Page 1

Free Standing Dual Fuel Cooker

Instructions for installation and use

KP100IX

Page 2

Contents

PAG E

Introduction 3

For Your Safety 4

Clock / Minute Minder Operation 6

Hotplate 8

Twin Grill 9

Ovens 10

Oven Cooking Charts 11

Care and Cleaning 13

Something Wrong with your cooker? 15

Installations 16

If it still won’t work 23

Key Contacts Back Cover

This appliance must be installed in accordance with the regulations in force and

only used in a well ventilated space.

The data badge is fitted on the rear panel. The model/serial number can also be

found on a badge located below the left-hand oven door beneath the door seal.

Read these instructions before installing or using the appliance and retain

them for future reference.

2

Page 3

Introduction

To help you make the best use of your cooker, PLEASE READ THIS BOOKLET

CAREFULLY.

Your new cooker is guaranteed and will give lasting service. The guarantee is only

applicable if the cooker has been installed in accordance with the Installation

Instructions.

The cooker is designed specifically for domestic use and responsibility will not be

accepted for use in any other installation.

When first using the cooker ensure that the room is well ventilated (e.g. open a

window or use an extractor fan) and that persons who may be sensitive to the odour

avoid any fumes. It is suggested that any pets be removed from the room until the

smell has ceased. This odour is due to any temporary finish and also any moisture

absorbed by the insulation.

Our policy is one of continual improvement in design and development,

therefore strict accuracy of illustrations and descriptions cannot be

guaranteed.

This appliance conforms to the following EEC Directive:

Gas Appliances

90/396/EEC

Low Voltage Equipment

73/23/EEC

93/68/EEC

Electromagnetic Compatibility

89/336/EEC

92/31/EEC

93/68/EEC

3

Page 4

For your Safety

Please read the precautions below before using your cooker.

ALWAYS . . .

ALWAYS make sure you understand the controls before using the cooker.

ALWAYS check that all controls on the cooker are turned off after use.

ALWAYS stand back when opening an oven door to allow heat to disperse.

ALWAYS use dry, good quality oven gloves when removing items from the ovens.

ALWAYS take care when removing items from the grill when the oven below is on, as

the contents may be hot.

ALWAYS keep the oven and grill doors closed when the cooker is not in use.

ALWAYS place pans centrally over the hotplate burners and position them so that

the handles cannot accidentally be caught or knocked or become heated

by other burners.

ALWAYS keep the cooker clean, as a build up of grease or fat from cooking can

cause a fire.

ALWAYS allow the cooker to cool before cleaning.

ALWAYS follow the basic principles of food handling and hygiene to prevent the

possibility of bacterial growth.

ALWAYS keep ventilation slots clear of obstructions.

ALWAYS turn off the electricity supply before cleaning or replacing an oven lamp.

ALWAYS refer servicing to CORGI registered appliance service engineers.

4

Page 5

For your Safety

NEVER . . .

NEVER leave children unsupervised where the cooker is installed as all surfaces will

get hot during and after use.

NEVER allow anyone to sit or stand on any part of the cooker.

NEVER store items that children may attempt to reach above the cooker.

NEVER heat up unopened food containers as pressure can build up causing the

container to burst.

NEVER

NEVER fill a deep fat frying pan more than 1/3 full of oil, and never use a lid.

NEVER place flammable or plastic items on or near the hotplate.

NEVER use proprietary spillage collectors on the hotplate.

NEVER use the cooker as a room heater.

NEVER dry clothes or place other times over or near to the hotplate or oven/ grill

NEVER wear garments with long flowing sleeves whilst cooking.

NEVER operate the grill with the grill door closed.

NEVER line the shelves, floor or sides of the oven or grill with aluminium foil as over

NEVER clean the cooker with steam cleaners.

NEVER touch the heating elements inside the oven or grill even when off.

NOTE: The use of a gas cooking appliance results in the production of heat and

moisture in the room in which it is installed. Always ensure that the kitchen is well

ventilated; keep natural ventilation holes open or install a mechanical ventilation device

(mechanical extractor hood).

store chemicals, food stuffs, pressurised containers in or on the cooker,

cabinets immediately above or next to the cooker.

DO NOT LEAVE UNATTENDED WHILE COOKING.

doors.

This may cause overheating of your cooker.

heating and damage can result.

or in

In particular, when using more than one hotplate burner, open a window if a

mechanical ventilation device is not operating.

5

Page 6

Clock / Minute Minder

CLOCKFACE

0.00

-

0.00

+

Minute

Minder

The timer incorporates a 24 hour clock.

SYMBOLS

A ‘Bell’ symbol will light up when you select a Minute Minder Period

and will remain lit for the period set.

At the end of the Minute Minder Period, the timer will emit an audible

tone and the ‘Bell’ symbol will disappear.

