INDCO TM Series, TMG Series Owner's Manual

TM & TMG

Series

Mixers

OWNERS

TM(G) SERIES

TOP ENTRY MIXERS

MANUAL

Warranty

Our products are guaranteed against

defective materials and workmanship, we will

repair or replace such items as may prove

defective at our option. Warranty period is

one year on items manufactured by INDCO.

On items not manufactured by INDCO, the

manufactures warranty applies. All

component parts of our products are covered

by this warranty, except for normal wear items

such as belts or impellers. We cannot be

responsible for damage or abuse to equipment

caused by improper installation or operation.

Warranties can also be voided by

unauthorized disassembly of equipment. For

warranty repairs, equipment is returned to

INDCO at the customer’s expense; we will

repair and return to customer at our expense.

Under no circumstances will we allow labor

charges or other expense to repair defective

merchandise. This warranty is exclusive and

is in lieu of all other warranties, whether

express or implied. INDCO shall not be liable

for any other damages, whether

consequential, indirect, or incidental, arising

from the sale or use of its products.

Contents Page

Model Data ......2

Safety & General Info ....3

Installation ......4

Maintenance ......6

INDCO, Inc.

P.O. Box 589

New Albany, IN 47151

phone: 812-941-5954

fax: 812-944-9742

web: www.indco.com

INDCO, Inc. M-M-30127 mixer manual TM(G) date: 1/5/05

page 1 of 8

Model:

Serial No.:

Date:

Order No.:

TM & TMG Series Top Entry Mount Mixers

- SPECIFICATION SHEET -

100 - Motor:

Part no.:

HP: RPM:

volts: cycles: phase:

frame: enclosure:

200 - Gear Reducer:

mounting flange

see page 4.

Part no.:

Model No.:

99”

Rotation:

clock-wise looking

downward into tank

Ratio:

RPM output:

300 - Shaft:

Diameter

402 - Impeller, upper:

Diameter

Type

401 - Impeller, center:

Diameter

Type

402 - Impeller, lower:

Diameter

INDCO, Inc. M-M-30127 mixer manual TM(G) date: 1/5/05

Type

page 2 of 8

Safety

General

Please read this complete manual before trying to install or

operate your mixer.

• High voltage and rotating equipment can cause serious

or fatal injury.

• Never move the unit without a suitable lifting device

and do not lift mixer by shaft.

• Have a qualified individual operate and service this

equipment.

• Never run the unit in open air.

• Always lockout the power when working on the unit.

Electric Motor Safety:

Motors should be installed, protected and fused in

accordance with latest issue of National Electrical Code,

NEMA Standard Publication No. MG 2 and local codes.

Frames and accessories of motors should be grounded in

accordance with National Electrical Code (NEC) Article 430.

For general information on grounding refer to NEC Article

250.

Not all rotating parts are guarded. Keep hands and clothing

away from moving parts.

Trained, qualified personnel should make electrical repairs

and non-standard connections.

If environment has hazardous combustible fumes present,

use only explosion-proof electric motors.

