Page 1

Built-in hobs

Instructions for use and installation

P 640 TC (IX) GB

Page 2

Built-in hobs

Instructions for use and installation

Page 3

Congratualtions on choosing an Indesit appliance, which you will find is dependable and easy to use. We recommend

D

that you read this manual for best performance and to extend the life of your appliance. Thank you.

Contents

Contents...................................................................................................................................................... pag 1

Close-up View ...............................................................................................................................................pag 1

How To Use Y our Appliance ........................................................................................................................ pag 1

How to Keep Your Cooktop in Shape.... ...................................................................................................... pag 2

Is there a problem? ..................................................................................................................................... pag 2

Safety Is a Good Habit to Get Into .............................................................................................................. pag 3

Instructions for the installer ......................................................................................................................... pag 3

Is there a problem? ..................................................................................................................................... pag 2

Safety Is a Good Habit to Get Into .............................................................................................................. pag 3

Instructions for the installer ......................................................................................................................... pag 3-4

Instructions for the installer ......................................................................................................................... pag 5-6

Burners and nozzles characteristics.............................................................................................................pag 7

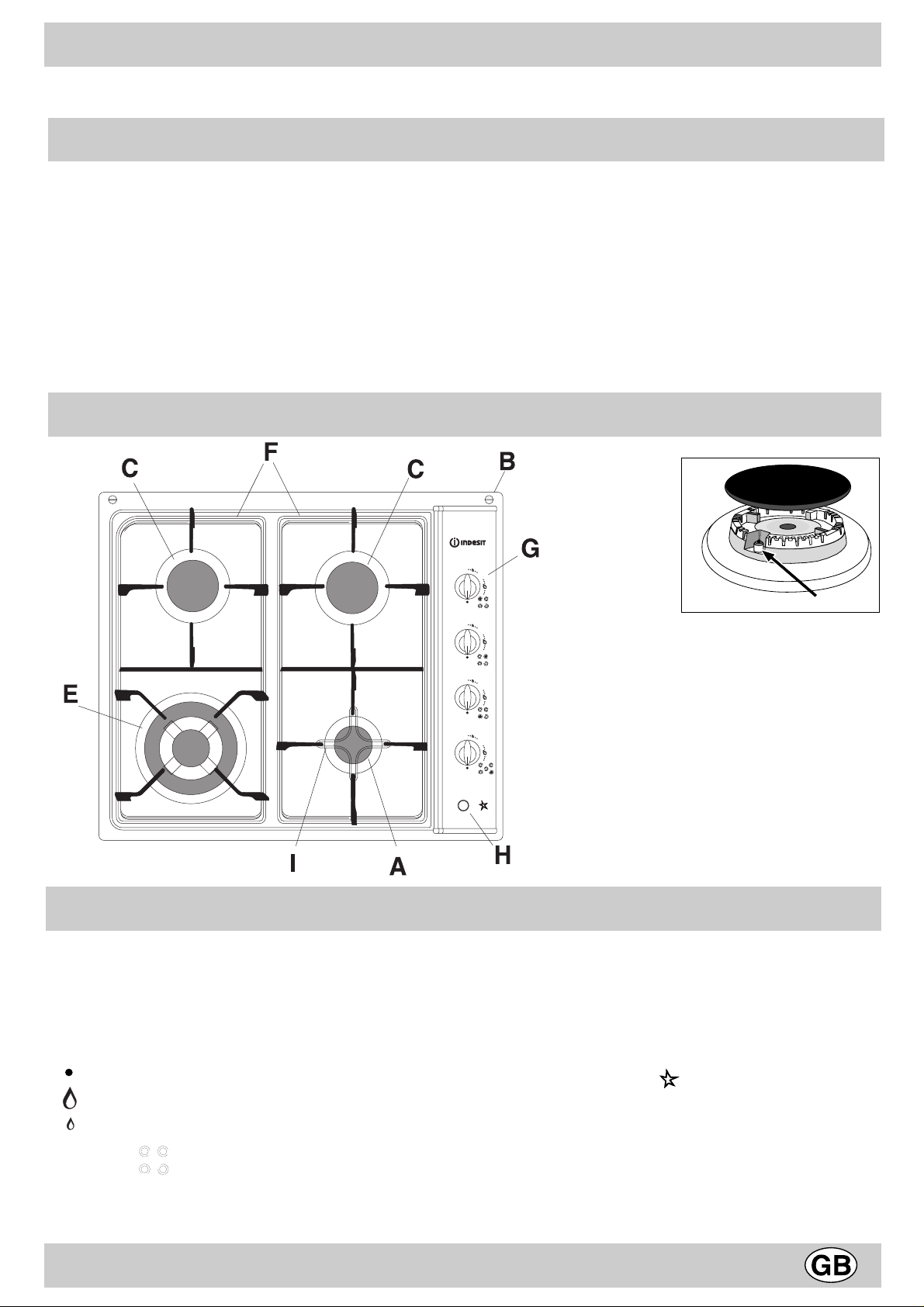

Close-up View

How To Use Your Appliance

Gas burners

The burners differ in size and power. Choose the most

appropriate one for the diameter of the cookware being used.

