Product

Manual

The Essential Guide for

Safety Teams and

Instrument Operators

Edition 3

March 23, 2016

Part Number: 17156830-1

Industrial Scientific Corporation, Pittsburgh, PA USA

Industrial Scientific Co., Ltd. Shanghai, China

© 2015, 2016 Industrial Scientific Corporation

All rights reserved. Published 2016.

Revision 1

www.indsci.com/ventispro

Contents

General Information .......................................................................................................................................................................... 1

Certifications ................................................................................................................................................................................. 1

Warnings and Cautionary Statements .......................................................................................................................................... 2

Recommended Practices .............................................................................................................................................................. 4

Instrument Maintenance ........................................................................................................................................................... 4

First Use .................................................................................................................................................................................... 5

Wearing the Instrument ............................................................................................................................................................. 5

Remote Sampling ..................................................................................................................................................................... 6

Cold-weather Operation ............................................................................................................................................................ 6

Product Information ........................................................................................................................................................................... 7

Overview ....................................................................................................................................................................................... 7

Key Features ................................................................................................................................................................................. 7

Compatibility ................................................................................................................................................................................. 8

Sensors ..................................................................................................................................................................................... 8

Batteries .................................................................................................................................................................................. 10

Specifications .............................................................................................................................................................................. 11

Instrument ............................................................................................................................................................................... 11

Battery Specifications ............................................................................................................................................................. 12

Sensor Specifications ............................................................................................................................................................. 12

Getting Started ................................................................................................................................................................................ 21

Unpacking the Instrument ........................................................................................................................................................... 21

Hardware Overview .................................................................................................................................................................... 22

Display Overview ........................................................................................................................................................................ 24

Power On .................................................................................................................................................................................... 30

Power Off .................................................................................................................................................................................... 33

Settings ........................................................................................................................................................................................... 35

Guidelines ................................................................................................................................................................................... 35

Accessing and Protecting Settings ............................................................................................................................................. 35

Settings Menus ........................................................................................................................................................................... 36

Examples for Working in Settings ............................................................................................................................................... 36

Reviewing and Editing Settings .................................................................................................................................................. 38

Maintenance menu ................................................................................................................................................................. 39

Start-up menu ......................................................................................................................................................................... 41

Operation menu ...................................................................................................................................................................... 42

Alarm menu ............................................................................................................................................................................. 43

Sensor menu ........................................................................................................................................................................... 45

Admin Menu ............................................................................................................................................................................ 46

Operation ........................................................................................................................................................................................ 49

The Instrument Buttons ............................................................................................................................................................... 49

The Instrument Display ............................................................................................................................................................... 50

Operating the Instrument ............................................................................................................................................................ 50

Information .............................................................................................................................................................................. 50

Utilities .................................................................................................................................................................................... 50

Wearing the Instrument ............................................................................................................................................................... 52

Alarms and Warnings At-a-glance .............................................................................................................................................. 52

Alarms ..................................................................................................................................................................................... 52

Warnings ................................................................................................................................................................................. 53

User-site Assignments ................................................................................................................................................................ 54

Alarms, Warnings, and Other Notifications ..................................................................................................................................... 55

Overview ..................................................................................................................................................................................... 55

Alarms ......................................................................................................................................................................................... 55

Warnings ..................................................................................................................................................................................... 58

Indicators .................................................................................................................................................................................... 59

Failures and Errors ..................................................................................................................................................................... 59

Maintenance ................................................................................................................................................................................... 61

Guidelines ................................................................................................................................................................................... 61

Process At-a-glance .................................................................................................................................................................... 61

Supplies and Preparation ............................................................................................................................................................ 62

Instruction ................................................................................................................................................................................... 63

Service and Warranty ..................................................................................................................................................................... 67

Service ........................................................................................................................................................................................ 67

Guidelines ............................................................................................................................................................................... 67

Supplies .................................................................................................................................................................................. 67

Instruction ............................................................................................................................................................................... 68

Warranty ..................................................................................................................................................................................... 77

Limitation of Liability ................................................................................................................................................................ 77

Assignments ................................................................................................................................................................................... 79

Introduction ................................................................................................................................................................................. 79

iAssign Overview ........................................................................................................................................................................ 79

Procedures .................................................................................................................................................................................. 81

Appendix ......................................................................................................................................................................................... 85

Supplemental Information about Gases and Sensors ................................................................................................................ 85

Toxic Gases ............................................................................................................................................................................ 85

Combustible Gases ................................................................................................................................................................. 86

Contact Information ....................................................................................................................................................... Back cover90

Tables and Figures

Table 1.1 Hazardous area certifications ........................................................................................................................................... 1

Table 1.2 Wireless certifications ....................................................................................................................................................... 2

Table 1.3 Warnings and cautionary statements ................................................................................................................................ 2

Table 1.4 Recommended frequencies for instrument maintenance ................................................................................................. 5

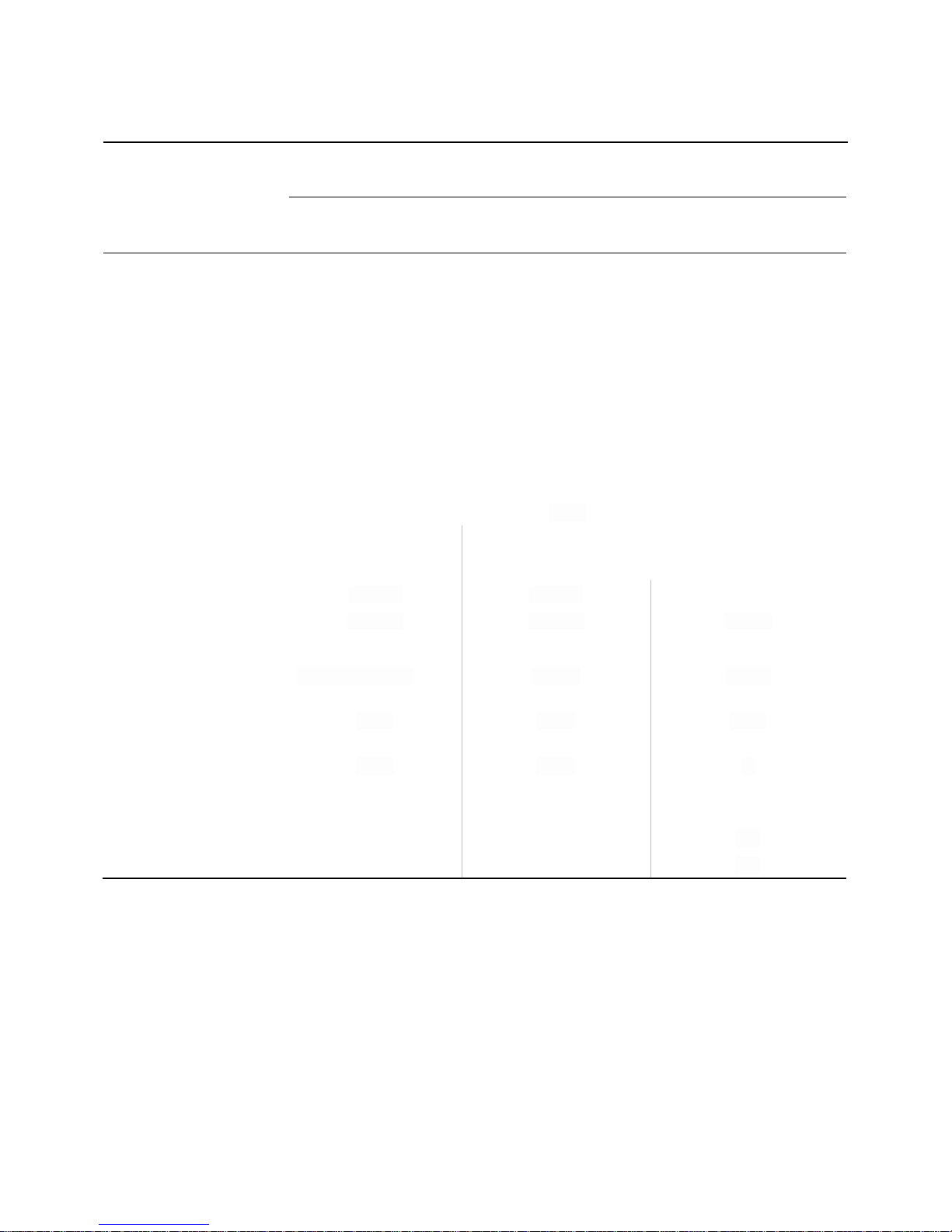

Figure 2.1.A Sensor compatibility and installation locations for the Ventis Pro4 .............................................................................. 9

Figure 2.1.B Sensor compatibility and installation locations for the Ventis Pro5 .............................................................................. 9

