Product

Manual

The Essential Guide for

Safety Teams and

Instrument Operators

Part Number: 17154993-1

Edition: 5

August 12, 2014

Industrial Scientific Corporation.

Oakdale, PA USA

Shanghai, China

© 2012, 2013, 2014 Industrial Scientific Corporation

All rights reserved. Published 2014

Revision 7

ii

Contents

General Information .................................................................................................................................................................................................. 1

Introduction ........................................................................................................................................................................................................... 1

Certifications .................................................................................................................................................................................................... 1

Product Overview ................................................................................................................................................................................................. 2

Product Specifications .......................................................................................................................................................................................... 3

Recommended Practices .......................................................................................................................................................................................... 7

Introduction ........................................................................................................................................................................................................... 7

Procedures ........................................................................................................................................................................................................... 7

Recommendations ................................................................................................................................................................................................ 8

First Use ............................................................................................................................................................................................................... 9

Wearing the Instrument ........................................................................................................................................................................................ 9

Instrument Basics ................................................................................................................................................................................................... 11

Unpacking the Instrument ................................................................................................................................................................................... 11

Hardware Overview ............................................................................................................................................................................................ 12

Display Overview ................................................................................................................................................................................................ 12

Start-up and Shutdown ....................................................................................................................................................................................... 14

Instrument Preparation and Use ............................................................................................................................................................................. 17

Configuration ...................................................................................................................................................................................................... 17

Operation ............................................................................................................................................................................................................ 25

Zero, Calibration, and Bump Test....................................................................................................................................................................... 28

Alerts, Warnings, and Alarms ................................................................................................................................................................................. 31

Overview ............................................................................................................................................................................................................. 31

Event Causes and Recommended Actions ........................................................................................................................................................ 32

Service and Warranty ............................................................................................................................................................................................. 37

Service Instructions ............................................................................................................................................................................................ 37

Supplies.......................................................................................................................................................................................................... 37

Three-dimensional Diagrams ......................................................................................................................................................................... 38

Service Tasks ................................................................................................................................................................................................. 40

Warranty Policy .................................................................................................................................................................................................. 44

Limitation of Liability ....................................................................................................................................................................................... 44

Contact Information…………………………………………………………………………………………………………………………………Back Cover

iii

Tables and Figures

Table 1.2 Warnings and cautionary statements ....................................................................................................................................................... 2

Table 1.3 Sensor-type options .................................................................................................................................................................................. 3

Table 1.4 Instrument specifications .......................................................................................................................................................................... 4

Table 1.5 Sensor specifications ................................................................................................................................................................................ 4

Table 1.6 Battery properties ...................................................................................................................................................................................... 5

Figure 1. Probability of sensor failure by bump test frequency ................................................................................................................................. 9

Table 2.2 Securing the garment or belt clip .............................................................................................................................................................. 9

Table 3.1 Package contents ................................................................................................................................................................................... 11

Table 3.2. Hardware overview ................................................................................................................................................................................ 12

Table 3.3 Display screen indicators and abbreviations .......................................................................................................................................... 12

Table 3.4 Start-up and shutdown ............................................................................................................................................................................ 14

Table 4.1 Configuration instruction ......................................................................................................................................................................... 18

Table 4.2 Operation instruction ............................................................................................................................................................................... 26

Table 4.3 Zero, calibration, and bump test ............................................................................................................................................................. 28

Table 5.1 Overview ................................................................................................................................................................................................. 31

Table 5.2 Events ..................................................................................................................................................................................................... 31

Table 5.3 Recommended action by event type ...................................................................................................................................................... 32

Figure 6.1 Disassembled Tango TX1 ..................................................................................................................................................................... 38

Figure 6.2 Disassembled Tango TX1 case top assembly ...................................................................................................................................... 38

Table 6.1 Key for the Tango TX1 diagram .............................................................................................................................................................. 39

Table 6.2 Service tasks ........................................................................................................................................................................................... 40

Table A.1. Sensor cross interference (percent response) ...................................................................................................................................... 45

Table A.2. ATEX and IECEx marking requirements ............................................................................................................................................... 45

iv

1

General Information

Introduction

Certifications

Product Overview

Product Specifications

Introduction

C

ERTIFICATIONS

Each Tango TX1TM is certified by one or more certifying bodies (CBs). The approved uses for which a unit is certified

appear on label(s) affixed to the instrument.

When a new certification is received, it is not retroactive to any unit that does not bear the new marking on its label.

Instrument certifications at the time of this document's publication are noted below (see Table 1.1). To determine for

which uses a unit is certified, always refer to the unit's labels.

CBs issue warnings and cautionary statements to notify the safety team and instrument operators of important

information, or to restrict instrument use or service (see Table 1.2). Those items listed under the heading, "General",

are issued by more than one CB or by Industrial Scientific Corporation (ISC); these apply to each unit regardless of

its certifications. Additionally, those items listed under the heading of a specific CB apply to units that bear its

markings.

Table 1.1 Certifications

Directive or CB Area Classifications Approved Temperature Range

Americas

CSA Ex ia IIC T4; Class 1; Groups A, B, C, D; T4 -40 °C to +50 °C (-40 °F to +122 °F)

IECEx Ex ia I Ma

Ex ia IIC T4 Ga

INMETRO

UL (C-US) Class I, Groups A, B, C, and D;

Ex ia IIC T4 Ga

Ex ia I Ma

Class II, Groups E, F, and G; T4; Exia

Class I, Zone 0, AEx ia IIC T4

-40 °C to +50 °C (-40 °F to +122 °F)

-40 °C ≤ T amb ≤ +50 °C (-40 °F ≤ T amb ≤ +122 °F)

-40 °C to +50 °C (-40 °F to +122 °F)

General Information

Table 1.1 Certifications

Directive or CB Area Classifications Approved Temperature Range

Europe and Russia

ATEX Ex ia I Ma

Ex ia IIC T4 Ga

Equipment Groups and Categories: I M1 and II 1G

GOST EAC PO Ex ia I X

0 Ex ia IIC T4 X

Asia and Pacific

China Ex Ex ia IIC T4 Ga -20 °C to +50 °C (-4 °F to +122 °F)

KOSHA Ex ia IIC T4 -20°C ≤ Ta ≤ +50°C

Note: See the Appendix for ATEX and IECEx marking requirements.

-40 °C to +50 °C (-40 °F to +122 °F)

-40 °C to +50 °C (-40 °F to +122 °F)

Failure to perform certain procedures or note certain conditions may impair the performance of this product. For

maximum safety and optimal performance, please read and follow the procedures and conditions listed below.

Table 1.2 Warnings and cautionary statements

For maximum safety and optimal performance, read and understand the manual before operating or servicing the unit. Failure

to perform certain procedures or note certain conditions may impair the performance of this product.

For safety reasons, this equipment must be operated and serviced by qualified personnel only.

Substitution of components may impair intrinsic safety and may cause an unsafe condition.

Do not replace battery in hazardous locations. Only certified for use with one Tadiran TL-5955 battery cell.

Obstruction of sensor openings – due to dust, dirt, water, or another cause – can inhibit the unit’s ability to measure gas

concentrations accurately. When this occurs, readings may appear lower than the actual gas concentration. Keep sensor

openings clean, dry, and properly exposed to the ambient air.

