A

IB-30B002

LUMINARY SERIES MOTION CONTROLLER FEBRUARY 2014

LUMINARY CONTROLLER

LMC-400

INSTRUCTION BOOK

INDUSTRIAL INDEXING SYSTEMS, Inc.

Revision - 0

pproved By:

Proprietary information of Industrial Indexing Systems, Inc. furnished for customer use only.

No other uses are authorized without the prior written permission of

Industrial Indexing Systems, Inc.

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

TABLE OF CONTENTS

List of Illustration................................................................................................................................................... v

Introduction..........................................................................................................................................................vi

SECTION 1 - OVERVIEW

1.1 Identifying the Luminary Controller......................................................................................1 - 1

1.2 Luminary Controller Mounting Plates……….………………………………………………. 1 - 2

SECTION 2 - DESCRIPTION

2.1 Components.........................................................................................................................2 - 2

2.1.1 Status Indicators.....................................................................................................2 - 2

2.1.2 Connectors .............................................................................................................2 - 2

SECTION 3 – LUMINARY CONTROLLER SPECIFICATIONS

3.1 General.................................................................................................................................3 - 1

3.2 Power Requirement.............................................................................................................3 - 1

3.3 SBI Interface.........................................................................................................................3 - 1

3.4 Environment.........................................................................................................................3 - 1

3.5 Communication Ports...........................................................................................................3 - 2

3.6 I/O Interface..........................................................................................................................3 - 2

3.7 Encoder Interface......................................................................................................... ........3 - 2

SECTION 4 – LUMINARY WIRING

4.1 J6 Executive Port.................................................................................................................4 - 3

4.2 J7 Applications Port .............................................................................................................4 - 3

4.3 J1 & J2 Digital Inputs ...........................................................................................................4 - 4

4.4 J3 Digital Outputs.................................................................................................................4 - 5

4.5 J4 Power Input.....................................................................................................................4 - 6

4.6 J5 & J9 Factory Configuration Ports....................................................................................4 - 6

4.7 JP1 Jumper Selection..........................................................................................................4 - 6

FEBRUARY 2014 TABL E OF CONT E N T S iii

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

SECTION 5 - STATUS & ERROR CODES

5.1 Controller Status ..................................................................................................................5 - 1

5.2 Device Port Status Display ..................................................................................................5 - 3

SECTION 6 - INSTALLATION GUIDELINES

6.1 General.................................................................................................................................6 - 1

6.2 Enclosure Cabinet Requirements........................................................................................6 - 1

6.3 Mounting the System Unit....................................................................................................6 - 1

6.4 Cable Isolation Requirements .............................................................................................6 - 1

6.5 Grounding Requirements.....................................................................................................6 - 1

6.6 Installation Drawings............................................................................................................6 - 2

SECTION 7 - CABLES AND ACCESSORIES

TABLE OF CONTENTS iv FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

LIST OF ILLUSTRATIONS

SECTION 1 - OVERVIEW

SECTION 2 - DESCRIPTION

Figure 2.1 LMC-400 Layout.....................................................................................................2 - 1

SECTION 3 – LUMINARY CONTROLLER SPECIFICATIONS

SECTION 4 - LUNIMARY WIRING

Figure 4.1 Luminary Controller Wiring.....................................................................................4 - 2

Figure 4.2 Input Wiring.............................................................................................................4 - 4

Figure 4.3 Output Wiring..........................................................................................................4 - 5

SECTION 5 - STATUS & ERROR CODES

Figure 5.1 SBI Status Displays................................................................................................5 - 3

SECTION 6 - INSTALLATION GUIDELINES

SECTION 7 - CABLES AND ACCESSORIES

FEBRUARY 2014 LIST OF ILLUSTRATIONS v

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

INTRODUCTION

Thank you for selecting Industrial Indexing Systems LUMINARY Series products. You join many other

companies around the world in your choice of these powerful, flexible motion control products.

The LMC-400 embodies a blend of open architecture features with a true real-time operating system. The

result is a state-of-the art performance and superior connectivity to other systems and network components.

The LMC-400 has a wide array of hardware features, including

a 32-bit ARM processor,

a Executive serial port (USB-B),

an Application serial port (rs232),

Eight configurable general purpose isolated digital input’s (Can be configured for up to Two Encoder

master follower input’s with Position Trap input),

four general purpose isolated digital outputs,

Configurable programmable limit switch (PLS) functions,

two software simulated motors (master pacers),

high visibility status displays.

The LMC-400 has a wide array of software features, including:

The controller is programmed using our friendly Emerald Motion Programming Language (EML)

and powerful new Emerald Development Environment (EDE) software tools for the PC.

A Dynamic Link Library (DLL) is available to communicate with the LMC-400 using your own Visual

Basic, Visual C++, or other programming language allowing for full system integration, automation,

and data logging solutions.

A Human Machine Interface (HMI) touch screen can easily be added to the LMC-400 system using

either the USB port or the rs232 port.

The External computer and or HMI will have unlimited access to the system memory area with the

ability to control the LMC-400 remotely.

Contact IIS for full system solutions utilizing computer programming or HMI systems.