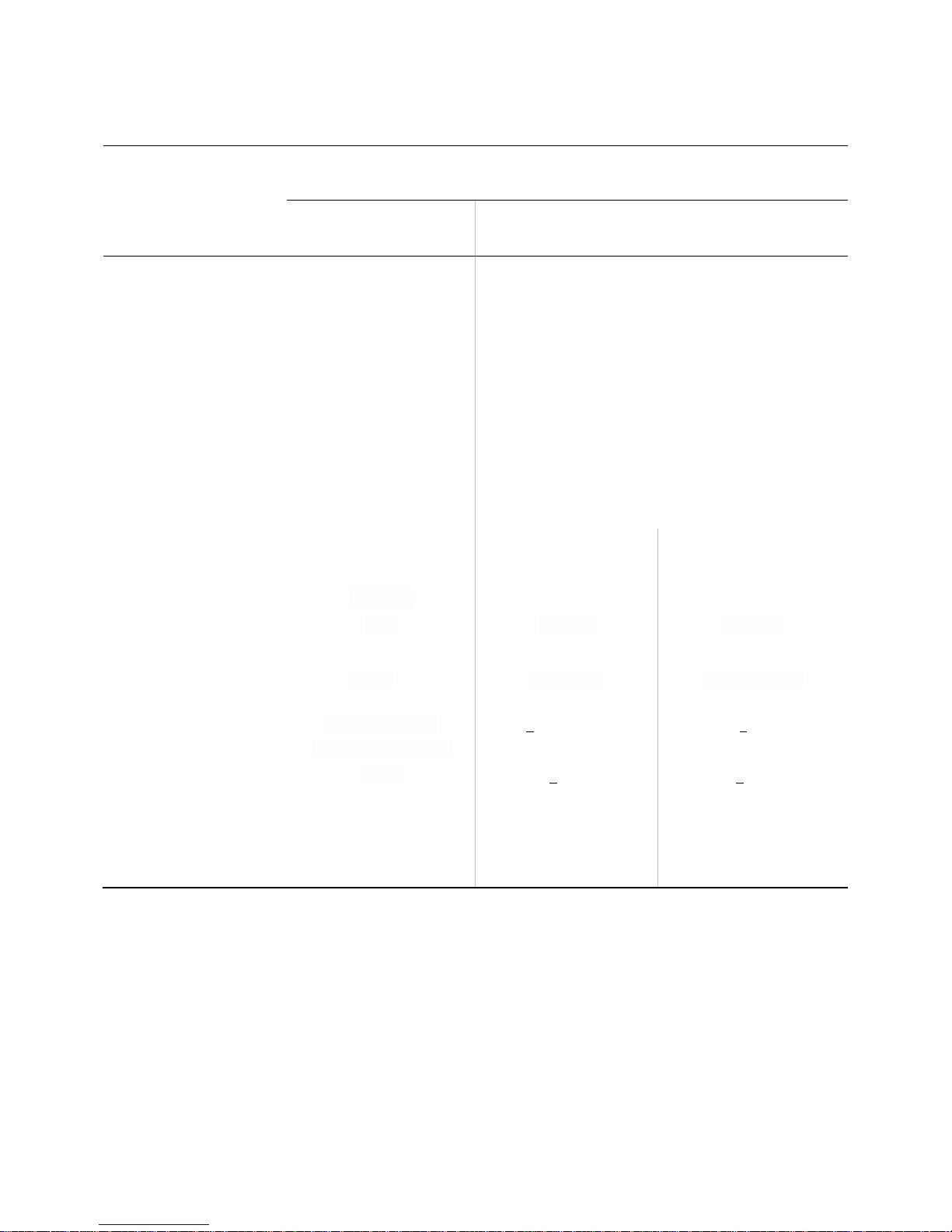

Table 2.1 Sensor compatibility and installation locations................................................................................................................ 10

Table 2.2 Battery compatibility ........................................................................................................................................................ 10

Table 2.3 Instrument and pump specifications ............................................................................................................................... 11

Table 2.4 Battery specifications ...................................................................................................................................................... 12

