Indu-Sol Proftest II, NetTEST II User Manual

Contents

© COMSOFT i

Table of Contents

1 Scope of Delivery............................................................... 1

2 Safety Advice.....................................................................2

3 Introduction ...................................................................... 3

4 Line Tests..........................................................................5

4.1 Line Measurement......................................................5

4.2 LiveList, SlaveDiag, and Level Detection ...................6

4.3 Measurement at the Running Bus ............................... 6

5 NetTEST II Menu Guide .................................................. 7

5.1 Start-Up / Setting in Operation...................................7

5.2 Main Menu.................................................................8

5.2.1 Test without PLC ...............................................9

5.2.1.1 Segment list.............................................10

5.2.1.2 Test with no terminators .......................... 12

5.2.1.3 Test with 1 terminator.............................. 16

5.2.1.4 Test with 2 terminators ............................ 18

5.2.1.5 Generate livelist....................................... 19

5.2.1.6 Slave ident number .................................. 20

5.2.1.7 Slave signal quality.................................. 21

5.2.1.8 Baud rate detection .................................. 22

5.2.2 Test protocol .................................................... 23

5.2.2.1 Create new protocol .................................23

5.2.2.2 Delete ...................................................... 25

5.2.2.3 Display .................................................... 25

5.2.2.4 Transmit.................................................. 25

5.2.2.5 Test company........................................... 26

5.2.2.6 User name list.......................................... 26

5.2.2.7 Customer list............................................27

5.2.2.8 Plant list .................................................. 27

5.2.2.9 Segment list............................................. 28

5.2.3 System configuration........................................ 28

5.2.3.1 RS232 Interface....................................... 28

5.2.3.2 Device properties ..................................... 29

5.2.3.3 Date / Time.............................................. 30

Contents

ii © COMSOFT

5.2.3.4 Basic parameters...................................... 30

5.2.3.5 Load parameters ......................................32

5.2.3.6 Send parameters.......................................32

5.2.3.7 Firmware update...................................... 33

5.2.4 GSD - library ................................................... 33

5.2.4.1 New File.................................................. 33

5.2.4.2 Receive GSD File..................................... 34

5.2.4.3 Delete GSD File....................................... 34

5.2.4.4 Display / Edit........................................... 34

6 Communication with a PC .............................................. 35

6.1 Characteristics of HyperTerminal ............................. 35

6.2 COM Interface Configuration................................... 36

6.3 Receive Test Protocol ............................................... 37

6.4 Send File to NetTEST II........................................... 38

6.5 Send file from NetTEST II to the PC ........................ 39

7 Systems with PROFIBUS -Master Option..................... 40

7.1 Slave line-up ............................................................ 41

7.1.1 Set outputs ....................................................... 43

7.1.2 Read inputs ...................................................... 43

7.1.3 Set value .......................................................... 43

7.1.4 Read value .......................................................43

7.1.5 Read diagnostics .............................................. 43

7.2 Extended master....................................................... 44

7.2.1 Master parameters............................................ 44

7.2.1.1 PROFIBUS Address................................. 45

7.2.1.2 Profibus parameters ................................. 45

7.2.1.3 Copy from segment .................................. 46

7.2.2 Config. with livelist.......................................... 46

7.2.3 COMSOFT Configurator Tool.......................... 47

7.2.3.1 Creation of a configuration ...................... 47

7.2.4 Config. with download ..................................... 49

7.2.5 Slave menu ...................................................... 51

7.2.5.1 New slave ................................................51

7.2.5.2 Copy slave ...............................................54

7.2.5.3 Delete slave.............................................. 54

7.2.5.4 Process slave............................................ 54

Contents

© COMSOFT iii

7.3 Process slave ............................................................55

7.3.1 Edit parameters................................................ 55

7.3.1.1 Profibus address....................................... 56

7.3.1.2 General parameters.................................. 56

7.3.1.3 Prm data .................................................. 56

7.3.1.4 Cfg data................................................... 56

7.3.1.5 DP tag definitions .................................... 56

7.3.2 Line-up ............................................................ 56

7.3.2.1 Line-up.................................................... 58

7.3.2.2 Edit slave address ....................................58

7.3.2.3 Edit slave parameters............................... 58

7.3.2.4 Edit prm. data.......................................... 58

7.3.2.5 Edit cfg. data ........................................... 59

7.3.2.6 Edit xchg. data......................................... 59

7.3.2.7 Show xchg. data....................................... 59

7.3.2.8 Edit DPTag output ................................... 59

7.3.2.9 Show DPTag input................................... 59

7.3.2.10 Show Slave diagnostic............................60

7.3.3 Single DP services............................................ 60

7.4 DPTag definitions .................................................... 61

7.4.1 Display/edit tag................................................ 62

7.4.2 Create new tag ................................................. 63

7.4.3 Delete tag......................................................... 63

8 System with Online Functionality .................................. 64

8.1 Baud rate detection................................................... 66

8.2 Generate livelist ....................................................... 67

8.3 Rotation time............................................................ 68

8.4 Signal level measurement......................................... 69

8.4.1 Measurement with livelist ................................ 70

8.4.2 Measurement with filter ................................... 70

8.4.2.1 Define filter ............................................. 71

8.5 Signal level summary list..........................................72

8.6 Event log.................................................................. 73

8.7 Event count .............................................................. 74

8.8 Diagnostic event....................................................... 75

8.9 Settings .................................................................... 76

Contents

iv © COMSOFT

9 Operation of the Battery Charger.................................. 77

10 Tips & Tricks................................................................ 78

10.1 Cable Lengths in PROFIBUS Segments.................. 78

10.2 Segment Cascading ................................................ 78

10.3 Use of Stub Lines....................................................79

11 Pin Assignment.............................................................. 80

12 Key Allocation............................................................... 81

13 Problematic Slaves........................................................ 82

14 Frequently Asked Questions: FAQ............................... 83

15 Technical Data .............................................................. 85

15.1 NetTEST II............................................................. 85

15.2 Plug Charger .......................................................... 86

Tables

Table 1 Segment length specification ...............................78

Table 2 Pin assignment of D-SUB 9 connector................. 80

Table 3 Key allocation NetTEST II .................................81

Table 4 Technical data NetTEST II................................. 86

Table 5 Technical data Plug charger ................................86

Contents

© COMSOFT v

Figures

Figure 1: Connection NetTEST II in the cable thread.....5

Figure 2: Screen ‘Start-up’..............................................7

