User Manual

SUPPORT@INERTIALSENSE.COM WWW.INERTIALSENSE.COM

µINS, µAHRS, and µIMU

Product

User Manual

11/30/2017

Inertial Sense LLC

72 N 720 E

Salem, UT 84653

801-610-6771

support@inertialsense.com

www.inertialsense.com

User Manual

© 2017 Inertial Sense, LLC 2 11/30/2017

Contents

1 Overview ............................................................................................................................................................... 4

1.1 Description of differences between IMU, AHRS, INS ................................................................................... 4

2 Getting Started...................................................................................................................................................... 5

2.1 Unpacking Your Unit .................................................................................................................................... 5

2.2 Downloading the EvalTool and SDK ............................................................................................................. 5

2.3 EvalTool GUI ................................................................................................................................................. 5

2.4 Connecting To Your Unit .............................................................................................................................. 5

2.5 System LED and Solution Status ................................................................................................................... 6

2.6 Inertial Sense CLTool .................................................................................................................................... 6

2.6.1 Compiling in Linux/Mac ........................................................................................................................... 6

2.6.2 Compiling in Windows (MS Visual Studio) ............................................................................................... 7

2.6.3 Running CLTool ........................................................................................................................................ 7

2.7 Additional Development .............................................................................................................................. 8

3 Coordinate Frames ................................................................................................................................................ 9

3.1 Sensor Frame ............................................................................................................................................... 9

3.2 INS Output Frame......................................................................................................................................... 9

3.3 North-East-Down (NED) Frame .................................................................................................................... 9

3.4 Earth-Centered Earth-Fixed (ECEF) Frame ................................................................................................... 9

3.5 Translation Between Coordinate Frames ................................................................................................... 10

4 Hardware Integration ......................................................................................................................................... 11

4.1 Noise Coupling ........................................................................................................................................... 11

4.2 Vibration Isolation ...................................................................................................................................... 11

4.3 Sensitivity to Temperature Change ............................................................................................................ 11

5 SDK Library .......................................................................................................................................................... 12

5.1 Binary Protocol ........................................................................................................................................... 12

5.2 ASCII Protocol ............................................................................................................................................. 13

5.2.1 ASCII Messages ...................................................................................................................................... 14

5.3 C Binding .................................................................................................................................................... 17

5.3.1 Connecting to the Device ....................................................................................................................... 17

5.3.2 Communicating with the device ............................................................................................................ 18

5.3.3 Updating Firmware (Bootloader) ........................................................................................................... 18

5.4 C++ Binding ................................................................................................................................................ 19

6 Binary Protocol Data Sets ................................................................................................................................... 20

6.1 Configuration ............................................................................................................................................. 20

6.1.1 DID_FLASH_CONFIG ............................................................................................................................... 20

6.2 Using Com Manger to Write Data Set Parameter ...................................................................................... 20

7 System Health and Status Flags .......................................................................................................................... 21

7.1 Status Flags................................................................................................................................................. 21

User Manual

© 2017 Inertial Sense, LLC 3 11/30/2017

7.1.1 insStatus – INS Status Flags .................................................................................................................... 21

7.1.2 hdwStatus – Hardware Status Flags....................................................................................................... 21

7.1.3 Built-in test (BIT) Flags ........................................................................................................................... 22

7.2 Typical Health Monitoring .......................................................................................................................... 22

8 Magnetometer Calibration ................................................................................................................................. 24

8.1 Magnetometer Recalibration ..................................................................................................................... 24

8.1.1 External Recalibration ............................................................................................................................ 24

8.1.2 Automatic Recalibration ........................................................................................................................ 25

8.2 Magnetometer Continuous Calibration ..................................................................................................... 25

8.3 Magnetometer Calibration Settings ........................................................................................................... 25

9 Data Logging ....................................................................................................................................................... 26

9.1 Log File ....................................................................................................................................................... 26

9.1.1 Log Chunk .............................................................................................................................................. 26

9.1.2 Chunk Header ........................................................................................................................................ 26

9.1.3 Chunk Data ............................................................................................................................................ 27

9.1.4 Chunk Sub-Header ................................................................................................................................. 27

9.1.5 Data Set Header ..................................................................................................................................... 27

9.2 Data Loggers ............................................................................................................................................... 27

9.3 EvalTool Data Logging ................................................................................................................................ 27

10 Plotting Log Files ................................................................................................................................................. 29

10.1 Matlab (*.dat) ............................................................................................................................................ 29

10.2 Python (*.sdat) ........................................................................................................................................... 29

10.3 Excel (*.csv) ................................................................................................................................................ 29

11 Troubleshooting .................................................................................................................................................. 30

User Manual

© 2017 Inertial Sense, LLC 4 11/30/2017

1 Overview

The µINS GPS aided Inertial Navigation System, µAHRS Attitude Heading Reference System, and the µIMU Inertial

Measurement Unit monitor many different types of measurements including rotation, acceleration, GPS position,

magnetic flux density, pressure and velocity. The Inertial Sense SDK provides a software interface to allow

communication with the device including setting configuration options, retrieving specific data, and listening for

data broadcasts.

For example, you could configure the device to broadcast the current latitude, longitude, and altitude as well as

the heading and velocity at up to 500Hz. This manual will cover the underlying protocol and message format

(binary and ASCII) involved in communicating with the device, along with a C, C++ and C# binding.

1.1 Description of differences between IMU, AHRS, INS

The μIMU™ is a miniature calibrated sensor module consisting of an Inertial Measurement Unit (IMU),

magnetometer, barometer, and L1 GPS (GNSS) receiver. Data out includes angular rate, linear acceleration,

magnetic field, barometric altitude, and GPS WGS84 geo-position. All systems include a comprehensive sensor

calibration for bias, scale-factor, and cross-axis alignment, minimizing manufacturing variation and maximizing

system performance.

The μAHRS™ is an Attitude Heading Reference System (AHRS) that includes all functionality of the μIMU™ and

fuses IMU and magnetometer data to estimate roll, pitch, and heading.

The μINS™ is a GPS (GNSS) aided inertial navigation system (GPS-INS) module that includes all functionality of the

μIMU™ and provides orientation, velocity, and position. Sensor data from MEMs gyros, accelerometers,

magnetometers, barometric pressure, and GPS/GNSS is fused to provide optimal measurement estimation.

User Manual

© 2017 Inertial Sense, LLC 5 11/30/2017

2 Getting Started

This section provides instructions on how to quickly set up the µINS, µAHRS, or µIMU and start collecting data.

2.1 Unpacking Your Unit

Most customers will choose to purchase the EVB (Evaluation Board) and Semi-Rugged Case with their µINS, µAHRS,

or µIMU. The EVB allows for multiple types of serial connections to be made with the µINS, µAHRS, or µIMU

including RS232, RS485, RS422, TTL, and USB. (Coming soon CAN bus, SPI and I2C.) A FTDI USB to serial converter

on the EVB connects the EVB USB port to a serial port on the µINS, µAHRS, or µIMU.

2.2 Downloading the EvalTool and SDK

The EvalTool and CLTool (part of the SDK) are provided to help users quickly evaluate and integrate the µINS,

µAHRS, and µIMU.

You can visit the Inertial Sense website’s Resources page at https://inertialsense.com/resources to get access to

the source code downloads (EvalTool and SDK). The EvalTool Windows installer comes with the SDK and firmware.

The installer will automatically save the EvalTool in C:\Program Files\Inertial Sense, and a desktop shortcut will also

be created. The SDK and firmware will be saved in C:\Users\UserName\Documents\Inertial Sense. The SDK and

firmware can also be downloaded individually and saved into a directory of your choosing.

2.3 EvalTool GUI

The EvalTool is a graphical Windows-based desktop program that allows you to explore and test functionality of

the Inertial Sense products in real-time. It has scrolling plots, 3D model representation, table views of all data, a

data logger, and a firmware updating interface for the µINS, µAHRS, or µIMU. The EvalTool can simultaneously

interface with multiple Inertial Sense devices.

In the EvalTool under the Settings tab, make sure to select the Auto Refresh check box next to the COM port

connected to the µINS, µAHRS, or µIMU. Once the correct COM port is selected data will immediately begin to be

received.

