Indeeco 961, 961-U5000V-T, 961-U5000K-T, 961-U5000U-T Series Manual

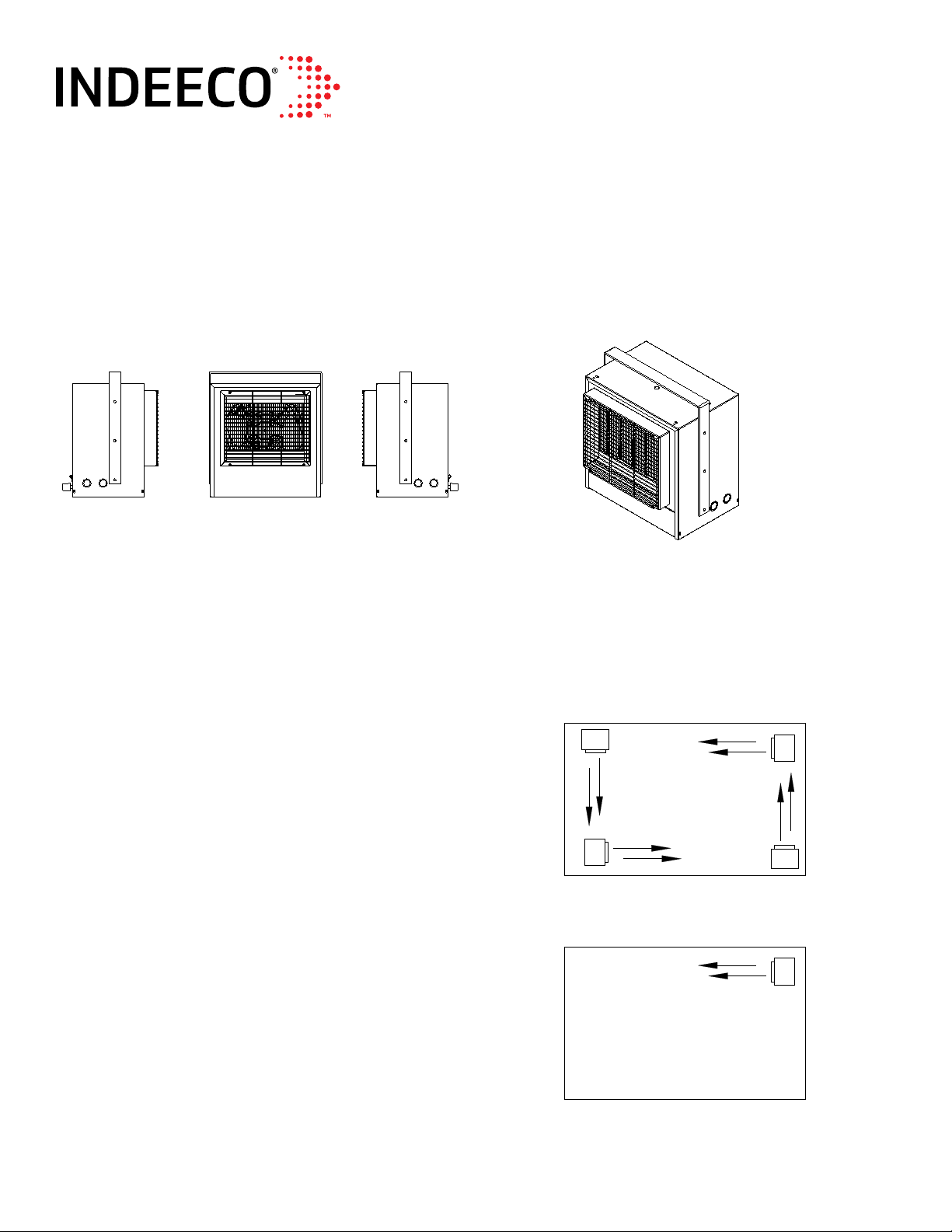

961 SERIES

EXPOSED

EXPOSED

H

H

H

H

H

EXPOSED

EXPOSED

CONFINED SPACE

UNIT HEATER

Horizontal or Vertical Mounting

ATTENTION: Read carefully before attempting to install or

operate Unit Heater.

