Page 1

Operating Instructions

COOKER

GBGB

GB

GBGB

English, 1

KP9F11S/G

Contents

GB

Installation, 2-5

Positioning

Electrical connection

Disposal

Burner and nozzle specifications

Description of the appliance, 6

Overall view

Start-up and use, 7-9

Hob operation

Electric oven

Data plate

Cooking tips

Precautions and tips, 10

Practical advice on using the appliance

General safety

Care and maintenance, 11

Switching the appliance off

Cleaning the appliance

Changing the oven light bulb

Disassembling the oven door

Page 2

Installation

GB

! Before operating your new appliance please read

this instruction booklet carefully. It contains important

information concerning the safe operation, installation

and maintenance of the appliance.

! Please keep these operating instructions for future

reference. Pass them on to possible new owners of the

appliance.

The following instructions are provided for qualified

installers so that they may accomplish installation,

adjustment and technical maintenance operations

correctly and in compliance with current regulations

and standards.

Important: the appliance should be disconnected

from the mains electricity supply before any

adjustment, maintenance, etc. is carried out.

Maximum caution should be used should it be

necessary to keep the appliance connected to the

electricity supply.

The appliance has the following technical

specifications:

Category: II 2H3+

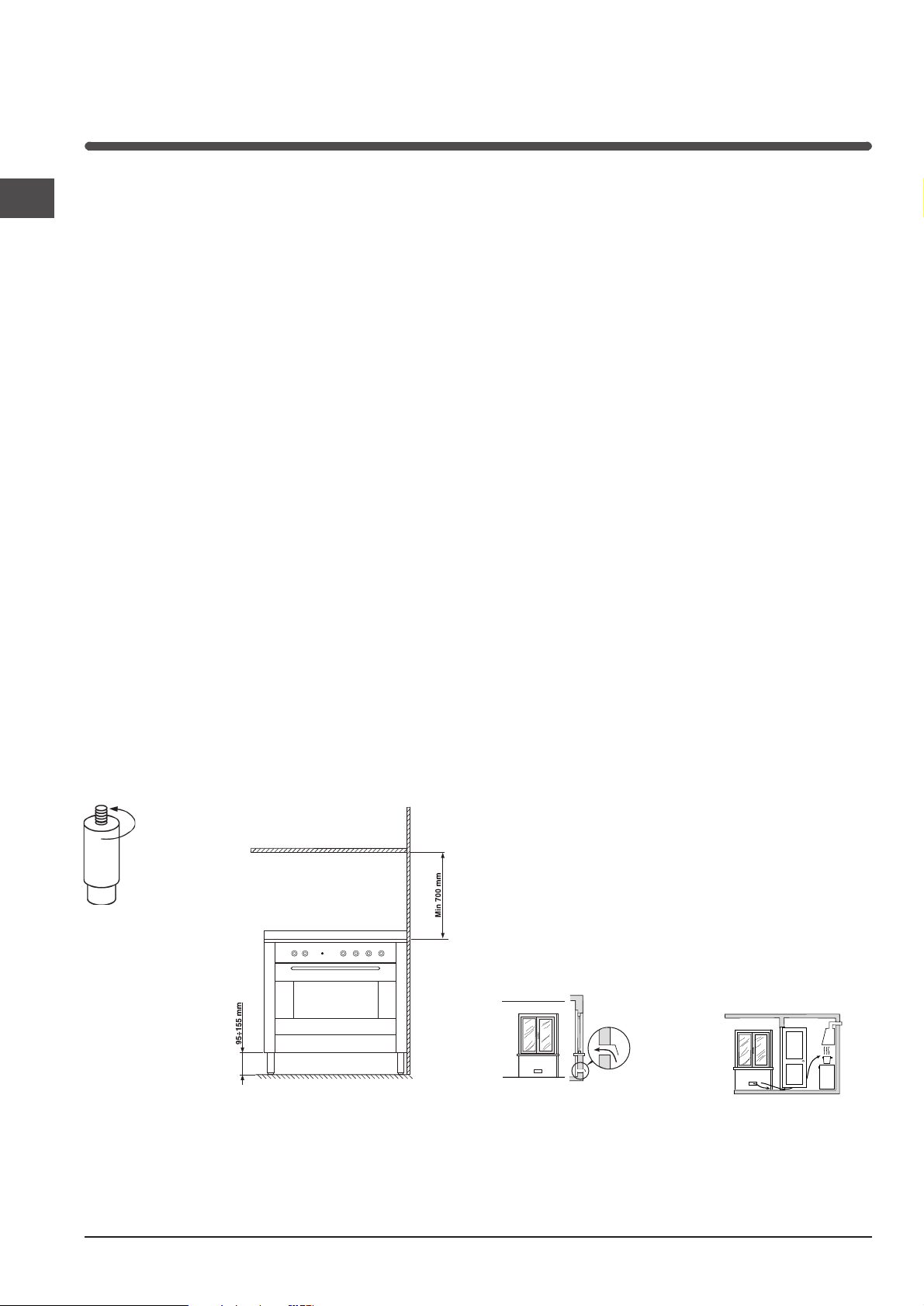

Positioning

The dimensions of the appliance are given in the

figure. For trouble-free operation of appliances

installed in housing units, the minimum distances

shown in figure should be observed. Adjacent

surfaces and the wall at the rear should also be able

to withstand an overheating temperature of 65 °C.

