Index Braille EVEREST Series User Manual

Verson 8.20/9.20

Manual Index Everest

Table of contents

January 2000

1. Unpacking 3

1.1 Unpacking instructions 3

1.2 Unpacking checklist 4

1.3 Safety instructions 4

2. Before start printing 5

2.1 How to use this manual 5

3 Operating the printer 5

3.1 How to start up 5

3.1.1 Loading paper 5

3.1.2 Document guide position 6

3.1.3 Paper support position 6

3.1.4. Paper length setting 6

3.1.5 Paper sensor calibration 6

3.1.6 Computer connection 6

3.1.7 Serial communication cable 6

3.1.8 Communication parameters 6

3.2 Front panel 7

3.2.1 Start embossing 7

3.3 Default setup 7

3.4 Setup 7

3.4.1 Number of printed pages 7

3.5 Flow schematic for Setup 8

4 The sheet feeder 9

4.1 General function 9

4.2 Paper quality 9

4.3 Loading the sheet feeder 10

4.3.1 Random double-feed 11

4.3.2 No paper feed. 11

5. Front panel 12

5.1 Standard commands 12

5.1.1 On/off line 12

5.1.2 Form Feed 12

5.1.3 Help 12

5.2 Print mode 13

5.2.1 Double sided 13

5.2.2 Single sided 13

5.2.3 Normal 13

5.2.4 Reformatted 13

5.2.5 Split page 14

5.3 Copy 14

5.3.1 Multiple 14

5.3.2 Repeat 14

5.3.3 Load buffer 14

6. Setup commands 15

6.1 Default setup = A/B/C 15

6.2 Setup 15

6.2.1 Change Setup 15

6.2.2 Setup keys 15

6.2.2.1 Group 15

6.2.2.2 Item 15

6.2.2.3 Value 15

6.2.2.3.1 Page layout information 15

6.3 Change Setup 16

6.3.1 Braille code 16

6.3.2 Serial communication 16

