machine-service-no.

M16999 F

Indutherm order service

for consumables:

Tel.: +49 7203 9218-40

sales@indutherm.de

Indutherm

technical service

Tel.: +49 7203 9218-41

support@indutherm.de

INDUTHERM Erwärmungsanlagen GmbH

Brettener Straße 32

D-75045 Walzbachtal

Germany

Tel.: +49 (0)7203 9218-0

Fax: +49 (0)7203 9218-70

e-mail: info@INDUTHERM.de

Instruction Manual for

Vacuum Pressure Casting Machine

VC 400 LCD

Contents

Contents .......................................................................................................................... 2

1 Introduction ............................................................................................................. 3

1.1 General description of the VC400 ....................................................................... 3

1.2 Machine components .......................................................................................... 3

1.3 Technical data ..................................................................................................... 4

1.4 General information ............................................................................................. 5

2 Putting into operation .............................................................................................. 7

2.1 Set-up directions .................................................................................................. 7

2.2 Mains supply ........................................................................................................ 7

2.3 Cooling water ....................................................................................................... 7

2.4 Protective gas (Argon or Nitrogen) ...................................................................... 8

2.5 Vacuum ............................................................................................................... 8

2.6 Gas out ................................................................ ................................................ 8

2.7 Vacuum pump socket .......................................................................................... 8

2.8 RS232 Connector ................................................................................................ 8

3 Safety ..................................................................................................................... 9

3.1 Intended use ........................................................................................................ 9

3.2 Demands on staff, duty for utmost care ............................................................. 10

3.3 Protective measures .......................................................................................... 10

3.4 Safety marking ................................................................................................... 13

3.5 Safety advices ................................................................................................... 14

3.6 Residual risks .................................................................................................... 17

3.7 Behaviour in an emergency situation ................................................................. 17

4 Operation .............................................................................................................. 18

4.1 Operating elements ........................................................................................... 18

4.2 Casting .............................................................................................................. 23

4.3 Possible causes for dissatisfying casting results ............................................... 26

4.4 Configuration of flask ......................................................................................... 27

4.5 Granulating ........................................................................................................ 28

5 Consumable parts ................................................................................................ 29

5.1 Assembly drawing VC400 .................................................................................. 29

5.2 Consumables and spare parts list ..................................................................... 30

6 Service .................................................................................................................. 33

6.1 Troubleshooting ................................................................................................. 33

6.2 Diagram casting flasks without flange ............................................................... 34

6.3 Diagram casting flasks with flange .................................................................... 34

6.4 Maintenance ...................................................................................................... 35

6.5 Declaration of conformity ................................................................................... 36

7 Connection diagrams ............................................................................................ 38

8 Test result chart .................................................................................................... 41

9 Software documentation ....................................................................................... 42

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 2

Revision

date

document

index

topic

technical

responsible

30.09.13

-

first version

Schmidt

15.12.14

86014010_01

safety advice added

Schmidt

16.12.14

86014010_02

special function „automatic pressure start“

Schmidt

15.04.16

86014010_04

revised

RK

14.06.16

86014010_04

last corrections

RK

1 Introduction

1.1 General description of the VC400

With this vacuum pressure-casting machine, the melting charge is heated up by

induction under protective gas. The liquid metal is poured into evacuated, preheated

flasks for jewellery production (lost wax process) or is poured directly into the

granulating apparatus for the production of granules.

The special advantage of inductive heating is that the melting temperature is reached

rapidly, because the heat is directly generated in the metal and in the crucible. During

the melting process, the metal is thoroughly mixed by means of a magnetic field,

ensuring a homogenous mixing even when using new alloys. As the metal is poured

through the crucible bottom, only pure metal can reach the form, i.e. the die; whereas

contamination stays on the surface and can only cover the top of the cast.

Installing the thermocouple in the crucible allows an exact temperature measuring and

also the output of the unit is controlled in such a way that the set temperature remains

constant.

1.2 Machine components

The machine consists of separate units built into one casing:

1. Inside the casing, the following components are installed:

- microprocessor controlled induction generator F-type with

serial number F and 4 digits (Important for INDUTHERM!),

- medium frequency transformer,

- oscillation circuit capacities,

- pneumatic valves,

- pressure control for sealing pressure of sealing rod cylinder and

- pressure control for protection gas.

2. The front panel consists of:

- operating elements for the control of melting and casting cycles.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 3

VC400 single phase

VC400 3 phase

Crucible volume

170 cm3 2.5 kg/Au

Flask

max. Ø 130 mm (5“) * 260 mm (10“) height

Crucible temperature

max. 1400 °C with type S thermocouple

Generator

INDUTHERM F type

Melting performance

3.5 kW

4.5 kW

Mains supply

1x230V/1x16A, 50 or 60 Hz

3x400V/3x16A, 50 or 60 Hz

Cooling water supply

2.5 - 5 bar/at least 200 l/h

2.5 - 5 bar/at least 200 l/h

Cooling water recoil

without pressure

Cooling water entry

temperature

15 – 25 °C

Room temperature

10 – 35 °C

Relative atmospheric

humidity

20 – 80 %

Protective gas supply

=>8 bar, pure N2 or pure Argon

Vacuum

0 - 20 mbar max., at least 21 m³/h

Weight

approx. 120 kg

Dimensions (width *

height * depth)

500 mm * 1450 mm * 810 mm

3. The casting unit consists of:

- water cooled inductor casing with inductor, crucible, insulation parts,

sealing rod device, thermocouple,

- water cooled bell,

- water cooled vacuum chamber,

- flask lift,

- vacuum chamber lift and

- granulating device (option).