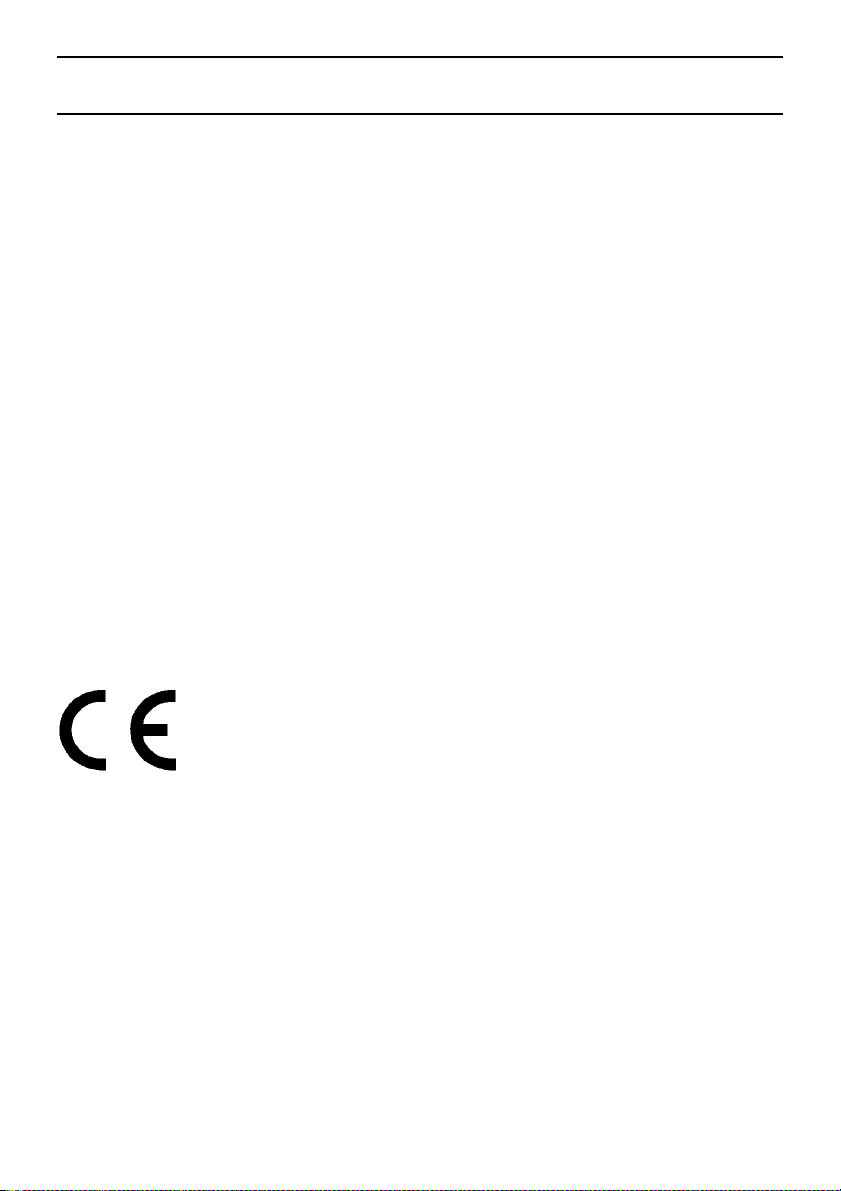

SETTING THE TIME OF DAY

6

0.00

0.00

Step 1 Make sure all oven controls are turned off.

Step 2 Check the electricity supply to the cooker is turned on.

Step 3 When switched on, the display will show 0.00

Step 4 Press and release both buttons simultaneously.

Step 5 Press the ‘+’ button to set the Time of Day.

The Time of Day can be adjusted, by using the ‘+’ button to

increase the time setting or the ‘-’ button to decrease the

time setting.

The Time of Day is set if no adjustments are made within 10

seconds.

THE TIME OF DAY IS NOW SET.

To change the time of day repeat Steps 4 & 5 above.

Page 7

Clock / Minute Minder

Here you can set a time period of up to 10 hours, that will count down.

When it reaches zero, the timer will emit an audible tone.

For Example: If you set 20 minutes, the audible tone will occur 20

minutes later.

SETTING THE MINUTE MINDER

Step 1 Ensure the time of day is set correctly.

Step 2 Press and release the ‘+’ button.

0.00

0.00

19.50

Note: Step 3 must be started within 10 seconds, otherwise

you must repeat Step 2.

Step 3 Press the ‘+’ button to set the required time period.

A ‘Bell’ symbol will light up.

The time period can be adjusted, by using the ‘+’ button to

increase the time period or the ‘-’ button to decrease the

time period.

Release all buttons, the timer display will show the remaining time

period. The ‘Bell’ symbol will remain lit to signify that a time period has

been set.

At the end of the set time an audible tone will be heard and the ‘Bell’

symbol will disappear.

Step 4 To cancel the audible tone press the ‘+’ button.

To cancel the minute minder period press the ‘-’ button until 0.00 is

displayed in the window then press the ‘+’ button.

If at any time the display shows flashing zero’s, it is likely that the

electricity supply has been interrupted.

Reset the timer to the correct time of day.

Note: The Timer display will show the minute minder

period as follows:

Any period up to 99 minutes and 50 seconds -

The display shows MINUTES and SECONDS (10s intervals)

eg. 19 minutes 50 seconds

1.41

Any period between 100 minutes (1 hour 40 minutes) and up

to 10 hours -

The display shows HOURS and MINUTES

eg. 1 hour 41 minutes

7

Page 8

Hotplate

The hotplate has one high speed wok burner, one large high speed burner, four

normal simmering burners and two small simmering burner that will accommodate

pans between 100mm (4”) and 200mm (8”) diameter.

All pans should be placed centrally over the burners.

TO USE THE HOTPLATE

1. Press the ignition button and then push in and turn the control knob of the

chosen burner anti-clockwise to the large flame symbol. Continue to press

the ignition button until the spark lights the gas.

2. Turn the control knob anti-clockwise to the desired setting.

Only turn the control knob between the large flame symbol and the small

flame symbol for adjusting the setting.

3. To turn off, turn the control knob fully clockwise to the O position.

DO NOT use mis-shapen pans which may be unstable.

DO NOT use round base woks directly on the pan supports.

