Industrial Scientific Ventis LS Product Manual

Ventis LS

Multi-gas Monitor

Product Manual

Set-up

Operation

Service

17153965-1

Edition 2

Aug. 24, 2018

Multilingual

user documentation resources

available at

www.indsci.com/VentisLSresources

Chinese

French

German

Spanish

and more!

(Revision 2)

Ventis LS Product Manual

Table Of Contents

Copyright Notice .......................................................................................................................................................... 3

Warnings and Cautionary Statements ....................................................................................................................... 3

General ...................................................................................................................................................................... 3

Personnel ................................................................................................................................................................... 3

Hazardous Conditions, Poisons, and Contaminants .................................................................................................. 3

Factors that Affect Monitor Performance .................................................................................................................... 4

Certifications .............................................................................................................................................................. 4

Recommended Practices ........................................................................................................................................... 5

Ventis LS Resources ................................................................................................................................................... 6

Ventis LS Capabilities .................................................................................................................................................. 6

Unpacking the Monitor ................................................................................................................................................ 7

Contents ..................................................................................................................................................................... 7

Reporting a Problem .................................................................................................................................................. 7

Monitor Overview ......................................................................................................................................................... 8

Hardware Features and Functions ............................................................................................................................. 8

Display Screen ........................................................................................................................................................... 9

Alarms ...................................................................................................................................................................... 11

Monitor Set-up ............................................................................................................................................................ 13

Battery Properties .................................................................................................................................................... 14

Charging the Lithium-ion Battery Packs ................................................................................................................... 14

Power-On and -Off ................................................................................................................................................... 15

Configuration ............................................................................................................................................................ 16

Introduction .......................................................................................................................................................... 16

Instructions ........................................................................................................................................................... 16

Monitor Use and Service ........................................................................................................................................... 23

Zero, Calibration, and Bump Testing ........................................................................................................................ 23

Introduction .......................................................................................................................................................... 23

Prepare the gas cylinder for use .......................................................................................................................... 25

Zero and Quick Calibration Process ................................................................................................................. 26

Quick Bump Test Process ................................................................................................................................ 29

Recommended Practices for In-field Air Sampling ................................................................................................... 31

Cleaning ................................................................................................................................................................... 31

Service ..................................................................................................................................................................... 31

Battery Packs ................................................................................................................................................... 31

Sensor, Sensor Barrier, LCD, and Vibrating Motor Replacement .................................................................... 32

Specifications and Certifications .............................................................................................................................. 35

Monitor Specifications .............................................................................................................................................. 35

Sensor Specifications ............................................................................................................................................... 35

Certifications ............................................................................................................................................................ 36

Wireless certification ................................................................................................................................................ 36

Warranty ..................................................................................................................................................................... 36

Limitation of Liability ................................................................................................................................................. 36

2 © Industrial Scientific Corporation

Ventis LS Product Manual

General

IMPORTANT

www.indsci.com/ VentisLSresources.

Personnel

CAUTION: For safety reasons, this equipment must be operated and serviced by qualified personnel only.

d'entretenir ou de réparer l'équipement.

Hazardous Conditions, Poisons, and Contaminants

WARNING: Servicing the unit, replacing or charging battery pack s, or using the co mmu ni cat ions port must only

be done in an area known to be nonhazardous. Not for use in oxygen-enriched atmospheres.

WARNING: Power-off the monitor before servicing the unit or replacing the battery.

WARNING: Substitution of components may impair intrinsic safety and may cause an unsafe condition.

AVERTISSEMENT: La substitution de composants peut compomettre la securite intrinseque.

CAUTION: High off-scale readings may indicate explosive gas concentration(s).

CAUTION: Any rapid up-scale reading followed by a declining or erratic reading may indicate gas

concentration(s) beyond the upper scale lim it w hich may be haz ar dou s.

Silicone compound vapors or other known contaminants may affect the combustible gas sensor and cause

measurements.

Copyright Notice

Ventis™ is a trademark of Industrial Scientific Corporation.

All trademarks and registered trademarks are the property of their respective owners.

These help materials or any part thereof may not, without the written consent of Industrial Scientific Corporation, be

copied, reprinted, or reproduced in any material form including but not limited to photocopying, transcribing,

transmitting, or storing it in any medium or translating it into any language, in any form or by any means, be it digitally,

electronic, mechanical, xerographic, optical, magnetic, or otherwise.

The information contained in this document is proprietary and confidential and all copyright, trademarks, trade names,

patents, and other intellectual pr operty rights in the documentation are the exclusive property of Industrial Scientific

Corporation unless otherwise specified. The information (including but not limited to data, drawings, specification,

documentation, software listings, source or object code) shall not at any time be disclosed directly or indirectly to any

third party without prior written consent.

The information contained herein is believed to be accurate and reliable. Industrial Scientific Corporation accepts no

responsibility for its use by any means or in any way whatsoever. Industrial Scientific Corporation shall not be liable

for any expenses, costs by damage that may result from the use of the information contained within this document.

Although every effort is made to ensure accuracy, the specifications of this product and the content herein are subject

to change without notice.

Warnings and Cautionary Statements

Failure to perform certain procedures or note certain conditions may impair the performance of this

product. For maximum safety and optimal performance, please read and understand the Ventis LS

Product Manual available online at the Ventis LS Resource Center at

Read and understand the product manual completely before oper at ing or ser vici ng.