2.4 Connecting To Your Unit

A serial port is the standard interface on the µINS, µAHRS, and µIMU. The EVB provides an optional RS232 and

USB interface to the serial ports. When the EVB USB port is connected to a PC, it will appear as a virtual com port

to Ser1. Both the EvalTool and the InertialSenseCLTool project connect using a serial port. The baud rate can be

configured by modifying the ser0BaudRate or ser1BaudRate fields of DID_FLASH_CONFIG, which can be accessed

in the DataSets tab of the EvalTool.

Table 1 – Serial Communication Ports

Serial

Port

µINS, µAHRS,

µIMU Pins

Interface Type

EVB Pins

Interface Type

Ser 0 18,19 (Rx,Tx)

TTL

H4: 3,4 (Rx,Tx)

TTL, RS232,

USB (default)

Ser 1 6,7 (Rx,Tx)

TTL

H6: 4,5 (Rx,Tx)

TTL, RS232,

RS485/RS422, USB

EVB USB connection toggles between Ser0 and Ser1 by setting “USB” jumpers.

User Manual

© 2017 Inertial Sense, LLC 6 11/30/2017

2.5 System LED and Solution Status

Each unit is equipped with an RGB LED on the top face. This LED indicates the unit’s system and solution status and

can pulse various combinations of the behaviors listed below.

LED Behavior

Status

Description

White

1

Solution Aligning

The solution is aligning on startup.

Cyan

2

Solution Alignment

Complete

The solution has aligned but insufficient dynamics have

been completed for the variance to reach nominal

conditions.

Green

3

Solution Good – NAV

The solution is in Navigation mode and state estimate is

good.

Blue

5

Solution Good – AHRS

The solution is in AHRS mode and state estimate is good.

There is no valid position or velocity data from GPS or

other aiding sensor. Only the attitude states are

estimated.

Orange

4 6 Solution High Variance

The solution is in Navigation or AHRS mode but variance

(uncertainty) is high. This may be caused by excessive

sensor noise such as vibration, magnetic interference, or

poor GPS visibility or multipath errors. See

DID_INL2_VARIANCE.

Purple

Magnetometer

Recalibration

The system is collecting new magnetometer calibration

data and requires rotation.

Purple fast blink

Firmware Upload

The bootloader is uploading the embedded firmware.

Orange fast blink

Firmware Verification

The bootloader is verifying the embedded firmware.

Red

Bootloader Failure

The bootloader has experienced a failure on startup.

Can combine with behaviors above

Red/purple pulse every 1s

RTK Base Data Received

The system is receiving RTK base station data.

Purple pulse every 1s

RTK Fix Status

The GPS has valid RTK fix and high precision positioning.

Red pulse every 1s

GPS PPS Sync

The system has received and synchronized local time to

UTC time using the GPS PPS signal.

2.6 Inertial Sense CLTool

The Inertial Sense CLTool is a command line utility that can be used to read and display data, update firmware, and

log data from Inertial Sense products. Additionally, CLTool serves as example source code that demonstrates

integration of the Inertial Sense SDK into your own source code. The CLTool can be compiled in Linux, Mac,

Windows and embedded platforms.

2.6.1 Compiling in Linux/Mac

1. Create build directory.

$ cd InertialSenseCLTool

$ mkdir build

2. Run cmake from within build directory.

$ cd build

User Manual

© 2017 Inertial Sense, LLC 7 11/30/2017

$ cmake ..

3. Compile using make.

$ make

4. Add current user to the "dialout" group in order to read and write to the USB serial communication ports:

$ sudousermod -a -G dialout $USER

$ sudousermod -a -G plugdev $USER

(reboot computer)

5. Run executable

$ ./bin/cltool

2.6.2 Compiling in Windows (MS Visual Studio)

1. Open Visual Studio solution file (<Path to SDK>/InertialSenseCLTool/VS_project/InertialSenseCLTool.sln).

2. Build (F7).

2.6.3 Running CLTool

The Windows executable is “cltool.exe” and the Linux/Mac executable is “cltool”.

2.6.3.1 Command Line Options

Run the CLTool with the “-h” option to display the command line options.

$ ./bin/cltool -h

DESCRIPTION

Command line utility for communicating, logging, and updating

firmware with Inertial Sense product line.

EXAMPLES

cltool -c=/dev/ttyS2 # stream post processing data (PPD) with INS2 (default)

cltool -c=/dev/ttyS2 -lon -lts=1 # logging to timestamp directory, stream PPD + INS2 data

cltool -c=/dev/ttyS2 -lon -msgSol=3 # logging, stream PPD + INS3 data

cltool -c=/dev/ttyS2 -baud=115200 -msgINS2 -msgGPS -msgBaro # stream multiple data sets at 115200 baud rate

cltool -c=/dev/ttyS2 -msgSol=0 # disable solution stream

cltool -rp=logs/20170117_222549 # replay log files from a folder

cltool -c=/dev/ttyS2 -b= fw/IS_uINS-3.hex # bootload firmware

cltool -c=* -baud=921600 # 921600 mbps baudrate on all serial ports

OPTIONS (General)

-h --help display this help menu

-c=COM_PORT select the serial port. Set COM_PORT to "*" for all ports and "*4"

to use only the first four ports. Not specifying this parameter is same as “-c=*”

-baud=BAUDRATE set serial port baudrate. Options: 115200, 230400, 460800, 921600, 3000000 (default)

-b=FILEPATH bootload firmware using .hex file FILEPATH

-q quite mode, no display

-s scroll displayed messages to show history

-stats display statistics of data received

OPTIONS (Solution Streaming)

-msgSol[n] Post Process Data (PPD) = DID_GPS + DID_MAGNETOMETER1 + DID_MAGNETOMETER2 +

DID_BAROMETER + DID_FLASH_CONFIG. Use -msgSol0 to disable solution streaming.

n= 1: PPD + DID_DUAL_IMU + DID_INS1

n= 2: PPD + DID_DUAL_IMU + DID_INS2 (recommended default)

n= 3: PPD + DID_DUAL_IMU + DID_INS3

n= 4: PPD + DID_DUAL_IMU + DID_INS4

n=11: PPD + DID_DELTA_THETA_VEL + DID_INS1

n=12: PPD + DID_DELTA_THETA_VEL + DID_INS2

n=13: PPD + DID_DELTA_THETA_VEL + DID_INS3

n=14: PPD + DID_DELTA_THETA_VEL + DID_INS4

INS output only without PPD

n=21: DID_INS1, n=22: DID_INS2, n=23: DID_INS3, n=24: DID_INS4

OPTIONS (Message Streaming)

-msgINS[n] message DID_INS_[n], where [n] = 1, 2, 3 or 4 (without brackets)

-msgIMU[n] message DID_IMU_[n], where [n] = 1 or 2 (without brackets)

-msgDualIMU message DID_DUAL_IMU

-msgDThetaVel message DID_DELTA_THETA_VEL

-msgMag[n] message DID_MAGNETOMETER_[n], where [n] = 1 or 2 (without brackets)

-msgBaro message DID_BAROMETER

-msgGPS message DID_GPS

-msgSensors message DID_SYS_SENSORS

OPTIONS (Logging to file, disabled by default)

User Manual

© 2017 Inertial Sense, LLC 8 11/30/2017

-lon enable logging

-lp=PATH log data to path (default: IS_logs)

-lms=PERCENT log max space in percent of free space (default: 0.5)

-lmf=BYTES log max file size in bytes (default: 5242880)

-lmm=BYTES log max memory in bytes (default: 131072)

-lts=0 log sub folder, 0 or blank for none, 1 for timestamp, else use as is

-r replay data log from default path

-rp=PATH replay data log from PATH

-rs=SPEED replay data log at x SPEED

OPTIONS (Read or write flash configuration)

-flashConfig=. - read flash config and display.

-flashConfig=key=value|key=value - set key / value pairs in flash config.

OPTIONS (Client / server)

-svr=connectionInfo, used to retreive external data and send to the uINS. Examples:

For retrieving RTCM3 data: -svr=RTCM3:192.168.1.100:7777:url:user:password - url, user and password optional.

For retrieving SERIAL data: -svr=RTCM3:SERIAL:COM9:57600 (port, baud).

For retrieving InertialSense data: -svr=IS:192.168.1.100:7777 - no url, user or password.

For retrieving UBLOX data: -svr=UBLOX:192.168.1.100:7777 - no url, user or password.

-host=ipAndPort, used to host a tcp/ip InertialSense server.