Figure 3: Screen ‘Main menu’.........................................8

Figure 4: Screen ‘Test without PLC’ ...............................9

Figure 5: Screen ‘Segment list’ .....................................10

Figure 6: Screen ‘Segment configuration’ .....................10

Figure 7: Screen ‘Test with no term’ .............................13

Figure 8: Screen after ‘Test with no term’ ..................... 13

Figure 9: Screen after ‘Test with 1 term.'.......................16

Figure 10: Screen after ‘Test with 2 term.’...................... 18

Figure 11: Screen ‘Generate livelist’ ............................... 19

Figure 12: Screen ‘Slave ident number’...........................20

Figure 13: Screen ‘Slave signal quality’ ..........................21

Figure 14: Screen ‘Baud rate detection’........................... 22

Figure 15: Screen ‘Test protocol’ ....................................23

Figure 16: Selection menu ‘Test protocol’....................... 23

Figure 17: Screen ‘Test protocol with PLC’.....................24

Figure 18: Screen ‘Test Company’ ..................................26

Figure 19: Screen ‘User name list’ .................................. 26

Figure 20: Screen ‘Customer list’ .................................... 27

Figure 21: Screen ‘Plant List’..........................................27

Figure 22: Screen ‘System configuration’........................ 28

Figure 23: Screen ‘Device properties’..............................29

Figure 24: Screen ‘License code’..................................... 29

Figure 25: Screen ‘Basic parameters’ .............................. 30

Figure 26: Screen ‘GSD - library’ ...................................33

Figure 27: Connection Setting via COM1........................35

Figure 28: Characteristics of the serial interface..............36

Figure 29: "Start-up" Screen with the PB-Master ............40

Figure 30: Screen ‘Line test’...........................................40

Figure 31: Screen ‘Profibus master mode’....................... 41

Figure 32: Screen ‘Slave line-up’ ....................................41

Figure 33: Screen ‘Slave line-up’ ....................................42

Figure 34: Screen ‘Extended master’............................... 44

Figure 35: Screen ‘Master parameters’............................ 44

Figure 36: Screen ‘Other address’................................... 45

Figure 37: Entry mask ‘Master configuration’................. 45

Figure 38: Screen ‘Config. with livelist’..........................46

Figure 39: Screen ‘context menu in the Configurator’ .... 47

Figure 40: Slave –Configuration Dialogue.......................48

Figure 41: Screen ‘Receive CFG file’ ..............................49

Figure 42: Download Configurator -Tool dialogue .........50

Contents

vi © COMSOFT

Figure 43: Confirmation Screen ‘Receive CFG file’ ........ 50

Figure 44: Screen ‘Slave menu’.......................................51

Figure 45: Selection menu ‘New address’........................51

Figure 46: Entry mask ‘Parameter’..................................52

Figure 47: Entry mask ‘User prm’...................................53

Figure 48: Entry mask ‘Cfg data’.................................... 53

Figure 49: Selection menu ‘Copy slave’ ..........................54

Figure 50: Screen ‘Process slave’ ....................................55

Figure 51: Screen ‘Edit parameter’..................................55

Figure 52: Screen ‘Line up’.............................................58

Figure 53: Screen ‘Single DP services’............................60

Figure 54: Screen ‘Tag(s) use/modify’.............................61

Figure 55: Selection menu ‘Display/edit tag’................... 62

Figure 56: Entry mask ‘Tag data’.................................... 62

Figure 57: "Start-up" Screen with Online Function .........64

Figure 58: Screen Line test..............................................64

Figure 59: Screen Test with PLC..................................... 65

Figure 60: Baud rate detection......................................... 66

Figure 61: Generate Slave livelist.................................... 67

Figure 62: Generate Master livelist..................................67

Figure 63: Rotation time .................................................68

Figure 64: Signal level measurement............................... 69

Figure 65: Selection menu Signal level measurement ...... 70

Figure 66: Measurement with filter ................................. 70

Figure 67: Screen ‘Filter name’....................................... 71

Figure 68: Screen ‘DP-Slave list’ .................................... 71

Figure 69: Screen ‘DP-Slave sorting’ .............................. 72

Figure 70: Screen ‘Signal level summary list’ ................. 72

Figure 71: Screen ‘Event log’.......................................... 73

Figure 72: Screen ‘Event count’......................................74

Figure 73: Screen ‘Diagnostic event’............................... 75

Figure 74: Screen ‘Settings’............................................76

Scope of Delivery

© COMSOFT 1

1 Scope of Delivery

Included in the scope of delivery of the NetTEST II service

case are the following items:

• one PROFIBUS NetTEST II cable tester

• two battery packs NiMH 4,8 V/1500 mAh

• one battery charging holder

• one 230 VAC plug-in battery charger

• power supply adapter

• one PROFIBUS Stub line 0.15 m, DB9M / DB9M

• one RS232 Cable connector DB9M / DB9F

• one PROFIBUS Y-Cable, 0.15 m, DB9M / 2xDB9F

• one PROFIBUS Bus disconnector, DB9M / DB9F

• one Gender Changer DB9M / DB9F (mounted on

NetTEST II)

• one Gender Changer DB9M / DB9M

• one Gender Changer DB9F / DB9F

• one Transport case

• one User’s guide

• one COMSOFT Configurator-Tool

(for DP Master Option)

Safety Advice

2 © COMSOFT

2 Safety Advice

The NetTEST II may only be operated with licensed NiCd

batteries or NiMH batteries.

• Do not immerse battery pack under water or expose it to

open fire.

• Do not open battery pack and do not try to replace

individual battery cells.

• Do not dispose of faulty battery packs with normal

household garbage!

• The battery pack could warm up during charging. This is

a normal process and not dangerous.

• Do not use other chargers than supplied and specified by

COMSOFT, the batteries could otherwise be damaged.

• Do not use NetTEST II in surroundings with explosion

hazard.

In case that water or other liquids should have

penetrated your NetTEST II, remove the battery pack or

the power supply adapter. Then have your NetTEST II

checked by our Service Department. The same applies

for the battery charging holder and the plug-in battery

charger.

Introduction

© COMSOFT 3

3 Introduction

With the PROFIBUS NetTEST II you have acquired a highquality tool for the examination of RS485-based PROFIBUS

segments.

COMSOFT’s aim is to provide its users with a valuable tool

for an easy check, without extensive test methods of the

correct cabling of their PROFIBUS net and to document this.

Furthermore, the search for errors in already installed

PROFIBUS systems shall be as easy as possible. We guess that

we reached this target with NetTEST II,the 2

nd

generation of

COMSOFT PROFIBUS test tools.

Therefore it goes without saying that with NetTEST II,the

checks can be run with connected and disconnected devices. It

does not matter if the devices are powered or not. For physical

testing you only have to ensure that there is no active Master

(PLC) polling the bus.

Besides the standard cable test, i.e. the verification of the lines

regarding cable length, line impedance, correct termina-

tion, cable rupture, broken shield, stub lines, inhomogeneous cable segments, mixed up cables, short circuits,

faulty PROFIBUS connectors and faulty device connections, NetTEST II disposes of PROFIBUS DP specific test

functions. So, e.g. the livelist and the Slave Ident Number

are indicated, also the transmission level of the Slaves

connected to the bus is detected per device. Furthermore,

NetTEST II detects the current baud rate at the running bus.

During the baud rate scan a signal analysis indicates faults or

errors in the cabling.

Introduction

4 © COMSOFT

Apart from these basic functions the following options are

available for NetTEST II:

• DP Master Option

With the DP Master Option the set into operation of

DP Slaves is possible without the PLC. The

DP Slaves can be configured with the COMSOFT

PROFIBUS configuration tool based on the DP Slaves

appropriate GSD file.

• Online-Function

This function performs a detailed analysis of the

telegram traffic and the physical state of the

PROFIBUS line.

To make installation checks and error retrieval as easy as

possible, we divided this manual into the following sections:

• Line tests

• Menu guide

• PC connection

• DP Master functionality (optional)

• Online functionality (optional)

• Tips & Tricks

We hope that we can give you with our test tool NetTEST II

and this manual all necessary means for a faultless function of

your PROFIBUS plant. In case of queries, please contact our

hotline, we will be pleased to help you with our advice.