The burner can be regulated with the corresonding control

knob by using one of the following settings:

Off

High

Low

The symbols near the knobs also show the position of

the relative burner on the hob.

A Auxiliary gas burner

B Hooks

C Semi-fast gas burner

D Ignitor for Gas Burners

E Triple ring gas burner

F Support Grid for Cookware

G Control Knobs for Gas Burners

H Ignition Pushbutton for gas burners

I Pan reducing support

Lighting the burners

Automatic ignition "D":

• turn the relative knob counter-clockwise until the pointer

is on the high-flame symbol;

• press the automatic gas ignition by pushing the button

marked with the symbol ;

• Checking that the flame is stable. If it is not, repeat the

operation.

For minimum power, turn the knob towards the low flame

symbol. Intermediate positions are possible by putting the

knob anywhere between the high and the low flame symbol.

1

Page 4

To turn off the burner, turn the knob clockwise to the off

position “ “ .

• Difficulty in ignition is sometimes due to air inside the gas

duct.

• When the equipment is not in operation, check that the

knobs are in the off position “ “ . The main gas supply cutoff cock should also be closed.

Practical tips for using the burners

T o obtain maximum efficiency from the burners, it is advisable

to use only pans with a diameter that is suitable for the

burner being used, so that the flame does not extend beyond

the pan base (see following table).

When a liquid starts boiling, it is advisable to turn the flame

down just enough to keep the liquid simmering.