1.3 Technical data

Those values marked with a * apply to the standard machine and can be modified on request.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 4

1.4 General information

Safety information

In order to ensure a constant, ideal performance of the machine and to ensure safe

working conditions, the user is to observe the following safety measures:

The complete electrical wiring is to be performed only by qualified and specially

trained personnel.

Check the machine and the supply devices regularly on possible damages.

When opening cabinet/casings or when removing parts (exception: when this is

possible by hand), certain parts under electric power can cause danger. If opening

up the machine is necessary (before maintenance, change of machine settings,

repair or exchange of parts) the machine must be cut off the mains voltage. If

working on the opened machine is inevitable, only qualified trained personnel aware

of the danger caused hereby and aware of the relevant regulations may be

instructed to do this work.

Capacitors in the machine can still be charged even when the machine’s mains

supply is switched off.

When it seems that the machine can no longer be worked safely it has to be taken

out of production and secured against further unintentional use. The following

incidents indicate that safe working is no longer possible:

- the machine is visibly damaged

- the machine does not function

- uncommonly heavy wear from transportation

The safety valves placed inside the machine casing may not be removed, closed or

altered in any way.

As melted metal is processed with this machine (temperatures up to 1400 °C), the

utmost care and attention has to be applied when working with the VC400. The

following necessary safety clothing is principally to be worn:

- fireproof clothes,

- fireproof closed shoes,

- fireproof gloves and

- safety goggles.

Special caution is essential when working with graphite crucibles and graphite dies

because these are only visibly hot at temperatures above 500 °C!

In commercial enterprises the regulations for the prevention of accidents of the

relevant authority for electrical machinery are to be followed.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 5

People with pacemakers must not be near the machine while it is running.

Trained responsible staff has to be supervised to work with this machine.

Use as determined/liability

This casting machine is designed and manufactured to comply with the latest technical

knowledge and according to approved safety regulations. When not putting into

operation correctly or not using the machine as determined, however, danger and

damages may occur. Therefore we suggest reading carefully and completely this

manual before putting the machine into operation and to follow the instructions given

therein:

This machine is only to be used for melting, casting and granulating of precious

metals normally used for the production of jewellery.

This machine may only be connected as mentioned in this manual. The mains

supply as well as in- and outgoing pressures are to be provided as stated on the

machine label.

This machine was designed for use in closed spaces (indoors) and may only be

used for the above-mentioned purpose.

Only original INDUTHERM consumable and spare parts are to be used.

The machine may not be modified in any way. Technical changes may only be

effected with INDUTHERM GmbH’s prior written permission.

Damages caused by disregard or false interpretation of the contents of this

instruction manual result in an immediate expiration of the machine guarantee.

This instruction manual is corresponding to the latest technical condition of the

machine when printed. Technical changes and fittings subject to change.

INDUTHERM GmbH cannot and will not take responsibility for any damages

resulting of the above mentioned.

This instruction manual may not even partially be reproduced (photocopy, micro

film, computer processing etc.) without prior written permission of INDUTHERM

GmbH.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 6

2 Putting into operation

On delivery, immediately check if the machine is complete and if there are any

transportation damages. In the case of damages, please contact at once supplier or

forwarding agent.

2.1 Set-up directions

The machine should be placed on clean and dry ground. The ground should be even,

solid and level. The rear side of the machine must remain freely accessible to ensure

sufficient circulation of cooling air. The cooling air temperature must not exceed 35°C

and must not be contaminated. Only after all supply and connecting systems have been

connected, the machine may be put into operation.

2.2 Mains supply

Only trained personnel may connect the machine. Please pay attention to the nominal

voltage and frequency stated on the machine label. The voltage may differ +/- 10%

(maximum) from the nominal value. The mains supply must at least be furnished with a

16 A delay-action fuse. All lines (L1, L2, L3 and PE) must be connected correctly

2.3 Cooling water

Use two hoses with an inner ø of 8 mm for the cooling water. The water entry pressure

must be at least 2.5 bars and must not be more than 5 bars. The water drainage must

be without pressure. The water entry temperature must be above 15 °C and must not

exceed 25 °C. The concentration of lime in the water must not be more than 60 mg

CaO/l. The cooling water must not be contaminated.

The supply hose for the granulating apparatus (option) must have an inner ø of 8 mm

also, the draining hose an inner diameter of 19 mm.

Caution: As long as the crucible temperature is above 100 °C, the cooling water supply

must be open; otherwise the inductor insulation could be destroyed. In case the cooling

water supply stops while there is still a hot crucible inside the machine, the crucible

must be removed at once.

2.4 Protective gas (Argon or Nitrogen)

Purity to be no less than 99.95% must be used as protective gas. Use a compressed air

hose with an inner ø of 6 mm. The inlet pressure must be 8 bars. The machine will start

adding protective gas into the inductor housing at temperature higher the 500 °C.

2.5 Vacuum

When putting into operation, check the motor rotation direction (direction of arrow). Oil

level and air filter should be checked weekly. The first oil change should be done after

100 working hours. Later on, we recommend changing it regularly every 500 - 2000

working hours, depending on the working process, though at least every 6 months.

Recommended oil type: HD30 / SAE30.

The oil filter should be replaced on every second oil change. The pump should have a

minimum suction power of 21 m³/h and an end pressure of 2 mbar.

For more detailed information please refer to the instruction manual for the vacuum

pump.

The vacuum connection is through a suction hose with an inner diameter of 13 mm at

the rear side of the casing to the vacuum pump.

