Operating Instructions

Contents

GB

COOKER

GB

English, 1

I5GSH1 /UK

WARNING,2

Installation, 3-6

Positioning and levelling

Electrical connection

Gas connection

Adapting to different types of gas

Technical data

Table of burner and nozzle specifications

Description of the appliance, 7

Overall view

Control panel

Start-up and use, 8-10

Using the hob

Using the oven

Electronic timer

Oven cooking advice table

Precautions and tips, 11

General safety

Disposal

Respecting and conserving the environment

Care and maintenance, 12

Switching the appliance off

Cleaning the appliance

Gas tap maintenance

Replacing the oven light bulb

Assistance

You must read these instructions prior to using

your appliance and retain them for future use.

WARNING

GB

WARNING: The appliance and its

accessible parts become hot

during use.

Care should be taken to avoid

touching heating elements.

Children less than 8 years of age

shall be kept away unless

continuously supervised.

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance in

a safe way and understand the

hazards involved. Children shall not

play with the appliance. Cleaning

and user maintenance shall not be

made by children without

supervision.

The internal surfaces of the

compartment (where present) may

become hot.

Never use steam cleaners or

pressure cleaners on the appliance.

Remove any liquid from the lid

before opening it.

! When you place the rack inside,

make sure that the stop is directed

upwards and in the back of the cavity.

WARNING: Unattended cooking on

a hob with fat or oil can be

dangerous and may result in fire.

NEVER try to extinguish a fire with

water, but switch off the appliance

and then cover flame e.g. with a lid

or a fire blanket.

Do not close the glass cover (if

present) when the gas burners or

electric hotplates are still hot.

WARNING: Ensure that the

appliance is switched off before

replacing the lamp to avoid the

possibility of electric shock.

CAUTION: the use of inappropriate

hob guards can cause accidents.

Do not use harsh abrasive cleaners

or sharp metal scrapers to clean the

oven door glass since they can

scratch the surface, which may

result in shattering of the glass.

2

Installation

! Before operating your new appliance please read

this instruction booklet carefully. It contains

important information concerning the safe installation

and operation of the appliance.

! Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualified

professional according to the instructions provided.

! Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

Positioning

! !

! This unit may be installed and used only in

! !

permanently ventilated rooms according to the

British Standards Codes Of Practice: B.S. 6172/B.S.

5440, Par. 2 and B.S. 6891 Current Editions. The

following requirements must be observed:

a)a)

a )The cooker should not be installed in a bed sitting

a)a)

room with a volume of less than 20m

installed in a room of volume less than 5m

vent of effective area of 110cm2 is required, if it is

installed in a room of volume between 5m

10m3 a supplementary airvent area of 50cm2 is

required, if the volume exceeds 11m

required. However, if the room has a door or a

window which opens directly to the outside no air

vent is required even when the volume is between

3

and 11m3.

5m

b)b)

b )During prolonged use of the appliance you may

b)b)

consider it necessary to open a window to the

outside to improve ventilation.

c)c)

c )If there are other fuel burning appliances in the

c)c)

same room, B.S.5440 Part 2 Current Edition,

should, be consulted to determine the requisite air

vent requirements.