ATTENTION: Pour des raisons de sécurité, cet équipment doit étre utilesé entretenu et réparé uniquement par

un personnel qualifié. Étudier le manuel d'instructions en entier avant d'utiliser,

ATTENTION: Des lectrures supérieures a l'échelle peuvent indiquer des concentrations explosives.

readings of combustible gas to be lower than actual gas concentrations. If the monitor has been used in an

area where silicone vapors were present, always calibrate the monitor before next use to ensure accurate

© Industrial Scientific Corporation

3

Ventis LS Product Manual

Factors that Affect Monitor Performance

Oxygen-deficient atmospheres may cause combustible gas readings to be lower than actual concentrations.

Oxygen-enriched atmosphere s may cau se combu stib le gas readings to be higher than actual concentratio ns.

Sudden changes in atmospheric pressure may cause temporary fluctuations in the oxygen reading.

Verify the calibration of the combustible gas sensor after any incident where the combustible gas content has

caused the monitor to display an over-range con diti on.

Sensor openings and water barriers must be kept clean. Obstruction of the sensor openings and/or

contamination of the water barriers may cause readings to be lower than actual gas concentrations.

Do not use the ISC Alkaline battery pack (P/N:17150608) with the Ventis LS monitor.

The Ventis LS is CSA certified according to the Canadian Electrical Code for use in Class I, Division 1 and

CSA Standard C22.2 No. 152. This is applicable only when the monitor has been calibrated to 50% LEL CH

4.

CAUTION: CSA C22.2 No. 152 requires before each day’s usage, sensitivity must be tested on a known

section of the Product Manual.

Certifications

The EC type examination certificate is DEMKO 11 ATEX 1104473 with marking code Ex d ia I Mb/Ex d ia IIC

T4 Gb for equipment category II 2G and I M2.

The IECEx examination certificate is IEC Ex UL11.0023 with marking code Ex d ia IIC T4 Gb.

The model Ventis LS complies with relevant provisions of European ATEX directive 94/9/EC and EMC

directive 2004/108/EC

The Ventis LS Multi-gas monitor is constructed with reference to published standards of directive 2006/95/EC,

These detectors have been investigated for risk of explosion, fire, and electric shock only. They have not been

investigated for performance relative to their ability to detect gases or vapors.

The radio in the Industrial Scientific Ventis LS Portable Multi Gas monitor has been assessed to and found to

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

authority to operate the equipment.

Class I, Zone 1 Hazardous Locations within an ambient temperature range of T

: -20°C to +50°C. CSA has

amb

assessed only the %LEL combustible gas detection portion of this instrument for performance according to

concentration of pentane or methane equivalent to 25% or 50% of full scale concentration. Accuracy must be

within -0% to +20% of actual concentration. Accuracy may be corrected by referring to the zero/calibration

to eliminate electrical risks and fulfill 1.2.7 of ANNEX II of directive 94/9/EC.

be below limits as defined in FCC; Innovation, Science and Economic Development Canada; and European

Council recommendation 1995/519/EC requirements for human exposure to electromagnetic fields.

Part 15 B and C of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the interference at

their expense.

• The instrument complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

• This device must accept any interference received, including interference that may cause undesired

operation.

Changes or modification made that are not expressly approved by the manufacturer could v oid the user’s