2.6 Gas out

Pressure release output. This output must be open all the time.

2.7 Vacuum pump socket

The vacuum pump socket is for 3 phase vacuum pumps (3 * 400 V AC) with a

maximum load of 1.5 kVA. During installation the rotation of the vacuum pump must be

checked. Otherwise the pump might be destroyed.

2.8 RS232 Connector

At this connector our modem article no. 71000320 or the serial cable article no.

50500060 can be connected.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 8

3 Safety

3.1 Intended use

Operational safety of the plant for vacuum casting is only guaranteed at intended use.

The vacuum casting machine serves exclusively for melting and pouring of metals and

alloys. The specified temperature ranges must be complied with.

Every other use of the overall plant or parts is considered as not intended.

Unauthorized modifications of the plant are prohibited because of reasons for safety!

Intended use includes reading, knowing and obeying the operating instructions. That

also contains observing of servicing and maintenance regulations.

Set up, operation and maintenance is only allowed to be carried out by trained qualified

personal that has read and understood all documents.

The plant may affiliate only to the specified media. Supply voltage and input

respectively output pressure have to be observed to the given device labeling

accordingly.

The machine has been developed for use in enclosed spaces and for the above

mentioned application.

Only original INDUTHERM consumables and spare parts are admitted for operation.

It is not allowed to change or vary the system in any way. Technical changes need

explicit written approval of INDUTHERM.

Predictable abuse:

warming of human body parts on hot surfaces.

3.2 Demands on staff, duty for utmost care

Work on and with the machine is allowed to be accomplished by reliable, trained and

instructed staff only. Responsibilities for the separate sections have to be regulated

clearly which include operation, preparation, service and repair.

Only authorized personnel may act at the system.

The machine may never be operated by personnel under influence of reflex diminishing

medicine or people not able to work because of illness or disorder.

Running of the system has to be always supervised by trained staff.

Personnel which has to be trained und introduced to this job or within in the course of

vocational training may work only under permanent observation of a person

experienced with the machine.

Work on the electrical equipment is only allowed for workers skilled in the field of

electricity.

The instruction manual has to be freely disposable at the location of the system. The

employees have to know the storage place.

Every person working at the system has to read and apply the instruction manual

especially the safety advices. The personnel has to read and understand the chapters

referring to safety aspects for the particularly components of the machine. Please read

before beginning the work.

Please control the personnel for paying attention to all facts of safety and danger

prevention.

3.3 Protective measures

This operator’s guide contains all important advices to operate the system secure.

Basic prerequisite for safe dealing and trouble-free running of this system is the

knowledge of fundamental safety advices and industrial safety rules.

In commercial facilities you have to regard the accident prevention regulations of the

professional association for electrical systems and tools.

The internal regulations of industrial safety are to be observed.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 10

Caution!

Wear always for every process step the right protective gear.

Caution!

Safety equipment protect from unintentional access of the staff

to danger spots. They prevent possible injuries. Never

manipulate the safety devices!

3.3.1 Concept of safety

Objective is the safety

of the staff against injuries

of the system against damage or standstill

of the environment against endangering

The list of actions taken:

deployment of protective equipment like covers and main-switch with emergency

stop function,

water-cooled inductor housing,

duty of wearing protective clothing with gloves and safety goggles (PPE),

affix safety markings on the installation and

create safety advices in the manual.

3.3.2 Protective gear

Protective gear (PPE) includes:

heat-resistant clothes,

heat-resistant, closed shoes,

heat-resistant protective gauntlets protecting artery,

face guard.

3.3.3 Safety equipment

The safety of the machine is only guaranteed if all safety equipment is proper installed

and working proper. Don’t use the system without the safety equipment!

Disassembling safety equipment is only allowed with locked main-switch. Install every

part of the safety equipment after repair. Perfect function has to be checked.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 11

Caution!

With the emergency stop function you can stop the machine

in critical moments of health hazard. You help to diminish

potential consequences of injury.

safety

marking

meaning

safety

marking

meaning

warning of dangerous

electrical voltages

wear heatresistant

safety clothing

warning of hot

surfaces

wear heat-resistant

protective gauntlet

gloves protecting

artery

forbidden for persons

with pacemaker

wear face guard

wear protective

shoes

Advice

Keep the safety markings always clean. Replace the markings

if they aren’t recognizable. Observe the warnings and

commands. Don’t expose yourself careless to dangerous

situations.

3.3.4 Main switch with emergency stop function

It is allowed to start the machine or operation only with proper emergency stop function.

Don’t manipulate the emergency stop equipment.

Don’t obstruct the way to the emergency stop equipment.

3.3.5 Safety markings placed on the machine casing

A necessary condition for safe dealing with and undisturbed running of the machine is

the knowledge of safety instructions and industrial safety regulations.

On the front of the machine casing the following safety markings are attached.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 12

Danger!

Death, serious body injury or substantial property damage will

result if proper precautions are not taken.

Warning!

Death, serious injury or substantial property damage can

result, if proper precautions are not taken.

Careful!

Minor personal injury can result if proper precautions are not

taken.

Danger!

Property damage can result, if proper precautions are not

taken.

Information/advice

Here you get information and advices to carry out the following

activities effective and safe.

3.4 Safety marking

The following signal words are used in this document which are associated with safety

markings for presentation of possible dangerous situations.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 13

Danger!

Danger because of strong electromagnetical fields

(induction). For persons with pacemaker it is not

allowed to approach or to be near to the machine.

Warning!

