Page 1

OWNER’S MANUAL

Please read this Owner’s Manual before

use and keep it at hand for reference.

In the few years since its first appearance in

woodworking shops around the globe, Incra

Jig has quickly established itself as the finest

and most versatile woodworking system

available. At the top of its list of features has always

been its unparalleled positioning accuracy. As a fence

system, Incra Jig’s amazing precision allows precise fence

placement to within a few thousandths of an inch, regardless of

your skill level. As a joint making machine, these same positioning

capabilities permit an endless variety of box joints and half blind, through

and sliding dovetails to be created. And with decorative joints like the exquisite

Incra Double Dovetail (described in the optional

Incra Master Reference Guide

and Template Library

), Incra Jig makes the impossible quite possible.

Introducing the newest member of the Incra family:

The Incra Jig Ultra Lite

. With built-in micro

adjusting, velvet smooth tracking, and the Incra heritage of precision, your new Incra Jig Ultra Lite

combines some of the best features of its big brother, the Incra Jig Ultra, in a refined, more compact

unit perfect for the router table or drill press. The Ultra Lite carries on the tradition of performance and

accuracy you’ve come to expect from the Incra line of precision tools.

From the

makers of

Incra Jig!

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Applications/General Purpose Fence . . . . . . . . . . . . 5

Zeroing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Applications/Joint Maker . . . . . . . . . . . . . . . . . . . . . 6

Setting the router bit depth of cut . . . . . . . . . . . . . . 6

Centering the bit and installing the template . . . . . . 7

Box joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Half blind dovetails . . . . . . . . . . . . . . . . . . . . . . . . .11

Variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Parts and Optional Accessories . . . . . . . . . . . . . . . .16

CONTENTS

■ Important safety instructions for using the Incra Jig Ultra Lite:

before using the Incra Jig Ultra Lite, read and follow all of the

instructions and safety information in this manual.

■ When using Incra Jig Ultra Lite in conjunction with any other

tool, first read and follow all instructions and safety

information in that tool’s owner’s manual.

■ When Incra Jig Ultra Lite is mounted to a wooden base or

table surface, make sure that all six mounting screws are

securely tightened and the Incra Jig Ultra Lite is firmly held in

place.

■ When using the Incra Jig Ultra Lite with a wooden base,

always make sure that the base is securely clamped,

screwed, or otherwise fastened to the work surface before

making a cut.

■ Always turn off the power and make sure that the bit or blade

is fully stationary before moving the Incra Jig Ultra Lite to any

new setting.

■ Always keep both hands behind the fence when moving the

Incra Jig Ultra Lite to any new setting.

■ Before making a cut, always make sure that the carriage

clamp is fully engaged and the jig is securely locked in place.

■ When using the Incra Jig Ultra Lite with other tools, make sure

that all safety guards and other safety equipment supplied by

the manufacturer of that tool are securely in place and

functional. Never let the Incra Jig Ultra Lite interfere with

another tool’s safety equipment.

■ Use appropriate safety devices. Keep hands clear of the bit

or blade. Always use a push stick, rubber soled push block,

or other safety devices to keep your hands safely away from

the cutting tool.

■ Wear safety glasses, hearing protection, and a dust mask,

and follow all normal shop safety practices.

■ Do not alter or modify the Incra Jig Ultra Lite in an attempt to

use it with non-Incra accessories.

SAFETY

Precision

Woodworking System

®

TM

Page 2

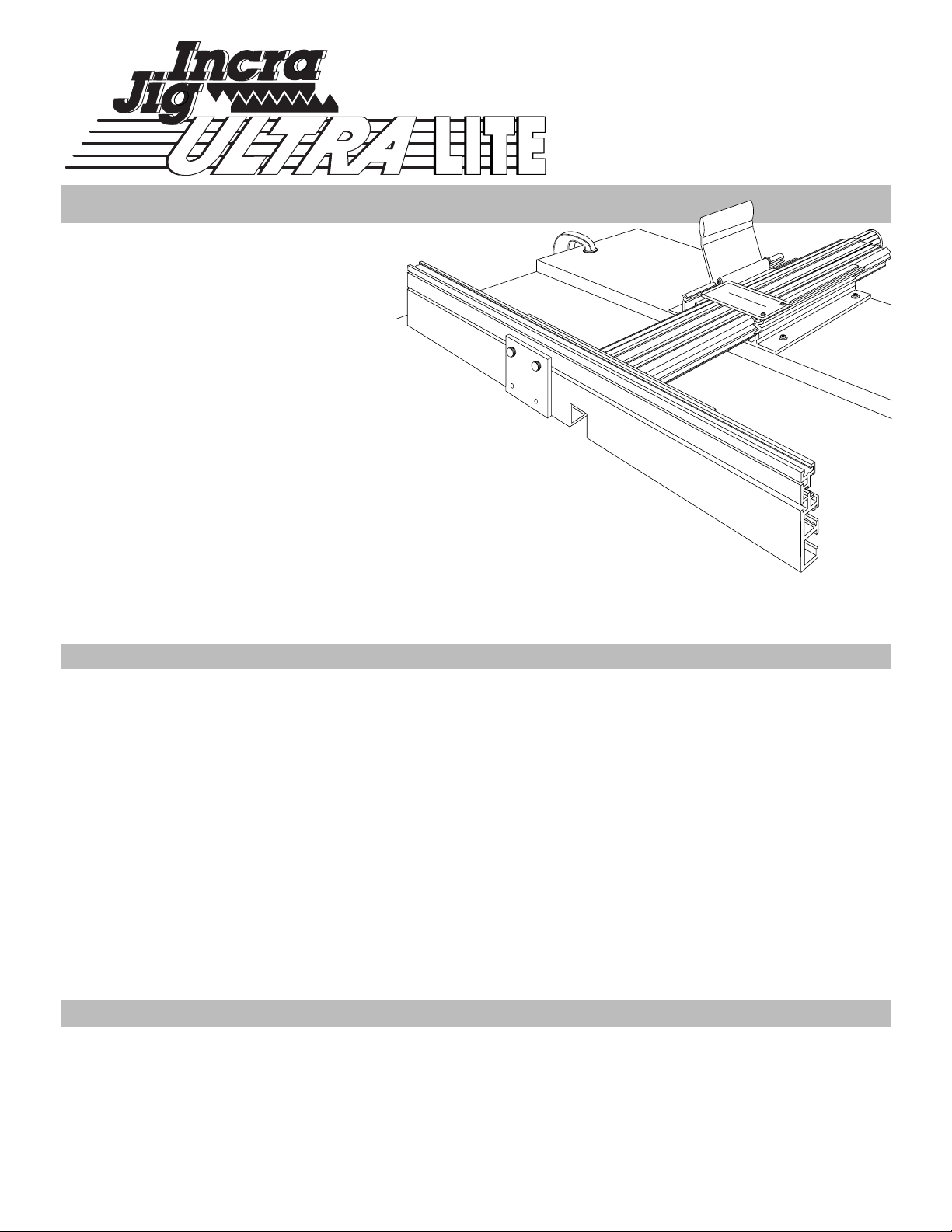

Attach the Incra Jig Ultra

Lite to a

3

/

4

” plywood base

Begin with a piece of

3

⁄

4" plywood (or

hardwood) that is 8" wide. The length of the

plywood should match the width of your

router table. Clamp the plywood to the edge

of your router table using (2) C-clamps.