4 © Industrial Scientific Corporation

Ventis LS Product Manual

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the

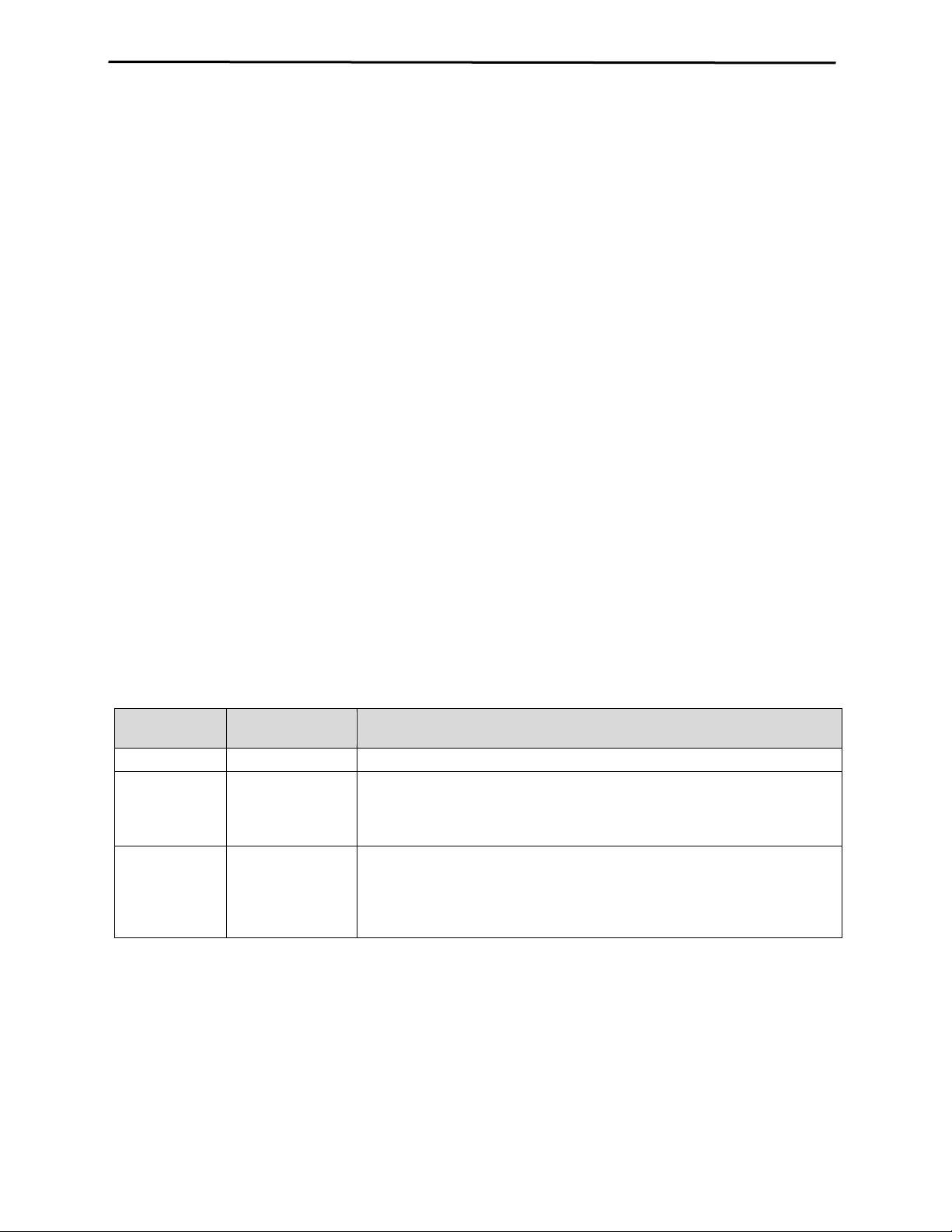

The Ventis LS Portable Multi Gas Monitor contains 1 radio communication module that generates radio

Wifi Radio

Maximum Radiated Transmit Power

2405 to 2480 MHz

8.2 dBm (6.6 mW)

Recommended Practices

Industrial Scientific recommends persons with a pacemaker or implantable cardio defibrillator (ICD) should

recommendations.

Industrial Scientific Corporation recommends the monitor be charged, configured, and calibrated b efor e fir st

time use.

Industrial Scientific Corporation recommends a full monitor calibration be performed monthly (at a minimum),

using a certified concentration(s) of Industrial Scientific calibration gas(es) to help ensure monitor accuracy.

Industrial Scientific Corporation recommends the monitor be zeroed and bump tested before each use with a

certified concentration(s) of Industrial Scientific calibration gas(es).

Battery contacts are exposed on battery packs when they are removed from the monitor. Do not touch the

battery contacts and do not stack battery packs on top of one another.

Contact your service representative immediately if you suspect that the Ventis LS is working abnormally.

following two conditions: (1) this device may not cause interference, and (2) this device must accept any

interference, including inter fer ence that may cause unde sired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en com prom ettr e le fon ctio nne me nt .

frequency energy. They frequency and output power are listed below:

maintain a minimum separation distance of 15 cm (6 ") between the pacemaker or ICD and a wireless-enabled

instrument. Please consult your physician or pacemaker or ICD manufacturer for additional guidance and

© Industrial Scientific Corporation

5

Ventis LS Product Manual

Sensor

Category

Number available

per monitor

Gases Monitored

Oxygen

1

O2 (Oxygen) only

Combustible

1

Monitor can be configured for sensor to measure ONE of the following:

• CH4 (0%-5%)

Toxic

2

Each sensor detects and measures only ONE of the following:

• SO2 (Sulfur Dioxide)

Ventis LS Resources

The Ventis LS Product Manual is the primary resource, within a full suite of learning tools, developed for the monitor

user. Its step-by-step “walk through” format covers everything from unpacking to set-up, operation, and service. All

Ventis LS users should read and understand the Product Manual prior to unpacking or using the monitor.

A companion to the manual, the Ventis LS Reference Guide ships with the monitor. It serves to announce all warnings

and cautionary statement s relev ant to gener al mon itor use . The guide also features process charts that provide an

overview of four fundamental tasks: operation/start-up, configuration, calibration, and functional “bump” testing. These

charts are tools for the user who is both familiar with the manual and proficient in the performance of the given t as k.

A collection of audio-visual learning tools is also available online at the Ventis LS Resource Center. Here the user can

watch fully narrated step-by-step demonstrations of instruction sets outlined in the manual. These training modules

allow the user to view the full presentation of a process, such as calibration, or to access a particular segment within

that process. These Ventis LS product-specific resources are part of the organization’s broader training line-up,

featuring face-to-face classroom programs for technicians, operators, first responders, trainers, and distributors.

Courses combine theory with hands-on learning, and can be tailored to the customer’s unique requirements and gas

monitoring applications.

The organization’s customer and technical support call centers provide product and order information, how-to product

assistance, and guidance for in-depth technical applications. Its service centers offer comprehensive factory repair

and maintenance services.