6.3.3 Page layout 16

6.3.3.1 Characters per line 17

6.3.3.2 Left margin 17

6.3.3.3 Binding margin 17

6.3.3.4 Top margin 17

6.3.3.5 Bottom margin 17

6.3.3.6 Line distance 17

6.3.3.7 Page mode 17

6.3.3.8 Print mode 17

6.3.3.9 Page number 17

6.3.3.10 Page layout Guideline 18

6.3.4 Options 18

6.3.4.1 Word wrap 19

6.3.4.2 Auto line-feed 19

6.3.4.3 Form Feed 19

6..4.4 Volume 19

6.3.4.5 Impact level 19

6.3.4.6 Delay time 19

6.3.4.7 Print quality 19

6.3.4.8 Graphic dot distance 19

6.3.4.9 Text dot distance 19

6.3.4.10 Set up 19

Sir N D:\PM-filer\Manualer\Edeng810.P65

Index Braille

Page 1

January 2000 Verson 8.20/9.20

Manual Index Everest

7 Support CD 20

7.1 CD contents 20

7.2 Start the CD 20

7.3 WinBraille system 20

7.3.1 Install WinBraille 21

7.3.2 Install printer driver for WinBraille 21

7.4 Embosser software installation. 22

7.4.1 Firmware upgrade 22

7.4.2 Select language 22

7.4.3 Set embosser in upgrade mode 23

7.4.4 Firmware transfer 23

7.4.5 Software Installation from CD. 24

7.4.6 Support Software for Everest 24

7.4.7 Paper sensor calibration 24

7.5 WinBraille 25

7.5.1 Start WinBraille 25

7.5.2 Register WinBraille 25

7.5.3 Upgrade WinBraille 25

8 Control sequences 26

8.1 Pro-printer emulation 26

8.2 Defined codes 27

8.3 ESC Sequences - Index commands. 27

8.4 VersaPoint graphic 27

8.5 Multiple copies selection by

ESC sequences 27

8.6 Changes in setup from computer 28