Example: -host=:7777 or -host=192.168.1.43:7777. The ip address part is optional.

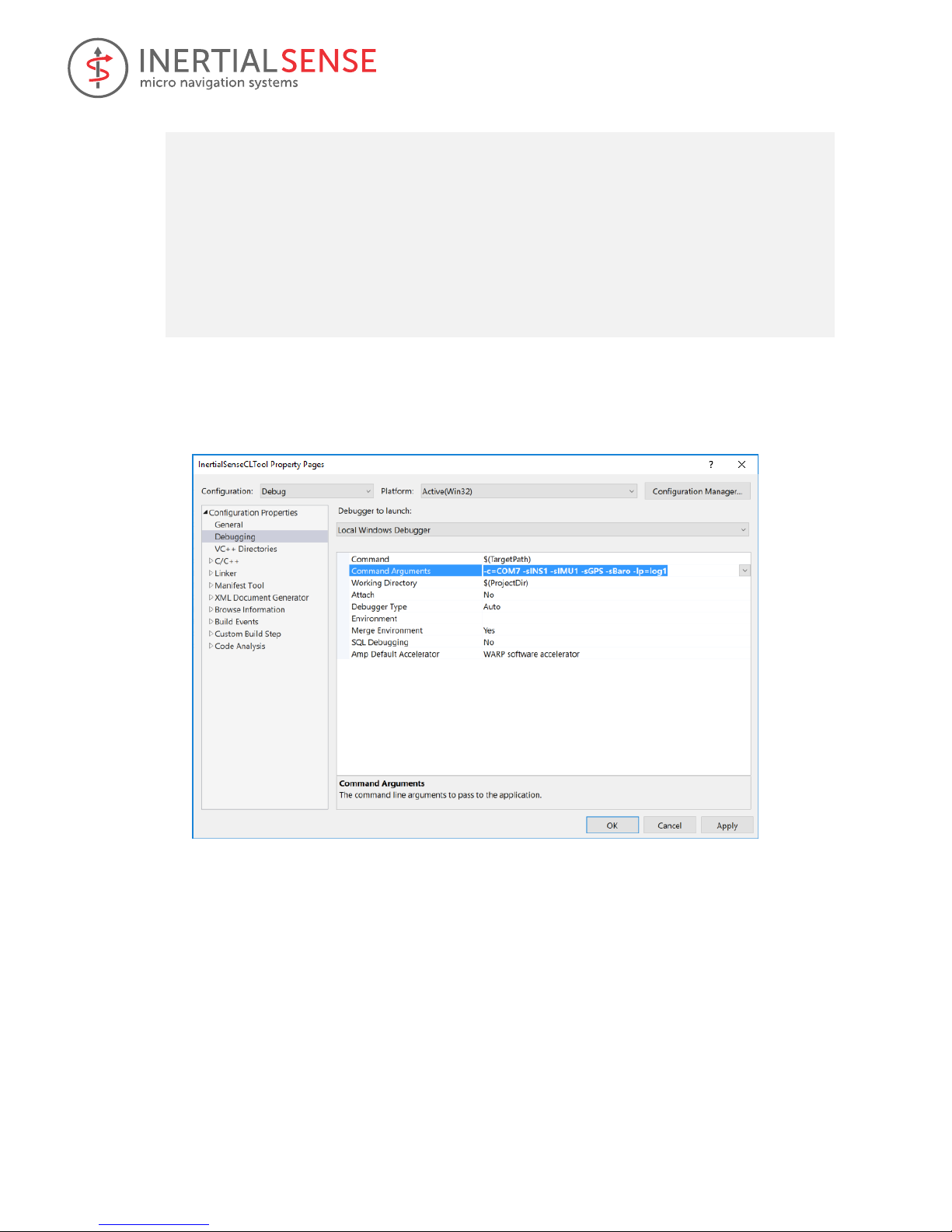

2.6.3.2 Command Line Options in MS Visual Studio

When using MS Visual Studio IDE, command line arguments can be supplied by right clicking the project in the

solution explorer and then selecting Configuration Properties -> Debugging -> Command Arguments (see image

below).

2.7 Additional Development

The basic methods of interfacing with the µINS, µAHRS, and µIMU have been shown. Additional development, such

as configuring the system, calibrating the magnetometer and logging data, can be taken and instructions constitute

the remainder of this manual.

User Manual

© 2017 Inertial Sense, LLC 9 11/30/2017

3 Coordinate Frames

In this manual, coordinate frame systems are simply referred to as frames. This section is to assist the developer in

choosing and implementing the appropriate coordinate frames for their respective application. It should be noted

that the following frames are in relation to the uINS itself.

3.1 Sensor Frame

IMU, magnetometer, and INS velocity data are in the Sensor Coordinate Frame, or Sensor Frame, and are

identified by the X, Y, and Z axes labeled on the hardware. The z-axis is positive down into the image.

3.2 INS Output Frame

The INS output data (DID_INS_1, DID_INS_2, DID_INS_3) is in the INS Output Frame. Translation from Sensor

Frame to INS Output Frame is defined as:

1. Sensor Frame → Intermediate Output Frame by rotation of DID_FLASH_CONFIG.insRotation euler angles

(in order of heading, pitch, roll angle) In radians.

2. Intermediate Output Frame → INS Output Frame: Offset by DID_FLASH_CONFIG.insOffset in meters.

If DID_FLASH_CONFIG.insRotation and DID_FLASH_CONFIG.insOffset are zero, the Sensor Frame and the INS

Output Frame are the same.

3.3 North-East-Down (NED) Frame

Position estimates can be output in the North-East-Down (NED) coordinate frame defined as follows:

• Right-handed, Cartesian, non-inertial, geodetic frame with origin located at the surface of Earth (WGS84

ellipsoid).

• Positive X-axis points towards North, tangent to WGS84 ellipsoid.

• Positive Y-axis points towards East, tangent to WGS84 ellipsoid.

• Positive Z-axis points down into the ground completing the right-handed system.

3.4 Earth-Centered Earth-Fixed (ECEF) Frame

The Earth-Centered Earth-Fixed (ECEF) frame is defined as follows:

• Right-handed, Cartesian, non-inertial frame with origin located at the center of Earth.

• Fixed to and rotates with Earth.

• Positive X-axis aligns with the WGS84 X-axis, which aligns with the International Earth Rotation and

Reference Systems Service (IERS) Prime Meridian.

X

+Roll

Z

+Yaw

Y

+Pitch

X

+Roll

Z

+Yaw

Y

+Pitch

User Manual

© 2017 Inertial Sense, LLC 10 11/30/2017

• Positive Z-axis aligns with the WGS84 Z-axis, which aligns with the IERS Reference Pole (IRP) that points

towards the North Pole.

• Positive Y-axis aligns with the WGS84 Y-axis, completing the right-handed system.

3.5 Translation Between Coordinate Frames

This section is intended to be an example of how to rotate between frames using methods defined within the SDK.

For Example, converting body frame to NED frame is implemented by:

quatRot(vel_ned, DID_INS_2.qn2b, DID_INS_2.uvw);

User Manual

© 2017 Inertial Sense, LLC 11 11/30/2017

4 Hardware Integration

4.1 Noise Coupling

To ensure that noise is not being coupled into the Inertial Sense sensor module designed into your product, it can

be compared with a stock EVB demo unit to compare noise figures. This is done by using the following steps. If

both steps pass, you can know there is no noise being coupled into the module. You may optionally connect more

than one sensor module to the EvalTool at a time to compare noise.

1. Evaluate the IMU sensor - Make sure the unit is stationary (on a table or non-moving surface) and not

seeing any vibrations. Watch the standard deviation column labeled "σ" in the Sensors tab of the

EvalTool. This shows the noise level over the past 5 seconds, which means the device needs to be

completely stable for 5 seconds to be accurate. Compare this figure between your integrated sensor

module and EVB demo unit.

2. Evaluate GPS sensitivity – In clear view of the sky, monitor the satellite signal strength through the

"DID_GPS_CNO" item in the "Data Sets" tab of the EvalTool. See that the strongest (largest) CNO values

are roughly the same between your integrated sensor module and the EVB demo unit.

4.2 Vibration Isolation

The system accuracy will degrade in the presence of constant vibrations that exceed 3 g of acceleration. Adding

vibration isolation to the mount may be necessary to reduce the vibrations seen by the product.

