Page 1

®

SYSTEM OWNER’S MANUAL

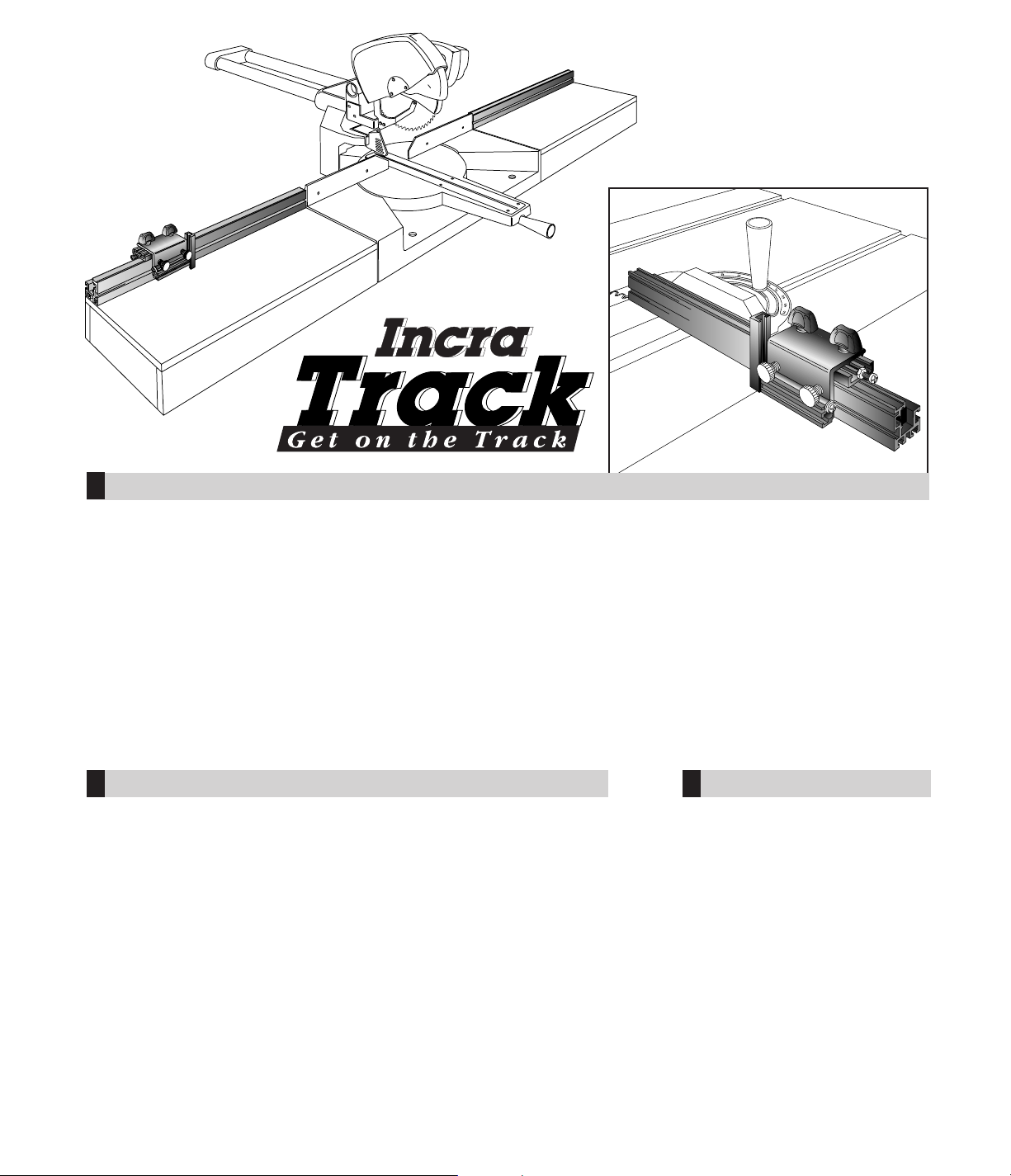

hat does an INCRA tool do better than any other? Just ask

that question to any of the thousands of satisfied INCRA router

table or table saw fence owners and they’ll all give the same

answer, “It positions your work with perfect accuracy and repeatability.”

