IndigoVision XP Quick Start Manual

INDIGOVISION

XP HD PTZ CAMERA

BX RANGE

QUICK START GUIDE

COPYRIGHT © INDIGOVISIONLIMITED. ALL RIGHTS RESERVED.

INDIGOVISIONIS A TRADEMARK OF INDIGOVISIONLIMITED AND IS

REGISTEREDIN CERTAIN COUNTRIES.SMS4, CAMERA GATEWAY,

ANDMOBILE CENTER ARE UNREGISTEREDTRADEMARKS OF

INDIGOVISIONLIMITED. ALL OTHER PRODUCTNAMES REFERREDTO

INT HISMANUAL ARET RADEMARKSOF THEIR RESPECTIVE OWNERS.

THIS MANUALIS PROVIDEDWITHOUT EXPRESS REPRESENTATION

AND/ORWARRANTY OF ANY KIND.

PLEASE CONTACTI NDIGOVISIONLIMITED (EITHERBY POST OR BY E-

MAILAT PARTNER.SUPPORT@INDIGOVISION.COM)WITH ANY

SUGGESTED CORRECTIONSAND/OR IMPROVEMENTST OT HIS

MANUAL.

CONTACT ADDRESS

CHARLESDARWIN HOUSE,

EDINBURGH TECHNOPOLE,

EDINBURGH, EH260PY, UK

FURTHER INFORMATION

FOR FURTHERINFORMATION, SEE THE USER GUIDE:

YOUCAN DOWNLOADA COPY FROM:

WWW.INDIGOVISION.COM/XF-HD-PTZCAMERA-QUICKSTARTGUIDE

ALTERNATIVELY, SCANTHE QRCODEBELO W.

