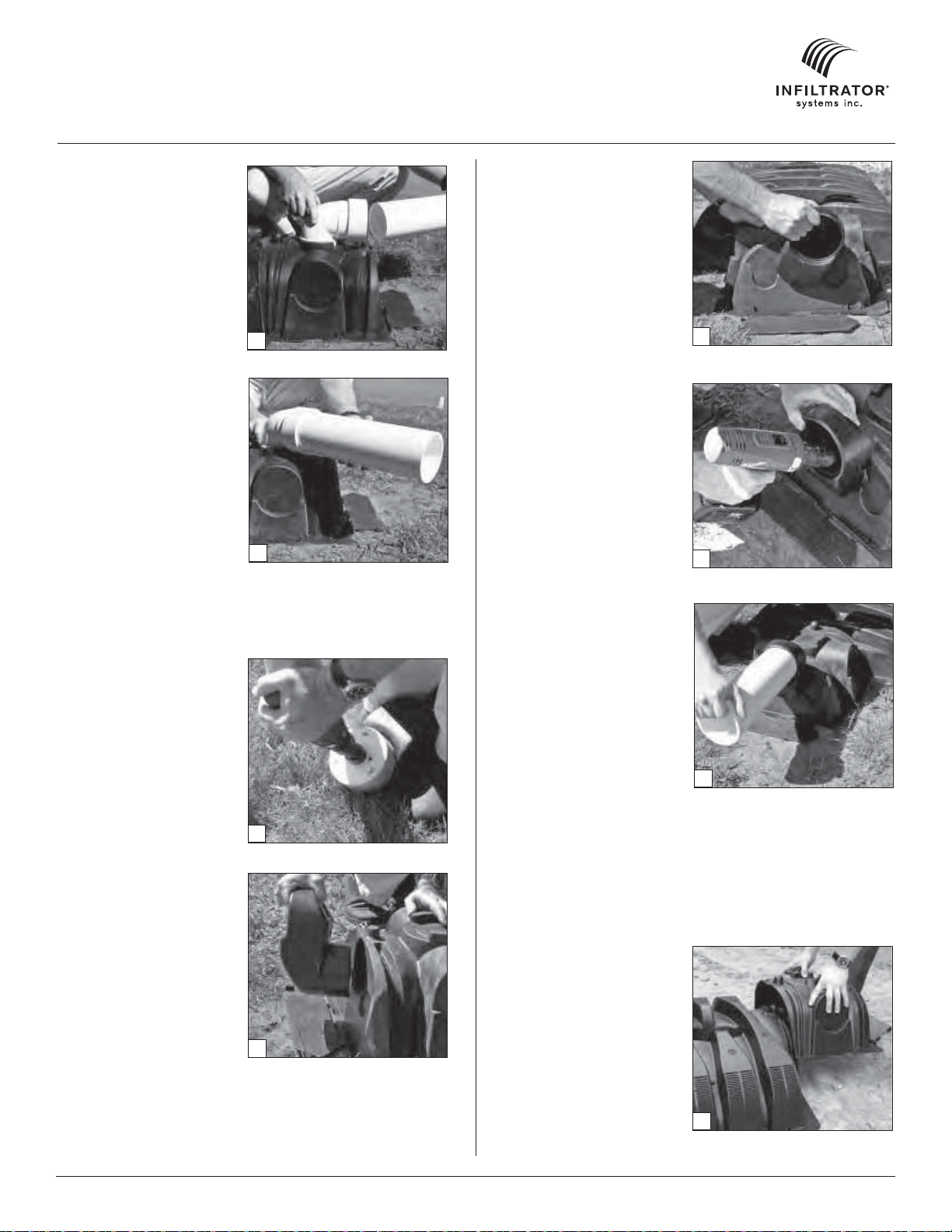

Installing Chambers and End Caps

1. To allow pressure laterals to drain after each dose, drill a hole

in the bottom of the pipe at the end of the pressure line. Place

the snap-off splash plate or a paving block at the bottom of the

trench to protect the infiltrative surface from erosion.

1" PRESSURE LATERAL (TYP.)

2" PRESSURE LATERAL (TYP.)

2. With a hole saw, drill out

the appropriate diameter

hole to accommodate the

pressure lateral pipe.

3. Insert the pressure lateral

pipe into the end cap’s drilled

opening and slide it into the

manifold pipe. Glue the

pressure lateral pipe to the

manifold pipe.