Obstructed, contaminated, or damaged sensor water barriers (or their gaskets) can inhibit the unit’s ability to measure gas

concentrations accurately. When this occurs, readings may appear lower than the actual gas concentration. Replace the

sensor water barriers and gaskets as needed (see “Service” for instructions).

Service the unit, use its communications port, and change its battery cell only in nonhazardous locations. Not for use in

oxygen-enriched atmospheres.

Contact your service representative immediately if you suspect that the unit is working abnormally.

Product Overview

The Tango TX1 is a portable, long-life, single-gas monitor (instrument) for personal protection. It is a diffusion

instrument for use in detecting and measuring gas present in open space. Based on the customer’s order, two

redundant sensors – sensors of the same type – are factory installed. Four sensor types are available (

see Table 1.3).

2

Table 1.3 Sensor-type options

Product Overview

Sensor Category Number of sensors

available per

instrument

Toxic Two of the same type Carbon Monoxide (CO) only, Hydrogen Suflide (H

Note: See Table 1.5 for sensor specifications.

Sensor type

only, or Sulfur Dioxide ( SO

) only

2

S) only, Nitrogen Dioxide (NO2 )

2

When two working sensors are installed, they measure gas simultaneously and independently and the Tango TX1

operates on DualSense

TM

Technology from ISC. If only one sensor is installed or only one installed sensor is

operational, the unit operates as a single-sensor or non-DualSense unit.

If two working sensors are installed, the data log contains a data set for each sensor, plus a third data set. This third

data set – labeled "VIRTUAL" or "3" – is created by the DualSense technology. Each VIRTUAL data point is an

algorithm-calculated value that is based on sensor 1 and sensor 2 data. The VIRTUAL data are saved to and

downloaded from the data log just as data are for the installed sensors. VIRTUAL gas readings are displayed to the

instrument operator.

The Tango TX1 multiplane sensor ports each sample air from three directions; this promotes continuous operation if

one or two planes become obstructed.

Tango TX1 measures gas at two second intervals, and continuously logs data every ten seconds. The data log can

store approximately three months of data for a unit that is on 24 hours a day and has two installed, operational

sensors. As the newest data are logged to memory, the oldest data are overwritten. The data log's date- and timestamped event log records and stores event data for 60 alarm events and 30 error events. It also stores the data for

up to 250 manual calibrations and bump tests. The data log is downloaded when the unit is docked in a compatible

docking station.

The instrument has two modes: configuration and operation. When in configuration mode , a unit's settings can be

manually edited. Entry to configuration mode can be password protected. When the instrument is on and is not in

configuration mode, it is said to be in operation mode.

The instrument features an always-on option that can be enabled or disabled from configuration mode.

The Tango TX1 has a multisensory (audible, visual, and vibration), multilevel warning and alarm system. Warnings

indicate a service need (calibration due) or an operating condition (confidence indicator). Alarms indicate potentially

hazardous gas concentrations or system faults. Alarms can be set to latch. The instrument also features a country-of-

origin option that automatically sets the values for the low-gas and high-gas alarm set points for each of five different

countries or regions; each alarm set point value can also be manually edited. An optional AlarmAmp

TM

is available;

when used, the audible alarm volume is increased by approximately 10 decibels (dB).

The user interface consists of two buttons and an LCD (liquid crystal display). The buttons are used to power on and

power off the instrument, navigate the operation and configuration loops, perform tasks, and access information. The

unit can be set to display select information in English or French.

The unit's suspender clip is intended for attachment to a garment; it is not intended for attachment to a belt or hard

hat. An optional belt clip is available from ISC (see "Service").

The Tango TX1 is iNet ready and compatible with the Tango TX1 iNet DS (docking station).

Product Specifications

Effective use of the Tango TX1 includes knowledge of the instrument's specifications and its sensor and battery

specifications (see Tables 1.4 through 1.6).

3

General Information

A

A

r

Table 1.4 Instrument specifications

Item Description

Display Segment LCD

Keypad buttons Two buttons

Case materials Case top: polycarbonate with a protective rubber over-mold

Case bottom: conductive polycarbonate

Alarms Three strobe-emitting visual alarm LEDs (two red; one blue)

100 dB audible alarm at a distance of 10 cm (3.94"), typical

Vibration alarm

Dimensions 99 x 51 x 35 mm (3.9" x 2.0" x 1.4")

Weight 126 g (4.4 oz.), typical

Ingress protection IP66 and IP67

Operating temperature range

Operating humidity range 15 to 95% relative humidity (RH) noncondensing (continuous)

1

Operating temperatures above 50 °C (122 °F) may cause reduced instrument accuracy. Operating temperatures below -20 °C (-4 °F) may cause reduced

instrument accuracy and affect display and alarm performance.

1

-20 °C to +50 °C (-4 °F to +122 °F)

Table 1.5 Sensor specifications

1

2

Sensor

Measurement

Category

Gas Names

bbreviation

Sensor technology

Toxic

Carbon Monoxide

with H2 low

interference

CO/

Low

E

H2

Carbon Monoxide CO E 0-1000

Hydrogen Sulfide H2S E 0-200

Nitrogen Dioxide NO2 E 0-150

range

(% vol, % LEL, or ppm) degrees (°) (%)

0-1000

ppm

ppm

ppm

ppm

Sensor properties Accuracy Response

time

(typical)

2

ture and

Measurement

resolution

Sensor

temperature

range

1 ppm -20 to +50 °C

(-4 to +122 °F)

range

t time and

temperature of

calibration

(%) (%)

Sensor RH

15-95 ± 5% (0-300

ppm)

Over full sensor

± 15% 9 s 18 s

tempe

RH ranges

T50 T90

Seconds (s)

± 15% (301-

1000 ppm)

1 ppm -40 to +50 °C

15–95 ± 5 ± 15 12 s 48 s

(-40 to +122 °F)

0.1 ppm -40 to +50 °C

15–95 ± 5 ± 15 7 s 14 s

(-40 to +122 °F)

0.1 ppm -40 to +50 °C

15–95 ± 10 ± 15 10 s 30 s

(-40 to +122 °F)

Sulfur Dioxide SO2 E 0 to 150

4

ppm

0.1 ppm -20 to +50 °C

(-4 to +122 °F)

15 – 95 ± 10 ± 15 20 s 80 s

Product Overview

1

"E" stands for electrochemical.

2

ppm stands for parts per million; vol for volume; and LEL for lower explosive limit. Note: See the Appendix for

supplemental information about sensor types and gases.

Table 1.6 Battery properties

Battery Pack Properties

3.6 V Primary Lithium-thionyl

chloride (Li-SOCl2), 1.5AH, 2/3AA

* See "Service" for instructions. Some restrictions may apply (see "Introduction", Table 1.2 Warnings and cautionary statements).

Replaceable*

Nonrechargeable

Run time of 36 months depending on operating conditions; the amount of time the unit is in

alarm; and the enablement of unit's confidence indicator, bump test due alert, or calibration

due alert.

5

6

Recommended Practices

Introduction

Procedures

First Use

Wearing the Instrument

Introduction

2

Gas detection instruments are potentially life-saving devices. When completed regularly, the procedures defined

below help to maintain proper instrument functionality and enhance operator safety.

