P/N 1709-5753

Rev 9

Printed September 2011

Specifications Subject to Change

1001 Oakdale Road, Oakdale, PA 15071-1500

(412) 788-4353 • Toll Free 1-800-DETECTS

FAX 412-788-8353 • Service Dept. 1-888-788-4353

Multi-Gas Monitor

Instruction

Manual

GUARANTEED.

FOR LIFE.

O U R M I S S I O N

Preserving human life on,

above and below the earth

Delivering highest quality,

best customer service …

every transaction, every time

Dear Valued Customer,

Thank you for buying and using Industrial Scientific’s

iTX Multi-Gas Monitor.

Your iTX can be relied upon for dependable service, day

after day. It has been designed, manufactured, tested and

proven under the most scrutinizing conditions possible.

With the minimal care and maintenance described in this

Instruction Manual, it will provide you with years of

reliable monitoring.

I am most concerned that you be pleased with the

performance of your iTX in the months and years ahead.

I urge you to call us with any questions or comments you

may have. Often times a phone call and a question can

save you hours of frustration. Please never hesitate to

contact me at 1-800-DETECTS (338-3287).

All of us at Industrial Scientific appreciate the opportunity

to serve you.

Sincerely,

Kent D. McElhattan

Chairman

Industrial Scientific Corporation

3

W

ARNINGS ANDCAUTIONARYSTATEMENTS

Failure to perform certain procedures or note certain conditions may

impair the performance of the instrument. For maximum safety and

performance, please read and follow the procedures and conditions

outlined below.

Oxygen deficient atmospheres may cause combustible gas readings to

be lower than actual concentrations.

Oxygen enriched atmospheres may cause combustible gas reading to

be higher than actual concentrations.

Verify the calibration of the combustible gas sensor after any incident

where the combustible gas content has caused the instrument to latch in

the OVER-RANGE alarm condition.

Silicone compound vapors or other known contaminants may affect the

combustible gas sensor and cause readings of combustible gas to be lower

than actual gas concentrations. If the instrument has been used in an area

where silicone vapors were present, always calibrate the instrument before

next use to ensure accurate measurements.

Sensor openings and water barriers must be kept clean. Obstruction of

the sensor openings and/or contamination of the water barriers may cause

readings to be lower than actual gas concentrations.

Sudden changes in atmospheric pressure may cause temporary

fluctuations in the oxygen reading.

Recharge battery only in a non-hazardous location.

Instrument is tested for intrinsic safety in explosive gas/air (21%

oxygen) mixtures only.

CAUTION: High Over-Range (+OR) combustible gas readings may

indicate an explosive concentration of combustible gas. This condition

locks the iTX in high alarm and must be manually reset by clearing the

gas hazard and turning the iTX off and on again.

iTX units equipped with bias sensors will self discharge a fully charged

battery in approximately four days. Because of this, bias sensor equipped

units are shipped without the battery installed. Upon receipt, install the

battery and allow the bias sensors to stabilize for 24 hours. Always store

bias sensor equipped iTX units on the appropriate charger (lithium-ion

versions only).

The use of leather cases can produce inaccurate readings with diffusion

(non-aspirated) gas detection instruments for specific monitoring applications.

Leather cases should be used ONLY as carrying cases, and NOT for

continuous monitoring, with diffusion instruments configured to measure

gases other than O2, CO, CO2, H2S, and combustible gases (LEL/CH4).

!

!

!

!

!

!

!

!

!

!

!

2

Multi-Gas

Monitor

W

ARNINGS AND

C

AUTIONARYSTATEMENTS

................................................3

U

NPACKINGTHEINSTRUMENT

....................................................................6

V

IEW OFINSTRUMENT

................................................................................7

I

NSTRUMENTOPERATION

............................................................................8

Turning the iTX On and Off..........................................................8

Gas Reading Mode.........................................................................8

V

IEWING THE

iTX O

PERATINGMODES

.......................................................9

PPM Explosive Gas Reading .........................................................9

Zeroing and Calibration .................................................................9

Peak Readings ..............................................................................10

STEL Readings.............................................................................10

TWA Readings..............................................................................10

Pause Datalog...............................................................................10

Resetting Datalogging Session.....................................................11

Datalog Session ............................................................................11

Last Calibration/Calibration Due .................................................11

Time/Date/Temperature................................................................12

User Identification........................................................................12

Site Identification .........................................................................13

C

ONFIGURING THE

iTX’SC

USTOMSETTINGS

...........................................13

Security Code ...............................................................................14

Security Features..........................................................................14

Alarm Configuration ....................................................................15

Sensor Calibration Gas.................................................................15

Quick Calibration .........................................................................16

Zero Sensors.................................................................................16

Zero Sensors On Startup ..............................................................16

Allow Sensor Zeroing in the Field...............................................16

Allow Calibration in the Field .....................................................16

Numeric Display ..........................................................................17

Peaks.............................................................................................17

Allow Viewing Peak Readings in Field.......................................17

Allow Viewing STEL/TWA Reading in Field .............................17

TWA .............................................................................................17

Non-Latching................................................................................18

Confidence Beep ..........................................................................18

Data Logging Configuration ........................................................18

Allow Over-Writing of Data................................................18

Log Data On Alarm Only....................................................19

Allow Manual Pause/Resume in Field................................19

Data Logging Interval..........................................................19

Clear Data Logging Memory ..............................................19

Calibration Dates..........................................................................19

Next Calibration Dates.................................................................20

Allow Viewing Calibration Dates................................................20

Current Date Screen .....................................................................20

Allow Viewing Date and Time in Field.......................................20

Backlight Shut-Off .......................................................................21

Active User...................................................................................21

Active Site....................................................................................22

Allow Changing of Site and User In Field ..................................22

Allow Viewing Site and User in Field.........................................22

Allow Viewing Combustible PPM...............................................23

C

ALIBRATING THE

iTX .............................................................................23

Standard Calibration.....................................................................24

Quick Calibration .........................................................................25

R

EMOTESAMPLING

..................................................................................25

Using the iSP (Motorized Sampling Pump).................................26

Using the Hand Aspirated Pump..................................................26

M

AINTENANCE

....................................................................................27-29

S

PECIFICATIONS

...................................................................................29-30

E

XPLODEDVIEW

& R

EPLACEMENTPARTS

...........................................31-33

W

ARRANTY

.............................................................................................34

ATEX D

ECLARATION

...............................................................................36

TABLE OF CONTENTS

54

W

ARNINGS AND

C

AUTIONARY

S

TATEMENTS

WARNING (UL CLASSIFICATION, DEMKO CERTIFICATION AND CSA

CERTIFICATION ONLY):

USE ONLY WITH RECHARGEABLE BATTERY PACK P/N 1715-3303, P/N 17088618 OR 4.5V ALKALINE BATTERY PACK P/N 1708-9376 CONTAINING THREE

IDENTICAL ALKALINE CELLS FROM THE FOLLOWING LIST: DURACELL

MN1500 OR RAYOVAC LR6. DO NOT MIX BATTERIES FROM DIFFERENT

MANUFACTURERS. REPLACE ALL BATTERIES AT THE

SAME TIME.

THE FOLLOWING ARE TO BE PERFORMED IN NON-HAZARDOUS

LOCATIONS ONLY: RECHARGE Li BATTERY PACK, CHANGE Li BATTERY

PACK, CHANGE ALKALINE BATTERY PACK, REPLACE ALKALINE CELLS,

SERVICE UNIT OR USE COMMUNICATION PORT.

DO NOT USE THE ITX IN OXYGEN ENRICHED ATMOSPHERES.

WARNING (MSHA APPROVAL ONLY):

USE ONLY WITH RECHARGEABLE BATTERY PACK P/N 1715-3290, P/N 17088618 OR 4.5V ALKALINE BATTERY PACK P/N 1708-9376 CONTAINING THREE

IDENTICAL ALKALINE CELLS FROM THEFOLLOWING LIST: DURACELL

MN1500 OR RAYOVAC LR6. DO NOT MIX BATTERIES FROM DIFFERENT

MANUFACTURERS. REPLACE ALL BATTERIES AT THE SAME TIME.