8.6.1 Change setup by ESC-sequences 28

8.7 Page numbering selection by

ESC sequences 31

8.8 Remaining copies to print 31

8.9 Transparent mode 31

8.10 Power on commands 32

8.10.1 Self test 32

8.10.2 Factory setting 32

8.10.3 Transport mode 32

8.10.4 Upgrade mode 32

8.11 Fault messages 33

8.11.1 Failure "No reference-pulse" 33

8.11.2 Failure Paper length fault 33

8.11.3 Failure Paper jam 33

8.11.4 Failure 140 - invalid setup command33

8.11.5 Failure invalid setup value 33

8.11.6 Failure 160 - EEPROM failure 33

8.11.7 Failure 170 - Printer buffer exceeded 33

9 Serial communication cables 33

9.1 Serial cable Everest-IBM 33

10. ASCII-table 34

Index 35

Page 2

Index Braille

Verson 8.20/9.20

Manual Index Everest

INDEX EVEREST

Interpoint Braille Embosser

USER manual

January 2000

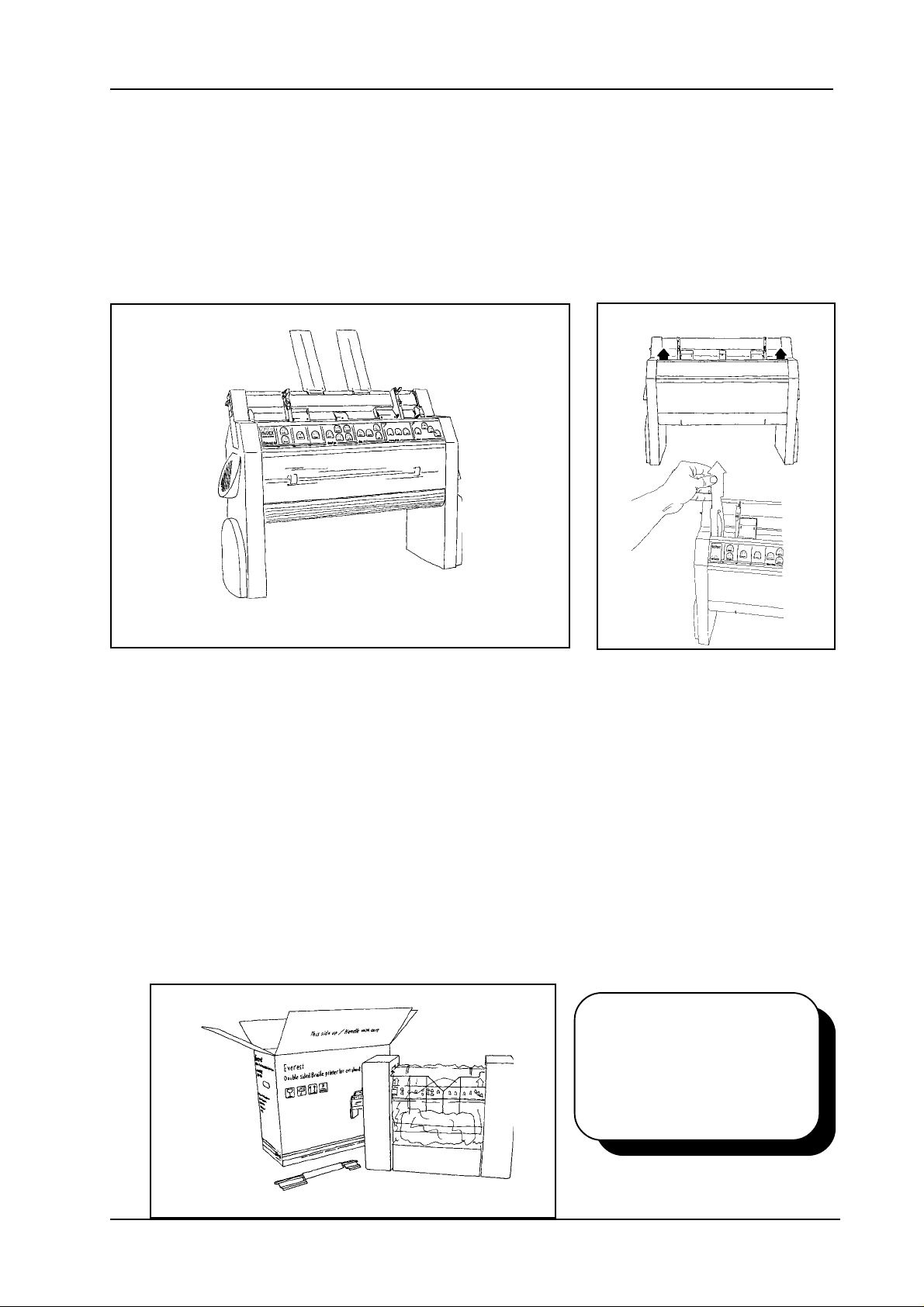

1. Unpacking

1.1 Unpacking instructions

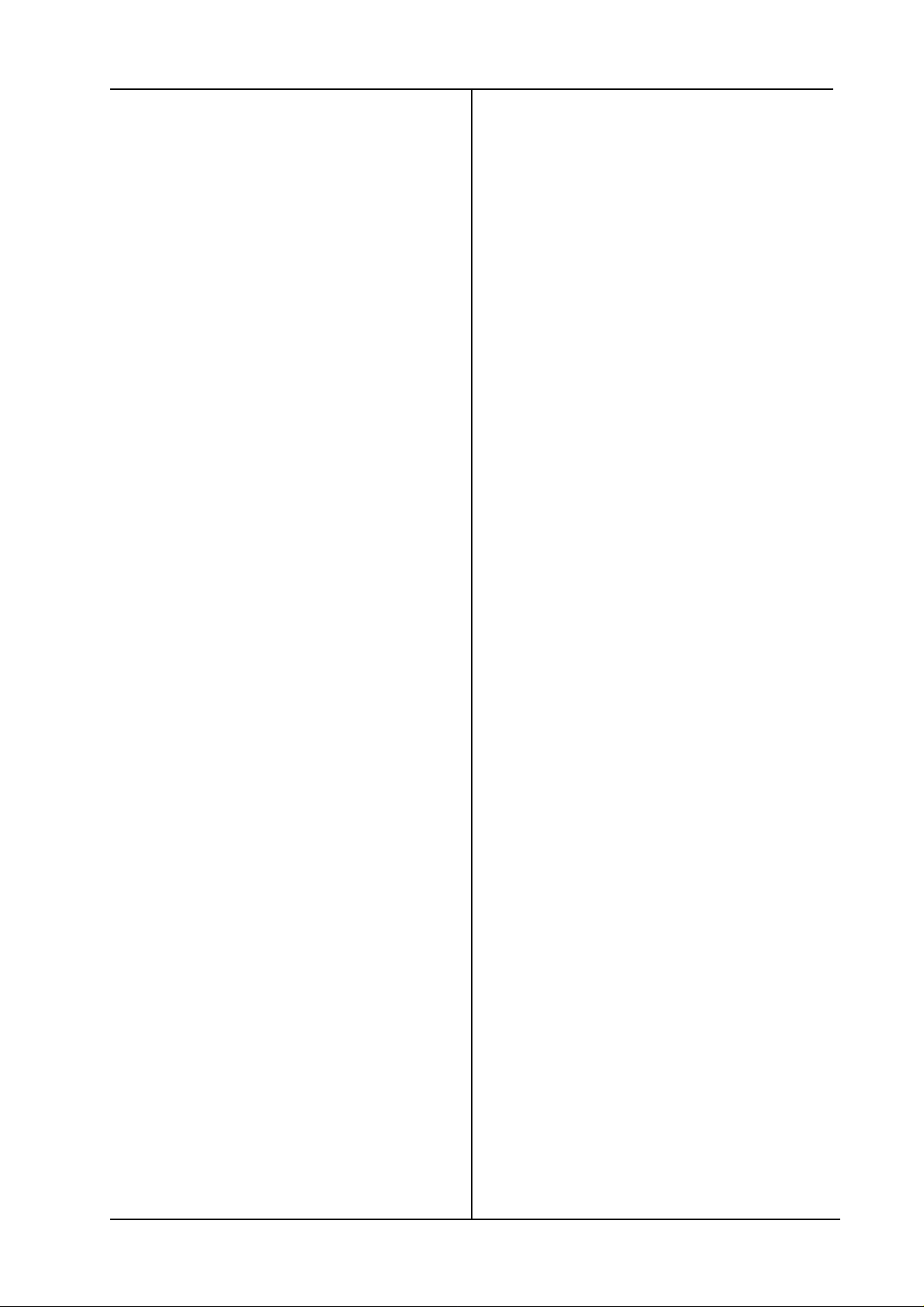

Take the printer up from the box. Remove the two print-head transport locking, red coloured

plastics, placed inside the sheet feeder. Save the transportation material.

Note! When shipping the printer, it is important to replace the printing head lockers and use the

original packing!

Before installing the printer make sure that there is no visible damage to the printer and that the

delivery is complete. If you encounter any problems, contact your dealer.

PLEASE DO

NOT DISCARD

THE ORIGINAL

PACKAGING.

