Page 1

B

efore you Begin

This document presents a method for assessing buoyancy control

needs for Infiltrator Water Technologies (Infiltrator) IM-Series tanks.

Tank buoyancy control measures must be implemented according to

state and/or local regulations, which may supersede these guidelines.

If unsure of the requirements for a particular site, contact the local

health department or permitting authority.

If tank buoyancy control measures are implemented, refer to Infiltrator

IM-Series Tank Installation Instructions and Riser Connection

Guidance documents, as applicable, for completing the installation.

How to Use this Document

1. Using Step 1, Table 1 and Figures 1 and 2, verify that the water level

outside the tank is below the outlet pipe saddle height and determine if

buoyancy control is required.

2. Use the appropriate row in Step 2, Table 2 to determine the minimum

buoyancy control methods for the site conditions.

3. Once the preferred buoyancy control method is selected, follow the

implementation procedures provided in Step 3.

Step 1 – Determine Need for Buoyancy Control

Required information: (1) maximum height of water outside the tank and

above the tank bottom; and (2) the depth of soil cover above the tank top.

Tank buoyancy control may be required if:

• the water level outside the tank has the potential to rise 30 inches (750

mm) or more above the bottom of the tank; and

• less than 12 inches (300 mm) of soil cover is to be placed as backfill over

the tank top.

Allowable Subsurface Water Elevation

Groundwater elevation, groundwater table, and water table are terms for

the subsurface condition where water is held in the subsurface soil pores

or rock. The seasonal high groundwater elevation represents the sustained

highest point the water table has the potential to reach at any time of the

year. That point is not necessarily the level at which groundwater may be

observed seeping from the soil at the time of tank installation. In general,

a qualified soil evaluator or engineer can estimate the seasonal high

groundwater elevation from careful examination of the soil profile.

Under certain conditions, a perched water table may be present in the

subsur face. A perched water table occurs where there is an impermeable

or low-permeability soil that causes water to be present in the soil pores

above the main water table. A perched water table elevation may exceed the

seasonal high elevation of the main water table. The vertical position of the

tank must account for both the seasonal high groundwater table and any

existing or future perched water table condition. Verify that the subsurface

water elevation will not exceed the height of the outlet pipe saddle of

the tank, as shown in Figure 1 and described in Table 1.

Table 1 Instructions

1. In the left-hand column of Table 1, locate the row corresponding to the

height of the water elevation outside the tank and above the tank bottom

(Parameter I) for the site conditions. See Figure 2.

2. Follow that row to the right until reaching the column corresponding to

the depth of soil cover proposed above the tank top (Parameter II). See

Figure 2.

3. If the tank model is listed in that cell, then buoyancy control is required

(proceed to Step 2). If the tank model is not listed in that cell, then no

buoyancy control is required.

4. IM-Series tanks shall not be installed where the water level outside the

tank exceeds the height of the outlet pipe saddle.

Infiltrator IM-Series Tank

Buoyancy Control Guidance

OCTOBER 2016

Table 1:

Infiltrator Tank Models1 and Conditions Requiring Buoyancy Control

Parameter I:

Water height

2

above tank bottom

Parameter II:

Soil cover depth above tank top

3

A B

6 in (150 mm) to

12 in (30 0 mm)

Above 12 in

(300 mm)

1

Above outlet pipe saddle

4

(grea ter than 43” [1,075 mm])

Do not install Do not install

2

36” (9 00 mm) to 43” (1,075 mm)

(to outlet pipe saddle)

All models Not Required

3 30” (750 mm) to 36” (900 m m)

IM -15 3 0 Not Required

4 Less than 30” (75 0 mm)

Not Required Not Required

NOTES:

1. Infiltrator tank models include: IM-540, IM-1060, and IM-1530.

2. Water height corresponds to seasonal high groundwater elevation or perched

water elevation measured from bottom-of-tank elevation.

3. Minimum 6 inches (150 mm) soil cover backfill is required.

4. IM-Series tanks shall not be installed where the water level outside the tank

exceeds the height of the outlet pipe saddle.

Figure 2: Buoyancy Control Parameters for Table 1

Figure 1: Assessing Water Elevation

Parameter I

Water Height

Above Tank Bottom

Parameter II

Depth Of Soil Cover Above Top Of Tank

NO BUOYANCY CONTROL IS REQUIRED IF THERE IS AT LEAST

12 INCHES (300 MM) OF SOIL COVER ABOVE THE TANK TOP.

Maximum Allowable Water Elevation

Outside of the Tank Corresponds to

Outlet Pipe Saddle Invert

Tank Bottom

6” (150 mm) min – 48” (1,200 mm) max.

