Indesit KP9F96S Operating Instructions Manual

Operating Instructions

COOKER

Contents

Installation, 2-6

Adjacent cabinetry

Electrical connection

Post Installation Checks

Technical specifications

Description of the appliance, 7

Overall view

Start-up and use, 8-11

Hob operation

Multi-function oven

Cooking tips

Cooking programmer, 12

Precautions and tips, 13-14

Practical advice on using the appliance

General Appliance Warnings

Installation Warnings

Safety With The Cooktop

Maintenance Warnings

Gas And Electrical Safety

Care and maintenance, 15-17

Switching the appliance off

Cleaning the appliance

Changing the oven light bulb

Disassembling the oven door

Cleaning The Cooktop

Service schedule

GB

KP9F96S /AUS

English, 1

GB

2

GB

Installation

! Before operating your new appliance please read

this instruction booklet carefully. It contains important

information concerning the safe operation, installation

and maintenance of the appliance.

! Please keep these operating instructions for future

reference. Pass them on to possible new owners of the

appliance.

The following instructions are provided for qualified

installers so that they may accomplish installation,

adjustment and technical maintenance operations

correctly and in compliance with current regulations

and standards.

Compliance with standards

This cooktop must be installed in accordance with

the requirements of local gas and electrical

authorities, as well as the latest published versions

of the following standards:

AS/NZS 5601 Gas Installation code

SAA Wiring Rules.

Important: the appliance should be disconnected

from the mains electricity supply before any

adjustment, maintenance, etc. is carried out.

Maximum caution should be used should it be

necessary to keep the appliance connected to the

electricity supply.

The appliance has the following technical

specifications:

Category: II 2H3+

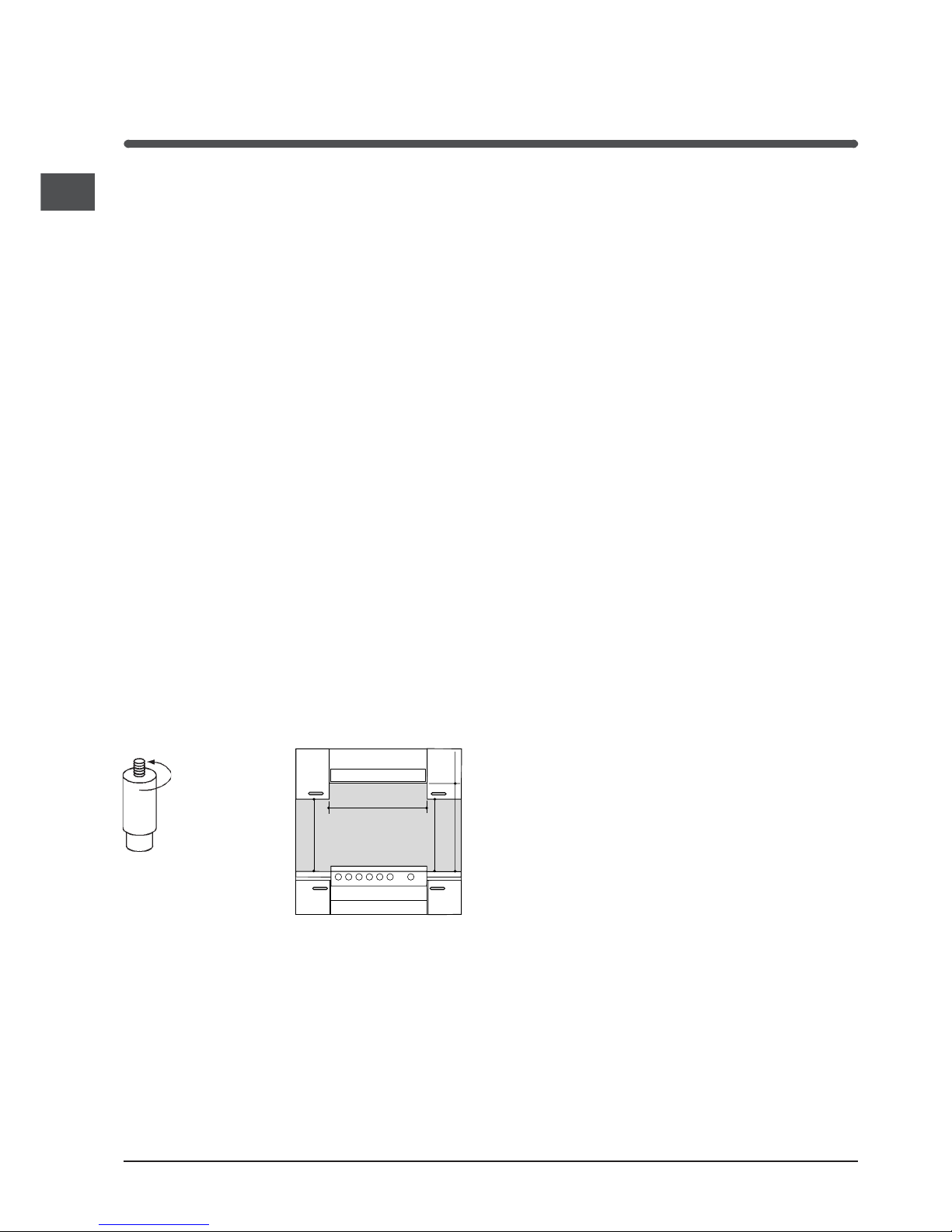

Adjacent cabinetry

The dimensions of the appliance are given in the

figure on page 2, and the location of connection

point sin the table on page 10 . For trouble-free

operation of appliances installed in housing units,

the minimum distances shown in fig.4 should be

observed. It is recommended that the adjacent

kitchen surfaces should be capable of withstanding

temperatures of 65°C. Also, the following must be

observed:

The appliance should be installed next to

cabinetry which is no taller than the top of the

cooker hob.

The wall in direct contact with the back panel of

the cooker must be made of non-flammable

material. During operation of the cooker, the back

panel of the cooker could reach a temperature of

50°C above room temperature.

Kitchen cabinets installed next to the cooker that

are higher than the top of the hob, must be at

least 600 mm from the edge of the hob itself.

If the hood is installed below a wall cabinet, the

latter must be at least 700 mm (millimetres) above

the surface of the hob.

Cabinets installed adjacent to the hood must be

at least 420 mm above the hob,

The following minimum clearances to combustible

materials must be observed:

Minimum clearance from edge of burner to side

wall must be 200 mm.

Minimum clearance from edge of burner to rear wall

must be 200 mm.

In the lower part of the cooker there are 4 height

adjustable screw-in feet with which it is possible to

level the cooker if necessary.

Kitchen ventilation

Where the total input of all appliances exceeds 3

MJ/h for each cubic metre of the room or enclosure

volume, the space shall be ventilated by one of the

methods detailed below. For the purpose of

assessing the adequacy of ventilation, the space

that cannot be isolated by doors is the volume of a

room.

Natural ventilation direct from outside

Two permanent openings shall be provided directly

to outside. The openings shall be located to ensure

the distance between the top of the upper opening

and the ceiling of the room or enclosure, and the

distance between the bottom of the lower opening

and the floor of the room or enclosure does not

exceed 5% of the height of the room or enclosure.

The minimum free ventilation area provided by each

opening shall be calculated using the following

formula:

A = 3 × T

where

A = the minimum free ventilation area (cm

2

)

T = the total gas consumption of all appliances

(MJ/h)

The minimum vertical dimension of any free

ventilation opening shall be 6 mm.

NOTE 1 When used in this Clause, the term directly

to outside means any one of the following options,

provided that the ventilation path is unobstructed by

building material or insulation:

(a) Directly through an outside wall (preferred

option).

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min. mm.

420

Min. mm.

GB

3

(b) Through to an outside wall but offset.

(c) Into a cavity ventilated to outside.

(d) Into an underfloor space ventilated to outside.

(e) Into a roof space ventilated to outside.

NOTE 2 The two openings may be combined

provided that the top and bottom of the opening

reach the limits set by this Clause.

Natural ventilation via adjacent room

Two permanent openings shall be provided in the

room or enclosure. The openings shall be located to

ensure the distance between the top of the upper

opening and the ceiling of the room or enclosure,

and the distance between the bottom of the lower

opening and the floor of the room or enclosure does

not exceed 5% of the height of the room or

enclosure.

The minimum free ventilation area provided by each

opening shall be calculated using the following

formula:

A = 6 × T

where

A = the minimum free ventilation area (cm

2

)

T = the total gas consumption of all appliances

(MJ/h)

These requirements shall apply to all subsequent

rooms until a room is ventilated to outside, in

accordance with the previous section, or the total

input of the appliances does not exceed 3 MJ/h for

each cubic metre of the total volume of the

enclosure and rooms.

