Indesit KP900GX User Manual

Operating Instructions

Contents

GB

Installation, 2-5

English,2

KP900GX

Room ventilation

Disposing of combustion fumes

Positioning and levelling

Electrical connection

Gas connection

Table of burner and nozzle specifications

Table of characteristics

Description of the appliance, 6

Overall view

Control panel

Start-up and use, 7-11

Using the hob

Setting the time

Using the oven

Cooking modes for Multi-function (1rst Oven)

Cooking modes for conventional-function (2nd Oven)

Practical cooking advice

Oven cooking advice table

COOKER AND OVEN

GB

Precautions and tips, 12

General safety

Disposal

Respecting and conserving the environment

Care and maintenance, 13

Switching the appliance off

Cleaning the appliance

Replacing the oven light bulb

Gas tap maintenance

Assistance

Installation

GB

! Before operating your new appliance please read

this instruction booklet carefully. It contains

important information concerning the safe installation

and operation of the appliance.

! Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualified

professional according to the instructions provided.

! Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

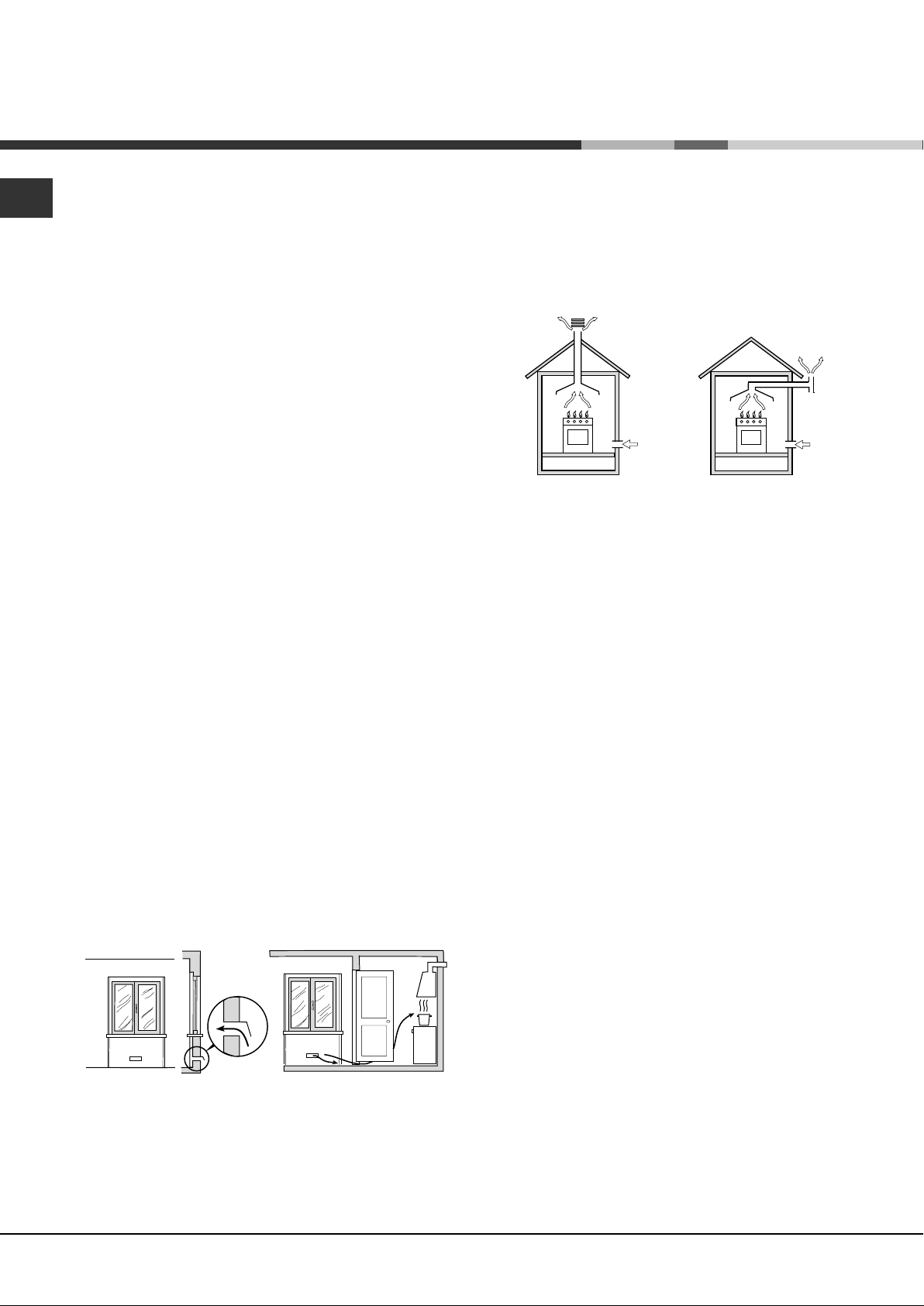

Room ventilation

The appliance may only be installed in permanentlyventilated rooms, in accordance with current national