Over the years, many of these same customers have requested a

means of adding these benefits to many of the other tools in their

shops. Your new INCRA Track does just this by providing the same

patented automatic positioning control used on the famous INCRA Jig

in a versatile track system. Combined with the modular design of the

INCRA Shop Stop, you'll be able to add INCRA precision to virtually

every jig, fixture, miter gauge, and stationary tool in your shop.

W

CONTENTS

General Mounting Instructions

Slotted Hole Mount

. . . . . . 2

Rear T -slot Mount

. . . . . . . 2

Bottom T -slot Mount

. . . . . . 2

Attaching the Racks . . . . . . . 3

Positioning the Scales . . . . . . 3

Auxiliary Fences . . . . . . . . . . 4

Applications . . . . . . . . . . . . . . 5

Miter Gauge

. . . . . . . . . . . 5

Jigs and Fixtures

. . . . . . . 6

Miter, Compound Miter,

and Radial Arm Saw

. . . . . 7

Drill Press

. . . . . . . . . . . . . 7

SAFETY

Important safety instructions for using the INCRA Track System:

◆ Before using the INCRA Track, read and follow all of the instructions and

safety information in this manual.

◆ When using the INCRA Track in conjunction with any other tool, first read and

follow all instructions and safety information in that tool’s owner’s manual.

◆ Use appropriate safety devices. Keep hands clear of the bit or blade. Always

use a push stick, rubber soled push block, or other safety devices to keep

your hands safely away from the cutting tool.

◆ Never let any part of the INCRA Track interfere with another tool’s safety

guards or other safety equipment.

◆ Never let the bit or blade come into contact with the aluminum body of the

INCRA Track.

◆ Always turn off the power and make sure the bit or blade has come to a

complete stop before changing the setting of any part of the INCRA Track or

INCRA Shop Stop.

◆ Wear safety glasses, hearing protection, and follow all normal shop safety

practices.

From the

makers of

INCRA JIG

FOR USE WITH …

◆

Miter Gauge

◆

Jigs & Fixtures

◆

Miter Saws

◆

Radial Arm Saws

◆

Compound Saws

◆

Drill Press Fence

◆

INCRA Jig

Page 2

GENERAL MOUNTING INSTRUCTIONS

Your INCRA Track is designed to provide a variety of mounting options to meet the requirements of your applications.

Each mounting option offers certain benefits. When considering a mounting preference, check the benefits of each

option. In some applications, you may find combinations of two or more mounting options are useful.