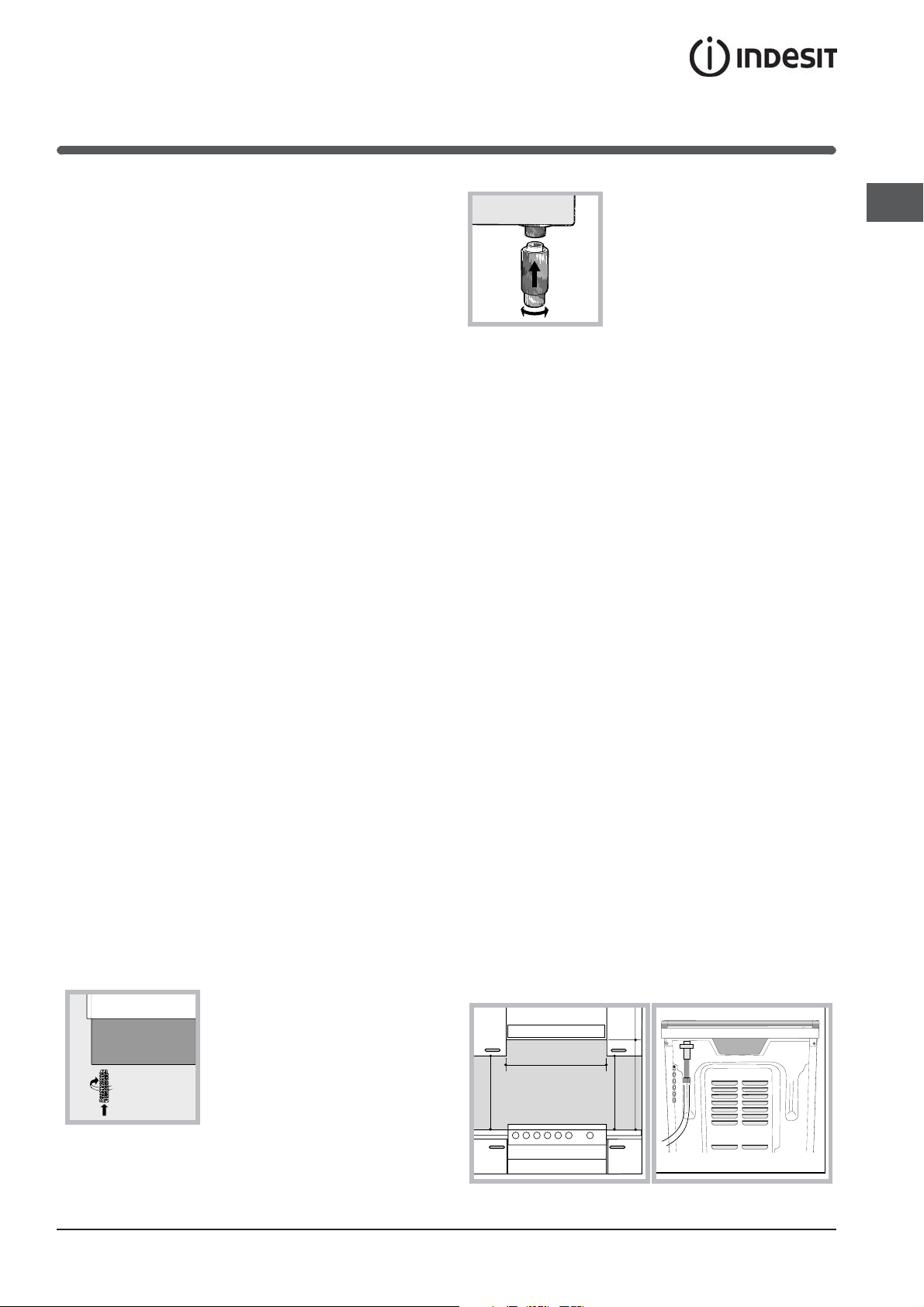

Levelling

If it is necessary to level the

appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (

figure

).

3

. If it is

3

an air

3

and

3

no airvent is

see

The legs* fit into the slots on

the underside of the base of

the cooker.

Installation of the cooker

The appliance can be installed next to furniture units

which are no taller than the top of the cooker hob.

The wall in direct contact with the back panel of the

cooker must be made of non-flammable material.