Risk of burning on hot surfaces and hot metal

(until ~ 2100 °C). Wear always personal protective

equipment when you work with the machine.

Utmost caution during using graphite crucibles and

graphite molds. The heat of these parts is only

visible when the temperatures are over 500 °C.

Warning!

Maintenance and servicing of the machine only when the

system is disconnected from the mains supply. (Pull out mains

plug).

Danger!

Danger of burning. When you melt the metal without the supply

of protective gas a jet flame or a blow up can happen in the

moment you open the inductor chamber.

At temperatures exceeding 500 °C always use protective gas.

Use argon or nitrogen exclusively.

3.5 Safety advices

Check always the condition of the system before you switch on the system. Examine

the supply pipes and insulations if there are leaks and damages. Operate the system

only if it is in proper and faultless shape.

Operate the system never:

if there are malfunctions,

if it is showing damage or

after heavy transportation stress.

The system has to be constantly controlled when running to be able to recognize and

avoid dangerous situations. The system may not run if it is unsupervised.

Do never change, remove or close the safety valves inside the machine.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 14

Danger!

Danger for the eyes.

Always place the gold coated foil for eye protection against

thermal radiation on top of the inspection window of the

crucible chamber.

In addition wear safety goggles suitable for welding operations.

Danger!

Danger because of touching parts conducting

voltage.

Work on the electrical equipment is only allowed for

authorized qualified staff.

Access to the electrical distribution box is only

allowed for authorized qualified staff with key or tool.

Work on the electrical equipment is only allowed

when the system is disconnected from power supply

(pull out power plug).

The capacitors can retain their charge even after

deactivation of the system.

Keep electrical distribution boxes closed

continually.

No work must be carried out on parts conducting

high voltage.

Remove loose connections.

Replace immediately damaged, scorched or

slightly burned cables. Perform work only when

mains plug is pulled out.

Cables may not wedge in or rather squeezed.

Cables have to be laid in a way that they not

become a tripping hazard or can be not

damaged.

Danger!

Threat of health injury by escape of medias from damaged

hoses. Danger of system damages.

Remove loose connections. Replace damaged hoses

immediately. Perform work only when mains plug is pulled

out.

Hoses may not wedge in or rather squeezed. Hoses have

to be laid in a way that they not become a tripping hazard

or can be not damaged.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 15

Danger!

At crucible temperatures over 100 °C the cooling water supply

must be switched on. If it is not turned on, the inductor will be

destroyed. If cooling water supply fails, the heating system

immediately is turned off. Inspect the system for damage

before putting back into operation again.

Danger!

Lethal injuries happen because of false transport by forklift

truck.

Pay attention of the right attachment of the means of

transportation, otherwise the system can fall from forklift

truck. The system must be lifted from the side only,

because the center of gravity is located in front and

towards the upper third of the machine.

With too small dimensioned or forks adjusted too narrowly

there is danger for the system to fall from the means of

transportation.

Wear appropriate personal protective equipment. (PPE).

Move the system only by skilled personnel qualified for

transportation jobs.

For damages resulting from non-compliance of regulations in

transit there is no assertion possible for warranty claims.

Warning!

Risk of burns because of leaking molten metal.

Warning!

Risk of injury.

Make pressure leading system parts depressurized before you

carry out servicing.

Warning!

Risk of slip on the floor around the installation in case

someone had spilled lubricant or solvent.

Clean the floor from dirt immediately! Dispose cleaning tissues

in the particular collecting boxes.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 16

Caution!

Observe regulations for the mains supply written

from the responsible electric power supply

company, the association VDE and the local electric

power station.

Inappropriate connecting can lead to injuries and

damages of the machine.

risk characterisation

risk reduction

Health risk for persons with

cardiac pacemaker who

approach the running system.

Instruct people.

Burn injury on hot surfaces or

hot molten metal.

Teach people.

Wear personal protective gear.

Jet flame or explosion when

opening the lid of the melting

chamber in case of melting

without protective gas.

Always melt with protective gas

at temperatures above 500 °C.

Tilting and toppling of the

system due to improper

transportation.

Consider shipping instructions.

3.6 Residual risks

3.7 Behaviour in an emergency situation

The personnel working at the facility must be trained about the behaviour in an

emergency situation.

All persons who are working with the machine must be informed of the possibility of

rapid standstill of the plant.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 17

Top level =

Actual program

status

Bottom level =

Selectors for

different values

4 Operation

4.1 Operating elements

4.1.1 VC400 screen when starting the machine

On the top level shown:

378 °C == actual temperature

1000 °C == set temperature

‘1.46 bar crucible == actual crucible pressure (-1 to 1.5 bars)

‘-1.00 bar flask == actual flask pressure (-1 to 0 bars)

‘4.5 kW == actual heating power in kW

1 Program == active program with name "18 ct ye b"

On the bottom level shown:

Temp - == lower the set temperature even within a program

Temp + == rise the set temperature even within a program

Program - == go the next program one place below

Program + == go the next program one place higher (program 1)

Program setup == level to modify the selected program (here program 0)

Top level =

Actual program

status

Bottom level =

Selectors for

different values

4.1.2 VC400 modify program screen

On the top level shown:

0001 program == selected program to modify

1000 °C temperature == set temperature inside the crucible

0100 % heating power == heating power from 5-100%

00.8 s Turbo pressure start == time between confirming the “manual cast” start

1.50 bar turbo pressure

maximum == casting pressure maximum value

On the bottom level shown:

Λ == go to the value one step higher (here “Turbo Pressure Start”)

V == go to the value one step lower (change Label)

- == lower the value (here set Turbo pressure to 1.49 bar)

+ == rise the value (not possible)

Main page == go back to main page

If you go with the cursor down the VC400 allows you to modify the program name to

your needs (e.g.: 18ct ye b = 18 carat yellow gold and big pieces.

and turbo pressure rise

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 19

VC400 /

VC500

Material

Bronze

Yellow

gold 14k

(with

zinc)

Yellow

gold 18k

Aluminium

Brass

Silver

935

Test

Crucible

Graphite

Graphite

Graphite

Graphite

Graphite

Graphite

Graphite

Program No.