Mark the center of the plywood’s length and

position the operator’s side of the Ultra Lite’s

base 2

1

⁄

4" from the center mark. See Fig. 1.

Attach the base to the plywood through the

six holes using (6) #10 x

7

⁄

8" phillips pan

head wood screws and #10 flat washers.

Attach hairline cursor

to base

Place one of the #6 flat washers on each of

the #6-32 x

3

⁄

8" screws. Insert the screws

through the holes in the plastic cursor and

loosely attach the #6-32 hex nuts. slide the

two nuts into the T-slot at the front of the

Ultra Lite’s base as shown in Fig. 1a. Align

the cursor flush with edge of the base and

tighten the mounting screws.

Attach the Incra Fence

With the plywood base still clamped to

the edge of your router table, carefully slide

the carriage into the base and pull the

carriage clamp up into the locked position.

Insert the #10-32 x 1

1

⁄

8" phillips pan head

screws through the thick (gold) washers,

then through the holes on the back of the

fence mounting bracket. Place a thin (silver)

washer on the end of each screw, then

loosely attach the rectangular nut. See

Fig. 2. The raised rim on the nut should

face toward the mounting bracket. Now

slide the thin washer and rectangular nut

into the T-slot on the back of the Incra

Fence. Make sure the thin washer is

captured in the T-slot provided as shown in

Fig 3. Position the fence so that the

mounting bracket is approximately centered

on the fence length and tighten the two

mounting screws.

FIG. 1

Attach Ultra Lite to 3⁄ 4" plywood base

FIG. 2

Attach the Incra Fence

To achieve a silky smooth

carriage motion when moving the

fence, it is important that your table

surface is flat and smooth. If you find

that your carriage tends to bind slightly

during some portion of its travel, try

loosening the fence mounting screws

then retightening at different locations

along the table’s length.

2

1

SETUP

FIG. 1a

Attach hairline cursor

3

FIG. 3

2

#10 x 7/8"

phillips pan head

wood screws

#10 washer

Center of

plywood

Align cursor flush

with edge of base

#6-32 x

3

/8" screw

#6 flat washer

#6-32 hex nuts

Incra Fence

Fence

mounting

bracket

Raised rim on rectangular nut

faces the mounting bracket

#10-32 x 1

1

/8" phillips

pan head wood screw

Thick (gold)

5

/8" o.d.

flat washer

Thin (silver) 5/8" o.d.

flat washer

Thick gold

washer

Thin silver washer

captured here

8"

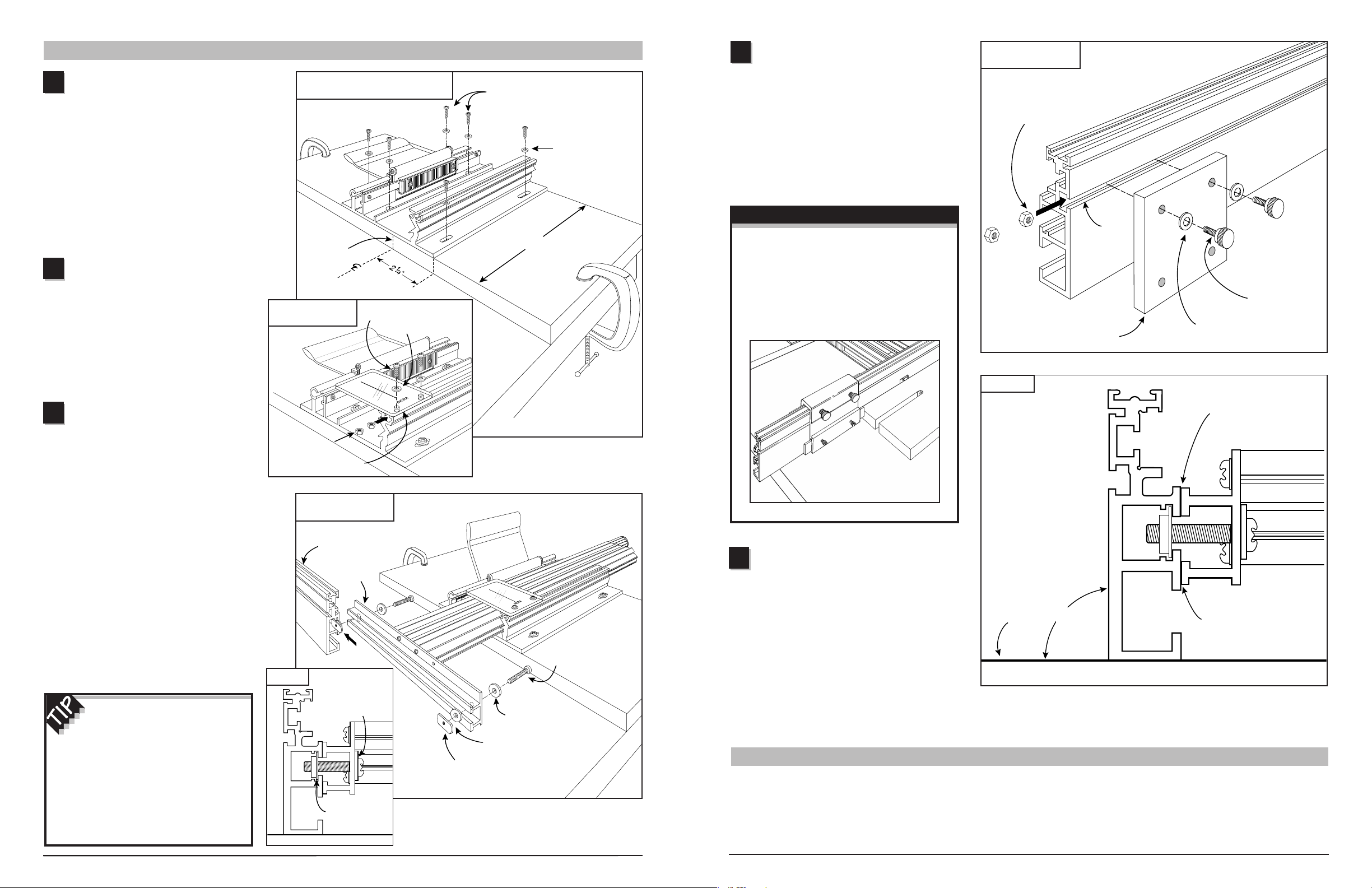

Adjusting the fence angle

After mounting the Incra Fence to your

Ultra Lite, check the angle of the fence to

the router table using a machinist’s or

carpenter’s square. Sometimes, as a result

of the plywood not being perfectly flat, the

angle may be slightly more or less than 90°.