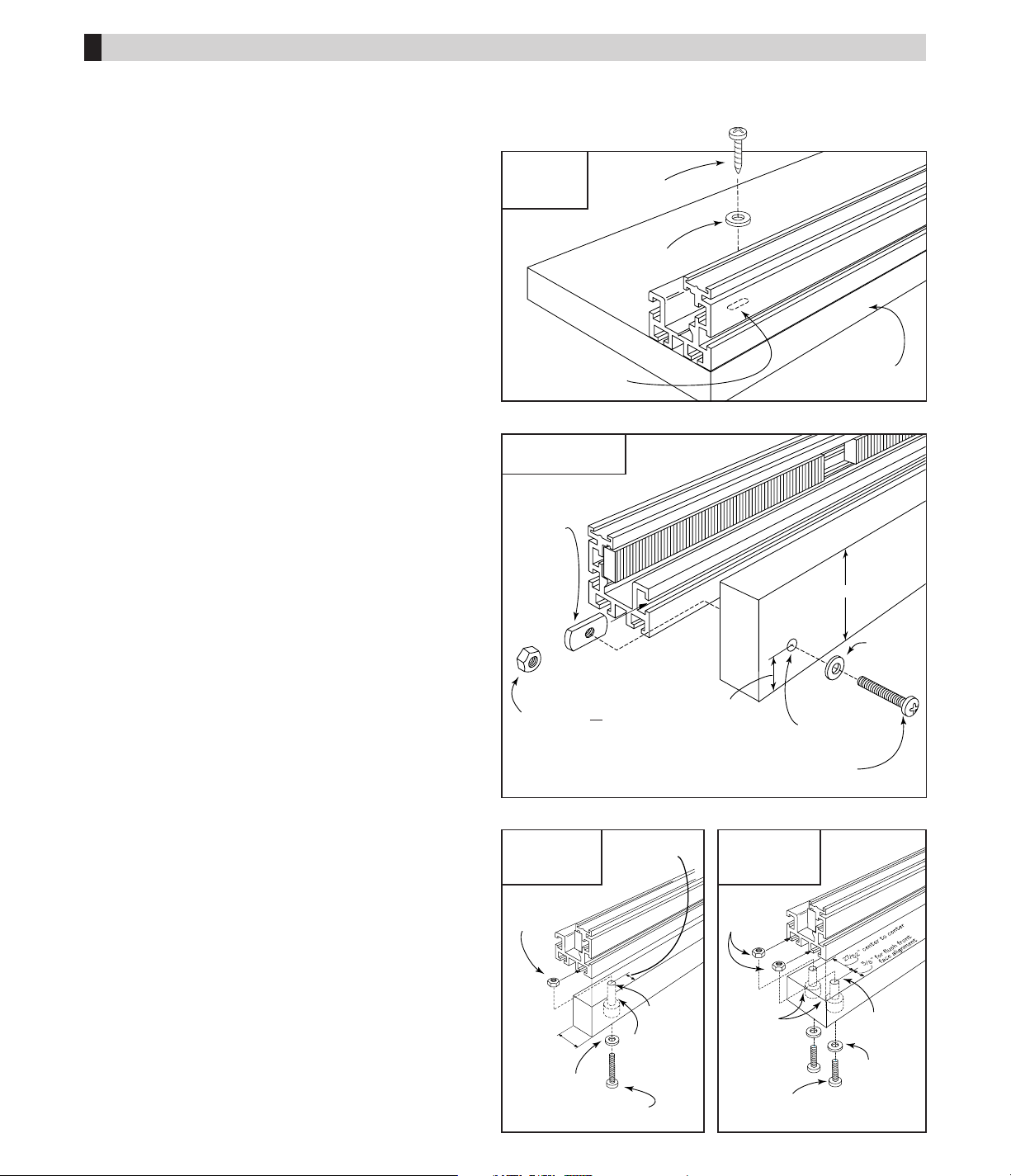

Option #1: Slotted Hole Mount –

(Fig. 1)

Benefits:

◆

Quick and easy mounting

◆

Good for fixed INCRA Track applications

Applications:

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

◆

Jigs & Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . 6

◆

Sliding Crosscut Boxes . . . . . . . . . . . . . . . . . . . 6

◆

Drill Press Fence . . . . . . . . . . . . . . . . . . . . . . . 7

◆

Miter and Compound Miter Saws . . . . . . . . . . . 7

Note:

When using the slotted hole mounting, always screw

the INCRA Track to your application before adding the

INCRA saw toothed racks.

Option #2: Rear T-slot Mount –

(Fig. 2)

Benefits:

◆

Allows for sliding the INCRA Track relative to applications

◆

Good for applications where the ability to slide the fence

toward or away from the cutter is important

◆

Enables quick removal of INCRA Track from application

Applications:

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

◆

Miter Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

◆

Jigs and Fixtures . . . . . . . . . . . . . . . . . . . . . . . 6

◆

Radial Arm Saw . . . . . . . . . . . . . . . . . . . . . . . . 7

◆

Compound Miter Saw . . . . . . . . . . . . . . . . . . . . 7

Note:

When using any T-slot mount, first install screws and

washers through your application and loosely attach nuts.

