Indeeco ZCA Series, XCA Series, TFZCA Series, TFXCA Series, ZCBA Series Installation, Operating And Maintenance Instructions

...

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS FOR

INDEECO ELECTRIC DUCT HEATERS

APPLICATION INFORMATION

1. Follow the procedure given on the reverse side of this sheet

to find the minimum air velocity for safe operation. At least this

minimum velocity must be provided at all points over the heater

face area. Failure to meet this requirement may result in serious

damage or nuisance thermal cutout tripping.

2. The maximum air inlet temperature for open coil heaters is

100F (37.8C), and for finned tubular heaters, 80F (26.7C).

3. The heater must be located at least 4’ (1220mm) from any

grills, registers, filters, abrupt duct size changes, humidifiers, air

conditioning or air handling units, or any other change or

obstructions in the duct which may result in nonuniform airflow,

and not less than 30” (762mm) from the end of the warm air duct.

Duct elbows or turns must be located at least 4’ (1220mm) from

the inlet of the heater and 2’ (610mm) from the outlet of the heater.

Sufficient working space must be provided per paragraph 2-308 of

the Canadian Electrical Code.

4. These duct heaters are not intended for installation in series

in the airstream; the heaters are designed for use only as a single

unit within a duct with the exception of Series ZCA, XCA, ZCBA,

XCBA, TFZCA, TFXCA which are designed for stacked installation

for use as a single unit within a duct. (See Fig. No. 3)

MECHANICAL INSTALLATION

1. Heater terminal outlet box should not be enclosed. Heaters

with expanded metal terminal box covers must be installed in a

position where air passing out of the terminal box does not enter

into confined areas of the building structure (such as a space

behind a false ceiling, a hollow space in a wall, etc.)

2. All heaters are suitable for installation with zero spacing

between the duct and combustible surfaces.

3. The heater must be installed in the correct position as shown

by the arrows in the terminal box.

4. Sufficient clearance for convection cooling must be allowed

for all heaters with built-in SCR Power Controllers. Provide at least

5” (127mm) of free air space above and below cooling fins

extending from heater terminal box.

5. For proper operation of heaters equipped with a built-in

airflow switch, a minimum of .07” (1.8mm) WC of static pressure is

required in the duct system, and the velocity pickup tube for the

airflow switch must be pointed in the proper direction. When the

heater is installed on the downstream or positive pressure side of

the air moving fan, the arrow on the mounting flange of the pickup

tube must point in the same direction as the airflow. When the

heater is installed on the upstream or negative pressure side of the

air moving fan, the arrow must point in the direction opposite to the

airflow. If incorrectly installed, remove the two screws holding the

pickup tube in place, rotate 180 and reinstall. See separate

instruction sheet for installation of heaters supplied with a remote

pickup tube.