During operation the back panel of the cooker could

reach a temperature of 50°C above room

temperature. For proper installation of the cooker,

the following precautions must be taken:

a)a)

a )The appliance can be placed in a kitchen, dining

a)a)

room or bedsit, but not in a bathroom.

b)b)

b )All furniture around the appliance must be placed

b)b)

at least 200 mm from the top of the cooker,

should the surface of the appliance be higher than

the worktop of this furniture. Curtains should not

be placed behind the cooker or less than 200 mm

away from the sides of the appliance.

c)c)

c )Any hoods must be installed according to the

c)c)

requirements in the installation manual for the

hoods themselves.

d)d)

d )If the cooker is installed beneath a wall cabinet,

d)d)

the latter must be situated at a minimum of 420

mm above the hob. The minimum distance

between the worktop and kitchen units made of

combustible material is 700 mm (Fig. A).

e)e)

e )The wall in direct contact with the back panel of

e)e)

the cooker must be made of non-flammable

materials.

f)f)

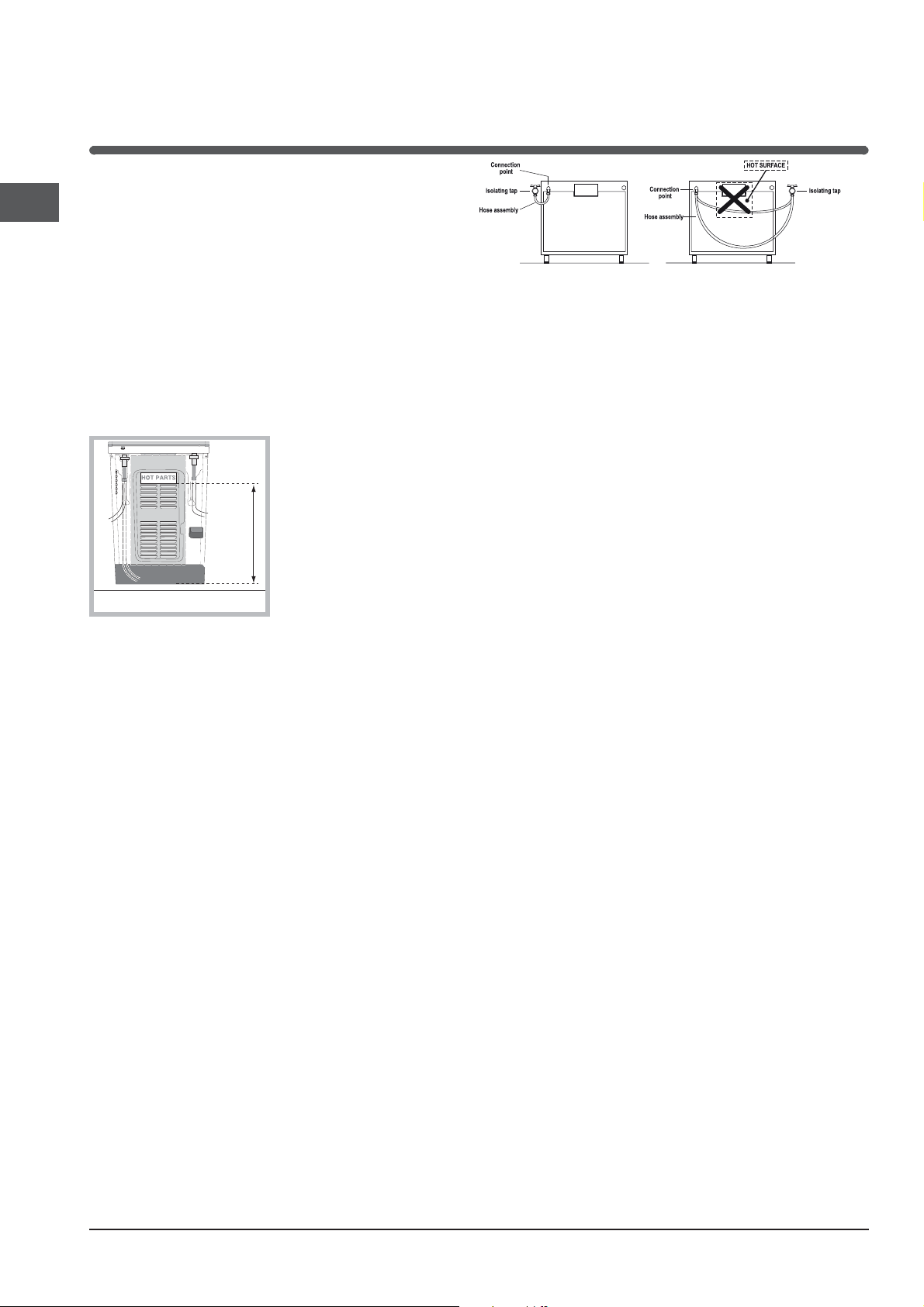

f ) The cooker is fitted with a safety chain that must

f)f)

be attached to a hook, secured to the wall behind

the appliance.

