Industrial Labeling Systems Ultimate 3000 Series Quick Operator's Manual

ULTIMATE 3000 Series

Thermal Transfer Printers

Quick Operator’s Guide

The ULTIMATE Printers!

The ULTIMATE Printers!

This manual is intended for all ULT printers in the

ULTIMATE 3000 Series, including the ULT-3320, 3330,

3430, 3460, 3630, 3830

ULTIMATE 3000 Series

EU - Conformity Declaration

We declare herewith that as a result of the manner in which the machine designated below was designed,

the type of construction and the machines which, as a result have been brought on to the general market

comply with the relevant fundamental regulations of the EU Rules for Safety and Health. In the event of any

alteration which has not been approved by us being made to any machine as designated below, this

statement shall thereby be made invalid.

Description: Type :

Transfer Printer A-series (A3)

Applied EU Regulations and Norms:

- EC Machinery Regulations 98/37/EU

- Machine Safety EN 292-2:1991

- EC Low Voltage Regulations 73/23/EEC

- Data and Office Machine Safety EN 60950:1992+A1:1993

EN 60950/A2:1993

- EC Electromagnetic Compatibility Regulations 89/336/EEC

- Threshold values for the Interference EN 55022 :1998

of Data Machines

- Limits for harmonic current emission EN 61000-3-2:1995+A1:1998+A2:1998

+A14:1999:2000

- Limits of voltage fluctuation and flicker EN 61000-3-3:1995

- Interference Resistance in both EN 50082-1: 1992-12

Industrial and Small Plants

General Safety Instructions

1. The printer is built exclusively to print die-cut labels, continuous media, and similar

materials !

2. Connect the printer to an outlet with the correct volt age ! The printer is configured for

voltages of 100 to 240 V. Connect only to a power outlet with a grounded contact !

3. The printer must only be connected to devices which have extra low volt age !

4. Power must be OFF before plugging in any accessory, connecting to a computer and

before performing any maintenance on the printer. Also turn the power off on all

appliances before disconnecting from the printer !

5. Do not expose the printer to any moisture, or use in damp or wet areas !

6. The printer will operate with the cover open if necessary. If the printer must be operated

with the cover open, extra care must be taken to avoid allowing hair, jewelry, clothing,

etc. near the moving parts !

7. During the print process the printhead will become hot. Use extra caution when touching

the printhead. Do not touch the printing surface of the printhead with your hand !

8. Before starting any maintenance, power OFF the printer and disconnect the printer from

the outlet !

9. Any adjustments or repairs which are not described in this manual, should only be

carried out by an authorized service technician !

WARNING !

To avoid possible electric shock, do not open the backside cover !