P/N 1715-3290 AND P/N 1708-8618 LI-ION RECHARGEABLE PACKS ARE NOT

TO BE REPLACED BY THE USER. CHARGE IN FRESH AIR ONLY.

THE FOLLOWING ARE TO BE PERFORMED IN NON-HAZARDOUS

LOCATIONS ONLY: RECHARGE Li BATTERY PACK, CHANGE ALKALINE

BATTERY PACK, REPLACE ALKALINE CELLS, SERVICE UNIT OR USE

COMMUNICATION PORT.

DO NOT USE THE ITX IN OXYGEN ENRICHED ATMOSPHERES.

CAUTION (UL CLASSIFICATION, MSHA APPROVAL, AND CSA

CERTIFICATION ONLY):

JACK FOR USE ONLY WITH INDUSTRIAL SCIENTIFIC EXTERNALALARM,

P/N 1810-1154 OR VIBRATING ALARM, P/N 1810-2146 ONLY.

CANADIAN STANDARDS ASSOCIATION (CSA) HAS ASSESSED ONLY THE

COMBUSTIBLE GAS DETECTION PORTION OF THIS INSTRUMENT FOR

PERFORMANCE.

CAUTION: BEFORE EACH DAY'S USAGE SENSITIVITY MUST BE TESTED

ON A KNOWN CONCENTRATION OF PENTANE OR METHANE EQUIVALENT TO

25-50% OF FULL SCALE CONCENTRATION. ACCURACY MUST BE WITHIN -0+20% OF ACTUAL. ACCURACY MAY BE CORRECTED BY REFERING TO

SECTION 5 OF THE INSTRUCTION MANUAL.

CAUTION: ANY RAPID UP-SCALE READING FOLLOWED BY A DECLINING

OR ERRATIC READING MAY INDICATE A GAS CONCENTRATION BEYOND

UPPER SCALE LIMIT WHICH MAY BE HAZARDOUS.

!

W

ARNINGS AND

C

AUTIONARY

S

TATEMENTS

READ AND FULLY UNDERSTAND THE ENTIRE INSTRUCTION MANUAL

AND THIS INSTRUCTION SHEET BEFORE USING OR SERVICING THE MODEL

ITX.

S'ASSURER DE BIEN LIRE ET DE BIEN COMPRENDRE TOUTES LES

INSTRUCTIONS DU MANUEL ET DE CE FEUILLET AVANT D'UTILISER ET DE

PROCÉDER AU DÉPANNAGE DU MODÈLE ITX.

OBSERVE ALL LAWS AND REGULATIONS OF THE LOCAL AUTHORITY IN

REGARDS TO BATTERY DISPOSAL.

THE MODEL ITX MULTI-GAS MONITOR (P/N 1810-4307) AND MODEL ISP

SAMPLE PUMP (P/N 1810-4646) COMPLIES WITH EUROPEAN ATEX

DIRECTIVE 94/9/EC AND EMC DIRECTIVE 89/336/EEC, AMENDED BY

DIRECTIVES 92/31/EEC AND 93/68/EEC.

THE MODEL ITX MULTI-GAS MONITOR (P/N 1810-4307) AND MODEL ISP

SAMPLE PUMP (P/N 1810-4646) IS CONSTRUCTED WITH REFERENCE TO

PUBLISHED STANDARDS OF DIRECTIVE 72/23/EEC, TO ELIMINATE

ELECTRICAL RISKS AND FULFILL 1.2.7 OF ANNEX II OF DIRECTIVE 94/9/EC

WARNING: SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC

SAFETY AND MAY CAUSE AN UNSAFE CONDITION!

AVERTISSEMENT: LA SUBSTITUTION DE COMPOSANTS PEUT

COMPROMETTRE LA SÉCURITÉ INTRINSÈQUE!

PERFORMANCE CLAIMS ARE BASED UPON THE USE OF BATTERIES

WHICH HAVE AN ADEQUATE CHARGE AND ADEQUATE AIR FLOW

SAMPLING.

ANY LOW BATTERY INDICATION BY THE MODEL ITX, CAUTIONS THE

USER THAT THE BATTERIES INSTALLED DO NOT HAVE AN ADEQUATE

CHARGE, AND THAT THE USER SHOULD REPLACE THE BATTERIES, WITH

BATTERIES KNOWN TO HAVE AN ADEQUATE CHARGE, IN A

NONHAZARDOUS AREA, TO AVOID THE RISK OF AN EXPLOSION.

ANY INDICATION BY THE MODEL ISP SHOWING THAT A LOW FLOW OR

BLOCKAGE CONDITION EXISTS CAUTIONS THE USER THAT THE AIR FLOW

SAMPLING IS INADEQUATE AND THAT THE USER SHOULD ENSURE THAT

THE MODEL ISP HAS ADEQUATE AIR FLOW SAMPLING BEFORE

CONTINUING USE.

THE MODEL ITX IS CERTIFIED FOR USE WITHIN AN AMBIENT

TEMPERATURE RANGE OF -20ºC TO 40ºC ONLY.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

ATTENTION

LE JACK DOIT ÊTRE UTILISÉ SEULEMENT AVEC UNE ALARME EXTERNE

INDUSTRIAL SCIENTIFIC N/P 1810-1154 OU UNE ALARME À VIBRATIONS N/P

1810-2146.

L'ASSOCIATION CANADIENNE DE NORMALISATION (CSA) A ÉVALUÉ

UNIQUEMENT LA PERFORMANCE DELA PORTION DÉTECTION DE GAZ

COMBUSTIBLES DE CET APPARELL.

!

!

76

U

NPACKING THE

I

NSTRUMENT

The shipping box should contain the following items.

Account for each item before discarding the box.

QUANTITY P

ART NUMBER DESCRIPTION

1 18104307 iTX Multi-Gas Monitor

1 17095753 iTX Instruction Manual

1 18104661 Nylon Carrying Case

1 17092339 Calibration Cup

1 17093659 Polyurethane Tubing

1 17095746 Maintenance Tool

After unpacking, if any listed item is missing, contact

either your local distributor of Industrial Scientific

products, or call Industrial Scientific Corporation at 1-800DETECTS (338-3287) in the United States and Canada, or

412-788-4353.

WARNING: iTX units equipped with bias sensors

will self discharge a fully charged

battery in approximately four days.

Because of this, bias sensor equipped

units are shipped without the battery

installed. Upon receipt, install the

battery and allow the bias sensors to

stabilize for 24-52 hours. Always

store bias sensor equipped iTX units

on the appropriate charger (lithiumion versions only). It is not

recommended to use alkaline

batteries in instruments with bias

sensors.

!