13” (330 mm)

Seasonal High

Groundwater 43”

(1,075 mm) max.

Above Tank Bottom

Depth of Soil Cover Above Tank Top

Top Of Tank

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436.

Page 2

Step 2 – Determine Buoyancy Control Method

Step 2 is used if the Step 1 analysis shows that buoyancy control is required for the tank model and installation conditions. The site-specific maximum

height of water outside of the tank and above the tank bottom and the depth of soil cover above the tank top must be known to complete Step 2.

Table 2 Instructions

For the appropriate tank model, select the desired buoyancy control method under each method description column. Refer to the Compatible Devices and

Products and Step 3 – Implementation sections of this document for additional information on the buoyancy control methods shown in Table 2.

Supplemental Force

The minimum supplemental downward force required is included in Table 2 to allow custom buoyancy control methods. These values include a factor

of safety of 1.5 applied to the calculated force required to restrain the tank. Custom-designed buoyancy control methods shall conservatively consider

saturated conditions from the bottom-of-tank elevation to ground surface. As long as buoyancy control is provided that supplies the minimum weight listed

in the table (for poured-concrete blocks or other methods designed by third par ties), the tanks are calculated to be stable for the water height outside

the tank and above the tank bottom and corresponding soil cover conditions. All Infiltrator strapping and fastening recommendations apply for customdesigned buoyancy control methods. Contact Infiltrator’s Technical Services Department with any questions regarding supplemental force requirements.

Table 2: Buoyancy Control Method Selection

Tan k

Model

Parameter I:

Water height above tank bottom

Parameter II:

Soil cover depth above

tank top

Minimum

supplemental

downwa rd

force required

1

(tota l, bot h tank

sides)

Buoyancy Control Methods

Concrete-filled

half pipe

(min. length/

side)

Concrete

parking

bumpers

(min. length/

side)

Concrete

traffic

barriers

(min. length/

side)

Helical

anchors

(min.

no./side)

Concrete collar

(min. width x min.

height)

IM-540 36 in (900 mm) to outlet pipe saddle

2

6 in (150 mm) to 12 in (300 mm) 2,200 lbs (1,000 kg) 3.8 ft (1.2 m) 3.8 ft (1.2 m) 3.8 ft (1.2 m) 2

6 in (150 mm)

x 9 in (225 mm)

IM -10 6 0 36 in (900 mm) to outlet pipe saddle

2

6 in (150 mm) to 12 in (300 mm) 2,700 lbs (1,225 kg) 4.2 ft (1.3 m) 4.5 ft (1.4 m) 4.2 ft (1.3 m) 2

12 in (300 mm)

x 9 in (225 mm)

IM -15 3 0 30 in (750 mm) to outlet pipe saddle

2

6 in (150 mm) to 12 in (300 mm) 4,300 lbs (1,955 kg) 6.3 ft (2.0 m) 6.5 ft (2.0 m) 6.3 ft (2.0 m) 2

12 in (300 mm)

x 9 in (225 mm)

NOTES:

1. See Supplemental Force discussion below.

2. IM-Series outlet pipe saddle height is 43 inches (1,075 mm) above tank bottom (see Figure 1).

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436.