How to Keep Your Cooktop in Shape

renruB .mcninapehtforetemaiD

)llams(AyrailixuA41ot6morf

)muidem(Stsaf-imeS02ot51morf

)egral(TgnirelpirT03ot12morf

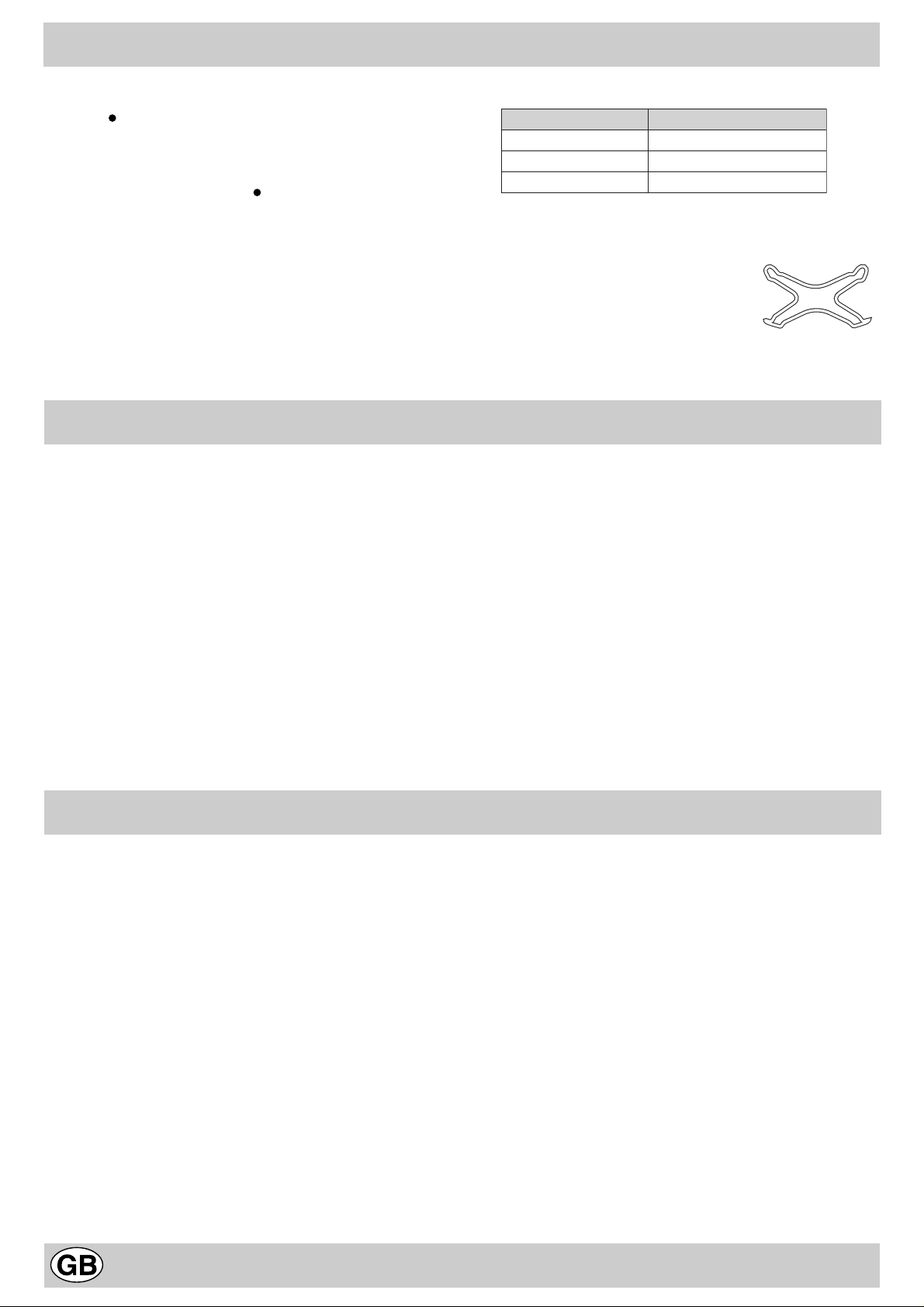

The hob is fitted with pan reducing

support (fig.1), which should only be

used on the auxiliary "A" burner (small).

fig.1

Before cleaning or performing maintenance on your

appliance, disconnect it from the electrical power supply .

To extend the life of the cooktop, it is absolutely

indispensable that it be cleaned carefully and thoroughly

on a frequent basis, keeping in mind the following:

• The enameled parts and the glass top, if present, must

be washed with warm water without using abrasive

powders or corrosive substances which could ruin them;

• The removable parts of the burners should be washed

frequently with warm water and soap, making sure to

remove caked-on substance. Check that the gas outlet

slits are not clogged. Dry the burners carefully before

using them again.

• Frequently clean the end part of the automatic glow plugs

of the hob.

• The steel parts and especially the areas with the screen-

Is there a problem?

It may occur that the cooktop does not function or does not

function properly. Before calling customer service for

assistance, lets see what can be done.

First of all, check to see that there are no interruptions in

the gas and electrical supplies, and, in particular, that the

gas valves for the mains are open.

The burner does not light or the flame is not uniform

around the burner.

Check to make sure that:

• The gas holes on the burner are not clogged;

• All of the movable parts that make up the burner are

mounted correctly;

• There are no draughts around the cooking surface.

The burner does not remain on when set to "Low".

Check to make sure that:

• The gas holes are not clogged.

• There are no draughts near the cooking surface.

• The minimum has been adjusted correctly (see the

section entitled, "Minimum Regulation").

printed symbols should not be cleaned with diluents or

abrasive detergents. It is advisable to use only a a damp

cloth with tepid water and a liquid detergent;

• Avoid cleaning appliance parts when they are still warm;

• Avoid leaving acidy liquids (vinegar, lemon juice, aggressive detergents, etc.) on enamelled or painted parts;

Greasing the Gas Valves

Over time, the gas valves may stick or become difficult to

turn. If this is the case, they must be cleaned on the inside

and then regreased.

Important: This procedure must be performed by a

technician authorized by the manufacturer.

The cookware is not stable.

Check to make sure that:

• The bottom of the cookware is perfectly flat.

• The cookware is centered correctly on the burner or

electric hot plate.

• The support grids have not been inverted.

If, despite all of these checks, the cooktop does not function

properly and problem persists, call the nearest Merloni Elettrodomestici Customer Service Centre, informing them of:

- The type of problem.

- The abbreviation used to identify the model (Mod. ...) as

indicated on the warranty .

Never call upon technicians not authorized by the

manufacturer, and refuse to accept spare parts that are not

original.

2

Page 5

Safety Is a Good Habit to Get Into

• This manual is for a class 3.

• This appliance is designed for non-professional use in

the home and its features and technical characteristics

must not be modified.

• The electrical system of this appliance is safe only when

it is correctly connected to an adequate earthing system,

as required by current safety standards.