Standards Codes Of Practice: B.S. 6172/B.S. 5440,

Par. 2 and B.S. 6891 Current Editions. The following

requirements must be observed:

a) The cooker should not be installed in a bed sitting

room with a volume of less than 20m

installed in a room of volume less than 5m

vent of effective area of 110cm

installed in a room of volume between 5m

3

a supplementary airvent area of 50cm2 is

10m

required, if the volume exceeds 11m

3

. If it is

3

2

is required, if it is

an air

3

and

3

no airvent is

required. However, if the room has a door or a

window which opens directly to the outside no air

vent is required even when the volume is between

5m3 and 11m3.

b) During prolonged use of the appliance you may

consider it necessary to open a window to the

outside to improve ventilation.

c) If there are other fuel burning appliances in the

same room, B.S.5440 Part 2 Current Edition, should,

be consulted to determine the requisite air vent

requirements.

Kitchen ventilation

The air flow into the room where the appliance is

installed must equal the quantity of air that is required

for regular combustion of the gas and for ventilating

the same room. Air must enter naturally through

permanent apertures made in the outside walls of the

room or through single or branching collective

ventilation ducts in compliance with the norms. The air

must be taken directly from the outside, from an area

far from sources of pollution. The ventilation aperture

must have the following characteristics:

• total free cross section of passage of at least 6 cm²

for every kW of rated heating capacity of the

appliance, with a minimum of 100 cm² (the heating

capacity is indicated on the rating plate);

• it must be made in such a way that the aperture,

both on the inside and outside of the wall, cannot

be obstructed;

• it must be protected, e.g. with grates, wire mesh,

etc. in such a way that the above-mentioned free

section is not reduced;

• it must be situated as near to floor level as possible.

In the lower part of the cooker there are 4 height

adjustable screw-in feet with which it is possible to

level the cooker if necessary.

Important: this unit may be installed and used only in

permanently ventilated rooms according to the British

2

A

Examples of ventilation holes

for comburant air.

Adjacent

Room

Enlarging the ventilation slot

between window and floor.

Room to be

Vented

The air inflow may also be obtained from an adjoining

room, provided the latter is not a bedroom or a room

where there is a risk of fire, such as warehouses,

garages, fuel stores, etc. and is ventilated in

Page 3

compliance with the norms. The air flow from the

A

adjoining room to the one to be ventilated may pass

freely through permanent apertures with a cross

section at least equal to that indicated above. These

apertures may also be obtained by increasing the gap

between the door and the floor. If an electric fan is

used for extracting the combustion products, the

ventilation aperture must be increased in relation to its

maximum performance. The electric fan should have a

sufficient capacity to guarantee an hourly exchange of

air equal to 3 ÷ 5 times the volume of the kitchen.

Prolonged, intensive use of the appliance may require

extra ventilation, e.g. an open window or a more

efficient ventilation system by increasing the extraction

power of the electric fan if installed. Liquid petroleum

gas descends towards the floor as it is heavier than

air. Apertures in the outside walls in rooms containing

LPG cylinders should therefore be at floor level, in

order to allow any gas from leaks to be expelled. Do

not store LPG cylinders (even when empty) in

basements or rooms below ground level; it is

advisable to keep only the cylinder in use in the room

at any one time and connected far from heat sources

which could raise its temperature to above 50 °C.

Gas supply

• Check that the appliance is set for the type of gas

available and then connect it to the mains gas

piping or the gas cylinder in compliance with the

applicable norms in force.

• This appliance is designed and set to work with the

gas indicated on the label situated on the actual

hob. If the gas supply is different from the type for

which the appliance has been set, replace the

corresponding nozzles (provided), following the

instructions given in the paragraph "Adaptation to

different types of gas".

• For trouble-free operation, suitable use of energy

and a longer life cycle for the appliance, make sure

that the supply pressure complies with the values

indicated in table 1 "Burner and nozzle

specifications", otherwise install a special pressure

regulator on the supply pipe in compliance with

current standards and regulations.

• Connect in such a way that the appliance is

subjected to no strain whatsoever.

Either a rigid metal pipe

with fittings in

compliance with the

standards in force must

be used for connecting

to the nipple union

(threaded ½"G male

fitting) situated at the

rear of the appliance to

the right, or flexible steel

pipe in compliance with

the standards in force, which must not exceed 2000

mm in length.

Should it be necessary to turn the fitting, the gasket

(supplied with the appliance) must be replaced. Upon

completion of installation, check the gas circuit, the

internal connections and the taps for leaks using a

soapy solution (never a flame).

Also check that the connecting pipe cannot come into

contact with moving parts which could damage or

crush it.

Make sure that the natural gas pipe is adequate for a

sufficient supply to the appliance when all the burners

are lit Important: A pressure regulator, in compliance

with the standards in force, must be inserted when

connecting to a liquid gas supply (in a cylinder).