The minimum vertical dimension of any free

ventilation opening shall be 6 mm.

NOTE: The two openings may be combined

provided that the top and bottom of the opening

reach the limits set by this Clause.

If an electric fan is used for extracting the

combustion products, the ventilation aperture must

be increased in relation to its maximum

performance. The electric fan should have a

sufficient capacity to guarantee an hourly exchange

of air equal to 3 ÷ 5 times the volume of the kitchen.

Prolonged, intensive use of the appliance may

require extra ventilation, e.g. an open window or a

more efficient ventilation system by increasing the

extraction power of the electric fan if installed. Liquid

petroleum gas descends towards the floor as it is

heavier than air. Apertures in the outside walls in

rooms containing LPG cylinders should therefore be

at floor level, in order to allow any gas from leaks to

be expelled. Do not store LPG cylinders (even when

empty) in basements or rooms below ground level; it

is advisable to keep only the cylinder in use in the

room at any one time and connected far from heat

sources which could raise its temperature to above

50 °C.

Range hoods

Range hoods and overhead exhaust fans must be

installed according to manufacturers instructions

but in no case shall clearance from hob burners be

less than 600 mm for range hoods and 750 mm for

overhead exhaust fans.

If the hood is installed below a wall cabinet, the

latter must be at least 700 mm (millimetres) above

the surface of the hob.