Prevent children and the disabled from coming into

contact or having access to the following, as they are

possible sources of danger:

- The controls and the appliance in general;

- The packaging (plastic bags, polystyrene, nails, etc.);

- The appliance, during and immediately after use given

the heat generated by its use;

- The appliance when no longer in installed (in this case,

all potentially dangerous parts must be made safe).

The following should be avoided:

- Touching the appliance with wet parts of the body;

- Using the appliance with bare feet;

- Pulling on the appliance or the power supply cord to

disconnect them from the electrical outlet;

- Improper and/or dangerous use;

- Obstructing the ventilation or heat dissipation slots;

- Allowing the power supply cord of small appliances to

come into contact with the hot parts of the cooktop;

- Exposure to atmospheric agents (rain, sun);

- Using flammable liquids nearby;

- Using adaptors, multiple outlet plugs and/or extensions;

- Using unstable or deformed cookware;

- Leaving the electric hobs on without cookware on top of

them;

- Closing the glass top (if present) while the gas burners

are still hot;

- Trying to install or repair the appliance without the

assistance of qualified personnel.

The assistance of qualified personnel must be called

upon in the following cases:

- Installation (in accordance with the manufacturer's

instructions);

- When in doubt about the operation of the appliance;

- Replacement of the electrical outlet becuase it is

incompatible with the plug.

Contact service centers authorized by the manufacturer

in the following cases:

When in doubt about the condition of the appliance after

having removed the packing;

- Damage to or replacement of the power supply cord;

- In the case of a breakdown or malfunction: ask for original

spare parts.

It is recommended that you follow the guidelines below:

- Only use the appliance to cook food, avoiding all other

uses;

- Check the condition of the appliance after it has been

unpacked;

- Disconnect the appliance from the power supply in the

event of malfunction and always before cleaning or

maintenance;

- When not in use, disconnect the appliance from the power

supply and turn off the gas valve (if present);

- Always check to make sure that the control knobs are on

the " " setting when the appliance is not in use;

- Cut the power supply cord after disconnecting it from the

electrical mains when you decide to no longer use the

appliance.

The manufacturer will not be held liable for any damages

arising out of : incorrect installation or improper, incorrect or

unreasonable use.

Instructions for the installer

The following instructions are provided for qualified installers

so that they may accomplish installation, adjustment and

technical maintenance operations correctly and in

compliance with national current regulations and standards.

Important: the appliance should be disconnected from

the mains electricity supply before any adjustment,

maintenance, etc. is carried out. Maximum caution should

be used whenever it is necessary to keep the appliance

connected to the electricity supply .

The hobs have the following technical characteristics:

-Category II 2H3+ Class 3

Positioning

This appliance may only be installed and operated in

permanently ventilated rooms in compliance with provisions

laid down by current regulations and standards. The following

requirements must be observed:

The appliance must discharge combustion products into a

special hood, which must be connected to a chimney, flue

pipe or directly to the outside (fig.2). If it is impossible to fit a

hood, the use of an electric fan is permitted, either installed

on a window or on an external wall, which must be switched

on at the same time as the appliance.

fig.2

In a chimney stack or branched flue Directly to the outside

(exclusively for cooking appliances)

Kitchen ventilation

The air flow into the room where the appliance is installed

must equal the quantity of air that is required for regular

3

Page 6

Instructions for the installer

combustion of the gas and for ventilating the same room.

Air must be taken in naturally through permanent apertures

made in the outside walls of the room or through single or

branching collective ventilation ducts in compliance with the

standards in force. The air must be taken directly from the

outside, from an area far from sources of pollution.

The ventilation aperture must have the following

characteristics (fig.3A):

· total free cross section of passage of at least 6 cm² for

every kW of rated heating capacity of the appliance, with

a minimum of 100 cm² (the heating capacity is indicated

on the rating plate);

· it must be made in such a way that the aperture, both on

the inside and outside of the wall, cannot be obstructed;

· it must be protected, e.g. with grills, wire mesh, etc. in such

a way that the above-mentioned free section is not reduced;

· it must be situated as near to floor level as possible.

Detail A Adjacent Room to be

room ventilated

The hob must be at least 60 mm from the rear wall. If the

hob is to be installed near a corner, it must be at least 100

mm. from the side wall (fig.5). If the hob is installed on a

base unit with doors, hob operation is not influenced by the

opening and closing of these doors.

fig.4

A

Examples of ventilation holes Enlarging the ventilation slot

for comburant air between window and floor

Fig. 3A Fig. 3B

The air inflow may also be obtained from an adjoining room,

provided the latter is not a bedroom or a room where there

is a risk of fire, such as garages, mews, fuel stores, etc. and

is ventilated in compliance with the standards in force.