Index Braille

Page 3

January 2000 Verson 8.20/9.20

Manual Index Everest

1.2 Unpacking checklist

Index Everest Braille Embosser

Cables

Paper Supports and Sound cover

Everest user manual ink print

Installation CD

Braille paper

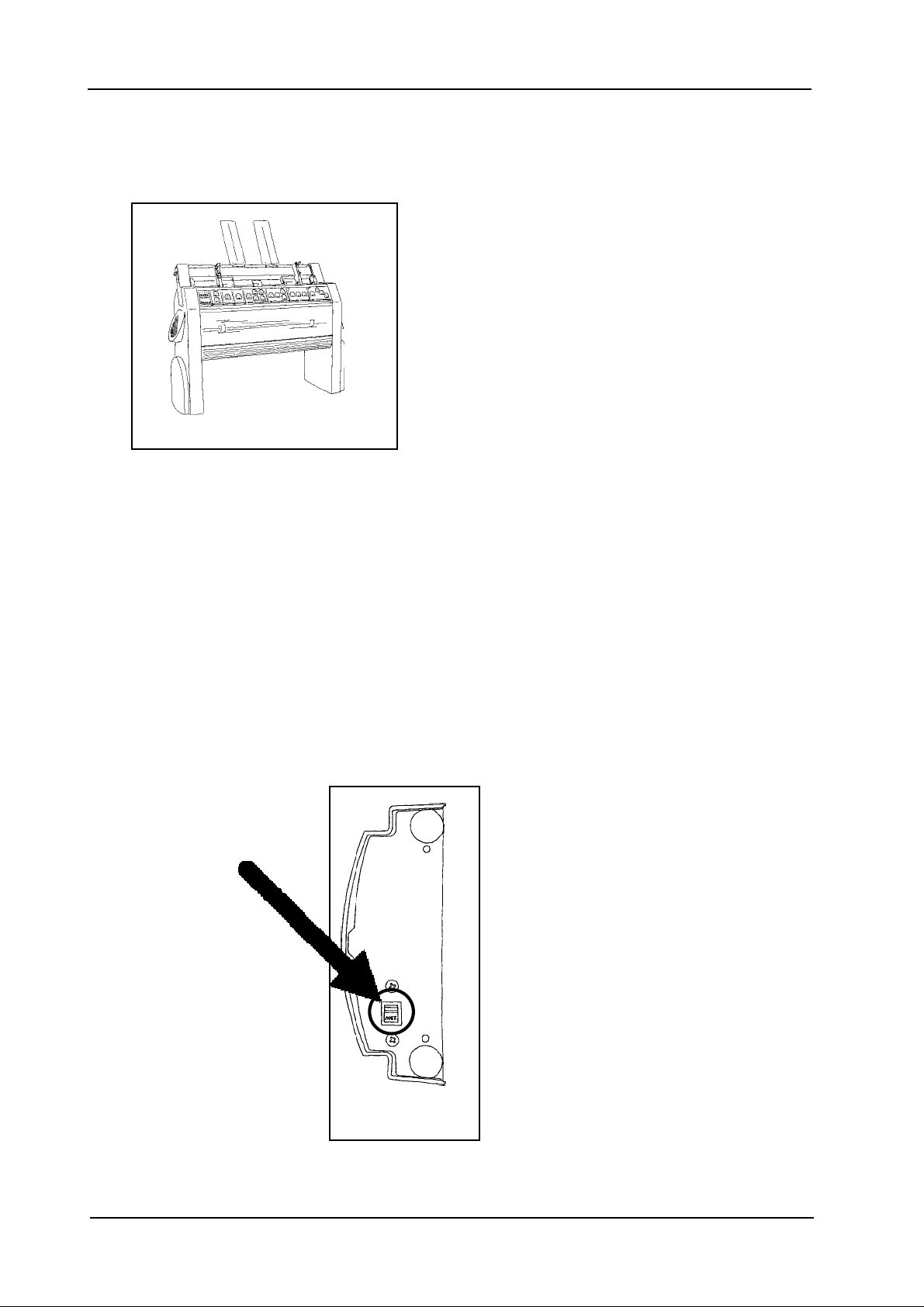

1.3 Safety instructions

Before power on, make sure that the voltage selection switch is set for the

correct value. The switch is located under the left leg of the printer.

Page 4

Index Braille

Verson 8.20/9.20

Manual Index Everest

January 2000

2. Before start printing

2.1 How to use this manual

This manual is organised in 10 chapters.

Chapters 1-3 contains basic information install the printer.

We recommend that you read these chapters before you start the printer.

Chapters 4-7 includes detailed information about the different functions of the Everest.

Chapter 8 is an appendix of ESC control sequences.

Chapter 9 contains information about different communication cables.

Chapter 10 is a complete ASCII table based on the IBM 437 standard table.

3 Operating the printer

3.1 How to start up

3.1.1 Loading paper

1. Release the pick-up rollers, by moving the control on the button on the side of the sheet feeder

upwards and fill it with paper.

2. Adjust the paper margins guides in the sheet feeder to the correct paper width and lock them,

with the lever on the top of each margin guide.

3. Set the Sheet/card selectors, located on the front of the paper margin guides in the correct

position. When using a more stiff paper like Braille paper, the sheet feeder should be in the

lower, card position, and when using softer paper like copy paper, the sheet feeder should be in

the upper, sheet position.

4. Do not overfill the paper magazine. Leave a space between the paper bin and the pick-up

rollers of about 1-2 mm before closing it.

Sheet / Card

selector

Open/close

sheetfeeder

Index Braille

Page 5

January 2000 Verson 8.20/9.20

Manual Index Everest

3.1.2 Document guide position

On the lower edge of the front panel cover there are two plastic document

guides. The correct position for these is to be lined up with the margin

guides and follow the side edges of the sheet, in order to lift the paper to

the correct position in the document stack.

Note! If the document guides are too close to the center or used together

with a stiff type of paper, it can cause paper jam.

3.1.3 Paper support position

The paper supports is used to keep the paper straight position to avoid multiple feeds.

On the top of the sheet feeder, there is a slot for the paper supports. Place the paper supports and

press them down into the slot so they are properly fixed and positioned at the margins of the

paper.

3.1.4. Paper length setting

The standard paper length for Everest is A4 (297 mm). If a paper with a different length should

be used, change the default paper length value by pressing the Form Feed. The printer will feed

one sheet of paper, in order to measure it and store the new value in the memory. The new length

will be stored until the next time the Form Feed key is pressed. Everest accepts all paper lengths

between 100-350 mm (4-14 Inch).

3.1.5 Paper sensor calibration

If the type of paper is changed, e.g. from a thick to a thin paper or from a dark to a light coloured

paper, the paper sensor has to be re-calibrated. Please refer to chapter 7.1.5, item A, B and C to

perform the paper calibration process.

The command to start the paper sensor calibration is ITEM + Power on.

3.1.6 Computer connection

Connect Index Everest to the computer with the Serial or Centronics interface. In stand-by mode,

both ports are open to recieve information.

3.1.7 Serial communication cable

Everest is equipped with a 9 pin female (D-sub) on the serial interface, and a standard centronics

connector for the centronics interface.

Serial Pin configuration:

2=RXD in, 3=TXD out, 4=DTR out, 5=GND, 6=DSR in, 7=RTS out, 8=CTS in.

Transmitting parameters (factory setting) are:

Baud Rate=9600, Data Bits=8, Parity=N, Stop Bits=1, Handshake=DTR hardware handshake.

3.1.8 Communication parameters

The communication parameters on the serial-port and centronics port on your PC are normally

set with the following command in the AUTOEXEC.BAT file.