4.3 Sensitivity to Temperature Change

The system is designed to compensate for the effects of temperature drift, which can be found in typical

operation. However, rapid hardware temperature changes can result in degraded accuracy of the IMU calibration,

GPS position, and INS estimate. Rapid temperature change can be caused by direct exposure to wind, sun, and

other elements.

User Manual

© 2017 Inertial Sense, LLC 12 11/30/2017

5 SDK Library

This section describes the InertialSense Software Development Kit (SDK) used to communicate and interface with

the Inertial Sense products.

5.1 Binary Protocol

The Inertial Sense binary protocol provides the most efficient way to communicate with the µINS, µAHRS, and

µIMU. This section is provided to detail the packet and data structures format used in this binary protocol. You do

not need to be concerned with this section if you are using the Com Manager built-in binary interface, discussed

later in this manual. The µINS, µAHRS, and µIMU communicate using the following packet formatting:

Figure 1 - Packet Structure

Packet Header (4 bytes)

1 byte – packet start byte (0xFF)

1 byte – packet identifier, determines the format of packet data

1 byte – packet counter (for retries)

1 byte – flags, ePktHdrFlags enum

// in com_manager.h:

enum ePktHdrFlags

{

// bit set for little endian, bit cleared for big endian

CM_PKT_FLAGS_LITTLE_ENDIAN = 0x01,

// has any valid packet been received

CM_PKT_FLAGS_RX_VALID_DATA = 0x02,

// multi-packet data set

CM_PKT_FLAGS_MORE_DATA_AVAILABLE = 0x04,

// Allow for arbitrary length in bytes of data, not necessarily multiple of 4.

Don't auto-swap bytes for endianness

CM_PKT_FLAGS_RAW_DATA_NO_SWAP = 0x08,

// Checksum is the new 24 bit algorithm instead of the old 16 bit algorithm

CM_PKT_FLAGS_CHECKSUM_24_BIT = 0x10

};

Packet data (may be 0 bytes, depending on packet identifier)

Figure 2 – Packet Data Structure

User Manual

© 2017 Inertial Sense, LLC 13 11/30/2017

The format of the packet data is determined by the packet identifier. For a data packet (PID_DATA (4) or

PID_SET_DATA (5)) the first 12 bytes are always the data identifier (4 byte int), the offset into the data (4 byte int),

and the length of data (4 byte int, not including the 12 bytes or packet header / footer).

Packet footer (4 bytes)

1 byte – checksum byte A (most significant byte)

1 byte – checksum byte B (middle byte)

1 byte – checksum byte C (least significant byte)

1 byte – packet stop byte (0xFE)

The packet checksum is a 24-bit integer (little-endian) that can be created as follows:

- Start the checksum value at 0x00AAAAAA and skip the packet start byte

- Exclusive OR the checksum with the packet header (identifier, counter, and packet flags)

o checksum ^= packetId

o checksum ^= (counter << 8)

o checksum ^= (packetFlags << 16)

- Exclusive OR the checksum with each data byte in packet, repeating the following three steps, until all

data is included (i == dataLength).

o checksum ^= ( dataByte[i++] )

o checksum ^= ( dataByte[i++] << 8 )

o checksum ^= ( dataByte[i++] << 16 )

- Decode encoded bytes (bytes prefixed by 0xFD) before calculating checksum for that byte.

- Perform any endianness byte swapping AFTER checksum is fully calculated.

- The checksum is stored in the packet footer in little endian format (see packet footer structure above).

If your CPU architecture does not match the packet flags, you need to swap bytes appropriately. The SDK does this

for you automatically. Bytes 0x0A, 0x24, 0xB5, 0xD3, 0xFD, 0xFE and 0xFF are reserved bytes, with 0xFD being a

reserved byte prefix. When those bytes are written to a packet, they are prefixed with 0xFD and then written with

all the bits inverted. The packet start and end byte are never encoded. When calculating a checksum, decode the

byte if necessary first and then add the byte to the checksum calculation.

A raw packet can never be more than 2048 bytes. A decoded packet will never be more than 1024 bytes.

For a full example of encoding and decoding binary packets, please reference the following files in the SDK source:

com_manager.c, com_manager.h, data_structures.c and data_structures.h, and in particular, the functions

encodeBinaryPacket() and decodeBinaryPacket().

5.2 ASCII Protocol

For simple use, the Inertial Sense device can communicate back and forth using plain ASCII text. This format is

based on NMEA (http://www.gpsinformation.org/dale/nmea.htm). ASCII packets follow the NMEA 0183 structure

and have the following format:

1 byte – Start packet, always the $ byte (0x24)

n bytes (usually 4 or 5) – packet identifier

1 byte – a comma (0x2C)

n bytes – comma separated list of data, i.e. 1,2,3,4,5,6

1 byte – checksum marker, always the * byte (0x2A)

2 bytes – checksum in hex format (i.e. f5), 0 padded if necessary

2 bytes – End packet, always carriage return and line feed (\r\n or 0x0D, 0x0A)

User Manual

© 2017 Inertial Sense, LLC 14 11/30/2017

The packet checksum is an 8 bit integer and is calculated by calculating the exclusive OR of all bytes in between

and not including the $ and * bytes. The packet checksum byte is converted to a 2 byte ASCII hex code, and left

padded with 0 if necessary to ensure that it is always 2 bytes. The checksum is always lowercase hexadecimal

characters. See https://en.wikipedia.org/wiki/NMEA_0183#Message_structure for more details.

The hardware has the following built in messages that can be broadcast. These can be enabled by sending the

following ASCII packet:

5.2.1 ASCII Messages

The following ASCII messages are supported. Field codes are: lf = double, f = float, d = int.

ASCB – Enable ASCII message and set broadcast periods. The period is in milliseconds with no thousands

separator character. “xx” is the two-character checksum. Each field can be left blank in which case the

existing broadcast period for that field is not modified, or 0 to disable.

$ASCB,d,d,d,d,d,d,d,d,d*xx\r\n

Field

Units

Description

IMU

ms

Broadcast period for PIMU message

DTV

ms

Broadcast period for PDTV message

INS1

ms

Broadcast period for PINS1 message

INS2

ms

Broadcast period for PINS2 message

GPSP

ms

Broadcast period for PGPSPOS message

GPSV

ms

Broadcast period for PGPSVEL message

GGA

ms

Broadcast period for NMEA GPGGA message

GLL

ms

Broadcast period for NMEA GPGLL message

GSA

ms

Broadcast period for NMEA GPGSA message

STPB – Stopping all broadcasts (both binary and ASCII) can be accomplished by sending the following packet:

$STPB*15\r\n

PIMU – Dual IMU sensor data (two sets of 3-axis gyros and accelerometers) in the body frame.

$PIMU,lf,d,f,f,f,f,f,f,f,f,f,f,f,f *xx\r\n

Field

Units

Description

timeSinceBoot

sec

Time since system power up

IMU1 pqr[0]

rad/sec

IMU1 angular rate gyro – pitch

IMU1 pqr[1]

rad/sec

IMU1 angular rate gyro – roll

IMU1 pqr[2]

rad/sec

IMU1 angular rate gyro – yaw

IMU1 acc[0]

m/s2

IMU1 linear acceleration – X

IMU1 acc[1]

m/s2

IMU1 linear acceleration – Y

IMU1 acc[2]

m/s2

IMU1 linear acceleration – Z

IMU2 pqr[0]

rad/sec

IMU2 angular rate gyro – pitch

IMU2 pqr[1]

rad/sec

IMU2 angular rate gyro – roll

IMU2 pqr[2]

rad/sec

IMU2 angular rate gyro – yaw

IMU2 acc[0]

m/s2

IMU2 linear acceleration – X

IMU2 acc[1]

m/s2

IMU2 linear acceleration – Y

IMU2 acc[2]

m/s2

IMU2 linear acceleration – Z

PDTV – Delta theta velocity (conning and sculling integrals) in the body frame.

User Manual

© 2017 Inertial Sense, LLC 15 11/30/2017

$PDTV,lf,d,f,f,f,f,f,f,f *xx\r\n

Field

Units

Description

timeSinceBoot

sec

Time since system power up

dTheta[0]

rad

Delta theta integral – pitch

dTheta[1]

rad

Delta theta integral – roll

dTheta[2]

rad

Delta theta integral – yaw

dUVW[0]

m/s

Delta velocity integral – X

dUVW[1]

m/s

Delta velocity integral – Y

dUVW[2]

m/s

Delta velocity integral – Z

dt s Delta integral period

PINS1 – INS output with Euler angles and NED offset from the reference LLA.