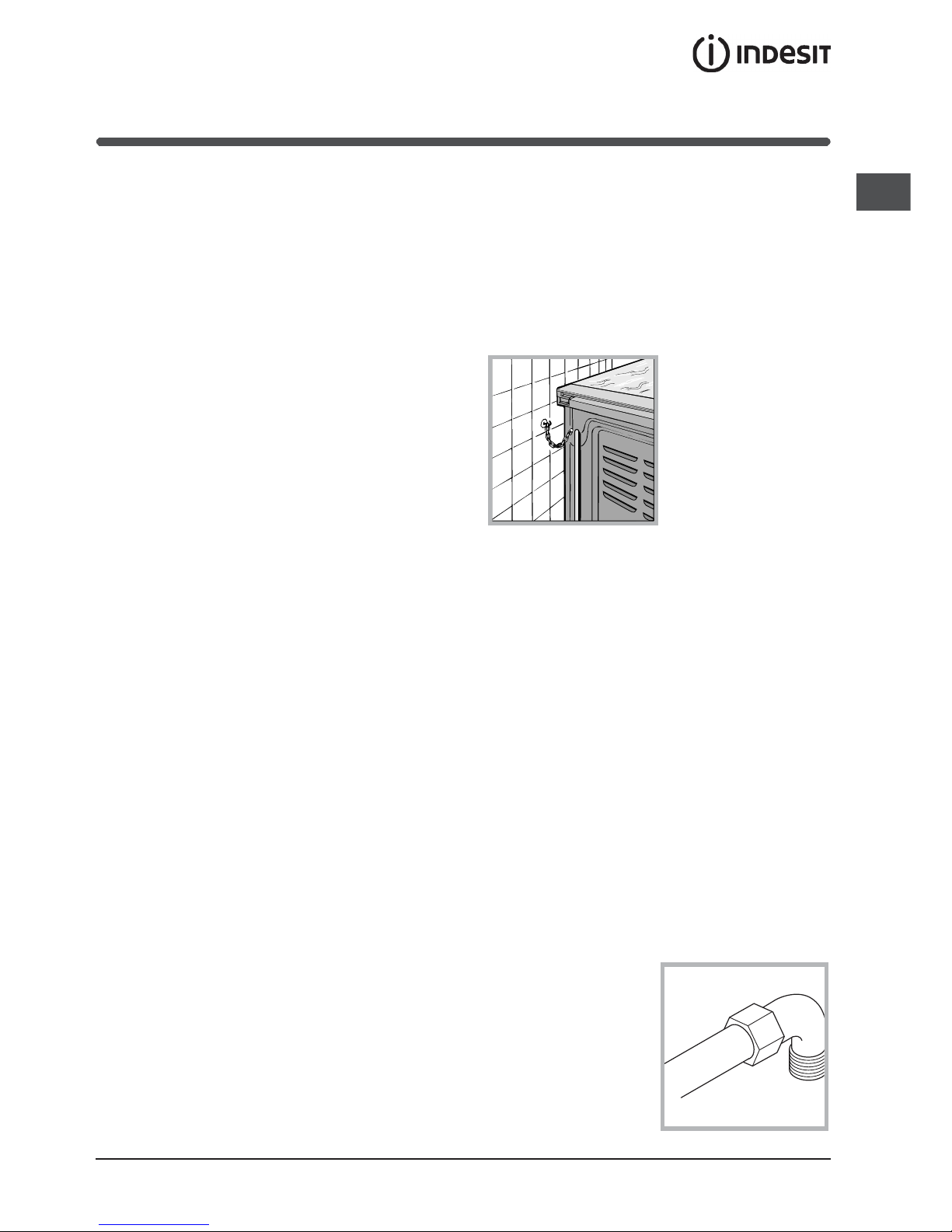

Safety Chain

In order to prevent

accidental tipping of

the appliance, for

example by a child

climbing onto the open

oven door, the supplied

safety chain must be

installed.

Ensure the chain is

secured to the rear wall

of the oven, and attach

the chain to a hook or screw secured to the wall

behind the appliance.

NOTE: If the cooker is placed on a base, measures

must be taken to prevent the appliance slipping

from the base.

This appliance is suitable for use with either a

flexible connection or rigid copper connection.

Check The Gas Type

! Before installation, check that the gas type (natural

gas or LPG/Propane) of the cooker is suitable for the

gas type available to the installation. It is extremely

dangerous to use the wrong gas type with any

appliance, as fire or serious injury can result.

This cooker is supplied from the factory already set

for Natural Gas. To convert the cooker to LPG (or

back to Natural Gas from LPG), follow the directions

later in this section.

Fit regulator supplied for Natural Gas (if applicable)

at rear of appliance, and as close as practicable to

the appliance.

It is recommended that an isolating valve and union

be fitted, to enable simple disconnection for

servicing. These are to be in an accessible location.

Either a rigid metal pipe

with fittings in

compliance with the

standards in force must

be used for connecting

to the nipple union

(threaded ½G male

fitting) situated at the

rear of the appliance to

the right, or an

4

GB

approved flexible hose of class B or D.

Should it be necessary to turn the fitting, the gasket

(supplied with the appliance) must be replaced.

If a flexible hose is used, it should be as short as

possible with a maximum length of 1.5 metres;

The flexible connection must be approved to

class B or D of AS/NZS1869 as a minimum.

it should not be bent, kinked or compressed;

it should not be in contact with the rear wall of the

appliance or in any case with parts which may

reach a temperature of 50°C;

it should not come into contact with pointed parts

or sharp corners;

it should not be subject to any pulling or twisting

forces;

it should be easy to inspect along its entire length

in order to be able to check its condition.

The supply connection point must be accessible

with the appliance installed.

The inner diameters of the pipe are as follows:

8 mm for LPG;

13 mm for Natural Gas.

Upon completion of installation, check the gas

circuit, the internal connections and the taps for

leaks using a soapy solution (never a flame). Also

check that the connecting pipe cannot come into

contact with moving parts which could damage or

crush it. Make sure that the natural gas pipe is

adequate for a sufficient supply to the appliance

when all the burners are lit

! A pressure regulator, in compliance with the

standards in force, must be inserted when

connecting to a liquid gas supply (in a cylinder).