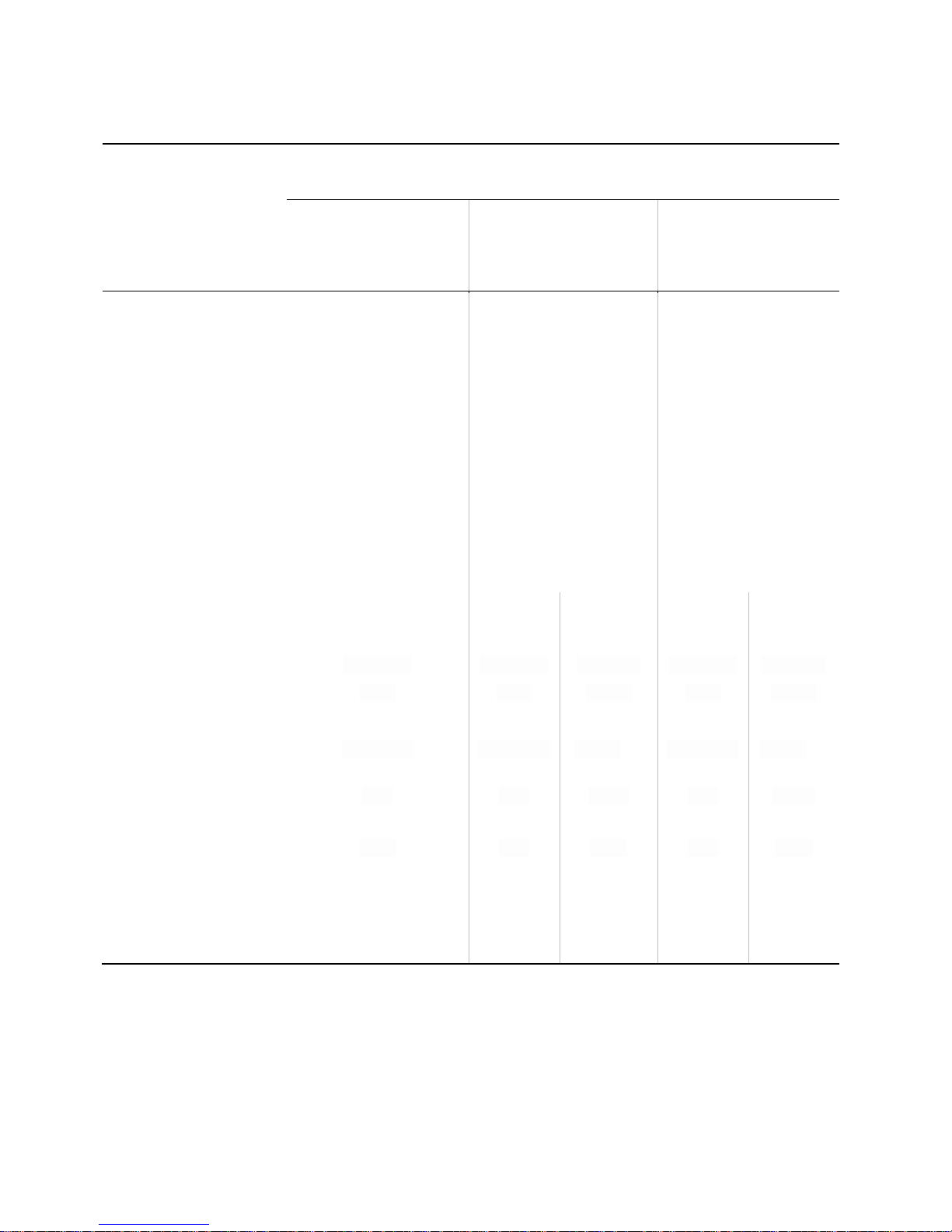

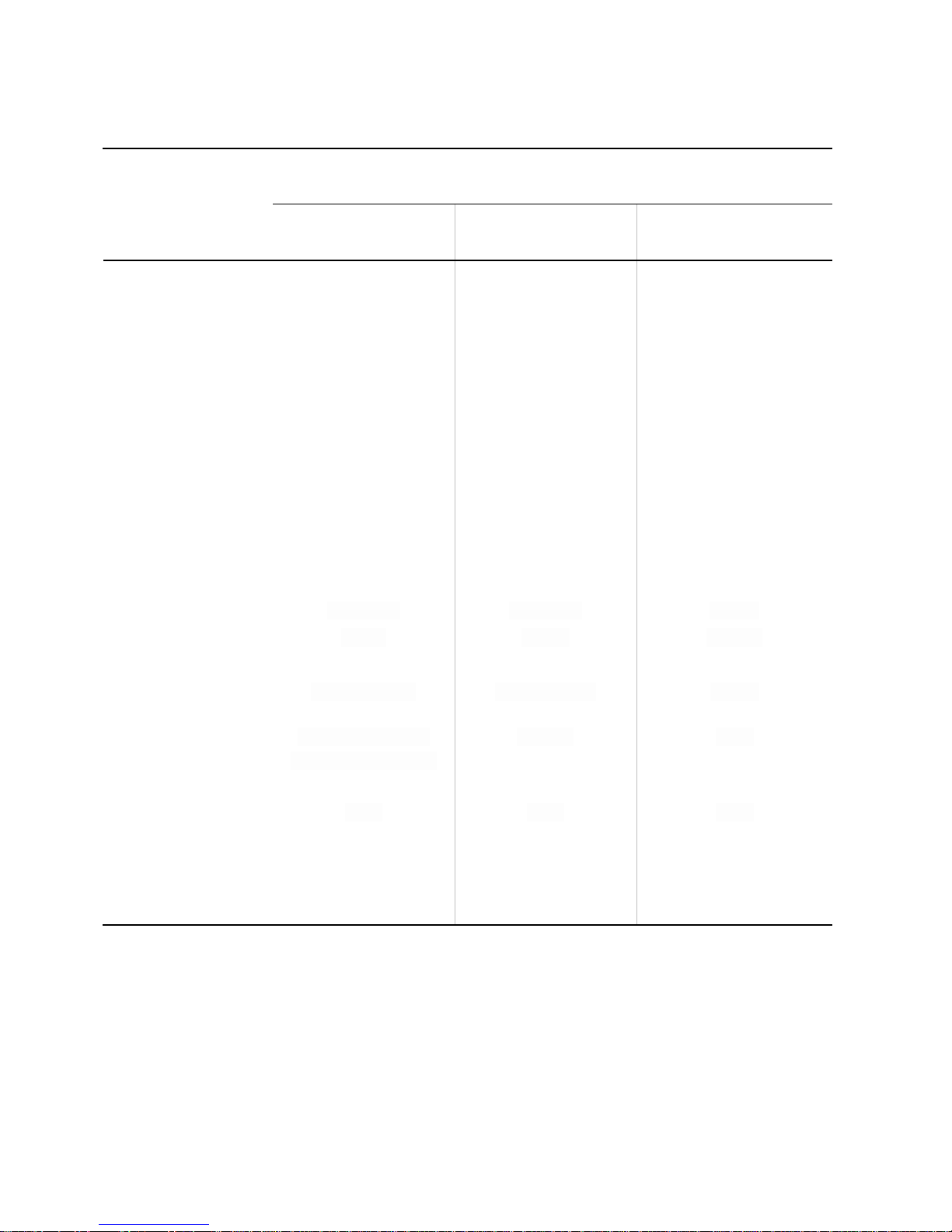

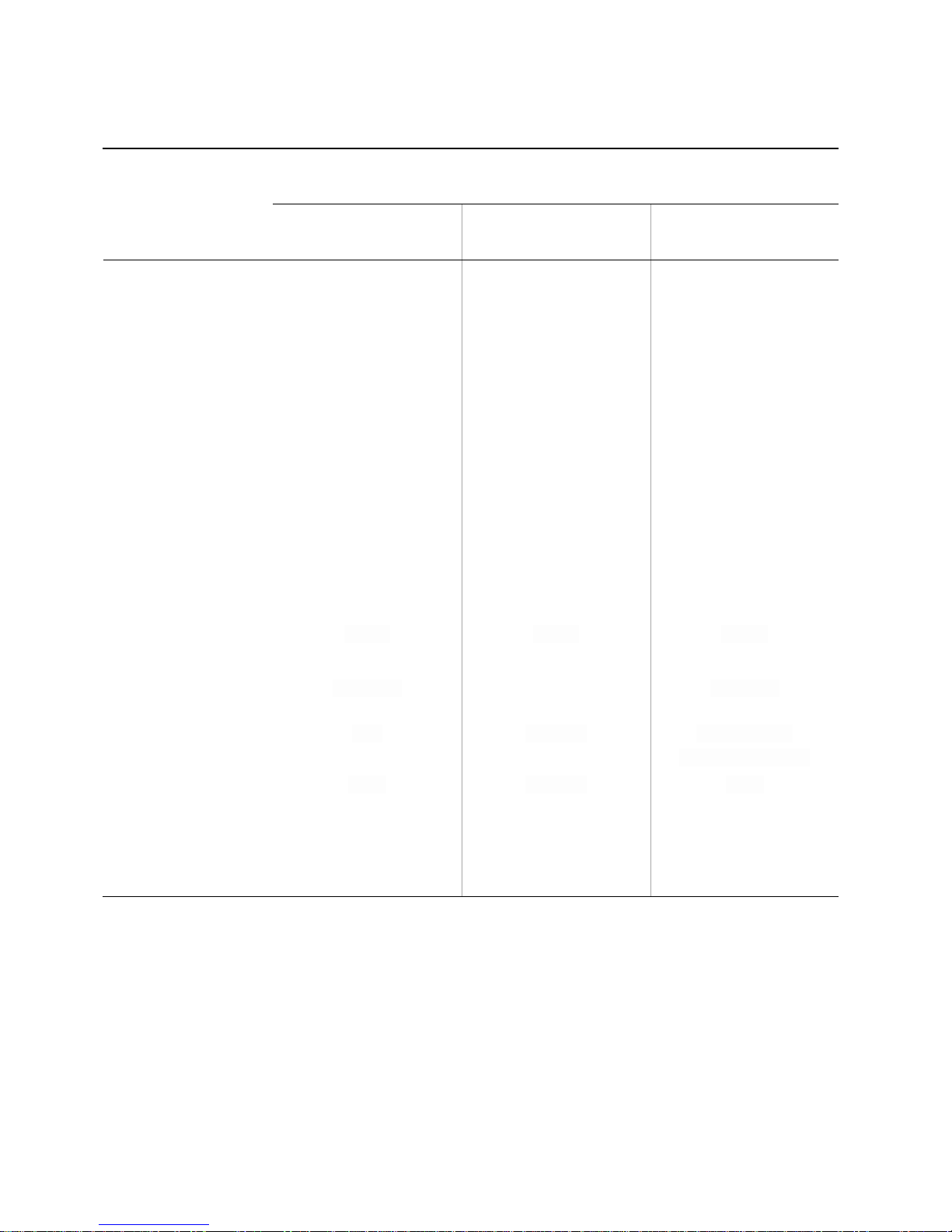

Table 2.5 Sensor specifications ...................................................................................................................................................... 13

Table 3.1 Package contents ........................................................................................................................................................... 21

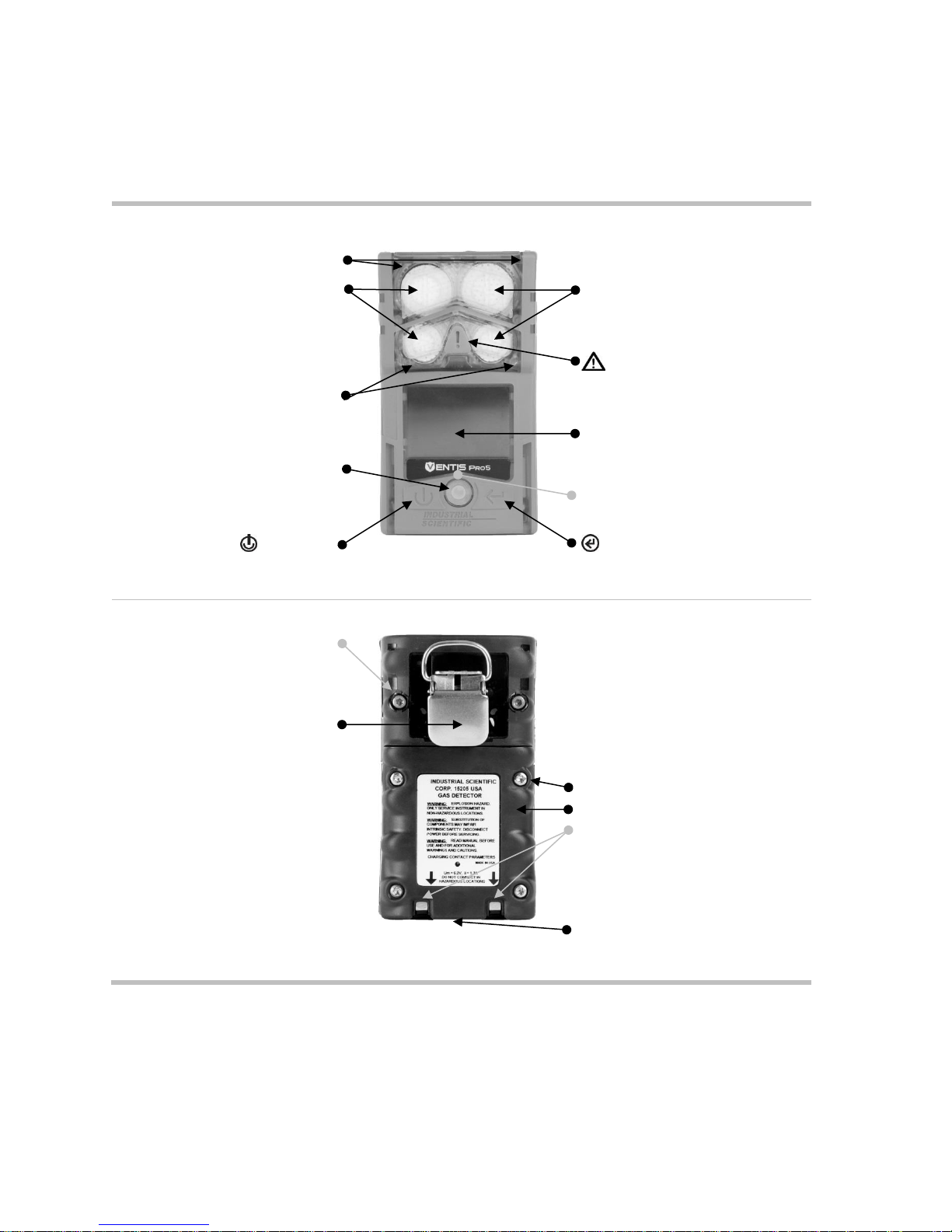

Figure 3.1.A Hardware overview diffusion instrument .................................................................................................................... 22

Figure 3.1.B Hardware overview aspirated instrument ................................................................................................................... 23

Figure 3.2.A Reading the display during operation ......................................................................................................................... 25

Figure 3.2.B Reading the display during an event (warning or alarm) ............................................................................................ 26

Figure 3.2.C Reading the display during maintenance ................................................................................................................... 27

Figure 3.2.D Reading the display while working in settings ............................................................................................................ 28

Figure 3.3 Power on ........................................................................................................................................................................ 32

Figure 3.4 Power off ........................................................................................................................................................................ 33

Table 4.1 Settings menus ............................................................................................................................................................... 36

Figure 4.1.A Example for editing a single-item setting .................................................................................................................... 37

Figure 4.1.B Example for editing a multi-item setting ..................................................................................................................... 38

Figure 4.2.A Navigating and using maintenance options................................................................................................................ 40

Figure 4.2.B Navigating and editing start-up settings .................................................................................................................... 41

Figure 4.2.C Navigating and editing operation settings ................................................................................................................. 43

Figure 4.2.D Navigating and editing alarm settings ....................................................................................................................... 44

Figure 4.2.E Navigating and editing sensor settings...................................................................................................................... 45

Figure 4.2.F Navigating and editing admin settings ....................................................................................................................... 47

Figure 5.1 Using the buttons during operation ................................................................................................................................ 49

Figure 5.2 Home ............................................................................................................................................................................. 50

Figure 5.3 Operation instruction ...................................................................................................................................................... 51