Line Tests

© COMSOFT 5

4 Line Tests

4.1 Line Measurement

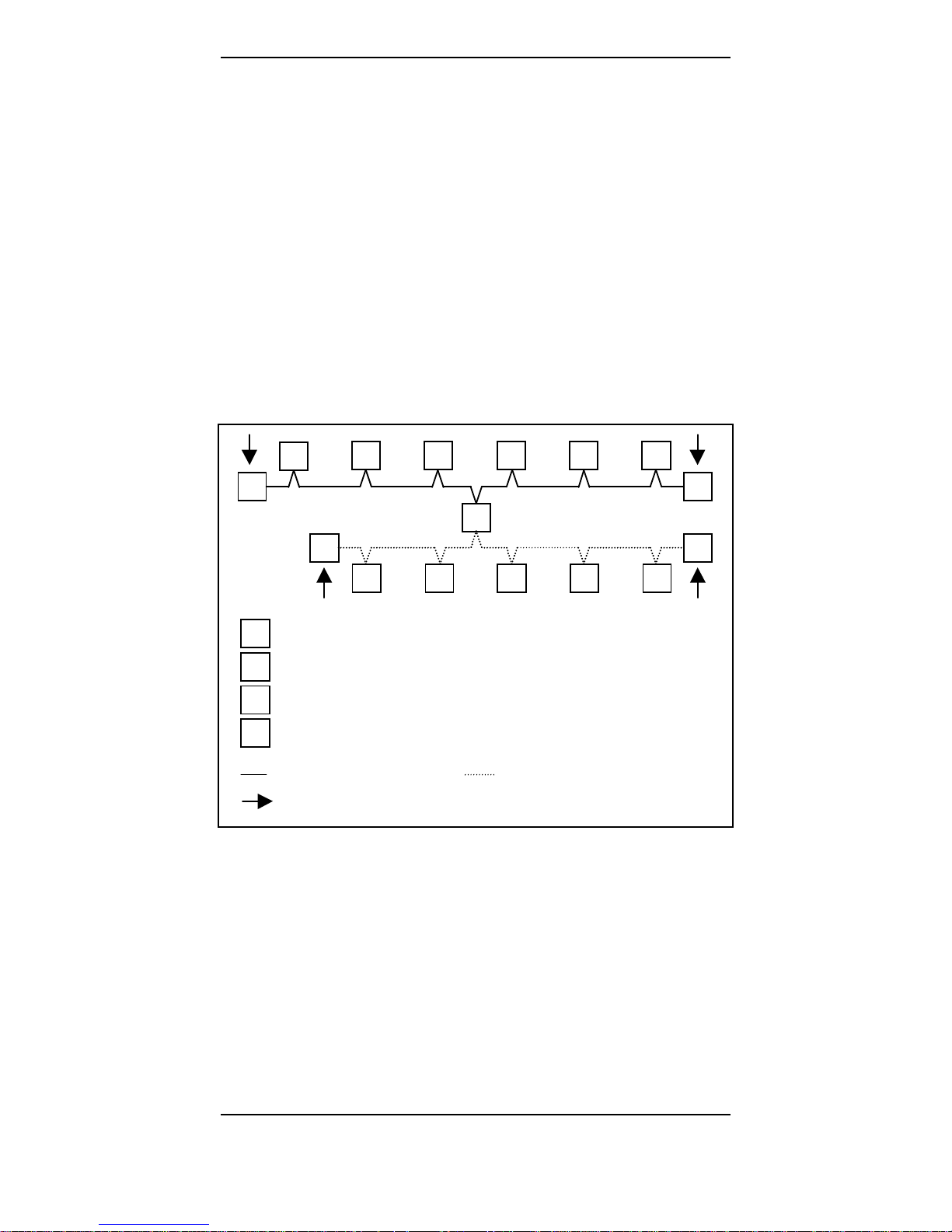

Generally, measurements regarding line physics can only be

made from one end of the PROFIBUS line. If you try to

measure from any other place within the segment, you will

obtain faulty results.

Furthermore please make sure that during measurements no

Master is polling the bus or is sending tokens. Pure

PROFIBUS DP Slave devices as well as e.g. repeaters and

optical couplers must not be disconnected from the bus. An

oversight over the possible measuring points in line segments

for line measurement is depicted below:

S

M

T

R

T

S S S S

S S S S S

TT

T

M

S

R

=Terminato

r

=Maste

r

=Slave

= Repeater / Segment coupler / Optical coupler

= Segment 1 = Segment 2

= Measuring point

Figure 1: Connection NetTEST II in the cable thread

Line Tests

6 © COMSOFT

4.2 Livelist, SlaveDiag, and Level Detection

To make detections as easy as possible, the generating of the

livelist, the Slave diagnosis and Slave-related transmission

level detection should be effected as well from the bus end.

However, you can also make these from any other available

measuring point within one segment. Here, please observe that

the function of the livelist and of the SlaveDiag also work via

a repeater, segment coupler or optical coupler. The level

detection of a Slave connected via such a device reflects only

the transmission level of the repeater and not the one of the

detected Slaves!

4.3 Measurement at the running bus

The measurements at the running bus are limited to an

indication of the current baud rate, as well as of the general

transmission level quality of the connected Slaves. By this

means, a qualitative evaluation of the level on the bus line is

made. If the test tool shows reflections, the reasons for those

can only be found with the line detection, which implies that

the Master(s) is / are being turned off.

NetTEST II Menu Guide

© COMSOFT 7

5 NetTEST II Menu Guide

5.1 Start-Up / Setting in Operation

Check the completeness of the scope of delivery and charge

batteries before first setting in operation. Remove the battery

by gently pressing the locking and at the same time pulling

down the battery placed at the rear lower side of the

NetTEST II. Now place the battery into the charging holder,

and check the loading procedure by means of the LED in the

battery charger. For detailed information refer to the enclosed

documentation of the battery charger. Remove the battery from

the charging holder and push it onto the NetTEST II until

you can hear it snapped in.

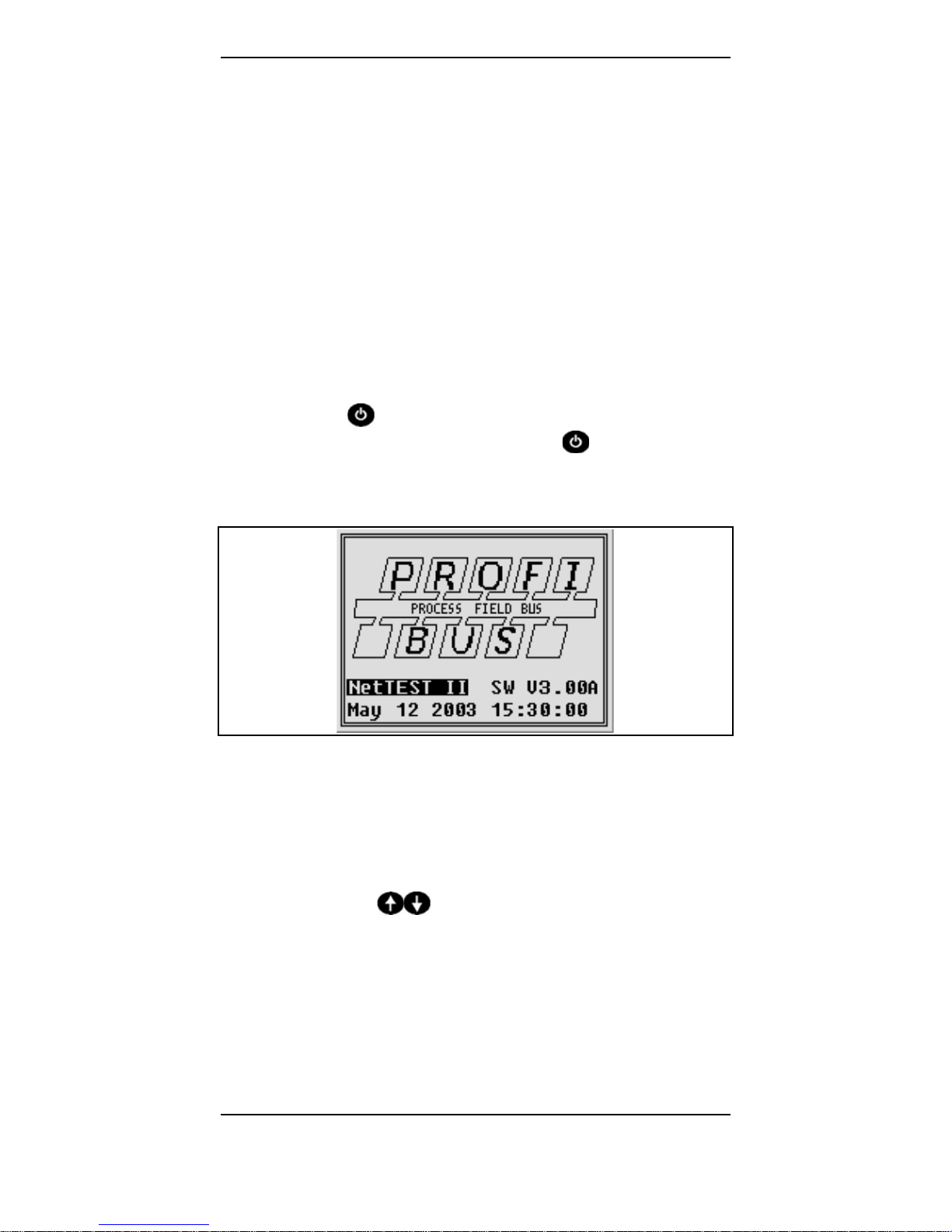

Now push the

key approx. 1s, until the PROFIBUS logo

appears on the screen. Then release the

key. Besides the

PROFIBUS logo, the firmware version and date appears for

approx. 2s.