Page 3

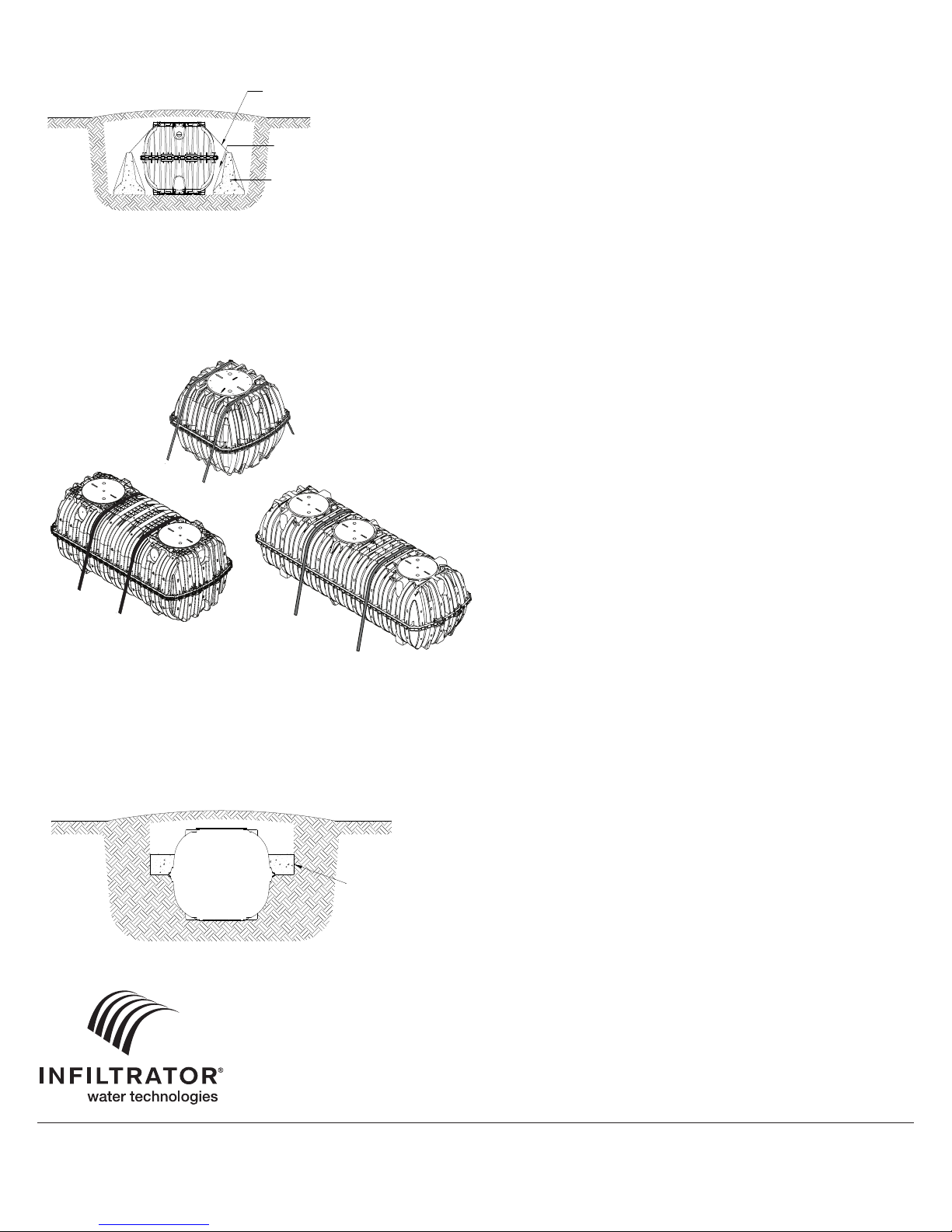

Compatible Devices and Products

Infiltrator tanks are compatible with the following products for buoyancy

control:

• Tie-down straps: high-tensile-strength, 10,000 lb (4,500 kg) minimum

capacity, nylon or polyester, with corrosion-resistant hardware.

• Concrete deadmen anchors: concrete-filled plastic half pipe, precast

parking bumper, precast traffic barrier, or precast block.

• Helical anchors: Chance™ No-Wrench Screw Anchors with minimum

6-inch (150 mm) diameter, Class 7 or equal.

• Mid-Seam Concrete Collar: cast-in-place concrete (minimum 3,000 psi

compressive strength at 28 days and minimum 6% air entrainment).

Tie-Down Straps

Straps are commercially available in varying

lengths and with assorted hardware and

tightening options. Nylon or polyester

strapping with minimum 10,000 lb (4,500 kg)

capacity is required for buoyancy control use

with Infiltrator tanks. Place straps over the tank at specified locations only

(see Figure 5). Tighten straps snugly with a ratchet or turnbuckle system to

remove all slack and slightly pre-load the system. All connections, fittings,

and hardware must be corrosion resistant or coated with epoxy or other

corrosion-resistant materials to inhibit deterioration in the subsurface

environment. Consider encapsulating such components in heat-shrink

tubing or applying a corrosion-resistant coating prior to burial.

Concrete Deadmen Anchors

Recommended concrete deadmen anchors include filled plastic half pipe,

precast parking bumpers and traffic barriers, and precast blocks. The

weight of the deadmen anchors combined with the weight of soil above

them provides buoyancy control when properly secured. Deadmen anchors

are placed at the bottom of the tank excavation on opposite sides of the

tank. The deadmen anchors are fastened to each other with tie-down

straps placed over the tank at the locations specified for each tank model

(see Figure 5).