To correct the angle, place a masking tape

shim between the mounting bracket and the

fence as shown in Fig. 5.

Assemble stop positioner

Place a #8 flat washer on each of the

(2) #8-32 x

1

⁄

2" thumb screws and insert

through two of the holes in the black plastic

stop positioner. Loosely install the (2) #8-32

hex nuts, then slide the nuts into the T-slot

on the front of the Incra Fence. Fig. 4.

When not in use, simply slide the stop

positioner off the fence.

If you wish to upgrade your Incra

Fence to add the ultra-precise stop

positioning abilities of the New Incra

Stop, see the fence upgrade

package offered on page 16.

5

FIG. 4

Assemble stop positioner

FIG. 5

4

#8 flat washer

#8-32 hex nut

#8-32 x 1/2"

thumb screw

Stop

positioner

T-slot

Table

top

Place shim here if angle

is greater than 90°

Place shim here if

angle is less than 90°

Fence upgrade option:

MAINTENANCE

In general, just keeping your Incra Jig clean is all

you need to do to keep the tool in tip top shape.

Occasionally, remove the carriage from the base and

brush or blow out any sawdust or debris that may have

accumulated on the base and the UHMW guide

bearing strips. Use a toothbrush to clean the teeth

on the Incra racks on both the carriage clamp and

on the carriage.

90°

3

Page 3

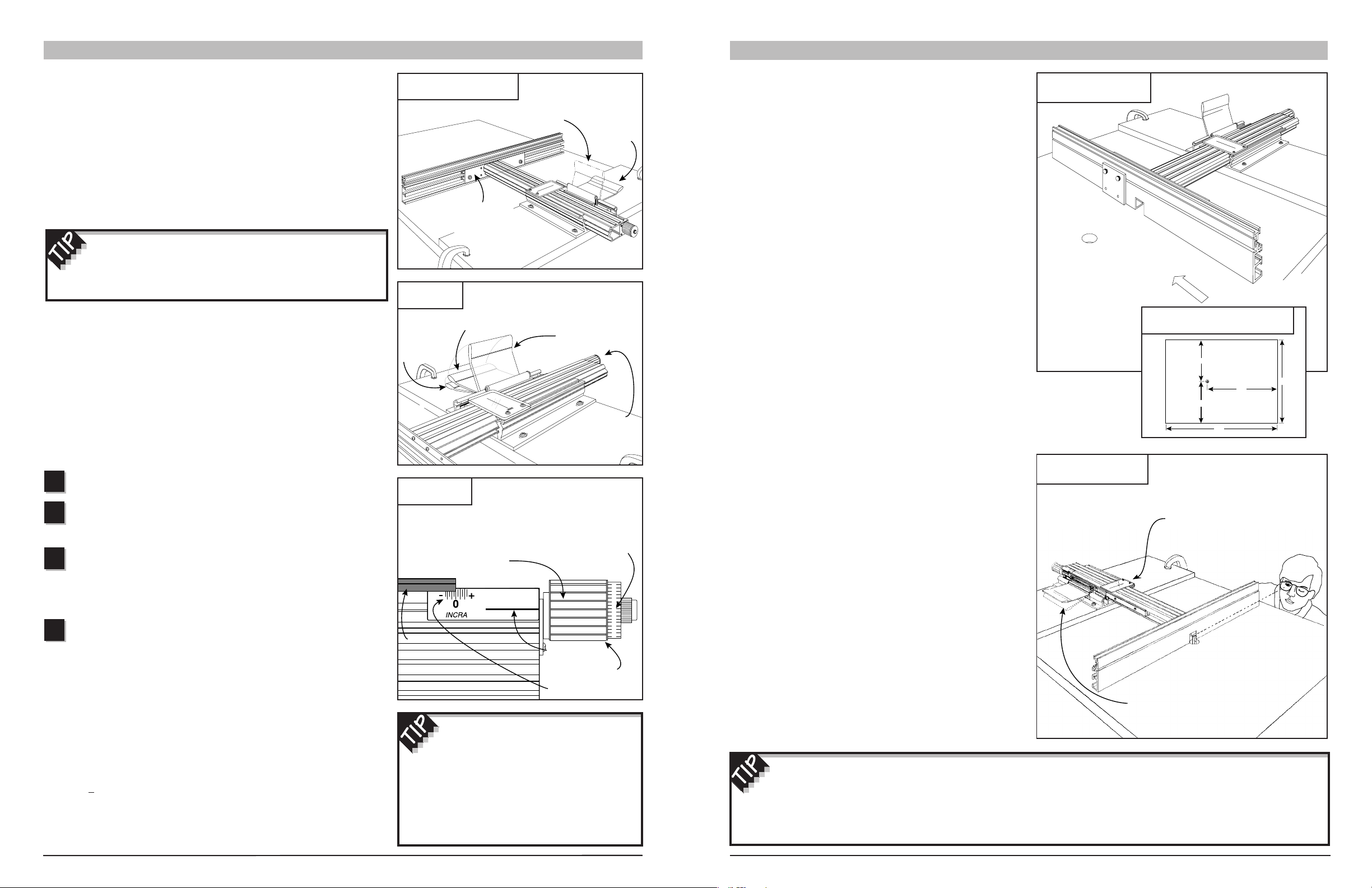

Micro adjusting

The micro adjust feature of your new Incra Jig Ultra Lite allows for

precise positioning of the fence to any location between the 1⁄32" tooth

spacing of the Incra sawtoothed racks. You’ll find this feature extremely

handy the next time you need to widen a mortise by a few thousandths

of an inch for a great fitting mortise and tenon joint. Use the micro

adjuster for a flawless fit when cutting grooves to accept inlay strips,

or to loosen up a tight fitting box joint cut with an undersized bit. You’ll

find it especially useful for setup operations like “zeroing” (page 5) or

“centering” (page 7). Here’s a step-by-step look at operating your

Ultra Lite micro adjuster. See Fig. 7 as you follow the steps

Unlock the carriage clamp

Push the carriage clamp down to unlock the carriage.

Engage the micro adjust mechanism

Continue pushing the carriage clamp handle down until it

touches your plywood sub-base, then hold it there.

Micro adjust the fence position

Turn the micro adjust knob clockwise to move the fence toward

the cutter (forward), counterclockwise to move the fence away from

the cutter (backward). The carriage clamp handle must be held down

as the knob is turned.

Lock the carriage clamp

Pull the carriage clamp up to lock the carriage back in place.

Gauging the distance moved when micro adjusting is easy. A full

turn of the knob equals 1⁄32" of adjustment; a half turn equals 1⁄64".

For smaller adjustments, use the grooves on the knob as a reference.

For each groove that passes the corresponding cursor decal on the

carriage (see Fig. 8), you have moved the fence .002" (two

thousandths of an inch). At the end of the knob, you’ll find a scale

that can be aligned to read zero at any of the grooves on the knob.