Figure 2: Screen ‘Start-up’

Now the main menu is displayed automatically. The test tool is

ready for operation. With various different text outputs the

display is too small, this will be indicated by "^^" at the right

upper and "vv" at the right lower corner of the text. By

pressing the keys

you may scroll up or down in the

text.

NetTEST II Menu Guide

8 © COMSOFT

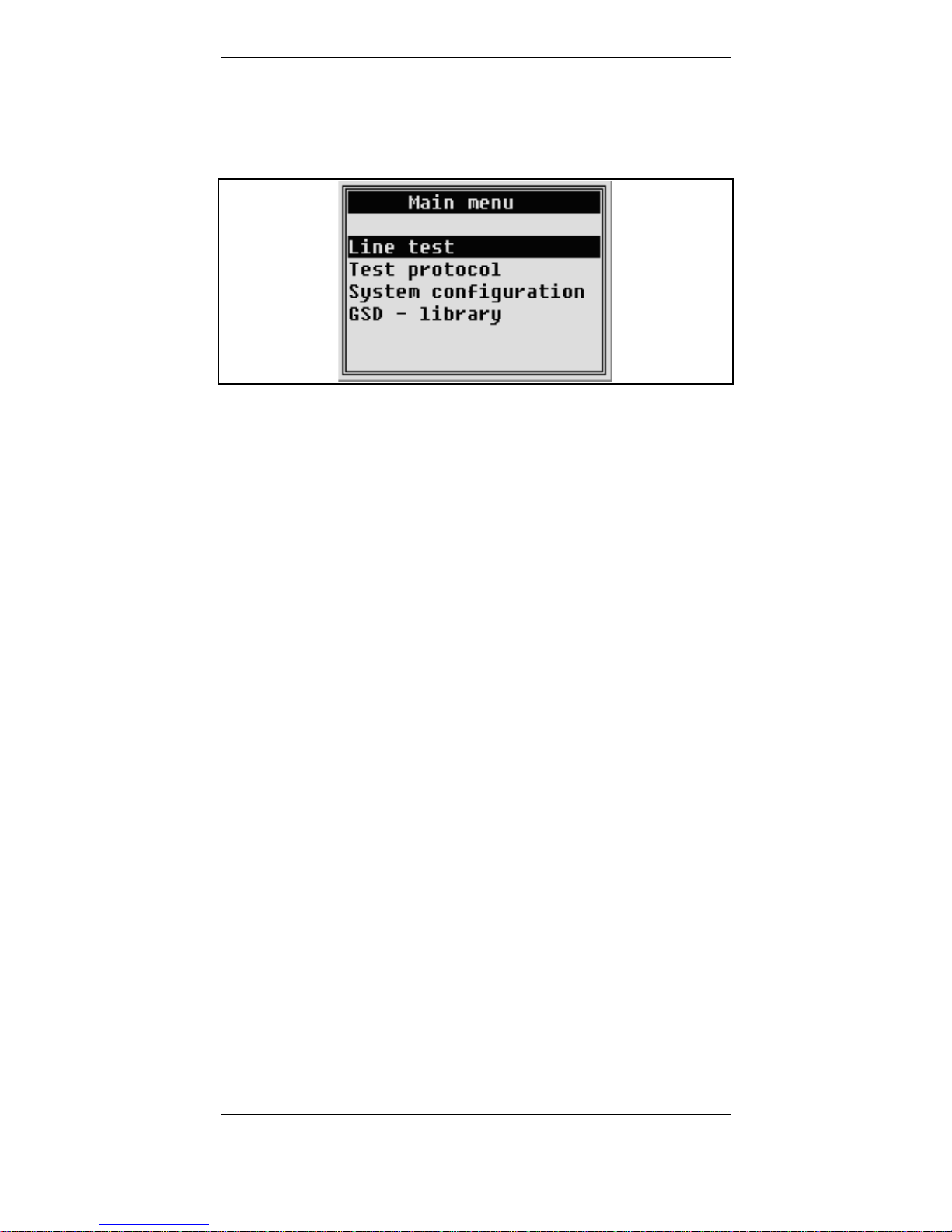

5.2 Main Menu

The main menu automatically appears on the display after

having started the NetTEST II.

Figure 3: Screen ‘Main menu’

The main menu comprises the following submenus:

• Line Test

• Test without PLC

Stepwise check of cabling and test of DP Slaves,

without protocol generation.

• PROFIBUS Master mode (optional)

Set into operation of DP Slaves without PLC.

• Test with PLC (optional)

Detailed analysis of the telegram traffic and the

physical state of the PROFIBUS line.

• Test Protocol

• Test without PLC

Like Line Test – Test without PLC, however, the

results of all tests are stored in a test protocol for

documentation purposes.

• Test with PLC (optional)

Like Line Test – Test with PLC, however, the results

of all tests can be stored in a test protocol for

documentation purposes.

• System Configuration

For all device-specific settings.

• GSD - library

Submenu for the administration of GSD files.