Each burner is fitted with a spark ignition electrode for lighting the gas.

To ensure rapid lighting of the burners every time they are used, the electrodes must be

kept clean and dry. Remove any food spillage or cleaning materials from the electrodes

using a small nylon brush such as a tooth brush.

Access to the ignitor can be achieved by lifting off the loose burner parts carefully when

the burners are cool.

If aluminium based pans are used, a silvery deposit may appear on the top edge of the

pan support fingers. See ‘Care and Cleaning’ section for further information.

SAFETY REQUIREMENTS FOR DEEP FAT FRYING

1. Never fill chip pans more than one third full with oil or fat.

2. Never leave oil or fat unattended during the heating or cooling period.

3. Never heat fat or fry with a lid on the pan.

4. Always dry food thoroughly before frying, and lower it slowly into the hot oil

or fat. Frozen foods in particular will cause frothing and spitting if added too

quickly.

5. Always keep the outside of the pan clean and free from streaks of oil or fat.

HOW TO DEAL WITH A FAT FIRE

1. Do not move the pan.

2. Turn off the hotplate burners.

3. Smother the flames with a fire blanket or damp cloth to extinguish the fire.

Do not use water or a fire extinguisher as the force of it may spread the

burning fat or oil over the edge of the pan.

4. Leave the pan for at least 60 minutes before moving it.

8

Page 9

Twin Grill

CAUTION – ACCESSIBLE PARTS MAY BECOME HOT WHEN THE GRILL IS IN USE.

YOUNG CHILDREN SHOULD BE KEPT AWAY.

GRILLING SHOULD NEVER BE UNDERTAKEN WITH THE GRILL DOOR CLOSED.

The grill control is designed to provide variable heat control of either the full width of

the grill or just the half. Turning the control knob clockwise will switch on the full

width and turning anticlockwise will switch on just the half.

A gentle flow of air will be blown from underneath the control panel when the grill is

in use.

If the fan fails to blow air beneath the control panel when the grill is in use, you

should contact your service engineer immediately (see Key Contacts, back page).

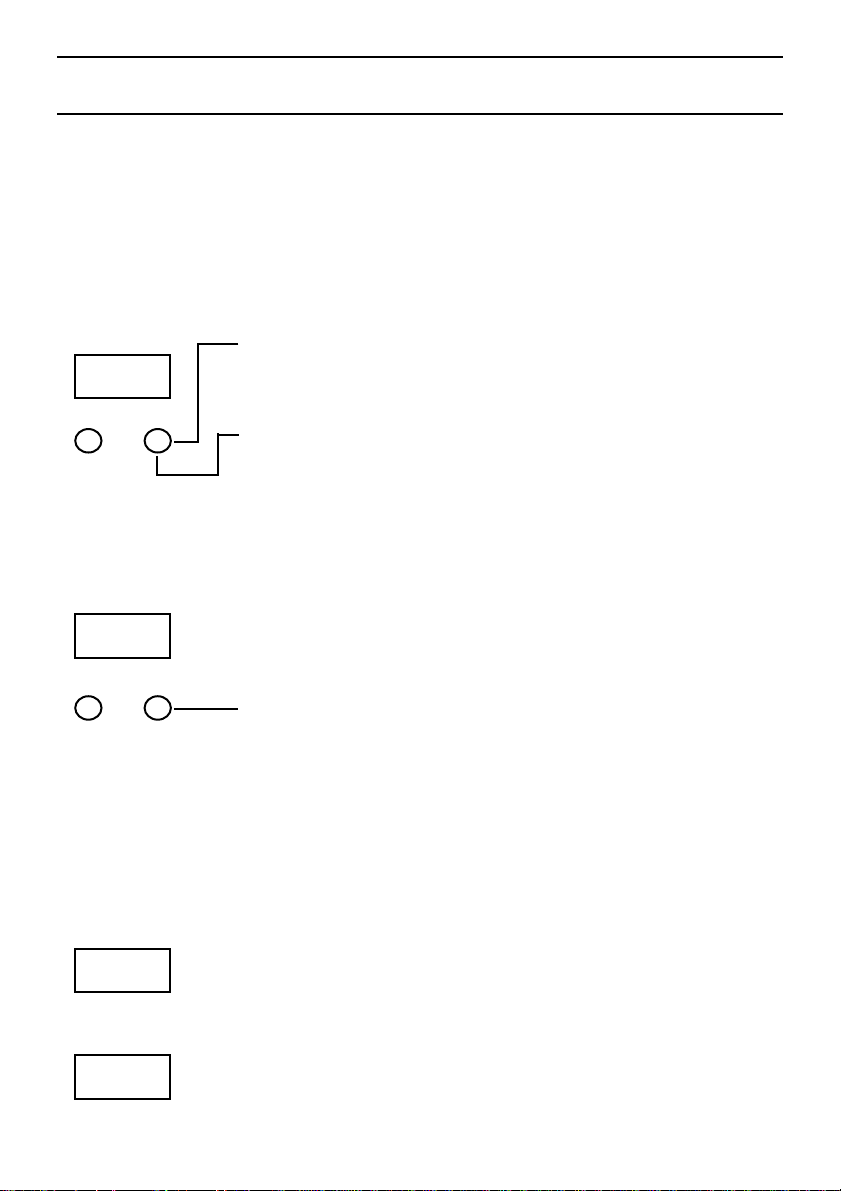

GRILL PAN HANDLE

The grill pan handle is detachable from the pan to facilitate cleaning. The handle can

be either detachable from or fixed to the pan.