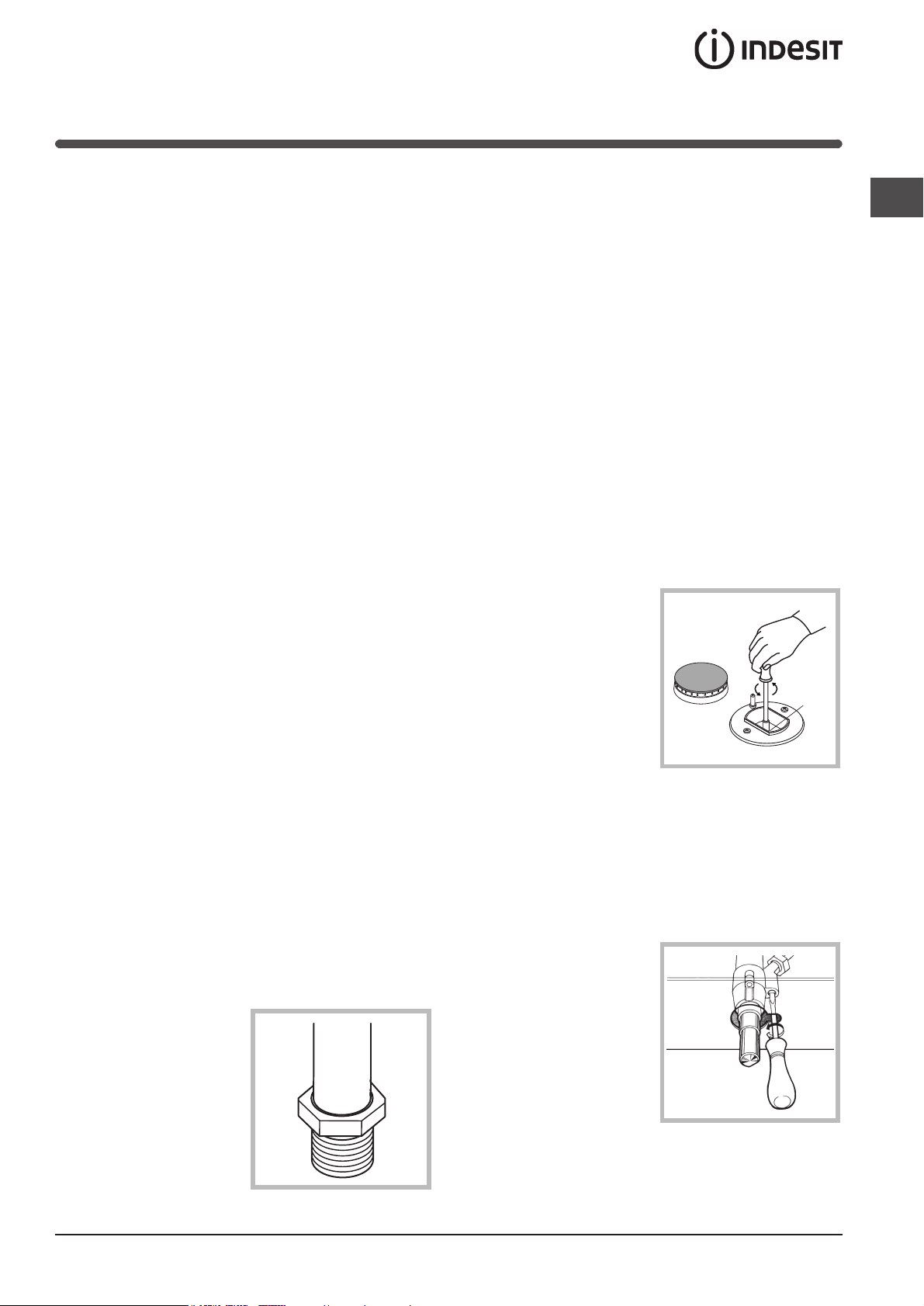

Adapting to different types of gas

To adapt the hob to a different type of gas from the

factory-set one (indicated on the rating plate at the top

of the hood or on the packaging), the burner nozzles

should be replaced as follows:

• Remove the hob grids and slide the burners off their

seats.

• Unscrew the nozzles

(see figure), using a 7

mm socket spanner

and replace them with

nozzles for the new

type of gas (see table

1 "Burner and nozzle

characteristics").

Reassemble the parts

following the above

procedure in the

reverse order.

• On completing the operation, replace the old rating

label with the one showing the new type of gas; the

sticker is available from our Service Centres.

Adjusting the primary air of the burners The primary

air of the burners does not need to be adjusted.

Adjusting the low flame

• Turn the tap to the low flame position;

• Remove the knob and

turn the adjusting

screw, situated to the

right of the tap (see

figure) until you obtain

a regular small flame,

using a screwdriver

(loosening the screw

increases the height

of the flame,

tightening decreases

it).

N.B.: In the case of liquid gas, the regulation

screw must be screwed in all the way.

GB

3

Page 4

GB

• Having obtained the low flame setting required

and with the burner lit, abruptly change the

position of the knob several times from minimum

to maximum and vice versa and check that the

flame does not go out.