PACKAGE CONTENTS

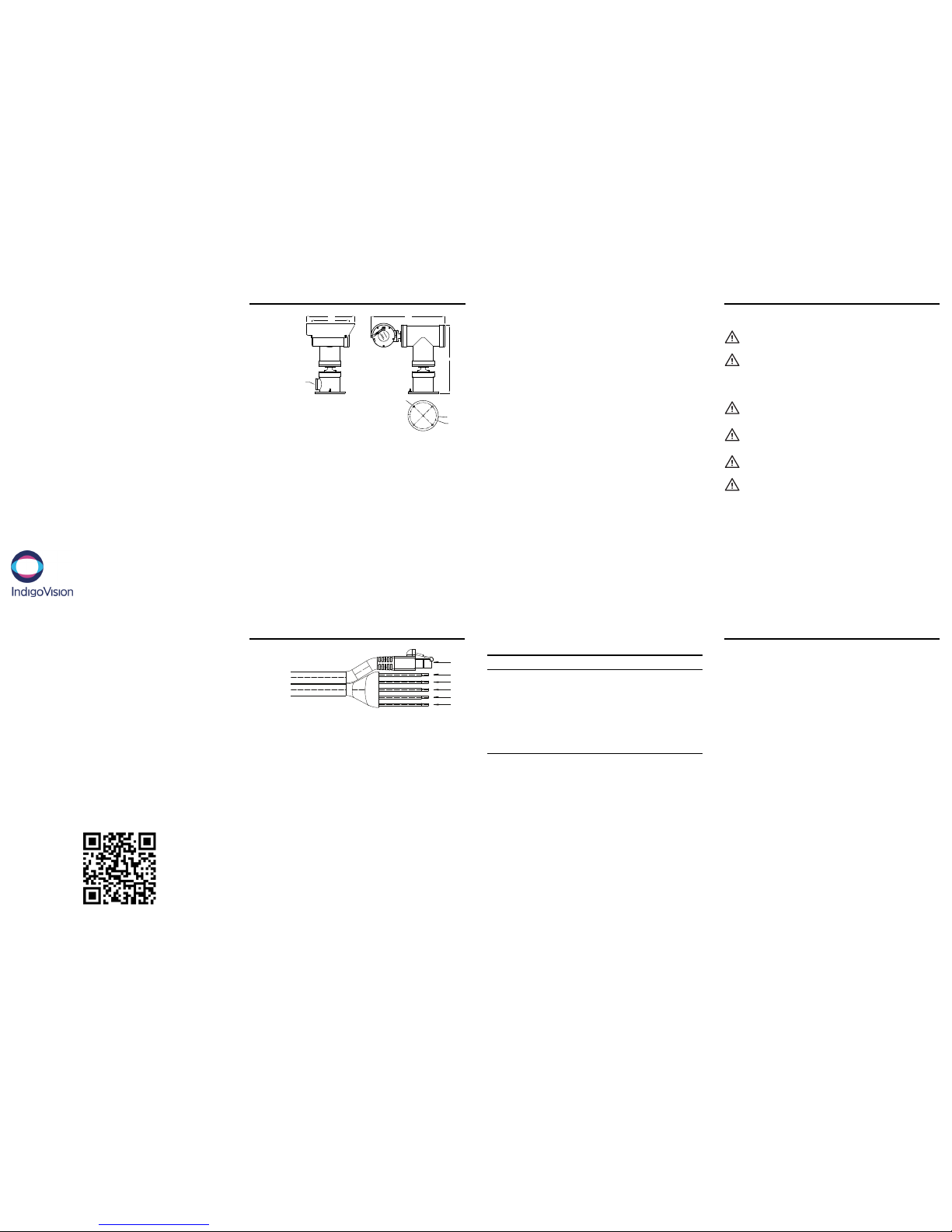

Ø210

Ø182

M25 CA BLE

ENTRY

Ø11

512

475

334

260

Camera

• 1 xM25

• FlexibleCond uit(AT EX,IEC Exand INMET ROmod elsonly)

• Cable Bundle( UL and CSA modelsonly)

Additional items

• Sunshieldand fixings

• IndigoVisionlogo stickersfor sunshield

• Envelopecontaining ATEX Technical Manualsand wiring

diagrams

SAFETY INFORMATION

Warning

Ensure the power supplyis switched off during installation.

When installing the camera, fasten it securely to the surface. A falling

camera may causeper sonalinjury.

Caution

Onlyinstall insuitable environments. For more information, see the Atex

TechnicalManua ls.

Handle the camera with care so the mainelectronics and components

are not damaged.

For security reasons, you must change the camera's default username

and password.

Ensure each camera hasa unique IPaddress.

Notices

Use only hex socket head fasteners with property class of A4-7 0

for securing end coversand shafts to housing.

Read thisgu idebefor einstalling the camera.