Procedures

Configuration. The configuration process allows qualified personnel to review and adjust a unit's settings.

Self-test. The self-test verifies the functionality of the instrument’s memory operations, battery, and each alarm

indicator (audible, visual, and vibration).

Note: a self-test does not verify sensor functionality (see “Bump Test”) or instrument accuracy (see “Calibration”).

Bump Test (or "functional test"). Bump testing checks for sensor and alarm functionality. The installed sensors are

briefly exposed to an expected concentration of calibration gas that is greater than the sensors’ low alarm set point.

When one or more sensors “pass” the test, they are “functional” and the unit will alarm. Each sensor’s “pass” or “fail”

result is indicated on the unit’s display.

Note: a bump test does not measure for accuracy (see “Calibration”).

Zero. Zeroing sets each installed sensor to recognize the ambient air as clean air. If the ambient air is not truly clean

air, any gases that are present and relevant to the installed sensor types will be measured and displayed as zero.

Readings will be inaccurate until the unit is correctly zeroed in truly fresh air or with a zero air cylinder.

Calibration. All sensors gradually degrade over time. This diminishes a sensor's ability to measure gas

concentrations accurately; however, regular calibrations adjust the instrument to compensate for this decline in

sensitivity. During calibration, the installed sensors are exposed to an expected concentration of calibration gas and,

when needed, the instrument will self-adjust to ensure the accurate measurement and display of gas concentration

values.

Note: when a sensor has degraded beyond an acceptable level, no further adjustment is possible and the sensor will no longer pass

calibration.

Recommended Practices

Peak Readings. The instrument stores the highest detected gas readings, the "peak readings" or "peaks". Bump

testing and calibration will often register new peak readings. Therefore, the clearing of the peak readings should

follow each calibration. The instrument operator may also wish to clear the peak readings after a bump test, before a

change in location, or after an alarm is addressed and cleared.

Note: The peak readings and the data log readings are stored independently of one another; therefore, clearing the peak reading does not

affect the data log. Powering the instrument off or changing its battery does not affect the peak reading. These checks and balances help

promote operator safety, and serve to contain the peak readings in a "black-box" manner. In the event of a gas-related incident, this black-box

record can be useful to the safety team or a prospective investigator.

Recommendations

Industrial Scientific Corporation (ISC) minimum frequency recommendations for each procedure are summarized in

the table below. These recommendations are based on field data, safe work procedures, industry best practices, and

regulatory standards to help ensure worker safety. Industrial Scientific is not responsible for setting safety practices

and policies.

ISC recommendations include a daily bump test for any ISC instrument that is not operating on DualSense

technology. This includes the Tango TX1 when it is operating with only one working sensor.

When two redundant, working sensors are installed in the Tango TX1, the instrument is operating on DualSense and

the probability of sensor failure – compared with a single-sensor instrument – is diminished regardless of bump test

frequency (see Figure 1). The frequency of bump testing for DualSense instruments, between monthly calibrations, is

best determined by a company's safety policies. These policies may be affected by the directives and

recommendations of regulatory groups, environmental conditions, operating conditions, instrument use patterns and

exposure to gas, and other factors.

Table 2.1 ISC recommended practices

Procedure Recommended minimum frequency

DualSense instruments

Configuration Before first use, when there is a change in the installed sensor type, and as otherwise needed.

Calibration

Bump test

Self-test

Non-DualSense instruments

Configuration Before first use and as needed thereafter.

Calibration

Bump test

Self-test

a

Between regular calibrations, ISC also recommends a calibration be performed immediately following each of these incidences: the unit falls,

is dropped, or experiences another significant impact; is exposed to water; fails a bump test; or has been repeatedly exposed to an over-range

(positive or negative) gas concentration. A calibration is also recommended after the installation of a new (or replacement) sensor.

b

If conditions do not permit daily bump testing, the procedure may be done less frequently based on company safety policy.

c

The Tango TX1 self-test is performed automatically during the start-up process. It can be user-initiated from operation mode.

Note: The use of calibration gases not provided by ISC may void product warranties and limit potential liability claims.

a

Before first use and monthly thereafter.

b

As desired between monthly calibrations.

c

Prior to each day’s use for a unit that is always on or is left on.

a

Before first use and monthly thereafter.

b

Prior to each day’s use.

c

As desired between daily bump tests.

8

1 in 1

1 in 10

1 in 100

1 in 1,000

use-days

1 in 10,000

1 in 100,000

First Use

Average number of failures per instrument

1 in 1,000,000

0 5 10 15 20 25 30

Bump test interval (days)

Non-DualSense instruments

DualSense instruments

Figure 1. Probability of sensor failure by bump test frequency

First Use

To prepare the Tango TX1 for first use, qualified personnel should configure and calibrate the unit.

Wearing the Instrument

Based on the U.S. Department of Labor's Occupational Safety and Health Administration (OSHA) definition of the

breathing zone, it is recommended that the unit be worn within a 25.4 cm (10") radius of the nose and mouth. Refer

to OSHA and to other agencies or groups as needed for additional information.

ISC also recommends that the unit be worn within the instrument operator's sight line.

The instrument operator may wear the unit with its factory-installed suspender clip or with the optional belt clip. The

suspender clip is solely intended for attachment to a garment. The belt clip may be attached to a hard hat, belt, or

garment.

The clips should be securely fastened and attached in a manner that ensures the unit's sensor portals are fully

exposed to the air. No part of the unit should be covered by any garment, part of a garment, or other item that would

restrict the flow of air to the sensors or impair the operator's access to the audible, visual, or vibration alarms.

Attach the desired clip as shown below.

Table 2.2 Securing the garment or belt clip

Suspender clip

Lift the clip cover.

Position the garment between the clip's upper and lower teeth.

Press down on the clip cover to secure the clip in place.

9

Recommended Practices

Table 2.2 Securing the garment or belt clip

Belt clip

Position the hard hat or

garment between the clip and

clip back.

Slide the clip to secure it in place.

The instrument can be worn right side up or upside down.

10

Instrument Basics

Unpacking the Instrument

Hardware Overview

Display Overview

Start-up and Shutdown

3

Unpacking the Instrument

The items that are shipped with the unit are listed below (see Table 3.1); each item should be accounted for in the

unpacking process.

Table 3.1 Package contents

Quantity Item Notes

1 as ordered Tango TX1 Part number 18109075

1 Suspender clip (installed) Optional belt clip sold separately.

1 Calibration cup

1 Calibration and bump test tubing 60.96 cm (2 ') of urethane tubing; 4.762 mm (3/16 ”) ID

1 Reference Guide Companion to the Tango TX1 Product Manual

1 Final Inspection & Test Report and

Declaration of Conformity

1

At the time of shipment.

Note: If any item is missing or appears to have been damaged, contact ISC (see "Contact Information") or a local distributor of ISC products.