$PINS1,lf,d,f,f,f,f,f,f,lf,lf,lf,f,f,f*xx\r\n

Field

Units

Description

timeOfWeek

sec

Seconds since Sunday morning in GMT

GPS week

weeks

Number of weeks since January 1st of 1980 in GMT

theta[0]

rad

Euler angle – pitch

theta[1]

rad

Euler angle – roll

theta[2]

rad

Euler angle – yaw

UVW[0]

m/s

Velocity in body frame – X

UVW[1]

m/s

Velocity in body frame – Y

UVW[2]

m/s

Velocity in body frame – Z

LLA[0]

deg

WGS84 Latitude

LLA[1]

deg

WGS84 Longitude

LLA[2]

m

Hight above ellipsoid (vertical elevation)

NED[0]

m

Offset from reference LLA – North

NED[1]

m

Offset from reference LLA – East

NED[2]

m

Offset from reference LLA – Down

PINS2 – INS output with quaternion attitude.

$PINS2,lf,d,f,f,f,f,f,f,lf,lf,lf*xx\r\n

Field

Units

Description

timeOfWeek

sec

Seconds since Sunday morning in GMT

GPS week

weeks

Number of weeks since January 1st of 1980 in GMT

qn2b[0]

Quaternion rotation (NED to body) – W

qn2b[1]

Quaternion rotation (NED to body) – X

qn2b[2]

Quaternion rotation (NED to body) – Y

qn2b[3]

Quaternion rotation (NED to body) – Z

UVW[0]

m/s

Velocity in body frame – X

UVW[1]

m/s

Velocity in body frame – Y

UVW[2]

m/s

Velocity in body frame – Z

Latitude

deg

WGS84 Latitude

Longitude

deg

WGS84 Longitude

Altitude

m

Height above ellipsoid (vertical elevation)

NED[0]

m

Offset from reference LLA – North

NED[1]

m

Offset from reference LLA – East

NED[2]

m

Offset from reference LLA – Down

User Manual

© 2017 Inertial Sense, LLC 16 11/30/2017

Fields: timeOfWeek, weeks, roll, pitch, yaw, velocity u, velocity v, velocity w, latitude, longitude, altitude

PGPSP – GPS position data.

$PGPSP,d,d,d,lf,lf,lf,f,f,f,f*xx\r\n

Field

Units

Description

GPS week

weeks

Number of weeks since January 1st of 1980 in GMT

timeMsOfWeek

ms

Milliseconds since Sunday morning in GMT

status

[7:0] number of satellites used in solution,

[15:8] status flags, [23:16] fix type.

See the eGpsStatus maks in SDK data_sets.h for

details.

Latitude

deg

WGS84 Latitude

Longitude

deg

WGS84 Longitude

HAE altitude

m

Height above ellipsoid elevation

MSL altitude

m

Mean sea level elevation

pDOP

m

Position dilution of precision

hAcc

m

Horizontal accuracy

vAcc

m

Vertical accuracy

PGPSV – GPS velocity data.

$PGPSV,d,f,f,f,f,f,f,f,f*xx\r\n

Field

Units

Description

timeMsOfWeek

ms

Milliseconds since Sunday morning in GMT

Velocity north

m/s

Velocity in local tangent plane – North

Velocity east

m/s

Velocity in local tangent plane – East

Velocity down

m/s

Velocity in local tangent plane – Down

s2D

m/s

Ground speed magnitude

s3D

m/s

Speed magnitude

sAcc

m/s

Speed accuracy

course

rad

Velocity ground course (heading)

cAcc

rad

Velocity ground course (heading) accuracy

GPGGA – NMEA global positioning system fix (see NMEA GPGGA specification).

$GPGGA,123519,4807.038,N,01131.000,E,1,08,0.9,545.4,M,46.9,M,,*47

Where:

GGA Global Positioning System Fix Data

123519 Fix taken at 12:35:19 UTC

4807.038,N Latitude 48 deg 07.038' N

01131.000,E Longitude 11 deg 31.000' E

1 Fix quality:

0 = invalid

1 = GPS fix (SPS)

2 = DGPS fix

3 = PPS fix

4 = Real Time Kinematic

5 = Float RTK

6 = estimated (dead reckoning) (2.3 feature)

7 = Manual input mode

8 = Simulation mode

08 Number of satellites being tracked

0.9 Horizontal dilution of position

545.4,MMSL altitude in meters

46.9,MHAE altitude (above geoid / WGS84 ellipsoid)

(empty field) time in seconds since last DGPS update

(empty field) DGPS station ID number

User Manual

© 2017 Inertial Sense, LLC 17 11/30/2017

GPGLL – NMEA geographic position, latitude / longitude and time (see NMEA GPGLL specification).

$GPGLL,3751.65,S,14507.36,E*77

$GPGLL,4916.45,N,12311.12,W,225444,A

Where:

4916.46,N Latitude 49 deg. 16.45 min. North

12311.12,W Longitude 123 deg. 11.12 min. West

225444 Fix taken at 22:54:44 UTC

A Data valid

$GPGLL,5133.81,N,00042.25,W*75

1 2 3 4 5

Where:

1 5133.81 Current latitude

2 N North/South

3 00042.25 Current longitude

4 W East/West

5 *75 checksum

$--GLL,lll.ll,a,yyyyy.yy,a,hhmmss.ss,A llll.ll = Latitude of position

Where:

a = N or S

yyyyy.yy = Longitude of position

a = E or W

hhmmss.ss = UTC of position

A = status: A = valid data

GPGSA – NMEA GPS DOP and active satellites (see NMEA GPGSP specification).

$GPGSA,A,3,04,05,,09,12,,,24,,,,,2.5,1.3,2.1*39

Where:

GSA Satellite status

A Auto selection of 2D or 3D fix (M = manual)

3 3D fix - values include: 1 = no fix

2 = 2D fix

3 = 3D fix

04,05... PRNs of satellites used for fix (space for 12)

2.5 PDOP (dilution of precision)

1.3 Horizontal dilution of precision (HDOP)

2.1 Vertical dilution of precision (VDOP)

5.3 C Binding

For pure C solutions such as embedded systems or situations where memory is limited, the C binding is provided.

The C binding contains an interface for communicating with the device using the binary protocol, as well as

updating firmware (discussed later).

5.3.1 Connecting to the Device

Communication with the device is done via serial port, so the first step in getting set up is to create a serial port

connection. Depending on the platform you are on, there may be some set up to implement the methods

necessary to open, read, write, and close the serial port. For Windows, Mac and Linux, this interface is provided for

you, but for other platforms you will need to implement this functionality.

SDK/src/serialPort.h defines the interface structure for serial port data. serialPortPlatform.c provides Windows,

Mac, and Linux implementations of a serial port for you.

To create and open a serial port, do the following:

serial_port_t serialPort = { 0 }; // must be zeroed out fully

serialPortPlatformInit(&serialPort);

serialPortOpen(&serialPort, "COM4", 3000000, 0); // 0 for non-blocking

If you need to write your own serial port code, you will need to provide the following functions to the serial_port_t

structure instead of calling serialPortPlatformInit:

User Manual

© 2017 Inertial Sense, LLC 18 11/30/2017

typedefint(*pfnSerialPortOpen)(serial_port_t* s, constchar* port, intbaudRate,

intallowPartialReads);

typedefint(*pfnSerialPortRead)(serial_port_t* s, unsignedchar* buf, intlen,

inttimeoutMilliseconds);

typedefint(*pfnSerialPortWrite)(serial_port_t* s, constunsignedchar* buf, intlen);

typedefint(*pfnSerialPortClose)(serial_port_t* s);

typedefvoid(*pfnSerialPortSleep)(serial_port_t* s, intwaitMilliseconds);

// Allows communicating over a serial port

struct serial_port_t

{

pfnSerialPortOpenpfnOpen;

pfnSerialPortReadpfnRead;

pfnSerialPortWritepfnWrite;

pfnSerialPortClosepfnClose;

pfnSerialPortSleeppfnSleep;

};

5.3.2 Communicating with the device

Step-by-step instructions for implementing the Inertial Sense Com Manager and communicating with the µINS,

µAHRS, or µIMU are found in the InertialSenseCLTool project file, main.cpp. This file contains certain keywords

that identify the specific function calls necessary to implement the SDK. Use your search tool to find each of these

steps and its corresponding description in this file.