INTRODUCTION vi MARCH 2011

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

(21)

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

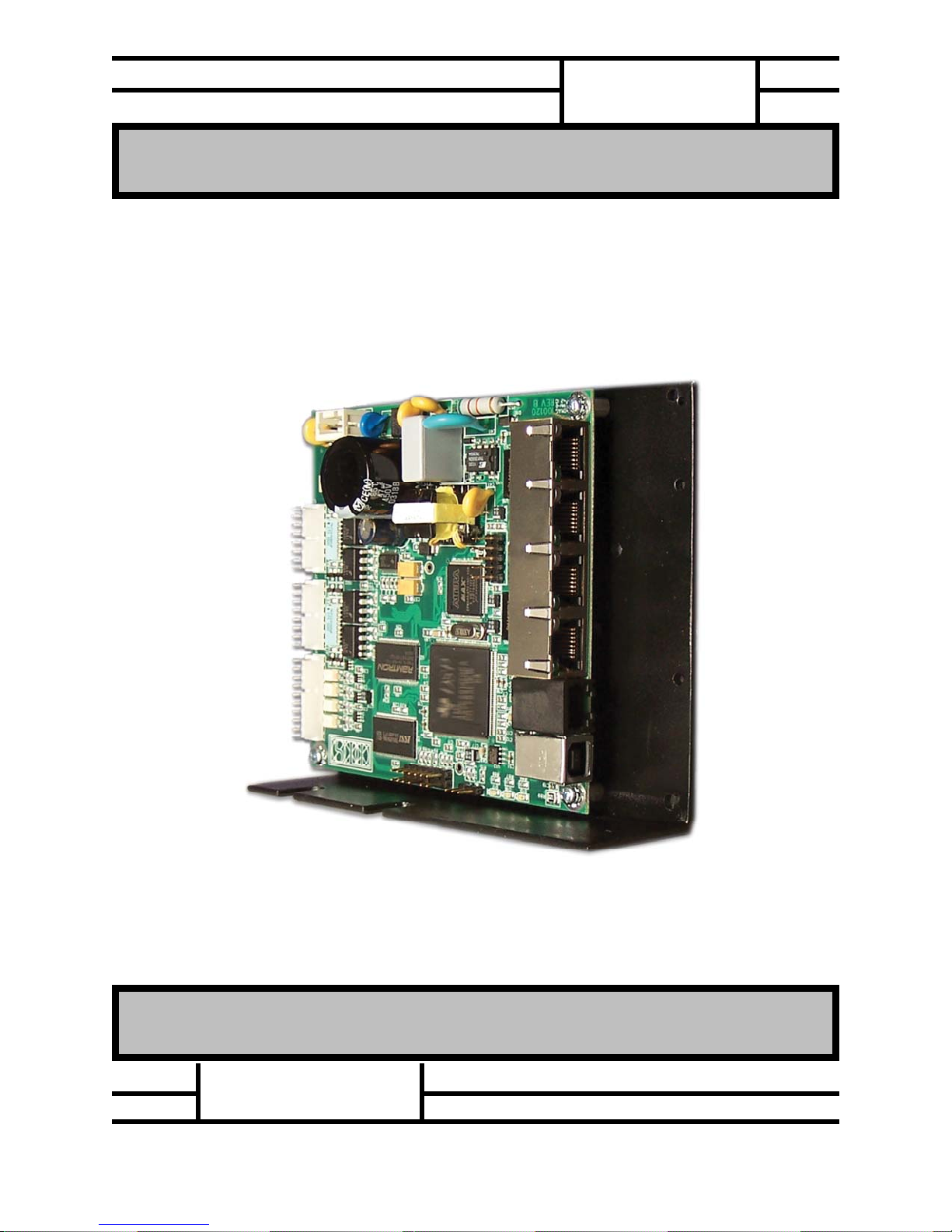

SECTION 1 - OVERVIEW

This manual is organized so that information is easy to find and easy to use. It begins by detailing how to

identify the LMC-400 Controller. This section is followed by a general description of the product and its

components. Next, a comprehensive hardware specification is provided followed by connector wiring

diagrams. The section that follows documents the controller status displays. Sections on LMC-400

installation guidelines and cables drawings round out the manual.

1.1 IDENTIFYING THE LUMINARY CONTROLLER

Luminary Controller packages can be identified as follows.

Your LUMINARY Controller model number uses the following designations:

The LMC-400-00 is the basic controller without a base plate or mounting options

Part number identification

LMC400XX

Example part numbers:

LMC-400-00 Luminary Controller without mounting base plate option

LMC-400-21 Luminary Controller with L bracket mounting plate

Mounting Option

(00) = No Mounting Plate

(01) = Flat Plate

= L Bracket

Special Options

(00) None

Number of Master Ports

(4)

Controller Series

(LMC)