Remove the screw and washer from the grill pan bracket, tilt the handle over the

recess adjacent to the bracket (A). Slide the handle towards the centre of the pan (B)

and let the handle locate over the bracket (C).

For a detachable handle: Remove the screw and washer from the grill pan and keep

safe.

For a fixed handle: Replace the screw and washer and ensure they are fully tightened.

Warning: Ensure when using grill pan handle in the detachable manner it is

centralised and secure.

AB

TO USE THE GRILL

1. Open the grill door.

2. Turn the grill control knob clockwise to 4 for full width grilling or anticlockwise for

half width grilling.

3. Slide the grill pan toward the back of the grill compartment until it stops.

4. Leave the control at 4 for toast and for sealing and for fast cooking of foods. For

thicker foods requiring longer cooking, turn the control to a lower setting after

sealing on both sides at 4.

Grilling can be started from cold but for best results preheat for approximately 2

minutes.

DO NOT cover the grill pan or grid with aluminium foil as this can hold fat,

intensify the heat and create a fire hazard.

C

9

Page 10

Ovens

The left hand oven is a fan oven where as the right hand oven is a conventional oven

without a fan. The heating of the oven is achieved by turning the control knob clockwise

to the required temperature as recommended in the temperature charts. The pilot light

will immediately come on and will automatically go off and on during cooking as the

oven thermostat maintains the correct temperature.

It should be noted that at the end of a cooking period there may be a momentary puff

of steam when the oven door is opened, this will disperse in a few seconds and is a

perfectly normal characteristic of an oven with a good seal.

The right hand conventional oven will need to be preheated before cooking. Since the

left hand fan oven heats up more quickly and generally cooks food at a lower temperature

than a conventional oven, pre-heating the oven is often unnecessary. However, foods

such as bread, scones, Yorkshire pudding do often benefit from being placed in a preheated oven.

The charts on pages 12 and 13 are a guide only, giving approximate cooking temperatures and times. To suit personal taste and requirements, it may be necessary to increase

or decrease temperatures by 10˚C.

Unless otherwise indicated in the charts, the cooking times for the fanned oven are for

food placed in a cold oven ie. without preheat. If food is placed in an already hot oven,

the suggested cooking time should be reduced, depending on the type and quantity of

food being cooked.

OVEN SHELF POSITIONS

The distribution of heat in a fan oven is very even, most foods will cook satisfactorily on

any shelf position in the left hand oven, but the shelves should be evenly spaced.

Refer to the cooking chart regarding shelf positions in the right hand conventional oven.

Items should be positioned centrally on the oven shelf.

To ensure even circulation do not use meat pans larger than 390 x 300mm (15ins x 12ins)

and baking trays no larger than 330 x 255mm (13ins x 10ins).

- Do not fit shelves in the oven upside down and do not place food or cooking utensils

should not be placed on the floor of the oven.

To avoid unnecessary cleaning, rod shelves which are not in use should be removed

from the oven.

FROZEN MEAT AND POULTRY

Joints of meat and whole birds should be defrosted slowly, preferably in a domestic

refrigerator (allowing 5-6 hours per 450g, 1lb), or at room temperature (allowing 2-3

hours per 450g, 1lb). Frozen meat or poultry must be completely defrosted before

placing in the oven.

10

Page 11

bottom

Oven from

Position in

Time (approx.)

25-30 mins per 450g

(1 lb) + 25 mins over.

runner 2

n meat pan on

I

(1 lb)+ 30 mins over

30-35 mins per 450g

25-30 mins per 450g

(1 lb) + 25 mins over.

(1 lb) + 30 mins over

25-35 mins per 450g

Runner 2

(1 lb) + 20 mins over

20-25 mins per 450g

5.5kg (11lb) = 242 mins

18 mins per 450kg (1 lb)

22 mins per 450g (1 lb) eg.

eg. 10kg (22lb) = 352 mins

Runner 3

hrs

2

/

1

2-2

Conventional Oven

OVEN COOKING CHART - BAKING

˚C

190/200

Temperature

Yes

Pre-

heat

Beef

Meat

Time (approx.)

20-25 mins per 450g

(1 lb) + 20 mins extra

˚C

160/180

Temperature

No

Pre-

heat

190/200

190/200

Yes

Yes

Pork

Lamb

25 mins per 450g

25 mins per 450g

(1 lb) + 25 mins extra

(1 lb) + 25 mins extra

160/180

160/180

No

No

190/200

190

180/190

Yes

Yes

Yes

Veal

Poultry/Game

up to 4kg (8lb)

Turkey up to

5.5kg (12lb)

25-30 mins per 450g

18-20 mins per 450g

(1 lb) + 25 mins extra

160/170

No

(1 lb) + 20 mins extra

160/180

No

13-15 mins per 450g (1 lb)

180

140/160

Yes

Yes

Turkey over

5.5kg (12lb)

Casserole

Cooking

- 2 Hrs

2

/

1

1

e.g. 5kg (11lb) =143-165 mins

12 mins per 450g (1 lb) e.g.

10kg (22lb) = 264 mins

150

150-160

No

140-150

No

It is not necessary to pre-heat the fan oven before roasting. Note: Where times are stated, they are approximate only.

Medium: 70˚C Pork: 90˚C

Well Done: 75˚C Veal: 75˚C

If using aluminium foil, never: 1. Allow foil to touch sides of oven. 2. Cover oven interior with foil. 3. Cover shelves with foil.