! Some models can have their gas connection

inverted. It is important to make sure the safety

chain is always situated on the side which

corresponds to the hose holder (Fig. B).

HOOD

Min. mm.

600

mm.

420

Min.

mm. with hood

420

650

Min. mm.

min.

mm. without hood

700

min.

GB

Fig. A Fig. B

3

GB

Gas connection

T he cooker should be connected to the gas-supply

by a corgi registered installer. During installation of

this product it is essential to fit an approved gas tap

to isolate the supply from the appliance for the

convenience of any subsequent removal or

servicing. Connection of the appliance to the gas

mains or liquid gas must be carried out according to

the prescribed regulation in force, and only after it is

ascertained that it is adaptable to the type of gas to

be used. If not, follow the instructions indicated in

the paragraph headed “Adaptation to different gas

types”. On some models the gas supply can be

connected on the left or on the right, as necessary;

to change the

connection, reverse the

HOT PARTS

regulation in force. The gas supply must be

connected to the left of the appliance. Be sure that

the hose does not pass through the rear of the

cooker touching hot parts.

! Make sure the supply pressure conforms with the

values shown in the table entitled “Caracteristics of

the burners and nozzles”.

installed between cabinets (recessed), theinstalled between cabinets (recessed), the

installed between cabinets (recessed), the

installed between cabinets (recessed), theinstalled between cabinets (recessed), the

gas connection must be effected by angas connection must be effected by an

gas connection must be effected by an

gas connection must be effected by angas connection must be effected by an

approved flexible hose with bayonet fittingapproved flexible hose with bayonet fitting

approved flexible hose with bayonet fitting

approved flexible hose with bayonet fittingapproved flexible hose with bayonet fitting

(BS 669 Current Edition). The gas inlet for(BS 669 Current Edition). The gas inlet for

(BS 669 Current Edition). The gas inlet for

(BS 669 Current Edition). The gas inlet for(BS 669 Current Edition). The gas inlet for

the cookers is a threaded G 1/2 gas femalethe cookers is a threaded G 1/2 gas female

the cookers is a threaded G 1/2 gas female

the cookers is a threaded G 1/2 gas femalethe cookers is a threaded G 1/2 gas female

fitting.fitting.

fitting.

fitting.fitting.

Connecting the gas supply

To make the connection, a flexible hose should be

used corresponding to the current gas regulations

which are:

• the hose must never be at any point in its lenght

in contact with the “hot” parts of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension or

torsional stress and it must not have any

excessively narrow curves or bottlenecks;

• the hose must be easy to inspect along its entire

length to check its condition;

• the hose must always be in good condition, never

attempt to repair.

! The installation must comply with gas safety

(installation and use) regulations 1984. In all cases

for the above, by low, a qualified, corgi approved

engineer must be called for installation.

position of the hose

holder with that of the

cap and replace the

gasket (supplied with

the appliance). In the

700 mm

case of connection to

liquid gas, by tank, use

pressure regulators that

conform to the

When the cooker isWhen the cooker is

When the cooker is

When the cooker isWhen the cooker is

Electrial connection

Power supply voltage and frequency: 230-240V a.c.

50/60 Hz.

!!

! The supply cable must be positioned so that it

!!

never reaches at any point a temperature 50°C

higher than the room temperature. The cable must

be routed away from the rear vents. Should you

require it, you may use a longer cable, however, you

must ensure that the cable supplied with the

appliance is replaced by one of the same

specifications in accordance with current standards

and legislation.

Your appliance is supplied with a 13 amp fused plug

that can be plugged into a 13 amp socket for

immediate use. Before using the appliance please

read the instructions below.