10

11

12

13

14

15

18

Temperature

°C

1150

1060

1080

740

1080

1000

0010

Heating

power

%

0100

0100

0100

0100

0100

0100

100

Turbo

pressure

start

s

00.8

00.8

00.8

00.8

00.8

00.8

00.8

Turbo

pressure

maximum

bar

1.00

1.00

1.00

1.00

1.00

1.00

0.50

Label

Bronze

YG 585

750/YG

Aluminum

Brass

935/Ag

InduTest

4.1.3 Pre-set casting programs

4.1.4 VC400 modify system parameter

If you start from the start page and you press“ Program setup“ for 5 seconds you get

access to the system parameter.

On the top level shown:

000:00002 == selected parameter == 000

value of parameter 00002: equals two == type N thermocouple

If you press “Λ” you get access to the parameter 001 and higher.

By pressing “+” you change the value of parameter 000 to 3

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 20

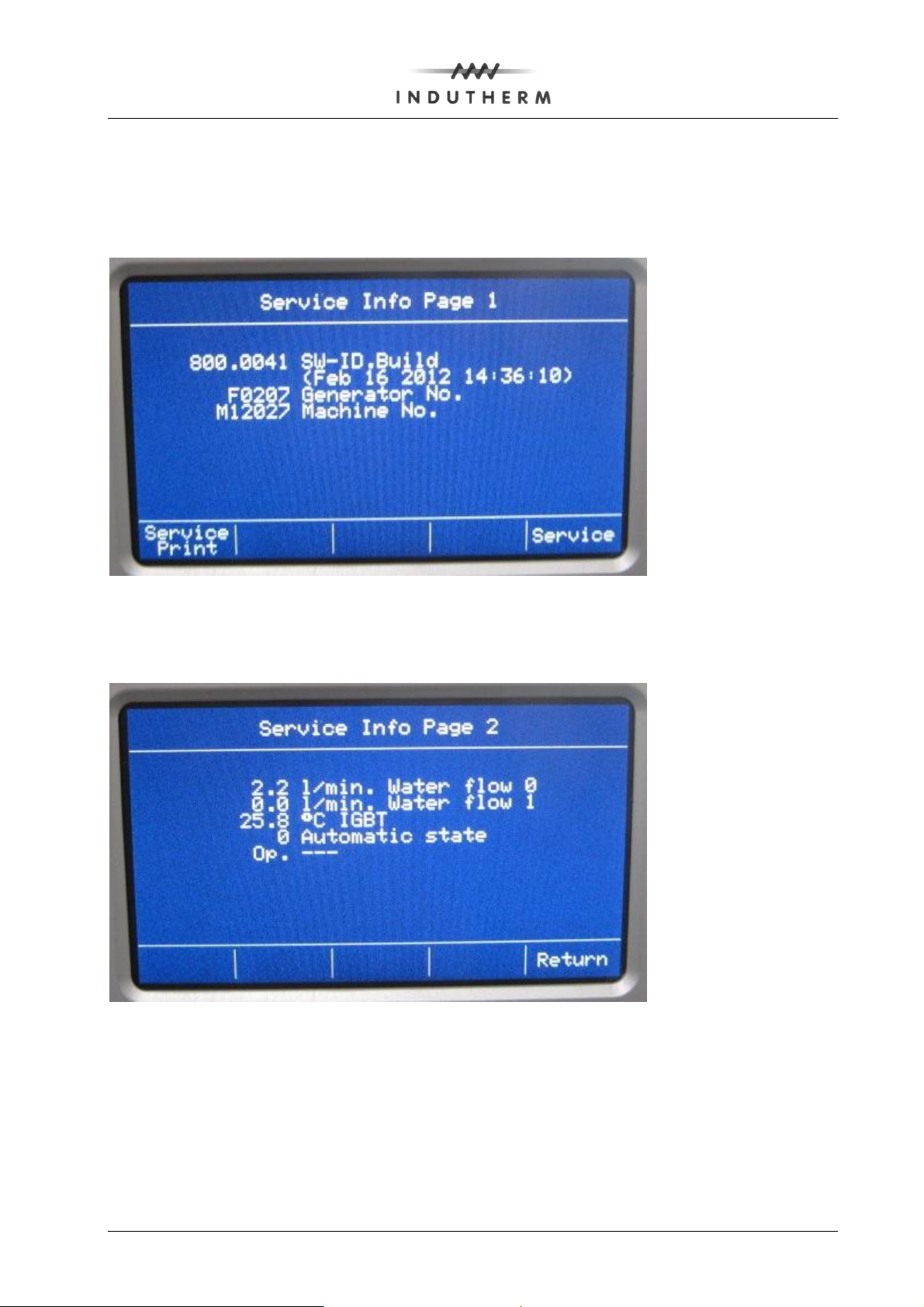

4.1.5 VC400 service info page 1

If you press now „Service“-button you see the software ID, generator number and

machine number.