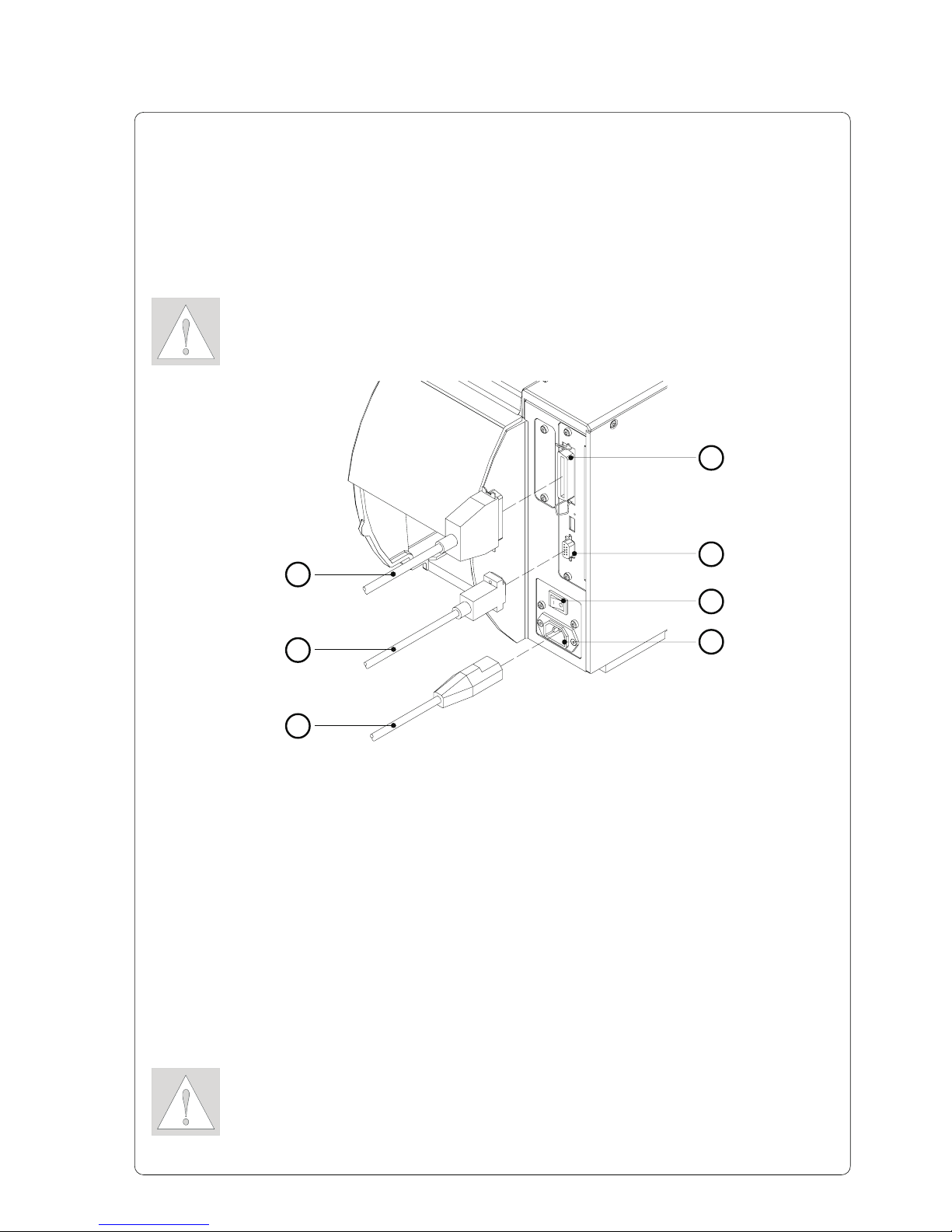

Connecting the Printer

Connection to Power Supply

The printer is equipped with a wide range power unit (100-240V~), so it is

possible to use the printer both with a voltage of 230V~/50 Hz and with a

voltage of 115V~/60 Hz without making changes to the printer.

CAUTION !

Make sure the power switch (6) is in position " O" (OFF) before

connecting the printer to a power supply !

Connection to a Computer

As standard, the printer is equipped with a bi-directional parallel interface ( 4)

and a serial RS-232-interface with a 9 pin connector (5).

For serial connection, make sure the serial interface RS-232 of the printer is

correctly configured to the settings of your computer (see Operator's Manual).

Connect the computer and the printer with a suitable cable ( 1,2) and secure the

cable connections with screws provided on the connectors.

CAUTION !

Make sure that all connected computers and their connecting cables are

correctly grounded.

1

2

Figure 1

Insert the power cable (3) supplied in the accessories carton into the power

supply connector (

7) and contact the cable to a grounded outlet.