—

The Final Inspection & Test Report includes these values:

Unit setup date

Unit part number

Unit serial number

For each sensor:

Part number

Serial number

Type

Alarm settings

Span information

1

1

Instrument Basics

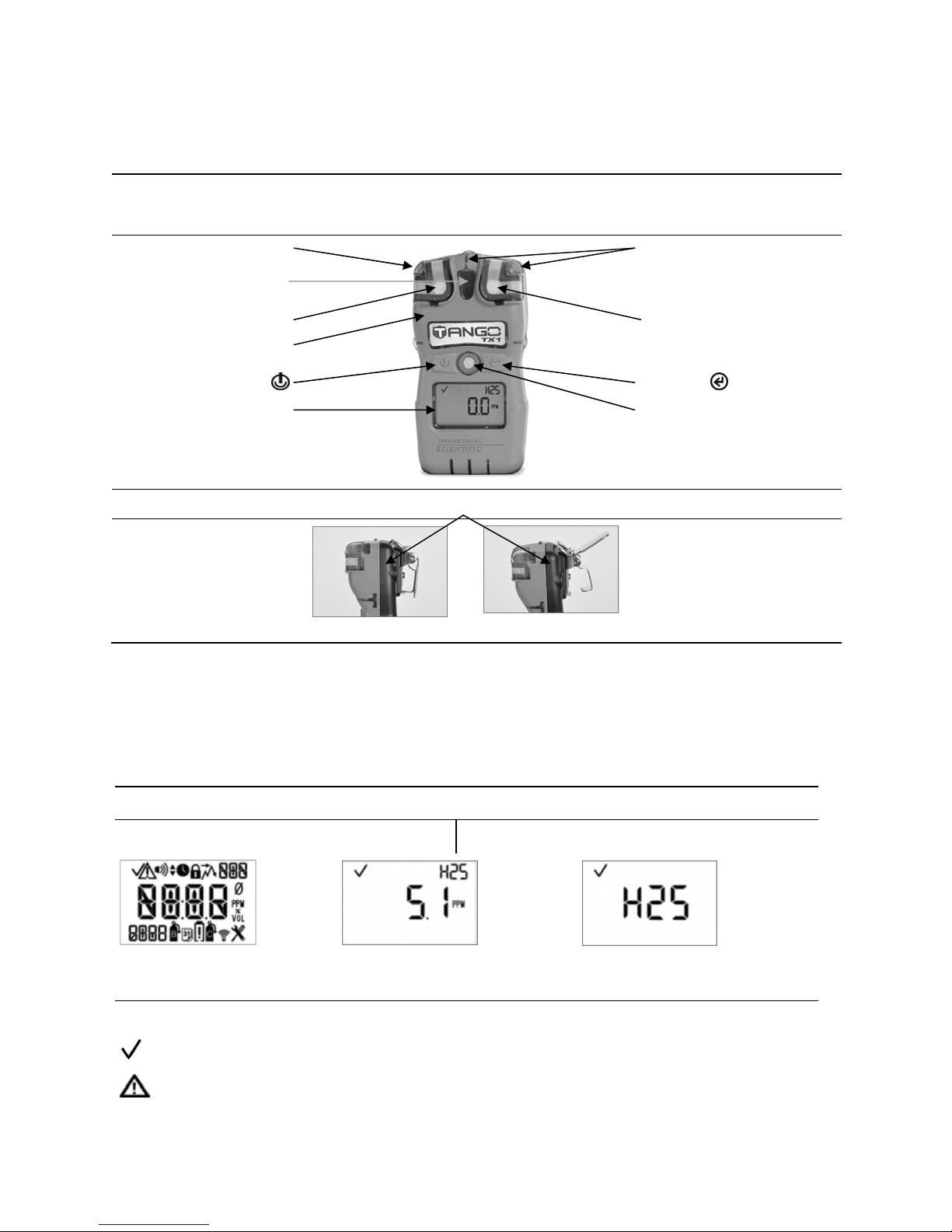

Hardware Overview

The instrument's main hardware components are identified below (see table 3.2).

Table 3.2. Hardware overview

Tango TX1

Visual alarm (or alert) indicator

IrDA (infrared data exchange)

window

Sensor port 1 and dust filter Sensor port 2 and dust filter

Case top

On-off-mode button

Case bottom

Enter button

LCD Audible alarm (or alert) indicator and

Garment clip (closed)

Garment clip (open)

Visual alarm (or alert) indicators

dust filter

Display Overview

The visual test screen shown below contains all the indicators that can appear on the display screen. Each indicator

is stationary and appears only when relevant to the task being performed. For example, in the gas-monitoring screen

shown below (numeric display), the following apply: the check mark indicates there are no sensor faults; the sensortype icon indicates that H2S sensors are installed; the numeric display shows a gas reading of 5.1 ppm.

Table 3.3 Display screen indicators and abbreviations

Display screens

Visual test screen

Status indicators

only

12

Two sensors are installed and neither is in fault.

Two sensors are installed and one is in fault; a

in fault.

Gas-monitoring screen

(numeric display)

Gas-monitoring screen

(text display)

sensor location icon also displays to indicate which sensor is

Table 3.3 Display screen indicators and abbreviations

Display Overview

and

!

Alarms indicators

and ▲

and ▼

and

and

and

and

Process and time-based indicators

Only one sensor is installed and is not in fault.

Two sensors are installed and both are in fault or one sensor is installed and in fault. The warning icon is also

used in combination with other indicators to communicate a system alarm or an alert condition.

The unit is in configuration mode.

The alarm icon is used in combination with other indicators to communicate a variety of conditions.

High-level gas alarm.

Low-level gas alarm.

STEL alarm.

TWA alarm.

Positive over-range gas alarm.

Negative over-range gas alarm.

Low battery alarm.

The zero icon is used in combination with other indicators to communicate sensor zero information.

The bump test icon is used in combination with other indicators to communicate bump test information.

The calibration icon is used in combination with other indicators to communicate calibration information.

A process is in progress. In configuration mode, indicates a time-based setting (e.g. bump test response

time).

Used in combination with other indicators to communicate overdue warnings. In configuration mode,

Gas name and unit-of-measure abbreviations

PPM

Other abbreviations

indicates a date-based setting (e.g., bump test interval).

Carbon Monoxide (CO)

Sulfur Dioxide (SO

Nitrogen Dioxide (NO

Hydrogen Sulfide (H

Parts per million is the unit of measure for CO, SO2, NO2, and H2S.

Positive over-range: the detected gas concentration is greater than the upper limit measurement range of the

sensor. Display variations: “Or” (English) and “Sup” (French).

Negative over-range: the detected gas concentration is less than the lower limit measurement range of the

sensor. Display variations: “-Or” (English) and “InF” (French).

Short-term exposure limit. Display variations: “STEL” ( English) and “VLE” (French).

or SO2)

2

or NO2)

2

S or H2S)

2

13

Instrument Basics

Table 3.3 Display screen indicators and abbreviations

Time-weighted average. Display variations: “TWA” (English) and “VME” (French).

Security code is set or to be entered. In configuration mode, indicates a feature may be operation-mode

enabled or disabled.

Peak reading.

Start-up and Shutdown

The start-up and shutdown sequences are outlined below and feature reproductions of the display screens the

instrument operator will see during these processes (see Table 3.4). Instructions accompany any display screen

where the instrument operator must press a button to proceed.