NetTEST II Menu Guide

© COMSOFT 9

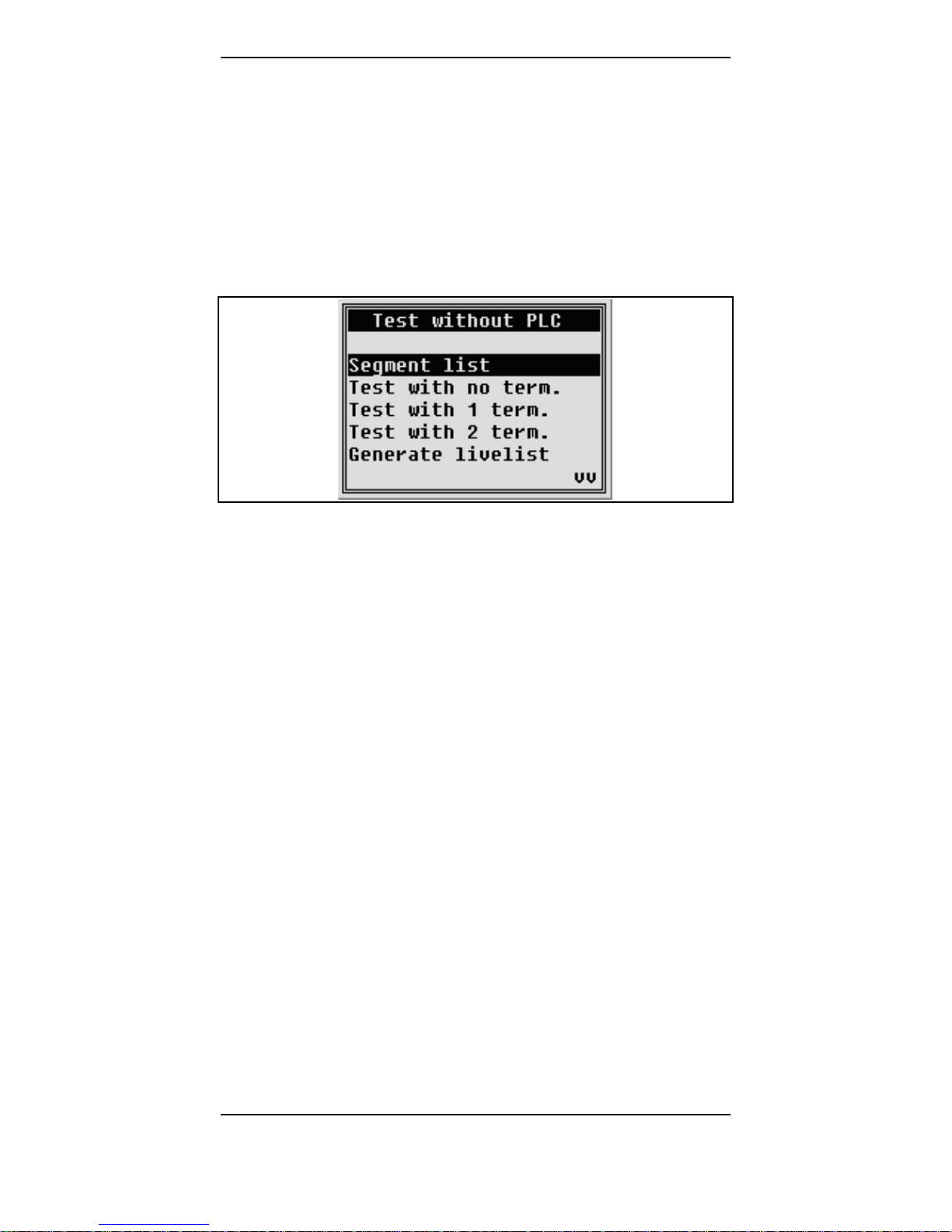

5.2.1 Test without PLC

The menu Test without PLC serves for stepwise physical

analysis of lines. This means that the test can be executed as

often as desired. Some tests are based on the reference data of

the preceding test, so that this one must be run beforehand.

The individual items are interlocked, so that wrong operation

is impossible. For tests run under this menu, no protocol is

made out.

Figure 4: Screen ‘Test without PLC’

For a line test, at first the design parameters for the

PROFIBUS segment that has to be checked must be indicated.

These indications are necessary, so that, e.g. the PROFIBUS

DP specific measurements at the line segment may be

executed with the real bus settings used in your plant. The

settings are made in the submenu Segment list.

As soon as a option is activated (DP Master or OnlineFunction), the Line test menu appears under Test

without PLC.

NetTEST II Menu Guide

10 © COMSOFT

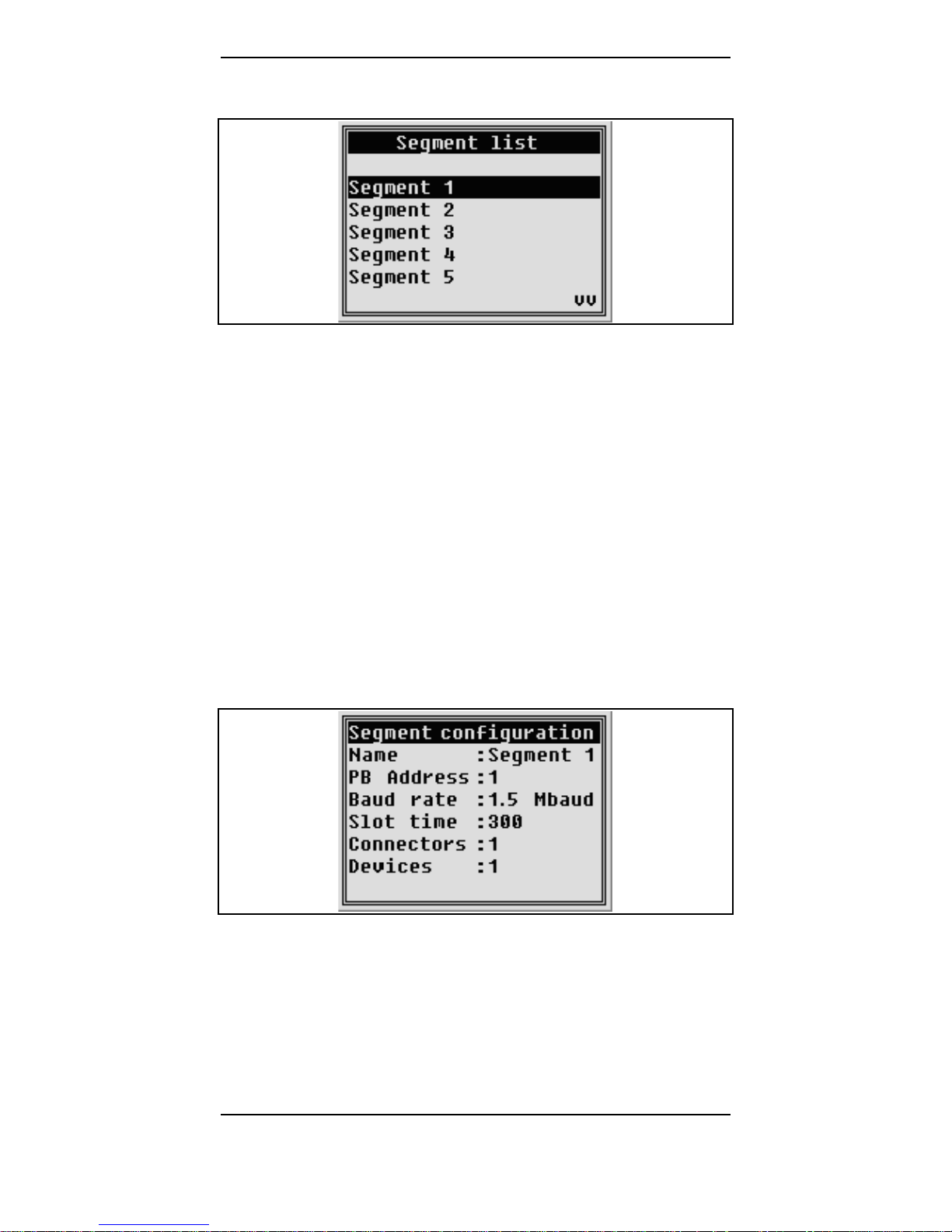

5.2.1.1 Segment list

Figure 5: Screen ‘Segment list’

Under Segment list, segment-specific data are stored serving

as basis for the following measurements. The data are stored

in the data base for line segments under the assigned segment

name. From there, they can be used as basis for both

individual tests and the creation of test protocols. Indications

must be made as to the points listed below:

• Name of line segment (max. 30 characters)

• PROFIBUS baud rate (9.6 Kbit/s - 12 Mbit/s)

• PROFIBUS address for master operation of NetTEST II

(0-126)

• PROFIBUS slot time tslot (300-5000)

Figure 6: Screen ‘Segment configuration’

NetTEST II Menu Guide

© COMSOFT 11

The PROFIBUS baud rate, address and slot time are necessary

for the parameterization of the installed PROFIBUS Master.

With these settings, the tests Generate livelist, Slave i dent

number, as well as Slave signal quality are executed.

Moreover, indications regarding number of:

• Connectors (only number of 12 Mbit/s plugs!)

• Devices (all devices with PROFIBUS plug, or connected

cable)

Connected devices and 12 Mbit/s PROFIBUS plugs

considerable change by their inductivity resp. capacity the

measuring abilities and characteristics for the NetTEST II.In

order to keep these measuring insecurities in a tolerable scale,

please indicate before each measurement the number of

installed 12 Mbit/s plugs as well as the number of the devices

connected to the bus. Please only indicate the plugs which

dispose of incorporated direct-axis inductances. Devices stands

for all units connected to a bus segment. This applies to

Master and Slaves as well as to net components like segment

couplers, repeaters, optical couplers etc.

Once the data are stored in the data base, they can always be

used for new tests. The data in this data base cannot be

deleted, only changed by overwriting. In order to have enough

spare capacity for this function, 20 memory locations are

available. The respective memory locations can be reached by

actuating the

or the key.