If you press service again you get to the next page.

4.1.6 VC400 service info page 2

Here you see the water flow, the generator temperature and other features.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 21

Generator area:

Generator Stop

==

stops heating ( if not operating in program )

Generator Starts

==

starts heating

Generator +

==

increases output power of generator

Generator -

==

decreases output power of generator

PGM Start

==

downloads the program settings into memory and

starts program

S.- rod dynamic

==

movement of sealing rod as long as the button is

pressed

S.- rod static

==

movement of sealing rod from close to open and

opposite

Turbo Press.

==

adds overpressure to the inductor housing as long

as the button is pressed (up to "Turbo pressure

maximum")

Vacuum pump

==

switches vacuum pump on and off

Crucible:

Use this rotary switch to select between standard pressure,

vacuum or over-pressure in the crucible area.

Normal No vacuum, no over-pressure in the crucible

area, only flow of protective gas (a very frequently used

casting mode!)

Pressure With this mode, the inductor housing is sealed,

which means that the pressure depends on the amount of

protection gas that is used. When less gas is used than is

exhausted under the flask, there is an under-pressure.

Vacuum In this mode, the inductor housing is directly

connected with the vacuum pump, so that the maximum

possible vacuum is created. This enables, for example, to

melt the metal under vacuum.

4.1.7 VC400 buttons below display

Additional operating elements

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 22

Flask (rotary switch):

By using this rotary switch, select if the flask is to be

evacuated or ventilated.

Locked- Standard position to add or remove the flask

into the vacuum chamber.

Vacuum- After putting in place the flask, the vacuum is

turned on. Approx. 20 seconds afterwards the casting

process can be started.

Release- Having this position the vacuum chamber will be

filled with protective gas.

Flask:

When this switch is in upper position, the pneumatic cylinder

installed in the vacuum chamber rises so that the flask can

be taken out easily.

When putting in a larger flask, the cylinder should be in high

position.

When now turning the FLASK switch, the flask moves back

into the vacuum chamber.

Vacuum chamber:

When this pneumatic switch is in upper position, the vacuum

chamber is lifted, so that – when the chamber is closed – the

whole casting area is sealed. When moving the switch down,

the vacuum chamber moves to lower position and can then

be moved aside.

Main switch:

The machine is turned on/turned off by turning this switch.

- Granulating tank (option):

Regulate the water stream in a way that the water is in motion, but does not

sprinkle.

After the granulating process the metal can be taken out by lifting out the insert.

4.2 Casting

Before starting check crucible, sealing rod and crucible insulation for dirt

residues/possible damages. It is recommended to use a vacuum cleaner to clean the

entire inductor. The metal filter (left of the sealing rod) should be taken out and cleaned

with compressed air.

A suggestion for a general casting process (vacuum in flask, normal pressure in

crucible):

1. Open cooling water, compressed air and protective gas supplies.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 23

2. Switch on vacuum casting machine and vacuum pump.

3. Grind in the sealing rod into the crucible bottom (rotating movement)

4. Set the desired melting program.

5. Select 'normal’ with the valve ‘crucible’ (standard selection: normal-pressure).

If pressure or vacuum is selected, the vacuum chamber must be closed with your

flask already inside.

6. Start program with the button “PGM start”.

7. The generator will start to preheat the crucible to almost set-temperature.

8. If the crucible reaches the set temperature, fill the melting charge into the

crucible.

9. Shortly before the set-point temperature is reached, set in the flask without delay

and switch on vacuum with the valve ‘Flask’.

10. The machine will show now “confirm manual cast”.

11. Now change the rotary switch “crucible” to the desired position. For overpressure

to the position “12 o’clock”.

12. Take a final look at your metal if the metal surface meets your requirements.

13. The machine will show now “confirm turbo pressure end” and count the cooling

time (here 26 seconds gone).

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 24

14. Release the vacuum with the valve ‘flask’.

If the crucible was put under over- or under-pressure, also release it with the

valve ‘crucible’ to ‘normal’ position.

15. Lower the vacuum chamber with the valve ‘chamber lift’ and swing out the

chamber.

Now the flask can be removed.

- Before or just after opening the sealing rod, the pressure at the top of the flask

can be changed with the valve ‘crucible’ to normal-pressure, under-pressure or

over-pressure.

A new casting cycle can start, beginning with step 3.

If casting process is finished:

1. Press "Generator stop".

2. Vacuum pump should run at least 5 minutes after last casting to remove humidity.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 25

1.

Casting temperature is too low/too high.

2.

Flask temperature is too low/too high.

3.

Configuration of flask is disadvantageous ("branches" too thin or too close to

the top).

4.

Flask is not totally heated up (at least 2 hours on end temperature).

5.

Flask was slaked too early/too late.

6.

Contamination in the alloy (for example "bad copper").

7.

Material was not pre-alloyed/granulated.

8.

Investment for flask was bad/old

9.

Eventually not enough protective gas or the gas had water inclusions.

10.

Wrong crucible position (different crucible temperatures).

11.

Not enough vacuum inside the vacuum chamber (at least - 0.9 bar for good

casting).

12.

Vacuum was turned on too late/turned off too early.

13.

Contamination in the investment because of wax residues (steam out flasks).

14.

Graphite contamination (use ceramic insert or crucible of better graphite quality).

Please note that INDUTHERM cannot be held responsible for dissatisfying casting

results.

4.3 Possible causes for dissatisfying casting results

Dissatisfying casting results can have various causes and, depending on the material,

can have various effects. The following "check list" is to help find the different causes:

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 26

4.4 Configuration of flask

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 27

Remove container.