This allows you to re-zero the scale after any micro adjustment.

Simply loosen the thumbscrew to rotate the scale.

The micro adjust feature of the Incra Jig Ultra Lite has as adjustment

range of +5⁄32" from mid-range. The range scale decal on the

carriage shows how much range remains in either direction. To read

the scale, just sight along the end of the black bar that holds the blue

Incra racks. When the end of the black bar is aligned with the zero

on the range scale, you are at mid-range. See Fig. 8.

OPERATION

FIG. 6

Moving fence to a new position

Although the clamping pressure has been factory adjusted,

you may wish to fine-tune the pressure to suit your individual

preference. If so, use the thin plastic shims provided and follow the

instructions shown on page 14.

FIG. 7

Micro adjusting

Moving to a new scale setting

With the plywood base clamped to the stationary tool of your choice,

moving the fence to any new scale setting is simple. First, push the

carriage clamp down and release the clamp handle to unlock the

carriage. Grasp the fence mounting bracket as shown in Fig. 6 and

slide the fence to the new position, aligning the mark on the scale or

template directly under the hairline cursor. To secure the carriage at

the new scale location, simply pull the carriage clamp handle up into

the locked position. When moving the carriage, take care not to

accidentally slide the scale in its slot. Caution: For your safety, keep

both hands behind the fence when moving to any new scale position.

FIG. 8

Micro adjust scale

1

2

3

4

First:

Push

carriage

clamp down

to unlock

carriage

Third: Pull

carriage clamp

up to lock

carriage

First: Push carriage

clamp down to “unlock”

Second: Press

clamp all the

way down and

hold.

Third: Turn

micro adjusting

knob to finetune fence

position

Fourth: Pull carriage

clamp up to lock

carriage back in place

As knob is rotated, each groove

that passes the cursor decal

on the carriage represents

.002" (two thousandths of an

inch) movement of the fence

Use the scale on the end of

the knob to accurately gauge

the distance moved. After

micro adjusting, scale on knob

can be rotated to read zero

Cursor decal

Black bar

Range scale

Micro adjust knob

Second: Grasp fence

mounting bracket and slide

fence to new position

To avoid running out of micro adjustment

range in the middle of a project, you need

to remember two things. First always micro

adjust back to mid-range before beginning a new

project. Second, whenever you need to micro

adjust a distance greater than

1

⁄32"

, use the Incra

positioning racks to get as close as possible

before reaching for the micro adjust knob.

25

26

27

28

29

30

31

0

1

2

3

4

5

6

7

8

4

5

FIG. 9

Ultra Lite at the router table

The essence of any Incra Jig is its ability to accurately

position your board for a cutting operation. In a nutshell,

it is a precision fence system. Even when used as a joint

maker, the fact is, you are simply applying a technique to

a very accurate fence system in order to produce the

various possible joints. Using your Incra Jig Ultra Lite as

a general purpose fence is just as easy as using any

other fence in your shop. In fact, it shares in common four

things that all fences have: the straight edge or fence that

your board will be pushed along as you make a cut, a

scale, a hairline cursor, and a clamp. You will use your

Incra Fence as you would any fence, that is, first you’ll

unclamp, then look through the hairline cursor as you

move the fence. When you see your measurement come

under the hairline, you’ll clamp the fence in place. Of

course, this is where the comparison ends because, unlike

other fences, when you clamp your Incra Jig Ultra Lite in

place, it is exactly where you want it to be. Just get the

mark on the scale close to the hairline cursor and the

automatic positioning controls of the patented Incra racks

move the fence to the exact location as you clamp the jig

in place. It’s just that easy. You’re sure to find many

places in your shop where the precision of the Ultra Lite

will benefit you and your work.

To use Incra Jig Ultra Lite at your router table, position the

plywood base on your router table top as shown in Fig. 9.

The fence should always be on the right hand side of the

router bit as seen from the operator’s side of the table.

If you do not yet own a router table top, the dimensions

shown in Fig. 10 will produce a comfortable table size

which allows enough room to use the full range of your

Incra Jig Ultra Lite. Now all you need to do is install a

router bit and “zero” the fence to the bit.

“Zeroing” the Fence to your

Router Bit

In order to ensure accurate results from any fence for

general purpose cutting, the fence must first be “zeroed”

to the cutter. To zero your Incra Fence to the cutter,

release the carriage clamp and slide the fence up to the

edge of the cutter. Sight down the length of the fence to

check for a gap between the fence and the cutter. Finetune any remaining distance by holding the clamp handle

down as you micro adjust the fence position. When the

gap of light disappears, the cutter will be “zero” distance

from the fence. Check to make sure that the router bit is

safely centered on the opening in the fence. Return the

carriage clamp to the locked position, then slide the

1

⁄

32"

scale to read 0" under the hairline cursor. See Fig. 11.

APPLICATIONS/GENERAL PURPOSE FENCE

For a truly precise “zeroed” setup, follow the

instructions above, then move your fence to a scale

reading of

1

⁄

4"

and make a test cut on a piece of scrap

stock. (Make sure the scrap stock has a square edge

and that this edge is against the fence during the cut.)

Use a pair of machinist calipers to measure the distance

between the groove and the edge of the board. If it

does not measure exactly .250" (

1

⁄

4"

), just use the

micro adjuster to accurately fine-tune the remaining

distance.

12"

12"

20"

32"

24"

FIG. 10

Router table top suggested dimensions

FIG. 11

Zeroing the fence to your bit

Feed direction

First: Unlock carriage

clamp and slide fence

up to bit

Second: Hold clamp handle down and

turn micro adjusting knob until gap

between fence and bit disappears

Third: Pull carriage clamp

up into locked position

Fourth: Slide scale to read 0"

under the hairline cursor

Page 4

6

Joint making represents one of the most exciting applications for

your new Incra Jig Ultra Lite. Just by applying a little technique to

the accuracy of your Incra Jig, you’ll soon be able to add joinery for

box and drawer making to your list of shop skills. The two templates

included with the basic set will allow you to produce equally spaced

3

⁄

8" box joints and equally spaced

1

⁄

2" half blind dovetails.

There are three important operations that must take place each

time you use your Incra Jig for joint making at the router table:

1. Setting the router bit depth of cut

2. Centering the bit on your workpiece and installing

the template

3. Cutting the joint

We’ll begin with a look at the first two operations. These are

simple setup procedures with which you will want to become

familiar. They will be used every time you prepare to cut a joint at

your router table. Beginning on page 10, we will apply these two

setup operations in a step-by-step description for cutting box joints

and half blind dovetails.

Setting the Router Bit Depth of

Cut for Box Joints

After installing the appropriate diameter straight bit for the template

pattern you have selected, (a

3

⁄

8" straight bit is required for the

Box1 template included with your Ultra Lite System) simply raise or

lower the bit in your router table to set the depth of cut at slightly

greater than the thickness of the stock you will be cutting. See

Fig. 12. Just remember, router bit manufacturers suggest that you

not cut any deeper than the diameter of the bit in any single pass.