The instrument operator may be prompted to complete the time- and date-setting tasks during start-up. This may

happen after a battery has been removed or changed. If prompted by the unit to do so, it is essential – for data log

accuracy – that the time- and date-setting tasks be completed. The data log plays an important role in preserving

operator safety and in the prospective investigation of an incident.

The instrument operator may be prompted to enter a security code during shutdown. This will occur if the unit is

configured for "always-on" and is security-code protected.

Table 3.4 Start-up and shutdown

Start-up.

Start-up screens.

Press and hold for three seconds, then release to initiate the start-up sequence and power on the unit.

If all start-up diagnostics pass, the audio, visual, and vibration indicators turn on then off. Four start-up

screens display followed by the gas-monitoring screen.

If any start-up diagnostic fails, an error message displays (see "Alarms and Warnings").

Gas-monitoring screen.

14

Visual test screen Version display screen Calibration date screen

No-fault indicator

Gas concentration

(last calibration date

shown above)

Installed sensor type

Unit of measure

Countdown screen

For qualified personnel only:

During the 15-second

countdown, press both buttons

and hold for three seconds to

enter configuration mode (see

"Configuration").

Table 3.4 Start-up and shutdown

What to do if the time setting screen is activated.

This display screen features the clock icon and the current time setting.

The instrument's clock uses a 24-hour time format. Its values are edited in this order using these ranges*:

Hours: 00 to 24

Minutes: 00 to 59

Time setting

Date setting

The first press activates the first value to be edited. Continued presses increment the value; hold to speed the

increment pace.

One press saves the displayed value and activates the next value to be edited.

Continue to use the buttons,

After all values are edited and saved, one press activates the next configuration-mode screen.

This display screen features the calendar icon and the current date setting. The year is displayed in the lower

left corner. In the main display, the first two digits represent the date and the second two digits represent the

month. The values are edited in this order using these ranges:

Year: 2012 to 9999

Day: 00 to 31

Month: 00 to 12

The first press activates the first value to be edited. Continued presses increment the value; hold to speed the

increment pace.

One press saves the displayed value and activates the next value to be edited.

Continue to use the buttons,

After all values are edited and saved, one press activates the gas-monitoring screen.

Start-up and Shutdown

and , to edit and save the values, respectively.

and , to edit and save the values, respectively.

Shutdown.

Press and hold for five seconds.

After a five-second countdown:

The instrument powers off if

the always-on feature is disabled or

Countdown

Enter security code

Enters the value. If the value is correct, the unit powers off. If the value is incorrect, the gas-monitoring screen

*When editing a value, once the last value in the range is reached, the display starts again with the first value.

the always-on feature is enabled and the security code is set to 000.

If this screen is activated, the shutdown process is security-code protected. To complete shutdown, the user

must enter the correct three-digit code.

Value range: 000 to 999

Increments the value by one; hold to speed the increment pace.

is activated.

Dock the unit or store it for next use.

To prepare the instrument for first use, qualified personnel should proceed with the configuration process (see

"Configuration").

To operate a field-ready unit, refer to "Operation".

15

16

4

Instrument Preparation and Use

Configuration

Operation

Zero, Calibration, and Bump Testing

Configuration

Read and understand all configuration instruction before configuring the unit.

As noted in "Recommended Practices", the unit should be configured before first use, when there is a change in the

installed sensor type (e.g., H2S sensors are replaced with CO sensors), and as needed. Only qualified personnel

should access the configuration mode and adjust the unit's settings.

Configuration mode can be accessed only during the start-up sequence (see “Start-up and Shutdown”).

Review the unit's configured settings for compliance with company policy and any applicable regulations, laws, and

guidelines as issued by regulatory agencies and government or industry groups. Determine which settings, if any,

require adjustment.

Choose alarm- and warning-related options that maximize safety within the air-sampling environment.

When the unit is in configuration mode, the following apply:

The tool icon (

With successive short presses of the on-off-mode button (

The enter button (

When editing a value, the enter button (

value.

When editing a value, once the last value in the range is reached, the display starts again with the first value.

When both buttons (

configuration mode; it enters operation mode and the gas-monitoring screen is activated.

Unless otherwise noted, when no button is pressed for 30 seconds, the unit enters operation mode and the gas-

monitoring screen is activated.

Any changes made in configuration mode are automatically saved to the unit and take effect immediately. Upon next

docking, settings are updated according to the unit's settings in iNet Control.

) displays in the lower right corner of each screen.

), the user can scroll through the configuration loop.

) is used to start the editing process or start a task (e.g., zero).

) increments the value and the on-off-mode button ( ) saves the

and ) are simultaneously pressed and held for three seconds, the unit leaves

The configuration-mode loop is outlined below (see Table 4.1). Instructions for button use accompany each

configuration-mode display screen.

Instrument Preparation and Use

Table 4.1 Configuration instruction

Screen

Button

Enter security code

Notes:

Initiate zero

Low gas alarm set point

High gas alarm set point

Saves the displayed value.

Skips the zero process and activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

Description

Button effect

If this display screen is activated, the configuration mode is security-code protected. To enter configuration, the

user must enter the correct three-digit code.

If the security code is set to 000, entry to configuration mode is not security-code protected. The first

configuration-mode screen is activated, the initiate-zero screen.

Increments the value by one; hold to speed the increment pace.

If an incorrect code is entered, the unit does not enter configuration mode and the gas-monitoring screen is

activated.

If the security code is unknown, configuration mode can be accessed as follows: enter 412, then press both

buttons simultaneously and hold briefly. This activates the next configuration mode screen. This also resets the

security code to 000, leaving configuration mode unprotected. The security code can be reset in configuration

mode at the security-code-setting screen.

This screen's activation allows the technician to complete the zero and calibration processes from configuration

mode.

Starts the zero process.

See also country-of-origin setting.

This display screen features the low alarm and sensor-type icons, and the alarm's current set point and unit of

measure. The alarm set point can be edited based on the following:

Value range = within the sensor measurement range

Value increment = sensor measurement resolution

See Table 1.5 for the measurement range and resolution for the installed sensor type.

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

See also country-of-origin setting.

This display screen features the high alarm and sensor-type icons, and the alarm's current set point and unit of

measure. The alarm set point can be edited based on the following:

Value range = within the sensor measurement range

Value increment = sensor measurement resolution

See Table 1.5 for the measurement range and resolution for the installed sensor type.

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

18

Table 4.1 Configuration instruction

Configuration

Screen

Button

TWA operation-mode

setting

TWA alarm set point

TWA time-base setting

STEL operation-mode

setting

Description

Button effect

This display screen features the lock icon to indicate the technician can enable or disable the option for

operation-mode access.

When enabled, the instrument operator is permitted to view and clear the unit's TWA reading while the unit is in

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

operation mode.

Values:

0 = disabled

1 = enabled

Increments the value.

This display screen features the alarm and sensor-type icons, and the alarm's current set point and unit of

measure. The alarm set point can be edited.

Value increment = within the sensor measurement resolution

See Table 1.5 for more information about the installed sensor type.

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

This display screen features the clock and TWA icons, and the current TWA time-base. The set point value can

be edited based on the following:

Value range: 01 to 40 hours

Value increment: 1 hour

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

This display screen features the lock icon to indicate the technician can enable or disable the option for

operation-mode access.