Concrete-filled Plastic Half Pipe

Use Schedule 40 PVC plastic pipe with a minimum

inside diameter of 15 inches (375 mm) or HDPE

corrugated pipe with a minimum inside diameter of

18 inches (450 mm) cut in half lengthwise. Fill with

concrete having a minimum unit weight of 145 lbs/ft3

(2.32 metric tons/m3) reinforced with three equally

spaced 40-grade,

1/2-inch (13 mm) diameter steel bars. Weight is 61

lbs/ft (91 kg/m) minimum.

Concrete Parking Bumper

Use commercially available steel-reinforced

parking bumpers with typical dimensions of 12

inches wide by 6 inches high (300 mm x 150 mm).

Weight is 58 lbs/foot (86 kg/m) minimum.

Concrete Traffic Barrier

Use commercially available steel-reinforced concrete traffic barrier or

equivalent. Typical dimensions include a

24-inch-wide base tapering to a 6-inch-

wide top, with a height of approximately

32 inches (600 mm x 150 mm x 800 mm).

Weight is 390 lbs/foot (580 kg/m) minimum.

Precast Blocks

Concrete precasters can fabricate blocks

of various dimensions and weights. Blocks

are often an affordable option if they satisfy

the minimum weight requirements for use

as buoyancy control (see Table 2 and the

Supplemental Force section of Step 2 for

more information).

Helical Anchors

Chance™ No-Wrench Screw Anchors with a

6-inch (150 mm) diameter flight, Class 7, or

equal. These anchors rely on the shear strength

of the soil combined with the weight of the

soil above the anchor flight to provide holding

strength. Proper installation is to 4 feet (1.2 m)

below the bottom of the tank excavation and to

within 5° of alignment with the strap alignment.

Determine the proper locations for anchor

installation to ensure that tie-down straps will

be aligned properly for each tank model (see

Step 3: Implementation), and follow the anchor

manufacturer installation instructions.

Concrete Collar

A ballast may be constructed along the mid-

height seam of the tank using cast-in-place concrete (minimum 3,000

psi compressive strength at 28 days and minimum 6% air entrainment).

Concrete shall be cast in contact with the exterior sur face of the tank to

allow interlock with sidewall ribs and the mid-height flange. Reinforcing

steel is not required, but may be added if desired.

Step 3 – Implementation

Effective buoyancy control of Infiltrator tanks requires careful preparation,

thorough excavation, precise placement, secure strapping and proper

backfilling, as described and illustrated below.

Excavation Requirements

It is recommended that the excavation width provide a minimum of 36

inches (900 mm) clearance beyond the tank on all sides when utilizing

buoyancy control. This will allow sufficient space within the excavation to

place anchoring equipment and fasten strapping. The excavation should

provide a minimum 48-inch (1,200 mm) clearance beyond the tank when

using Chance™ No-Wrench Screw Anchors to allow for room to properly

install the screw anchors. The actual excavation size shall be determined by

the installer. Refer to Infiltrator IM-Series Tank Installation Instructions for

additional excavation procedures.

Concrete-filled Half Pipe Construction

Concrete-filled half pipe shall be supported with soil or other stabilizing

means below the pipe haunches prior to concrete placement. The

stabilization shall prevent the pipe from rolling during placement and curing

of the concrete. Concrete shall be allowed to cure for a minimum of one

day prior to tank back filling.

Placement of Deadmen and Anchors

Concrete deadman anchors are to be installed at the bottom of the tank

excavation, parallel to the long axis of the tank (see Figure 3).

Figure 3: Plan View

The deadmen should be placed close to, but not touching, the tank on both

sides of the tank to allow the placement of backfill between the deadman

anchor and tank sidewall (see Figure 4).

18 in

[450mm]

12 in

[300 mm]

6 in

[150 mm]

24 in

[600 mm]

32 in

[800 mm]

Quick4 Plus Equalizer 36 LP

Typical working torque:

¾” Rod 400 ft. lbs. (542 N

•m)

1” Rod 1,000 ft. lbs. (1,356 N

•m)

1¼” Rod 2,300 ft. lbs. (3,118 N

•m)

15 in [375 mm] to

18 in [450 mm]

Steel Rebar

24 in

[600 mm]

32 in

[800 mm]

STRAPPING

DEADMAN

ANCHOR

(TYPICAL)

STRAP

WIDTH

6" (150 mm)

MIN EXTENSION

6" (150 mm)

MIN EXTENSION

Contact Infiltrator Water Technologies’ Technical Services Department for assistance at 1-800-221-4436.