APPLICATIONS/JOINT MAKER

FIG. 12

Depth of cut for box joints

For even more variety,

including through and

double dovetail

techniques, the optional

Incra Master Reference

Guide and Template

Library

contains a large

selection of new joinery

templates. For pricing

and ordering information,

see page 16.

FIG. 13

Set approximate depth of cut

Setting the Router Bit Depth of Cut

for Dovetail Joints

As with any half blind dovetail jig, the depth of cut of your

dovetail bit will determine how well the finished joint fits. Just a

little practice using the following steps will ensure that your

dovetail joints will always have a perfect fit.

Set the approximate depth of cut

Install the dovetail bit that corresponds to the template you

are using. (A

1

⁄

2", 14° dovetail bit is required for the DOV1

template included with your Ultra Lite System.) Raise or lower

the bit to the approximate depth of cut listed under the diagram of

your template pattern. (

1

⁄

4" for the DOV1 template, see diagram

on page 11.) Position your fence as shown in Fig. 13 so that

about half of the bit is inside the fence notch. Now slide the

1

⁄

32"

scale on your Incra Jig to read 0" under the hairline cursor.

Make the test cuts

Clamp two pieces of square cut stock to your Right Angle

Fixture. You are now going to make two dovetail cuts on the

boards as shown in Fig. 14. The spacing between these two

cuts is listed under the diagram of your selected joint pattern.

For example; if you were setting the depth of cut for the DOV1

pattern included with the Ultra Lite System, the diagram shows:

Spacing to set depth of cut =

7

⁄

8". Using the

1

⁄

32" scale set in

Step 1, you would make a cut at the 0" setting, then move to

7

⁄

8"

to make the second cut.

1

2

Raise or lower bit to

slightly greater than

the thickness of

your stock

Board to be joined

First: Set bit height

to recommended

approximate depth of cut

More Joinery Templates

FIG. 14

Make the test cuts

Second: Position the fence

so that about half of the bit

is inside the fence notch

Third: Slide the 1/32" scale

to read 0" under the cursor

First: Clamp two

boards to Right Angle

Fixture

Second: Make

a cut at the 0"

setting

Third: Move fence

back to dimension listed

under diagram of your

joint pattern (7/8" for

DOV1 pattern) and

make second

cut

Centering the Router Bit on your

Workpiece

After setting your router bit depth of cut, you need to

position your Incra Jig and install the joinery template so

that all the cuts are made in the right places on your

wood. This is accomplished through a setup operation

called “centering”. Centering locates your Incra Jig so

that the router bit is aligned with the center of the stock

width you wish to use. Once you find the center, install

the selected template and you’ll be ready to cut a

perfect joint. The simple steps to follow should always

be used when setting up your Incra Jig for joint making.

Align board with bit

Begin by cutting a piece of

3

⁄

4" thick stock to the

same width as the boards you wish to join later on. Mark

the center of this piece’s width on one end and place

the board face down on the router table with the center

of the board aligned with the approximate center of the

bit. See Fig. 17.

Set initial fence position

Unlock the carriage clamp and slide the fence up to

the edge of the board, then lock the carriage clamp

back in place. See Fig. 18. Make sure the center mark

on the board is still aligned with the approximate center

of the router bit.

Test the fit and adjust as necessary

Unclamp the two boards and test the fit by joining

them as shown in Fig. 15. As with any half blind dovetail

jig, a little trial and error is needed to achieve a snug

fitting joint. To tighten the fit, raise the bit up slightly; to

loosen the fit, lower the bit slightly. Just remember this

phrase: “Heighten to tighten, lower to loosen.” After

adjusting the bit height, make a new set of trial cuts on

the opposite end of the boards. After a few adjustments

and trial cuts, you’ll have a perfect fit. If you’ll mark the

properly fitting cuts on one edge of the boards, you can

save this piece to use as a depth gauge the next time

you set up this particular bit for joinery.

7

FIG. 15

Test the fit

When the fit is too loose, the trial cuts provide a

gauge to let you know how much to raise the bit. Just

join the trial pieces end to end and gently pull the boards

to wedge the dovetails together. The gap that appears is

equal to the distance you need to raise your dovetail bit to

achieve a tight fit. See Fig. 16.

FIG. 16

FIG. 17

Align board with bit

FIG. 18

Set initial fence position

2

1

3

Gap

Raise bit this much

Mark center

of board

Center of board

aligned with

approximate

center of bit

First: Unlock

carriage clamp

Second: Slide fence

up to edge of board

Third: Lock carriage

clamp back in place

Page 5

8

FIG. 19

Rout the test groove

Rout the test groove

Turn the router on, and using a good rubber soled push

block, cut a groove along the entire length of the board. See

Fig. 19. Now turn the stock end for end with the groove still

face down and make a second pass over the router bit. The

second pass should widen the groove slightly (unless you are

already perfectly centered). Make sure you have turned the

stock end for end before making the second pass. (This

places the center mark at the back of the board.)

Fine-tune the fence position

With the router unplugged, turn the bit to its widest cut

angle (viewed from the infeed side of the router table). Place

the board against the fence with the router bit just inside the

test groove cut. There should be a small gap between the

edge of the bit and one side of the groove. See Fig. 20.

Now all that is needed is to micro adjust the fence position so

that with the board against the fence, the bit is in the center

of the groove. Use the Ultra Lite’s micro adjuster to move the

fence until there appears to be an equal gap on both sides of

the router bit. See Fig. 21. Once the bit is in the middle of

the groove, make sure to lock the carriage clamp in place.

FIG. 20

Position board against fence

with bit just inside the groove

FIG. 21

Micro adjust fence to place bit

in the middle of the groove

4

3

First: Rout a groove along

the entire length of the stock

Second: Turn

end for end

and make a

second pass

over the bit

Small gap on one

side of the bit

Equal gap on

both sides of bit

This is a large template and must be output accurately,

Please, call us and we will send you this template.

972-418-4811

Once you have successfully found the center of the

board’s width with your router bit, slide the template you

have selected for joinery into one of the scale slots on your

Incra Jig’s carriage. This must always be done with the

carriage still locked at the center position you just found. Slide

the template until the suggested center cut on the template is

directly under the hairline cursor. You’ll find the suggested

center cut listed under the diagram of each template pattern

shown above. You are now ready to cut the joint.

9

5

FIG. 22

Install the Incra template

FIG. 23

With the jig still locked at the

center of your board, slide the

template in to position the “center

cut” under the hairline cursor

In order to save wood when centering the bit on

wide stock, just leave one of the boards you’ve cut for

your box about an inch to two longer than necessary. Clamp

this piece to your Right Angle Fixture as shown in Fig. 23

and make the test cuts described in Step 3 through the end

of the board, flipping the piece edge for edge before making

the second cut. After you are centered, just crosscut the

extra length off of the board’s end.