3

4

5

6

7

1

2

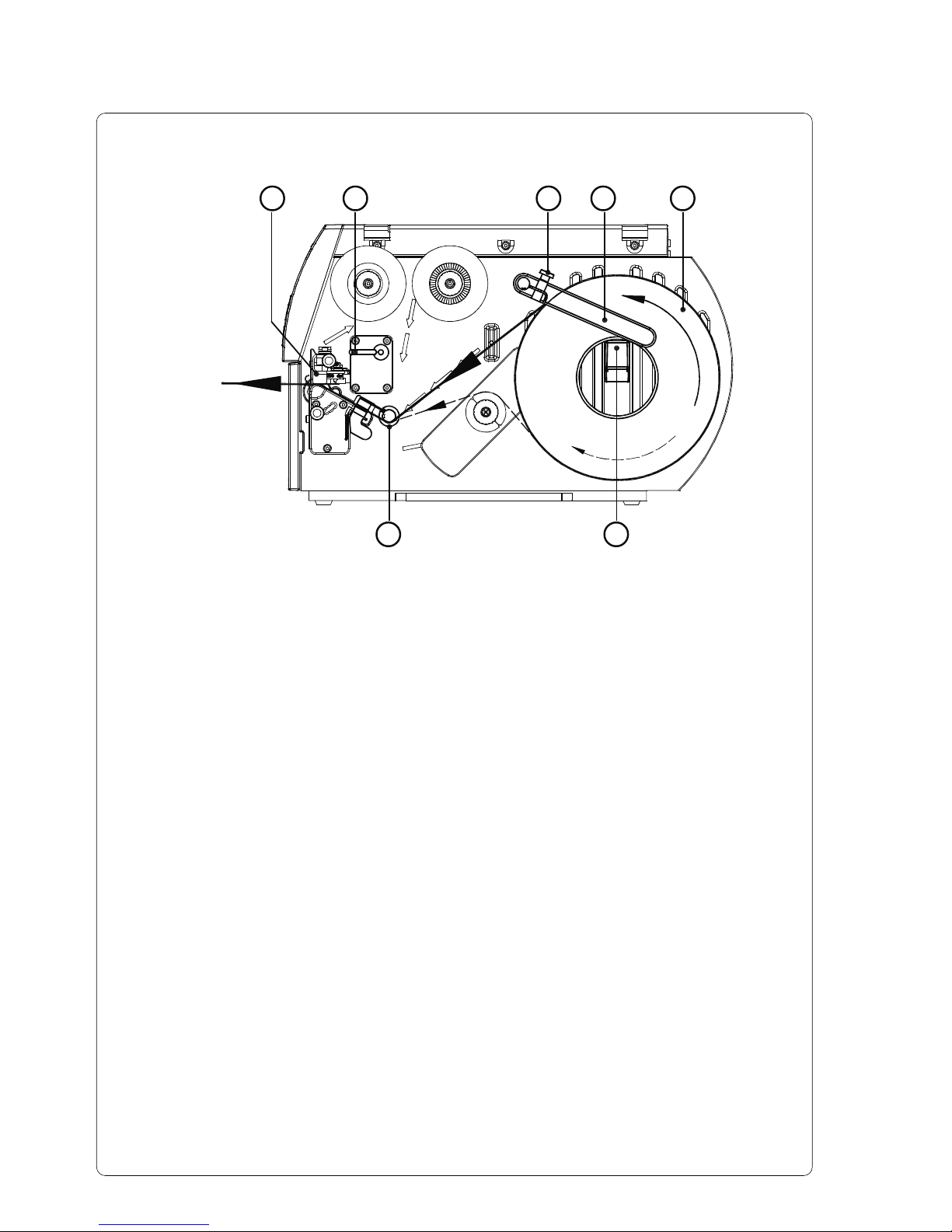

Loading Labels

Figure 2

The following steps are valid for loading labels in tear-off mode.

Instructions for loading labels in rewind or dispense mode and for loading

fanfold labels can be found in the Printer's Operator Manual or in the

documentation of the Present Sensor.

1. Loosen the knurled screw (3), swing the media retainer (4) upwards and

slide it out as far as possible.

2. Place the media roll (5) onto the media hub (6) and unwind a strip of

media from the media roll. Make sure the labels are facing up. Slide the

roll onto the media hub (6) until its stops.

3. Swing the media retainer (4) downwards until it touches the media hub (6).

Push the media retainer against the supply role until it rests against the

label media. Tighten the knurled screw (3).

4. Raise the printhead assembly (1) by rotating the lever (2) clockwise until it

stops.

5. Slide the media guide ring (7) outward, allowing enough clearance for the

label stock's width when loaded.

6. Slide the media strip through the printer as shown in figure 2. The feed

path for labels wound-out is represented by a solid line, and the feed path

for wound-in labels is represented by a broken line.

7. Move the label edge sensor assembly ( 8) in such a position that the

sensor (9) itself can detect label gaps, notches or reflective marks.

The adjustment of the sensor is performed by sliding the handle ( 10) in

and out.

1 2 3 4 5

67

Loading...

Loading...