Instructional keywords found in main.cpp:

KEYWORD - SDK IMPLEMENTATION

"// [COMM INSTRUCTION]" - Communications (open, read, etc.)

"// [LOGGER INSTRUCTION]" - Log data

"// [REPLAY INSTRUCTION]" - Data log replay

"// [BOOTLOADER INSTRUCTION]" - Firmware bootloader

5.3.3 Updating Firmware (Bootloader)

The C binding contains easy-to-use functions to allow uploading firmware to the device. inertialSenseBootloader.h

contains the interface to use when you need to update firmware.

For example:

static int bootloadUploadProgress(const void* serialPort, floatpercent)

{

printf("Boot load upload: %d%% \r", (int)(percent * 100.0f));

if (percent == 1.0f)

{

printf("\r\n");

}

return 1; // could return 0 to abort

}

static int bootloadVerifyProgress(const void* serialPort, floatpercent)

{

printf("Boot load verify: %d%% \r", (int)(percent * 100.0f));

if (percent == 1.0f)

{

printf("\r\n");

}

return 1; // could return 0 to abort

}

void main()

{

User Manual

© 2017 Inertial Sense, LLC 19 11/30/2017

serial_port_t serialPort = { 0 };

serialPortPlatformInit(&serialPort);

serialPortSetPort(&serialPort, "COM4");

char error[128];

enableBootloader(&serialPort, error, sizeof(error));

if (error[0] != '\0')

{

printf("Error enabling boot loader: %s", error);

}

else if (!bootloadFile(bootloadPath, &serialPort, error, sizeof(error),

&serialPort, bootloadUploadProgress, bootloadVerifyProgress))

{

printf("Bootload error: %s\n", error);

}

}

The firmware process takes a few seconds to fully initialize, so you may not see progress right away. In addition,

once the progress reaches 100% there may be some clean-up and final processing that will happen before the

verify step begins.

The SDK supports two file types, a .hex (Intel hex) file or a .bin (Inertial Sense firmware binary) file. The .bin file is

smaller and requires very little memory to upload to the device, so it is ideal for cases where storage and/or

memory is constrained.

5.4 C++ Binding

A higher level, C++ class is provided to simplify the process of communicating with the binary protocol, logging or

updating firmware. Please reference InertialSense.h /.cpp in the InertialSenseSDK for more details. The

InertialSenseCLTool is an example source code project that illustrates how to implement the InertialSenseSDK.

User Manual

© 2017 Inertial Sense, LLC 20 11/30/2017

6 Binary Protocol Data Sets

Data Sets in the form of C structures are available through binary protocol and provide access to system

configuration and output data. The data sets are defined in SDK/src/data_sets.h of the InertialSense SDK.

6.1 Configuration

6.1.1 DID_FLASH_CONFIG

The data set contains various nonvolatile system configuration parameters that are stored in flash memory and

applied at startup. Many of these parameters only take effect after system restart.

Field

Type

Description

ser0BaudRate

uint32_t

Serial port 0 baud rate (9,600 - 3,000,000 baud) applied at startup.

ser1BaudRate

uint32_t

Serial port 1 baud rate (9,600 - 3,000,000 baud) applied at startup.

InsRotation[3]

float

Roll, pitch, yaw rotation in radians from INS computational frame to INS

output frame. Order applied: heading, pitch, roll.

InsOffset[3]

float

X,Y,Z offset to INS output (in INS output frame) in meters. INS rotation is

applied before this.

gpsAntOffset[3]

float

X,Y,Z offset from IMU origin (in IMU frame) to GPS antenna in meters.

sysCfgBits

uint32_t

0x1=DisableAutobaud,

0x2=AutoMagRecal,

0x4=DisableLeds,

0x8=SendLittleEndian

0x10=Output U-blox raw data

0x20=RTK Rover

0x40=RTK Base Station

0x100=Single-Axis Magnetometer Calibration

6.2 Using Com Manger to Write Data Set Parameter

The following is an example on modifying data set parameters. In this example, we are changing the INS output

rotation.

// Set INS output Euler rotation in radian

float rotation[3] = { 0.0f, 0.0f, 3.1415f };

sendDataComManager (0, DID_FLASH_CONFIG, &rotation, 12, offsetof(nvm_flash_cfg_t, insRotation));

User Manual

© 2017 Inertial Sense, LLC 21 11/30/2017

7 System Health and Status Flags

Status flags described in this section that can be observed by bitwise ANDing any of the status flag bitmasks with

the corresponding status flags variable.

7.1 Status Flags

This section lists the commonly used status flags. A complete listing of status flags is available in data_sets.h.

7.1.1 insStatus – INS Status Flags

The INS status flags, insStatus, are found in the DID_INS1, DID_INS2, DID_INS3, and DID_SYS_PARAMS messages.

Bitmasks for the insStatus flags are defined in eInsStatusFlags in data_sets.h.

Field

Description

INS_STATUS_ALIGN_COARSE_MASK

Position, Velocity & Attitude are usable. Variance of the

state estimate are outside spec.

INS_STATUS_ALIGN_GOOD_MASK

Position, Velocity & Attitude are good. Variance of state

estimate are within spec

INS_STATUS_USING_GPS_IN_SOLUTION

GPS is being fused into the INS

INS_STATUS_USING_MAG_IN_SOLUTION

Magnetometer is being fused into the INS

INS_STATUS_NAV_MODE

AHRS = 0 (no position or velocity), NAV = 1

INS_STATUS_MAG_RECALIBRATING

Magnetometer is recalibrating

INS_STATUS_MAG_NOT_GOOD

Magnetometer is experiencing interference

INS_STATUS_SOLUTION_MASK

0=INS_INACTIVE – The INS is not runnning

1=INS_ALIGNING – The INS is aligning on startup

2=INS_ALIGNMENT_COMPLETE – The INS has aligned but

insufficient dynamics have been completed for the variance

to reach nominal conditions.

3=INS_NAV_IS_GOOD – The INS is in NAV mode and the

state estimate is good.

4=INS_NAV_HIGH_VARIANCE – The INS is in NAV mode and

the state estimate is experiencing high variance. This may be

caused by excessive noise on one or more sensors, such as

vibration, magnetic interference, poor GPS sky visibility

and/or GPS multipath errors. See DID_INL2_VARIANCE.

5=INS_AHRS_IS_GOOD – INS is in AHRS mode and the

solution is good. There is no valid position correction data

from GPS or other aiding sensor. Only the attitude states

are estimated.

6=INS_AHRS_HIGH_VARIANCE – INS is in AHRS mode and

the state estimate has high variance. See

DID_INL2_VARIANCE.

7.1.2 hdwStatus – Hardware Status Flags

The hardware status flags, hdwStatus, are found in the DID_INS1, DID_INS2, DID_INS3, and DID_SYS_PARAMS

messages. Bitmasks for the hdwStatus flags are defined in eHdwStatusFlags in data_sets.h.

Field

Description

HDW_STATUS_MOTION_MASK

Accelerometers and Gyros are operational

HDW_STATUS_GPS_SATELLITE_RX

Antenna is connected to the receiver

HDW_STATUS_SATURATION_MASK

Acc., Gyro, Mag or Baro is saturated

HDW_STATUS_SELF_TEST_FAULT

BIT has failed

User Manual

© 2017 Inertial Sense, LLC 22 11/30/2017

HDW_STATUS_ERR_TEMPERATURE

Outside of operational range

HDW_STATUS_FAULT_BOD_RESET

Low Power Reset

HDW_STATUS_FAULT_POR_RESET

Software or Triggered Reset

7.1.3 Built-in test (BIT) Flags

Built-in test (BIT) is enabled by setting DID_BIT.state = 2. BIT takes about 1 second to run, and is completed when

DID_BIT.state == 1. All BIT tests except those related to GPS require the system to be stationary to be accurate.

7.1.3.1 hdwBitStatus – Hardware BIT Flags

Hardware BIT flags are contained in hdwBitStatus, found in the DID_BIT message. Bitmasks for the hdwBitStatus

flags are defined in eHdwBitStatusFlags in data_sets.h.