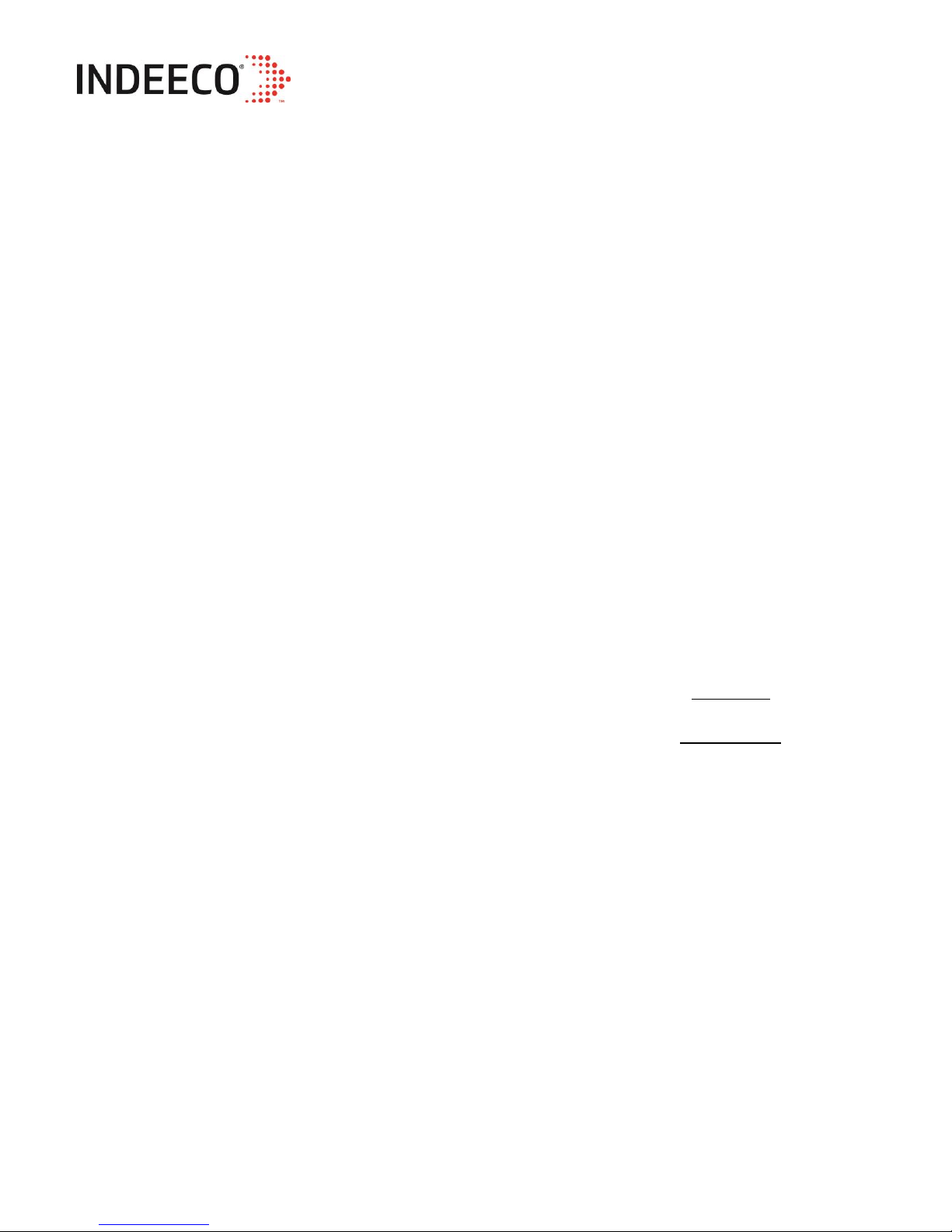

FOR FLANGE TYPE HEATERS ONLY: (See Fig. No. 1)

6. Provide flanges on the duct to match the heater flanges, both

on the entering and leaving air sides.

7. Attach the duct flanges to the heater flanges with bolts, sheet

metal screws or slip and drive connectors when the heater has

matching connectors for this purpose.

FOR SLIP-IN TYPE HEATERS ONLY: (See Fig. No. 2)

8. Cut a hole in the side of the duct to accommodate the body of

the heater (excluding terminal box). This hole should be 1/8”

(3.175mm) larger than the heater frame.

9. Slip the heater into the duct and attach the back of the terminal box to

the duct with sheet metal screws.

10. If heater has built-in PE switches they must be calibrated to field

control system. Calibrate the PE switch marked No. 1 to come on first.

FOR STACKED TYPE HEATERS ONLY: (See Fig. No. 3)

11. The heaters with catalog prefix ZCA, XCA, ZCBA, XCBA, TFZCA and

TFXCA must be stacked as indicated in Fig. No. 3.

FOR HEATERS TO BE INSTALLED IN FIBERGLASS DUCTS:

12. Write factory for special instructions. Note that the fiberglass duct

material itself must be CSA approved.

FOR HEATERS TO BE INSTALLED IN INTERIOR INSULATED DUCTS:

13. All slip-in type heaters are suitable for installation in ducts with up to

1” (25.4mm) of interior insulation as long as they have been sized for the

dimensions inside the insulation. The heaters are not suitable for

insulation depths of greater than 1” (25.4mm) unless a special construction

has been ordered. Flange type heaters are only suitable for installation in

insulated ducts if specially ordered for this application.