Figure 5.4 Using iAssign tags ......................................................................................................................................................... 54

Table 6.1 Alarm events (list) ........................................................................................................................................................... 56

Figure 6.1 Alarm events (display screens) ...................................................................................................................................... 57

Table 6.2 Warning events (list) ....................................................................................................................................................... 58

Figure 6.2 Warning events (display screens) .................................................................................................................................. 59

Table 6.3 Failures and errors .......................................................................................................................................................... 59

Table 6.4 Critical errors ................................................................................................................................................................... 60

Figure 7.1 Maintenance supplies and preparation .......................................................................................................................... 62

Table 7.1 Calibration failure: possible causes and recommendations ............................................................................................ 66

Figure 8.1 Instrument diagram ....................................................................................................................................................... 68

Figure 8.2 Pump module diagram .................................................................................................................................................. 69

Table 8.1 Instrument and pump module parts list ........................................................................................................................... 69

Figure 8.3 Service Tasks ................................................................................................................................................................ 76

Table 9.1 iAssign functionality ........................................................................................................................................................ 82

Table A.1 Cross-sensitivity guidelines (%) ..................................................................................................................................... 85

Table A.2 LEL correlation factors for the sensors 17155304-K, -L, and -M ................................................................................... 86

Table A.3 LEL correlation factorsa for the sensor 17155304-U ..................................................................................................... 87

General Information

Certifications

Warnings and Cautionary Statements

Recommended Practices

Table 1.1 Hazardous area certifications

Certifying Body

(CB)

Area Classifications or Identification Number

Approved

Temperature Range

ATEX

Equipment Group and Category II 1G, Ex ia IIC, with the protection

category Ga, in the Temperature Class T4

Equipment Group and Category II 2G, Ex d ia IIC, with the protection

category Gb, in the Temperature Class T4, with IR sensor

-40 °C to +50 °C

(-40 °F to +122 °F)

CSAa

Class I, Division 1, Groups A, B, C, and D, in the Temperature Class T4

Class I, Zone 1, Ex d ia IIC, in the Temperature Class T4

-40 °C to +50 °C

(-40 °F to +122 °F)

C22.2 No. 152 applies to %LEL reading for the sensor Part Number

17155304-M only

-20 °C to +50 °C

(-4 °F to +122 °F)

IECEx

Class I, Zone 0, Ex ia IIC, with the protection technique Ga, in the

Temperature Class T4

Class I, Zone 1, Ex d ia IIC, with the protection technique Gb, in the

Temperature Class T4, with IR sensor

-40 °C to +50 °C

(-40 °F to +122 °F)

UL

Class I, Division 1, Groups A, B, C, and D, in the Temperature Class T4

Class II, Division 1, Groups E, F, and G, in the Temperature Class T4

Class I, Zone 0, AEx ia IIC, in the Temperature Class T4

Class I, Zone 1, AEx d ia II C, in the Temperature Class T4, with IR sensor

-40 °C to +50 °C

(-40 °F to +122 °F)

1

Certifications

Instrument certifications at the time of this document's publication are listed below in Tables 1.1 and 1.2.

a

The following apply to instruments that are to be used in compliance with the CSA certification: Ventis Pro4 and Ventis Pro5 instruments are

CSA certified according to the Canadian Electrical Code for use in Class I, Division 1 and Class I, Zone 1 Hazardous Locations within an

ambient temperature range of T

: -40 °C to +50 °C.

amb

Table 1.2 Wireless certifications

Agency

Identification

FCC

PHH-VPX

IC

20727-VPX

Table 1.3 Warnings and cautionary statements

If it appears that the instrument is not working correctly, immediately contact Industrial Scientific.

Only qualified personnel should operate, maintain, and service the instrument.

Substitution of components may impair intrinsic safety, which may cause an unsafe condition.

Substituer des composants peut compromettre la sécurité intrinsèque, ce qui peut résulter en une situation

dangereuse.

Do not use in oxygen-enriched atmospheres. If the atmosphere becomes oxygen enriched, it may cause

inaccurate readings.

Oxygen-deficient atmospheres may cause inaccurate readings.

A rapid increase in a gas reading that is followed by a declining or erratic reading may indicate an over-range

condition, which may be hazardous.

Sudden changes in atmospheric pressure may cause temporary fluctuations in gas readings.

Temperatures below -20 °C (-4 °F) are likely to cause decreased functionality in the instrument's display screen

and man-down feature.

Sudden changes in ambient-air temperature will cause a form of sensor drift in the Carbon Monoxide/Hydrogen

Sulfide (CO/H2S) sensor (part number 17155306-J) that will produce temporary variations in the sensor's

readings:

If the temperature suddenly increases, the CO reading will temporarily decrease and the H

2

S reading may

temporarily increase.

CSA has assessed only the %LEL combustible gas detection portion of this instrument (the sensor part number 17155304-M only) for

performance according to CSA Standard C22.2 No. 152. Within an ambient temperature range of T

±3%. Within an ambient temperature range of T

been calibrated to 50% LEL CH

CAUTION: CSA C22.2 No. 152 requires before each day’s usage, sensitivity must be tested on a known concentration of pentane or

methane equivalent to 25% or 50% of full scale concentration. Accuracy must be within -0% to +20% of actual concentration. Accuracy

may be corrected by referring to the zero and calibration section of the Product Manual.

ATTENTION : CSA C22.2 N°152 exige que la sensibilité de l’instrument soit testée avant l’utilisation quotidienne de l’instrument sur une

concentration connue de pentane ou de méthane équivalente à 25 % ou 50 % de la concentration totale. L'exactitude doit être entre -0 %

et +20 % de la concentration réelle. L’exactitude peut être corrigée en se référant à la partie concernant la mise à zéro et l’étalonnage

dans le Manuel du produit.

4.

: -20°C up to 0°C, the accuracy is ±5%. This is applicable only when the monitor has

amb

: 0 °C to +50 °C, the accuracy is

amb

Warnings and Cautionary Statements

Read and understand this Product Manual before operating or servicing the instrument. Failure to perform

certain procedures or note certain conditions—provided below and throughout the manual—may impair the

performance of the product, cause unsafe conditions, or both.

2

Table 1.3 Warnings and cautionary statements

If the temperature suddenly decreases, the CO reading will temporarily increase and the H

2

S reading may

temporarily decrease.

The readings will stabilize when the sensor has acclimated to the change in temperature. For example, if the

ambient-air temperatures changes from a "room temperature" of 20 °C (68 °F) to an outdoor temperature of 0

°C (32 °F), the stabilization time is approximately 15 minutes; with smaller or larger changes in temperature,

stabilization time will be shorter or longer, respectively.

Note: If the sensor is to be zeroed after a sudden change in ambient-air temperature, allow the sensor and its

readings to stabilize before zeroing.

To avoid potentially inaccurate readings for some applications—monitoring for gases other than O2, CO, CO2,

H2S, and combustible gases [LEL/CH4]—only use a leather case as a carrying case. Do not power on, operate,

or power off the instrument while it is in a leather case.

Silicone and other known contaminants may damage the instrument’s combustible gas sensors, which can

cause inaccurate gas readings.

To support accurate readings, keep clean and unobstructed all filters, sensor ports, water barriers, and pump

intake port.

Charge the instrument’s battery only in nonhazardous locations using compatible accessories from Industrial

Scientific.

Chargez la batterie de l’instrument uniquement dans des lieux sans danger.

Perform all instrument service tasks and maintenance procedures in nonhazardous locations only. This

includes the removal, replacement, or adjustment of any part on or inside the instrument or its pump.

Exécutez toutes les procédures de service les tâches de service sur l’instrument uniquement dans des lieux

sans danger. Ceci comprend la dépose d’une pièce positionnée sur l’instrument ou à l’intérieur de celui-ci, ou

bien la rechange ou le réglage d’une telle pièce.

Battery contacts are exposed on battery packs when they are removed from the instrument. Do not touch the

battery contacts and do not stack battery packs on top of each other.

Do not use solvents or cleaning solutions on the instrument or its components.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

The instrument complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

This device may not cause harmful interference.

This device must accept any interference received, including interference that may cause undesired

operation.

Changes or modification made that are not expressly approved by the manufacturer could void the user’s

authority to operate the equipment.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

3

Table 1.3 Warnings and cautionary statements

licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d'en compromettre le fonctionnement.

Recommended Practices

Instrument Maintenance

The procedures defined below help to maintain instrument functionality and support operator safety.

Industrial Scientific minimum-frequency recommendations for these procedures are summarized below in

Table 1.4. These recommendations are provided to help support worker safety and are based on field data,

safe work procedures, industry best practices, and regulatory standards. Industrial Scientific is not

responsible for determining a company’s safety practices or establishing its safety policies, which may be

affected by the directives and recommendations of regulatory groups, environmental conditions, operating

conditions, instrument use patterns and exposure to gas, and other factors.

Settings

Settings control how an instrument will perform. They are used to help ensure the instrument is in

compliance with company safety policy and applicable regulations, laws, and guidelines as issued by

regulatory agencies and government or industry groups.

Utilities

Maintenance procedures are known as "utilities". Utilities are used to test the instrument or its components

for functionality or performance, or to clear an instrument's summary readings. Each utility is defined below.

Self-test.

The self-test is used to test the functionality of the instrument’s memory operations, battery, display screen,

and each alarm signal type (audible, visual, and vibration).

Bump Test (or "functional test").

Bump testing is a functional test in which an instrument's installed sensors are to be briefly exposed to (or

“bumped” by) calibration gases in concentrations that are greater than the sensors’ low-alarm setpoints.

This will cause the instrument to go into low alarm and will indicate which sensors pass or fail this basic test

for response to gas.

Zero.