Air from the adjoining room to the one to be ventilated may

be made to freely pass through permanent apertures with a

cross section at least equal to that indicated above. These

apertures may also be obtained by increasing the gap

between the door and the floor (fig.3B). If an electric fan is

used for extracting the combustion products, the ventilation

aperture must be increased in relation to its maximum

performance. The electric fan should have a sufficient

capacity to guarantee an hourly exchange of air equal to 35 times the volume of the kitchen. Prolonged, intensive use

of the appliance may require extra ventilation, e.g. an open

window or a more efficient ventilation system by increasing

the extraction power of the electric fan if installed. Liquid

petroleum gas descends towards the floor as it is heavier

than air. Apertures in the outside walls in rooms containing

LPG cylinders should therefore be at floor level, in order to

allow any gas from leaks to be expelled. Do not store LPG

cylinders (even when empty) in basements/rooms below

ground level; it is advisable to keep only the cylinder in use

in the room at any one time and connected far from heat

sources which could raise its temperature to above 50 °C.

Fitting into modular kitchen units

For correct operation of the hob built into a kitchen unit or

other compartment, the latter must be suitable.

The installation diagram plus dimensions of the housing hole

is given in fig. 4.

fig.5

Installation above an oven

Suitable precautions must be taken to ensure that the

installation is in compliance with current accident-prevention

regulations regarding electrical and gas connections.

Both the electricity supply cable and the gas pipe must not

touch hot parts of the oven housing, in order to avoid

overheating. When installing above a built-under oven without

forced cooling ventilation, suitable air vents should be

provided for as shown in fig.6 (inlet at least 200 cm² from the

bottom, outlet at least 120 cm² from the top part) to allow

adequate ventilation inside the housing unit.

Also a wooden panel "A" should be installed beneath the

hob as insulation, positioning it at a minimum distance of 15

mm from the hob housing (fig.6).

Fixing to the housing unit

Proceed with fixing to the housing unit as follows (fig.7):

· mount the hooks "B", partly tightening the provided screws

"A" into the relative holes;

· position the provided sealing gasket "X" 5÷6 mm from the

edge of the installation hole, matching up the two ends of

4

Page 7

Instructions for the installer

appliance to the right (fig.8), or flexible steel pipe in compliance

with the standards in force, which must not exceed 2000 mm

in length. Should it be necessary to turn the fitting, the gasket

(supplied with the appliance) must be replaced.

Upon completion of installation, check the gas circuit, the

internal connections and the taps for leaks using a soapy

solution (never a flame). Also check that the connecting pipe

cannot come into contact with moving parts which could

damage or crush it. Make sure that the natural gas pipe is

adequate for a sufficient supply to the appliance when all the

burners are lit.

Important: A pressure regulator, in compliance with the

standards in force, must be inserted when connecting to a

liquid gas supply (in a cylinder).

fig.6

200 cm²

A

B

the seal without overlapping;

· insert the hob into the hole, making sure it is positioned

centrally and that the edge adheres to the sealant;

· position the hooks "B" correctly, as shown in figure and

then tighten the screws "A" to hold them in place;

Gas supply connection

Check that the appliance is set for the type of gas available

and then connect it to the mains gas piping or the gas

cylinder in compliance with current regulations and

standards.

This appliance is designed and set to work with the gas

indicated on the label situated on the actual hob. If the gas

supply is other than the type for which the appliance has

been set, proceed with replacing the corresponding nozzles

(provided), following instructions given in the paragraph

“Adaptation to different types of gas”.

For trouble-free operation, suitable use of energy and longer

life of the appliance, make sure that the supply pressure

complies with the values indicated in the table 1 "burners

and nozzles specifications, otherwise install a special

pressure regulator on the supply pipe in compliance with

current standards and regulations.

Connect in such a way that the appliance is subjected to

no strain whatsoever.

Either a rigid metal pipe with fittings in compliance with the

standards in force must be used for connecting to the nipple

union (threaded ½"G male fitting) situated at the rear of the

fig.8

fig.7

Adaptation to different types of gas

If the hob is to be converted for use with a type of gas other

than that for which it was set in the factory (indicated on the

label to be found on the hob), the burner nozzles should be

replaced as follows:

• Remove the pan supports and the burners.