Dump the water.

Remove material.

4.5 Granulating

Before starting check crucible, sealing rod and crucible insulation for dirt

residues/possible damages. It is recommended to use a vacuum cleaner to clean the

entire inductor. The metal filter (left of the sealing rod) should be taken out and cleaned

with compressed air.

For the production of granules, a crucible with a casting opening of 2 mm in diameter is

recommended.

A suggestion for the granulating process:

1. Open cooling water, compressed air and protective gas supplies.

2. Fill the tank with water until overflow is reached.

3. Turn on the vacuum casting machine.

4. Set the desired melting temperature and start the heating (button “Start”).

Protective gas will be added at temperatures above 500 °C automatically.

5. When the set-point-temperature is reached, carefully grind in the sealing rod into

the crucible bottom (rotating movement) and fill in the material.

6. When the material is melted, regulate the water inlet through the spray nozzles in

a way that the water is in motion, but does not splash.

7. Depending on the alloy, the metal should be kept on temperature for a few

minutes or be stirred manually.

8. Open sealing rod.

9. If the crucible is not complete empty remove remaining material with the turbo

pressure button.

If you want to continue with the same alloy restart at 5. or

10. Stop heating.

11. Move granulating tank to the left side and remove inlet.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 28

Attention:

The numbers like C008 are placeholder for the

position in the machine. The article number to order

this piece is 8 digits and listed in your machine

specific order list G16999_00.pdf.

5 Consumable parts

5.1 Assembly drawing VC400

first digit

machine

service

number

function

(here

vacuum

casting)

crucible

outside

dimension

vacuum

chamber

inside

index

G

15033

VC

68

169

00

SI sintering

parts

GR parts to

granulate

name

function

where to find

optional spare

parts

list shows parts for:

e.g. high temperatures

and special alloys

replacement

parts

parts that might go

defective during the

years of operation

accessory parts

parts that might help

you to operate your

machine

5.2 Consumables and spare parts list

At following side the spare parts list for this machine will start.

INDUTHERM is now using only machine specific spare parts lists, which contain all the

information for your machine.

The name is encoded. One example could be G15033_VC_68_169_00

If spare parts are replaced by new parts, the index will be incremented. This ensures

that you always receive the latest version of consumables and spares. To be sure that

the data is correct, INDUTHERM and our sales partners or end customers must work

together.

G13xxx show you only the spare part that wears off. In the web shop you will find other

lists that might help you:

Genuine INDUTHERM parts are clearly marked with our 3D hologram.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 30

Attention!

To order parts or to receive your order list as PDF file please contact

your local sales partner.

E-mail

consumables@indutherm.de

Telephone no

+49-7203-9218-40.

Attention!

Please understand that INDUTHERM has to support more than 3000

machines. We cannot sort spare parts only with your customer name.

We always need your machine service number, to send you the

correct spare part.

If you open the accessory part list, you will see this screen:

For direct customers, please contact our order department

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 31

This page will be replaced with G16999_00

(16999= machine no.).

_00 is version of spare parts list. Changes will be

done with _01, _02, due to customer’s requirements.

Example: G16999_01 (second version of the list for

machine 16999).

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 32

6 Service

6.1 Troubleshooting

Only trained personnel should open the machine.

The machine cannot be turned on:

- when there is no mains supply.

The heating cannot be turned on:

- when there is no cooling water supply,

- when there is no compressed air supply,

- when there is no protective gas supply,

- when thermocouple is not in place or defective and

- when generator is running hot.

For other error codes and warnings, see chapter_Software_documentation software

documentation.

Incorrect temperature indication:

- thermocouple was not programmed correctly on temperature control

(in this case generator can be stopped)!

Low generator output:

- nominal value of temperature control too low.

Problems with pressure in the bell:

- bad flask gaskets (replace gaskets, lower gasket: use silicon, upper gasket: use

graphite),

- clean flask flange and

- error with vacuum supply (when using vacuum).

Problems with vacuum in the flask:

- bad flask gaskets (replace gaskets, lower gasket: use silicon, upper gasket: use

graphite),

- clean flask flange,

- clean vacuum pump filter and

- vacuum supply not in order.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 33

vacuum area

force of the air

pressure

force of the

overpressure

Possible problems of losing vacuum

1.) O-Ring vacuum chamber is

not OK.

2.) Flask top surface is not flat

enough.

3.) Silicon ring is missing or

defect.

4.) Flask lift cylinder is not in “up”

position.

5.) By using overpressure on the

crucible area you need 8 bars

air pressure. With 6 bars

pressure the flask will move

down and the vacuum will be

lost.

6.) Flask has cracks.

vacuum

area

force of the

overpressure

Possible problems of losing vacuum

1.) Flask flange is not flat enough.

2.) Silicon ring is missing or

defect.

3.) Flask has cracks.

6.2 Diagram casting flasks without flange

6.3 Diagram casting flasks with flange

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 34

6.4 Maintenance

A routine check/regular cleaning of the following is necessary: (Caution: disconnect the

machine first!):

Daily (before casting):

1. Remove thermocouple, sealing rod, crucible and insulation materials, carefully

clean inductor housing with a vacuum cleaner. Before reinstalling the above

parts, check those and replace if necessary.

2. Caution: The “sealing rod cylinder” must not be placed on lowest position when

sealing rod is in place. A sealing up of the casting hole is not guaranteed in this

case. If problems occur, check sizes of sealing rod, graphite ball, crucible and

crucible bottom insulations!