Field

Description

HDW_BIT_PASSED_ALL

All HBIT are passed

HDW_BIT_PASSED_AHRS

All Self Tests passed without GPS signal

HDW_BIT_FAULT_GPS_NO_COM

No GPS Signal

HDW_BIT_FAULT_GPS_POOR_CNO

Poor GPS signal. Check Antenna

HDW_BIT_FAULT_GPS_ACCURACY

Poor GPS Accuracy or Low number of satellites

7.1.3.2 calBitStatus – Calibration BIT Flags

Calibration BIT flags are contained in calBitStatus, found in the DID_BIT message. Bitmasks for the calBitStatus

flags are defined in eCalBitStatusFlags in data_sets.h.

Field

Description

CAL_BIT_PASSED_ALL

Passed All Calibration Checks

7.2 Typical Health Monitoring

This section illustrates tests used for system health monitoring in common application.

1. Communication Check

To check that cabling between the unit and your application is working after initialization, expect that the

initial expected packets are received within 3 seconds.

2. Sensor Test (Must be Stationary)

These tests are ideal for manufacturing and periodic in-field testing. Initiate by setting DID_BIT.state = 2.

Test

Description

hdwBitStatus & HDW_BIT_PASSED_ALL

Hardware is good

calBitStatus & CAL_BIT_PASSED_ALL

Sensor calibration is good

3. GPS Hardware Test

Initiate by setting DID_BIT.state = 2.

Test

Description

hdwBitStatus & HDW_BIT_FAULT_GPS_NO_COM

No GPS serial communications.

hdwBitStatus & HDW_BIT_FAULT_GPS_POOR_CNO

Poor GPS signal strength. Check antenna.

4. GPS Lock Test

Test

Description

hdwStatus & INS_STATUS_USING_GPS_IN_SOLUTION

GPS is being fused into INS solution

5. INS Output Valid

User Manual

© 2017 Inertial Sense, LLC 23 11/30/2017

Test

Description

insStatus & INS_STATUS_ATT_ALIGN_GOOD

Attitude estimates are valid

insStatus & INS_STATUS_VEL_ALIGN_GOOD

Velocity estimates are valid

insStatus & INS_STATUS_POS_ALIGN_GOOD

Position estimates are valid

6. System Temperature

System temperature is available at DID_SYS_SENSORS.temp.

7. Communications Errors

HDW_STATUS_COM_PARSE_ERROR_COUNT(DID_SYS_SENSORS.hStatus) is the number of parsed packet

errors encountered.

User Manual

© 2017 Inertial Sense, LLC 24 11/30/2017

8 Magnetometer Calibration

The magnetometer is used to estimate heading when the system is in any of the following conditions:

1.) is in AHRS mode

2.) has no GPS fix

3.) has GPS fix and constant velocity (non-accelerating motion)

To have accurate heading under these conditions, the magnetometer must be calibrated. The system allows for

two types of modes for recalibration, external initiated and automatically initiated re-calibration. Regardless of the

recalibration mode, a slower online background calibration runs that continuously improves the magnetometer

calibration to handle local magnetic environment changes. All magnetometer calibration is stored in flash

memory and available on bootup.

8.1 Magnetometer Recalibration

Occasionally the magnetometer will require a complete recalibration, replacing the old calibration with an entirely

new calibration. This is accomplished either through external or automatic initiated recalibration. Use of the

different modes is generally governed by the particular use case for the end customer and is intended to allow for

the most flexibility in an integrated product design.

8.1.1 External Recalibration

External magnetometer recalibration allows the most flexibility in determining when an end user will need to

recalibrate the system. This control over the timing of the recalibration is critical for many use cases and allows

product designers to implement their desired workflows for customers. Further there are use cases where

automatic recalibration is not possible because the quality of the magnetometer calibration is not observable. Such

use cases would include AHRS operation, extended periods without motion or no GNSS fix. External magnetometer

recalibration, as the name suggests is triggered by an external command from the application managing the uINS

hardware. The uINS provides a set of status messages indicating the quality of the magnetometer calibration and

leaves the timing and implementation of a recalibration up to the product designer. Specifically,

INS_STATUS_MAG_NOT_GOOD is an indication of the quality of the magnetometer calibration (see chapter 6 for

more details on the indicators.

During the calibration process, the system should be clear of steel, iron, magnets, or other ferrous materials (i.e.

steel desks, tables, building structures). The uINS should be attached to the system in which it is operating and

rotated together during the calibration process. The following is the

Force magnetometer recalibration procedure:

1. Set DID_MAG_CAL.enMagRecal to either:

a. “0” for Multi-Axis which is more accurate and requires 360⁰ rotation about two different axes.

b. “1” for Single-Axis which is less accurate and requires 360⁰ rotation about one axis.

2. Rotate the system accordingly.

Recalibration completion is indicated by either:

1. INS_STATUS_MAG_RECALIBRATING bit of the insStatus word set to zero. The insStatus word is found in

standard INS output messages (DID_INS_1, DID_INS_2, DID_INS_3, and DID_INS_4).

2. DID_MAG_CAL.enMagRecal set to 100.

Recalibration progress is indicated as a percentage (0-100%) is indicated can be observed from variable

DID_MAG_CAL.progress.

The “Mag used” indicator in the EvalTool INS tab will be green when magnetometer data is being fused into the

solution, black when not being fused into the solution, and red during recalibrating.

User Manual

© 2017 Inertial Sense, LLC 25 11/30/2017

8.1.2 Automatic Recalibration

Automatic magnetometer recalibration is useful for systems where user intervention to start external calibration is

not convenient or practical. In this mode, the solution will determine that the system needs to be recalibrated and

will attempt to do so while in normal operation. In the period while the system is recalibrating, the uncalibrated

magnetometer data is used to prevent the INS heading from drifting but it does not provide heading

measurements to the state estimator. This feature is enabled by setting the SYS_CFG_BITS_AUTO_MAG_RECAL bit

of DID_FLASH_CONFIG.sysCfgBits non-volatile word.

// Enable automatic magnetometer calibration.

DID_FLASH_CONFIG.sysCfgBits |= SYS_CFG_BITS_AUTO_MAG_RECAL;

// Disable automatic magnetometer calibration.

DID_FLASH_CONFIG.sysCfgBits &= ~SYS_CFG_BITS_AUTO_MAG_RECAL;

8.2 Magnetometer Continuous Calibration

To mitigate the need for recalibration (completely replace calibration data), continuous calibration improves the

magnetometer calibration slowly over time. Continuous calibration always runs in the background.

8.3 Magnetometer Calibration Settings

The magnetometer calibration algorithm can produce higher quality calibrations when data more data is collected

across multiple axes of rotation. However, there are use cases where data collection beyond a single axis is

impractical if not impossible. To address this issue there is a setting in the flash to configure the data requirement

threshold for magnetometer calibration. The available settings include:

• Single Axis Calibration – This setting requires a full rotation in the yaw axis (relative to earth) to

determine the calibration. Additional data that is collected via motion on other axes is used but not

required. Once a full rotation is completed the calibration is calculated and the online continuous

calibration is started.

• Multi Axis Calibration – This setting requires data to be collected across at least two axes, where one is

the yaw axis. This calibration mode does not have any specific angular rotational requirements in any

given axes, but it does require that data has been collected across a sufficient angular span. There is an

indicator (mag_cal_threshold_complete) in the DID_SYS_PARAMS message that relates the total percent

of the required threshold that has been collected. As more data is collected this value will increment to

100% at which point the calibration will be calculated and the online continuous calibration will continue

to run

/*! Magnetometer recalibration. 0 = multi-axis, 1 = single-axis */

SYS_CFG_BITS_MAG_RECAL_MODE_MASK = (int)0x00000700,

SYS_CFG_BITS_MAG_RECAL_MODE_OFFSET = 8,

User Manual

© 2017 Inertial Sense, LLC 26 11/30/2017

9 Data Logging

Inertial Sense provides data loggers written in C++ , which can read and write data in various formats to file. These

loggers are useful for storing, replaying, and analyzing data. SDK/src/ISLogger.h defines the logging interface.