FEBRUARY 2014 PAGE 1 - 1

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

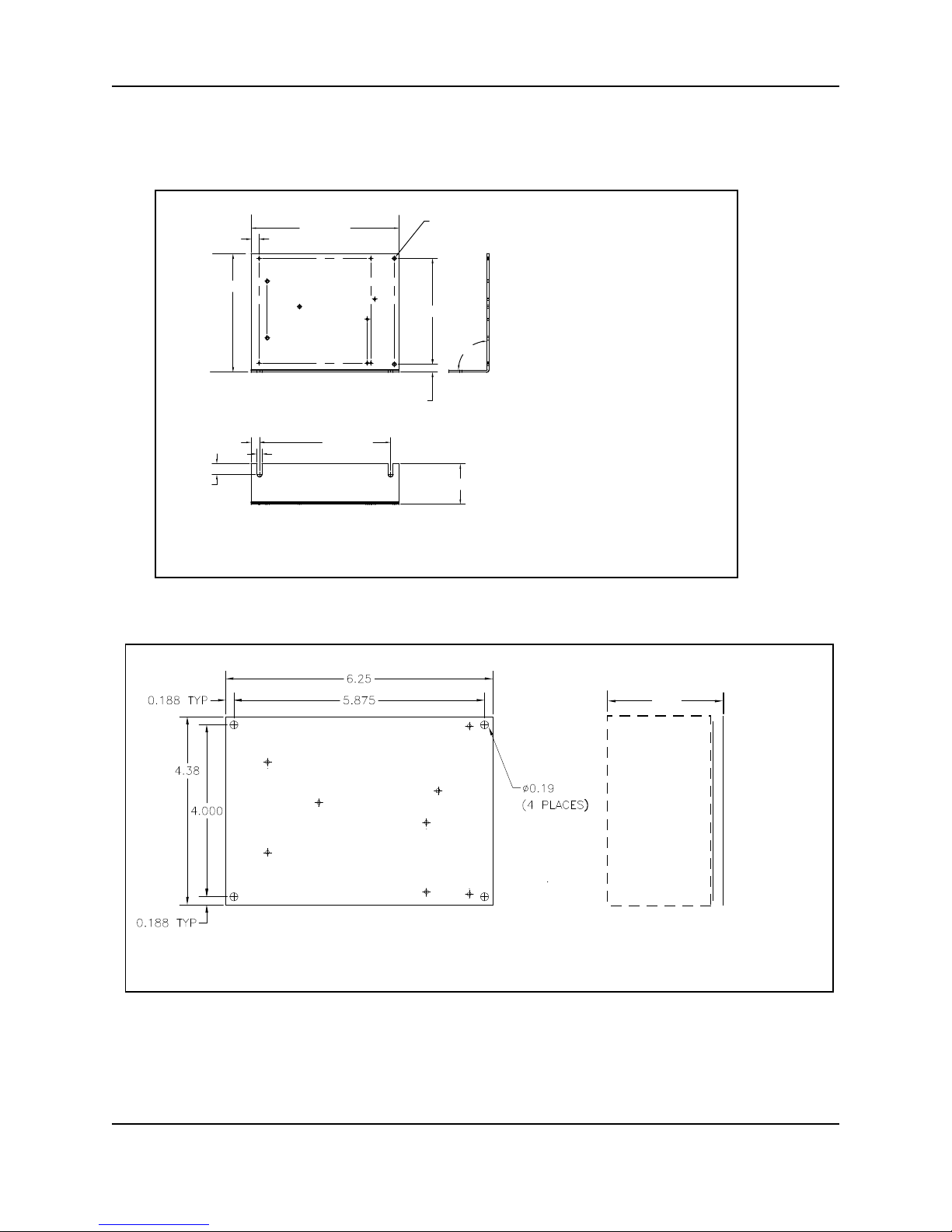

1.2 LUMINARY CONTROLLER MOUNTING PLATES

The Luminary Controller mounting plate drawings are shown below. Other options may be available.

0.29 [7.5]

5.50 [139.7]

4.38 [111.1]

0.19 [4.8]

4.88 [124.0]0.31 [7.9]

0.39 [10.0]

For a compact single axis positioner, one Luminary Drive (LD-330) can be the

mounted on the opposing side of the “L” bracket.

0.13 [ 3.2 ] (5 PL ACES)

3.91 [99.3]

90°

0.30 [7.5]

1.50 [38.1]

Flat plate mounting

Minimum Height C learance

2.50

PAGE 1 - 2 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

r

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

SECTION 2 - DESCRIPTION

The Luminary LMC-400 product is a SBI Master servo motion controller, with the ability to command up to

Four Slave Luminary Devices. The application program that operates the controller is created on a PC

using the EDE software tools and sent serially to the controller via the USB or RS-232 link.

All commands used by the LUMINARY are part of the Emerald Motion

Language (EML). Refer to the Emerald Development Environment

(EDE) PC tools online help for detailed information on the commands

and their proper usage.