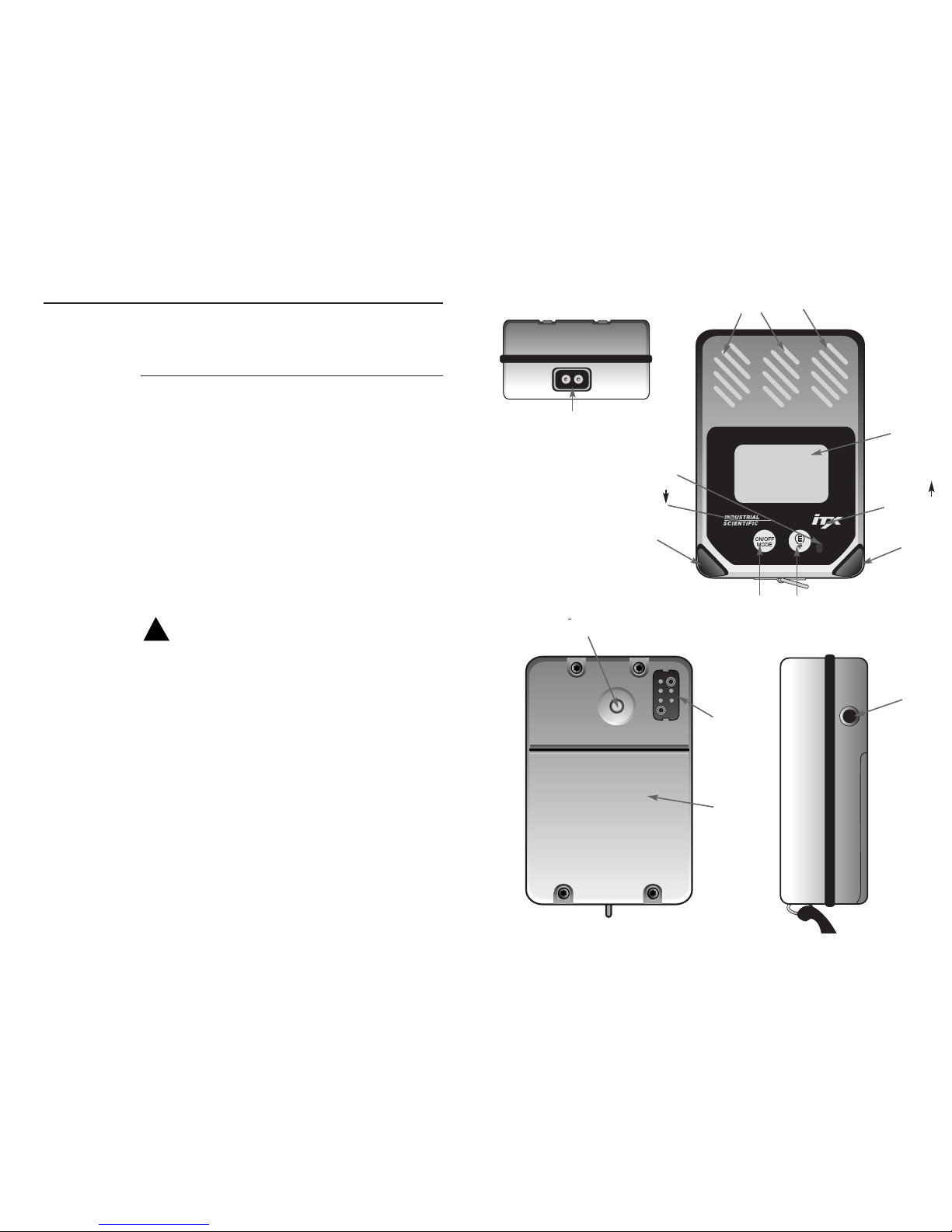

PPM PPMPPM

PPM LEL/CH4%VOL

Unmarked Key

Unmarked

Key

Audible Alarm

Sampling Pump Contact

Visual Alarm

Visual Alarm

Enter/Backlight Key

On/Off Mode Key

Sensor Openings

Display

External

Alarm

Jack

Charger/

Datalink

Connector

Battery

Cover

i

-Button

®

Contact

BOTTOM

FRONT

BACK

SIDE

98

I

NSTRUMENT

O

PERATION

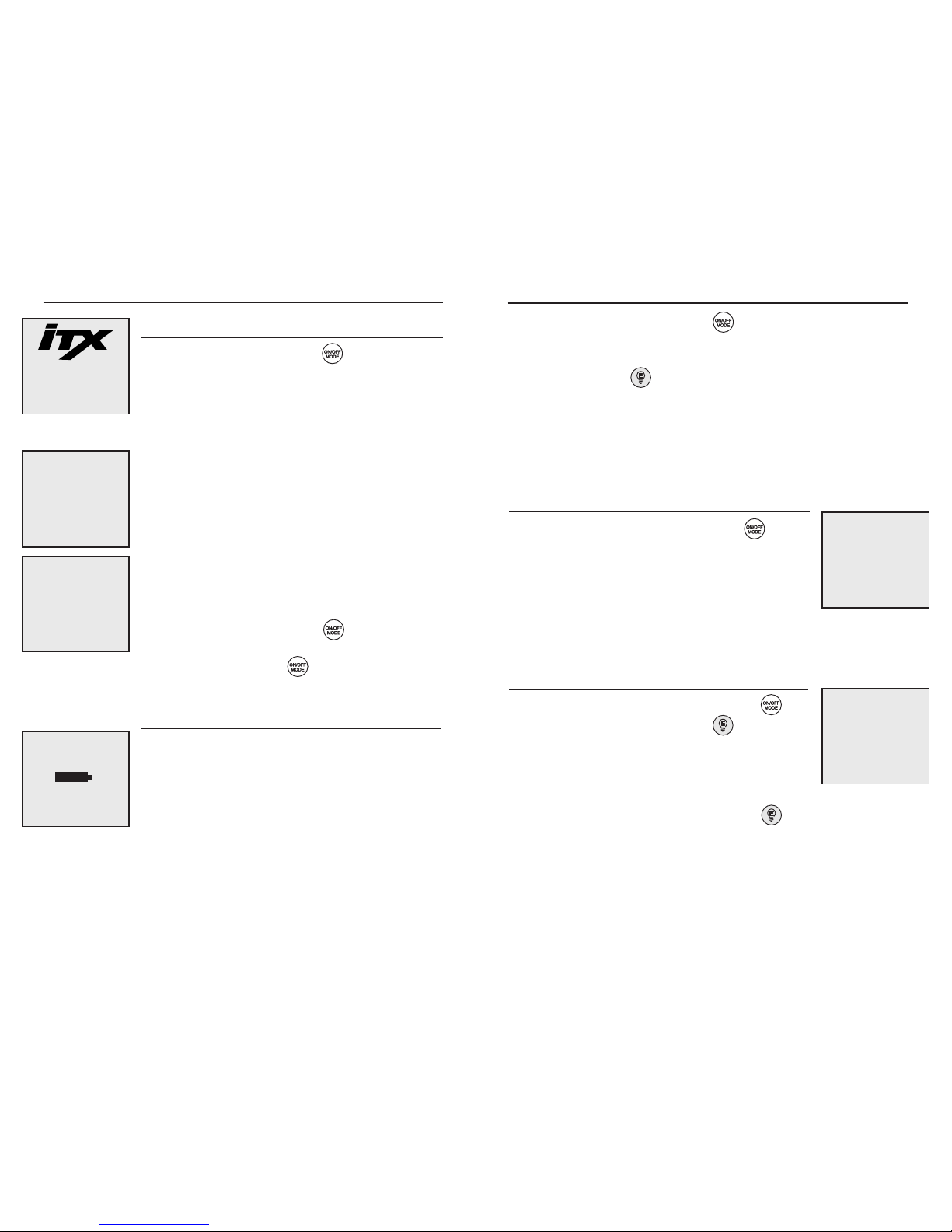

TURNING THE iTX ON AND OFF

To turn the iTX on, press and hold until the

instrument emits a short beep and the iTX welcome screen

appears on the display. The current revision of instrument

operating software is shown below the instrument model

name.

Revision 1.0

After the iTX warm-up screen, the display will identify

any new sensors installed which have not been calibrated

in the instrument. If this screen appears, the instrument

must be calibrated prior to further use. If the system clock

has not been set, you will be prompted to do so.

Prior to entering the normal operating mode, the iTX

display will show the type of each sensor installed in the

instrument along with a brief countdown timer until

normal gas readings appear.

To turn the iTX off, press and hold at any time

during operation until the instrument display shows

RELEASE. After releasing the instrument’s display

will blank and all operation will cease.

GAS READING MODE

In the Gas Reading Mode the iTX will show the type of

each sensor currently installed with the corresponding gas

concentration shown directly underneath it. A battery

status indicator is shown in the center of the display. As

the instrument battery life is reduced, the shaded area of

the battery indicator will clear until the instrument reaches

the low battery condition. With 15 minutes of battery life

left, a low battery condition occurs. The instrument will

make a periodic tone alerting the user that the battery

needs charged or replaced. If a preset gas alarm level is

exceeded for either low, high, STEL or TWA, the iTX will

activate audible and visual alarms and the corresponding

gas display will flash.