legislation. The room in which the appliance is

installed must be ventilated adequately so as to

provide as much air as is needed by the normal gas

combustion process (the flow of air must not be

lower than 2 m3/h per kW of installed power).

The air inlets, protected by grilles, should have a

duct with an inner cross section of at least 100 cm2

and should be positioned so that they are not liable

to even partial obstruction (see figure A).

These inlets should be enlarged by 100% - with a

minimum of 200 cm2 - whenever the surface of the

hob is not equipped with a flame failure safety

device. When the flow of air is provided in an indirect

manner from adjacent rooms (see figure B), provided

that these are not communal parts of a building,

areas with increased fire hazards or bedrooms, the

inlets should be fitted with a ventilation duct leading

outside as described above.

Adjacent room Room requiring

ventilation

AB

Disposing of combustion fumes

The disposal of combustion fumes should be

guaranteed using a hood connected to a safe and

efficient natural suction chimney, or using an electric

fan that begins to operate automatically every time

the appliance is switched on (see figure).

Fumes channeled outside

Fumes channelled through straight a

chimney or a branched flue system

(reserved for cooking appliances)

! The liquefied petroleum gases are heavier than air

and collect by the floor, therefore all rooms containing

LPG cylinders must have openings leading outside so

that any leaked gas can escape easily.

LPG cylinders, therefore, whether partially or

completely full, must not be installed or stored in

rooms or storage areas that are below ground level

(cellars, etc.). Only the cylinder being used should be

stored in the room; this should also be kept well

away from sources of heat (ovens, chimneys,

stoves) that may cause the temperature of the

cylinder to rise above 50°C.

Positioning and levelling

! It is possible to install the appliance alongside

cupboards whose height does not exceed that of the

hob surface.

! Make sure that the wall in contact with the back of

the appliance is made from a non-flammable, heatresistant material (T 90°C).

A

Ventilation opening Increase in the gap between

for comburent air the door and the flooring

! After prolonged use of the appliance, it is advisable

to open a window or increase the speed of any fans

used.

2

To install the appliance correctly:

• Place it in the kitchen, the dining room or the bedsit (not in the bathroom).

• If the top of the hob is higher than the cupboards,

the appliance must be installed at least 600 mm

away from them.

• If the cooker is installed underneath a wall cabinet,

there must be a minimum distance of 420 mm

between this cabinet and the top of the hob.

This distance should be increased to 700 mm if the

wall cabinets are flammable (see figure).

mm.

420

Min.

HOOD

Min. mm.

900

• Do not position

blinds behind the

cooker or less than 200

mm away from its

sides.

mm. with hood

mm. without hood

420

• Any hoods must be

650

700

Min. mm.

installed according to

min.

min.

the instructions listed in

the relevant operating

manual.

Green & Yellow wire to terminal marked “E” or

or coloured

Green or Green & Yellow.

Brown wire to terminal marked “L” or coloured Red.

Blue wire to terminal marked “N” or coloured Black (see fig.

B).

l fix the feeding cable in the special cable stop and

close the cover.

N.B.: the power supply cable must have these minimum

requirements:

Type: H05RR-F

Section: 3x2.5 mm

2

GB

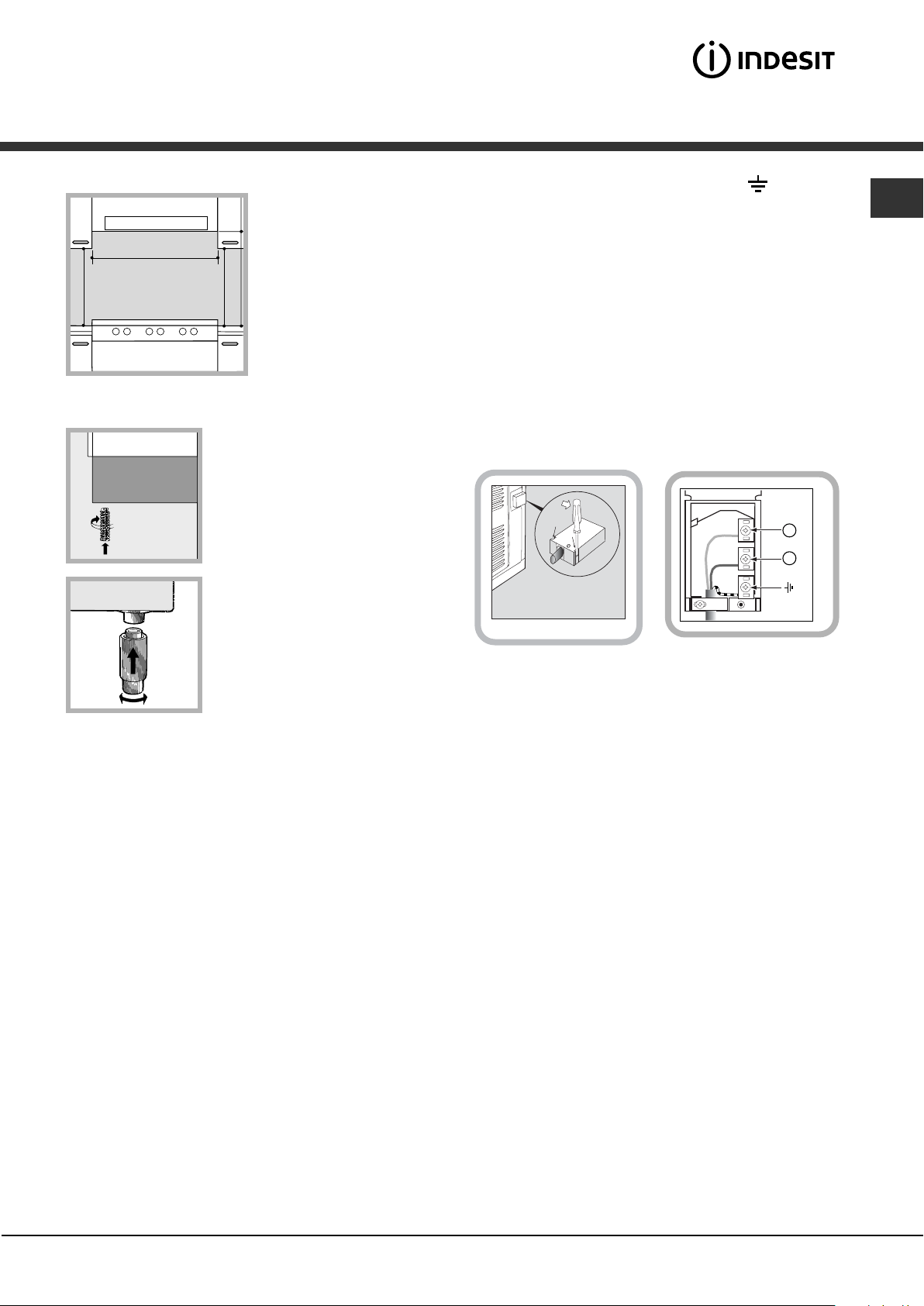

Levelling

If it is necessary to level the

appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (see

figure).

The legs* fit into the slots on

the underside of the base of

the cooker.

Electrical connection

WARNING – THIS APPLIANCE MUST BE EARTHED.

Electrical connection

Electric cookers come without a power supply cable. The

cooker is designed to operate on an electricity supply which

conforms to the electrical data shown on the Rating Plate. The

cooker can be connected to the mains only after removing

the back panel of the cooker itself with a screwdriver.

N.B.: the following installation procedure must be carried out

by a qualified electrician. The electrical installation must comply

with the IEE Regulations, Building & local By-Lays.

For the installation of the feeding cable carry out the following

operations:

l Using a screwdriver, prise on the side tabs of the

terminal board cover (see fig. A);

l Pull and open the junction blok lid

Important: the wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow -Earth

Blue -Neutral

Brown -Live

As the colours of the wires in the mains lead may not

correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

Ensure that the mains cable is routed away from any brackets

affixed to the rear panel and is not trapped to the rear wall

when pushing the cooker into position between cabinets.

L

2

N

4

Fig. A

Fig. B

Gas connection

Connection to the gas network or to the gas cylinder

may be carried out using a flexible rubber or steel hose,

in accordance with current national legislation and after

making sure that the appliance is suited to the type of

gas with which it will be supplied (see the rating sticker

on the cover: if this is not the case see below). When

using liquid gas from a cylinder, install a pressure

regulator which complies with current national

regulations. To make connection easier, the gas supply

may be turned sideways*: reverse the position of the

hose holder with that of the cap and replace the gasket

that is supplied with the appliance.