Page 4

Strapping

Proper installation of straps over the tank is critical for tank stability under

constant and fluctuating water conditions both inside and outside the tank.

Straps must be placed at the specified strapping locations for each model,

as illustrated in Figure 5. Strapping locations are embossed on the exterior

surface of the tank with the following text: “SHIPPING /ANTI-BUOYANCY

STRAP HERE.” The IM-Series tank strapping locations correspond to

structurally reinforced areas of the tank body. Straps must never be placed

over access openings, lids, or inlet/outlet piping. Straps must be tightened

with a ratchet or turnbuckle system to remove slack and slightly pre-load

the system.

STRAPPING NOTES:

1. The buoyancy control shall be centered across the straps (excludes

helical anchors). The control shall extend a minimum of 6 inches (150 mm)

beyond the maximum strap width (see Figures 3 and 5).

2

.

The minimum deadman length corresponds to the tank model-specific strap

width plus 12 inches (300 mm).

Backfill and Cover

Place backfill between deadman anchor and tank sidewall to fully fill void

and tank body corrugations. A minimum 6” layer (150 mm) of suitable cover

material is required over all Infiltrator tank installations. Mound cover to

direct surface water drainage away from the tank excavation footprint to

prevent filling of the tank excavation with precipitation. Establish erosion-

resistant vegetation within the tank installation footprint. Refer to Infiltrator

IM-Series Tank Installation Instructions for complete backfilling and cover

procedures.

General Specifications

• Prior to ground disturbance, check for subsurface obstructions and

utilities in conformance with applicable regulatory requirements.

• Excavation safety provisions shall conform to applicable government

regulations.

• Follow manufacturer instructions for all products and devices used for

Infiltrator tank buoyancy control.

• Buoyancy control methods described herein do not account for

unanticipated conditions such as surface flooding, temporar y inundation

or other natural occurrences, unintended removal of cover fill over tank,

etc.

• Buoyancy control methods described herein are recommendations only;

consult a professional engineer for customized designs, if desired.

Parts and Supplies

The parts and supplies necessary are to be purchased separately from the

tank. All parts and supplies are either commercially available or available

through Infiltrator’s network of tank distributors. Some parts may require

fabrication on site using common construction practices.

4 Business Park Road

P.O. Box 768

Old Saybrook, CT 06475

860-577-7000 • Fax 860-577-7001

1-800-221- 4436

www.infiltratorwater.com

U.S. Patents: 4,759,661; 5,017,041; 5,156,488; 5,336,017; 5,401,116; 5,401,459; 5,511,903; 5,716,163; 5,588,778; 5,839,844 Canadian Patents: 1,329,959; 2,004,564 Other patents pending. Infiltrator, Equalizer, Quick4,

and SideWinder are registered trademarks of Infiltrator Water Technologies. Infiltrator is a registered trademark in France. Infiltrator Water Technologies is a registered trademark in Mexico. Contour, MicroLeaching,

PolyTuff, ChamberSpacer, MultiPort, PosiLock, QuickCut, QuickPlay, SnapLock and StraightLock are trademarks of Infiltrator Water Technologies. PolyLok is a trademark of PolyLok, Inc. TUF-TITE is a registered

trademark of TUF-TITE, INC. Ultra-Rib is a trademark of IPEX Inc.

© 2016 Infiltrator Water Technologies, LLC All rights reserved. Printed in U.S.A.

Figure 4: Section View

Helical anchors should be installed so that the eye loop is level with the

bottom of the tank excavation. They must be in line with the tank model

strapping locations (see Figure 5) or lifting lugs, as appropriate. Anchors

must also be installed at such a distance from and angle to the tank so that

the strapping is within 5° of alignment with the anchor shaft per the anchor

manufacturer’s recommendations.

Figure 5: Strap Positioning

Concrete Collar

Backfill the tank to the mid-seam area. Concrete (minimum 3,000 psi at 28

days and minimum 6% air entrainment) shall be cast in contact with the

exterior surface of the tank to allow interlock with sidewall ribs and the midheight flange. The bottom of the concrete collar shall be cast at the top of

the mid-seam flange.

TANK03 1016

33"

(838 mm)

38"

(965 mm)

63"

(1,600 mm)

IM-1530

IM-540

IM -10 60

PROVIDE ADEQUATE SPACE FOR

BACKFILL PLACEMENT BETWEEN

DEADMAN ANCHOR AND TANK

STRAPPING (TYPICAL)

DEADMAN ANCHOR

CONCRETE COLLAR

SECTION VIEW

Loading...

Loading...