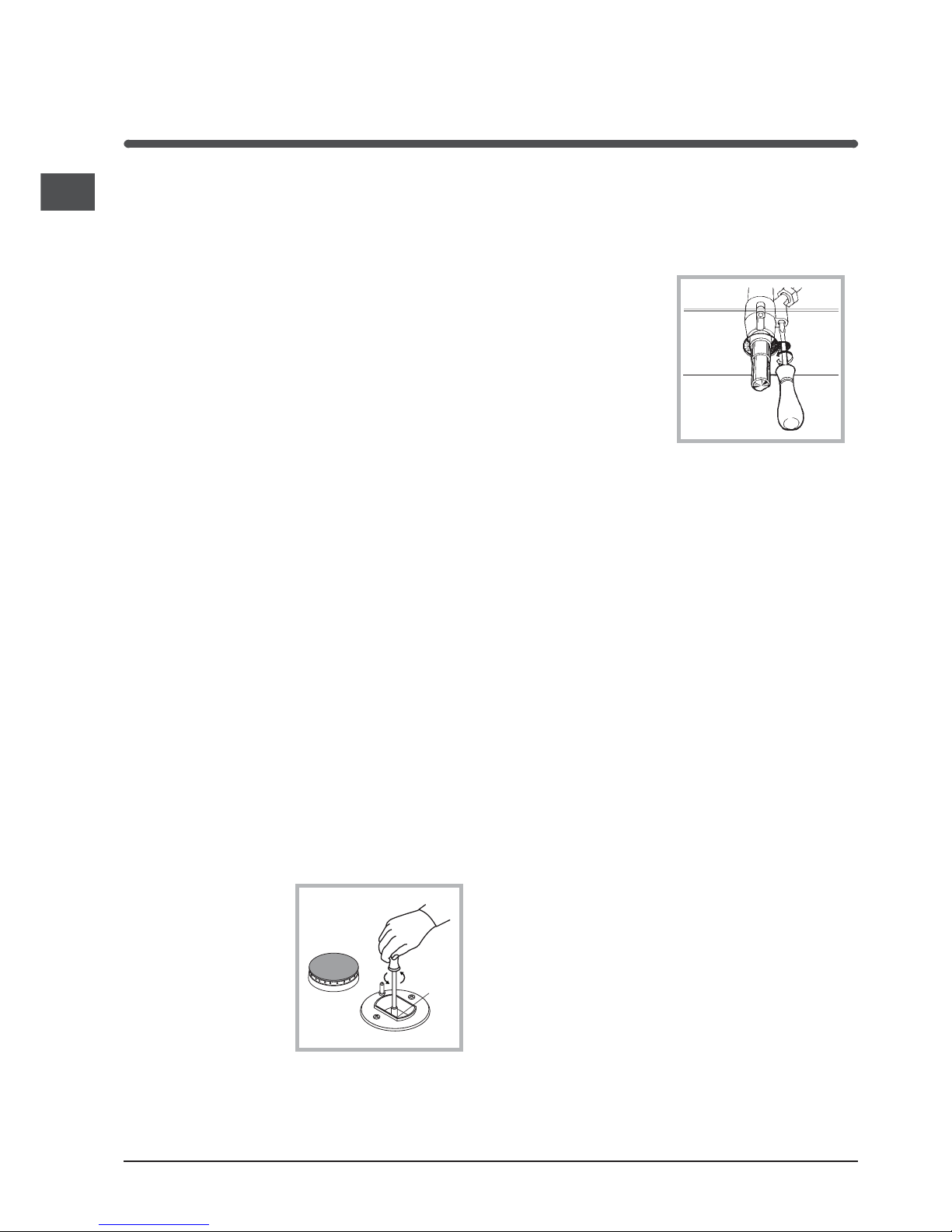

Adapting to different types of gas

To adapt the hob to a different type of gas from the

factory-set one (indicated on the rating plate at the

top of the hood or on the packaging), the burner

nozzles should be replaced as follows:

Remove the hob grids and slide the burners off

their seats.

Unscrew the nozzles (see figure), using a 7 mm

socket spanner and

replace them with

nozzles for the new

type of gas (see

table 1 "Burner and

nozzle

characteristics").

Reassemble the

parts following the

above procedure in

the reverse order.

On completing the operation, replace the old

rating label with the one showing the new type of

gas; the sticker is available from our Service

Centres.

Adjusting the primary air of the burners The

primary air of the burners does not need to be

adjusted.

Adjusting the low flame

Turn the tap to the low flame position;

Remove the knob

and turn the

adjusting screw,

situated to the right

of the tap (see figure)

until you obtain a

regular small flame,

using a screwdriver

(loosening the screw

increases the height

of the flame,

tightening decreases it).

N.B.: In the case of liquid gas, the regulation

screw must be screwed in all the way.

Having obtained the low flame setting required

and with the burner lit, abruptly change the

position of the knob several times from minimum

to maximum and vice versa and check that the

flame does not go out.

In appliances fitted with the safety device

(thermocouple), should the device fail to work with

the burners set to the low flame setting, increase the

low flame setting of the same on the adjusting

screw.

Once the adjustment has been made, remount the

seals on the by-passes using sealing wax or similar.

Duplicate Data Plate

Where the data plate is obscured by cabinetry when

the cooker is in the installed position, place a

duplicate data plate on a surface of the cabinetry

adjacent to the cooker.

Electrical connection

THE APPLIANCE MUST BE EARTHED

The appliance is designed to work with alternating

current at the supply voltage and frequency

indicated on the rating plate (situated on the rear

part of the appliance and on the last page of the

instruction booklet) or at the end of the instruction

booklet. Make sure that the local supply voltage

corresponds to the voltage indicated on the rating

plate.