Lamb

Pork

Veal

Chicken/ Turkey

Fan Oven

Beef

Meat

up to 4kg (8 lb)

Turkey up to 5.5kg

( 12 lb)

Over 5.5kg (2lb)

Casserole Stews

The most accurate method of testing the readiness of joints of meat or whole poultry is to insert a meat thermometer into the thickest part of a

joint, or the thickest part of poultry thighs, during the cooking period. The meat thermometer will indicate when the required internal temp has

been reached.

Beef - Rare: 60˚C Lamb: 80˚C Poultry: 90˚C

11

Page 12

Conventional Oven Cooking

Position in Oven

Pre-

from bottom

Temperature and Time

heat

Runner 3

Runner 3

220/230˚C approx. 10-15 mins.

180/190˚C approx. 20-25 mins.

Yes

Yes

Runner 3

”–7” tins approx. 20-25 mins.

2

/

1

170/180˚C 6

Yes

Runner 3

Runner 3

190/200˚C 7” tins 15-20 mins.

190/200˚C approx. 10-15 mins.

Yes

Yes

Runner 2

Runner 3

hours

2

/

1

–1

4

/

1

130/140˚C depending on use.

160/170˚C 7”- 8” tins 1

Yes

Yes

Runner 3

Runner 2

Runner 3

Runner 2 & 5

Runner 2

hours

2

/

1

200/210˚C 30-45 mins.

190/200˚C depending on use

220˚C approx. depending on use

Yes

Yes

210/220˚C approx. 20-25 mins.

150/160˚C approx. 2 – 2

Yes

Yes

Yes

Runner 2

Runner 2

150/160˚C approx. 45-55 mins.

230˚C 45-50 mins after first 10 minutes

230˚C 50-60 mins reducing to 210/220˚C

Yes

Yes

Runner 1

hours

2

/

1

– 4

– 3 hours

2

2

/

/

1

1

Small 2

100/110˚C Large 3

Yes

OVEN COOKING CHART - BAKING

Temperature and Time

hrs.

4

/

1

-1

4

/

1

140/150˚C

approx. 1

210/220˚C approx. 8-10 mins.

160/170˚C approx. 15-20 mins.

160/170˚C approx. 20-25 mins.

160/170˚C approx. 15-20 mins.

170/180˚C approx. 12-15 mins.

120/130˚C dependent on use

180/190˚C approx. 45-50 mins.

190/200˚C dependent on use

170/180˚C approx. 40-45 mins.

180/190˚C approx. 20-25 mins.

hrs.

4

/

1

-2

4

/

1

130/140˚C

approx. 1

140/150˚C approx. 40-50 mins.

Fan Oven Cooking

No

No

No

Pre-

Food

No

No

Yes

Sponge Sandwich

(Fatless)

Yes

Swiss Roll

Rich Fruit Cakes

Semi-rich Cakes

Yes

heat

Scones

Small Cakes

Victoria Sandwich

No

Yes

Puff Pastry

Yorkshire Pudding

Shortcrust Pastry

Note: If soft margarine is used for cake making, temperatures recommended by the

manufacturers should be followed. Temperatures recommended in this chart refer to cakes

made with block margarine or butter only.

12

Yes

Individual Yorkshire

Puddings

No

Milk Pudding

No

Baked Custard

200/210˚C approx. 45-50 mins.

Yes

Bread

70/80˚C approx. 3-4 hrs.

No

Meringues

Page 13

Care and Cleaning

Switch off the electricity supply and allow to cool before cleaning the cooker.

Clean the cooker regularly and wipe up spills soon after they occur to prevent

them from becoming burnt on. Never use biological washing powder, caustic

cleaners, harsh abrasives, scouring pads, steam cleaners, aerosol cleaners or oven

chemical cleaners of any kind.

Before moving your cooker ensure that it is cool and note that it is heavy so you

may require assistance. The cooker is fitted with rear wheels and will slide in and out

of position easily. Movement of your cooker is most easily achieved as follows:

Open the grill/oven door sufficiently to allow a comfortable grip on the underside

front edge of the oven roof, avoiding contact with any grill or oven furniture and then

lift and slide at the same time.

When repositioning the cooker, ensure that it is level. Take care to ensure that any floor

covering is not damaged.

REPLACEMENT OF OVEN LIGHT BULB

CAUTION: DISCONNECT THE APPLIANCE FROM THE ELECTRICITY SUPPLY BEFORE

REPLACING THE LAMP TO AVOID THE POSSIBILITY OF AN ELECTRIC SHOCK

Light bulbs are not covered by the manufacturer’s guarantee.

A new 15W, 300˚C rated SES bulb can be obtained from your cooker supplier or any

major electrical retailer.

1. Remove the shelves from the oven.

2. Unscrew the lens using a thick cloth to protect your fingers in the unlikely

event of a lens fracture.

3. Unscrew bulb.

4. Fit new bulb and refit lens.

13

Page 14

Care and Cleaning

COOKER FINISH CLEANING METHOD

Vitreous Enamel

Hotplate, pan supports,

burner caps, grill pan, inside

oven, grill and storage

compartments, door inner

panels.

Aluminium

Burner bodies, door handles.

Glass As for enamel cleaning. Polish with a clean dry cloth

Chromium Plating

Oven shelves, grill pan grid,

grill pan handle support

Plastic

Grill pan handle, control

knobs, door handle supports.

Cloth wrung out in warm soapy water. Stubborn

stains can be removed with a cream paste,

liquid cleaner or by rubbing with fine steel wool

soap pads e.g. Brillo, Ajax.

Check that the cleaning agent is approved by the

Vitreous Enamel Association.

Similar to paint cleaning above. Use a nylon brush to

remove any cleaning materials, water or dirt from

the hotplate burner ports. Care should be taken

when refitting the bodies over the electrodes.

or kitchen roll.