This is a large template and must be output accurately,

Please, call us and we will send you this template.

972-418-4811

TEMPLATE: DOV1

BIT TYPE: 1/2” 14° DOVETAIL

APPROX. DEPTH OF CUT: 1/4”

SPACING TO SET DEPTH OF CUT: 7/8”

DOV1BOX1

SUGGESTED CENTER CUT: 8B

APPROX. RABBET WIDTH: 7/32”

APPROX. STOCK THICKNESS: 1/2”

TEMPLATE: BOX1

BIT TYPE: 3/8” STRAIGHT

APPROX. STOCK THICKNESS: 3/8”

APPROX. DEPTH OF CUT: 3/8”

SUGGESTED CENTER CUT: 9B

Page 6

10

The first cut on either the

“A” or “B” series of cuts will be

an open cut. This means you

will be cutting away the edge of

the board adjacent to the fence.

To keep this edge cut clean and

splinterfree, begin with a light

1

⁄

32"

wide scoring pass, then sneak up

to the first template mark in

several light side-by-side passes.

See Fig. 28.

FIG. 26

Make the “A” cuts

Backing board to

prevent splintering

FIG. 27

Make the “B” cuts

Backing board to

prevent splintering

FIG. 28

Fence

open cut

One of the easiest of the

many interlocking joints that

can be cut with your Incra

Jig, box joints provide a

good introduction to the use of the

Ultra Lite and the joinery templates for joint

making. Just follow these steps to learn how:

You’ll want to begin by cutting your stock to the lengths

and widths necessary for your box construction. Also

cut a piece of

3

⁄

4" thick stock to the same width for use in

centering later on.

Install a

3

⁄

8" straight bit in your router table and set the

depth of cut to slightly greater than the thickness of

your stock.

Center the bit on your stock width and install the

template. Use the centering method described on

page 7 to find the center of your board’s width with the

router bit, Fig. 25. Remember, the board used for the test

cuts must be the same width as the pieces you will be

joining later on. After finding the center, slide the BOX1

template into one of the auxiliary scale slots and position the

suggested center cut (9B) directly under the hairline cursor.

Clamp two of your boards to the Right Angle Fixture

with a backing board as shown in Fig. 26. (You can use

your centering board from Step 3 as a backing board if you

like.) The backing board is used to prevent splintering as

the router bit exits the cut. Make cuts at the “A” marks on

the template. Of course, you will only need to make the “A”

cuts that position the boards in line with the router bit. After

completing the cuts, flip the boards end for end and repeat

the same cuts. Now clamp the remaining two boards with a

backing board to the Right Angle Fixture as shown in Fig. 27

and make the “B” series of cuts. Repeat these “B” cuts on

the opposite end of the boards.

Too tight or too loose?

Check the fit of your completed pieces. If the joint is too tight

or too loose, the problem is the router bit, not your Incra Jig.

An oversized bit will create a loose fit, while an undersized bit

will cut a tight joint. To loosen the tight fitting joint, you can

micro adjust the fence backward about five thousandths of an

inch and then re-cut one of the series of cuts.

FIG. 24

Set depth of cut

FIG. 25

Center bit on your stock width

1

2

3

Board to be joined

Depth of cut set slightly

greater than thickness

of stock

See Steps 1-5 starting on page 7

for complete centering instructions

Box Joints

4

Make several

light side-by-side

passes when

making open cut

adjacent to fence

Half Blind Dovetails

The easiest of the dovetail

joints, half blind dovetails add

strength and beauty to your

joinery. They are also the most

versatile of the many joints you

can cut with your Incra Jig. In fact,

many of the decorative joints we’ve

designed over the years are just variations

on the half blind technique you are about to learn. Once

you’ve mastered the steps below, you’ll find these

decorative joints (described in the optional

Incra Master

Reference Guide and Template Library

and in the

Incra Jig

Projects & Techniques

book) quite easy to complete.

You’ll want to begin by cutting your stock to the

lengths and widths necessary for your box

construction. Also cut a piece of

3

⁄

4" thick stock to the

same width to use in centering later on.

Install a

1

⁄

2" 14° dovetail bit in your router table and

set the depth of cut as described on page 6.

The two trial cuts should be spaced

7

⁄

8" apart for the

DOV1 template.

Center the bit on your stock width and install the

template. Use the centering method described on

page 7 to find the center of your board’s width.

Remember, the board used for the test cuts must be

the same width as the pieces you will be joining later on.

After finding the center, slide the DOV1 template into one

of the auxiliary scale slots and position the suggested

center cut (8B) directly under the hairline cursor.

Determine the Pin and Tail cuts. Fig. 31 details the

characteristics of a properly cut pin board and tail

board. You’ll notice that the tail board always begins and

ends with open cuts, while a pin board will always have

solid stock on its edges. As a result, it is important at this

point to determine which series of cuts (“A” or “B”) will be

used for the tail boards and which series will be used for

the pin boards. To do this, turn to the full sized diagram for

the DOV1 template shown on pages 8-9. With a pencil,

mark the center of the width of one of the boards to be

joined. Align the pencil mark with the center cut mark (8B)

on the drawing, see Fig. 32. On one side of the plans, the

outer edges of the board will overlap grooves. The series

of cuts on that side of the drawing will

become the tail cuts. On the other

side of the plans, the outer edges of

the board will overlap shaded pins on

the drawing. The series of cuts on

that side will become the pin cuts. In

the example shown in Fig. 32, you can

see the edges of the board overlap

grooves on the “A” side of the drawing.

The “A” series of cuts will be used for

the tails. The edges of the board

overlap shaded pins on the “B” side of

the drawing. The “B” series of cuts will

be used to cut the pins.

11

1

2

3

4

FIG. 29

Set depth of cut

See Steps 1-3 starting on page 6 for

complete depth of cut instructions

FIG. 30

Center the bit on your stock width

See Steps 1-5 starting on page 7

for complete centering instructions

FIG. 31

Pins and tails – half blind dovetails

Tail boards are always cut

VERTICALLY clamped to

the Right Angle Fixture

The first and

last cuts on

the tail boards

are always “open

cuts”. This

means the edges

are cut away

Tail boards always

begin with a dovetail

shaped rabbet

Pin boards will always

have half pins (solid

stock) on the outer

edges of the board

Pin boards are cut

FACE DOWN on the

router table

FIG. 32

Determine the pin

and tail cuts

Pins

Tails

Template: DOV1 Approx. Depth of Cut:1⁄4" Suggested Center Cut: 8B

Approx. Stock Thickness – Half Blind:

1

⁄2" – Through:1⁄4"

Bit Type:

1

⁄2" 14° Dovetail Spacing to Set Depth of Cut:7⁄8" Approx. Rabbet Width:7⁄32"

Page 7

Tail Cuts

To cut the tails for a half blind dovetail, begin by

cutting a dovetail shaped rabbet on both ends of the

two boards, see Figs. 33 and 33a. The rabbet needs to

be

7

⁄

32" wide. Do not cut the rabbet width in one pass.