Then slide nuts into the T-slots on the INCRA Track.

Note:

If your application requires a vertical attachment point

for the INCRA Track that is taller than 13⁄4", just place a

1

⁄2" thick spacer block no taller than 13⁄4" between the

application and the rear of the INCRA Track.

Option #3: Bottom T-slot Mount –

(Figs. 3 & 4)

Benefits:

◆

Allows mounting to the 3/4" edge of a piece of plywood

◆

Good for applications requiring a taller fence

◆

Use for fixed or sliding track applications

Applications:

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

◆

Miter Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

◆

Jigs & Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . 6

◆

Drill Press Fence . . . . . . . . . . . . . . . . . . . . . . . 7

Note:

When using any T-slot mount, first install screws

and washers through your application and loosely

attach nuts. Then slide nuts into T-slots on the

INCRA Track.

FIG. 1

Slotted hole

mount

FIG. 2

Rear T-slot mount

FIG. 3

Bottom T-slot

mount (single)

FIG. 4

Bottom T-slot

mount (double)

#10-32

rectangular nut

(supplied)

1

/4-20 hex or square nut

(If using 1/4 -20 mounting

hardware, drill 5/16" thru hole)

or

1

/4 "

thru hole

#10 flat

washer

#10-32 machine screw

(Adjust length for application)

#10-32

hex nut

3

/4"

3

/8"

(for flush

front face

alignment)

#10-32 machine screw

(Adjust length for application)

#10 flat washer

#10 flat

washer

#10-32

hex nuts

#10-32 machine screw

(Adjust length for application)

9

/16" or

5

/8" dia.

counterbore

1

/4" dia.

thru hole

1

/4" dia.

thru hole

1

3

/4" max.

#10 x 1"

wood screw

#10 flat

washer

Slotted holes

5

/8"

2

INCRA Woodworking Tools & Precision Rules

Plywood or

hardwood base

9

/16" or

5

/8" dia.