MODE COM1:9600,N,8,1,P

MODE LPT1:,,P

Page 6

Index Braille

Verson 8.20/9.20

Manual Index Everest

January 2000

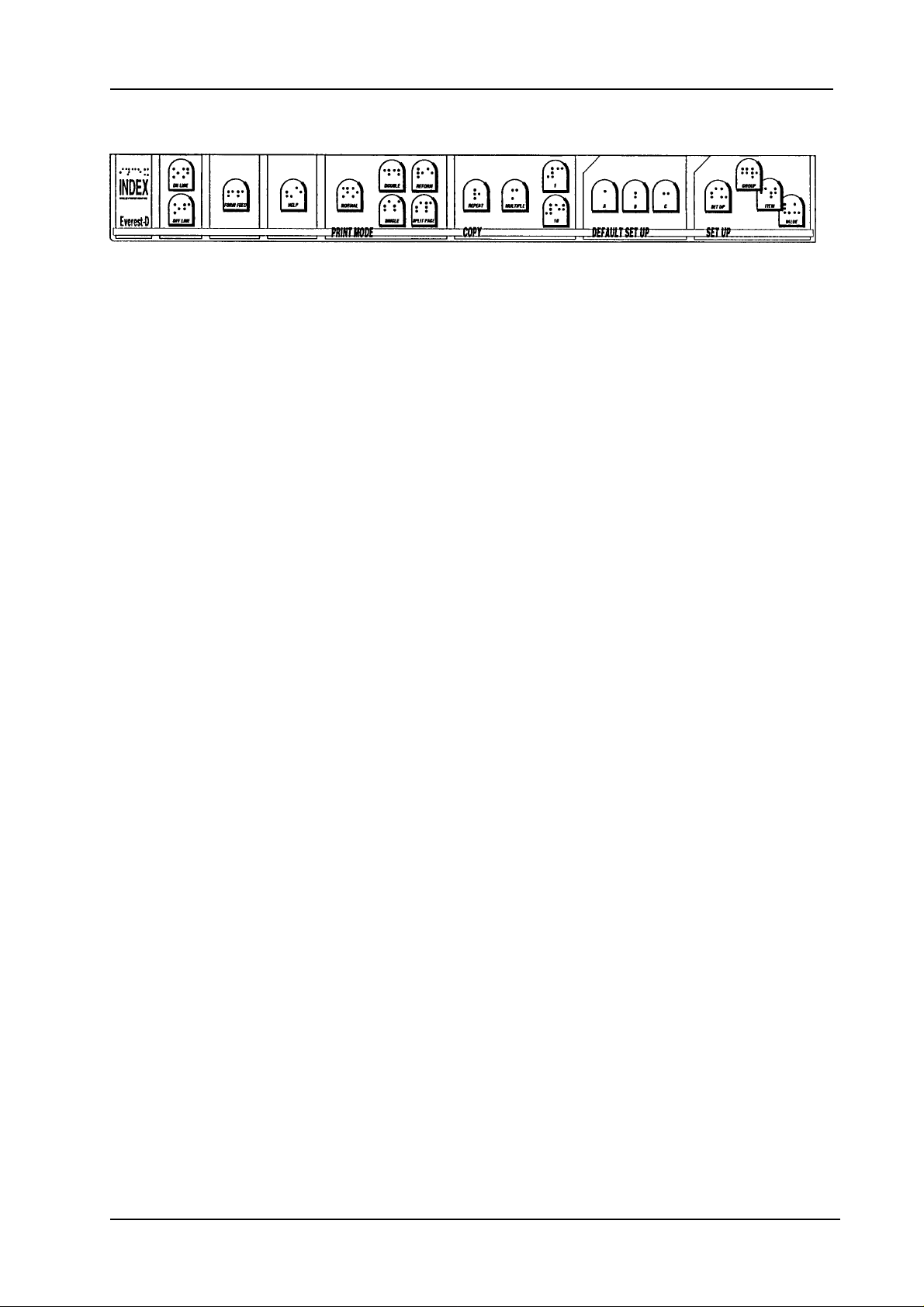

3.2 Front panel

The control panel and user logic on the Everest is designed to make the use and installation of

the printer as easy and efficient as possible. All the keys are marked both in Braille and ink print,

and organised in clearly marked modules. The user is guided by digitised speech.

Note! WinBraille will overtake all commands from the front panel. The commands on the front

panel are applicable only when the embosser is connected to a DOS operated computer or

together with a Braille editor working in Windows, controlling the embosser with a text based

driver, e.g. Duxbury.

3.2.1 Start embossing

Connect the printer to your computer, load the paper and turn it on. Everest is ready for use with

the default factory settings.

3.3 Default setup

To change the active default setup, press the DEFAULT SETUP KEY A, B or C. Each setup can

be individually set for different user preferences.