Instead, use three or four light side by side passes to

sneak up on the rabbet width. You can use the

1

⁄

32" scale

in your Ultra Lite as a reference so you’ll know how much

you have widened the rabbet with each pass.

Now clamp the two tail boards to your Right Angle

Fixture as shown in Fig. 34, and make the tail series

of cuts that you determined in Step 4. As always, using

good router technique, sneak up to the first tail cut in

several light side-by-side passes to avoid splintering the

edge of the stock (see Tip on page 10). After completing

the cuts, flip the boards end for end and repeat the cuts.

Pin Cuts

Set your Incra Jig to the first pin cut on the template

that places the bit in front of the fence. Slide the

stop positioner onto the fence and locate the stop as

close to the dovetail bit as possible (without actually

touching the bit) and clamp in place. See Fig. 35. The

stop positioner will be used to limit the length of the pin

cuts.

Place one of the pin boards face down on the router table

as shown in Fig. 36 and make the pin series of cuts

determined in Step 4. Be sure to use a good rubber

soled push block as shown. Make the cuts on only one

end of the board for now. After making the cuts, check

the fit between this board and one of the tail boards. If

the tails won’t fit all the way into the pin sockets, simply

lengthen the pin cuts by moving the stop positioner away

from the router bit. (See Tip below.) Recut the pin board

and again check the fit. Once you have a flush fit, make

the pin cuts on the opposite end of the board and on both

ends of the remaining piece.

5

6

7

FIG. 37

Move stop

back this far

to achieve a

flush fit

FIG. 33

Cut the rabbets

Dovetail shaped rabbet

cuts on both ends of

the tail boards

Rubber soled

push block

FIG. 33a

Rabbet width

7

⁄ 32"

rabbet

After making your first series of cuts, check the fit

with one of the tail boards. If the tail board won’t fit

all the way into the pin board, just measure the

distance it protrudes. See Fig. 37. This is the distance

you need to move the stop away from the bit to achieve a

flush fit.

Pin board

Tail board

FIG. 34

Cut the tails

Wooden

handscrew

clamp

FIG. 35

Set stop positioner

Position stop on

outfeed side of

bit as close as

possible to the

cutter

FIG. 36

Cut the pins

Rubber soled

push block

Clamp two boards

with rabbets facing

out as shown

Stop

positioner

Fence

12

13

After making a half blind dovetail, you may notice that the

joint looks symmetrical, but the edges of the two boards do

not align flush, see Fig. 38. This simply means that when

you centered the board using the method described in

your owner’s manual or

Incra Master Reference Guide and

Template Library

, you were close but not quite perfect. Of

course practice makes perfect, but there is another method

for cutting the tail boards that will ensure a flush alignment

regardless of how well your board was centered. Just

make sure when you clamp the tail boards to the Right

Angle Fixture that the dovetail shaped rabbets on all the

boards face the cutter, see Fig. 39. That’s all it takes!

Remember that even if you use this procedure, you should

still center first to ensure a symmetrical looking joint.

FIG. 38

Boards

not

aligned

flush

Dovetail shaped

rabbet cuts

face the cutter

Not

flush

FIG. 39

VARIATIONS

The drawings at right show a standard equally spaced

dovetail joint (Fig. 40) and several variably spaced dovetail

joints (Fig. 41). Although these joint patterns look quite

different from one another, they all have one thing in

common. They are all made using the same equally

spaced dovetail template. By learning the variations

technique described below, you can customize the joint

pattern produced by any template. This technique works not

only for half blind dovetails as pictured, but also for box

joints, through dovetails, and with a little study, you can

even customize the decorative Double and Double-Double

joints. In general, pattern variations can be designed by

observing a few simple rules.

Select cuts to be left out

Align the center of your board with the center cut you

plan to use on the diagram. Then choose the cuts you

want to leave off on one* side of the diagram. Determine

which side of the diagram will be the pin cuts and which will

be the tails (see Step 4 on page 11). Leaving cuts off of

the tail side of the diagram creates wider tails. (See

Example 1 on Fig. 41.) Leaving cuts off of the pin side of

the diagram creates wider pins.

*

Although a bit more complicated, cuts can be left off of both

sides of the diagram, resulting in a pattern variation that has

both wider pins and wider tails. (see Example 3, Fig. 41)

Always modify the pattern

symmetrically

For example: if you decide to leave out the

first

two “A” cuts

on your stock’s width, you must also leave off the

last

two

“A” cuts.

Cut the joint

Any cuts left out on one side of a pattern will be used

to modify the other side. If you decide, for example, to

leave off cuts 2A and 7A when you are cutting the “A” cut

boards, just make cuts 2A and 7A along with all of the “B”

cuts to automatically modify the “B” cut boards.

BEGINNER’S TIP

2

3

FIG. 40

FIG. 41

Equally spaced

dovetail

Tails Pins

EXAMPLE 1

Tails Pins

EXAMPLE 2

Tails Pins

EXAMPLE 3

FIG. 42

Designing

the pattern

variation

FIRST: Align center of board with “center cut” on diagram

SECOND: Determine which cuts will be pins and which will be tails.

(Step 4, page 11)

THIRD: Decide if you want the pins or the tails to be wider.

Example: Leaving out the “A” cuts will create wider tails; Leaving

out the “B” cuts will create wider pins.

FOURTH: Write down or circle the cuts you wish to leave out.

Center of

board

aligned

with

“center

cut”

Dovetail bit

1

Page 8

14

All of the components and features of your new Incra Jig

Ultra Lite have been factory set and should require no

further adjustment. If, however, you wish to recalibrate

these components, the following information is provided to

assist in performing the adjustments.

Adjusting the Clamping Pressure

The Ultra Lite carriage clamp was designed to make it

easy for the operator to adjust the clamping pressure to

his/her own individual preference using the supplied clamp

pad shims. Here’s how:

Note: The Ultra Lite must be attached to a

3

⁄

4" plywood

base with all six mounting screws (see Fig. 1, page 2)

before adjusting the clamping pressure.

Unlock the carriage clamp and remove the phillips head

screw and washer that caps either end of the clamp pad

slot. See Fig. 43. Your hardware pack for the Ultra Lite

includes (3) .005" x

7

⁄

8" x 4" clamp pad shims. If you want

to increase the clamping pressure, add one of the shims,

check the clamping pressure and adjust further as

necessary. The shims should be placed to the left of the

1

⁄

8" thick clamp pad shown in Fig. 43, so that the clamp

always touches the

1

⁄

8" thick pad, and not the thin shims.

To decrease the clamping pressure, simply remove one of

the existing thin shims. When you are satisfied with the

clamping pressure, replace the phillips head screw and

washer.

Caution: If you have decreased clamping pressure by

removing a shim, make certain that adequate pressure

remains to hold the carriage rigidly in place when clamped

in the fully extended position.