• Unscrew the nozzles “A” (fig.9) using a 7 mm socket

wrench and replace them with the ones which have a

diameter suitable for the type of gas to be used, according

to the table 1 "burners and nozzles specifications".

• Reassemble the parts following the instructions in reverse

order.

• On completing the operation, replace the old rating label

with the one showing the new type of gas;

A

fig.9

Regulation of Air Supply to the Burner

The burners do not need any primary air regulator.

Minimum Regulation

· Put the tap to the low flame position;

· Remove the tap knob and turn the adjusting screw, situated

inside the tap stem (fig.10), using a screwdriver (loosening

the screw increases the height of the flame, tightening

decreases it).

note: the adjusting screw must be fully screwed down for

liquid gas.

· Having obtained the low flame setting required and with

the burner lit, abruptly change the position of the knob

several times from minimum to maximum and vice versa

and check that the flame does not go out.

· In the event of a malfunction on appliances with the security

device (thermocouple) when the gas supply is set at

minimum, increase the minimum supply levels using the

regulator screw.

fig.10

5

Page 8

Instructions for the installer

Electrical connection

THE APPLIANCE MUST BE EARTHED

The hob is designed to work with alternating current at the

supply voltage and frequency indicated on the rating plate

(situated under the hob or at the end of the instruction

booklet). Make sure that the local supply voltage corresponds

to the voltage indicated on the rating plate.

Connecting the supply cable to the mains electricity

supply

For models supplied without a plug, fit a standard plug,

suitable for the load indicated on the rating plate, onto the

cable and connect to a suitable socket.

T o connect directly to the mains supply , a double-pole switch

with a contact separation of at least 3 mm suitable for the

load and complying with current standards and regulations,

must be fitted between the appliance and the mains supply

outlet. The yellow-green earth wire must not be interrupted

by the switch. The supply cable must be in such a position

that no part of it can reach a temperature of 50°C above

room temperature. For installation above a built-under oven,

the hob and the oven must be connected separately to the

electricity supply both for safety reasons and for easy removal

of the oven if necessary. Do not use adapters or shunts as

they could cause heating or burning. Before connecting to

the power supply , make sure that:

• the limiter valve and the domestic system can withstand

the load from the appliance (see rating plate);

• the supply system is efficiently earthed according to

standards and laws in force;

• the socket or double-pole switch are easily accessible when

the appliance is installed.

Important: the wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead may not

correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

Connect the Green & Yellow wire to terminal marked “E” or

or coloured Green or Green & Yellow.

Connect the Brown wire to the terminal marked “L” or

coloured Red.

Connect the Blue wire to the terminal marked “N” or coloured

Black.

FAILURE TO OBSERVE THE ACCIDENT-PREVENTION

REGULA TIONS RELIEVES THE MANUF ACTURER OF ALL

LIABILITY.

Replacing the cable

Use a rubber cable of the type H05RR-F with a cross section

3 x 0.75 mm².

The yellow-green earth wire must be 2-3 cm longer than the

other wires.

Burners and nozzles characteristics

1elbaTsagdiuqiLsaglarutaN

renruBretemaiD

)mm(

.nimoN.cudeR03G***13G**02G

Cdipar-imeS5756.14.0034602181169751

AyrailixuA5500.13.0720537171759

EgnirelpirT03152.33.17519632232421903

ylppuS

erusserp

* At 15°C and 1013 mbar-dry gas

** Propane G31 H.s. = 50,37 MJ/kg

*** Butane G30 H.s. = 49,47 MJ/kg

Natural gas G20 H.s. = 37,78 MJ/m

rewoplamrehT

)*.s.H(Wk

3

ssap-yB

001/1

)mm(

rotcejnI

001/1

*wolF

h/g

)mm(

rotcejnI

001/1

*wolF

h/l

)mm(

)rabm(lanimoN03-827302

This appliance conforms with the following European

Economic Community directives:

- 73/23/EEC of 19/02/73 (Low Voltage) and subsequent

modifications;

- 89/336/EEC of 03/05/89 (Electromagnetic Compatibility)

and subsequent modifications;

- 90/396/EEC of 29/06/90 (Gas) and subsequent

modifications;

- 93/68/EEC of 22/07/93 and subsequent modifications.

6

Page 9

Page 10

Page 11

Page 12

Merloni Elettrodomestici

Viale Aristide Merloni 47

60044 Fabriano

Italy

Tel +39 0732 6611

Fax +39 0732 662501

www .merloni.com

09/01 - Cod. 195032114.01

Loading...

Loading...