2

Drill pressure pipe hole.

Note: Health departments may

require a wet-run pressure check

to be done prior to chamber

installation when the pipe is laying on the ground. Check with

your local health department for

the proper procedure.

4

Place end cap over inlet end.

5. Secure the pressure lateral

pipe to the top of the first

chamber with a plastic pipe

strap at the outlet end of the

unit. Slide the strap up

through a slot in the chamber

top, down through the other

slot, and cinch the two ends

around the pipe.

6. Lift and place the next

chamber onto the previous

one at a 45-degree angle.

Line up the chamber end

5

Secure pressure pipe.

between the connector hook

and locking pin at the top of the first chamber. Lower it to the

ground to engage the interlocks.

7. Secure the lateral pipe to the top of the next chamber once in

place. Follow the same method in Step 5.

8. Continue interlocking chambers and securing the pipe until

the trench is completed.

9. Before attaching the final end cap, it may be necessary to

remove the tongue of the connector hook on the last chamber

with a pair of pliers depending on your pipe diameter.

10. Insert the pressure lateral

pipe through the hole in the

final end cap and slide the

end cap toward the last

chamber. Lift the end cap

over the modified connector

hook and push straight down

to secure it to the chamber.

Note: If cleanout extensions are

required, use a hole saw to cut a

hole in the top of the Quick4

Plus All-in-One Endcap so the

pressure lateral pipe with an

elbow can extend to the ground

surface. For cleanout access,

use the “Installing Optional

Inspection Ports” section in the

general installation instructions.

10

Lateral pipe through end cap.

ACCESS FOR DRAINFIELD MAINTENANCE AND FLUSHING

VALVE BOX

(OR IRRIGATION BOX)

4. With the pressure lateral pipe through the end cap, place the

back edge of the end cap over the inlet end of the first chamber.

Be sure to line up the locking pins on the top of both the

chamber and end cap.

Page 30 Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information.

QUICK4 PLUS

STANDARD LP

Page 31

QUICK4 PLUS CHAMBERS INSTALLATION

Advantages of Method A

• Pipe and orifice placed closer to the chamber dome offer

improved distribution.

• Pipe positioned at the top of the chamber places it well

above effluent.

• Plastic pipe hanger easily secures pipe in place.

ALL WEATHER PLASTIC PIPE STRAP WITH

120 POUNDS TENSILE STRENGTH AT EVERY

CHAMBER CONNECTION

PRESSURE PIPE WITH HOLES AT 12 O’CLOCK

(MAY BE INSTALLED ON EITHER SIDE)

34"

QUICK4 PLUS

STANDARD LP CHAMBER

8"

Advantage of Method B

• Pipe resting on the trench bottom allows easy installation

and maintenance.

• Stabilizing “T’s” keep pipe level.

• System promotes efficient pressure checks.

• Pipe resting on the trench bottom allows easier inspections

if monitoring ports are installed.

STABILIZE OR "T" EVERY 10' TO

PREVENT PIPE ROTATION AND

PRESSURE PIPE WITH HOLES AT 12 O’CLOCK

(MAY BE INSTALLED ON EITHER SIDE)

34"

MAINTAIN PROPER PIPE POSITION

QUICK4 PLUS

STANDARD LP CHAMBER

8"

Contact Infiltrator Systems, Inc. 1-800-221-4436 for additional Minnesota technical and product information. Page 31

Page 32

One Year Standard Warranty

(a) The structural integrity of each chamber, end plate, wedge and other accessory manufactured by Infiltrator (collectively referred to as “Units”), when installed and operated in a leachfield of an

onsite septic system in accordance with Infiltrator's installation instructions, is warranted to the original purchaser (“Holder”) against defective materials and workmanship for one year from the date

upon which a septic permit is issued for the septic system containing the Units; provided, however, that if a septic permit is not required for the septic system by applicable law, the one (1) year warranty period will begin upon the date that installation of the septic system commences. In order to exercise its warranty rights, Holder must notify Infiltrator in writing at its corporate headquarters in

Old Saybrook, Connecticut within fifteen (15) days of the alleged defect. Infiltrator will supply replacement Units for those Units determined by Infiltrator to be defective and covered by this Limited

Warranty. Infiltrator’s liability specifically excludes the cost of removal and/or installation of the Units.