Zeroing adjusts the sensors’ “baseline” readings, which become the points of comparison for subsequent

gas readings. During zeroing, the installed sensors are to be exposed to an air sample from a zero-gradeair cylinder or ambient air that is known—by the instrument user—to be clean air. The instrument makes no

judgement about the quality of the zero-air sample; its only task is to read that air sample as clean air.

Zeroing is also a prerequisite for calibration.

4

Table 1.4 Recommended frequencies for instrument maintenance

Procedure

Recommended minimum frequency

Settings

Before first use, when an installed sensor is replaced, and as needed.

Calibrationa

Before first use and monthly thereafter.

Bump testb

Before first use and prior to each day’s use thereafter.

Self-testc

As needed.

Calibration.

Regular calibrations promote the accurate measurement of gas concentration values. During calibration, an

instrument’s installed sensors are to be exposed to their set concentrations of calibration gases. Based on

the sensors’ responses, the instrument will self-adjust to compensate for declining sensor sensitivity, which

naturally occurs as the installed sensors are used or “consumed”.

Note: During calibration, the span reserve percentage value for each sensor is displayed. An indicator of a sensor's remaining

life, when the value is less than 50%, the sensor will no longer pass calibration

Summary Readings.

The time-weighted average (TWA), short-term exposure limit (STEL), and peak readings can each be

"cleared". When any summary reading is cleared, its value is reset to zero and its time-related setting is

also reset to zero.

a

Between regular calibrations, Industrial Scientific also recommends a calibration be performed immediately following each of these incidences:

the unit falls, is dropped, or experiences another significant impact; is exposed to water; fails a bump test; or has been exposed to an overrange (positive or negative) gas concentration. A calibration is also recommended after the installation of a new (or replacement) sensor.

b

When redundant sensors are operating on DualSense® technology, bump testing these sensors may be done less frequently based on

company safety policy.

c

The instrument performs a self-test during power on. For an instrument that is set for always-on, the instrument will automatically perform a

self-test every 24 hours. The self-test can also be completed on demand by the instrument user.

Note: The use of calibration gases not provided by Industrial Scientific may void product warranties and limit potential liability claims.

First Use

To prepare the Ventis Pro Series instrument for first use, qualified personnel should ensure the following

are completed:

Charge the battery.

Review instrument settings and adjust them as needed.

Calibrate the instrument.

Complete a bump test.

Wearing the Instrument

Based on the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) definition

of the breathing zone, it is recommended that the instrument be worn within a 25.4 cm (10") radius of the

nose and mouth. Refer to OSHA and to other agencies or groups as needed for additional information.

5

Remote Sampling

When sampling with the aspirated instrument, allow time for the air sample to reach the sensors and for the

sensors to respond to any gases that are present. Industrial Scientific recommends the allowance of two

minutes plus two seconds for each foot of sample tubing.

Cold-weather Operation

Use caution when operating the instrument in temperatures below -20 °C (-4 °F), which can diminish

display-screen legibility and man-down functionality. To help support functionality and available battery

power, the following practices are recommended.

Do not operate the instrument in temperatures that are not within the temperature ranges of the

installed sensors (see "Table 2.5, Sensor specifications").

Use a compatible, fully charged extended-run-time battery.

Before using the instrument in the cold-weather environment, power it on a warm-up environment

(approximately 20 °C [68 °F]).

Alternately operate the instrument in the cold-weather and warm-up environments.

Do not operate the instrument unmanned.

6

Product Information

Overview

Key Features

Sensor Compatibility

Specifications

2

Overview

The Ventis™ Pro Series portable gas monitors are used for personal protection to monitor for oxygen and a

variety of toxic gases and combustible gases.

Eleven compatible sensors are available for use with the Ventis™ Pro4 Multi-Gas Monitor, which can

provide readings for up to four gases. These sensors are among the 16 available for use with the Ventis™

Pro5 Multi-Gas Monitor, which can provide readings for up to five gases.

The instruments take gas readings every second and record readings-related data every ten seconds. Data

are stored in the instrument data log, which has these characteristics:

Capacity for approximately three months of readings for a unit that is on 10 hours a day and has four

installed, operational sensors

Data storage for up to 60 alarm events, 30 error events, and 250 manual calibrations and bump tests

Downloadable using compatible accessories that are supported by iNet®, DSSAC, or Accessory

Software from Industrial Scientific.

Ventis™ Pro Series instruments use a multisensory alarm-warning-indicator system comprising audible,

visual, and vibration signals.

The instrument's display-screen language can be set for English, French, German, or Spanish.

Key Features

These communication-enhancing features support operator safety:

Using iNet, DSSAC (Docking Station Software Admin Console), or Accessory Software, the safety

team can provide instrument operators with customized on-screen messages. The options include a

message that displays during the start-up sequence and those that display during gas events. A unique

instructional message can be set for each of these events for each sensor: gas present (alert, low

alarm, and high alarm), STEL, and TWA. the messaging options provide a total of 26 opportunities for

the safety team to communicate specific instructions to the instrument operator.

The panic button provides instrument operators with the ability to turn on (and off) the instrument’s

high-level alarm. This can alert others who are nearby that the instrument operator is in distress,

someone else is in distress, or there is some concern about in-field circumstances.

The man-down feature allows the instrument to sense when it has not moved. A man-down warning or

alarm may indicate the instrument operator is unable to move or press the panic button, or that the

instrument has become separated from its operator. Both the warning and alarm can be turned off by

the instrument operator.

Gas information screens can be set for operation-mode access for the instrument operator who needs

to view setpoints for gas events and calibration gas concentrations.

Several features support safety in ways that encourage operator attention and understanding, or that aid in

the prevention of operator misuse, however unintentional.

The full-screen alarm displays easy-to-read alarm details in “large type”.

The gas-alert feature warns the instrument operator of the presence of gas in concentrations that may

be approaching the instrument’s alarm setpoints. Because it can be reset by the user, the alert also

serves as a form of acknowledgement, prompting the instrument operator to check the display screen

for gas readings and an instructional message, and to optionally turn off the alert.

The alarm-latch feature is used to keep an alarm on after the alarm-causing condition no longer exists.

This serves to sustain alarm signals, which can encourage the instrument operator to check the display

screen for gas readings and an instructional message, and to optionally release the alarm latch.

Programmed iAssign™ tags can be used by the instrument operator to assign an instrument to the

user-site data on his or her tag. This can help promote a sense of ownership among instrument

operators, encouraging their responsible use of the equipment.

When used in combination with the security code feature, the instrument’s always-on option can help

prevent the instrument being powered off during operation.

When the instrument is powered-off, the quick-status feature allows users to view this instrument

information: installed sensors, available battery power, and instrument serial number.

These hardware features help protect and reduce damage to the instrument:

The raised ridge helps shield the sensor ports from dirt and damage when an instrument falls or is

dropped.

The display screen is recessed to protect it from scratches and other damage.

Rails help reduce wear from docking.

Compatibility

Sensors

Each instrument’s compatible sensors can be installed in one or more specific locations as depicted in

Figures 2.1 and 2.2 for Ventis Pro4 and Ventis Pro5, respectively. Table 2.1 provides the same information

but in list format, which is helpful for distinguishing among sensors of the same type. For example, there

are two H2S sensors that do not share installation locations or part numbers.

8

Locations 1 or 2

Hydrogen Sulfide (H2S); 17155304-2

Oxygen (O2); 17155304-3

Location 2 only

LEL (Pentane); 17155304-K

LEL (Methane); 17155304-L

Methane, 0-5% vol; 17155304-M

Locations 3 or 4

Carbon Monoxide (CO); 17155306-1

Carbon Monoxide with low Hydrogen cross-sensitivity (CO/H2 Low); 17155306-G

Hydrogen Cyanide (HCN); 17155306-B

Hydrogen Sulfide (H2S); 17155306-2

Nitrogen Dioxide (NO2); 17155306-4

Sulfur Dioxide (SO2); 17155306-5

Figure 2.1.A Sensor compatibility and installation locations for the Ventis Pro4

Locations 1 or 2

Carbon Monoxide/Hydrogen Sulfide

(CO/H2S); 17155304-J

Hydrogen Sulfide (H2S); 17155304-2

Oxygen (O2); 17155304-3

Location 2 only

Carbon Dioxide/Hydrocarbons (CO2/HC);

17155304-U

Carbon Dioxide/Methane (CO2/CH4);

17155304-V

LEL (Pentane); 17155304-K

LEL (Methane); 17155304-L

Methane, 0-5% vol; 17155304-M

Locations 3 or 4

Ammonia (NH3); 17155306-6

Carbon Monoxide (CO); 17155306-1

Carbon Monoxide/Hydrogen Sulfide (CO/H2S); 17155306-J

Carbon Monoxide with low Hydrogen cross-sensitivity (CO/H2 Low); 17155306-G

Hydrogen Cyanide (HCN); 17155306-B

Hydrogen Sulfide (H2S); 17155306-2

Nitrogen Dioxide (NO2); 17155306-4

Sulfur Dioxide (SO2); 17155306-5)

Figure 2.1.B Sensor compatibility and installation locations for the Ventis Pro5

9

Table 2.1 Sensor compatibility and installation locations

Ventis

Pro4

Ventis

Pro5

Installation

locations

Part number

Sensor

Ammonia (NH3)

No

Yes

3 or 4

17155306-6

Carbon Dioxide/Hydrocarbons (CO2/HC)

No

Yes 2 17155304-U

Carbon Dioxide/Methane (CO2/CH4)

No

Yes 2 17155304-V

Carbon Monoxide (CO)

Yes

Yes

3 or 4

17155306-1

Carbon Monoxide/Hydrogen Sulfide

(CO/H2S)

No

Yes

1 or 2

17155304-J

Carbon Monoxide/Hydrogen Sulfide

(CO/H2S)*

No

Yes

3 or 4

17155306-J

Carbon Monoxide with low Hydrogen

cross-sensitivity (CO/H2 Low)

Yes

Yes

3 or 4

17155306-G

Hydrogen Cyanide (HCN)

Yes

Yes

3 or 4

17155306-B

Hydrogen Sulfide (H2S)

Yes

Yes

1 or 2

17155304-2

Hydrogen Sulfide (H2S)

Yes

Yes

3 or 4

17155306-2

LEL (Methane)

Yes

Yes 2 17155304-L

LEL (Pentane)

Yes

Yes 2 17155304-K

Methane, 0-5% vol

Yes

Yes 2 17155304-M

Nitrogen Dioxide (NO2)

Yes

Yes

3 or 4

17155306-4

Oxygen (O2)*

Yes

Yes

1 or 2

17155304-3

Sulfur Dioxide (SO2)

Yes

Yes

3 or 4

17155306-5

Table 2.2 Battery compatibility

Rechargeable Batteries

Part number

Lithium-ion battery pack

Extended-run-time Lithium-ion

battery

17134453

17148313

Compatibility

Ventis Pro Series diffusion

Yes

Yes

Ventis Pro Series aspirated

No

Yes

*DualSense® technology capable.