• In appliances fitted with the safety device

(thermocouple), should the device fail to work with the

burners set to the low flame setting, increase the low

flame setting of the same on the adjusting screw.

Once the adjustment has been made, remount the

seals on the by-passes using sealing wax or similar.

Electrical connection

THE APPLIANCE MUST BE EARTHED

The appliance is designed to work with alternating

current at the supply voltage and frequency indicated

on the rating plate (situated on the rear part of the

appliance and on the last page of the instruction

booklet) or at the end of the instruction booklet. Make

sure that the local supply voltage corresponds to the

voltage indicated on the rating plate.

To connect directly to the mains supply, a doublepole switch with a contact separation of at least 3

mm suitable for the load and complying with current

standards and regulations, must be fitted between the

appliance and the mains supply outlet. The yellowgreen earth wire must not be interrupted by the switch.

The supply cable must be in such a position that no

part of it can reach a temperature of 50 °C above

room temperature. Do not use adapters or shunts as

they could cause heating or burning. Before

connecting to the power supply, make sure that:

• the limiter valve and the domestic system can

withstand the load from the appliance (see rating

plate);

• the supply system is efficiently earthed according to

standards and laws in force;

• the socket or double-pole switch are easily

accessible when the appliance is installed.

FAILURE TO OBSERVE THE ACCIDENT-PREVENTION

REGULATIONS RELIEVES THE MANUFACTURER OF

ALL LIABILITY.

Important: the wires in the mains lead are coloured

in accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead may

not correspond with the coloured markings

identifying the terminals in your plug, proceed as

follows:

Connect the Green & Yellow wire to terminal marked

“E” or

Connect the Brown wire to the terminal marked “L” or

coloured Red.

Connect the Blue wire to the terminal marked “N” or

coloured Black.

Replacing the cable

Use a rubber cable of the type H05VV-F with a

suitable cross section 3 x 1.5 mm².

The yellow-green earth wire must be 2-3 cm longer

than the other wires.

! The cable must not be bent or compressed.

! The cable must be checked regularly and replaced

by authorised technicians only (

The manufacturer declines any liability shouldThe manufacturer declines any liability should

!

The manufacturer declines any liability should

The manufacturer declines any liability shouldThe manufacturer declines any liability should

these safety measures not be observed.these safety measures not be observed.

these safety measures not be observed.

these safety measures not be observed.these safety measures not be observed.

or coloured Green or Green & Yellow.

see Assistance

).

Disposal

• When disposing of packaging material: observe

local legislation so that the packaging may be

reused.

• The European Directive 2002/96/EC relating to

Waste Electrical and Electronic Equipment (WEEE)

states that household appliances should not be

disposed of using the normal solid urban waste

cycle. Exhausted appliances should be collected

separately in order to optimise the cost of re-using

and recycling the materials inside the machine,

while preventing potential damage to the

atmosphere and to public health. The crossed-out

dustbin is marked on all products to remind the

owner of their obligations regarding separated

waste collection.

For further information relating to the correct

disposal of exhausted household appliances,

owners may contact the public service provided or

their local dealer.