! Check that the pressure of the gas supply is

consistent with the values indicated in the Table of

burner and nozzle specifications (see below). This

will ensure the safe operation and durability of your

appliance while maintaining efficient energy

consumption.

Gas connection using a flexible rubber hose

Make sure that the hose complies with current

national legislation. The inter nal diameter of the hose

must measure: 8 mm for liquid gas supply; 13 mm for

methane gas supply.

Once the connection has been performed, make sure

3

GB

that the hose:

• Does not come into contact with any parts that

reach temperatures of over 50°C.

• Is not subject to any pulling or twisting forces and

that it is not kinked or bent.

• Does not come into contact with blades, sharp

corners or moving parts and that it is not

compressed.

• Is easy to inspect along its whole length so that its

condition may be checked.

• Is shorter than 1500 mm.

• Fits firmly into place at both ends, where it will be

fixed using clamps that comply with current

regulations.

! If one or more of these conditions is not fulfilled or

if the cooker must be installed according to the

conditions listed for class 2 - subclass 1 appliances

(installed between two cupboards), the flexible steel

hose must be used instead (see below).

Connecting a flexible jointless stainless steel pipe to

a threaded attachment

Make sure that the hose and gaskets comply with

current national legislation.

To begin using the hose, remove the hose holder on

the appliance (the gas supply inlet on the appliance

is a cylindrical threaded 1/2 gas male attachment).

! Perform the connection in such a way that the hose

length does not exceed a maximum of 2 metres,

making sure that the hose is not compressed and

does not come into contact with moving parts.

Checking the tightness of the connection

When the installation process is complete, check

the hose fittings for leaks using a soapy solution.

Never use a flame.