V

IEWING THE

iTX O

PERATINGMODES

PPM EXPLOSIVE GAS READING

If the ppm explosive feature is enabled, press until

“PPM EXP” appears. This screen will display the current

concentration of explosive gas in parts per million (ppm)

in 50 ppm intervals up to 10,000 ppm. If any gas reading

increases to a level exceeding the low alarm set-points, the

instrument will automatically return to the gas reading

mode.

New CO2

Sensors NH3

Installed CO

O2

H2S

E to Continue

CO SO2 H2S

10

O2 CL2 LEL

CO SO2 H2S

O 0.0 0

O2 Cl2 LEL

20.9 0.0 0

PPM EXP

1000

During Normal Operation, pressing the will scroll

the instrument through all of the operating modes that

have been enabled. While scrolling through the modes of

operation, pressing the when prompted access the

desired functions. To add or remove items from the

operating modes, the user must enable/disable the features

through the iTX configuration settings. Accessing these

custom settings is described in the Configuring iTX’s

Custom Section on page 11.

Zero Sensors

Press E to Zero

ZEROING AND CALIBRATION

If the zero and calibrate feature is enabled, press

until “Zero Sensors” appears. Pressing while this

screen is displayed will activate the instrument’s 20

second ZEROING sequence. This resets the current

instrument reading and reference point to zero and

calibrates the oxygen sensor to 20.9% in ambient air.

After the zeroing sequence is complete, pressing will

allow you to perform a span calibration to adjust and

ensure the accuracy of the instrument, see Calibrating the

iTX, page 21.

1110

PEAK READINGS

If the peak hold feature is enabled, press until

“PEAKS” appears. The peak reading displayed represents

the highest toxic and explosive gas concentration and the

lowest oxygen concentration measured since the peak

reading was last cleared from memory. To clear and reset

the peak readings, press and release while the peak

reading is displayed.

STEL READINGS

If the iTX STEL and TWA features are enabled press

until “STEL” appears. This screen will display the current

15 minute short term exposure limit (STEL) average

readings for toxic gases measured since these readings

were last cleared and reset.

TWA R

EADINGS

If the TWA feature is enabled, pressing once at the

STEL screen will display the TWA screen. This mode

displays the current time weighted average (TWA)

readings of the toxic gas sensors since they were last

reset. To reset STEL/TWA values, see Resetting

Datalogging Session, page 8.

PAUSE DATALOG

If the iTX datalogging and pause datalogging functions

are enabled, press until “Data Logging Paused”

appears. The Pause/Datalog screen allows the user to

temporarily stop the instrument from logging data.

Datalogging may be paused or resumed by pressing

while this screen is displayed. In normal operation the

video tape icon will flash while datalogging is enabled.

CO SO2 H2S

38 10.6 13

PEAKS

E to Clear

O2 CL2 LEL

18.6 1.6 8

CO SO2 H2S

10 0.8 3

STEL

CL2

1.6

CO SO2 H2S

5 0.8 3

TWA

CL2

0.6

RESETTING DATALOGGING SESSION

If the datalogging features are enabled, press until

“Start New Datalog Session” appears. Pressing

while this screen is displayed will start a new datalogging

session in the instrument’s memory. Starting a new

session automatically resets all STEL and TWA readings

in the instrument, if they have been enabled. When a new

session has begun, the session start time and date along

with the data recording interval will be stamped in the

instrument’s memory so that they can be retrieved at a

later date.

DATALOG SESSION

If the datalogging functions are enabled, press until

“Datalog Session” appears. This screen will show the

elapsed time in the current datalogging session, the

amount of datalogging time remaining until the

instrument’s memory is full and the instrument’s current

recording interval in seconds. When the memory is

nearing the end of its storage capacity, care should be

taken to download data to a PC, the DS1000 Docking

Station, or the DS2, to ensure that critical survey data is

not lost.

L

AST CALIBRATION

/CALIBRATION DUE

If the last calibration and calibration date due functions are

enabled press until “Instrument Calibration Due”

appears. The iTX will display the date of the last

calibration or the date the instrument is next due to be

calibrated based on the users choice and selected time

interval. The calibration date will be automatically

updated each time the instrument is calibrated (and every

sensor passes) either manually or when using the DS1000

or DS2 Docking Stations.

Data Logging

Paused

E To Resume

StartNew

Datalog

Session

Press E For New

Datalog Session

Elapsed Time

10:24

Remaining Time

2:23

Record Interval

300 Sec

Calibration

Dates

Due

08/12/01

SITE IDENTIFICATION

Press until “Active Site” appears. Monitoring site

location codes can be entered into the instrument’s

datalogging memory to correspond to measured gas

concentrations in the same manner as the user

identification codes. Pressing the while in this mode

and following the on screen instructions will allow the

current site ID to be selected from memory

• Pressing , allows the user to select a site name from a list

previously programmed into the instrument’s memory through the

instrument configuration menus. Use the down arrow hidden key

to scroll through the names, and the to select the desired site

name.

• Pressing the up-arrow hidden key allows the user to key ID

information in through the instrument keypad. Use the two hidden

arrow keys to scroll through available characters, and the to

select your character. Once the desired site name is entered, press

and hold the to accept it.

• Pressing the down-arrow hidden key allows the user to enter ID

information automatically with an iButton memory device. When

prompted, press the to read the iButton. After pressed, the

user has 5 seconds to press their iButton onto the contact located

on the back of the instrument (see page 5). After 5 seconds if no

iButton is detected, the instrument will beep and let you know it

failed reading the iButton. It will then go back to the initial Active

Site screen.

13

12

TIME/DATE /TEMPERATURE

If the time/date/temperature function is enabled, press

until today’s date appears. The iTX will display the

current time and date along with the current temperature

(inside the iTX) in degrees Fahrenheit and Celsius.

Although the current temperature reading can be a useful

tool, it should not be relied upon to provide instantaneous

temperature measurements. The temperature sensor will

only be accurate after the instrument has had time to adjust

to the environment. This typically will take several

minutes and in extreme temperature conditions may take

up to one-half hour.

USER IDENTIFICATION

Press until “Active User” appears. This screen

allows the current user’s name, identification code, or

number to be recorded into the instruments datalogging

memory. The user indentification can be entered in one of

three ways. Pressing the while in this mode and

following the on screen instructions will allow the current

user ID to be selected.

• Pressing , allows the user to select a user name from a list

previously programmed into the instrument’s memory through the

instrument configuration menus. Use the down arrow hidden key to

scroll through the names, and the to select the desired name.

• Pressing the up-arrow hidden key allows the user to key ID

information in through the instrument keypad. Use the two hidden

arrow keys to scroll through available characters, and the to

select your character. Once the desired user name is entered, press

and hold the to accept it.

• Pressing the down-arrow hidden key allows the user to enter ID

information automatically with an iButton memory device. When

prompted, press the to read the iButton. After pressed, the

user has 5 seconds to press their iButton onto the contact located on

the back of the instrument (see page 5). After 5 seconds if no

iButton is detected, the instrument will beep and let you know it

failed reading the iButton. It will then go back to the Initial Active

User screen.

14 March 2002

11:45 AM

72F 22 C

Active User

None

E To Change

Active Site

None

E To Change

C

ONFIGURING

iTX’SC

USTOMSETTINGS

The iTX Multi-Gas monitor has many user configurable

options and features. These feature may be accessed

through the configuration software and a PC, the DS1000

or DS2 Docking stations, or adjusted manually by pressing

the and hidden keys (see page 5)

simultaneously during the warm-up cycle when the count

down timer is displayed. Configuring your iTX is very

intuitive. Every option is highlighted on the display.

CO SO2 H2S

10

O2 CL2 LEL

15

14

In General:

• Pressing or will step you through the modes

or set a value.