NetTEST II Menu Guide

12 © COMSOFT

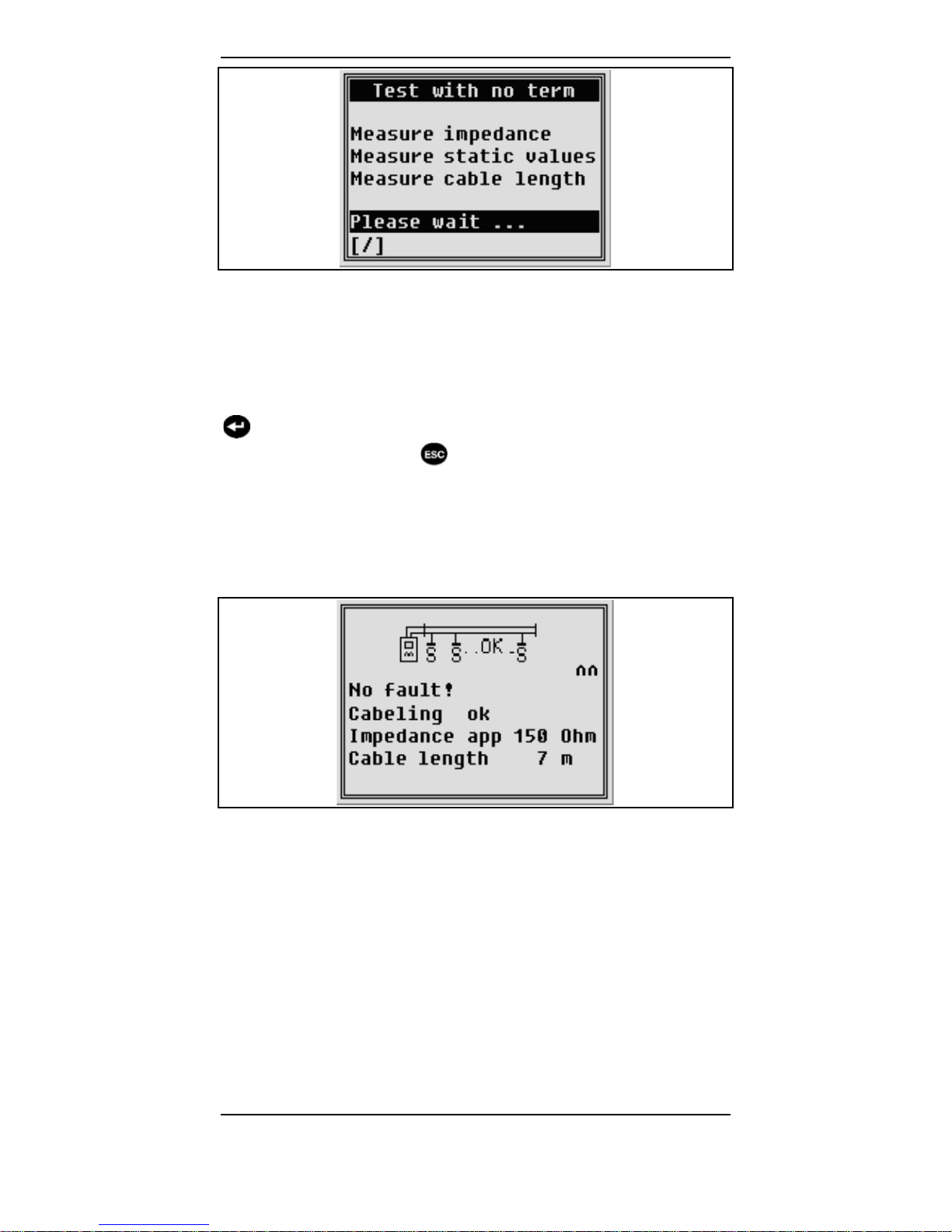

5.2.1.2 Test with no terminators

At the beginning of each test, the Test with no term. must be

carried out. For this, the NetTEST II must be connected to

one end of the PROFIBUS segment. Now the user makes sure

that all bus termination resistors (terminators) in the bus

segment are switched off resp. removed. Furthermore, no

Master may send data via the bus. Then the Test with no term.

can be carried out. If, by accident, a bus terminator or Master

should be active in the segment, the NetTEST II recognizes

and indicates this at once. Only if no more resistance in the

thread is activated and all Masters are deactivated, the

NetTEST II informs about:

• Line impedance

• Line length (segment length)

Detections in segments with PROFIBUS plugs with a

disconnection function can be tricky. If, e.g., in the

middle of a segment, the terminator of such a plug is

activated, the NetTEST II recognizes it, if it is measured

from the entrance side. However, if the measurement is

made from the other end of the plug, measuring is made

into the open end and a cable length, shorter than the one

expected, is indicated. Therefore please check very

thoroughly if all bus terminators are switched off.

Another possibility of finding such a plug is measuring

from the other side of the bus.

NetTEST II Menu Guide

© COMSOFT 13

Figure 7: Screen ‘Test with no term’

The Test with no term. lasts for a few seconds. The duration

depends on the cable length. To show the user that the system

is still working, a star bar appears on the lower left hand side

of the display as progress indication. Terminate the test with

. Upon conclusion the result will be displayed. Attention: If

you quit the test with

,theTest with 1 term. cannot be

executed any more, as the just scanned data were deleted.

If no error is detected on the PROFIBUS segment, a "positive

acknowledgement" message will appear, displaying the cable

impedance and cable length according to the following figure.

Figure 8: Screen after ‘Test with no term’

The following error indications, that impede correct length

and impedance measurement, may occur:

• "No error: Impedance not detected": Cable length for the

impedance measurement is too short.

• "Error: No length measured": Cable length is either too

short for length measurement or there is no cable

connected.

• "Error: A<->shield / B<->shield short circuit":Thereis

a low ohmic resistance between signal wire and shield.

NetTEST II Menu Guide

14 © COMSOFT

• "Error: A<->B Short circuit or unpowered termination":

There is a low ohmic resistance between the signal wires,

which might be caused for example by a bus termination

without power supply.

• "Error: A<->B Irregularity, wrong termination or illegal

termination ": There is an unacceptable ohmic resistance

between the signal wires, that stands in no relation to the

magnitude of a bus termination either with or without

power supply. The cause might be for example an

incorrectly connected bus termination.

• "Error: A<->B Terminator": There is a powered bus

termination (possibly along the line), which impedes

impedance and length measurement.

• "Error: A<->shield / B<->shield high imp. fault":There

is a high ohmic resistance between signal wire and shield.

• "Error: A<->B Capacitive load, junction or Impedance

changes": There is a capacitive resistance between the

signal wires, which might be caused by a PROFIBUS

device with unauthorized bus coupling, a branch or switch

over to a inadmissible cable type.

• "Error: Possible broken line of shield / of signal line A/B

distance XX m": Result of the length measurement is

significantly different for the various lines and shields.

• "Error: uncertain situation / possibly broken line of

shield or of signal line A/B. Please repeat measurement

at the opposite segment-end": Result of the cable length

measurement for the various different lines and shields is

so different, that no specific statement about the respective

line segment is possible. Should the measurement on the

other line end give correct results, then the measurement

may be considered o.k. In particular, this effect may be

observed with cable coils or cable drums in the

PROFIBUS network.

NetTEST II Menu Guide

© COMSOFT 15

With each of these error messages there may be an

indication of a distance. Some errors (e.g. invalid

termination) do not give conclusive information about the

distance.

Moreover, all error messages may also include the indication

"uncertain error". This may be indicated, if the cause of the

error could be detected only roughly, thus permitting only an

error estimation.

Also with uncertain error situations, the PROFIBUS

segment has problems in any case, even if the

measured error is relatively small. Due to EMV and

high baud rates (≥1.5 Mbit) this may lead to severe

communication problems.

An effective method for determining errors in their

position is to divide the segment into several subsegments, and to submit them to separate

examinations.

All error indications are also displayed with the key.