counterbore

Page 3

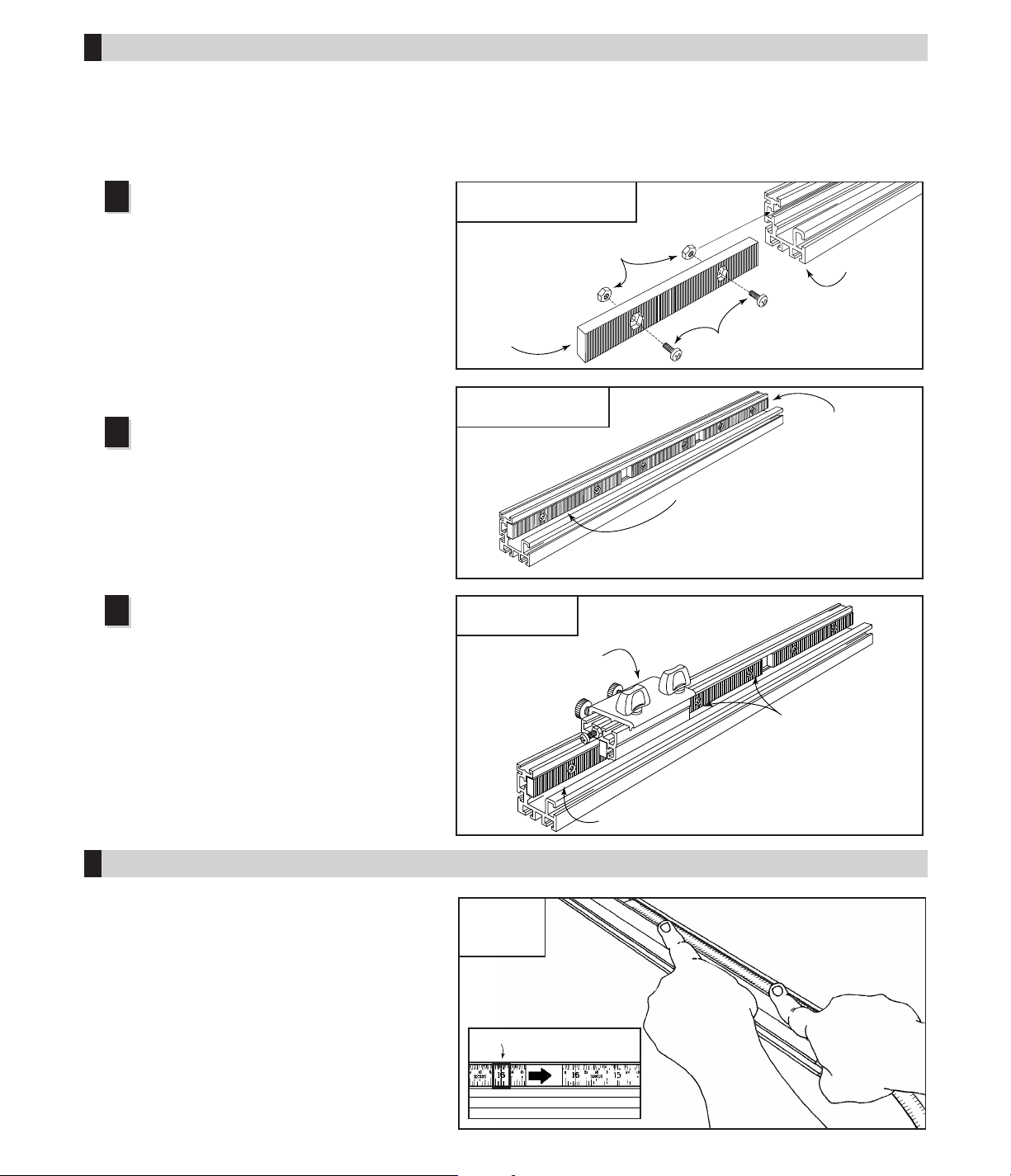

Insert the #8-32 x 3⁄8" machine screws through

the INCRA racks as shown and loosely install the

hex nuts. Slide the hex nuts into the T-slot on your

INCRA Track.

Note:

Some track sections may include both 4" and

6" racks. Use all racks supplied in any order.

(Fig. 5)

Note:

If you will be using the slotted hole mounting as

described in Fig. 1, always screw the INCRA Track to

your application before adding the INCRA sawtoothed racks.

After sliding all of the supplied racks onto

your INCRA Track, align the rack at one end

flush with the end of the track and tighten the

screws for this rack only. Evenly space the

remaining racks along the length of your track.

This is not a critical alignment, just eyeball the

spacing. (Fig. 6)

INCRA Track System Owner’s Manual

3

FIG. 5

Loosely install INCRA racks

1

2

FIG. 6

Slide racks onto Track

FIG. 7

Clamp Shop Stop

All INCRA Track scales come in 16" lengths (0-16",

16-32", 32-48", etc.) To position the 0-16" scale, zero

your Shop Stop to the cutter as described in the

Shop Stop owner’s manual, then slide the 0-16"

scale to read 0" directly under the end of the gold

stop cap on the Shop Stop. For longer INCRA Track

sections you'll now need to slide the 16-32" scale

into the track, overlapping the two scales at the 16"

mark. You'll notice on the 16-32" scale a rectangular

shaped window at the 16" mark. This window makes

it easy to perfectly align the two scales. Adding the

32-48" scale is done in the same way using the

rectangular shaped window at the 32" mark.

ATTACHING THE SAWTOOTHED RACKS

POSITIONING THE SCALES

#8-32 hex nuts

#8 -32 x 3/8 machine screws

INCRA

Track

INCRA

Rack

First: Align 1st rack flush with end of

Track and tighten two mounting screws

Second: Evenly space remaining racks

Last rack

should be flush

with track end

First: Bridge the gap

between the 1st and

2nd racks with the

Shop Stop

Second: Tighten

the two screws on

the second rack

Third: Repeat the bridge and

tighten process down the

length of the INCRA Track

1st rack already tightened

FIG. 8

Slide scales

in channel

Overlap the two scales

at the 16" mark

Now clamp your Shop Stop to the INCRA

Track so that it bridges the gap between the

already tightened first rack and the loose second

rack. Tighten the screws on the second rack.