• Pressing selects a function or accepts (saves) a

value.

• Pressing moves you backwards in the

configuration or steps you completely out of set up to

the “Gas Readings Mode.”

SECURITY CODE

Once the configuration mode has been entered, the

instrument will prompt you to enter the 3-digit security

access code if this feature has been enabled. If the

security code feature is activated in the instrument no

configuration changes can be made to the iTX without

entering the proper security code. The security code is

entered by pressing and to scroll through the

digits from 0 to 9. Pressing will shift the display

cursor to the next digit. Once the code has been entered

successfully, press to accept the value. The iTX

display will step to the next available configuration screen

if the proper code has been entered.

SECURITY FEATURES

If no security code has been established, the first

configuration screen you will view is “Security Features.”

Pressing allows you to configure a custom code.

You will then see “Change Setup Mode Security Code”

prompting you to press to change. Using the

and keys you can set the code, use to verify the

number, and hold to exit.

Enter Security

Code

or to Change

Mode to Select

Field

E To Accept

Alarm

Configuration

E to Change

Security

Features

E to Configure

ALARM CONFIGURATION

The “Alarm Configuruation” mode allows you to change

alarm set values for each sensor installed. Pressing the

will enter you into this menu item. All present gas sensors

appear on the screen. The hidden arrow keys allow you to

scroll to the different gas types. Pressing the will

select the highlighted gas sensor. Once a gas type is

selected, the hidden down arrow key allows you to select

which alarm type to change. Pressing the again will

select the alarm type and display the currently

programmed value. Using the two hidden arrow keys, the

alarm set points can be adjusted up or down. Once the

desired value is met, press the to accept it. Once

accepted, you can scroll to the next alarm type you want

to change, or press the to select a new gas sensor. If

no more changes are required, pressing the again will

bring you to the “Save Configuration Screen”.

saves the new alarm settings, while aborts all

changes.

SENSOR CALIBRATION GAS

The “Sensor Calibration Gas” mode allows you the option

of changing the concentrations of the calibration gases. To

change concentrations, simply press the to enter this

mode. Once entered, the user can use the hidden down

arrow key to select which calibration gas is to be changed.

When the desired gas is highlighted press to change

the concentration. Using the hidden arrow keys, you can

adjust the concentration up or down. Pressing will

accept the new calibration gas concentration. Once

accepted, you can select the next calibration gas

concentration to change. If no more changes are required,

pressing the again will bring you to the “Save

Configuration Screen”. saves the new alarm settings,

while aborts all changes.

Sensor

Calibration

Gas

E to Configure

17

16

QUICK CALIBRATION

The “Quick Calibration” mode allows you to turn this

feature on or off. For details on the Quick Calibration

feature, please refer to Quick Calibration, page 25.

ZERO SENSORS

The “Zero Sensors” mode allows you to adjust the

baseline of toxic and explosive gas sensors to zero and

span calibrate the oxygen sensor. Once the zeroing is

complete you have the option of continuing with a full

span gas calibration.

ZERO SENSORS ON STARTUP

The “Zero Sensors On Startup” mode allows you to

choose whether your iTX will automatically reset your

toxic and exposive gas sensors to “0.0” and your oxygen

reading to “20.9”. This setting should never be used if you

normally power up your iTX in a contaminated

environment.

A

LLOW SENSOR ZEROING IN THE FIELD

The “Allow Sensor Zeroing in the Field” mode allows you

to determine whether your iTX should be able to be

zeroed in the field. By selecting “NO” the unit will not be

able to be zeroed unless the function is accessed during

configuration. If “YES” is selected, this mode can be

entered from the “Gas Reading Mode” by pressing the

A

LLOW C

ALIBRATION IN FIELD

The “Allow Calibration In Field” mode allows you to

determine whether your iTX should be able to be span

calibrated in the field. By selecting “NO” the unit will not

be able to be span calibrated unless the function is

accessed during configuration. If “YES” is selected, this

mode can be entered from the “Gas Reading Mode” by

pressing the

NUMERIC DISPLAY

The “Numeric Display” mode allows you to choose whether

your iTX will display actual gas concentrations or relate the

condition of the ambient air through text messages. Text

readings show “OK” in non-alarm conditions and “ALARM”

when an unsafe gas condition is detected. During an alarm

condition, the gas/sensor that is in alarm will flash.

PEAKS

The “Peaks” mode allows you to view or clear the highest

concentration of explosive and toxic gas or the lowest

concentration of oxygen since the peak readings were last

cleared. Pressing in this mode will clear all peak

readings.

ALLOW VIEWING PEAKS READING IN FIELD

The “Allow Viewing Peaks Reading In Field” mode lets

you decide whether peak readings will be accessed in the

field. Choosing “Yes” will display the peaks while

choosing “No” blocks them from the Gas Reading Mode

and can only be accessed during configuration.

ALLOW VIEWING STEL/TWA READING

IN FIELD

The “Allow Viewing STEL/TWA Reading In Field” mode

lets you decide whether STEL and TWA average gas

readings will be accessed in the field. Choosing “Yes”

will display these average values while choosing “No”

blocks them from the Gas Reading Mode.

TWA

The “TWA” mode allows you to set the time duration used

to calculate the Time Weighted Average gas reading.

Normally this value is 8 hours, representing a normal

work shift but it is adjustable from 1 to 40 hours. Press

allows you to change the time duration. Once is

pressed, the value can be adjusted by using the two hidden

up/down arrow keys.

Quick

Calibration

Yes

E to Change

Zero Sensors

E to Zero

Zero Sensors

On Startup

No

E to Change

Allow Sensor

Zeroing

in Field

No

E to Change

Allow

Calibration

in Field

Yes

E to Change

Numeric

Display

E to Change

Allow Viewing

STEL/TWA Reading

in Field

Yes

E to Change

Allow Viewing

Peaks Reading

in Field

Yes

E to Change

TWA

40 Hrs

E to Change

CO SO2 H2S

38 10.6 13

PEAKS

E to Clear

O2 CL2 LEL

18.6 1.6 8

19

18

Log Data On Alarm Only

The “Log Data On Alarm Only” mode allows you to

choose whether the iTX’s datalogger will log continuously

or only after the unit has gone into gas alarm. Default

logging interval is one second.

Allow Manual Pause/Resume In Field

The “Allow Manual Pause/Resume In Field” mode allows

you to manually pause and resume datalogging while

monitoring for gases in the field.

Data Logging Interval

The “Data Logging Interval” mode allows you to choose

the average interval for writing data to the data logger.

Once is pressed, you can adjust the recording interval

by using the two hidden arrow keys. The recording

interval is adjustable from 1 second to 300 seconds.

Pressing will enter the desired interval. For example,

if 60 seconds is chosen, the iTX will take a gas reading for

each installed sensor once every second, average those

readings over 60 seconds, and write that value to the

datalogger.

Clear Data Logging Memory

The “Clear Data Logging Memory” mode allows you to

clear the data currently in memory with the touch of a key.

Pressing during this mode will clear logged data

from memory.

CALIBRATION DATES

The “Calibration Dates” mode gives you control over how

you would like to have calibration date data portrayed.

Choosing to accept allows you to toggle between last

calibration date and calibration date due display screens.

Calibration data screens are displayed during the Gas

Reading Mode.

NON-LATCHING

The “Non-Latching Alarm Configuration” mode allows

you to configure whether the iTX gas alarms will latch or

not. Choosing latching alarms will cause the iTX to alarm

continuously whenever a gas alarm value has been

exceeded. The alarm condition will continue until the gas

hazard has been cleared and the alarm has been manually

reset by the user by pressing .

CONFIDENCE B

EEP

The “Confidence Beep” mode allows you to control

whether their iTX will sound a confidence beep once

every 30 seconds. Choosing “Yes” in this mode will

employ this feature while choosing “No” disables it.

Confidence beep will not trigger external alarm.