WARNING - THIS APPLIANCE MUST BE

EARTHED.

THE FOLLOWING OPERATIONS SHOULD BE

CARRIED OUT BY A QUALIFIED ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA

approved fuse to BS 1362 should always be used,

and the fuse cover re-fitted. If the fuse cover is lost,

the plug must not be used until a replacement is

obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must be of

the correct colour as indicated by the coloured

marking or the colour that is embossed in words on

the base of the plug. Replacements can be obtained

directly from your nearest Service Depot.

Removing the plug:

If your appliance has a non-rewireable moulded plug

and you should wish to remove it to add a cable

extension or to re-route the mains cable through

partitions, units etc., please ensure that either:

• the plug is replaced by a fused 13 amp rewireable plug bearing the BSI mark of approval.

or:

• the mains cable is wired directly into a 13 amp

cable outlet, controlled by a switch, (in

compliance with BS 5733) which is accessible

without moving the appliance.

!!

! For appliances with a rating greater than 13 amp

!!

(eg: electric hob, double ovens and freestanding

electric cookers etc.) the mains cable must be wired

into a cooker output point with a rating of 45 amp. In

this case the cable is not supplied.

4

Disposing of the plug:

Ensure that before disposing of the plug itself, you

make the pins unusable so that it cannot be

accidentally inserted into a socket. Instructions for

connecting cable to an alternative plug:

!!

! The wires in the mains lead are coloured in

!!

accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

If the colours of the wires in the mains lead do not

correspond with the coloured markings identifying

the terminals in your plug, proceed as follows:

Connect Green & Yellow wire to terminal marked “

or or coloured Green or Green & Yellow.

LL

Connect Brown wire to terminal marked “

L” or

LL

coloured Red.

NN

Connect Blue wire to terminal marked “

N” or

NN

coloured Black.

If a 13 amp plug (BS 1363) is used it must be fitted

with a 13 amp fuse. A 15 amp plug must be

protected by a 15 amp fuse, either in the plug or

adaptor or at the distribution board. If you are in any

doubt about the electrical supply to your machine,

consult a qualified electrician before use.