ATTENTION: This appliance has a maximum

power exeeding 3kW; it is therefore necessary for

it to be connected to a socket able to support a

rated current higher than 13A (the appliance rated

current is 15A). Connecting the supply cable to

A

GB

5

the mains electricity supply A 13.

To connect directly to the mains supply, a doublepole switch with a contact separation of at least 3

mm suitable for the load and complying with current

standards and regulations, must be fitted between

the appliance and the mains supply outlet. The

yellow-green earth wire must not be interrupted by

the switch. The supply cable must be in such a

position that no part of it can reach a temperature of

50 °C above room temperature. Do not use adapters

or shunts as they could cause heating or burning.

Before connecting to the power supply, make sure

that:

the limiter valve and the domestic system can

withstand the load from the appliance (see rating

plate);

the supply system is efficiently earthed according

to standards and laws in force;

the socket or double-pole switch are easily

accessible when the appliance is installed.

FAILURE TO OBSERVE THE ACCIDENTPREVENTION REGULATIONS RELIEVES THE

MANUFACTURER OF ALL LIABILITY.

Important: the wires in the mains lead are coloured

in accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead may

not correspond with the coloured markings

identifying the terminals in your plug, proceed as

follows:

Connect the Green & Yellow wire to terminal marked

E or

or coloured Green or Green & Yellow.

Connect the Brown wire to the terminal marked L or

coloured Red.

Connect the Blue wire to the terminal marked N or

coloured Black.

Post Installation Checks

Perform post installation checks and ensure proper

and safe operation before leaving. Test all burners

individually and in combination.

Leak Check

Ensure all gas control knobs are in the Off

position.

Ensure the gas supply is switched on.

Spray a solution of soapy water onto all gas joints

as well as the full length of any flexible hoses.

UNDER NO CIRCUMSTANCES USE A NAKED

FLAME IN CHECKING FOR LEAKS.

If bubbles appear anywhere, turn the gas supply off,

check all connections and retest. If satisfactory

operation cannot be achieved, contact place of

purchase or their appointed agent for service.

Flame check

Turn each burner on, and ensure that the flame is

blue with minimal yellow tipping. If there is

significant yellow tipping, flame lift off or excessive

noise, check pressure and adjust at the regulator if

necessary.

If satisfactory operation cannot be achieved, contact

place of purchase or their appointed agent for

service.

Igniter operation

Check that the igniter for each burner successfully

ignites the gas.

If an igniter fails to work, first remove the plug from

the electrical power outlet, and then check that all

the electrical connections are in place.

If satisfactory operation cannot be achieved, contact

place of purchase or their appointed agent for

service.

Low flame setting

Check the low flame setting for each hob burner to

ensure that the minimum flame will not be

extinguished by air draughts.

Light the burner.

Turn the control until it engages in the minimum

position.

Ensure the flame is stable and will not be

extinguished by air draughts.

To adjust the minimum flame:

Follow the procedure described in the gas

conversion instruction.

DO NOT MODIFY THIS APPLIANCE IN ANY WAY,

OTHER THAN AS DESCRIBED IN THESE

INSTRUCTIONS.

Disconnecting the cable

Ensure that the means for disconnection of the

power cable is incorporated intot he fixed wiring in

accordance with local wiring rules.

(New Zealand statutory warning): The cooker must

be connected to the electricity supply by a cable

fitted with an appropriately rated plug that is

compatible with the socket-outlet fitted to the final

subcircuit in the fixed wiring that is intended to

supply this cooker.

Replacing the cable

Use a rubber cable of the type H05VV-F with a

suitable cross section 3 x 1.5 mm².

The yellow-green earth wire must be 2-3 cm longer

than the other wires.