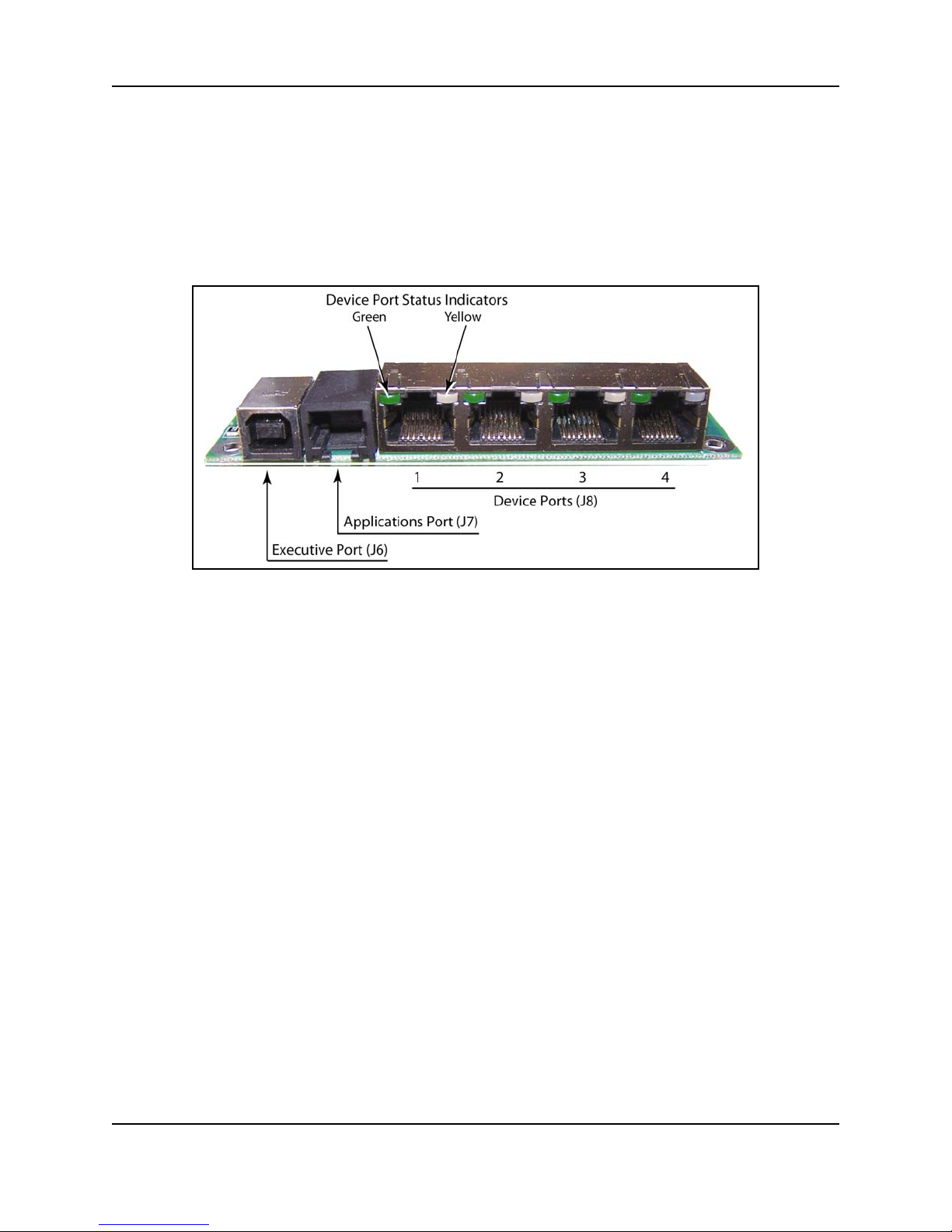

2.1 COMPONENTS

The external connections that exist on the Luminary are shown in Figure 2.1, and consist of USB,

RS-232 ports, General purpose Input’s and Output’s, Four SBI Ports, and a power connection.

Controller Status Indicators

Red Green Yellow

NOTE

Jumper JP1 must be installed between

pins 1 and 2 for controller to boot.

Executive Port (USB serial)

App Port (rs232 serial)

SBI Port 1

SBI Port 2

SBI Port 3

SBI Port 4

Device Network Hub

J6

J7

J8-1

J8-1

J8-2

J8-2

J8-3

J8-3

J8-4

J8-4

J4

Outputs 1 - 4

J3

Inputs 5 - 9 / Encoder B

J2

Inputs 1 - 4 / Encoder A

Power Input

Connecto

Figure 2.1 – LMC-400 Layout

FEBRUARY 2014 PAGE 2 - 1

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

2.1.1 STATUS INDICATORS

Controller Status Display – These three LED’s define the current status of the controller. See section 5

and figure 2.1.For indicator status information, refer to Section 5 - Status & Error Codes

SBI Status LEDs - These 2 LED’s indicate the status of the SBI Interface. See Section 5 and

figure 2.1

.

2.1.2 CONNECTORS

Executive Port - This 4-pin USB-B connector is an USB 2.0 serial communication port. The

protocol is the EML custom protocol for communicating with the EDE software tools on a PC.

Application Port - This 6-pin RJ-11 connector is an RS-232 serial communication port. It can

be used to communicate with a Maple Systems Touch Screen OPI-7.0TFT or other size available

from IIS or similar RS-232 type devices. The protocol is selectable through the EML

programming language. This port defaults to the custom protocol for communicating with the

EDE software tools on a PC unless configured otherwise in the EDE program.

Device Network Hub - This Quad 8-pin header is the interface hub to the slave SBI devices.

The SBI devices are setup in the EDE project configuration.

Digital Inputs - These 8-pin headers are high-speed inputs that can be configured in the EML

programming language to be generic input’s, or master encoder pulse input’s with Trap. See

section 3.6 and 4.3.

Digital Outputs - This 10-pin connector provides four generic outputs that can be configured in

the EML programming language. See section 3.6 and section 4.4.

Power Input - This 3-pin connector is for powering the Luminary Controller. See section 3.2 and

section 4.5.

PAGE 2 - 2 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

SECTION 3 – LUMINARY CONTROLLER SPECIFICATIONS

3.1 GENERAL

Weight

LMC-400-00

LMC-400-01

LMC-400-21

0.25 lbs / 0.11 Kg

??? lbs / ??? Kg

??? lbs / ??? Kg

Dimensions

W x H x D

Minimum Enclosure

Depth

Minimum Enclosure

Depth

LMC-400-00

LMC-400-01

LMC-400-21

LMC-400-01

LMC-400-21

4.20 in (106.7 mm) x 1.10 in (28.0 mm) x 4.50 in (114.3 mm)

4.20 in (106.7 mm) x 1.10 in (28.0 mm) x 4.50 in (114.3 mm)

4.20 in (106.7 mm) x 4.50 in (114.3 mm) x 1.10 in (28.0 mm)

At Least 3.00 in (76.2 mm) Mounted On Flat Plate

(See Section 6 - Installation Guidelines)

At Least 6.00 in (152.4 mm) Mounted On L Bracket

(See Section 6 - Installation Guidelines)

3.2 POWER REQUIREMENT

Supply Voltage 100V to 240V volts AC +

10%

Supply Current 0.5 amp max. Internally Fused

Inrush Current 30A @ 1ms

3.3 SBI INTERFACE

Network Topology IIS Serial Bus Interface (SBI)

Transmission Rates 4.0 MB/second

3.4 ENVIRONMENT

Storage

Temperature

Operating

Temperature

-10 to 70C / 14-158F

0 to 45C / 32-113F

Humidity 35 to 90% Relative Humidity, non-condensing

Shock and Vibration 1 G or less

Operating

Conditions

FEBRUARY 2014 PAGE 3 - 1

Free of conductive dust, liquids, metallic particles and corrosive gases.