NetTEST II Menu Guide

16 © COMSOFT

5.2.1.3 Test with 1 terminator

Prior to the Test with 1 term.,inanycasetheTest with no

term. must be completed. If this was not made, the user is

being informed about this and can immediately make up for

this test. For the Test with 1 term., the terminator at the bus

end opposite to the NetTEST II must be switched on and set

under current. With a DP Slave unit or another passive bus

participant, the plug can be connected directly, the terminator

added and the unit switched on. If the unit at the end of the

line segment is a PROFIBUS Master, take care that the bus

participant does not actively send data onto the bus. This can

e.g. be realized by a bus disconnector. Via the bus

disconnector, the bus terminator in the PROFIBUS plug is

supplied with power, but the bus line is interrupted by a

mechanical switch in direction to the line segment.

Upon conclusion of the test the result will be displayed on the

screen.

If no error is detected with the Test with 1 term on the

PROFIBUS segment, a "positive acknowledgement" will

appear, according to the following figure.

Figure 9: Screen after ‘Test with 1 term.'

NetTEST II Menu Guide

© COMSOFT 17

In case of errors, the following error messages may be

displayed:

• "Error: no termination or switch defect": No valid

termination could be detected.

• "Error: Your terminator is not at the far end of the

segment !": Contrary to the instruction the terminator was

switched at the near segment end.

• "Error: A<->B twisted": Mix up of signal lines.

• "Error: A<->shield / B<->shield short circuit ":Thereis

a low ohmic resistance in the cable between signal wire

and shield.

• "Error: A<->B short circuit or bus terminal without

power supply": There is a low ohmic resistance in the

cable between the signal wires.

• "Error: A<->B Irregularity, Wrong termination or illegal

termination": There is an inadmissible ohmic resistance

between the signal wires, that stands in no relation to the

magnitude of a bus termination either with or without

power supply, for example caused by a wrongly connected

bus termination.

The Test with 1 term. must also be terminated by the

key

in order to be able to execute the following test.

NetTEST II Menu Guide

18 © COMSOFT

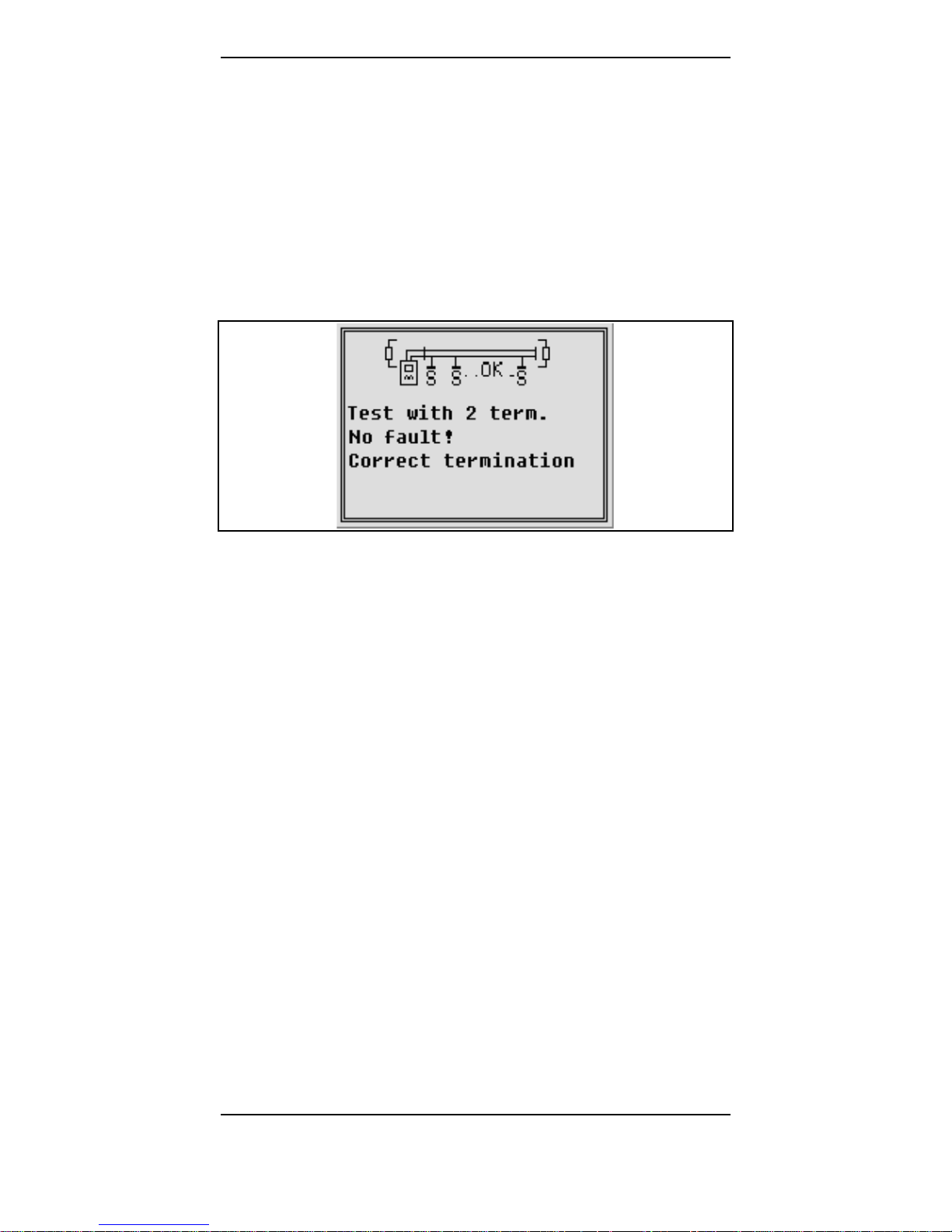

5.2.1.4 Test with 2 terminators

Following the Test with 1 term., the Test with 2 term. is

started. Here it is checked if the bus terminator at the line end

of the NetTEST II was switched on additionally. For this test,

the terminator must also be supplied with power. This can

easily be done from the last unit in the segment. If this should

be a Master which cannot be made passive, the data line has

again to be disconnected from the segment via a bus

disconnector.

Figure 10: Screen after ‘Test with 2 term.’

If the Test with 2 term. was terminated successfully, it can be

taken for granted that the cabling in the segment was done

correctly. If during the test with NetTEST II an error should

has been detected, this would be depicted on the display by a

graphic and text indication.