When enabled, the instrument operator is permitted to view and clear the unit's STEL reading while the unit is

in operation mode.

Values:

0 = disabled

1 = enabled

Increments the value.

STEL alarm set point

One press saves the displayed value and activates the next configuration-mode screen.

This display screen features the alarm, STEL, and sensor-type icons, and the current set point.

The set point can be edited.

Value increment: sensor measurement resolution

One press saves the displayed value; a second press activates the next configuration-mode screen.

See Table 1.5 for more information about the installed sensor type.

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

19

Instrument Preparation and Use

Table 4.1 Configuration instruction

Screen

Button

Calibration gas setting

Time setting

Date setting

Style setting

One press saves the displayed value; a second press activates the next configuration-mode screen.

One press saves the displayed value and activates the next value to be edited.

After all values are edited and saved, one press activates the next configuration-mode screen.

One press saves the displayed value and activates the next value to be edited.

After all values are edited and saved, one press activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

Description

Button effect

This display screen features the calibration cylinder and sensor-type icons, and the current calibration gas

setting.

This setting reflects the concentration of calibration gas that the instrument expects to read when calibrated; it

should be edited to match the cylinder's gas concentration.

Value range: within the sensor measurement range

Value increment: sensor measurement resolution

See Table 1.5 for the measurement range and resolution for each sensor type.

Increments the value; hold to speed the increment pace.

This display screen features the clock icon and the current time setting.

The instrument's clock uses a 24-hour time format. Its settings are edited in this order using these values:

Hours: 00 to 24

Minutes: 00 to 59

Value increment: 1

The first press activates

increment pace.

Continue to use the buttons,

This display screen features the calendar icon and the current date setting. The year is displayed in the lower

left corner. In the main display, the first two digits represent the date and the second two digits represent the

month. The settings are edited in this order using these values:

Year: 2012 to 2099

Day: 00 to 31

Month: 00 to 12

The first press activates

increment pace.

Continue to use the buttons,

This display screen allows the technician to choose the display style for the gas-monitoring

display will feature the numeric gas reading and the sensor type icon. A text display will feature the sensor type

in place of the numeric gas reading (see "Operation" for sample display styles).

Values:

0 = Numeric display

1 = Text display

Increments the value.

the first value to be edited. Continued presses increment the value; hold to speed the

the first value to be edited. Continued presses increment the value; hold to speed the

and , to edit and save the values, respectively.

and , to edit and save the values, respectively.

screen. A numeric

20

Table 4.1 Configuration instruction

Configuration

Screen

Button

Confidence indicator setting

Operation-mode bump test

setting

Bump test due alert setting

Bump test interval setting

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

Description

Button effect

This display screen features the alarm icon and check mark indicator. The technician can disable the indicator,

or enable the indicator and choose the indicator type.

When enabled, the unit will emit the selected signal every 90 seconds in operation mode.

Values:

0 = disabled

1 = enabled for audible chirp

2 = enabled for blue LED flash

Increments the value.

This display screen features the bump test icon. The lock icon indicates the technician can enable or disable

this operation-mode feature.

When enabled, the instrument operator is given access to bump test the unit from operation mode.

Values:

0 = disabled

1 = enabled

Increments the value.

This display screen features the alarm, bump test, calendar, and warning icons. The technician can disable the

warning, or enable the warning and choose the warning type.

When enabled, the alert screen will be activated and the unit will emit the selected indicator every 60 seconds

to notify its user that a bump test is due; the instrument will continue to operate.

Values:

0 = disabled

1 = enabled for audible chirp

2 = enabled for blue LED flash

3 = enabled for combination audible chirp and blue LED flash

Increments the value.

This display screen features the bump test and calendar icons. The technician can set the interval at which the

bump test due alert is to be activated.

Value range: 0.5 to 30.0 days

Value increment: 0.5 days

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

21

Instrument Preparation and Use

Table 4.1 Configuration instruction

Screen

Button

Bump test percentage

setting

Bump test response-time

setting

Alarm latch setting

Vibration alarm setting

One press saves the displayed value; a second press activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

Description

Button effect

This display screen features the bump test icon and the current setting. The technician can set the percentage

of calibration gas to which the unit will respond.

Value range: 50% to 95%

Value increment: 1%

See Table 1.5 for sensor information that can aid in the setting of bump test values.

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

This display screen features the bump test and clock icons, and the current setting in seconds. A sensor

passes a bump test when it senses the specified percentage of calibration gas within the specified response

time setting.

Value range: 30 to 120 seconds

Value increment: 1 second

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

This display screen features the alarm icon and the current setting. The lock icon indicates the technician can

enable or disable this operation-mode feature.

When disabled, a unit in alarm will turn off its alarm when the gas reading is no longer at the alarm-producing

concentration.

When enabled, a unit in alarm will remain in alarm until it is manually reset. The instrument operator can reset

a latched alarm from operation mode with a long press of the enter button (

not disable an enabled latch.

Values:

0 = disabled

1 = enabled

Increments the value.

This display screen features the alarm, check mark, and vibration motor icons. When enabled, the vibrating

alarm will be activated when the unit is in alarm.

Values:

0 = disabled

1 = enabled

Increments the value.

). This resets the alarm; it does

22

Table 4.1 Configuration instruction

Configuration

Screen

Button

Operation-mode zero

setting

Operation-mode calibration

setting

Calibration due alert setting

Calibration interval setting

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value; a second press activates the next configuration-mode screen.

Description

Button effect

This display screen features the zero icon. The lock icon indicates the technician can enable or disable this

operation-mode feature.

When enabled, the instrument operator is given access to zero the unit from operation mode.

Values:

0 = disabled

1 = enabled

Increments the value.

This display screen features the calibration icon. The lock icon indicates the technician can enable or disable

this operation-mode feature.

When enabled, the instrument operator is given access to calibrate the unit from operation mode.

Values:

0 = disabled

1 = enabled

Increments the value.

This display screen features the alarm, calibration, calendar, and warning icons. The technician can disable the

warning, or enable the warning and choose the warning type.

When enabled, the alert screen will be activated and the unit will emit the selected indicator every 60 seconds

to warn its user that a calibration is due; the instrument will continue to operate.

Values:

0 = disabled

1 = enabled for audible chirp

2 = enabled for blue LED flash

3 = enabled for combination audible chirp and blue LED flash

Increments the value.

This display screen features the calibration and calendar icons, and the current interval setting. The technician

can set the interval at which the calibration due alert is to be activated.

Value range: 1 to 365 days

Value increment: 1 day

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

23

Instrument Preparation and Use

Table 4.1 Configuration instruction

Screen

Button

Calibration date setting

Security code setting

Country-of-origin setting

Notes:

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

Description

Button effect

This display screen features the calibration cylinder, calendar, warning, and arrow icons. The technician can

choose whether the operation-mode calibration date screen will display the due date for the unit's next

calibration or the date of the unit's last calibration.

The up arrow (▲) will be featured on-screen when the unit is set to display the next the calibration due. The

down arrow (▼) will be featured when the unit is set to display the last calibration date.

Values:

0 = displays date of last calibration

1 = displays next calibration due date

Increments the value.