D

ATA

LOGGING CONFIGURATION

The “Data Logging Configuration” mode allows you to

turn the instrument’s data logger on or off. The data

logger in the iTX is designed to log 300 hours of

continuous data in one minute intervals. Pressing

will grant you access to the rest of the data logging set up

menus. The first prompt will ask if you if you want data

logging or not. If you select “Yes” you will continue with

the set-up. If you select “No” you will go back to the rest

of the Configuration Mode menus. The hidden arrow

keys allow you to navigate to through the data logging

configuration screens. Pressing will select that mode

option and allow you to make changes.

Allow Over-Writing Of Data

The “Allow Over-Writing Of Data” mode allows you to

configure whether or not the iTX’s datalogger will overwrite information whenever the data logger has reached its

capacity.

Data Logging

Configuration

E to Change

Data Logging

Interval

1 Sec

E to Change

Clear

Data Logging

Memory

E to Clear

Calibration

Dates

Last

E to Change

Allow

Over-Writing

Of Data

No

E to Change

Log Data On

Alarm Only

No

E to Change

Allow Manual

Pause/Resume

In Field

No

E to Change

Confidence Beep

Yes

E to Change

Non-Latching

Alarm

Configuration

E to Change

20 21

NEXT CALIBRATION DATES

The “Next Calibration Dates” mode allows you to set the

frequency of calibration in terms of days. The default

setting is 30 days but the value is fully adjustable. Once

is pressed, you can adjust the day interval by using the two

hidden arrow keys. The days interval is adjustable from 1

to 365 days. Pressing will enter the desired value

into memory.

ALLOW V

IEWING CALIBRATION D

ATES

The “Allow Viewing Calibration Dates” mode gives you

control over whether the calibration dates and dates due

will be accessible during the Gas Reading Mode.

C

URRENT DAT E SCREEN

The Current Date Screen displays the date the iTX has

been programmed to interpret as today’s date. Pressing

in this mode allows you to change either the date,

month, year, or time of day. Using the hidden arrow

keys allows you to adjust the highlighted values. Once a

desired value is selected, press to move to the next

field in the date or time. will allow you to move from

field to field, while the hidden arrow keys allows you to

make adjustments to the time or dates. Once everything is

set, press and hold to accept the new time and date.

ALLOW VIEWING DATE AND TIME IN FIELD

The “Allow Viewing Date and Time In Field” mode gives

you control over whether the time and date will be

accessible during the Gas Reading Mode.

Allow Viewing

Date and Time

in Field

No

E to Change

Backlight

Shut-Off

Manual

E to Change

Active User

None

E to Change

BACKLIGHT SHUT-OFF

The “Backlight Shut-Off” mode allows you to control

whether the backlight shuts off automatically or manually.

Choosing “Timed” control of the backlight will

automatically turn the backlight off 30 seconds after

activation. Choosing “Manual” control of the backlight

will leave the backlight on continuously until is

pressed.

ACTIVE U

SER

The “Active User” mode allows you to manually

configure an alpha-numeric User Identification into the

iTX’s datalogger. Manual entry of User IDs are not

necessary when using the i

Button®. Pressing enters

you into the Active User Mode. Pressing the hidden up

arrow key allows the user to edit the user list, while

pressing the hidden down arrow key allows the user to

change the current user. If you choose to edit the user list,

you can either add or delete users. Users are deleted by

highlighting the desired user and pressing . Adding

users to the list is accomplished two ways.

• Pressing the up-arrow hidden key allows the user to key ID

information in through the instrument keypad. Use the two hidden

arrow keys to scroll through available characters, and the to

select your character. Once the desired user name is entered, press

and hold the to accept it.

• Pressing the down-arrow hidden key allows the user to enter ID

information automatically with an iButton memory device. When

prompted, press the to read the iButton. After pressed, the

user has 5 seconds to press their iButton onto the contact located

on the back of the instrument (see page 5).

• After 5 seconds if no iButton is detected, the instrument will beep

and let you know it failed reading the iButton. It will then go back

to the initial Active User screen.

14 March 2002

11:45 AM

E to Change

Next Calibration

Dates

30 Days

E to Change

Allow Viewing

Calibration

Dates

No

E to Accept

2322

ACTIVE SITE

The “Active Site” mode allows you to manually configure

an alpha-numeric Site Identification into the iTX’s

datalogger. Manual entry of Site IDs are not necessary

when using the i

Button®. Pressing enters you into the

Active Site Mode. Pressing the hidden up arrow key

allows the user to edit the site list, while pressing the

hidden down arrow key allows the user to change the

current site location. If you choose to edit the site list, you

can either add or delete sites. Location sites are deleted by

highlighting the desired site and pressing . Adding

sites to the list is accomplished two ways.

• Pressing the up-arrow hidden key allows the user to key ID

information in through the instrument keypad. Use the two hidden

arrow keys to scroll through available characters, and the to

select your character. Once the desired site name is entered, press

and hold the to accept it.

• Pressing the down-arrow hidden key allows the user to enter ID

information automatically with an iButton memory device. When

prompted, press the to read the iButton. After pressed, the

user has 5 seconds to press their iButton onto the contact located on

the back of the instrument (see page 5).

• After 5 seconds if no iButton is detected, the instrument will beep

and let you know it failed reading the iButton. It will then go back

to the initial Active Site screen.

ALLOW

CHANGING OF

SITE AND USER IN FIELD

The “Allow Changing of Site and User In Field” mode

gives you control over whether the Site and User IDs will

be able to be changed in the field.

ALLOW VIEWING SITE AND USER IN FIELD

The “Allow Viewing Site and User In Field” mode gives

you control over whether the Active Site and User will be

accessable during Gas Reading Mode.

Active Site

None

E to Change

Allow Changing

Site and User

In Field

Yes

E to Change

Allow Viewing

Site and User

In Field

No

E to Change

ALLOW VIEWING COMBUSTIBLE PPM

The “Allow Viewing Combustible PPM” mode gives you

control over whether PPM levels of combustible gas will

be able to be viewed from the Gas Reading Mode. If any

gas reading increases to a level exceeding the low alarm

set-points, the instrument will automatically return to the

gas reading mode.

Allow Viewing

Combustibe

PPM

No

E to Change

C

ALIBRATING THE

iTX

Gas detection instruments are potential life-saving

devices. Recognizing this fact, Industrial Scientific

Corporation recommends that a functional (“bump”) test

be performed on every instrument prior to each days use.

A functional test is defined as a brief exposure of the

monitor to a concentration of gas(es) in excess of the

lowest alarm set-point for each sensor for the purpose of

verifying sensor and alarm operation and is not intended

to be a measure of the accuracy of the instrument.

Industrial Scientific further recommends that a full

instrument calibration be performed using a certified

concentration(s) of Industrial Scientific branded

calibration gas(es) monthly to ensure maximum

accuracy. Use of calibration gases from manufacturers

other than Industrial Scientific may void product

warranties and limit liability claims against the

manufacturer.

If an instrument fails to operate properly following any

functional “bump” test, a full instrument calibration

should be performed prior to use.

2524

STANDARD CALIBRATION

To calibrate the iTX, press until “Zero Sensors”

appears. Press to begin the zeroing process. All

toxic and combustible sensors will be reset to zero during

this procedure. Once these sensors have properly zeroed,

the oxygen sensor calibration screen will appear. This

screen will display “O2 CAL” along with the current full

span reading for the oxygen sensor. The full span value

reveals how much life remains in the gas sensor.

Interpretation of the full span value will be explained at

the completion of this section of this manual.

When the zeroing process is complete the instrument will

beep and the “Zeroing Complete; E to Continue” screen

will appear. Press and select calibration. Select

“Yes” then press to begin the instrument span

calibration. The display will show the first sensor to be

calibrated along with the calibration gas concentration and

the message “Apply Cal Gas.” At this point, apply the

sample of a known concentration of the appropriate

calibration gas at a flow rate of .5 LPM (1 SCFH) to the

iTX as shown. The iTX will automatically recognize the

presence of the calibration gas and display “Cal in

Process” along with the current full span value of the

sensor. The instrument will be calibrated automatically

when the sensor response to the calibration gas becomes

stable.