6

GB

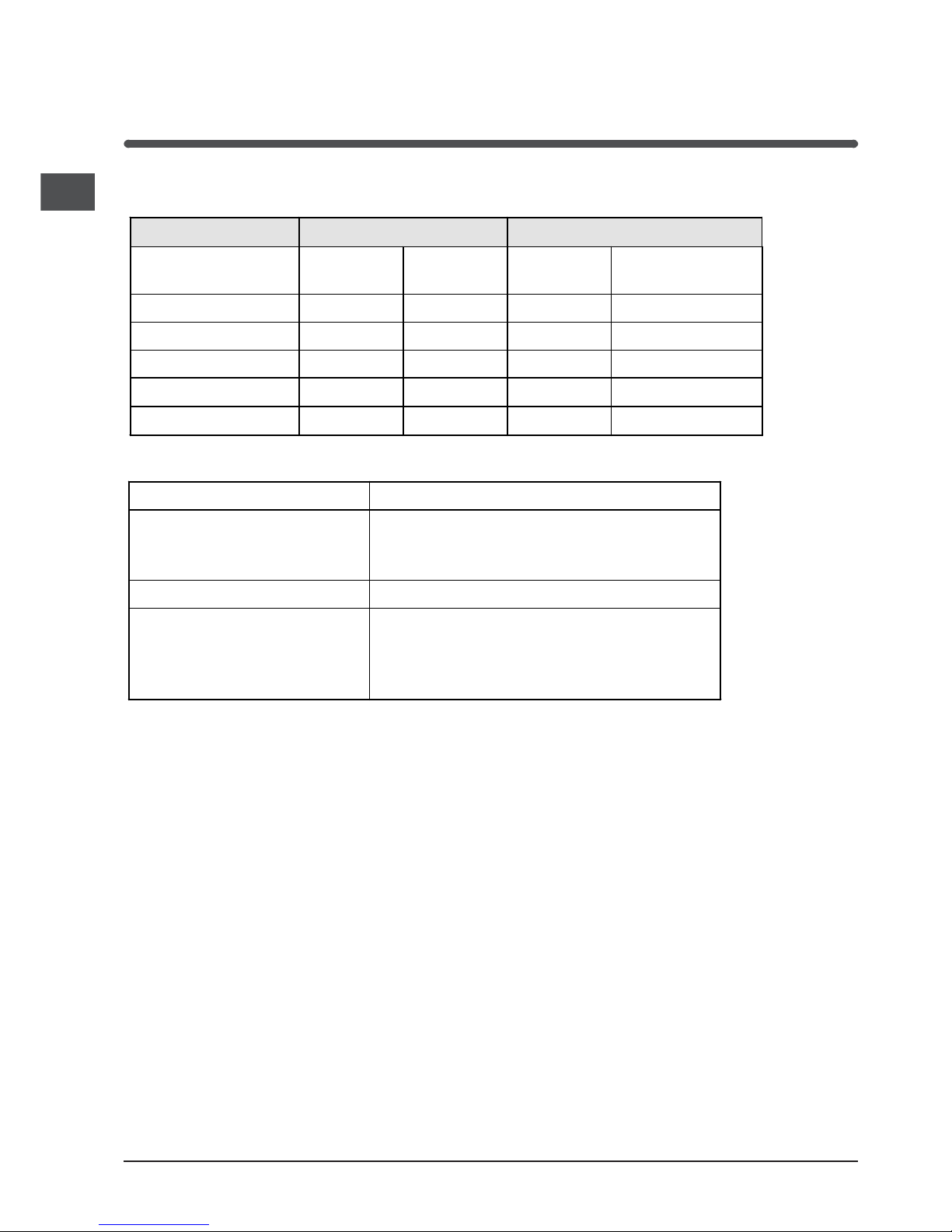

TECHNICAL SPECIFICATIONS

Gas Consumption

Natural Gas (1.0 kPa) ULPG (2.75 kPa)

Injector

Diameter

Gas Input

Injector

Diameter

Gas Input

Auxiliary Burner A 0.80 mm 3.3 MJ/hr 0.50 mm 3.5 MJ/hr

Semi Rapid Burner B 1.10 mm 6.0 MJ/hr 0.64 mm 5.5 MJ/hr

Rapid Burner C 1.29 mm 8.3 MJ/hr

0.80 mm 9.0 MJ/hr

Triple Ring Burner D 1.75 mm 15.0 MJ/hr 1.05 mm 15.0 MJ/hr

Total 38.6 MJ/hr 38.5 MJ/hr

Connections

Gas Inlet fitting 1/2 BSP (male) thread

Location of gas inlet Bottom rear of upright cooker

90 mm C/L from RH side (as viewed from front)

600 mm from base of upright cooker

Electrical input Flexible cord and earthed 10 Amp 3 pin plug

Location of Electrical Connection Rear of upright cooker

90 mm C/L from left hand side (as viewed from

front)

90 mm from base (without legs installed)

Loading...

Loading...