Industrial Scientific Corporation provides a full suite of resources to aid customers in the competent and safe use of

its products and service s. With manufac turing, support, and service centers and hundr ed s of distrib ut ors w orldwide,

Industrial Scientific serves the globe’s gas detection needs.

Ventis LS Capabilities

The Ventis LS is a portable multi-gas monitor. It detects and measures gas(es) present in open space. Its wireless

feature continuously communicates gas readings and alarm events to a control center. Based on the customer’s

monitor order, up to four sensors are factory installed enabling the monitor to continuously and simultaneously detect

and measure the presence of up to four specific gases.

• LEL (Pentane)

• LEL (Methane)

• CO (Carbon Monoxide)

S (Hydrogen Sulfide)

• H

2

• NO

Equipped with a multi-mode (audible, visual, and vibration) and multi-level alarm system, the Ventis LS monitor is

capable of notifying it s user of potentially hazardous gas concentr atio ns. It is also equipped with motion alarms and a

panic alarm.

The monitor performs continu o us datalogging at 10 second intervals. It can store approximately 90 days of data for a

four-sensor configuration. Its date- and time-stamped event log records and stores data for 24 alarm events and a

minimum of 15 error events. The memory, when full, overwrites the oldest data as the newest readings and events

are logged.

(Nitrogen Dioxide)

2

6 © Industrial Scientific Corporation

Ventis LS Product Manual

Quantity

Item

Notes

1 as ordered

Ventis LS Portable Multi-gas

-1

Ventis LS Reference Guide

A companion to the Ventis LS Product Manual.

1 installed as ordered

Battery Pack

One of two battery types is factory installed as

• Rechargeable Extended Range Lithium-ion

1 as ordered

Charger

Universal power cord. AC charger products includ e

interchangeable plugs (US, UK, EU, and AUS).

0 or 1

Calibration Cup

--

1

Calibration and Bump Test

--

1

Final Inspection & Test Report

Contains the following factory set* information:

*Some factory set sensor values subject to user changes.

1

Service Tool

Tool includes two screw heads; a #1 Phillips head

and a T10 Torx bit are stored inside the handle.

1

Warranty Card

--

The Ventis LS monitor functions as an independent device to monitor the environment for hazardous gas

concentrations. It is also part of the Ventis Syst em including products that charge, calibrate, bump test, datalink,

protect, and otherwise enable or enhance use of the monitor and its data. (Datalink refers to capabilities that enable

access to the download and use of monitor datalogs, reports, and other information.)

Unpacking the Monitor

Contents

The monitor box contains the following items including, when ordered, those marked optional. Each item ordered

should be accounted for in the unpacking process.

Monitor

Tubing

•

indicated on the box label. Options:

• Rechargeable Lithium-ion

Two feet of clear tubing

• Monitor Set-up Date

• Monitor Part Number (P/N)

• Monitor Serial Number (S/N)

• For Each Sensor*:

• P/N

• S/N

• Type

• Location

• Alarm level values

• Span gas values

• Span reserve values

Reporting a Problem

After unpacking, if any item is missing or appears to have been damaged, contact a local distributor of Industrial

Scientific products or Industrial Scientific Corporation (for contact information, please see the manual’s last page).