This display screen features the lock icon and the current security code. The security code controls two things:

access to a unit's configuration mode and the ability to power off a unit that is configured for always-on

operation.

If the security code is set at 000, entry to configuration mode is not security-code protected, and an always-on

unit can be powered off without a security code. Any other value will enable the security code.

Value range: 000 to 999

Value increment: 1

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

One press saves the displayed value; a second press activates the next configuration-mode screen.

This display screen features the country-of-origin icon and the current setting. This feature sets automatically

the low- and high-gas alarm set points. The technician must choose one of these options:

“DEF” = USA and default value

“CAn” = Canada

“EUr” = Europe

“CR” = Czech Republic

“AUS” = Australia

The unit's settings are immediately updated to reflect that country's (or Europe's) low- and high-gas alarm set

points for the installed sensor-type. When the country-of-origin selection does not contain a value for an alarm

set point, the default value (DEF) is automatically substituted.

The first press activates the value. Continued presses increment the value; hold to speed the increment pace.

Each alarm setting can be edited individually, in configuration mode, at that alarm's set point screen.

Because low- and high-gas alarm set points can be edited both individually and through the country-of-origin

option, it is important to understand override behavior.

Example. The H2S low-gas alarm set point was edited – at its set point screen – to a value of 9 ppm.

Afterwards, a country-of-origin selection was made where the H2S low-gas alarm set point value is 10 ppm.

The last-entered setting overrides the first. Therefore, in this example, the value of the H2S low gas alarm set

point is 10 ppm.

Another aspect to alarm settings applies to replacement or new sensors. For example:

If the installed H2S sensor(s) is replaced with other H2S sensor(s), the last-entered low-gas alarm set

point (a value of 10 ppm in the above example) will be applied to the newly installed sensor(s).

If the installed H2S sensors are replaced with a different sensor type (e.g., CO), the alarm settings will be

read from the newly installed sensor(s).

24

Table 4.1 Configuration instruction

Configuration

Screen

Button

Language setting

Always-on setting

Shutdown in alarm setting

One press saves the displayed value and activates the next configuration-mode screen.

One press saves the displayed value and activates the next configuration-mode screen.

Description

Button effect

This display screen features the language icon and the current setting. The technician can choose from these

options:

“En” = English

“F” = French

Increments the value.

This display screen features the battery icon. The lock icon indicates the technician can enable or disable this

feature.

When enabled, the entry of the unit's security code (if the security code is not 000) will be required to complete

the shutdown process.

Values:

0 = disabled

1 = enabled

Increments the value.

Disallow or allow operator-activated shutdown when the unit is in alarm.

Values:

0 = disallows shutdown

1 = allows shutdown

One press saves the displayed value and activates the next configuration-mode screen.

Increments the value.

After the configuration process is completed and before the unit’s first use, calibrate the instrument (see “Zero,

Calibration, and Bump Test”).

Operation

In operation mode, the following apply:

With successive short presses of the on-off-mode button (

operation-mode loop.

The zero, calibration, and bump test processes can be completed only if these task settings are enabled for

operation-mode access.

The peak reading can be viewed and cleared.

The TWA and STEL readings can be viewed and cleared only if these task settings are enabled for operation-

mode access.

In general, the buttons are used as follows:

Press

Press

to scroll through the operation-mode loop.

to initiate a task or to clear a reading.

), the instrument operator can scroll through the

25

Instrument Preparation and Use

A long press on will reset a latched alarm; it does not disable an enabled latch.

When

and are simultaneously pressed and held for three seconds, the unit will complete a self-test.

Except where noted, when no button is pressed for 30 seconds, the gas-monitoring screen is activated.

The operation-mode loop is outlined below (see Table 4.2). Instructions for button use accompany each display

screen.

Table 4.2 Operation instruction

Screen

Buttons

Gas monitoring

Calibration date

Screen description

Button effects

This display screen (numeric shown) features the check mark and sensor-type icons, and the current gas

reading and unit of measure.

The check mark indicates the unit is operational and there are no sensor faults.

One short press turns on the backlight if the unit senses it is not in a well-lit environment.

When the unit is in alarm, a long press will reset a latched alarm; the alarm will recur if the alarm-causing

condition is still present.

Activates the next enabled operation-mode screen.

This display screen features the calibration, calendar, and check mark icons, an up or down arrow, and a date

value.

When the up arrow (▲) is featured, the next calibration date is displayed. When the down arrow (▼) is

featured, the last calibration date is displayed.

Values:

Date: XX (day) and XX (month)

Year: XXXX

No effect.

Activates the next enabled operation-mode screen.

This display screen is activated if the unit is enabled for operation-mode zeroing. It features the check mark

and zero icons.

Initiate zero

Initiate bump test

26

Starts the zero process (see "Zero, Calibration, and Bump Testing").

Activates the next enabled operation-mode screen.

This display screen is activated if the unit is enabled for operation-mode bump testing. The screen features the

check mark and bump test icons.

Starts the bump test process (see "Zero, Calibration, and Bump Testing").

Activates the next enabled operation-mode screen.

Peak reading

Operation

This display screen features the check mark, peak, and sensor-type icons, and the most recent peak reading.

Clears the peak reading.

Activates the next enabled operation-mode screen.

This display screen is activated if this feature is operation-mode enabled. The screen features the check mark,

sensor-type, and TWA icons, and the current TWA reading.

TWA reading

STELreading

Clears the TWA reading.

Activates the next enabled operation-mode screen.

This display screen is activated if this feature is operation-mode enabled. The screen features the check mark,

sensor-type, and STEL icons, and the current STEL reading.

Clears the STEL reading.

Activates the next enabled operation-mode screen.

27

Instrument Preparation and Use

Zero, Calibration, and Bump Test

Perform the zero, calibration, and bump testing tasks in an area known to be nonhazardous.

Table 4.3 Zero, calibration, and bump test

Supplies, preparation, and instruction

Supplies

Calibration cup (shipped with the unit)

Calibration tubing (shipped with the unit)

Calibration gas cylinder suitable for the installed sensors and the unit's calibration gas settings

Positive flow regulator suitable for the calibration gas cylinder

Preparation

Holding the regulator, turn the calibration

gas cylinder in a clockwise direction to

tighten.

Connect either end of the calibration tubing

to the regulator's nipple.

Connect the other end of the tubing to the

calibration cup.

Proceed with the instruction set below for the

desired task: zero and calibration or bump

test.

28

Instruction

Zero

Zero, Calibration, and Bump Test

Initiate zero

Note: From anywhere in the

operation-mode loop, press

until the initiate-zero screen is

activated.

At the initiate-zero screen, press

to start the zero process.

Calibration

Place the calibration cup over the case top; align its top groove with

the small ridge at the top of the instrument.

Press down to secure the cup in place; a click will sound.

Visually inspect the calibration cup to ensure its edges along the top

and sides align with the case top edges.

Zero in-progress

While the sensors are zeroed, the

zero-in-progress screen is

activated.

Zero results (pass)

After the sensors are zeroed, the zero-results screen is activated and

an audible alert is emitted.

If the result for either sensor is an "F" for fail, press

the initiate-zero screen. Repeat the zero process.