Realigning the Carriage Racks

Unlock the carriage clamp and slide the carriage so you

can access the two phillips head screws that hold the rear

Incra rack to the black mounting track. Tighten the two

screws. Next, slide the carriage forward for access and

loosen the two screws that hold the front Incra rack. The

two racks should be spaced about 2" apart. Adjust the

spacing by sliding the loose rack as necessary. Now

position the carriage in the base so that when the carriage

clamp is pulled up into the locked position the short blue

clamping rack in the base bridges the gap between the

two racks on the carriage. See Fig. 44. Tighten the one

rack mounting screw that you have access to. Finally,

unclamp the carriage clamp and slide the carriage forward

to allow access to the remaining screw and tighten.

ADJUSTMENTS

FIG. 43

Adjusting the clamping pressure

First: Unlock carriage clamp

Second: Remove phillips

head screw and washer

Third: Add or remove shims to

the left of

1

⁄8" clamp pad

Shim

FIG. 44

Realigning carriage racks

First: Slide carriage

for access and

tighten screws on

rear rack

Second: Slide carriage for access

and loosen screws on front rack

Third: Position carriage so that short clamping rack

will clamp the ends of both

of the longer racks and

lock carriage clamp in place

Fourth: Tighten front screw

Fifth: Slide carriage forward

and tighten remaining screw

2" approx.

1

⁄8" clamp pad

15

TROUBLE SHOOTING GUIDE

Symptom

Carriage clamping

pressure is too tight

or too loose.

LEXAN™ scale or

template is difficult

to slide in scale slot.

Racks do not mesh

properly when

engaging the

carriage clamp.

When the jig is

moved to a new

position the carriage

does not glide

easily.

Fence is not square

to the table surface

at all jig positions.

Micro adjusting

knob will not rotate

or is difficult to

rotate.

Micro adjusting

knob rotates but no

movement of the

carriage or fence.

Probable Cause

Carriage clamp not adjusted

properly.

Dirty scale slot.

Sawdust on racks.

Scale mark is not aligned

directly under the hairline

cursor.

Carriage racks are

improperly aligned.

Fence is improperly mounted

to the carriage.

Router table surface not flat.

Fence is improperly mounted

to the carriage.

There are several possible

causes: Jig mounting board

is not flat, table is not flat,

debris between table and

mounting board or between

mounting board and jig.

Carriage clamp is not

“unlocked”.

Jig is micro adjusted to the

end of the forward travel

range.

Jig not in micro adjusting

mode.

Jig micro adjusted beyond

end of backward travel

range.

Solution

Adjust clamping pressure. See page 14.

Remove the scale and clean with paste wax or preferably, Top-Cote

(available from your Incra dealer). CAUTION: DO NOT allow wet

Top-Cote to come into contact with LEXAN scale or templates, or any

other plastic material.

Remove all debris from the racks’ teeth with a stiff brush, such as a tooth

brush. DO NOT attempt to clean the racks with solvents of any kind as this

may damage them.

After zeroing to a cutter, or after centering when joint making, make sure

the carriage clamp is pulled into the locked position before sliding the

scale or template into place and that the 0" or center cut mark is

positioned directly under the hairline cursor. When you begin your series

of cuts thereafter, always make sure the scale or template mark is aligned

directly under the hairline cursor BEFORE locking the carriage clamp.

Realign the carriage racks as described on page 14.

If the fence is mounted too high or too low on the carriage, it can cause

resistance when moving from one position to another. If this is the case

loosen the screws holding the fence and realign. See Step 3 page 2.

Bumps or dips on the table surface can force the carriage into non-parallel

alignment with the base. Check the table for flatness and correct as

necessary.

If the fence is mounted too high or too low on the carriage, it can change

the angle of the fence relative to the table when it is moved from one

position to another. If this is the case, loosen the screws holding the fence

and realign. See Step 3 page 2.

If you identify any of these, take steps to correct the problem. You can

also use shims to bring the fence into perfect square as described in

Step 5 on page 3.

Carriage clamp must be unlocked, then the clamp handle must be pushed

down and held to place the jig in the micro adjust mode. See Steps 1-4

page 4.

Micro adjust back to mid-range position as indicated by the micro adjust

range scale. Turn knob counter clockwise until “0” on the scale is aligned

with the end of the black bar on the far side of the carriage. See Fig. 8

page 4.

After unlocking the carriage clamp, the clamp handle must be pushed

down and held to place the jig in the micro adjust mode. See Steps 1-4

page 4.

Micro adjust jig forward to mid-range as indicated by the micro adjust range

scale. Turn knob clockwise until the “0” on the scale is aligned with the end

of the black bar on the far side of the carriage, see Fig. 8 page 4.

Page 9

16

Made in the U.S.A. by Taylor Design Group, Inc.

0299

Printed in the U.S.A. © 1999, 1996 Taylor Design Group, Inc. Incra is a registered trademark of Taylor Design Group, Inc.

Part # Part Description Price

IJUL-CURSOR Hairline Cursor (with mounting hardware) $ 4.95

IJUL-STOP Stop Positioner (with mounting hardware) as shown in Fig. 4 on page 3 $ 6.95

IJUL-FENCEUP Fence upgrade kit. Includes: (1) Incra Stop (premium model) $24.95

(4)

1

⁄32" Incra racks

(1) 16" long

1

⁄32" scale

Mounting hardware

MTL2

Incra Master Reference Guide and Template Library

$24.95

Exciting new joinery techniques plus 38 new patterns to choose

IJPT1

Incra Jig Projects & Techniques Book

$22.95

Features 14 original Incra projects, 4 exclusive new Incra joints, and

a wealth of tips and techniques that will help you master the Incra Jig

IJUL-MMRACK Metric conversion kit — set of 3 metric racks with 430mm metric scale $ 6.95

IJU-MMSCALE 430mm metric scale $ 2.95

IJU-32SCALE 16" long

1

⁄32" scale (set of 2) $ 3.95

PUSHBLOCK Rubber soled push blocks $ 7.95

PARTS AND OPTIONAL ACCESSORIES

PRODUCT INFORMATION

For a product information update on the complete

Incra line of tools, please see your nearest dealer.

If you are unable to locate a store nearby, or if you

have trouble finding a particular product, we will honor

your order directly.

For a product information brochure, call, write or fax to:

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, TX 75381

Tel: (972) 418-4811 Fax: (972) 243-4277

Web Site: www.incra.com

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects due to

faulty material or workmanship, or at our option, replace the product free of charge. Please return the failing component

only, postage prepaid, along with a description of the problem to the address below. This warranty does not apply to

parts which have been subjected to improper use, alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an Incra positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group will replace it free of

charge for as long as you own your tool. Return the damaged rack, postage prepaid, and allow 1 to 2 weeks for delivery.

NOTE:

Replacements cannot be sent unless damaged racks have been received by Taylor Design Group.

Loading...

Loading...