Continue this bridge and tighten process down

the length of your INCRA Track. (Fig.7)

3

In your INCRA Track package you'll find a number of

black sawtoothed racks. Once attached to your INCRA

Track, these racks are what give the INCRA Shop Stop

the ability to clamp to your track so accurately. You see

the teeth on the Shop Stop and the INCRA Track will

only mesh every 1⁄32". This is why the INCRA tools will

so easily duplicate any setting that is a multiple of 1⁄32".

You might think that with all this accuracy, attaching the

racks to your INCRA Track would be a demanding job.

Quite the contrary – it is really easy.

Clear rectangular window

Page 4

4

INCRA Woodworking Tools & Precision Rules

FIG. 9

Miter gauge with auxiliary fence

FIG. 10

Auxiliary fence mounting

AUXILIARY FENCES

Zero clearance

Adding a wooden auxiliary fence to the front face of your

INCRA Track offers several benefits. Often the most

important benefit is the ability to add zero clearance

backing for all of your crosscutting and mitering operations.

A zero clearance auxiliary fence for a miter gauge (Fig.9)

backs up your stock to provide tearout control during a cut

as well as carrying small cut off pieces safely past the

blade. In the expanded clamping mode, your INCRA Shop

Stop will still clamp to your INCRA Track with auxiliary

fences up to 3⁄4" thick attached. Zero clearance auxiliary

fences are useful at any station where you want backing

support right up to the blade. Candidates for zero

clearance auxiliary fences include the miter gauge, miter

and compound miter saws and radial arm saws.

Extending stop range or fence height

Another reason to add an auxiliary fence to your INCRA

Track is to extend the stopping range or fence height when

used in conjunction with your INCRA Shop Stop. Say you

have an 18" INCRA Track mounted to your miter gauge and

you need to crosscut several boards to 30" lengths. By

adding a 3⁄4" plywood or hardwood auxiliar y fence that

extends the necessary distance from the saw blade and

then using your Shop Stop in the standard clamping mode

you can clamp the stop directly to the auxiliary fence.

Using the Shop Stop in this way allows use of taller

auxiliary fences as well.

Attaching an auxiliary fence

For auxiliary fence applications where incremental use of

the Shop Stop is required, the wooden auxiliary fence

should be flush with the top of the fence track. The

unmodified height of the INCRA Track is 19⁄16" but if you've

raised the height for your application, adjust the height of

your auxiliary fence to match. (Fig. 10)

INCRA Track extension

INCRA Track sections are available in 18", 36", and 52"

lengths and should accommodate most of your jig and

fixture needs. For stopping range beyond the standard

lengths, sections of the INCRA Track can be attached to

your applications end to end. Just attach the track section

closest to the cutter first, then use a reliable straightedge to

align the second track before securing it to your application.

Attach the sawtoothed racks as though the joined tracks

were one continuous INCRA Track section, beginning at

one end and working your way to the other end.

3

/4"

1

/4" thru hole with

5

/8" dia. x 5/16" deep counterbore

#10 -32

machine

screw

#10 flat washer

#10-32 hex nut

Cut to

match

INCRA

Track

height

1

1

/32"

3

/4" thick auxiliary fence

Shop Stop

shown in

expanded

clamping mode

Page 5

Following are just a few examples of the many

applications you'll discover for your new INCRA Track.

The illustrations represent food for thought and contain

few actual dimensions since your INCRA Track

applications will require dimensions that depend on

your particular tools.

When designing your own applications just remember

the INCRA Track and Shop Stop are the perfect

solution to any cutting or drilling operation that requires

the duplication of multiple stop positions.