If the result for both sensors is a "P" for pass, press

display the initiate-calibration screen. If calibration is not desired, wait

approximately 30 seconds for the zero-results screen to deactivate;

the gas-monitoring

Initiate calibration

To start the calibration process,

. Both sensors will be

press

calibrated simultaneously.

To cancel the calibration,

.

press

screen will be automatically activated.

Zero results (fail)

Calibration apply gas

Once the calibration is started,

the apply-gas screen is

activated; the expected type and

concentration of calibration gas

are displayed.

This screen remains activated

for up to 5 minutes as the unit

awaits the application of

calibration gas.

To cancel the calibration,

.

press

to reactivate

then to

Calibration in progress

To start the flow of gas, turn the regulator knob in a counterclockwise

direction.

While the sensors are calibrated, the calibration-in-progress screen

displays the span reserve value.

If desired, press

to cancel the calibration.

Calibration results (pass)

If at least one sensor passes calibration, two results screens are

alternately activated; one indicates the pass or fail result for each

sensor and the other displays the span reserve value.

If neither sensor passes calibration, the audible, visual, and vibrating

alarms turn on. Two results screens are alternately activated; one

indicates the fail results and the other displays the span reserve

value.

Note: With two installed, working sensors, the span reserve value is

the algorithm calculation of the DualSense Technology.

Calibration results (fail)

29

Instrument Preparation and Use

Span reserve value

If at least one sensor passes the calibration, the gas-monitoring

screen will be automatically activated.

Note: The span reserve value divided by the calibration gas

concentration yields the span reserve percentage. A span reserve

To stop the flow of gas, turn the

regulator knob in a clockwise

direction and tighten.

To remove the calibration cup,

lift up from the cup's tabs. Set

aside or store for future use.

percentage of greater than 70% indicates a “good” sensor; 50%-70%

indicates “marginal” sensitivity. When the span reserve percentage is

less than 50%, the sensor will not pass calibration.

Bump testing

Place the calibration cup over the case top; align its top groove with

the small ridge at the top of the instrument.

Press down to secure the cup in place; a click will sound.

Visually inspect the calibration cup to ensure its edges along the top

and sides align with the case top edges.

Initiate bump test

Note: From anywhere in the

operation-mode loop, press

until the initiate-bump-test

screen is activated.

to start the bump test

Press

process.

Press to cancel the bump

test.

Bump test apply gas

Once the bump test is started,

the apply-gas screen is

activated; the expected type and

concentration of calibration gas

are displayed.

This screen remains activated

for up to 5 minutes as the unit

awaits the application of

calibration gas.

Bump test in progress

To start the flow of gas, turn the regulator knob in a counterclockwise

direction.

To stop the flow of gas, turn the

regulator knob in a clockwise

direction and tighten.

To remove the calibration cup, lift

up from the cup's tabs. Set aside

or store for future use.

30

Bump test results (pass)

Bump test results (fail)

If either or both sensors fail the bump test, the calibration due

warning screen will be automatically activated. Calibrate the

instrument.

If both sensors pass the bump test, the gas-monitoring screen will be

automatically activated.

5

Alerts, Warnings, and Alarms

Overview

An alert indicates an instrument operating condition; a warning, the unit is in need of service; and an alarm, the unit

has detected a potentially hazardous gas concentration or has encountered a system fault. Each category of

notification is listed in Table 5.1 along with its indicators (audible, visual, and vibration) and their patterns.

Table 5.1 Overview

Indicators Pattern

Notification

Category

Alert1 No No No n/a

Warning Yes2 Blue only2 No Intermittent

Low-battery alarm Yes Red only No Intermittent

Low-level alarm Yes Red and blue Yes2 Continuous sequence with pauses

High-level alarm Yes Red only Yes

System alarm Yes Red only Yes

1

Alert notifications are indicated on the display screen only.

2

When enabled.

Audible Visual (LEDs) Vibration

2

Continuous sequence

2

Continuous sequence

Table 5.2 lists all event types that can activate an alert, warning, or alarm. Here, they are grouped by gas-related

alarms, instrument-based alarms, instrument service warnings, and instrument status alerts.

The notification category is indicated below for each event type. Some categories can indicate more than one type of

event. For example, the low-level alarm can be activated by a TWA event or a low-alarm gas event, and the unit’s

display screen differentiates between the two (see Table 5.3 for more information).

Table 5.2 Events

Status

Event type Low-level High-level Low-battery System

Gas-related alarm events

Low-alarm gas event

TWA event

High-alarm gas event

STEL event

Over-range gas event

Instrument-based alarm events

Low-battery event

Dead battery indicator

Alert

─ ─

─ ─

─ ─ ─

─ ─ ─

─ ─ ─

─ ─ ─ ─

─ ─ ─ ─

Warning Alarms

√

√

─ ─

─ ─

√

√

√

─

─

─ ─

─ ─

─ ─

√

√

─

─

Alerts, Warnings, and Alarms

Table 5.2 Events

Status

Event type Low-level High-level Low-battery System

System fault

Instrument service warnings

Bump test overdue

Calibration overdue

Single-sensor zero failure

Single-sensor bump test failure

Single- sensor calibration failure

Instrument status alerts

One sensor installed*

Single-sensor data failure*

*Display screen indicators only.

Alert

─ ─ ─ ─ ─

─

─

─

─

─

√

√

Warning Alarms

√

√

√

√

√

─ ─ ─ ─ ─

─ ─ ─ ─ ─

─ ─ ─ ─

─ ─ ─ ─

─ ─ ─ ─

─ ─ ─ ─

─ ─ ─ ─

√

Event Causes and Recommended Actions

As noted earlier, more than one event type can activate the same notification category; the display screen icons, text,

and data help the instrument operator identify the event. For example, the low-alarm gas event and the TWA event

can activate the low-level alarm. The display screen for each event features the alarm icon (

these distinguishing icons: low-gas (▼) or TWA (

).The display screen for every event type is shown in Table

5.3.

) and only one of

Table 5.3 Recommended action by event type

Event type Possible causes Status and recommended actions

No events

The unit has no faults and needs no service.

Both sensors are functional and the unit is

operating on DualSense technology.

Gas-monitoring screen

▲ ▼ ! indicate that the unit is in alarm.

Gas-related alarm events

The detected gas concentration exceeds the

unit’s low-alarm set point.

Low-alarm gas event2

The unit is operational.

Gas warning: Respond according to company safety

policy and guidelines.

32

Event Causes and Recommended Actions

Table 5.3 Recommended action by event type

Event type Possible causes Status and recommended actions

The cumulative gas readings have reached the

unit’s setting for the time weighted average

(TWA) exposure limit.

TWA alarm event

Leave the area.

Respond according to company safety policy and

guidelines.

The detected gas concentration exceeds the

high-alarm set point.

High-alarm gas event2

The cumulative gas readings have reached the

unit’s setting for short-term exposure limit

(STEL).

STEL alarm event

The gas concentration is outside of the sensor's

measuring range.

Note: For a negative over-range condition, the

"—OR" icon displays.

Over-range alarm gas event2

(positive shown)

Instrument-related alarm events

Low-battery alarm event

Dead battery indicator

System alarm event (sample

screen)

From the time of initial display, there are fewer

than 96 hours of remaining battery life.