After each sensor has been calibrated, the instrument will

beep and the display will step to the next sensor to be

calibrated. The steps will be repeated automatically until

each sensor has been calibrated. To skip a sensor, press

when the appropriate gas is displayed. A summary

of full span values appears on the display at the

completion of the calibration sequence.

PPM

PPM

PPM

PPM

LEL/CH4

%VOL

27.8

O2 CAL

Calibrate CO

Cal Gas = 100ppm

Apply Cal Gas

CalibratingCO

Cal in Process

Span Reserve

112 ppm

Zeroing

CO 152 PASS

H2S 21 Marg

OXYG 24.7 PASS

LEL 11 Fail

E to Continue

QUICK CALIBRATION

If the Quick Cal feature of the iTX has been enabled, all

sensors capable of being calibrated using a multicomponent cylinder will be adjusted simultaneously. If a

sensor is installed in the instrument which cannot be

calibrated using the Quick Cal feature, the instrument

display will automatically step to that sensor prior to

starting the Quick Cal. This will save time as well as the

amount of gas used during calibration and eliminate the

repetition of the steps described above.

When the calibration process has been completed the

instrument will show the calibration status display. This

screen will show each sensor type along with the full span

value determined during the calibration and the result of

the calibration as PASS, MARGinal or FAIL. Any sensor

with a full span value greater than 70% of the calibration

gas value will show PASS. Full span values between 50

and 70 percent of the calibration gas value will allow the

sensors to calibrate successfully but will be considered

MARGinal calibrations. Marginal calibrations indicate that

sensor may soon need to be replaced. Full span values

less than 50% of the current calibration gas value will

FAIL calibration. Sensors which fail calibration should be

replaced immediately.

Quick Cal

LEL 25%

O2 100 ppm

CO 100 ppm

H2S 100 ppm

Apply Cal Gas

R

EMOTESAMPLING

USING THE iSP (MOTORIZED SAMPLING PUMP)

By itself, the iTX is a diffusion gas monitor capable of

monitoring the ambient air. When combined with the iSP

motorized sampling pump, the iTX can now be used to

evaluate an atmosphere up to 100 feet away.

FAULT

POWER

!

i

SP

PPM PPMPPM

27

26

PPM PPMPPM

PPMLEL/CH4%VOL

The iSP is a parasitic sampling pump, meaning it operates

without a dedicated battery and draws its power from the

iTX itself. To use the iSP, simply slide it over the top end of

the iTX. With the iTX turned on and the iSP fully engaged,

you will hear a short audible beep and the pump motor will

begin to run.

Verification of the flow alarm is recommended before each

day's use. To verify operation, restrict flow to the pump by

blocking the inlet with a finger until the iTX goes into flow

alarm. A flow alarm is indicated by the pump’s illuminated

red fault LED; and by the instrument’s high alarm and

display of the word PUMP. To clear the alarm, remove the

finger from the pump inlet.

During normal operation the green LED will be illuminated

signaling the pump is operating normally. At this point you

may connect the probe or tubing combination (up to 100

feet) of your choice and begin remote sampling. Allow 2

seconds per sampling foot as a purge time.

Should the sampling line become obstructed, the iSP will

emit an audible alarm and the red fault LED will illuminate.

If this occurs, check the sample line for an obstruction or

kink. Once the obstruction is removed the iSP will resume

normal operation.

USING THE HAND ASPIRATED PUMP*

For remote sampling applications of 10 feet or less, you may

choose the hand aspirated sampling pump. Before use,

inspect the hand aspirator to ensure it has not been damaged.

To use, simply slide the calibration cup over the sensor end

of the iTX, making sure to provide a good seal. Purge the

netted reservoir of its contents by completely compressing

it. Squeeze the aspirator bulb 10 full consecutive

compressions. Verify that each compression inflates the

netted reservoir bulb. Proper sampling is obtained when the

netted reservoir provides 40 to 80 seconds of constant flow

to the calibration cup.

* Not a CSA approved accesory.

FAULT

COMPLETE

CHARGING

INSTRUMENT/BATTERY

M

AINTENANCE

With normal routine maintenance the iTX can be relied

upon to provide years of reliable service. The following

guidelines should be followed when performing

maintenance on the iTX.

CLEANING

When necessary, wipe the outside of the instrument with a

soft, clean cloth. Never use solvents or cleaning solutions

of any type. Make sure the sensor diffusion membrane is

free of debris. Clean sensor openings with a soft, clean

cloth or soft brush.

CHARGING THE BATTERIES

The lithium-ion battery pack should be fully charged

before using the iTX. To charge the battery pack, plug the

flying lead from the iTX battery charger into the socket on

the back of the instrument. The iTX battery pack will be

fully charged within 5 hours. With a fully charged

lithium-ion battery pack the iTX should typically function

for up to 19 hours (10 hours with iSP sampling pump) of

continuous operation. As the battery life decreases, the

shaded area of the battery icon in the center of the display

will also decrease. With a minimum of 15 minutes of

battery life remaining the unit will emit a periodic tone

alerting you to charge/replace the battery.

A replaceable cell alkaline battery pack is also available

for use with the iTX. To remove the battery pack and

replace the 3 AA battery cells loosen the two screws from

the battery cover on the back of the instrument. Remove

the battery pack and replace the AA battery cells with

fresh alkaline batteries. Replace the battery pack and

battery cover in the same fashion.

29

28

CHANGING GAS SENSORS

iTX sensors are designed to be changed and replaced by

the user in the field without the need for factory service.

To replace a sensor in the iTX remove the battery from the

instrument as described above. Remove the three screws

that hold the instrument case top in place and remove the

case top. Be careful not to tear the cable that connects the

keypad to the display board. Grasp the sensor firmly and

remove from the instrument. Plug the new sensor into the

open sensor port and press firmly into place. Some toxic

gas sensors are shipped with a shorting wire in place on

the bottom of the sensor identification board. This

shorting wire must be removed prior to installing the

sensor in the instrument in order for the sensor to function

properly. Once the sensor has been installed, replace the

instrument case top and battery pack. New sensors

installed in the instrument will be recognized

automatically. If a new sensor type was installed in the

instrument, the display will prompt the user to calibrate

the instrument before further use. After installing any of

the bias sensors (NH3, NO, HCl), you must turn on the

instrument so the iTX identifies that a bias sensor is

installed and recognizes the need to supply a bias voltage.

Then turn off the unit and put it on charge for 24 to 48

hours to allow the sensor to stabilize before calibration.

The iTX should be calibrated prior to use to ensure

accuracy after a sensor has been changed in the unit.

TOXIC SENSOR CROSS SENSITIVITY CHART

Industrial Scientific has designed the iTX to respond as

specifically as possible to the target toxic gas.

Realistically, total specificity cannot be achieved in all

cases. The following chart demonstrates typical cross

sensitivity responses for a given sensor when exposed to a

different gas.

TOXIC 3

S

PECIFICATIONS

SIZE: 4.75” x 3.19” x 1.68” (121mm x 81mm x 43mm)

W

EIGHT: 18.5oz (with Li-ion battery pack)

524.5 grams (with Li-ion battery pack)

D

ISPLAY: 128 X 64 Graphic Dot-Matrix LCD with

backlighting for low light conditions. Display

protected by clear lens. RFI/EMI shielding

screen mounted over display area.

R

UN TIME: Run times are specified under the following

conditions: A fully charged Li-ion pack / new

alkaline pack; all sensors installed; room

temperature; and no alarms activated.