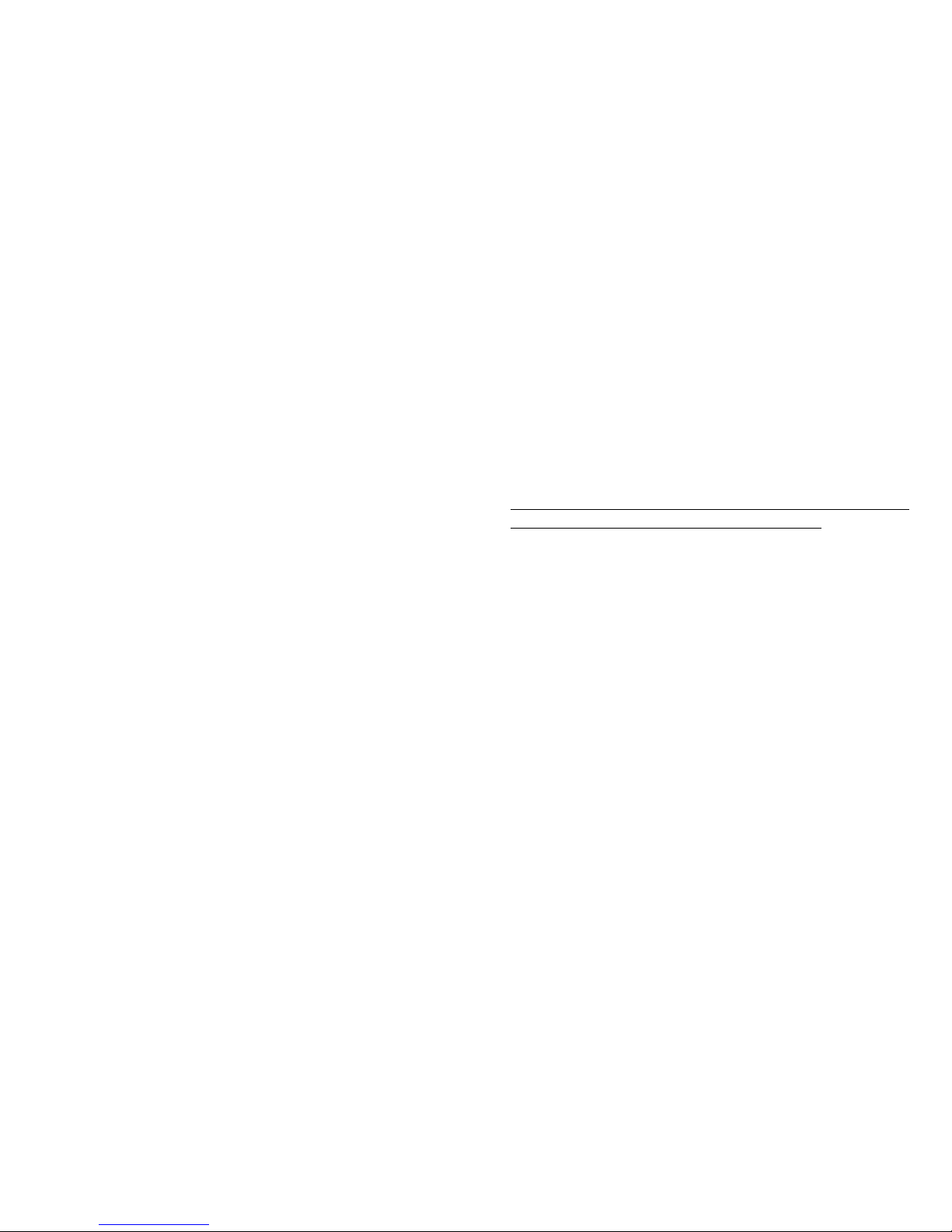

INDCO’s TM series - top mounted heavy duty gear drive

mixers are designed for handling large volumes and are

the most common and most efficient mixer used in the

process industry.

INDCO’s TMG series - top mounted heavy duty gear drive

mixers are designed for handling low viscosity materials in

large batches or small batches of heavy material that are

beyond the range of direct drive mixers.

Both the above mixers feature axial flow impellers that

generate downward flow for optimum circulation and mixing.

Receiving

Before removing any packing, visually inspect the exterior of

the shipment for any sign of damage. Should there be any

damage, bring it to the attention of the delivering UPS or

truck line and note the same on the receiving ticket. Should

there be damage you must place a claim with the truck line.

They are the only ones who will pay for the damage done and

you are the only one who can place that claim.

Air Motor Safety:

The air motor is designed to be driven by compressed air

and under no circumstances be driven with any other gases.

Fluids, particles, solids or any substance mixed with air,

particularly combustible substances likely to cause

explosions, must not drive air motor.

• Do not drive with flammable or explosive gases or

operate unit in an atmosphere containing them.

• Air motor is designed for air only. Do not allow corrosive

gases or particulate material to enter motor. Water

vapor, oil-based contaminants, or other liquids must be

filtered out.

• Do not use a hammer or force coupling or drive pulley

onto shaft when installing drive onto air motor. This

causes end thrust that could damage air motor.

• Ambient temperature should not exceed 250°F.

• Beware of any exposed and/or movable parts. Proper

guards should be in place to prevent personal and/or

property damage.

• Solid or liquid material exiting unit can cause eye or

skin damage. Keep away from air stream.

• Always disconnect air supply before servicing.

• Do not allow air motor to “run free” at high speeds with

no loads. Excessive internal heat build-up, loss of

internal clearances and rapid motor damage will result.

• Some models may exceed 85dB(A) sound level.

Hearing protection should be worn when in close

proximity to these models.

Operation

Electric Power: Once the electric motor has been wired,

check rotation to be sure the mixer shaft is rotating in a

clock-wise direction, looking downward into the container.

Air Power: Check to ensure the air valve is in the closed

position, then connect air supply. Check rotation to be

sure the mixer shaft is rotating in a clock-wise direction,

looking downward into the container.

Once the mixer is in the container, it is now safe to

operate. Always start and stop mixer in slowest speed.

CAUTION:

9 Never run mixer without an impeller.

9 Never run the impeller in open air.

INDCO, Inc. M-M-30127 mixer manual TM(G) date: 1/5/05

page 3 of 8

Loading...

Loading...