3. Clean metal filter placed left of sealing rod.

Weekly:

1. Lubricate threads of sealing rod holder (top) with high temperature grease.

2. Clean vacuum pump filter and check oil level/change oil. Recommended oil type:

HD30/SAE30.

Every 4 month:

1. Check vacuum pump filter and oil separator filter of vacuum pump.

Annually:

Depending on the water quality, the cooling system should be cleaned with 25 %-citric

acid. The cooling system should be treated with this acid for approx. 1 hour. Then clean

the system thoroughly with pure water and check on eventual leakages.

1. Tighten all electric wirings, especially those for power current.

2. Tighten all connections of water-cooling, pneumatic systems and protective gas.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 35

6.5 Declaration of conformity

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 36

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 37

7 Connection diagrams

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 38

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 39

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 40

6

5

4

3

2

1

Material

Quantity

Type of cast

pieces

Crucible

temperature

Flask

temperature

Casting mode

(standard, vacuum,

over-pressure)

Flask size

Investment

Particularities

Result

Test date

8 Test result chart

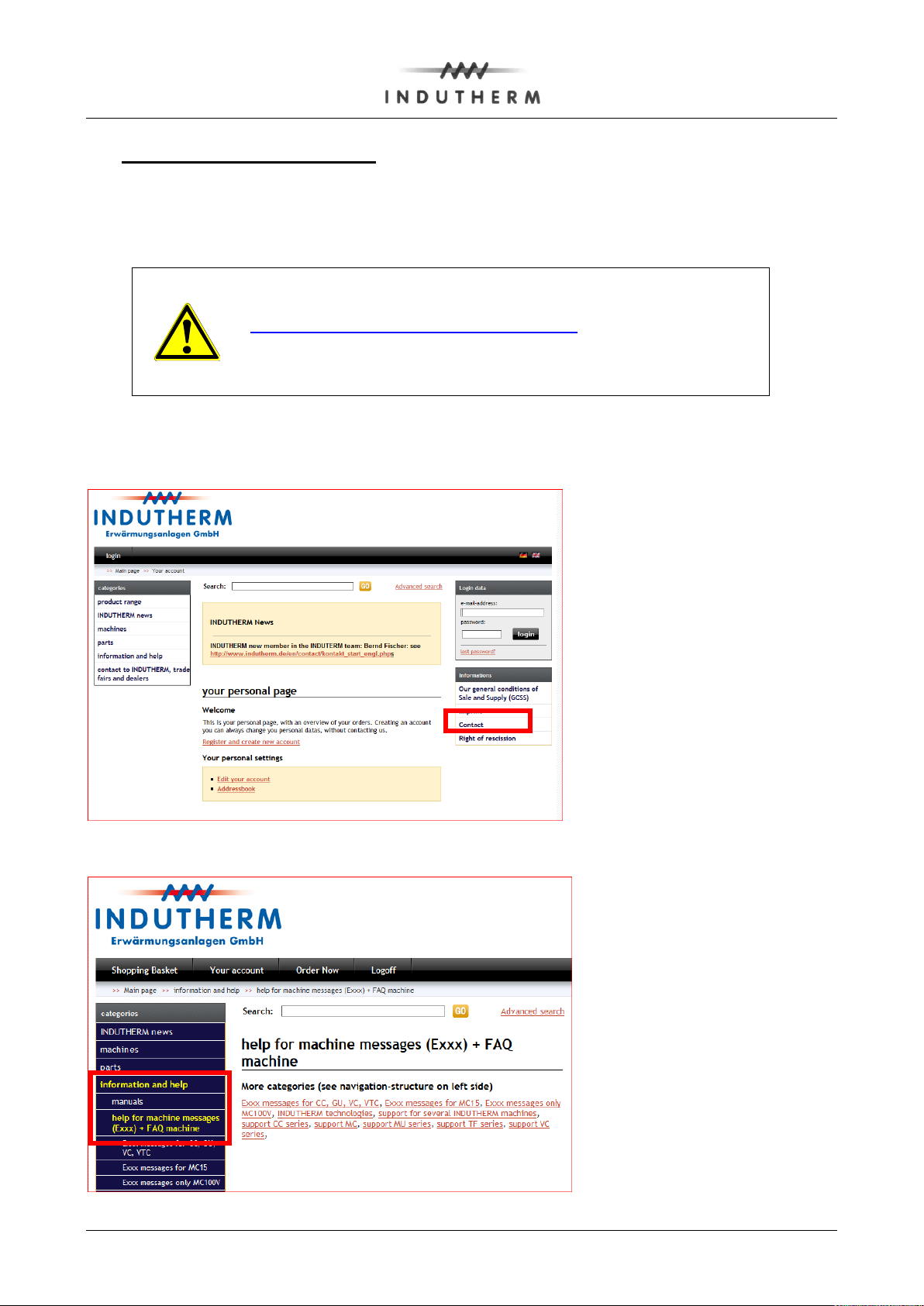

Attention: On our new Internet page

http://www.indutherm.de/webshop

you can find examples how to troubleshoot errors.

9 Software documentation

The software documentation INDUTHERM article no. 86380000 with the error and

warning codes start on the next pages. For the F generator the software starts with 80000

xx = software index.

Before you can do so, you need to apply for a login. Only with the serial number we can

give you complete access. Click contact form and send it to us.

Then we will send you the login information’s. At the subdirectory "Help for machine

messages", you will find support documents.

86014010_04_OPERATING_MANUAL_VC400_LCD_GB.DOC 25.11.2016 KS page 42

Loading...

Loading...