Use in a pollution degree 2 environment.

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

3.5 COMMUNICATION PORTS

USB-B

J6

RS-232 (RJ-11)

J7

SBI (RJ-45)

J8-1, -2, -3, -4

Classification: Serial Communications over USB 2.0

Data Transfer: EMC Packet protocol

Physical: 115200 baud, 1 stop bit, 8 data bits, No parity

Classification: Serial Communications over RS-232

Data Transfer: EMC Packet protocol (default), User Programmable

Physical: 38,400 or 19,000 baud, 1 stop bit, 8 data bits, No parity

Classification: IIS Device Network over SPI

Data Transfer; Full duplex, hi-speed serial (4.0 megabit / sec)

Physical: Four port hub

3.6 I/O INTERFACE

ON: 24V DC 10%

DIGITAL INPUTS

Connector Block

J1 and J2

OFF: 2V or Less

Input Resistance: 2K Ohms

Input Frequency: DC to 1.5 MHz.

Reverse polarity protected

24V DC 10%

DIGITAL OUTPUTS

Connector Block

J3

Output Load: 100mA DC Maximum non-inductive

Output Saturation Voltage (ON): 1.2V Maximum

Output Leakage Current (OFF): 0.2mA Maximum

Output Frequency: DC to 500Hz

3.7 ENCODER INPUT INTERFACE

(When inputs J1 or J2 are configured to accept encoder signals in the EDE project file.)

A (quadrature) B

With or without

marker

Position Capture

“Trap” input signal

Three differential Inputs A, B, Z.

Input Frequency DC to 1.5 MHz.

Input for trapping encoder’s 32 bit signed position.

Maximum Trap Rate: 1 kHz.

Trap Register is updated on falling edge of input.

PAGE 3 - 2 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

SECTION 4 - LUMINARY WIRING

This section details the pin-outs of the external connectors on the LUMINARY controller. Refer to

Section 7 INTERFACE CABLES for part numbers of cables to interface to these connectors.

CAUTION – This device is a high voltage product operating on 100V to 240V AC and may cause injury

or death if precautions are not followed when installing or servicing the LMC-400.

PRECAUTIONS:

1) Never service the LMC-400 with power applied to the unit. There are high voltage wire ways and

components that hold dangerous voltages. Internal components on the LMC-400 can hold

voltages reaching 350V DC.

2) Wait at least 1 minute from removal of power from the system to service the LMC-400. There are

capacitors that will hold dangerous voltages on the unit for up to 1 minute after removal of power.

See Figure 4.1 below for controller interface wiring and connector pin-outs.

FEBRUARY 2014 PAGE 4 - 1

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

3 OF 5

SH.

26OCT120

DATEREV

OUTPUT 4-

OUTPUT 4+

OUTPUT 3-

OUTPUT 3+

OUTPUT 2-

OUTPUT 2+

OUTPUT 1-

OUTPUT 1+

(PROBE 2-)

(PROBE 2+)

(Y ENCZ-)

(Y ENC Z+)

(Y ENCB-)

(Y ENC B+)

(Y ENCA-)

(Y ENC A+)

(PROBE 1+)

(PROBE 1-)

(X ENCA-)

(X ENC A+)

(X ENC B+)

(X ENCB-)

(X ENC Z+)

(X ENCZ-)

IC-068003

IN8+

IN8-

IN6-

IN5+

IN5-

IN6+

IN7+

IN7-

IN3-

IN4+

IN4-

IN1+

IN1-

IN2+

IN2-

IN3+

INTERCONNE CT

DRAWING NUMB ER

TITLE

CAD

SCALE:

0.4°

±

LUMINARY CONTROLLER CONNECTION DIAGRAM

NC

9

8

6745231

10

NC

5

213

486

7

6

7

8

1

243

5

LC-CO NK IT

0.005

www.iis -ser vo.com

0.020

X.XX± X. XXX±

INDUSTRIAL INDEXING SYSTEMS, Inc.

TOLERAN CES

DIMENSIONS ARE INCHES [mm]

LMC-400-XX

3

MATERI AL

FINISH

HYC/26O C T12

DRAWNBY / DATE

APPROVEDBY /DATE

L11L22NC GROUND

Figure 4.1 – LUMINARY CONTROLLER WIRING

C-894YYY

C-987YYY

OPI-433TFT

C-884000

OPI-7.0TF T

C-822000

USB

COMPUTER

RS232

COMPUTER

OPI

PAGE 4 - 2 FEBRUARY 2014

C-822000

OPI-10.4TF T

C-889000

C-822000

HMI-5100

OPTIONAL

RIGHT ANGLE

C-822000

OPI-5.6TF TE

ADAPTOR

C-866000

INPUT POWER

100-240VAC

50/60Hz

THIS DRAWING ANDTHEDATACONTAINEDTHEREIN

AXIS 1 C-885YYY

AXIS 2 C-885YYY

AXIS 3 C-885YYY

AXIS 4 C-885YYY

PROJECTION

ARE PROPRIETARY INFORMATION OF INDUSTRIAL

WHATSOEVERWITHOUTTHE PRIORWRITTEN

CONFI DEN CE AN DMAY NOT BE REPRODUCED,

COPIED OR USED FOR ANY PUR POSE

PERMISSION OF IND USTRIAL INDEXING SYSTEMS.