© Industrial Scientific Corporation

7

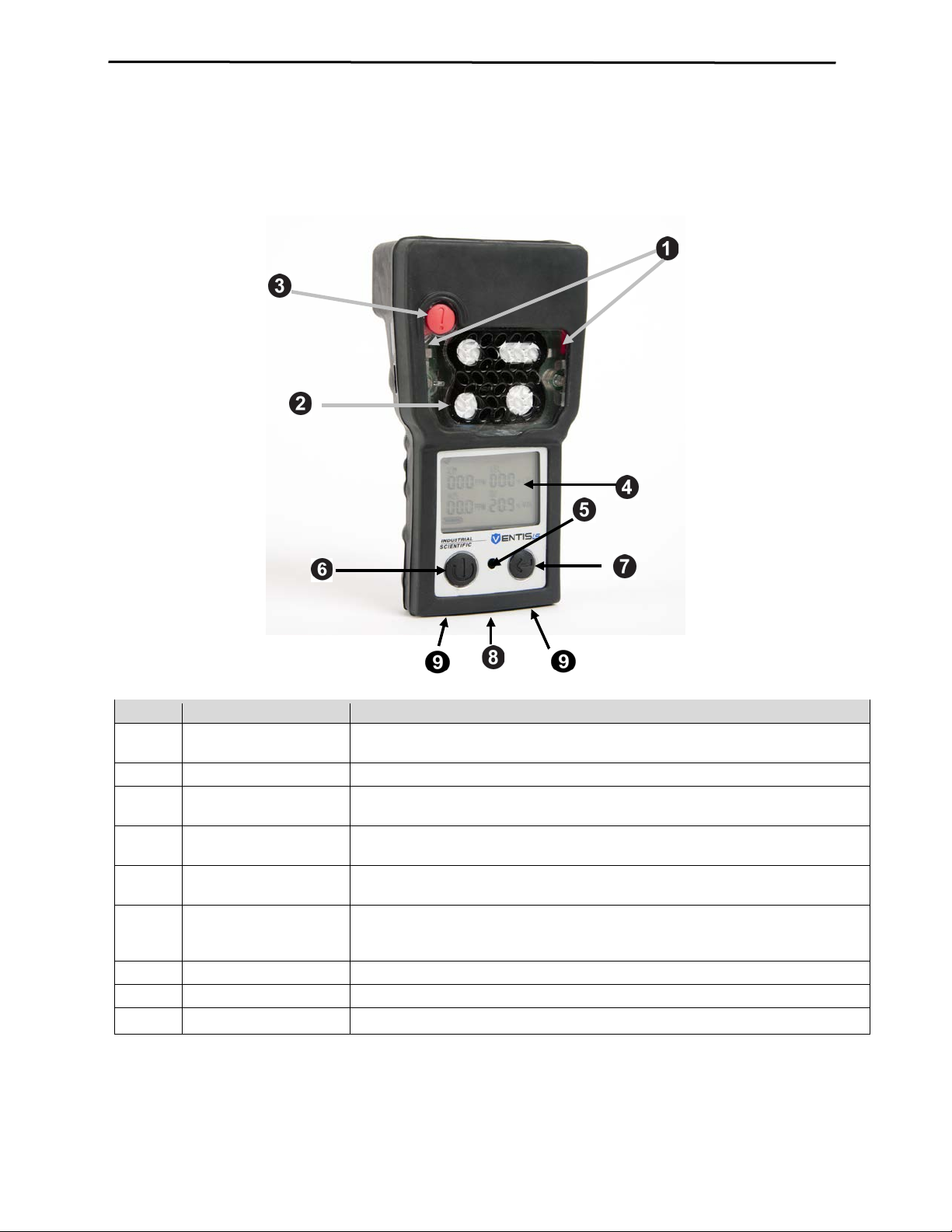

Ventis LS Product Manual

Number

Feature

Functions

1

Visual alarm indicator

Signals an alarm or warning; frequency varies by alarm level. Also used as a

confidence indicator.

2

Sensor ports

Air intake; calibration and bump test gas intake.

3

Panic button

Used to signal an alarm on the instrument and wirelessly to the communications

center.

4

LCD display

User interface; backlight flashes when monitor is in system, high, or low alarm

states.

5

Audible alarm ports

On when monitor is in system, high, or low alarm states; frequency and tone vary

by alarm level. Also used for warnings and as confidence indicator.

6

On/Off/Mode button

Used to power-on and power-off. Also used to bypass a process/step or advance

configuration mode.

7

Enter button

Used to begin a process/step in a process. Edits values in configuration mode.

8

IrDA interface

Indicates infrared light data exchange in-progress.

9

Charging contacts

Battery charging.

Monitor Overview

Hardware Features and Functions

to a next screen in both gas monitoring and configur ati on mo des. Sets va lue s in