4

Page 5

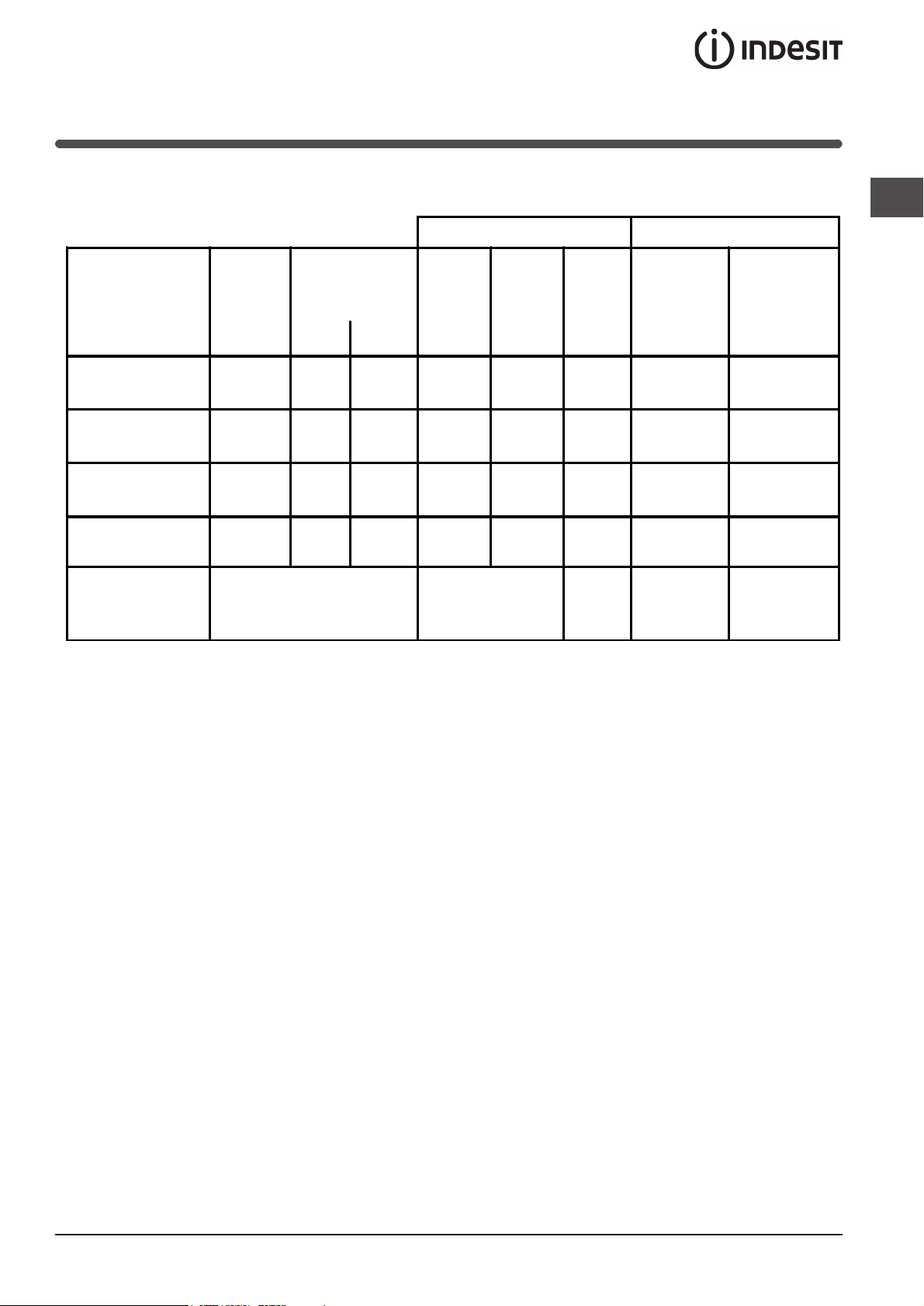

Burner and nozzle specifications

Table 1 Liquid Gas Natural Gas

GB

Burner Diameter

(mm)

Fast

(Large) (R)

Semi Fast

(Medium) (S)

Auxiliary

(Small) (A)

Triple Crown

(TC)

Supply

pressures

100 3.00 0.7 40 86 218 116 286

75 1.65 0.4 30 64 120 96 157

55 1.00 0.4 30 50 73 71 95

130 3.25 1.3 57 91 236 124 309

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

* At 15°C and 1013 mbar-dry gas

Propane G31 H.s. = 50,37 MJ/kg

Butane G30 H.s. = 49,47 MJ/kg

Methane G20 H.s. = 37,78 MJ/m

Thermal Power

kW (p.c.s.*)

By-pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzler

1/100

(mm)

Nom. Red. (mm) G30/31 (mm)

28-30

20

35

3

Flow*

l/h

20

17

25

5

Page 6

Description

of the appliance

GB

Overall view

SEMI-RAPID GAS BURNER

PAN REDUCING

SUPPORT

AUXILIARY

GAS BURNER

SUPPORT GRID

TRIPLE RING GAS BURNER

SEMI-RAPID GAS BURNER

RAPID

CONTROL KNOBS

FOR GAS BURNERS

Ignition for

GAS BURNERS *

SAFETY DEVICES *

(cooking programmer)

TIMER KNOB

IGNITION PUSHBUTTON FOR GAS BURNERS

ELECTRIC OVEN THERMOSTAT KNOB (temperature selection)

ELECTRIC OVEN SELECTOR KNOB (cooking function selection)

ELECTRIC OVEN OPERATION INDICATOR LIGHT

20 mm

120 - 180 mm

Only available on certain models.

*

6

Page 7

Start-up and use

0

Hob operation

The burners are fitted with automatic ignition and a

thermocouple safety device, which automatically cuts

off the gas from the burner in a few seconds if the

flame accidentally goes out during operation.

The burners differ in size and power. Choose the most

appropriate one for the diameter of the cookware

being used.

Each burner can be regulated with the corresonding

control knob by using one of the following settings:

Off

High flame

Low flame ,

The symbols

the relative burner on the hob.

To ignite a burner, proceed as follows:

• turn the relative knob counter-clockwise until the

pointer is on the high-flame symbol;

• press the knob down fully and activate the

automatic gas ignition by pushing at the same time

the button marked with the symbol

• keep the knob pressed down for about 10 seconds

with the flame lit to allow the safety thermocouple to

be heated;

• release the knob, checking that the flame is stable.

If it is not, repeat the operation.

For minimum power, turn the knob towards the low

flame symbol. Intermediate positions are possible by

simply putting the knob anywhere between the high

and the low flame symbol.

To turn off the burner, turn the knob clockwise to the

off position "

Important:

• Do not activate the automatic ignition device for

more than 15 consecutive seconds.

• Difficulty in ignition is sometimes due to air inside

the gas duct.

• If a burner flame accidentally goes out, the gas

continues to exit for a few moments before the

safety device activates. Turn the control knob to the

off position and do not attempt ignition again for at

least 1 minute, thereby letting the gas disperse,

which could otherwise be a danger.