Batteries

As shown below, the battery pack is compatible with the diffusion instrument only. The extended run-time

battery can be installed for use with a diffusion or aspirated instrument.

10

Table 2.3 Instrument and pump specifications

Item

Description

Display

Monochrome LCD with automatic backlight

User interface buttons

Three (power button, enter button, and panic button)

Case materials

Polycarbonate with static-dissipative protective rubber overmold

Alarm signals

Visual (two red and two blue lights); audible (95 dB at a distance of 10 cm [3.94 "],

typicala); and vibration

Dimensions

104 x 58 x 36 mm (4.09 x 2.28 x 1 42 ")

Weight

200 g (7.05 oz.), typicalb

Ingress protection

IP68 at 1.5 m (4.9 ′) for one hour

Pump

With 0.3175 cm (0.125 ") inside diameter sample tubing, sustains a continuous sample

draw for up to 30.48 m (100 ').

Temperature range

c and d

-40°C to + 50 °C (-40 °F to + 122 °F)

Humidity ranged

15−95 % relative humidity (RH) noncondensing (continuous)

Specifications

Instrument

The Ventis Pro Series’ instrument specifications are provided below in Table 2.3.

a

May vary based on in-field conditions.

b

May vary based on installed components.

c

Temperatures below -20 °C (-4 °F), can diminish display-screen legibility and man-down functionality. See also "Cold-weather Operation"

(Chapter 1, "Recommended Practices") and Table 1.1, "Certifications".

d

Sensor temperature and humidity ranges may differ from those of the instrument (see "Table 2.5, Sensor specifications").

11

Table 2.4 Battery specifications

Rechargeable Batteries

Part number

Lithium-ion battery pack

Extended-run-time Lithium-ion

battery

17134453

17148313

Llifetime

300 charge cycles

300 charge cycles

Run timea

12 hours

24 hours

Charge timeb

up to 4 hours

up to 7.5 hours

Ambient temperature required for

charging

0 − 40 °C (32 − 104 °F)

0 − 40 °C (32 − 104 °F)

Battery Specifications

Table 2.4 provides battery specifications, which include run time, charge time, charging temperature

requirements, and expected lifetime.

a

Approximate run time when the battery is fully charged and is operating at room temperature.

b

When a lithium-ion battery or battery pack becomes deeply discharged and the instrument is docked, it can take up to an hour for the

instrument display to indicate that the battery is charging.

Sensor Specifications

Table 2.5 provides specifications for each sensor, which include properties, installation locations, operating

conditions, and performance, accuracy, and response-time data.

12

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

Ammonia (NH3)

Carbon Dioxide/Hydrocarbons (CO2/HC)

17155306-6

17155304-Uc

Properties

Category

Toxic

Toxic/Combustible

Technology

Electrochemical

Infrared

DualSense™ capable

No

No

Installation location

Ventis Pro4

None

None

Ventis Pro5

3 or 4

2

Operating conditions

Temperature rangea

-20 to +40 °C (-4 to +104 °F)

-20 to +50 °C (-4 to +122 °F)

RH rangea

15-95%

0-95%

Performance

CO2

HC

Sensitivity

Measurement range

0−500 ppm

0-5% vol

0-100% LEL

Measurement resolution

1 ppm

0.01% vol

0.01% LEL

Accuracyc

Calibration gas and

concentration

50 ppm NH3

2.5% vol CO2

25% LEL Propane

Accuracy at time and

temperature of calibration

± 15% (0-100 ppm)

0 to 25% (101−500 ppm)

+10% or 0.1%

+5%

Accuracy over sensor’s full

temperature range

± 15%

+15%

+15%

Response Time

T50

30 s

17 s

17 s

T90

84 s

32 s

35 s

13

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

Carbon Dioxide/Methane (CO2/CH4)

17155304-Vc

Properties

Category

Toxic and Combustible

Technology

Infrared

DualSense™ capable

No

Installation location

Ventis Pro4

None

Ventis Pro5

2

Operating conditions

Temperature rangea

-20 to +50 °C (-4 to +122 °F)

RH rangea

0-95%

Performance

CO2

CH4

Sensitivity

Measurement range

0−5% vol

0−5% vol

5.01-100% vol

Measurement resolution

0.01% vol

0.01% vol

0.1% vol

Accuracyc

Calibration gas and

concentration

2.5% vol CO2

2.5% vol

99% vol

Accuracy at time and

temperature of calibration

± 10%

± 10%

± 10%

Accuracy over sensor’s full

temperature range

± 15%

± 15%

__

Response Time

T50

17 s

15 s

15 s

T90

32 s

30 s

30 s

14

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

Carbon Monoxide (CO)

Carbon Monoxide and

Hydrogen Sulfide

(CO/H2S)

Carbon Monoxide and

Hydrogen Sulfide

(CO/H2S)

17155306-1

17155306-J

17155304-J

Properties

Category

Toxic

Toxic

Toxic

Technology

Electrochemical

Electrochemical

Electrochemical

DualSense™ capable

No

Yes

No

Installation location

Ventis Pro4

3 or 4

None

None

Ventis Pro5

3 or 4

3 or 4

1 or 2

Operating conditions

Temperature rangea

-40 to +50 °C (-40 to +122

°F)

-20 to +50 °C (-4 to +122 °F)

-20 to +50 °C (-4 to +122 °F)

RH rangea

15-95%

15-95%

15-95%

Performance

CO

H2S

CO

H2S

Sensitivity

Measurement range

0-2000 ppm

0-1500 ppm

0−500 ppm

0-1500 ppm

0−500 ppm

Measurement resolution

1 ppm

1 ppm

0.1 ppm

1 ppm

0.1 ppm

Accuracyc

Calibration gas and

concentration

100 ppm CO

100 ppm CO

25 ppm H2S

100 ppm CO

25 ppm H2S

Accuracy at time and

temperature of calibration

± 5%

± 7%

± 10 %

± 5%

0 to 7%

Accuracy over sensor’s

full temperature range

± 10%

± 5%

± 10%

± 5%

± 10%

Response Time

T50

10 s

15 s

10 s

15 s

10 s

T90

20 s

35 s

20 s

35 s

20 s

15

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

Carbon Monoxide with low Hydrogen

cross-sensitivity (CO/H2 Low)

Hydrogen Cyanide (HCN)

17155306-G

17155306-B

Properties

Category

Toxic

Toxic

Technology

Electrochemical

Electrochemical

DualSense™ capable

No

No

Installation location

Ventis Pro4

3 or 4

3 or 4

Ventis Pro5

3 or 4

3 or 4

Operating conditions

Temperature rangea

-20 to +50 °C (-4 to +122 °F)

-30 to +40 °C (-22 to +104 °F)

RH rangea

15-95%

15-95%

Performance

Sensitivity

Measurement range

0−1000 ppm

0−30 ppm

Measurement resolution

1 ppm

0.1 ppm

Accuracyc

Calibration gas and

concentration

100 ppm CO

10 ppm HCN

Accuracy at time and

temperature of calibration

± 5% (0-300 ppm)

± 15% (301-10000 ppm)

0 to10%

Accuracy over sensor’s

full temperature range

± 15%

± 15%

Response Time

T50

8 s

15 s

T90

12 s

50 s

16

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

Hydrogen Sulfide (H2S)

Hydrogen Sulfide (H2S)

17155304-2

17155306-2

Properties

Category

Toxic

Toxic

Technology

Electrochemical

Electrochemical

DualSense™ capable

No

No

Installation location

Ventis Pro4

1 or 2

3 or 4

Ventis Pro5

1 or 2

3 or 4

Operating conditions

Temperature rangea

-40 to +50 °C (-40 to +122°F)

-40 to +50 °C (-40 to +122°F)

RH rangea

15-95%

15-95%

Performance

Sensitivity

Measurement range

0−500 ppm

0−500 ppm

Measurement resolution

0.1 ppm

0.1 ppm

Accuracyc

Calibration gas and

concentration

25 ppm

25 ppm

Accuracy at time and

temperature of calibration

± 5% (0-400 ppm)

± 7% (401-500 ppm)

± 7%

Accuracy over sensor’s

full temperature range

± 15%

± 15%

Response Time

T50

10 s

10 s

T90

25 s

25 s

17

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

LEL (Methane)

LEL (Pentane)

Methane, 0-5% vol

17155304-Lc

17155304-Kc

17155304-Mc

Properties

Category

Combustible

Combustible

Combustible

Technology

Catalytic bead

Catalytic bead

Catalytic bead

DualSense™ capable

No

No

No

Installation location

Ventis Pro4 2 2

2

Ventis Pro5 2 2

2

Operating conditions

Temperature rangea

-20 to +55 °C (-4 to +131 °F)