8 © Industrial Scientific Corporation

Ventis LS Product Manual

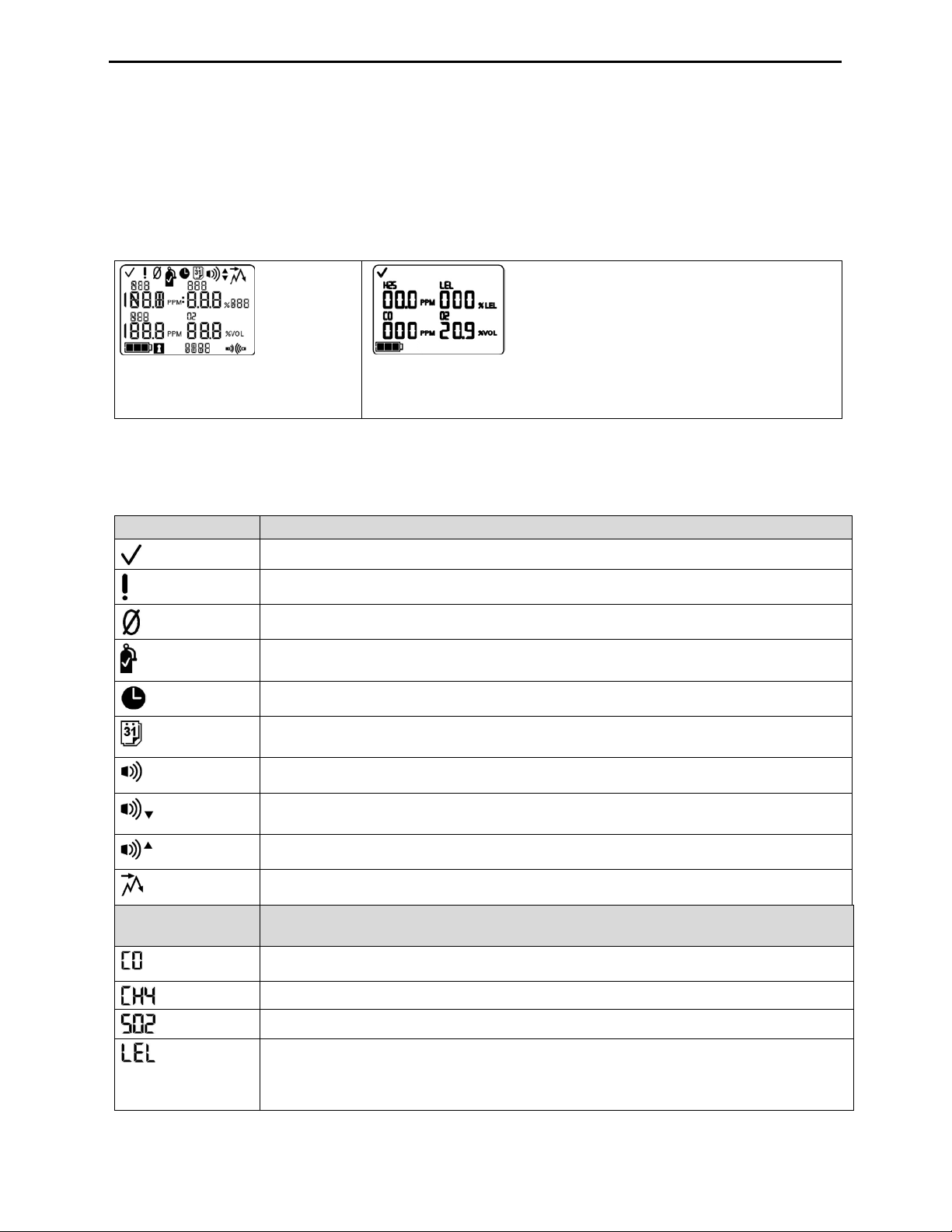

Top Row Icons

Definition

Status: indicates no monitor or sensor faults.

Warning: indicates monitor or sensor fault.

Zero: communicates zero status (e.g., zero results, zero in-progress, etc.).

Gas Cylinder: communicates calibration related information (calibration due, calibration apply

gas, etc.).

Clock: indicates a process is in-progress.

Calendar: communicates overdue warnings for service items (calibration, bump testing, etc.).

Alarm: indicates an alarm causing condition.

Low level audio alarm is on.

High level audio alarm is on.

Peak: displayed when peak detection values are viewed.

Alpha-numeric

display values

Definition

Carbon Monoxide (CO)

Methane (CH4)

Sulfur Dioxide (SO2)

Lower Explosive Limit. Display variations:

“UEG” (German)

Display Screen

The Ventis LS Boot-up Screen, as shown below, serves to introduce all icons and the alpha-numeric items (e.g.,

8.8.8) that can appear on the display when the monitor is in use, docked, or charging. Each display item is stationary,

communicates unique information, and appears only when relevant to the task being performed.

A sample Gas Monitoring Screen is also shown below, next to the boot-up screen. This illustrates how the icons and

the alpha-numeric characters work together to communicate several points of information to the monitor user.

Boot-Up Screen

All possible screen images.

Gas Monitoring Screen

Sample screen in gas monitoring mode.

It is helpful to view the boot-up screen in sections. The top and bottom rows each contain icons. The main function of

the middle section, in gas monitoring mode, is to communicate gas concentration readings. Definitions for all icons,

gas name abbreviations, gas measurement unit s, and oth er indi cators are provided below. Where appl icable, display

variations are noted.

“LEL” (English)

“LIE” (French)