Wipe with a cloth wrung out in warm soapy water.

A fine steel wool soap pad e.g. Brillo, Ajax, or a

chrome or stainless steel cleaner may be used.

Wipe with a cloth wrung out in warm soapy water.

Stainless Steel

Control panel.

Paint

Side panels.

14

Wipe with a cloth wrung out in warm soapy water.

Polish with a clean dry cloth or kitchen towel. For

stubborn stains, use a proprietary stainless steel

cleaner and follow the instructions on the container.

Wipe with a cloth wrung out in warm soapy water

only.

DO NOT USE ABRASIVES.

Page 15

Something Wrong with your Cooker

Before contacting your Service Centre or Installer, check the problem guide below, there

may be nothing wrong with your cooker.

PROBLEM

Slight odour or small

amount of smoke when

grill/oven used for first time.

CHECK

This is normal and should cease after a short period.

Oven cooks too fast or too

slow.

Ignition does not work.

Check that the oven setting and shelf positions are as

recommended in the Cooking Charts.

However, it may be necessary to increase or decrease

the recommended setting slightly to suit your taste.

f all burners fail to ignite:

I

Check that sparks appear at the burners; a clicking

noise should be heard.

If not

(i) Check that the electricity supply is turned on.

(ii) Check other appliances to see if you have had a

power cut.

f only one burner fails to ignite:

I

(i) Check the burner cap is seated correctly.

(ii) Check the slots in the burner bodies are not

blocked with any soap residue or cooking soil

(see care and cleaning).

(iii) Check, if the burners have recently been

cleaned using a wire wool pad eg. “Brillo Pad’,

ensure that no stray strands are caught on the

ignitor or burner body.

NOTE. Satisfactory ignition will only be achieved if all

the hotplate burners are fitted.

In the event of an electricity failure, all burners can be

lit with a match.

Oven lamp does not work.

If there is still a problem contact your local Service office

The oven lamp is not covered by the guarantee. The

part is easily changed (see the section on oven lamp

replacement). A new lamp may be obtained from our

Parts Department (see Key Contacts, back page).

(see KEY CONTACTS, back page).

15

Page 16

Installation Instructions

Prior to installation, ensure that the local distribution conditions (nature of the gas and

gas pressure) and the adjustment conditions are compatible. The adjustment

conditions for this appliance are stated on the data badge which is fitted on the rear

panel.

This appliance is not designed to be connected to a combustion products evacuation

device. It must be installed and connected in accordance with current installation

regulations. particular attention should be given to the relevant requirements

regarding ventilation.

MODEL NUMBER KP100IX

Category II

This model is set to burn NATURAL GAS (G20) at 20 mbar but can be converted for use

on BUTANE (G30) at 28-30mbar or PROPANE (G31) at 37mbar with the use of a service

kit available from our Service and Genuine Parts and Accessories department (see KEY

CONTACTS, back cover).

GAS SAFETY (INSTALLATION & USE) REGULATIONS

It is the law that all gas appliances are installed by competent persons in

accordance with the current edition of the above regulations. It is in your interest and

that of safety to ensure compliance with the law.

In the UK, CORGI registered installers work to safe standards of practice.

The cooker must also be installed in accordance with BS 6172.

Failure to install the cooker correctly could invalidate the warranty liability claims and

could lead to prosecution.

2H3+ (GB. IE)

LOCATION

The cooker may be located in a kitchen, kitchen/diner or a bed-sitting room, but not in

a room containing a bath or shower. The cooker must not be installed in a bed-sitting

room of less than 20m

3

.

When adjusted for use on BUTANE (G30) or PROPANE (G31) the cooker must not be

installed in a room or internal space below ground level, eg. in a basement.

PROVISION FOR VENTILATION

The room containing the cooker should have an air supply in accordance with

BS 5440: Part 2.

The room must have an opening window or equivalent; some rooms may also require

a permanent vent. If the room has a volume between 5 and 10m3, it will require an air

vent of 50cm2effective area unless it has a door which opens directly to outside. If the

room has a volume of less than 5m3, it will require an air vent of 100cm2effective area.

If there are other fuel burning appliances in the same room, BS 5440: Part 2 should be

consulted to determine air vent requirements.

16

Page 17

Installation Instructions

TECHNICAL DATA

DIMENSIONS

Height 900 - 915mm

Width 1000mm

Depth 600mm (excluding door handles)

GENERAL

Gas connection Rp 1/2(1/2” BSP female)

Pressure test point Hotplate burner injector

Gas rate adjustment None

Aeration adjustment None

Electrical connection 230/240V a.c. 50Hz.

Total electrical heat input 7.4 kW

Cat II

2H3+

INJECTOR

125

102

72

102

128

102

72

102

G30 at 28 - 30 mbar

HEAT INPUT

2.7 kW (195g/hr)

1.8 kW (130g/hr)

1.0 kW (75g/hr)

1.8 kW (130g/hr)

2.8 kW (205g/hr)

1.8 kW (130g/hr)

1.0 kW (75g/hr)

1.8 kW (130g/hr)

BURNER

HOTPLATE

outer front left

HOTPLATE

outer rear left

HOTPLATE

inner rear left

HOTPLATE

inner front left

HOTPLATE

inner front right

HOTPLATE

inner rear right

HOTPLATE outer

rear right

HOTPLATE outer

front right

GRILL

Left OVEN

240V a.c.