-20 to +55 °C (-4 to +131 °F)

-20 to +55 °C (-4 to +131 °F)

RH rangea

15-95%

15-95%

15-95%

Performance

Sensitivity

Measurement range

0−100% LEL

0−100% LEL

0-5% vol

Measurement resolution

1% LEL

1 % LEL

0.01% vol

Accuracyc

Calibration gas and

concentration

50% LEL methane

25% LEL pentane

2.5% vol

Accuracy at time and

temperature of calibration

± 3% LEL (0-50% LEL)

± 5% LEL (51-100% LEL)

± 5% LEL

± 10%

Accuracy over sensor’s

full temperature range

± 15%

± 15%

± 15%

Response Time

T50

7 s

10 s

7 s

T90

10 s

16 s

10 s

18

Table 2.5 Sensor specifications

Gas type (abbreviation)

Part number

Nitrogen Dioxide (NO2)

Oxygen (O2)

Sulfur Dioxide (SO2)

17155306-4

17155304-3

17155306-5

Properties

Category

Toxic

Oxygen

Toxic

Technology

Electrochemical

Electrochemical

Electrochemical

DualSense™ capable

No

Yes

No

Installation location

Ventis Pro4

3 or 4

1 or 2

3 or 4

Ventis Pro5

3 or 4

1 or 2

3 or 4

Operating conditions

Temperature rangea

-20 to +50 °C (-4 to +122 °F)

-20 to +55 °C (-4 to +131 °F)

-20 to +50 °C (-4 to +122 °F)

RH rangea

15-95%

5-95%

15-90%

Performance

Sensitivity

Measurement range

0-150 ppm

0-30% vol

0-150 ppm

Measurement resolution

0.1 ppm

0.1 ppm

0.1 ppm

Accuracyb

Calibration gas and

concentration

25 ppm NO2

20.9% vol O2

10 ppm SO2

Accuracy at time and

temperature of calibration

± 5%

± 0.3% vol

± 5% (0-20 ppm)

0 to 11% (21-150 ppm)

Accuracy over sensor’s

full temperature range

± 15%

± 0.2% vol

± 10%

Response Time

T50

10 s

5 s

10 s

T90

20 s

15 s

25 s

a

During continuous operation.

b

Apply when the instrument is calibrated using the stated calibration gas and concentration; accuracy is equal to the stated percentage or one

unit of resolution, whichever is greater.

c The sensor part number 17155304-M is CSA-assessed for %LEL combustible gas detection. The following sensors are not CSA-assessed

for combustible gas detection: part numbers 17155304-K, 17155304-L, 17155304-U, and 17155304-V.

“—” indicates no available data.

19

Getting Started

Unpacking the Instrument

Hardware Overview

Display Overview

Power On

Power Off

Table 3.1 Package contents

Quantity

Item

Notes

1 as ordered

Ventis Pro Series instrument

Ventis Pro4 or Ventis Pro5.

1 as ordered

Battery (factory installed)

Rechargeable Lithium-ion or Rechargeable Extended-run-time

Lithium-ion.

1

Suspender clip (factory installed)

—

1

Final Inspection & Test Report

Includes informationa about the instrument and its installed

sensors and factory calibration.

1

Reference Guide

Short-form instruction for powering on and using Ventis Pro

Series instruments.

1 as ordered

Ventis Charger

The universal power cord includes four plugs, one each for use

with US, UK, EU, and AUS receptacles.

1

Calibration cup

—

1

Calibration tubing

60.96 cm (2 ') of urethane tubing; 4.762 mm (3/16 ″) ID.

Unpacking the Instrument

3

The items that are shipped with the unit are listed below in Table 3.1. Each item should be accounted for

during the unpacking process. If any item is missing or appears to have been damaged, contact Industrial

Scientific (see back cover) or an authorized distributor of Industrial Scientific products.

a

At the time of shipment.

Front

Red lights

Sensor ports

Sensor ports

Panic button

Blue lights

Display screen

Speaker

iAssign™ touch area

Power button

Enter button

Back

Case bottom screw (x2)

Clip

Battery pack screw (x4)

Battery pack

Charging contacts

Infrared data window

Figure 3.1.A Hardware overview diffusion instrument

Hardware Overview

The instrument's main hardware components are identified below in Figures 3.1.A and 3.1.B for the

diffusion and aspirated instruments, respectively (Ventis Pro5 shown).

22

Front

Intake port

Cap

Pump door hinge

Barrel (houses water barrier)

Pump door screw

Pump door

Panic button

Red lights

Blue lights

Speaker

Display screen

iAssign™ touch area

Power button

Enter button

Infrared data window

Back

Pump case

(lower portion houses battery)

Pump case screw (x4)

Figure 3.1.B Hardware overview aspirated instrument

23

Status bar

During operation, the display screen’s

status bar communicates basic

information to the instrument operator:

instrument and battery status (shown),

ambient-air temperature, and the time of

day.

Instrument status symbol

The status bar checkmark indicates the instrument is

operational.

Other symbols

Pump installed.

The battery’s level of charge is between 67and 100%.

The battery’s level of charge is between 34 and 66%.

The battery’s level of charge is less than or equal to 33%.

The battery’s level of charge is approaching a critically low

level.

11:34a

The time of day (12-hour format shown).

76 F

The ambient-air temperature reading (Fahrenheit shown).

Display Overview

The instrument’s easy-to-read display screen has three main horizontal segments. From top to bottom, they

are:

Status bar

Gas readings area

Navigation bar

The instrument uses these areas to display symbols, numbers, abbreviations, and text in combinations that

allow it to clearly communicate with its user: the instrument operator in the field or the safety team

members who are responsible for maintaining the instrument.

See Figures 3.2.A through 3.2.D to become familiar with the display screen layout and content items the

user can expect to see at these times:

During operation

In the event of a warning or alarm

During maintenance

While working in settings

24

Gas readings area

In addition to the display of current gas

readings, this area communicates status

information about the installed sensors.

Gas reading

Gas, unit of measure, and current reading.

Other symbols

The indicated sensor is in a general state of failure.

The indicated sensor failed zeroing.

CAL

The indicated sensor failed calibration.

BUMP

The indicated sensor failed bump testing.

ERR

The indicated sensor is installed in the wrong location.

Navigation Bar

During operation, there may be

information screens or maintenance

utilities available to the instrument

operator. If so, the bottom area of the

display screen will feature the navigation

bar. The action displayed on the left is

controlled by the button underneath it, the

power button ; the action on the right is

controlled by the enter button .

Instructional symbols and text

Start the option (bump test utility shown above).

Skip the option and go to the next display screen.

Clear values.

Figure 3.2.A Reading the display during operation

Clear

25

Status bar

Gas readings area

Full-screen alarm format

In the event of a warning or alarm, the

gas readings area communicates the

event type, details about the alarm, and

gas readings for all sensors.

Event symbols (gas-related)

and

Gas present, over-range alarm

and

Gas present, high-alarm

and

Gas present, low-alarm

Gas present, alert (warning)

Short-term exposure limit (STEL) alarm

Time-weighted average (TWA) alarm

Alarm is latched

Other symbols (nongas-related, full-screen symbol)

Critical low battery

Panic alarm

Man-down alarm

System error (408 shown)

Figure 3.2.B Reading the display during an event (warning or alarm)

26

Status bar

The display screen’s status bar indicates

which maintenance procedure is in

progress (bump test utility shown here).

Utility symbols

Bump test utility

Zero utility

Calibration utility

Process in progress.

Gas readings area

The gas readings area communicates

information about the process and results

for any maintenance procedures (bump

test utility shown here).

Other symbols

Calibration gas type, unit of measure, and concentration

Results

Passed

Failed

Navigation Bar

The navigation bar provides instruction.

The action displayed on the left is

controlled by the button underneath it, the

power button ; the action on the right is

controlled by the enter button .

Instructional symbols

Cancel the utility (bump test shown here).

Start the utility.

Apply the calibration gas.