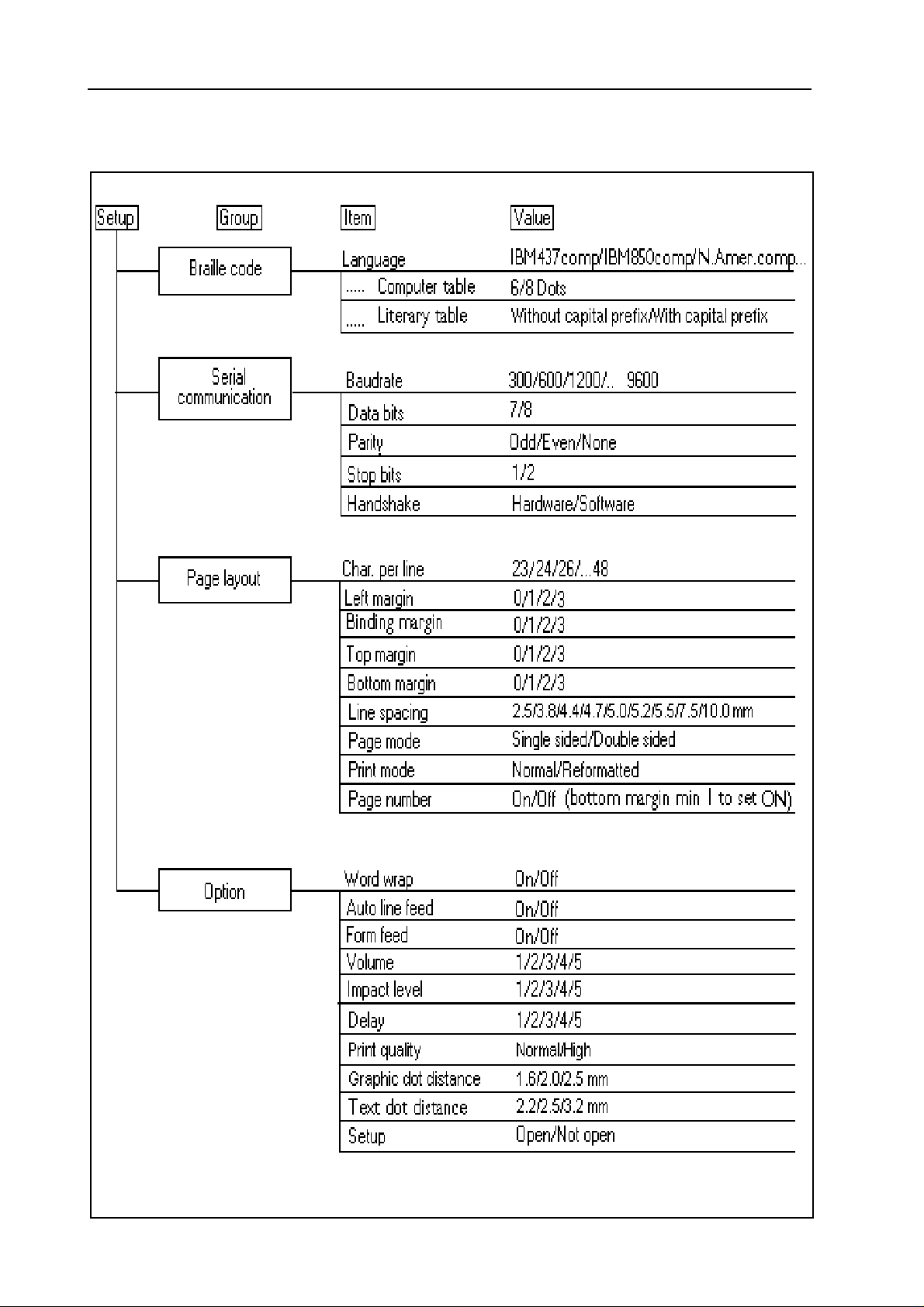

3.4 Setup

If you need to change the setup parameters use the front panel.

To start the setup sequence press SETUP. In setup mode you can change and save all parameters

in the group: BRAILLE CODE, SERIAL COMMUNICATION, PAGE LAYOUT and OPTION.

3.4.1 Number of printed pages

Press the key ITEM in stand by mode to get a spoken message of the total number of printed

pages.

Index Braille

Page 7

January 2000 Verson 8.20/9.20

Manual Index Everest

3.5 Flow schematic for Setup

Page 8

Index Braille

Verson 8.20/9.20

Manual Index Everest

January 2000

4 The sheet feeder

4.1 General function

The sheet feeder is designed to use paper in the weight range of 70-200 gsm. (grams per square

metre) Perfect function (a fault frequency maximum 1/1000) requires a paper suitable for the

printer, and a correctly installed sheet feeder. The experience we have from thousands of

Everest’s on the market, indicates that 80% of all good quality paper works perfectly with the

Everest.

4.2 Paper quality

There are a number of different paper qualities on the market which are labelled “Braille Paper”.

Normally they are in the range of 70-180 gsm (20-100 Pound).

To determine if the paper quality is suitable for the Everest check the following details:

a) The paper is properly cut. There should be a smooth and even surface when you feel with your

finger along the cutting edge of the paper.

b) Never use separated fan fold paper. The edges of this paper are very bad and can result in

double-feeding, or not feeding at all.

c) The paper must be a clean, with no holes or perforations on the sheet. Holes and perforation

are normally made with a punch, and as a result sheets can “stick” together.

d) Check that the surface of the paper has a texture similar to normal copy paper. The roughness

of the surface affects the difference between gliding and standing friction and is necessary for

proper function. The paper should not have a shiny or glossy surface. (Similar to playing cards.)