9.1 Log File

The data log file name has the format LOG_SNXXXXX_YYYYMMDD_HHMMSS_CNT.dat which contains the device

serial number, date, time, and log file count. The two primary log file formats are .dat and .sdat. These log files

consist of a series of data Chunks.

Data Log File

(.dat or .sdat)

=

CHUNK

1

CHUNK

2

CHUNK

3

CHUNK

4

…

CHUNK

N

Standard data types are stored in the log files and are defined as:

U32

unsigned int

U16

unsigned short

S8

char

U8

unsigned char

9.1.1 Log Chunk

The data log file is composed of Chunks. A Chunk is a data container that provides an efficient method for

organizing, handling, and parsing data in a file. A Chunk starts with a header which has a unique identifiable

marker and ends with the data to be stored.

CHUNK

=

CHUNK

Header

CHUNK

Data

Byte Size

40

9.1.2 Chunk Header

The header, found at the start of each Chunk, is as follows:

CHUNK

Header

=

Marker

Version

Classification

Name

Name

Inverted

Data

Size

Data

Size

Inverted

Group

Number

Device

Serial

#

Port

Handle

Reserved

Byte Size

4 2 2 4 4 4 4 4 4 4

4

Data Type

U32

U16

U16

S8 (x4)

S8 (x4)

U32

U32

U32

U32

U32

U32

The C structure implementation of the Chunk header is:

//!< Chunk Header

#pragma pack(push, 1)

struct sChunkHeader

{

Unsigned int marker; //!< Chunk marker (0xFC05EA32)

unsigned short version; //!< Chunk Version

unsigned short classification; //!< Chunk classification

char name[4]; //!< Chunk name

char invName[4]; //!< Bitwise inverse of chunk name

unsigned int dataSize; //!< Chunk data length in bytes

unsigned int invDataSize; //!< Bitwise inverse of chunk data length

unsigned int grpNum; //!< Chunk group number: 0=serial data, 1=sorted data

unsigned int devSerialNum; //!< Device serial number

unsigned int pHandle; //!< Device port handle

unsigned int reserved; //!< Unused

};

#pragma pack(pop)

User Manual

© 2017 Inertial Sense, LLC 27 11/30/2017

9.1.3 Chunk Data

The Chunk data is defined for both the .dat and .sdat file types.

CHUNK Data

(.dat file)

=

DATA

SET

Header

DATA SET

Data

DATA

SET

Header

DATA SET

Data

…

DATA

SET

Header

DATA SET

Data

Byte Size

12

12 12

CHUNK Data

(.sdat file)

=

CHUNK

Sub-

Header

DATA

SET

Serial #

DATA SET

Data

DATA

SET

Serial #

DATA SET

Data

…

DATA

SET

Serial #

DATA SET

Data

Byte Size

16 4 4 4

Data Type

U32

U32

U32

9.1.4 Chunk Sub-Header

The Chunk sub-header is used for .sdat file types.

.sdat CHUNK

Sub-Header

=

DATA SET

Header

DATA SET

Count

Byte Size

12

4

Data Type

U32

9.1.5 Data Set Header

The Data set header is used for both the .dat and .sdat file types.

DATA SET

Header

=

DATA SET

ID

DATA SET

Size

DATA SET

Offset

Byte Size

4 4

4

U32

U32

U32

9.2 Data Loggers

The following two data loggers are provided by Inertial Sense.

Serial Logger

Sorted Logger

Description

Stores data to file in the same serial

order it was passed into the logger. This

is the default logger used in the CLTool

and EvalTool.

Sorts data of similar types into separate

chunks, allowing for faster load times

into analysis tools.

Advantages

Optimized for real-time data logging.

Optimized for loading data into analysis

tools (i.e. Matlab, Python).

Source File

DeviceLogSerial.h / .cpp

DeviceLogSorted.h / .cpp

File extension

.dat

.sdat

9.3 EvalTool Data Logging

The EvalTool can be used to log data following the steps shown below.

1. Go to “Logger” tab in EvalTool.

2. Select the “Output” file type from the drop-down menu.

a. Comma separated (.csv) – ASCII format for Excel and other programs.

b. Serial binary (.dat) – binary format for Matlab.

c. Sorted binary (.sdat) – binary format for Python.

3. Select the “Log Mode” for the data you want to record.

User Manual

© 2017 Inertial Sense, LLC 28 11/30/2017

a. Manual Selection – allows the user to select the specific datasets to stream and their update

rates by setting the checkbox and period (ms) in Manual Selection table.

b. INS – log INS output (attitude, velocity, position) at 100 Hz.

c. Post Process – used with beta testers and internal testing. Includes IMU, GPS, INS and other

messages.

4. Press “Start Log” to begin logging data.

5. Press “Stop Log” to stop logging data.

6. The “Open Folder” button opens the File Explorer location to the data logs, i.e.

C:\Users\[username]\Documents\Inertial Sense\logs.

7. To change the root log folder in the Eval Tool, edit Documents/Inertial Sense/settings.json, and add or

change this key: "LOG_FOLDER": "FOLDER_FOR_LOGS".

User Manual

© 2017 Inertial Sense, LLC 29 11/30/2017

10 Plotting Log Files

Three methods of plotting are distributed with the IS-SDK, including Matlab, Python, and Excel. Each method of

plotting is only implemented to plot one specific file type. To plot with Matlab the data must be saved as *.dat file

type. To plot with Python the data must be saved as *.sdat file type. To plot with Excel the data must be saved as

*.csv file type. The EvalTool can be used to convert a *.dat or *.sdat data type into a *.dat, *.sdat, or *.csv data

type in the Logger tab > File Conversion Utility.

10.1 Matlab (*.dat)

To plot using matlab, open “main.m” and push run. A user interface will open asking you to, “Select Folder that

contains desired (.dat) log files to be read from.” Once you select the desired folder, the data will be read from the

files and plotted. If you desire to change which data types are plotted, open “plotData.m” and change the struct

“plotLog.[type]” to either a 1 or 0. “main.m” only needs to be run once, after which “plotData.m” can be run

multiple times.

10.2 Python (*.sdat)

The sorted data log (*.sdat) file format is provide for fast loading of uniform c type binary data from a file. It is the

fastest method for loading large data sets and is ideal for plotting data.

10.3 Excel (*.csv)

The comma separated value (.csv) file format can be imported into most software packages, including Excel,

Matlab, and Python.

User Manual

© 2017 Inertial Sense, LLC 30 11/30/2017

11 Troubleshooting

Please email support@inertialsense.com for help and assistance.

Inertial Sense LLC

72 N 720 E, Salem, UT 84653 USA

Phone 801-610-6771

Email support@inertialsense.com

Website InertialSense.com

© 2017 Inertial Sense

Inertial Sense®, Inertial Sense logo and combinations thereof are registered trademarks or trademarks of Inertial Sense LLC. Other terms and product

names may be trademarks of others.

DISCLAIMER: The information in this document is provided in connection with Inertial Sense products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Inertial Sense products. EXCEPT AS SET FORTH IN THE INERTIAL SENSE TERMS

AND CONDITIONS OF SALES LOCATED ON THE INERTIAL SENSE WEBSITE, INERTIAL SENSE ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY

EXPRESS, IMPLIED OR STATUTORY WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL INERTIAL SENSE BE LIABLE FOR ANY DIRECT,

INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS AND PROFITS, BUSINESS

INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF INERTIAL SENSE HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES. Inertial Sense makes no representations or warranties with respect to the accuracy or completeness of the contents of this

document and reserves the right to make changes to specifications and products descriptions at any time without notice. Inertial Sense does not make any commitment to

update the information contained herein. Unless specifically provided otherwise, Inertial Sense products are not suitable for, and shall not be used in, automotive applications.

Inertial Sense products are not intended, authorized, or warranted for use as components in applications intended to support or sustain life. SAFETY-CRITICAL, MILITARY,

AND AUTOMOTIVE APPLICATIONS DISCLAIMER: Inertial Sense products are not designed for and will not be used in connection with any applications where the failure of

such products would reasonably be expected to result in significant personal injury or death (“Safety-Critical Applications”) without an Inertial Sense officer's specific written

consent. Safety-Critical Applications include, without limitation, life support devices and systems, equipment or systems for the operation of nuclear facilities and weapons

systems. Inertial Sense products are not designed nor intended for use in military or aerospace applications or environments unless specifically designated by Inertial Sense as

military-grade.

Loading...

Loading...