HEAT INPUT

2.7 kW

2.5 kW

G20 at 20 mbar

HEAT

INPUT

2.7 kW

2.0 kW

1.0 kW

2.0 kW

3.0 kW

2.0 kW

1.0 kW

2.0 kW

Cat II

2H3+

G31 at 37 mbar

INJECTOR

82

65

50

65

82

65

50

65

Right OVEN

2.0 kW

17

Page 18

Installation Instructions

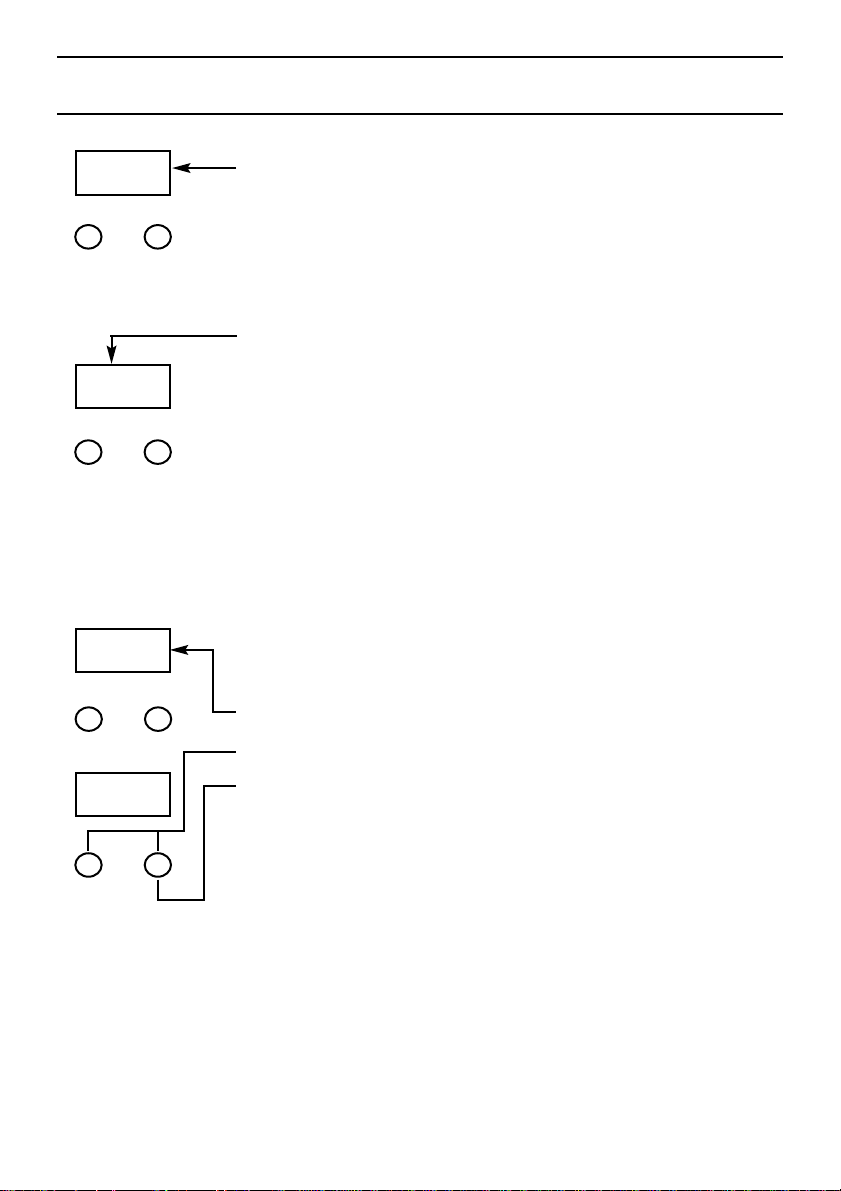

SPACE FOR FIXING

The cooker can be close fitted below hotplate level. This requires a minimum

distance of 1000mm between cupboard units of hotplate height.

When installing next to a tall cupboard, partition or wall, for a minimum distance of

400mm above hotplate level, allow a side clearance of at least 65mm.

The diagram below illustrates the minimum clearance between the cooker and

adjacent walls, cupboards etc.

The wall behind the cooker between the hotplate and 450mm above, and the width of

the cooker, must be a non-combustible material such as ceramic wall tiles.

If the cooker is to be fitted close to a corner on the left hand side, ensure that there is a

clearance to adjacent base cabinets of at least 50mm to allow the main oven door to

open fully for removing oven shelves.

750mm min

COOKER HOODS

If a cooker hood is to be installed, refer to the cooker hood manufacturers’ instructions

regarding fixing height.

18

Page 19

Installation Instructions

UNPACKING

Unpack the components from inside the grill and ovens: Check that the following parts

are present.

Pan supports (4) Oven shelves (4)

Grill pan, grid and handle Burner caps (8)

Aluminium burner bodies (8) Grill shelf (1)

Literature pack

After unpacking your cooker, make sure that you remove all the packing from the oven

and grill, and any stickers from the oven door and the hob.

LEVELLING

Your cooker is heavy, so it would be advisable for two people to move it. The cooker is

fitted with rear wheels and will slide into position easily. Movement of your cooker is

most easily achieved as follows. Open the grill/oven door sufficiently to allow a comfortable grip on the underside front edge of the oven roof, avoiding any grill or oven

interior furniture, and then lift and slide back at the same time.

Your cooker must stand on a flat surface so that the hob is perfectly level, and the

cooker is stable and cannot be rocked, this is easily achieved by adjusting the three

feet which are under the front of the cooker and the 3 castors under the rear of the

cooker, if necessary.