INDEXING SYSTEMS. IT IS ISSUED IN STRICT

12-0980HYC

PER ECN

SYM DR APP

DATE REVISION RECORD

26OCT 12

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

4.1 J6 Executive Port

This port is used for communication with the IIS EDE software development package and uses a

standard USB-A to USB-B cable to interface to a PC. A 15-foot cable is available from IIS; order part

number C-894015.

4.2 J7 Applications Port

This port is used for user communication and uses an RJ-11 connector to interface to rs232 devices.

Various adapters are available to convert connector on the device to the IIS cable C-987010 that

connects to the RJ-11 applications port connector. Users can connect various operator interface

terminals and communicate with them by using simple data transfers utilizing ASCII character commands

or the port can by configured to use the IIS data transfer protocol. The IIS EMC protocol is available as

selection on the Maple System touch-screen terminals.

When communicating with a PC app, IIS provides the user with a dynamic linked library (DLL) that can be

integrated into their application.

Device

Touchscreen 4.3

Touchscreen 5.6

Touchscreen 7.0

Touchscreen 10.4

Touchscreen

PC

Model

OPI-4.3TFT

OPI-5.6TFT

OPI-7.0TFT

OPI-10.4TFT

HMI-5100

With 9 pin serial port

Cable Adapter Cable

C-884000 C-987YYY

C-866000 C-987YYY

C-822000 C-987YYY

C-822000 C-987YYY

C-822000 C-987YYY

C-822000 C-987YYY

Note: the C-889000 adapter can also be used when there is the need to bring the cable out at a

right angle.

FEBRUARY 2014 PAGE 4 - 3

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

4.3 J1 & J2 Digital Inputs

The Input interface connection options are shown in Figure 4.2. They may be wired for sinking or

sourcing configurations.

Input Sinking

+5 or +24 Vdc

+in

-in

Input Sourcing

+5 or +24 Vdc

+in

-in

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

A

l

t

e

n

r

a

t

e

i

n

p

u

c

o

n

f

I

N

8

-

(

PR

N

I

8

+

P

(

I

N

I

N

N

I

I

N

I

N

N

I

I

N

I

N

N

I

N

I

N

I

I

N

N

I

N

I

R

7

-

(

Y

7

+

(

Y

6

-

(

Y

6

+

(

Y

5

-

(

Y

5

+

(

Y

E

4

-

(

P

R

O

4

+

(

P

R

O

3

-

(

X

E

3

+

(

X

E

2

-

(

X

E

2

+

(

X

E

1

-

(

X

E

1

+

(

X

E

t

i

g

u

r

a

t

i

o

n

O

B

E

2

-

)

O

B

E

2

+

)

E

N

C

Z

-

)

E

N

C

Z

+

)

E

N

C

B

)

-

E

N

C

B

+

)

E

N

C

A

-

)

N

C

A

+

)

B

E

1

-

)

B

E

1

+

)

N

C

Z

-

)

N

C

Z

+

)

N

C

B

-

)

N

C

B

+

)

N

C

A

-

)

N

C

A

+

)

Figure 4.2 – INPUT WIRING

PAGE 4 - 4 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

4.4 J3 Digital Outputs

The Output interface connector options are shown in Figure 4.3. They may be wired for sinking or

sourcing configurations.

Output Sinking

+out

-out

Output Sourcing

Use a reverse diode to reduce negative voltage transitions when driving inductive loads.

+out

-out

LOAD

+5 to +32 Vdc

LOAD

+5 to +32 Vdc

10

9

8

7

6

5

4

3

2

1

Figure 4.3 – OUTPUT WIRING

NC

NC

OUTP

OUTP

OUTP

OUTP

OUTP

OUTP

OUTP

OUTP

UT 4UT 4+

UT 3UT 3+

UT 2UT 2+

UT 1UT 1+

FEBRUARY 2014 PAGE 4 - 5

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

4.5 J4 Power Input

The AC Power input connector.

4.6 J5 & J9 Factory Configuration Ports

Used in the manufacturing process of the LMC-400.

Do not plug any connectors into these ports.

4.7 JP1 Jumper Selection

Used in the manufacturing process of the LMC-400.

Keep jumper between pin-1 and pin-2.