• When the appliance is not in operation, check that

the knobs are in the off position "

supply cut-off cock should also be closed.

near the knobs show the position of

;

" .

" . The main gas

Using the burners:

To obtain maximum efficiency from the burners, it is

advisable to only use pans with a diameter suitable for

the burner being used, so that the flame does not

extend beyond the pan base (see following table).

When a liquid starts boiling, it is advisable to turn the

flame down just enough to keep the liquid simmering.

Burner ø Cookware Diameter (cm)

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

Triple Crown (TC) 24 - 26

The hob is fitted with reducing pan stands, which

should only be used on auxiliary burner "A".

ELECTRIC OVEN

The maxi-oven gives four combinations of heating

elements; so the most suitable type of cooking for

each dish may therefore be chosen, with convincing

results.

By turning the knob of the selector switch marked

with the symbol

obtained, as shown in the following table:

Symbol Power

0

0) Off -

1) Top + Bottom heating

elements

2) Bottom heating element 1300 W

3) Top heating element 1050 W

4) Grill heating element 2000 W

After having selected the heat source, put the

thermostat knob (marked with the symbol

temperature required.

• For normal cooking (roasts, biscuits, etc.) in

conventional mode use the function

above+below). Only put the food to be cooked into

the oven when it has reached the selected

temperature and preferably use just one shelf for

cooking.

, different cooking functions are

2350 W

) to the

(hot

GB

7

Page 8

GB

• To provide heat only to the bottom or the top part

of the dishes, turn the selector to the position

(hot below) or (hot above);

• Grill operation: a high heat output is used for grilling,

so that the surface of the food is immediately

browned; this is particularly indicated for meats

which should remain tender inside.

To grill, turn the selector knob to the position

(grill).

During grilling, do not set the thermostat knob to

over 200 °C and keep the oven door closed.

Minute minder

To use the timer, you must wind the alarm by turning

the knob almost one complete turn clockwise; then

turn the knob back to set the time by positioning the

minutes required on the index of the facia.

Oven light

The oven light comes on automatically when the

selector knob

Indicator light

It indicates that the oven is heating up. When the light

goes out, the required temperature has been reached

inside the oven.

When the light alternately comes on and goes out, it

means that the thermostat is working properly to

maintain the oven temperature.

is turned to any of its positions.

DATA PLATE

Dimensions

HxWxD

Volume 68 l

Burners

Electrical

connections

ENERGY LABEL

32x54x38 cm

may be adapted for use with any

type of gas shown on the data plate

voltag e: 23 0-240 V ~ 50/60 Hz

maximum power absorbed 2400W

Directive 2002/40/EC on the label

of electric ovens Norm EN 50 304

Declared energy consumption for

Natural convection Class – heating

mode: Static

This appliance conforms to the

following European Economic

Community directives:

20 06 /95/ EE C of 12/1 2/06 (Low

Vol tage) and subs equen t

amendments ;

- 2 004/ 108/ EEC of 15/12/0 4

(Electromagneti c Compatibility)

an d s ub sequent amend ments;

- 9 3/68/ EEC of 22/0 7/9 3 and

subsequent amendments.

- 2002/96/EC and subsequent

amendments .

8

Page 9

Cooking tips

Cooking times may vary according to the nature of the foods, their homogeneity and their volume. When

cooking a certain food for the first time, it is advisable to choose the lowest values in the cooking time range

given in the table and then increase them if necessary.

CONVENTIONAL oven cooking

GB

Type of dish Temperature °C

Pastries and cakes

Fruit pie

Meringues

Sponge cake

Angel cake

Madeira cake

Chocolate cake

Flat sweet loaf

Puffs

Flaky pastry biscuits

Mille feuilles

Short crust pastry

130

130

150

160

160

170

170

200

200

200

200

Type of dish

Chops (0.5 kg)

Saussages

Grilled chicken (1 kg)

Veal on the spit (0.6 kg)

Chicken on the spit (1 kg)

Cooking time

(minutes)

60-70

30-40

20-30

40-50

40-50

30-40

40-50

15-20

15-20

15-20

15-20

Type of dish Temperature °C

Meat

Turkey (4-8 kg)

Goose (4-5 kg)

Duck (2-4 kg)

Capon (2½-3 kg)

Braised beef (1-1½

kg)

Leg of lamb

Roast hare (2 kg)

Roast pheasant

Chicken (1-1½ kg)

Fish

160

160

170

170

160

160

160

160

170

200

GRILLING

Cooking time

(minutes)

60

15

60

60

60

Position of

shelf

rd

guide rail

3

nd

guide rail

2

st

guide rail

1

-

-

Cooking time

(h ou rs )

3-4½

4-4½

1½-2½

2-2 ½

3-3½

1-1½

1-1½

1-1½

1-1½

15-25 minutes

The 1st guide rail is understood as being the lowest position.

Notes:Notes:

Notes:

Notes:Notes:

1) Cooking times do not include oven pre-heating, except for those marked with an asterisk.

2) The indication given in the table for the guide rails is the one that should preferably be used in the event of

cooking on more than one level.