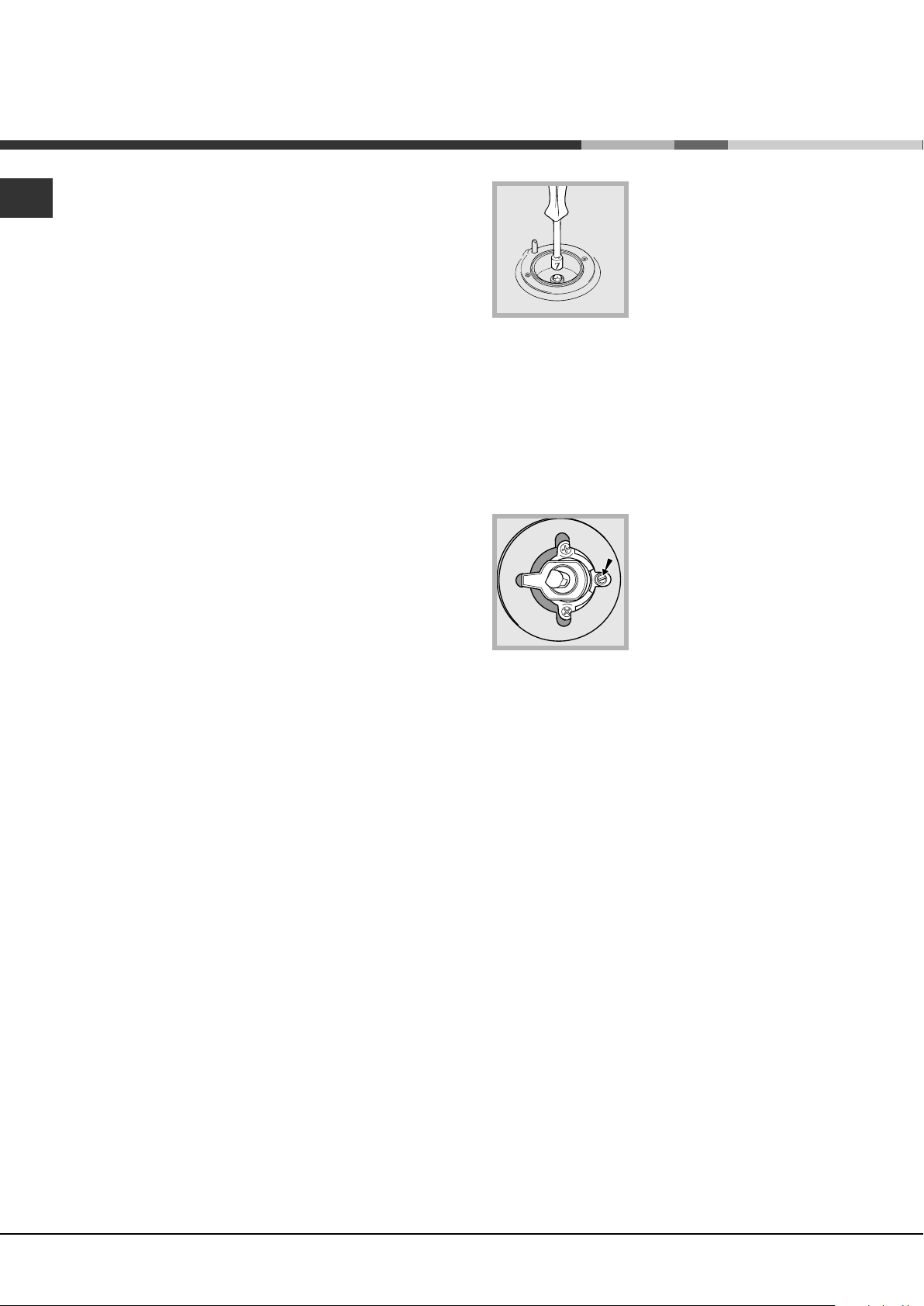

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

suited to the new type of gas

see Burner and nozzle

(

specifications table

3. Replace all the components

by fo llowin g the above

instructions in reverse.

Adjusting the hob burners’

minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory screw,

which is positioned inside or next to the tap pin, until

the flame is small but steady.

! If the appliance is connected to a liquid gas supply,

the regulatory screw must be fastened as tightly as

possible:

3. While the burner is alight, quickly change the position of

the knob from minimum to maximum and vice versa

several times, checking that the flame is not extinguished.

! The hob burners do not require primary air adjustment.

! After adjusting the appliance so it may be used with a

different type of gas, replace the old rating label with a

new one that corresponds to the new type of gas (these

labels are available from Authorised Technical Assistance

Centres).

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to “regulators for channelled gas”.

).