PAGE 4 - 6 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

SECTION 5 - STATUS & ERROR CODES

5.1 CONTROLLER STATUS

CONTROLLER NORMAL STATUS

LED DISPLAY STATUS SEQUENCE

CODE DESCRIPTION RED GREEN YELLOW

POWER-UP Boot in progress

System Reset / User program loaded

User Program loaded / Not running

User program running

Memory clearing in progress

SOLID SOLID SOLID

OFF OFF FLASHING

OFF FLASHING OFF

OFF SOLID OFF

SOLID OFF OFF

SEE FIGURE 5.1 FOR LOCATION OF STATUS LED’s

CONTROLLER WARNINGS

CODE DESCRIPTION

LED STATUS SEQUENCE

YELLOW

FLASHES

GREEN

FLASHES

21 Program divide by zero 2 1

22 Illegal instruction argument detected 2 2

23 Device found in wrong operating state 2 3

24 Out of bounds memory access detected 2 4

25 RESERVED 2 5

26 RESERVED 2 6

27 RESERVED 2 7

28 RESERVED 2 8

29 RESERVED 2 9

31 Communication Timeout - USB Port 3 1

32 Communication Timeout - RS-232 Port 3 2

FEBRUARY 2014 PAGE 5 - 1

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

33 RESERVED 3 3

34 RESERVED 3 4

35 Illegal packet code received - USB Port 3 5

36 Illegal packet code received - RS-232 Port 3 6

37 PRINT QUEUE FULL - USB Port 3 7

38 PRINT QUEUE FULL - RS-232 Port 3 8

39 RESERVED 3 9

SEE FIGURE 5.1 FOR LOCATION OF STATUS LED’s

CONTROLLER FATAL ERRORS

CODE DESCRIPTION

LED STATUS SEQUENCE

RED

FLASHES

GREEN

FLASHES

01 Unrecognized Instruction Opcode 1 0

02 Program Load Failure 2 0

03 Write to a read-only Flag 3 0

04 Instruction Opcode Aborted 4 0

05 Configuration Load Failure 5 0

06 Stack Memory Overflow 6 0

07 Stack Memory Underflow 7 0

08 Checksum Error in Program Memory 8 0

09 Main Processor Failure 9 0

10 Communication Error on SBI Device Port 1 5 1

11 Communication Error on SBI Device Port 2 5 2

12 Communication Error on SBI Device Port 3 5 3

13 Communication Error on SBI Device Port 4 5 4

PAGE 5 - 2 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

5.2 DEVICE PORT STATUS DISPLAY

The status LED’s of each device port on the hub show the current status of the SBI communications to

the device it is connected to.

DESCRIPTION LED STATE STATUS / SOLUTIONS

SBI communications

are ACTIVE

SBI communications

are INACTIVE

SBI receiving errors

in communications

GREEN SOLID

YELLOW OFF

GREEN OFF

YELLOW SOLID

GREEN SOLID

YELLOW FLASHING

No Problem

1) Check if program is loaded in LMC-400

2) Check if slave device is properly

configured in the EDE project.

3) Check power is on slave device.

4) Check routing of communications cable.

5) Check for proper grounding of both the

LMC-400 and the slave device.

6) Check for bad communications cable.

1) Check routing of communications cable.

2) Check for proper grounding of both the

LMC-400 and the slave device.

3) Check for bad communications cable.

FEBRUARY 2014 PAGE 5 - 3

Figure 5.1 - SBI Status Displays

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

SECTION 6 - INSTALLATION GUIDELINES

6.1 GENERAL

This section contains the specific information needed to properly install the Luminary LMC-400 controller

unit.

6.2 ENCLOSURE CABINET REQUIREMENTS

Ideally, the LMC-400 controller unit, along with other related electronic components, should be mounted

on a panel housed in a NEMA 12 enclosure. It is recommended that the cabinet have a depth of at least

3.00 inches (76.2 mm) or 6.00 inches (152.4 mm) depending on mounting option, to accommodate the

bend radius of the cables. The enclosure should be mounted as far away as practical from noise

generating devices, such as SCR equipment.

6.3 MOUNTING THE SYSTEM UNIT

The LMC-400 controller unit is designed for mounting on a grounded panel, and is secured to the panel

with four M3 screws. Be sure to provide adequate spacing around the controller unit for ease of

maintenance and proper ventilation. Typically wire ways are located at least 1 inch (25.4 mm) from the

edge of the controller unit back plate. When mounting the LMC-400 directly to a panel surface (not using

a back plate) a spacer of at least 0.17 inch (4.5mm) shall be used to maintain spacing between the

LMC-400 and any conductive surfaces. Refer to drawing number LMC-400 in Section 6.6 - Installation

Drawings for mounting dimensions.

6.4 CABLE ISOLATION REQUIREMENTS

It is imperative that any low-voltage signal conductors, such as resolvers, encoders or communications,

(24V or less) be routed in conduits or wire ways separate from high-voltage, such as motor cables, and

transformer lines (100V or more). This will insure that electromagnetic fields produced by high power

transmission do not corrupt the low level signals. All cabling shields must be connected according to

manufacturer specifications.

6.5 GROUNDING REQUIREMENTS

The site must have a suitable earth ground rod and ground bus installed. The NEMA 12 enclosure, wire

ways, conduits, and machine frame must be connected to this ground bus. The LMC-400 earth ground

and each slave device must be connected to this ground bus for proper operation.

FEBRUARY 2014 PAGE 6 - 1

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

6.6 INSTALLATION DRAWINGS

DRAWING NUMBER DESCRIPTION

LMC-400-21 Luminary Controller

LMC-400 drawing to show drill locations, tap sizes for mounting on a panel. Also to shows aside view

describing the recommended height from back panel using recommended spacers.

PAGE 6 - 2 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

SECTION 7 - CABLES AND ACCESSORIES

PART NUMBER

C-885YYY SBI Communications Cable

C-822YYY Cable Adaptor 9 pin female to 6 pin Modular Data Cable

C-987YYY 6 pin Modular Data Cable

C-894015 Exec Port USB Communication Cable

LC-CONKIT Connector/Pin Kit for I/O and Power interfaces

DESCRIPTION

FEBRUARY 2014 PAGE 7 - 1

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

PAGE 7 - 2 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

CKDRSYMDATE REVISION RECORD CK

EB CDR

PROPR IETARY INFOR MATION

www.iis-servo.com

PER ECN

RJ11

JACK

13MAR01 C 01-070 EB

PC-AT

DB-9F

YEL

(BLK)

2

RX

351

RED

GRN

(GRN)

(RED)

3

TX

4

WHT2BLK6BLU

(WHT)

N.C.