3) The indicated times refer to cooking on one shelf only; for cooking on more than one level, increase the time

by 5 ÷ 10 minutes.

4) For roast beef, veal, pork and turkey, on the bone or rolled, increase the times by 20 minutes.

9

Page 10

Precautions and tips

GB

! This appliance has been designed and manufactured

in compliance with international safety standards.

The following warnings are provided for safety

reasons and must be read carefully.

General safety

• The appliance was designed for domestic use

inside the home and is not intended for

commercial or industrial use.

• The appliance must not be installed outdoors, even

in covered areas. It is extremely dangerous to

leave the appliance exposed to rain and storms.

• Do not touch the appliance with bare feet or with

wet or damp hands and feet.

• The appliance must be used by adults only for

the preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous.

The manufacturer may not be held liable for

any damage resulting from improper, incorrect

and unreasonable use of the appliance.

• The instruction booklet accompanies a class 1

(insulated) or class 2 - subclass 1 (recessed

between 2 cupboards) appliance.

• Do not touch the heating elements or certain

parts of the oven door when the appliance is in

use; these parts become extremely hot. Keep

children well away from the appliance.

• Make sure that the power supply cables of other

electrical appliances do not come into contact

with the hot parts of the oven.

• The openings used for the ventilation and

dispersion of heat must never be covered.

• Always use oven gloves when placing cookware

in the oven or when removing it.

• Do not use flammable liquids (alcohol, petrol,

etc...) near the appliance while it is in use.

• Do not place flammable material in the lower

storage compartment or in the oven itself. if the

appliance is switched on accidentally, they could

catch fire.

• The internal surfaces of the compartment (where

present) may become hot.

• Always make sure the knobs are in the

when the appliance is not in use.

• When unplugging the appliance, always pull the

plug from the mains socket; do not pull on the

cable.

• Never perform any cleaning or maintenance work

without having disconnected the appliance from

the electricity mains.

• position

• If the appliance breaks down, under no

circumstances should you attempt to perform the

repairs yourself. Repairs carried out by

inexperienced persons may cause injury or further

malfunctioning of the appliance. Contact

Assistance.

• Do not rest heavy objects on the open oven door.

• The appliance should not be operated by people

(including children) with reduced physical,

sensory or mental capacities, by inexperienced

individuals or by anyone who is not familiar with

the product. These individuals should, at the very

least, be supervised by someone who assumes

responsibility for their safety or receive

preliminary instructions relating to the operation of

the appliance.

• Do not let children play with the appliance.

• If the cooker is placed on a pedestal, take the

necessary precautions to prevent the same from

sliding off the pedestal itself.

Disposal

• When disposing of packaging material: observe

local legislation so that the packaging may be

reused.

• The European Directive 2002/96/EC relating to

Waste Electrical and Electronic Equipment

(WEEE) states that household appliances should

not be disposed of using the normal solid urban

waste cycle. Exhausted appliances should be

collected separately in order to optimise the cost

of re-using and recycling the materials inside the

machine, while preventing potential damage to

the atmosphere and to public health. The

crossed-out dustbin is marked on all products to

remind the owner of their obligations regarding

separated waste collection.

For further information relating to the correct

disposal of exhausted household appliances,

owners may contact the public service provided

or their local dealer.

Respecting and conserving the

environment

• You can help to reduce the peak load of the

electricity supply network companies by using the

oven in the hours between late afternoon and the

early hours of the morning.

• Always keep the oven door closed when using the

GRILL modes: This will achieve improved results

while saving energy (approximately 10%).

• Check the door seals regularly and wipe them

clean to ensure they are free of debris so that

they adhere properly to the door, thus avoiding

heat dispersion.

10

Page 11

Care and maintenance

Switching the appliance off

Disconnect your appliance from the electricity supply

before carrying out any work on it.

Cleaning the appliance

! Do not use abrasive or corrosive detergents (for

example, products in spray cans for cleaning

barbecues and ovens), stain removers, anti-rust

products, powder detergents or sponges with

abrasive surfaces: these may scratch the surface

beyond repair.

! Never use steam cleaners or pressure cleaners on

the appliance.

To extend the life of your oven, it must be cleaned

frequently, keeping in mind that:

• The self-cleaning panels (if present) and the

enameled parts should be washed with warm water

- abrasive powders and corrosive substances

should be avoided;

• The inside of the oven should be cleaned

immediately after use with warm water and soap;

the soap should be rinsed away and the interior

dried thoroughly;

• Stainless steel can be stained if it remains in

contact with agressive detergents (containing

phosphorus) or water with a high lime content. We

recommend that you rinse these parts thoroughly

and dry them well after cleaning. It is also a good

idea to dry any water spills;

• Never line the bottom of the oven with aluminium foil

because the buildup of heat will not only impede

the cooking process, but could also damage the

enamel.

Disassembling/assembling the oven door

Clean the glass part of the oven door using a sponge

and a non-abrasive cleaning product, then dry

thoroughly with a soft cloth. Do not use rough abrasive

material or sharp metal scrapers as these could

scratch the surface and cause the glass to crack. To

clean more thoroughly, you can remove the oven door:

• Open the door completely and lift the 2 levers “B”;

• Now, shutting the door slightly, you can lift it out by

pulling out the hooks “A” as shown in figure.