Possible error messages are described in detail in chapters

5.2.1.2and 5.2.1.3

NetTEST II Menu Guide

© COMSOFT 19

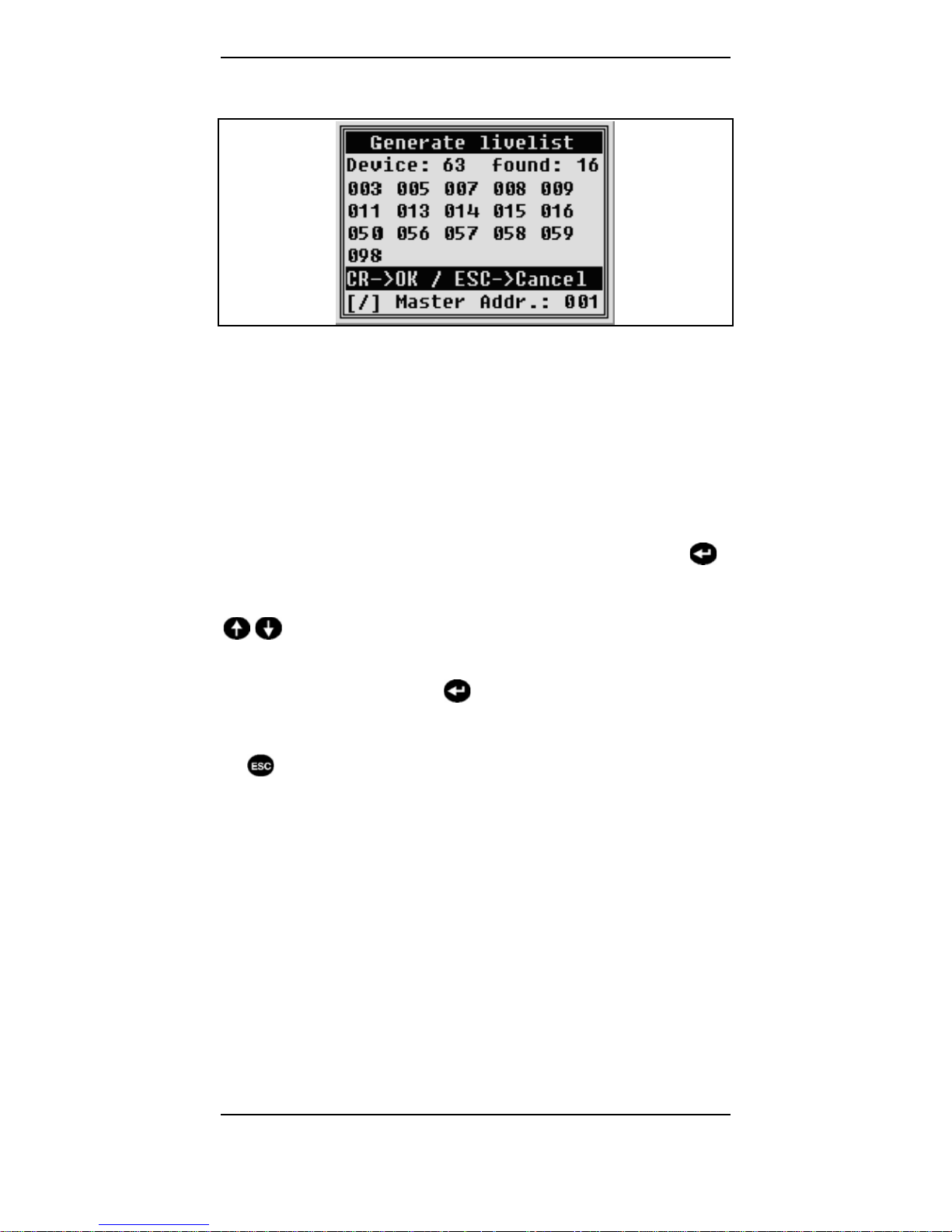

5.2.1.5 Generate livelist

Figure 11: Screen ‘Generate livelist’

In the menu Generate livelist, NetTEST II scans all possible

bus addresses from 0....126 for PROFIBUS DP Slave

participants. For this, a FDL request is effected several times

on each address. If a device answers with OK, its bus address

appears on the display. The unit counter is incremented by

one. To ensure that also extremely slow units are recognized,

the test takes approx. 30 seconds. Should all connected units

already be recognized, the user can truncate the test with

.

Should there be more units than depictable on one display

screen, the user can scroll through after the test with

keys.

To be able to execute further tests, Generate livelist must by

all means be terminated by

. Only then the recognized units

are registered in the internal memory, so that for these in the

following test, a Slave_Diag_Req can be run. If the test is quit

by

, no slave diagnosis can be executed afterwards!

NetTEST II Menu Guide

20 © COMSOFT

5.2.1.6 Slave ident number

Figure 12: Screen ‘Slave ident number’

Via the Slave ident number menu, the Ids for a better

assignment of the DP Slave addresses to the unit type can be

indicated. Here, a Slave_Diag_Request is executed on the

respective device, and this returns in its answer the ident

number. This will then be indicated behind the Slave address.

NetTEST II Menu Guide

© COMSOFT 21

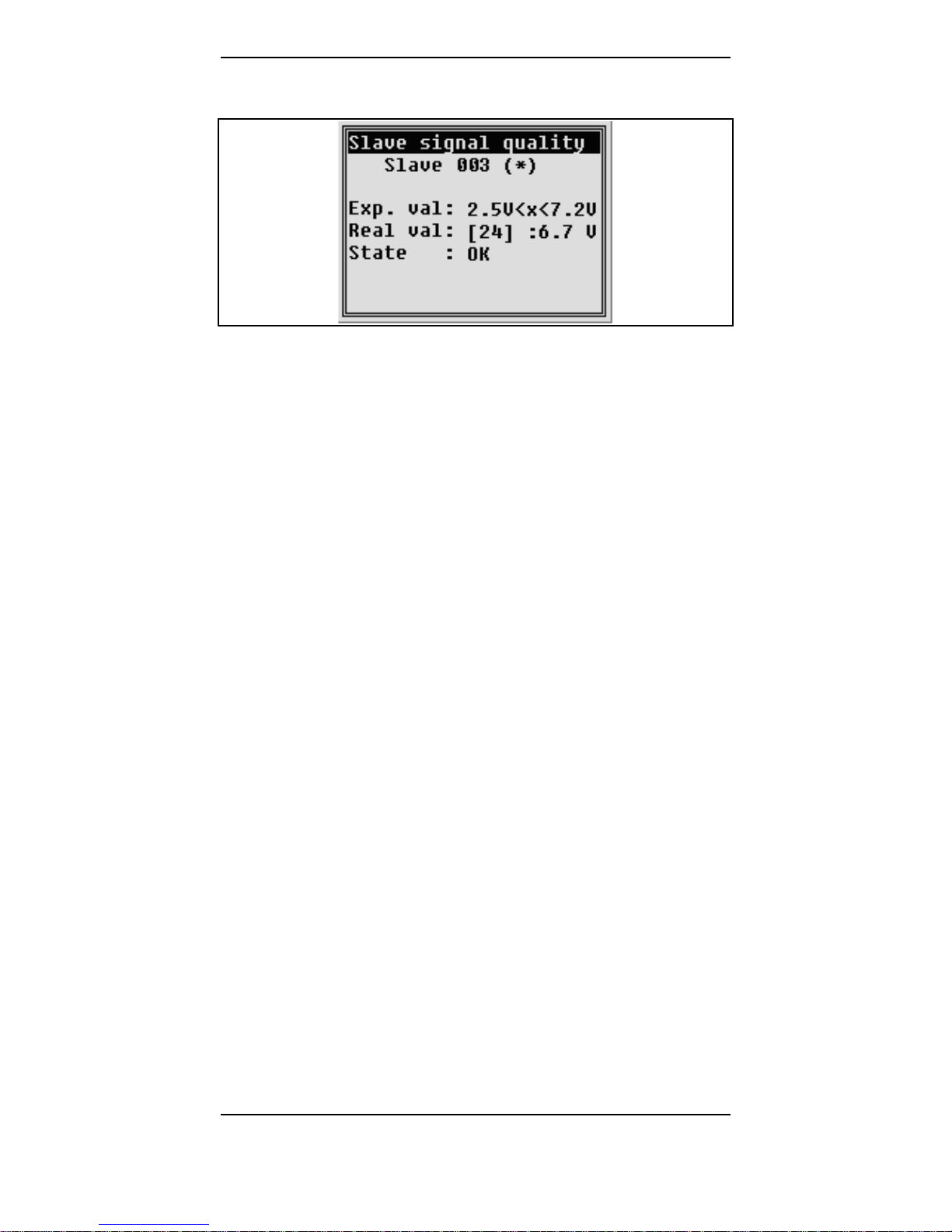

5.2.1.7 Slave signal quality

Figure 13: Screen ‘Slave signal quality’

With the Slave signal quality, the signal level of the addressed

DP Slave is measured. This should be with an impeccable unit

and correctly terminated bus and a cable length of 1 m from

the measuring point to the Slave at approx. 6.3 Volt. Per

100 m more cable between NetTEST II and the device to be

scanned, the level reduces by approx. 0.2 Volt.

U < 2.5 V: Weak level or no longer detectable.

2.5-7.2V: Levelisok.

U > 7.2 V: If the indicated level is >7.2 Volt, this is an

indication for a faulty power supply of the

Slaves or for reflections at the bus.

Loading...

Loading...