© Industrial Scientific Corporation

9

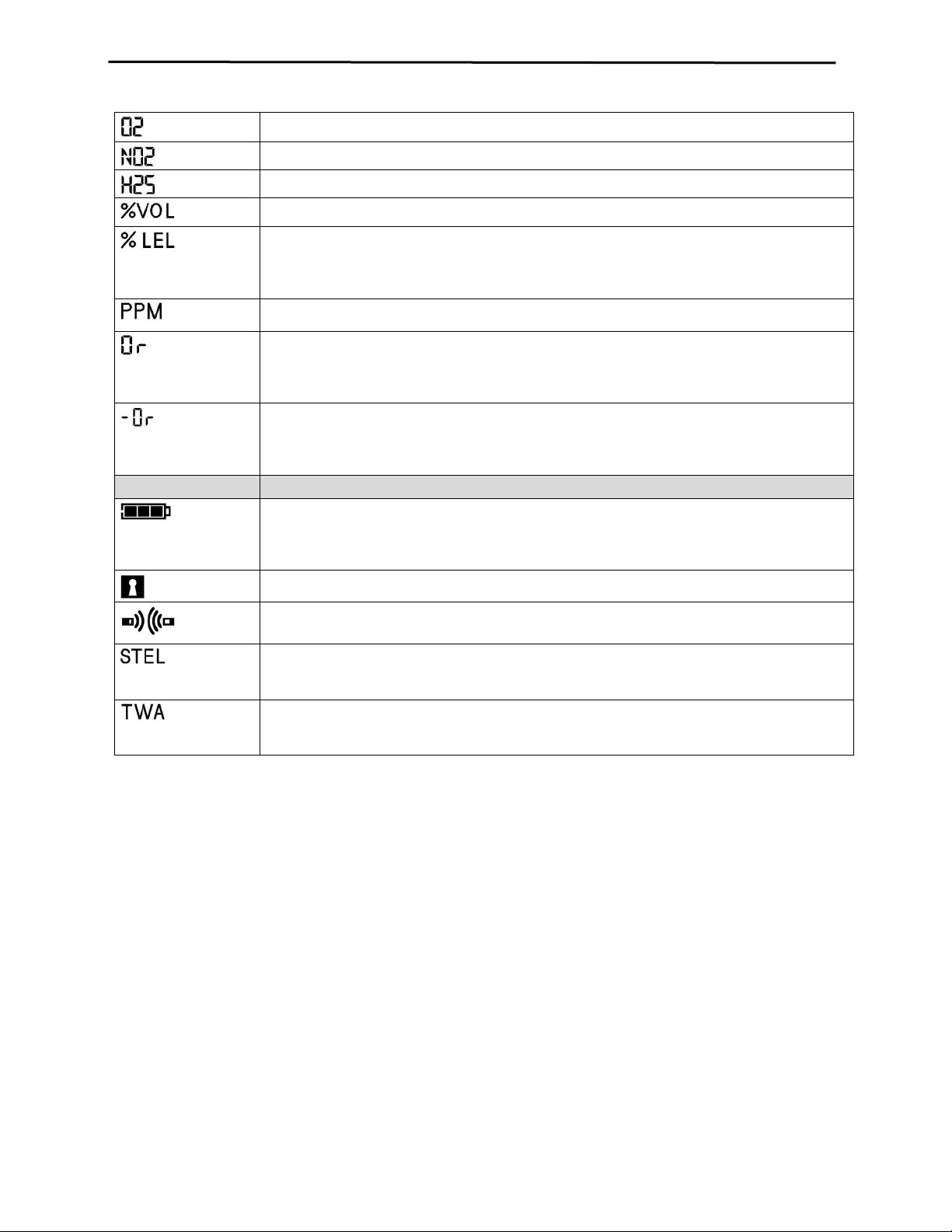

Ventis LS Product Manual

Oxygen (O2)

Nitrogen Dioxide (NO2)

Hydrogen Sulfide (H2S)

Percentage Volume: O

and CH4 measurement unit

Percentage unit for combustible gases; display variations:

“% UEG” (German)

Parts Per Million: H2S, CO, SO2 and NO2 measurement unit.

Over-range: for any sensor in over-range, indicates the measured gas concentration is greater

“Sup” (French)

Negative Over-range: for any sensor in negative over-range indicates the measured gas

“InF” (French)

Bottom Row Icons

Definition

Battery level indicator; display v ariations:

3 bars = 67% – 100% charge remaining

Security Code: indicates code is set or to be entered.

Indicates IrDA communication is in-progress when the monitor is docked.

Indicates wireless communication is active when the monitor is NOT docked.

Short Term Exposure Limit: communicates STEL values. Display variations:

“VLE” (French)

Time Weighted Average: communicates TWA values. Display variations:

“VME” (French)

2

“% LEL” (English)

“% LIE” (French)

than the measurement range of the sensor. Display variations:

“Or” (English and German)

concentration is less than the negative measurement range of the sensor. Display variations:

“-Or” (English and German)

1 bar < 33% charge remaining

2 bars = 34% - 66% charge remaining

“STEL” ( English and German)

“TWA” (English and German)