STABILITY CHAIN

The cooker must be fitted with a stability device firmly secured to the fabric of the building. The M6 bolt at the top of the rear of the cooker can be used to engage a stability

chain. Keep the chain clear of controls and pipes on the rear of the cooker.

The chain must be fitted to the wall behind the cooker.

NOTE: If the cooker is to be placed on a base, precautions must be taken to prevent it

from slipping off the base.

19

Page 20

Installation Instructions

The cooker is designed to match the depth of standard 600mm worktops.

An adaptor backplate should, therefore, be fitted within the shaded area shown to

allow the cooker to be pushed fully to the wall. If a forward facing backplate is used,

it must be chased into the wall.

180

370

750

500

250

450

750

Connection to the cooker should be made with an approved appliance flexible

connection to BS 669. A length of 0.9 to 1.25m is recommended. The length of hose

chosen should be such that when the cooker is in situ, the hose does not touch the

floor.

The temperature rise of areas at the rear of the cooker that are likely to come in

contact with the flexible hose do not exceed 70˚C.

LPG cookers should be connected with a hose suitable for LPG and capable of

withstanding 50mbar pressure.

20

Page 21

Installation Instructions

ELECTRICAL CONNECTIONS

WARNING - THIS APPLIANCE MUST BE EARTHED

Your cooker should have been checked to ensure that the voltage corresponds with

your supply voltage, which is stated on the data badge fitted on the rear panel.

The cooker must be connected by a contractor/engineer who is registered with the

National Inspection Council for Electrical Installation Contracting (NICEIC), to a suitable

double - pole control unit with a minimum rating of 30A and a minimum contact

clearance of 3mm, which should be fitted adjacent to (but not above) the cooker, in

accordance with IEE regulations.

The power supply cable should conform to BS6004 with a conductor size of 4mm

The control unit should be easily accessible in the event of an emergency.

This appliance conforms to EN55014 regarding suppression of radio and television

interference.

Access to the mains terminals is gained by removing the rear access cover.

The mains cable must pass through the cable clamp adjacent to the terminal block.

Sufficient cable should be used to allow the cooker to be pulled out for servicing.

INSTALLATION & OPERATIONAL CHECKS

After installation, check for gas soundness.

Fit the hotplate burner bodies, enamelled discs and pan supports referring to the

instructions for use where necessary.

1. Check that the hotplate burners ignite correctly and burn with a steady flame.

Check for a steady flame on the low setting.

2. Check that with the left hand oven set to 120˚C, the oven heats up and the

thermostat operates.

3. Check that with the right hand oven set to 120˚C, the oven heats up and the

thermostat operates.

4. Check the operation of the twin grill.

5. Check the operation of the clock.

Instruct the user on the operation of the cooker.

2

.

21

Page 22

Notes

22

Page 23

If It Still Won’t Work...

Contact the Service Office (UK: 08709 066 066)

If something is still wrong with your appliance after you have been through the

‘Something Wrong’ list:

1. Switch off and unplug the appliance from the mains.

2. Call your nearest Service Office or local importer.

When you contact us we will want to know the following:

1. Your name, address and postcode.

2. Your telephone number.

3. Clear and concise details of the fault.

4. The Model number and the Serial number of your appliance.

5. The date of purchase (please keep the receipt as evidence will be required when

an engineer calls) enter the date here:

.............................................................................

Please make sure you have all these details ready when you call.

Spare Parts

Please remember your new appliance is a complex piece of equipment.

‘DIY’ repairs or unqualified and untrained service people may put you in danger, could

damage the appliance and might mean you lose cover under the Parts Guarantee.

If you do experience a problem with the appliance don’t take risks, call in our Service

Engineer. Our Parts are designed exclusively to fit your appliance. Do not use them for

any other purpose as you may create a safety hazard.

Disposal of your product

To minimise the risk of injury to children please dispose of your product carefully and

safely. Remove all doors and lids. Remove the mains cable (where fitted) by cutting off

flush with the appliance and always ensure that no plug is left in a condition where it

could be connected to the electricity supply.

To help the environment, Local Authority instructions should be followed for the

disposal of your product.

Disposal of old electrical appliances

The European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE), requires that old household electrical appliances must not be disposed of in the

normal unsorted municipal waste stream. Old appliances must be collected separately in

order to optimise the recovery and recycling of the materials they contain and reduce

the impact on human health and the environment.

The crossed out “wheeled bin” symbol on the product reminds you of your obligation,

that when you dispose of the appliance it must be separately collected.

Consumers should contact their local authority or retailer for information concerning the

correct disposal of their old appliance.

23

Page 24

Key Contacts

After Sales Service

Over 1100 trained specialists, directly employed by us, ensure that you can have

complete confidence in both the appliances and services we offer.

Repair Service and Information Help Desk

UK: 08709 066 066

Monday to Friday, 8am to 7.30pm

Saturday, 8.30am to 5.30pm

Sunday, 9.30am to 3.30pm

www

.indesitservice.co.uk

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

Model number

Serial number

Extended Warranties

UK: 08709 088 088

Monday to Sunday, 8am to 8pm

www

.indesitservice.co.uk

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

UK: 08709 077 077

Monday to Friday, 8.30am to 5pm

Saturday, 8.30am to 12noon

www

.indesitservice.co.uk

Republic of Ireland: (01) 842 6836

.indesitcompany.co.uk

www

Indesit Company UK Limited, Morley Way, Peterborough, PE2 9JB

PRINTED BY SIMLEX .FOUR ASHES, WOLVERHAMPTON. 06/2005 195052148.01

Loading...

Loading...