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

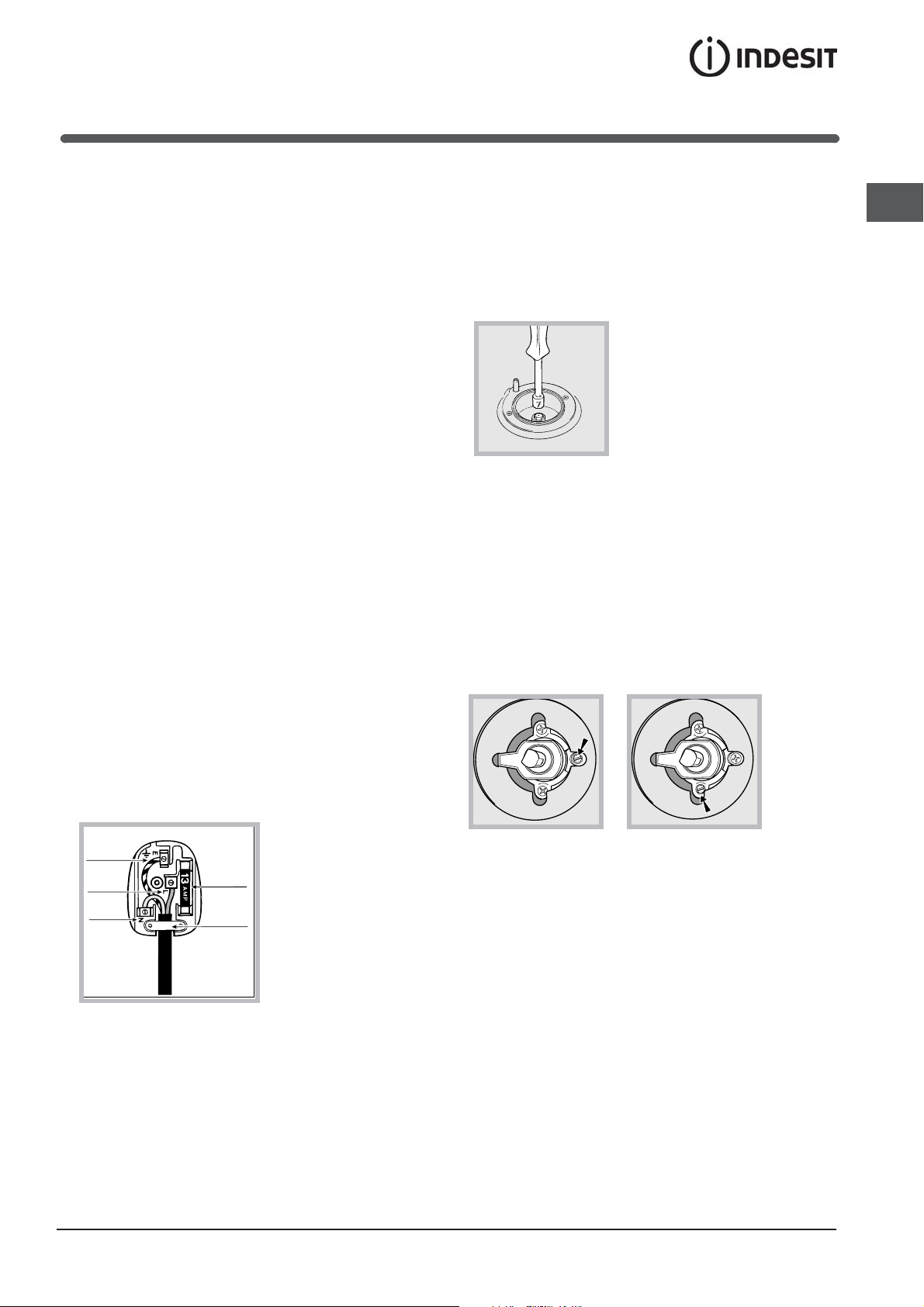

Adapting the hob

Replacing the nozzles for the hob burners:

1. Remove the hob grids and

slide the burners off their

seats.

2. Unscrew the nozzles using

a 7 mm socket spanner (

figure

), and replace them with

nozzles suited to the new type

EE

E”

EE

specifications table

of gas (

).

3. Replace all the components by following the

above instructions in reverse.

Adjusting the hob burners’ minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory

screw, which is positioned inside or next to the tap

pin, until the flame is small but steady.

! If the appliance is connected to a liquid gas

supply, the regulatory screw must be fastened as

tightly as possible.

see Burner and nozzle

GB

see

How to connect an alternative plug:

The wires in this mains lead are coloured in

accordance with the following code:

BLUEBLUE

BLUE “

BLUEBLUE

BROWNBROWN

BROWN “

BROWNBROWN

GREEN AND YELLOWGREEN AND YELLOW

GREEN AND YELLOW “

GREEN AND YELLOWGREEN AND YELLOW

GREEN &

YELLOW

BROWN

BLUE

13 amp fuse

CROSS-BAR

CORD GRIP

NEUTRALNEUTRAL

NEUTRAL” (“

NEUTRALNEUTRAL

LIVELIVE

LIVE” (“

LIVELIVE

EARTHEARTH

EARTH” (“

EARTHEARTH

LL

L”)

LL

EE

E”)

EE

NN

N”)

NN

Disposing of the appliance

When disposing of the appliance please remove the

plug by cutting the mains cable as close as

possible to the plug body and dispose of it as

described above.

Checking the connection for leaks

When the installation process is complete, check

the hose fittings for leaks using a soapy solution.

Never use a flame.

3. While the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame is not

extinguished.

! The hob burners do not require primary air adjustment.

! After adjusting the appliance so it may be used

with a different type of gas, replace the old rating

label with a new one that corresponds to the new

type of gas (these labels are available from

Authorised Technical Assistance Centres).

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to “regulators for channelled gas”.

5