10 © Industrial Scientific Corporation

Ventis LS Product Manual

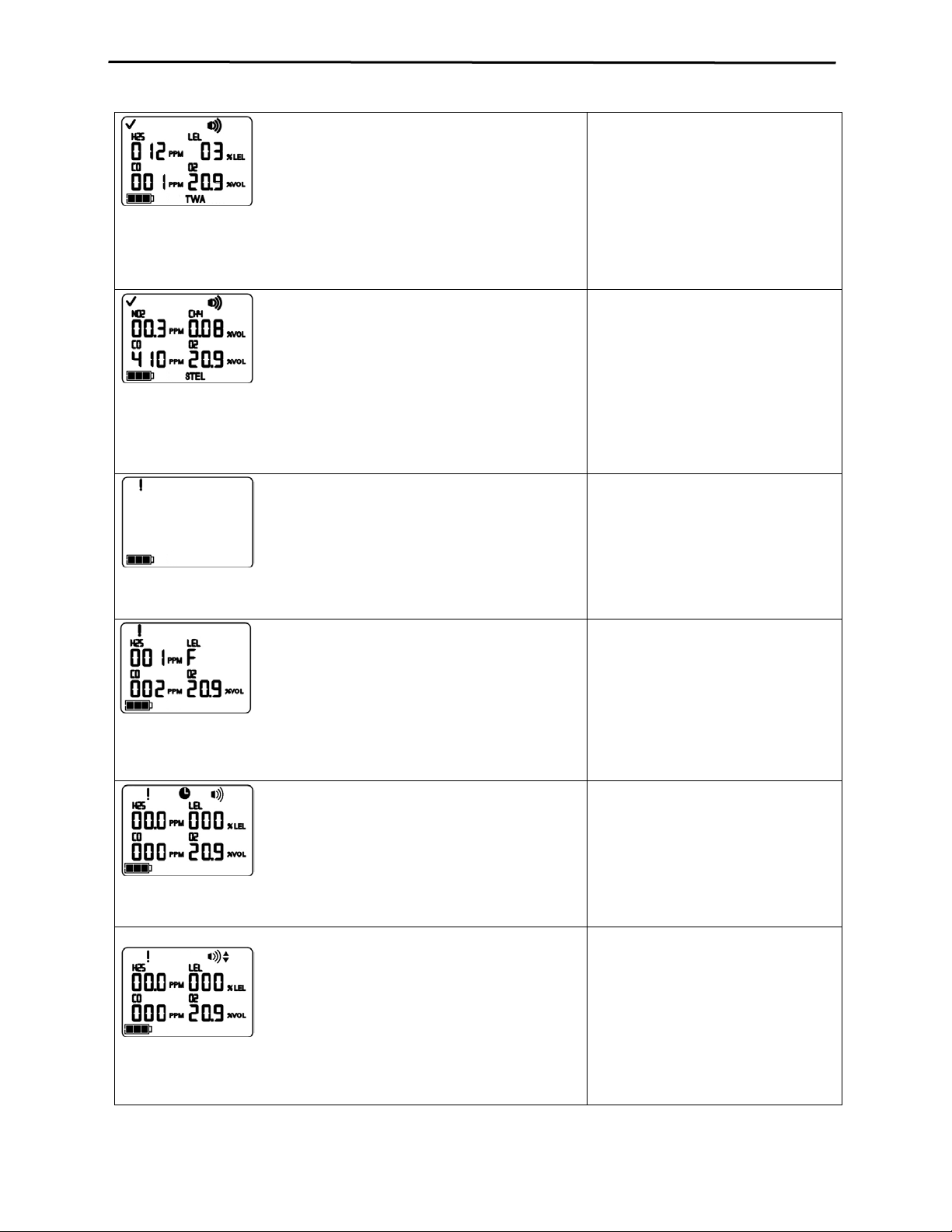

Display

Description

The high level alarms turn on and the alarm icon displays.

An over-range condition occurs when

readings*. The high level alarms turn on and the alarm icon displays.

A negative over-range condition occurs

displays.

A high alarm condition occurs when

displays.

A low alarm condition occurs when the

Alarms

NOTICE

→ All monitor alarms and warnings should be taken seriously and responded to as stated in company safety

standards.

It is practical for the monitor user to be aware of the possible alarms prior to monitor set-up and use. The Ventis LS

has multiple alarm and warning signals. A “system level” alarm generates the highest frequency tone and highest

level visual and vibration signals. It is used to indicate such events as a sensor failure. Compared to the system

alarm, gas alarms are of lower intensity, and a quick repetitive burst of signals is used to indicate a panic or motion

alarm. The lowest level indicator is a warning with low-level beep patterns to indicate service needs (e.g., low battery

or calibration due). The beep is also used as a confidence indicator when enabled.

Alarm types and their alarm generating conditions are described below.

the gas concentration value sensed is

above the sensor’s measuring range.

Over-range Alarm Screen

The “Or” message indicates which sensor(s) is reading an over-range

condition(s). All other sensors show their curre nt gas con cen t r ation

readings on a numeric display (left) or gas names on a text display (right).

After any over-range alarm, th e

monitor should be calibrated.

NOTE: The O2 and toxic sensor values normally

reset when the gas sensed reaches an acceptable

range. If the LEL sensor reads over-r an ge, t he

alarm “latches” or remains on until the monitor is

powered-off.

Negative Over-range Alarm Screen

The “-Or” message indicates which sensor is reading a negative overrange condition. All other sensors display their current gas concentration

High Alarm Screen

A flashing gas concentration value* indicates which sensor(s) reading(s) is

the cause for alarm. The high level alarms turn on and the up arrow icon

Low Alarm Screen

A flashing gas concentration value* indicates which sensor(s) reading(s) is

the cause for alarm. The low level alarms turn on and the down arrow icon

when the gas concentration value

sensed is less than the sensor’s

measuring range.

After any negative over-range alarm,

the monitor should be calibrated.

the concentration of gas sensed

reaches a level greater than the

monitor’s high alarm value setting for a

sensor(s).

concentration of gas sensed reaches

the monitor’s low alarm value setting

for a sensor(s).

© Industrial Scientific Corporation

11

Ventis LS Product Manual

flashes.

A TWA alarm occurs when the

The STEL alarm occurs when the short

The system level alarms turn on and the error icon displays.

Alarm occurs when the monitor

alarm turns on and the error icon displays.

Alarm occurs when any installed

The panic-motion alarm signals turn on.

The Motion 1 alarm occurs when the

The Motion 2 alarm occurs when the

calculated time weighted average

reaches the monitor’s hazardous value

for the set time frame.

TWA Alarm Screen

A flashing gas concentration value* indicates which sensor(s) reading(s) is

the cause for alarm. The low level alarms turn on and the TWA icon

STEL Alarm Screen

A flashing gas concentration value* indicates which sensor(s) reading(s) is

the cause for alarm. The low level alarms turn on and the STEL icon

flashes.

No Sensor Installed Screen

term exposure value exceeds the

acceptable limit.

registers no sensors installed.

sensor’s data-relat ed operations fail

and the sensor is not operational.

Sensor Data Fail Screen

A flashing “F” indicates which sensor is the cause for alarm. The audio

Motion 1 Alarm Screen

Motion 2 Alarm Screen

The panic-motion alarm signals turn on.

instrument has not moved for 1 minute

(default setting; subject to change). To

turn off the alarm, the user can move

the monitor or press the ENTER

button.

Motion 1 alarm has not been cleared.

The user can clear the Motion 2 alarm

by pressing the ENTER button for one

second.

12 © Industrial Scientific Corporation

Loading...

Loading...