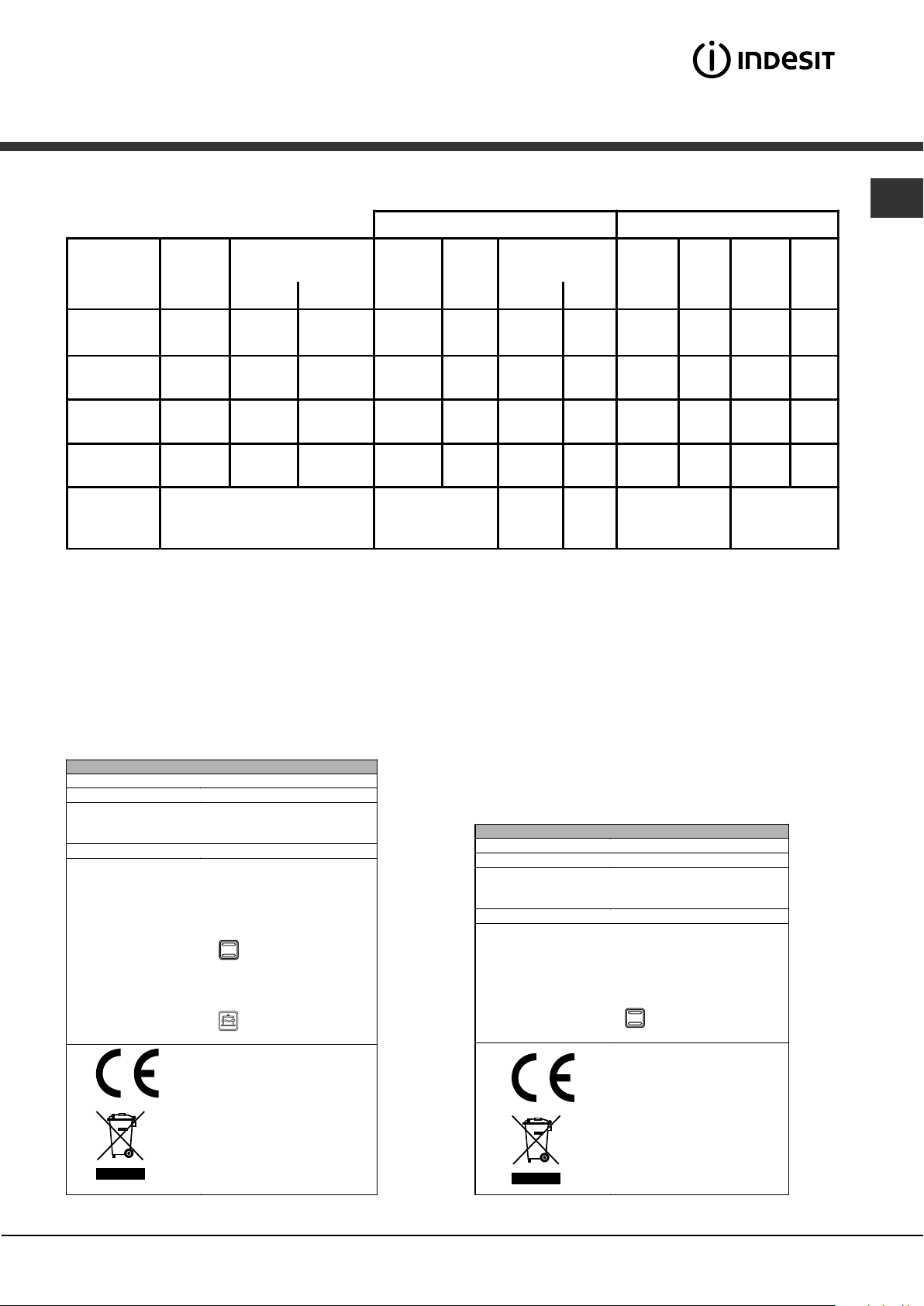

Table of burner and nozzle specifications

Adapting the hob

Replacing the nozzles for the hob burners:

1. Remove the hob grids and slide the burners off

their seats.

2. Unscrew the nozzles using a 7 mm socket

spanner (

4

see figure

), and replace them with nozzles

Table 1 Liquid Gas Natural Gas

GB

Burner Diameter

(mm)

Thermal Power

kW (p.c.s.*)

Nomi nal Re duc ed (mm) (mm) *** ** (mm) (mm)

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliary

(Small)(A)

Tr iple Ring

(TC)

Supply

Pressures

100 3,00 0,7 41 86 218 214 116 286 143 286

75 1,90 0,4 30 70 138 136 106 181 118 181

55 1,00 0,4 30 50 73 71 79 95 80 95

130 3.25 1.5 63 91 236 232 133 309 150 309

Nominal (mbar)

Minimum (mbar )

Maximum (mbar)

* At 15°C and 1013 mbar - dry gas

** Propane P.C.S. = 50.37 MJ/kg

*** Butane P.C.S. = 49.47 MJ/kg

Natural P.C.S. = 37.78 MJ/m³

By-Pass

1/100

Nozzle

1/100

28-30

20

35

Flow*

g/h

37

25

45

Nozzle

1/100

20

17

25

Flow*

l/h

Nozzle

1/100

Flow*

l/h

13

6,5

18

TECHNICAL DATA (1st Oven )

Oven dimensions

Volume

Burners

Voltage and frequency see data plate

ENERGY LABEL

H:34;W:39;D:41 cm

54 l

may be adapted for use with any

type of gas shown on the data

plate

Directive 2002/40/EC on the

label of electric ovens.

Regulation EN 50304

Energy consumption for Natural

convection – heating mode:

Traditional mode

Declared energy consumption

for Forced convection Class –

heating mode:

Baking.

EC Directive s: 73/23/EEC

dated 19/02/73 (Low Voltage)

and subsequent amendments 89/336/EEC dated 03/05/89

(Electromagnetic Compatibility)

and subsequent amendments 90/369/EEC dated 29/06/90

(Gas) and subsequent

amendments - 93/68/EEC

dated 22/07/93 and subsequent

amendments - 2002/96/EC.

TECHNICAL DATA (2nd Oven)

;

Dimensions

Volume

Burners

Voltage and frequency see data plate

ENERGY LABEL

H:33.8;W:24.5;D:43.8 cm

36 l

may be adapted for use with any

type of gas shown on the data

plate

Directive 2002/40/EC on the

label of electric ovens .

Regulation EN 50304

Energy consumption for Natural

convectio n – heating mode:

;

Traditional mode

EC Directives: 73/23/EEC

dated 19/02/73 (Low Vol tage)

and subsequent am end m ents 89/336/EEC dated 03/05/89

(Electromagnetic Compatibility)

and subsequent am end m ents 90/369/EEC dated 29/06/90

(Gas) and subsequent

amendments - 93/68/EEC

dated 22/07/93 and subsequent

amendments - 2002/96/EC.

5

Loading...

Loading...