ELECTRICAL INSTALLATION

14. Follow the wiring diagram on the inside of the terminal box.

15. Supply connections must be made with copper wiring rated 90C

minimum. Use aluminum wire only when specifically called for on

accompanying wiring diagram.

16. All wiring in the terminal box must be insulated for 600 volts.

17. When making line connections to heater element terminals FOR

FINNED TUBULAR DUCT HEATERS ONLY, apply a ¼” wrench to flat

section of terminal or nut immediately below threads. Otherwise damage

to terminal may result.

18. Line connection should be based upon the line current and the

requirements of the Canadian Electrical Code. The line current for either a

single or three phase load is calculated as follows:

Single Phase Line Current=

KW x 1000

Voltage

Three Phase Line Current=

KW x 1000

Voltage x 1.73

19. Supply wiring must be suitable for 90C. Subject to local inspection

authority, current carrying capacity of supply wiring should not exceed

values shown in the Canadian Electrical Code Table 2, Col. 90C for not

more than three conductors in a raceway, in a 30C ambient or as

specified on the wiring diagram.

20. When connecting heaters with more than one stage, wire stage No. 1

so that it is the first stage on and the last stage off. Heaters with built-in PE

switches must follow this rule also. The stage number will be indicated on

the front of each PE switch.

continued installation etc.

21. The heater must be wired so that it

cannot operate unless air is flowing over

it. This can be accomplished by using a

built-in airflow switch, a built-in fan relay

or any of several other methods. See

the accompanying wiring diagram for

the method used with this heater and

provide appropriate interlock wiring as

illustrated.

22. The steady-state control circuit

load must not exceed the thermal cutout

pilot duty rating shown on the heater

nameplate.

23. When heater is not supplied with

built-in fusing, fuses must be installed in

accordance with the requirements of the

Canadian Electrical Code.

24. If not supplied as part of this

heater, install a line disconnect switch or

main circuit breaker in accordance with

the Canadian Electrical Code.

Depending upon the heater’s location

and accessibility, a built-in disconnect

switch may meet this requirement.

25. All electrical connections in the

heater, including both field and factory

made connections, should be checked

for tightness before operating the

heater. In addition, after a short period

of operation, all connections should

again be checked for tightness.

26. If heater is wired to a heatingcooling thermostat, use the thermostat

with isolating circuits to prevent possible

inter-connection of Class 2 outputs.

27. Magnetic contactors when used in

the primary limit control circuit of this

heater must be CSA approved for

250,000 cycle operation. Contactors

used in the secondary limit control

circuit on heaters rated 30 KW and less

must be CSA approved for 6,000 cycle

operation.

28. If heater frame is smaller than the

duct by more than 1” (25.4mm) in length

or width, the watts per square foot of

duct area should be calculated as the

heater nameplate watts divided by the

area inside the sheet metal enclosure

directly around the heating elements.

OPERATION & MAINTENANCE

NOTICE: ALL SOURCES OF SUPPLY MUST BE DISCONNECTED BEFORE WORKING ON THIS EQUIPMENT

To operate this heater make sure all associated control equipment is

on, energize main supply disconnect and set controlling thermostat

above ambient temperature. This heater is equipped with automatic

and manual reset temperature limit controls. If it fails to operate,

make sure manual resets are operative by pushing reset buttons.

Note: All metric conversions are approximate.

The only routine maintenance required is to check all electrical

connections, including field and factory made connections, for

tightness at least once each year or operating season. In addition, of

course, any filters in the airstream must be kept clean so that

adequate airflow is maintained.