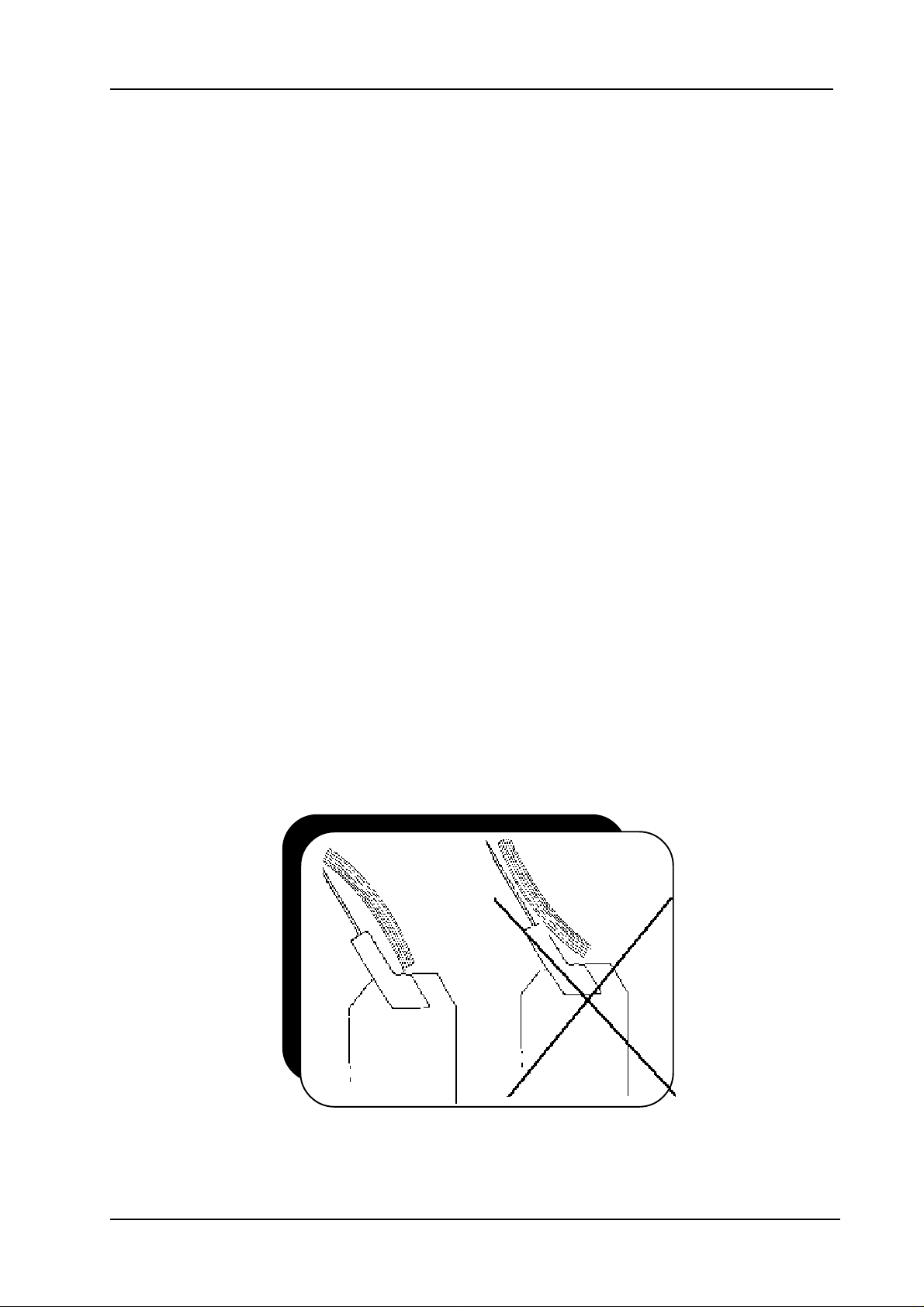

e) Ensure that the paper is flat and undamaged. If the paper is bent, it is important that the

curving of the paper is towards the front of printer. (See picture below)

f) Do not use dark coloured paper. It can interfere with the optical paper sensor.