To reassemble the door:

• With the door in a vertical position, insert the two

hooks “A” into the slots;

• Ensure that seat “D” is hooked perfectly onto the

edge of the slot (move the oven door backwards

and forward slightly);

• Keep the oven door open fully, unhook the 2 levers

“B” downwards and then shut the door again.

GB

Changing the oven light bulb

• Cutoff the supply of power to the oven by turning off

the omni-polar switch connecting it to the mains, or

by removing the plug if it is accessible;

• Unscrew the glass cover attached to the lamp

holder;

• Unscrew the lamp and replace it with another hightemperature lamp (300°C) with the following

characteristics:

- Voltage: 230/240 V

- Wattage: 15W

- Socket: E14

• Remount the glass cover

and reconnect the

appliance to the power

supply.

11

Page 12

Guarantee

12 months Parts and Labour Guarantee

Your appliance has the benefit of our manufacturer’s guarantee, which covers the cost of breakdown repairs for

twelve months from the date of purchase.

This gives you the reassurance that if, within that time, your appliance is proven to be defective because of either

workmanship or materials, we will, at our discretion, either repair or replace the appliance at no cost to you.

This guarantee is subject to the following conditions:

- The appliance has been installed and operated correctly and in accordance with our operating and

maintenance instructions.

- The appliance is used only on the electricity or gas supply printed on the rating plate.

- The appliance has been used for normal domestic purposes only.

- The appliance has not been altered, serviced, maintained, dismantled, or otherwise interfered with by any

person not authorised by us.

- Any repair work must be undertaken by us or our appointed agent.

- Any parts removed during repair work or any appliance that is replaced become our property.

- The appliance is used in the United Kingdom or Republic of Ireland.

The guarantee does not cover:

- Damage resulting from transportation, improper use, neglect or interference or as a result of improper

installation.

- Replacement of any consumable item or accessory. These included but not limited to: plugs, cables, batteries,

light bulbs, fluorescent tubes and starters, covers and filters.

- Replacement of any removable parts made of glass or plastic.

THIS GUARANTEE WILL NOT APPLY IF THE APPLIANCE HAS BEEN USED IN COMMERCIAL OR NONDOMESTIC PREMISES.

5 Year Parts Guarantee

Indesit also offers you a free 5 year parts guarantee. This additional guarantee is conditional on you registering

your appliance with us and the parts being fitted by one of our authorised engineers. There will be a charge for

our engineer’s time. To activate the extra parts warranty on your appliance, simply call our registration line on

08448 24 24 24 (Republic of Ireland 01 230 0800)

Extended Guarantees

We offer a selection of protection plans that enable you to fully cover yourself against the expense of repair bills

for the life of your policy. To find the ideal plan for you please call our advice line on 08448 226 226 (Republic of

Ireland 01 230 0233).

Free Helpdesk Service

We have a dedicated team who can provide free advice and assistance with your appliance if you experience

any technical difficulties within the first 90 days of ownership. Simply call our Indesit Service Hotline on 08448

224 224 (Republic of Ireland 0818 313 413) for telephone assistance, or, where necessary, to arrange for an

engineer to call.

Page 13

After Sales Service

No one is better placed to care for your Indesit appliance during the course of its working life than us – the

manufacturer.

Essential Contact Information

Indesit Service

We are the largest service team in the UK and Ireland offering you access to 400 skilled telephone advisors and

1000 fully qualified engineers on call to ensure you receive fast, reliable, local service.

UK: 08448 224 224

Republic of Ireland: 0818 313 413

www.indesitservice.co.uk

Please note: Our advisors will require the following information:

Model number:

Serial number:

Parts and Accessories

We supply a full range of genuine replacement parts as well as accessory products that protect and hygienically

clean your appliance to keep it looking good and functioning efficiently throughout its life.

UK: 08448 225 225

Republic of Ireland: 0818 313 413

www.indesitservice.co.uk

Appliance Registration

We want to give you additional benefits of Indesit ownership. To activate your free 5 year parts guarantee you

must register your appliance with us.

UK: 08448 24 24 24

Republic of Ireland: 01 230 0800

www.indesitservice.co.uk

Indesit Company UK Ltd. Morley Way, Peterborough, PE2 9JB

Indesit Company Unit 49 Airways Industrial Estate, Dublin 17

Recycling and Disposal Information

As part of Indesit’s continued commitment to helping the environment, Indesit reserves the right to use quality,

recycled components to keep down customer costs and minimise material wastage.

Please dispose of packaging and old appliances carefully. To minimise the risk of injury to children, remove the

door, plug, and cut the mains cable off flush with the appliance. Dispose of these parts separately to ensure that

the appliance can no longer be plugged into mains socket, and the door cannot be locked shut.

Page 14

GB

14

Page 15

GB

15

Page 16

GB

08/2009 - 195070160.01

XEROX FABRIANO

16

Loading...

Loading...