FEATURES:

• Forced air electric unit heater available in:

240/208 volt single phase, 5 kw and

240 and 480 three phase 5 kw.

• 240/208 single phase unit is factory wired

for 5 kw. The wattage may be changed by

moving jumpers as indicated in table 1.

• 24 volt control standard on three phase unit.

• All units with “T” sufx provided with unit

mounted hydraulic thermostat.

• Mounting bracket included with all units.

PROPER MOUNTING:

The heater(s) should be located along outside

walls or other areas of greatest heat loss.

Multiple heaters should be spaced to set up a

generally circular air movement, each heater

supporting the air stream of the other.

IMPORTANT: OWNER SHOULD RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

REV. LEVEL ECO 1-7305 07/2017 FORM 9763

PRINCIPLES OF OPERATION

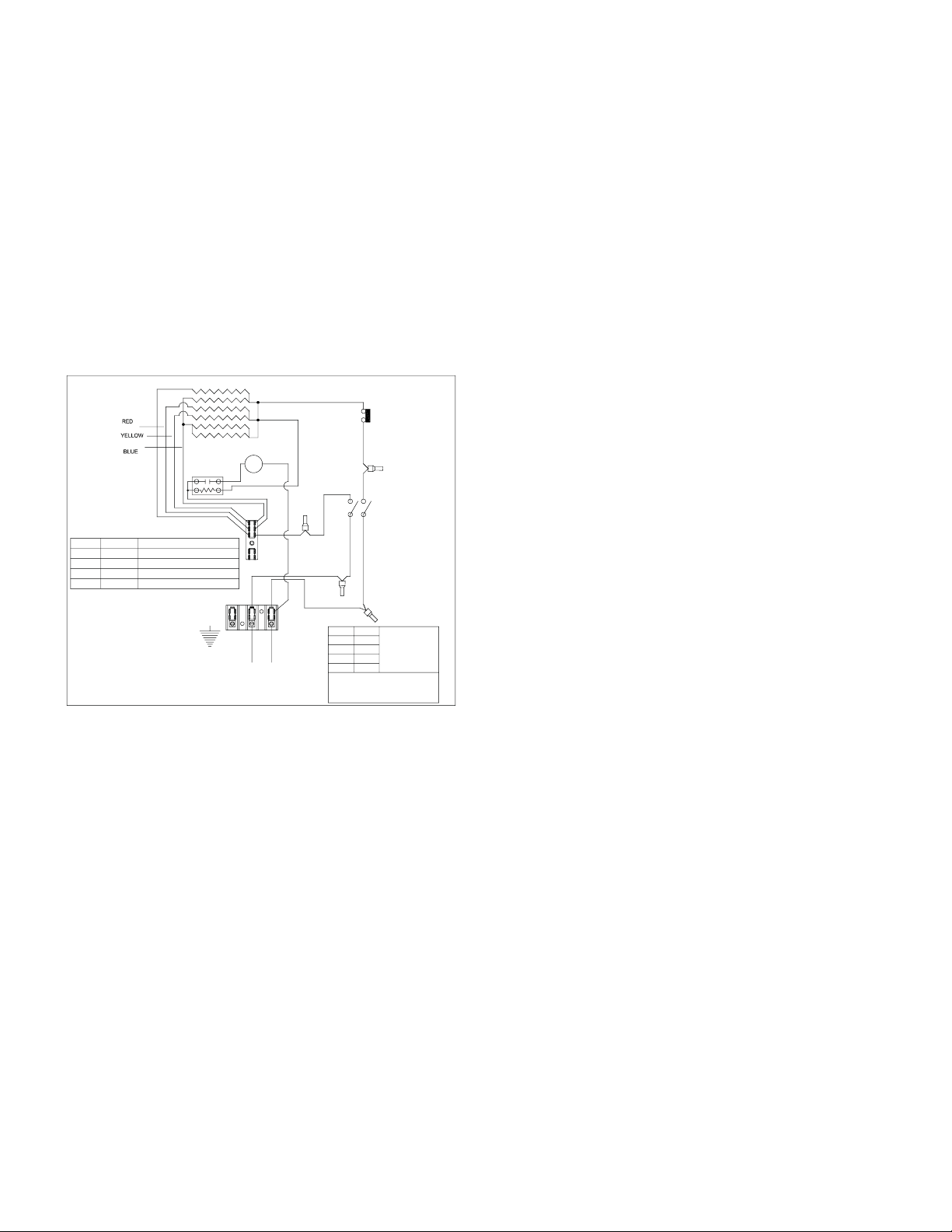

When the thermostat calls for heat, the elements

are immediately energized, a fan delay brings on

the fan after the elements are heated allowing

warm air to circulate. When the thermostat is

satised, the elements are de-energized and the

fan purges the heater of residual heat.

The heater wattage may be eld adjusted only on

model 961-U5000V-T. Select the desired wattage

from Fig.1 and move color coded jumpers as

indicated.

ELEMENT

LIMIT

CONTROL

M

A

C

B

L1 L2

240/208V 1

BLACK

RED

THERMOSTAT

RED

BLACK

LTB

AWG

14

12

10

8

CAUTION: USE SUPPLY WIRES SUITABLE FOR

PH

D'APPROVISIONNEMENT APRÈS AU MOINS 90 ° C

AMPS

12

USE COPPER

16

CONDUCTORS

ONLY

24

36

AT LEAST 90°C (194°F)

ATTENTION: UTILISEZ DES FILS

(194 ° F)

WATTAGE ADJUSTMENT TABLE

VOLTS

WATTS

240/208

4167/3120

240/208

240/208

240/208

2500/1875

USE COPPER CONDUCTORS ONLY

CONTROL CIRCUIT WIRING MUST BE

NEC CLASS 1 RATED 600V

USE WITH MODEL NUMBER

961-U5000V-T

ADJUSTMENT