INDUSTRIAL ENGINEERING & EQUIPMENT COMPANY

425 Hanley Industrial Court • St. Louis, MO 63144 USA • (314) 644-4300 • FAX (314) 644-5332

ENM - 2077 – 01 / 10-1081-83-4EF

INSTALLATION DRAWINGS

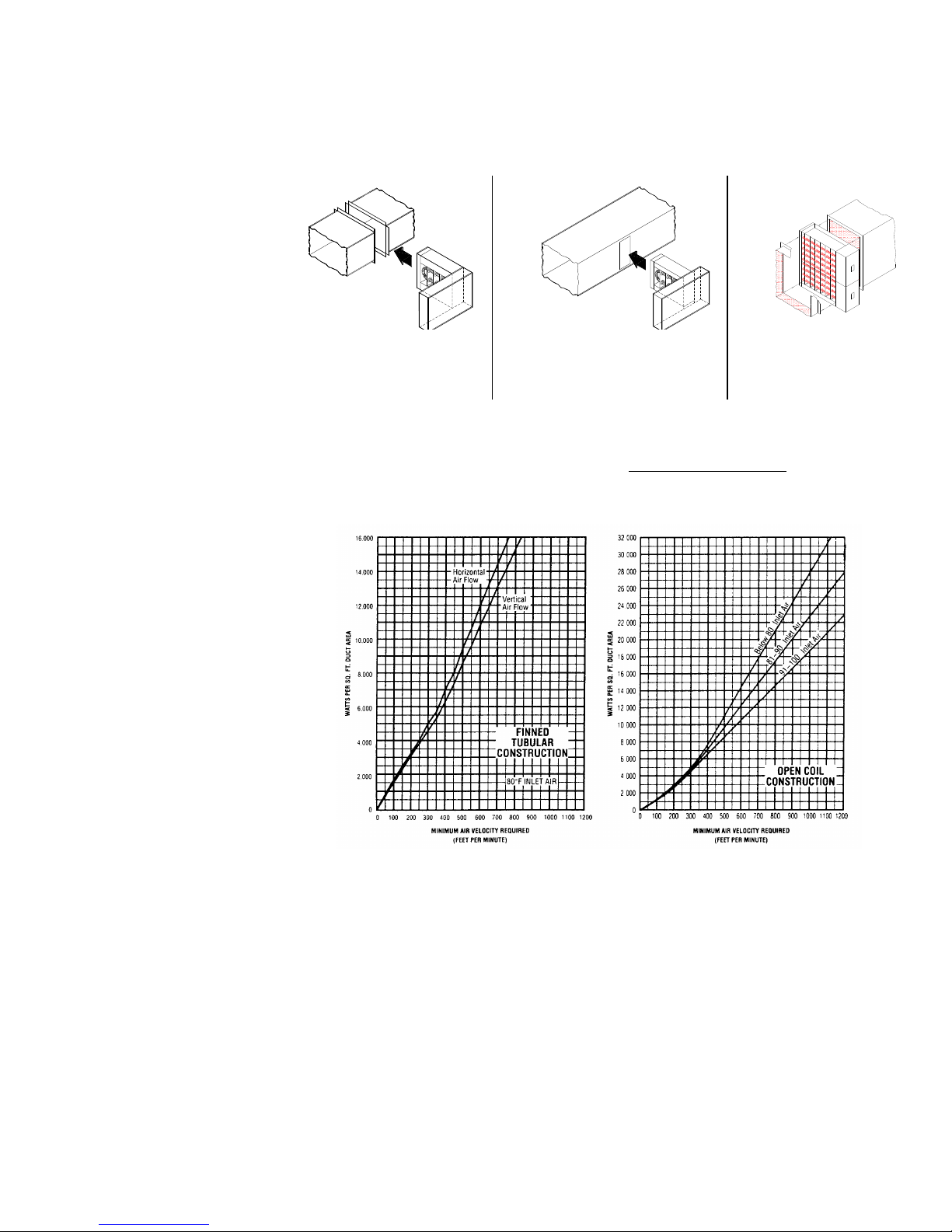

AIR FLOW REQUIREMENTS

Calculate watts per square foot of duct area as:

Heater nameplate watts

(See #28)

Duct area (Sq.Ft.)

Fig. 1 – Installation drawing

of flanged heater.

Fig. 2 – Installation drawing

of slip-in heater.

Fig. 3 – Installation drawing

of two stacked sections in a

duct.

Loading...

Loading...