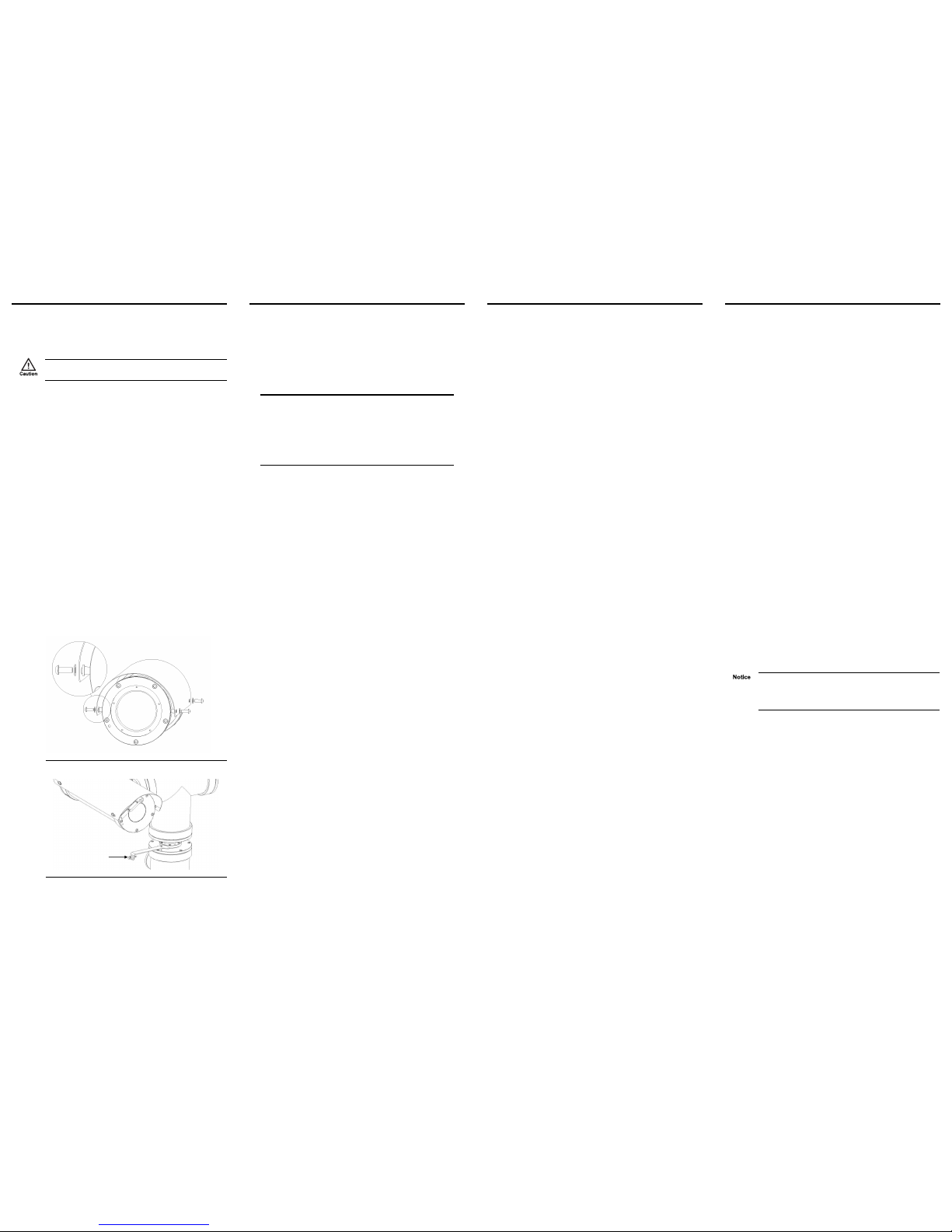

CONNECTIONS

1

2

3

4

5

6

Pin connections

Pin nu mber Type Descriptio n

1 CAT5 Multicore Ethernet connection

2 Green/Yellow Earth

3 Blue 24V AC (120W/5A) Common

4 Brown 24V AC (120W/5A) Live

5 Violet 24V AC Outputfo r water pump

6 Yellow 24VAC Pump Common

Document ID: IU-PTZ -MAN014-1

REGULATORY

Regulatory information is marked on the silver reg ulatory label

applied to r ear face of the camera. The regulatory approvals

appliedto the camera include one or more of the following

standards:

• EN60079-14:2008

• IEC60079-14:2007

• UL1203 (2006)

• UL 60065 (Edition 7)

• CAN/CSA-22.2 No 60065- 03( 2012)

• CAN/CSA-22.2 No 30 M1986 (2012 )

• CAN/CSA-22.2 No 25-1 966( 2009)

• INMETRO

• No modificationsmust be made to the flamepaths ofth eunit

without consultationof the drawings listed.

• Temperatur escould exceed 700C at the cablegland or 800C

at the branching point,suitably rate cable mustbe selected.

• No electromagnetic or ultrasonicradiating equipment to be

fitted intothe enclosures. However, a fibre optic transmitter

may bef itted,the output fr omw hichmust always be routed

out of the enclosurevia armoured cable or conduit and must

be terminated within asuitably certified enclosureor in a safe

area.

• A routine overpressure test inaccordance with IEC 600791:2007 Clause 16.1 shallbe carried out on allen closures,

Includingall cemented window assemblies,at a pressure of

27.3 Bar for a period of between 10 and 60 secondsand must

be recorded. There shall be no deformation or damage to the

enclosuresand no leakage through the cement of any of the

window assemblies.

1. POWERING UP THE CAMERA

The camera power req uirements are 24V AC (±10%) with a

maximum power of 120 Watts.

The camera should only be power ed from the specified voltage.

No allowanceis made for a varying voltagesupply.

Applyingthe incorrect power supplyvoltage will causeir reparable

damage to the unit.

Figure 1 Sunshieldinstallation

Figure 2 Washer nozzleinstallation

2. CONFIGURING THE CAMERA

Before you connect the camer a to your networ k, you must

configure the camera's IPaddressand subnet mask

appropriately.

Configure the network settings

1. Connectt hecamer a toa PC using an Ethernet crossover

cable.

2. Navigateto the camera's default IP address usinga web

browser, and enter the default user name and password.

Default Username Admin

Default Password 1234

Default IP Address 10.5.1 .10

Default Subnet Mask 255.0.0.0

Default Gateway 10.0.0.1

3. Enter the NTP server on the Date & Time menu.

4. Enter a new IPaddr essand subnet mask on the Network

menu.

Configure the serial port

The camera is configured bydefau lt to appear as a PTZ camera

within Control Center.

The serial communications between the internal camera and the

enclosure isconfigured as RS485 PelcoD at2400bp s. The serial

port controls the Wash/Wipe and Pan/Tilt functions within the

ATEX enclosure.