NONE REQUIRED5000/3750

BLUE JUMPER TO TERMINAL 'C'

BLUE AND YELLOW TO TERMINAL 'C'3333/2500

BLUE,YELLOW AND RED TO TERMINAL 'C'

FAN DELAY

MOUNTING THE HEATER

Select the mounting location. Be sure to observe

the minimum mounting clearances as shown in

Figure 2.

The heater can be mounted either from the

ceiling or wall depending on the application.

The mounting bracket is supplied with 3/8” holes,

10 inches on center for threaded rod mounting or

direct mounting to the structure.

The heater cabinet also has 3/8” weld nuts 10” on

center to allow threaded rod mounting without the

bracket.

1. Install the mounting bracket in the desired

location with threaded rod or hardware

that is appropriate for the mounting surface.

If using threaded rod, two nuts, one on the top

and one on the bottom of the bracket along

with a split washer is suggested.

2. Secure the heater to mounting bracket, using

the 1/4-20 x 3/4” machine screws and

lockwashers provided.

3. Position the heater, aligning the bracket holes

with the cabinet holes and secure bracket to

the cabinet with the 1/4-20 x 1/2” machine

screws and nuts that are provided. With the

mounting bracket in the vertical position the

1/4” nuts are not necessary, weld nuts are

supplied in the cabinet.

Fig.1

INSTALLATION INSTRUCTIONS

All electric unit heaters are shipped fully

assembled. Installation includes hanging the

unit and electrical wiring to the unit.

The wall and/or ceiling structure must be

sufcient to support the combined weight of the

heater and any mounting bracket and

accessories.

Be sure power source is de-energized before

installing heater. Check heater voltage and

phase listed on heater data label on back of unit

to make sure they are the same as the electrical

service supplied.

REV. LEVEL ECO 1-7305 07/2017 FORM 9763

Loading...

Loading...