5

COM

INDUSTRIAL INDEXING SYSTEMS, Inc.

INDUSTRIAL INDEXING SYST EMS, Inc.

TITLE

THIS DR AWING, AND THE D ATAC ONTAINED THEREIN, ARE O F; INDUSTRIAL

INDEXING S YSTEM S, In c. AND IS ISSUED IN STR I CT C ONFIDENC E, AND IT SHALL N O T BE REP RO DUCE D,

(YEL)

(BRN)

N.C.

N.C.

2

AC

SEE NOTE 1

COPIE D, OR USED FOR A NY PURPOSE W HATSO EVER, WITHOUT THE PRIOR WRIT TEN PERMISSION O F;

DATECHECKED BY

DATE

DATE

ELS 15AUG96

APPROVED BY

APPROVED BY

REVISION

C-822000

1 OF 1

DRAWING NUMBER

SHEET NO.

NTS C

SCALE

BOWMAN

09M AY96

DATE

Q:\DFTG\CABLES\C-8XX

AutoCAD FILE LOCATION

DRAWNBY

B

-±

ANGULAR

CABLE ADAPTOR, 9P, FE, STANDARD

ELS 10MAY96

--

--

TOLERANCES

--

UNLESS OTHER WISE SPECIFIED

X.X±

X.XX±

X.XXX±

DIMENSIONS ARE INCHES (mm)

--------

--------

MATERIAL

FINISH

1

RJ11

JACK

B

SEE NOTE 2

C-822000

PC-AT

DB-9F

3.) COLORS IN (*) ARE A LTERNATE COLORS.

2.) M ARK PER Q P-08-0001.

1.) INSULATE UNUSED WIRES.

NOTES:

FEBRUARY 2014 PAGE 7 - 3

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

CKDRSYMDATE REVISION RE CORD CK

CDR

EB

PROPRIETARY INF ORMATIO N

www.iis-servo.com

PER ECN

INDUSTRIAL INDEXING S YSTEMS, Inc.

1

29JAN99 A 98-270/99-027 CWB

A

SEE NOTE 2

A

INDUSTRIAL INDEXING S YSTEMS, Inc.

TITLE

THIS D RAW ING, AN D THE DATA CON TAINED THERE IN, AR E O F; INDU STR IAL

INDEXING S YSTEMS, Inc. AND IS ISSUED IN STRI CT CONFIDENC E, AND IT SHALL N OT BE REPRODUCED,

COPIED, OR USED FOR A NY PURPOSE WHATSOEVER, WITHOUT THE PRIOR WRITT EN PERMISSION O F;

DATECHECKED BY

DATE

DATE

8/31/92

8/31/92

J.C.

E. BAIER

APPROVEDBY

APPROVEDBY

REVISION

C-987 YY Y

1 OF 1

DRAWING NUMBER

SHEET NO.

--- A

SCALE

ERTURK

13AUG92

DATE

Q:\DF TG\ CA BLE S\C-9 X X

AutoCAD FILELOCATION

DRAWNBY

CABLE, DATA, MOD ULAR

MATERIAL

B

---

±

ANGULAR

---

---

TOLERANCES

---

UNLESSOT H ERWISE SPECIFIED

X.X±

X.XX±

X.XXX±

DIMENSIONS ARE INCHES (mm)

---------

---------

FINISH

2

C-987YYY

22

334455

66

A

WHT

YEL

BLK

BLU

RED

GRN

11

PIN 1 PIN 1

A

PART No. 1005-6P6C .

(ITEM 1) W ITH MODULAR CRIMP TOOL,

1) CRIMP C ABLE (ITEM 2) TO ENDS

NOTES:

2) MARK PER OP-08-0 001.

PAGE 7 - 4 FEBRUARY 2014

INDUSTRIAL INDEXING SYSTEMS, Inc. IB-30B002

LUMINARY SERIES MOTION CONTROLLER USER’S GUIDE

4

3

1

2

38

12 0 .2

USBB/M

C-894015

Red

White

Green

Black

Braid

1234G

Male

USB B

50

Pin Assignment

Male

USB A

1234G

15 Ft. Long

USB-A to USB-B Cable

FEBRUARY 2014 PAGE 7 - 5

4

1

USB A / M

IB-30B002 INDUSTRIAL INDEXING SYSTEMS, Inc.

USER’S GUIDE LUMINARY SERIES MOTION CONTROLLER

Connector - Pin Kit for I/O and Power Interfaces

As an alternative to purchasing complete cable sets, customers can assemble the system’s cables

using our standard connector kits.

Connector Kit Parts List Description Quantity

LC-CONKIT 22-01-3087 8 Terminal Connector 1

- 22-01-3107 10 Terminal Connector 1

- 734-103 3 pin Female Connector 1

- 08-55-02102 Socket Pins (note 1) 25

Note 1: Use the Molex MINI-KK Crimp Tool

PAGE 7 - 6 FEBRUARY 2014

IB-30B002

INDUSTRIAL

INDEXING SYSTEMS

INC.

626 FISHERS RUN

VICTOR, NEW YORK 14564

(585) 924-9181

FAX: (585) 924-2169

PRINTED IN USA

© 2014

Loading...

Loading...