Configure the Wipe and Wash

By default Wipe and Wash commands are saved as Presets 86

(Wipe) and 87 ( Wash). T hese appear in C ontrol Center as the

first two Presets available. If these Presets are deleted or

overwritten they can be r estored by accessing the Preset section

on the camera configuration page.

The wiper is configured tow ipefor 3 wipes then automaticallystop

on RECALL of Preset 86.

On RECALL of Preset 87 the switched output ( Wash) willactivate

for 5 seconds.

3. INSTALLATION

Sunshield install ation

The sunshield issupplied uninstalled to pr event damage during

shippingand unpacking. They are supplied with a protective white

filmthat must be removed prior to installation.

To mount the sunshield, position it correctly and fix with a nylon

spacer between the sunshield and the camera housing. The M6

A4 button head screws supplied must have t he red fibr e washer

fitted before fixingthe sunshield.

Washer nozzle installation

A suitable washer nozzle and mounting bracket may be fitted

during installation. T he washer nozzle should be positioned to

allowcleaning fluid to reach the camera housingwindow w henth e

wash command issent.

The wash command is configured as Preset 87 and can be saved

with a suitablename within the camera configuration pages.

Electrical installation

Electrical installation and servicing should only be carried out by

qualified service personnel and in accordance with all

local/nationalcodes of practiceand standar ds.

This guide only covers the standard installation. For de tailed

connection and configuration, refer to individual pr oject specific

drawings and information.

► For more information, refer to the ATEX TechnicalM anuals

and wiring diagrams.

• Alwaysuse color-coded conductors or other identificationof

conductors for easeo fw iringand identification.

• Keep a wiringd iagram withth esystem for later use and

reference.

• Provisionis made for one cable entry, att hebase mount of

the pan tilt.

• To maintain the certificationrequirements of the unit all

cables/conduitsmust be fitted atth eentr y,w ithcertified Exd

Flameproof, compound filled barrier glands, either brass,

nickelplated or stainlesssteel.

• The cable entry toth eunit is M25 x1 .5ISO thread, or M 20

usingan Exd certified reducer.

• A minimumof 10mm depth of engagemen tmust be

maintained for allglands.

• Allglands/reducers must be ingress protected to IP67 or

better, to maintain the weatherproof rating of the equipment.

• For maintenance purposes, consultthe separat elysupplied

additionalwiring dra wingsspecificto the unit.

4. OPERATIONS

This chapter describes common tasks r equired for the operation

of the ProductName.

Focus the camera using Control C enter

1. Addthe camera to the Contr olC enter sitedataba seensuring

you configureth eD evice Access credentials.

2. Right-clickthe camera in the Video Expl orer, select

Properties > Video an d Au dio, and selectthe appr opriate

Profile Token and Connection.

3. Right-clickthe camera in the Video Expl orera ndselect View

Video.

4. Inthe main window, clickthe Co nfigu ration tab.

5. Navigateto Video > Basic and use the Zoo mand Fo cus

optionsto focus the camera.

Configuring the camera

1. Youcan access thecamer a configurationpages using the IP

address of the camera.

Alternatively,you can accessthese pages through

IndigoVisionContr olCente r.

2. InSet up view, selectthe camera you want to configure.

3. Selectthe Con figuratio n tab, and enter a validuser name

and password.

Maintenance

• Recommended inspectioninterval - 6 months.

• Fixingsand fastenings should bechecked for tightness and

integritya tr egular intervals.

• Allcable entries and cablesshould be checkedfor integrityat

regular intervals.

• Clean the unit.

• Check the‘O’ ring weather seals and replace ifnecessary.

• Replace 'O'rings every 5 years.

• Check andif necessary replace the washer nozzle.

• Check andif necessary replace the window wiper blade.

Cameras operating in extremely harsh environmentsmay requ ire

more fr equent inspection and maintenance checks. Please read

and be familiarwith the instructions before servicingthe Pan/Tilt

or housing.

Corrision protection

Although all external metal components are produced from 316L

StainlessSteel, if the units ar e not corr ectlymaintained, hand led,

and cleaned re gularly there is the possibility of m ild discoloration

due to oxidation.

If ferrous metal equipmentis used when handling the units, small

ferrous deposits could be lefton thestainless steel, thiscan cause

accelerated cor rosion of the fer rous deposits and discolor the

unitsdue to oxidation.

In the eventof fer rous deposits,the units shouldbe cleaned

immediately.

In atmospheres that are high incorr osiveparticles the unitsshould

be cleanedever y3 to 4 months.

Loading...

Loading...