Figure 3.2.C Reading the display during maintenance

27

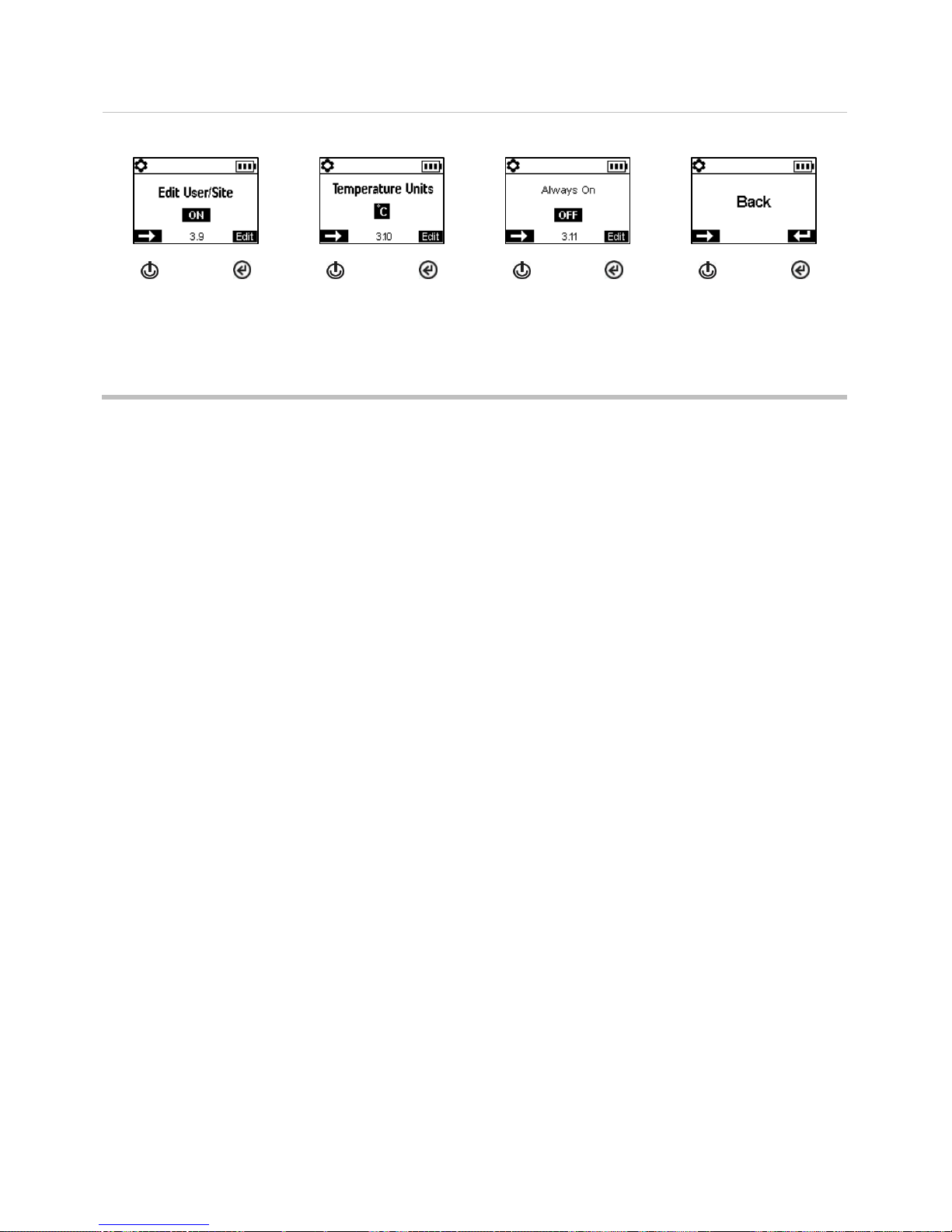

Status bar

When working in settings, the status bar

may indicate the setting name (H2S

settings shown here).

Multi-item setting

Single-item setting

Editing area

The editing area displays the settings'

values. The highlight bar indicates which

setting is being edited (gas-alert value

shown here).

Navigation bar

The navigation bar provides instruction for

navigating settings. The action displayed

on the left is controlled by the button

underneath it, the power button ; the

action on the right is controlled by the enter

button .

Status bar symbol

Settings.

Other symbols

Current setting.

Go to the next setting.

Edit the setting.

Edit the setting.

Scroll an options list.

Exit.

X.Y

"X" indicates the display screen's menu number; "Y"

indicates its setting number.

Figure 3.2.D Reading the display while working in settings

Gas names

CH4

CH4 (Methane)

CO

Carbon Monoxide

CO2

CO

2

(Carbon Dioxide)

ON

In addition to the items described above, the Ventis Pro Series’ display will also feature, when relevant, the

gas names, units of measure, and other symbols shown below.

28

H2S

H2S (Hydrogen Sulfide)

HC

Hydrocarbons

HCN

Hydrogen Cyanide

LEL

Combustible gases

NH3

NH3 (Ammonia)

NO2

NO2 (Nitrogen Dioxide)

O2

O2 (Oxygen)

SO2

SO2 (Sulfur dioxide)

Units of measure

ppm

Parts per million.

Mg/M

3

Milligrams per cubic meter.

% LEL

The lower explosive level (LEL) is the minimum concentration of a gas, which, if given an ignition

source, is capable of producing a flash of fire.

% vol

Percent by volume refers to a defined amount of the gas in 100 parts of air. For example, normal air

contains 21% vol oxygen, or 21 parts oxygen in every 100 parts of air.

Other symbols

Yes.

No.

Maintenance due (calibration shown).

The down arrow indicates the number of days since the maintenance procedure was last completed.

The up arrow indicates the number of days until the maintenance procedure is next due.

or

Peak readings.

User assignment.

Site assignment.

Return the instrument to Industrial Scientific.

Security code is required.

Data exchange or synchronization may be in progress.

Indicates that the sensor is operating on DualSense technology.

A sensor that was operating on DualSense has failed.

A sensor operating on DualSense is due for maintenance (sensor 1 shown here).

29

—

—

Attach one end of the sample tubing to the pump inlet's nipple (left); attach the other end

to a compatible water stop (right).

At each end, push on the tubing to ensure the connecting part is fully inserted into the

tubing (approximately .635 cm [.25 "]) . To test for a firm connection, gently pull on the

tubing.

Self-test

Light test

Display test

Audible and vibration test

Sample error message

The blue lights will flash

followed by the red lights.

Verify that all lights are

functional.

Observe the display screen

to verify that all pixels are

functional.

The instrument will vibrate

and then emit a loud beep.

Verify that both signal types

are functional.

If the instrument fails any

part of its self-test, an error

message will display. If the

instrument or its operator

detect problems, contact

Industrial Scientific for

assistance.

Power On

If a pump is installed, complete the following pump preparation steps before powering on the instrument.

If the use of the integrated pump is desired, but has not been installed, see Figure 8.2 Service Tasks.

To power on the instrument, press and hold the power button for approximately three seconds, until the

blue lights flash. The instrument will perform a self-test; its operator should observe the instrument and its

display screen to verify the unit is operating as expected (see Figure 3.3 below).

Immediately following the self-test is the start-up sequence, which will provide information and may prompt

the instrument operator to prepare the instrument for use. Preparation and utility options included in the

start-up sequence may vary from those shown below depending on instrument settings and whether or not

a pump is installed.

At the end of the power on process, the home screen will display.

30

Start-up sequence

Information

Date and time

Instrument information

Regulatory information

Instrument assignments

If the battery has been

reinstalled or replaced, the

instrument operator may be

prompted to set the date

and time, which can be

done manually or by

docking the instrument.

—

—

Indicates the company,

person (user), and location

(site) to which the

instrument is currently

assigned.

Maintenance information

Gas information

—

The dock information (above left) indicates maintenance is

due in the future (“days until”).

The calibration information (above right) indicates when the

maintenance was last performed (“days since”). Calibration

information can also appear as due in the future.

A series of information screens provide the setpoints for

each sensor (H2S shown). The values from left to right are:

Top row: gas present alert, low alarm, and high alarm.

Bottom row: STEL alarm, TWA alarm, and calibration gas

concentration.

Verify that the settings are appropriate.

Preparation and utilities

Start-up message

Compliance check

(German-language instruments

only)

Read and

understand

the

message.

If a pump has been installed, the instrument will prompt its

operator to complete the following pump test.

Acknowl-

edge

message.

Answer "no".

Answer

"yes".

31

Pump test

Block inlet

Wait

—

When prompted, use a thumb to block the end of the sampling

line, the water-stop opening.

While the test is in progress, the display screen will ask the

instrument operator to wait. Next, the test results will be

displayed as "Passed" or "Failed".

Test results: Passed

Test results: Failed*

Remove thumb from the

water-stop opening.

Restart the pump: Press .

It may take several seconds for

the pump to restart.

Remove thumb from the

water-stop opening.

—

Power off the

instrument.

*Note: A failed pump test may indicate a problem somewhere in the sampling line. Check and correct for cracks or other damage, debris, and

improper installation in these areas: all sampling line connections, and the pump's inlet cap, inlet barrel, and dust filter.

Zero utility

Bump test utility

Skip the

utility: wait 15

seconds.

Skip the

utility: wait

15

seconds.

Start the

utility.

Home

No fault status symbol

Home (five-gas instrument)

Battery status (shown), temperature, and time

Gas name

Home (four-gas instrument)

Unit of measure

Current gas reading

Figure 3.3 Power on

32

Home

Countdown

Enter security code

— —

Start power-off

countdown.

Hold for the full

five-second

countdown.

Enter the

diplayed value.

Edit the displayed

value.

Figure 3.4 Power off

When the instrument is powered off, the installed sensors, available battery power,

and instrument serial number can be viewed without powering on the instrument:

simultaneously press and hold and for two seconds.

Power Off

If the instrument is set to remain on, power off may require the entry of the unit’s security code.

Quick-status information

33

Settings

Guidelines

Accessing and Protecting Settings

Settings Menus

Examples for Working in Settings

Reviewing and Editing Settings

—

—

Press

Press

Press

Press

Enter the

displayed

value.

Edit the

value.

Next menu

Start

maintenance

Guidelines

4

Settings that can be adjusted manually through the instrument are described in this Product Manual. These

and other settings can also be adjusted through compatible Industrial Scientific docking stations and

accessories supported by iNet, DSSAC, and Accessory Software; any changes made manually to the

instrument will be overridden when the instrument is docked.

Only qualified personnel should access and adjust instrument settings; this person is referred to below as

the "safety specialist". To help guard against unintended access by nonqualified personnel, settings can be

security-code protected.

Accessing and Protecting Settings

Settings can be accessed while the instrument is powering on—any time during the start-up sequence—by

simultaneously pressing then releasing and . If the security-code screen is activated, settings are

protected and the instrument's security code must be entered. If the entered value matches the

instrument's security code, the first settings menu (1.0 Maintenance) will display; otherwise, access to

settings will be denied and the instrument will resume start-up.

Table 4.1 Settings menus

Menu number and topic

Settings summary

1.0

Maintenance

The primary purpose of the maintenance menu is to provide the safety specialist with

access to maintenance procedures (utilities). The specialist can also control from

here the NFC setting and make user or site assignments.

2.0

Start-up

Start-up settings allow the safety specialist to permit or prohibit all-user access—from

the start-up sequence—to some utilities and maintenance status information (e.g.,

number of days until calibration is due).

3.0

Operation