Index Braille

Page 9

January 2000 Verson 8.20/9.20

Manual Index Everest

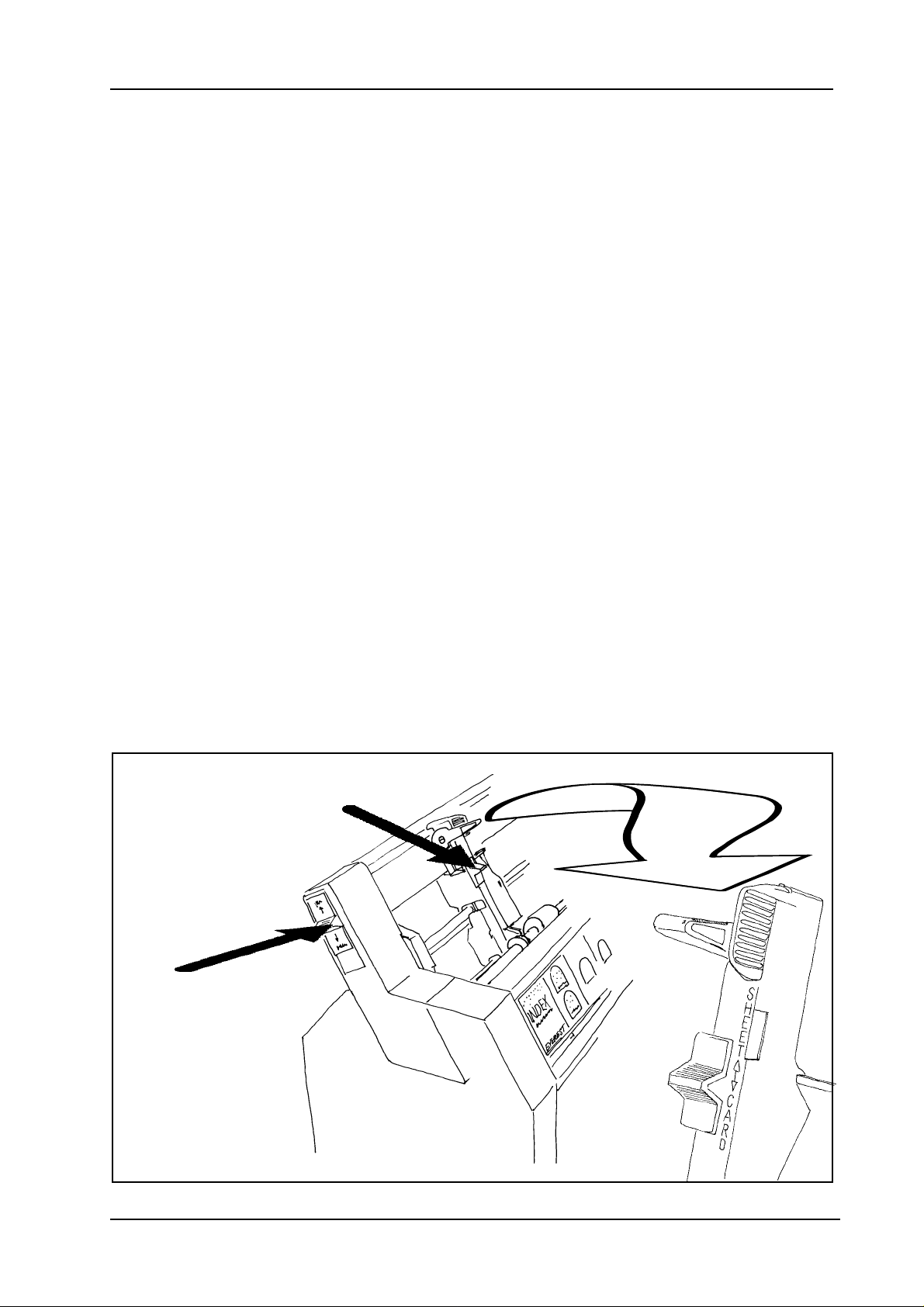

4.3 Loading the sheet feeder

a) Set the right margin guide to the correct position. To the right, if the margin is set by the

position of the paper, and to the left, if the margin is defined from the setup.

b) Open the sheet feeder with the button on the side of the sheet feeder.

Load the paper and move the left paper guide until is slightly touch the paper and lock both paper

guides properly.

Note that Everest prints the page up-side-down so that the right paper margin guide is against the

left side of the printed paper. (See picture below)

c) When loading the sheet feeder with paper, make sure it is not overfilled. For the best possible

function it is necessary to leave 1-2 mm free space between the pick-up rollers and the paper

stack before closing the sheet feeder.

d) Set the two paper supports close to the margins of the paper.

e) Adjust the two green DOCUMENT GUIDES at the lower part of the front panel so that they

touch about 5 mm of the paper when it leaves the printer. When using a stiff paper, or a paper

with a weight above 150 gram (90lbs) the document guides can be placed beside the paper.

f) Select card or sheet mode on the sheet feeder. CARD mode is normally for paper of 120-200

gsm, and SHEET mode for paper below this weight. Make sure that the CARD/SHEET selection

is set to the same position on both side of the paper.

Page 10

Index Braille

Verson 8.20/9.20

Manual Index Everest

January 2000

4.3.1 Random double-feed

With good quality paper and correct installation of the sheet feeder, a random double feed rate on

maximum 1/1000 must be accepted. If the fault frequency is higher we recommend that you

check the paper and installation against the following priorities. This following is a summary

from our experiences of a large number of Everest printers on the market.

a. To ensure a good paper quality look at the following details:

* Properly cut paper - never use separated fan folded paper

* There should be no binding holes or perforations on the paper

* The paper should have a rough surface (similar to copy paper)

* Paper should be flat and without damage

* Check that the card/sheet selectors are in the correct position. Test by changing between

sheet and card, using the same paper. We recommend use of the sheet position if it picks

up the paper properly.

b) To ensure good installation of the sheet-feeder, look at the following details:

* The margin guides should slightly touch the paper and be properly locked

* Are the card/sheet selectors in the correct position?

* The paper supports must be correctly installed.

c) To ensure good paper out control, look at the following:

*The document guides (green plastic) should be in the correct position, especially if light paper

is used. The correct position is about 5 mm from the side edge of the paper.

* If heavy Braille paper is used we recommend not using the document guides. Simply slide

them out from the paper area.

d) Avoid low humidity locations.

If the Everest is used in a room with low humidity, static electricity can cause the paper to

stick together. In this case we recommend an increase in the humidity and opening a new sealed

package of paper. Low humidity can also occur in a low temperature area or in an air

conditioned room.

E) Maintenance of the sheet feeder.

* We recommend a clean and rub up of the surface of the pick up rollers after 2,000-10,000

pages.

Clean the pick-up rollers with soft soap solution, or even more efficient is to carefully ruff up the

surface with a piece of fine sand paper. Hold the clutch against the pick up rollers when pressing

Form Feed key.

4.3.2 No paper feed.

The “no paper feed” situation can occur when the sheet position is used for heavy or very stiff

paper.

We recommend switching to CARD position and testing again. No feed can also be a result of a

combination of reasons such as; dusty pick-up rollers, damaged or holed paper and improper

paper installation of the sheet-feeder.

Index Braille

Page 11

Loading...

Loading...