Alkaline batteries, without parasitic pump 12hr

Alkaline batteries, with parasitic pump 6hr

Lithium-ion battery, without parasitic pump 24hr

Lithium-ion battery, with parasitic pump 15hr

Sensor CO H2SSO2NO2Cl2ClO2HCN HCl PH3NO H

2

Gas

CO 100 2 1 -5 0 0 0 1000 0 0 1

H

2

S 10 100 1 -8 -3 0 400 25 3 35 20

SO

2

0 10 100 0 0 0 0 0 0

NO

2

-20 -20 -100 100 12 -12 30 0

Cl

2

-10 -20 -35 -100 100 0 -20 20 -10 0 0

ClO

2

20 100

HCN 15 50 50 1 0 0 100 5 1 0 30

HCl 30002001000150

PH

3

100 0 300 100

NO 10 1 1 0 100 30

H

2

60 0.05 0.5 0 0 0 0 0 0 0 100

iTX SENSOR CROSS INTERFERENCE TABLE

The table above reflects the percentage response provided by the sensor listed

across the top of the chart when exposed to a known concentration of the

target gas listed in the left hand column.

31

30

MEASURING RANGES & RESOLUTION:

Range Resolution

CO 999 ppm 1 ppm

H

2

S 499 ppm 1 ppm

NO

2

99.9 ppm 0.1 ppm

SO

2

99.9 ppm 0.1 ppm

O

2

30.0 % 0.1 %

Cl

2

50.0 ppm 0.1 ppm

NO* 499 ppm 1 ppm

NH

3

* 100 ppm 1 ppm

HCN 30.0 ppm 0.1 ppm

HCl* 30.0 ppm 0.1 ppm

PH

3

1.00 ppm 0.01 ppm

H

2

999 ppm 1 ppm

O

3

1.00 ppm 0.01 ppm

ClO

2

1.00 ppm 0.01 ppm

Comb (%LEL) 100%LEL 1% LEL

Comb (%vol) 5.0% Vol 0.1% Vol

Comb (ppm) 10,000 ppm 50 ppm

* bias sensor

T

EMPERATURE AND H

UMIDITY RANGE:

Operating Temperature Range:

-20

o

to +50oC (-4oto 122oF), typical toxic/oxygen

0

o

to +40oC (32oto 104oF), for LEL sensor only

per C22.2 No. 152

Operating Humidity Range:

15 – 95% RH, typical

0 – 99% RH, intermittent, non-condensing

Storage Temperature Range:

0

o

to +20oC (32oto 68oF)

Intrinsically Safe Parameters for ATEX Certification:

Charging Port External Alarm Jack

Ui = 10V Uo = 6.5V Ui = 11.1V

Ii = 3.3A Io = 0.69mA Ii = 6mA

Ci = 0uF Co = 22uF Ci = 0uF

Li = 0mH Lo = 500mH Li = 0mH

ITEM. PART NO. DESCRIPTION

1. 17102484 iTX Main PCB Version 2.X

(17088667 for Version 1.X)

2. 17105255 iTX Sensor PCB Version 2.X

(17090473 for Version 1.X)

3. 17102526 iTX Interface PCB Version 2.X

(17090481 for Version 1.X)

5. 17104266 iTX Keypad Version 2.X

(17091307 for Version 1.X)

6. 17096389 iTX Case top assembly

7. 17096082 iTX Case bottom

8. 17091083 iTX Case gasket

10 17098450 iTX Battery cover assembly

11 17091901 Battery cover gasket

12 17092651 Battery insulator

13. 17092693 Screw retainer

14 17095332 Battery cover screws

18 17092198 iTX Chassis

19 17091620 Pump contact module

20 17091869 Pump contact gasket

21 17091588 Pump contact clip

22 17096371 iTX Water barrier kit

27 17092685 Screw, captive, #4x1.125

28 17086935 Screw, 2-56 x 0.31

29 17050453 Screw, 2-56x .188

30 17052558 Screw, 2-28 x .250

32 17049876 Wrist strap

35 17092776 RFI screen

36 17092750 Conductive adhesive

37 17084542 LCD holder

38 17084673 LCDisplay

39 17092743 Insulator pad

40 17099680 i

-Button®insulator

41 17028374 External alarm jack

42 17029273 Alarm jack plug

43 17050277 O-ring .250 ID

R

EPLACEMENT

P

ARTS

L

IST

33

32

35

34

W

ARRANTY

Industrial Scientific Corporation portable gas monitoring

instruments are warranted to be free from defects in material and

workmanship for as long as the instrument is in service.

The above warranty does not include sensors, battery packs,

internal pumps or filters, all of which are warranted to be free

from defects in material and workmanship for 18 months from

the date of shipment, or 1 year from the date of first use,

whichever occurs first, except where otherwise stated in writing

in Industrial Scientific literature accompanying the product.

All other Industrial Scientific products are warranted to be free

from defects in material and workmanship for a period of 18

months from the date of shipment, 1 year from the date of first

use, whichever occurs first, except where otherwise stated in

writing in Industrial Scientific literature accompanying the

product.

LIMITATION OF LIABILITY

INDUSTRIAL SCIENTIFIC MAKES NO OTHER

WARRANTIES, EITHER EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE.

SHOULD THE PRODUCT FAIL TO CONFORM TO THE

ABOVE WARRANTY, BUYER’S ONLY REMEDY AND

INDUSTRIAL SCIENTIFIC’S ONLY OBLIGATION SHALL

BE, AT INDUSTRIAL SCIENTIFIC’S SOLE OPTION,

REPLACEMENT OR REPAIR OF SUCH NONCONFORMING GOODS OR REFUND OF THE ORIGINAL

PURCHASE PRICE OF THE NON-CONFORMING GOODS.

IN NO EVENT WILL INDUSTRIAL SCIENTIFIC BE LIABLE

FOR ANY OTHER SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING LOSS OF

PROFIT OR LOSS OF USE, ARISING OUT OF THE SALE,

MANUFACTURE OR USE OF ANY PRODUCTS SOLD

HEREUNDER WHETHER SUCH CLAIM IS PLEADED IN

CONTRACT OR IN TORT, INCLUDING STRICT LIABILITY

IN TORT.

It shall be an express condition to Industrial Scientific’s warranty

that all products be carefully inspected for damage by Buyer

upon receipt, be properly calibrated for Buyer’s particular use,

and be used, repaired, and maintained in strict accordance with

the instructions set forth in Industrial Scientific’s product

literature. Repair or maintenance by non-qualified personnel will

invalidate the warranty, as will the use of non-approved

consumables or spare parts. As with any other sophisticated

product, it is essential and a condition of Industrial Scientific’s

warranty that all personnel using the products be fully acquainted

with their use, capabilities and limitations as set forth in the

applicable product literature.

Buyer acknowledges that it alone has determined the intended

purpose and suitability of the goods purchased. It is expressly

agreed by the parties that any technical or other advice given by

Industrial Scientific with respect to the use of the goods or

services is given without charge and at Buyer’s risk; therefore,

Industrial Scientific assumes no obligations or liability for the

advice given or results obtained.

Copyright

2003, 2011 © Industrial Scientific Corporation

All rights reserved. These help materials or any part thereof may not,

without the written consent of Industrial Scientific Corporation, be

copied, reprinted or reproduced in any material form including but not

limited to photocopying, transcribing, transmitting or storing it in any

medium or translating it into any language, in any form or by any

means, be it digitally, electronic, mechanical, xerographic, optical,

magnetic or otherwise.

The information contained in this document is proprietary and

confidential and all copyright, trade marks, trade names, patents and

other intellectual property rights in the documentation are the

exclusive property of Industrial Scientific Corporation unless otherwise

specified. The information (including but not limited to data, drawings,

specification, documentation, software listings, source or object code)

shall not at any time be disclosed directly or indirectly to any third

party without prior written consent.

The information contained herein is believed to be accurate and

reliable. Industrial Scientific Corporation accepts no responsibility for

its use by any means or in any way whatsoever Industrial Scientific

Corporation shall not be liable for any expenses, costs by damage

that may result from the use of the information contained within this

document. The information contained herein is subject to change

without notice.

36

Loading...

Loading...