INCRA Track System Owner’s Manual

5

APPLICATIONS

FIG. 13

Option #2

Miter gauge

Of course, any miter gauge will allow you to crosscut a

board to length, but for most miter gauges accurately

cutting to length means endless trial and error cutting

that usually leads to mediocre results. Adding an INCRA

Track and Shop Stop to your miter gauge will put an end

to trial and error forever. You'll find your crosscuts not

only accurate, but repeatable as well. For most miter

gauges the easiest mounting will be as shown in Figs.

12 or 13. Note that the wooden mounting bracket

shown in Fig. 12 must be 13⁄4" or less in height. Fig. 14

shows another mounting option where the rear T-slot on

the INCRA Track is raised to align with the holes in your

miter gauge by mounting an auxiliary fence to the front

face.

FIG. 14

Option #3

FIG. 11

Miter gauge

#10 -32

machine screws

#10 wood

screw

#10 flat

washer

1 1/2" wide

wooden piece cut

to match track

length. Thickness as required

to raise rear T-slot to align with

miter gauge mounting holes.

#10 -32 rectangular

nut (supplied)

FIG. 12

Option #1

#10 -32

machine screw

1

/4" thru

hole

#10 wood

screw

#10 flat

washer

5

/8"

1 3/4" max

Wooden

mounting bracket

#10 -32

rectangular nut

(supplied)

#10 flat washer

A 3/4" thick wooden auxiliary fence should be cut

to match track length (or longer if desired).

Adjust auxiliary fence height as required to

raise rear T-slot to align with miter

gauge mounting holes.

#10 -32

machine

screw

#10 flat washer

Note:

Use drill and counterbore

dimensions– shown in Fig.10, pg. 4.

#10 flat washer

#10 - 32

machine screw

#10 - 32 rectangular

nut (supplied)

#10- 32 hex nut

Side View

Side View

Side View

Page 6

6

INCRA Woodworking Tools & Precision Rules

There are many special use jigs and

fixtures in the shop that provide the

ability to accurately set and then

duplicate cutting positions.

Unfortunately, most jigs built for

specific applications are limited to the

size of that specific project. Any

change to the dimensions of the

project often means making another

jig since the stop positions must be

changed. Adding the INCRA Track

and Shop Stop to your next jig or

fixture design provides perfectly

repeatable stop positions at every

1

⁄32". So no matter what changes

you make in your project dimensions,

your INCRA Track-equipped jig will

always be able to handle the job

without expensive and timeconsuming rebuilding.

Illustrated in Fig. 15 is one of the

most common jigs used in the shop –

the sliding crosscut box for the table

saw. A plywood base is first attached

to a pair of miter bars that track along

the table saw's miter slots. (The

adjustable INCRA Miter Sliders,

available in 18" and 24" lengths are

perfect for this). Glue and/or screw a

front and rear bridge to the plywood

base. With your blade raised about

1", engage the miter bars with your

table saw miter slots and make a cut

through the jig. Turn off the saw and

screw the INCRA Track to the

plywood base at whatever angle to

the blade is required for your jig. Do

not place the track directly against

the rear bridge since it is probably

not square to the blade and its

vertical height will interfere with the

Shop Stop. Place a piece of INCRA

Track on both sides of the kerf for

stopping range and support both left

and right of the blade. (Fig. 16)

JIGS & FIXTURES

FIG. 15

Sliding crosscut box

FIG. 16

Crosscut box – exploded view

Bridge

INCRA Miter Slider

Plywood panel cut after

attaching bridge pieces

and Miter Slider

Page 7

INCRA Track System Owner’s Manual

7

MITER, COMPOUND MITER AND RADIAL ARM SAWS

FIG. 17

Adding INCRA Track to

the radial arm saw

FIG. 19

Attach INCRA Track

to plywood box

FIG. 18

Miter saw equipped with

the INCRA Track

You’ll find many uses for your INCRA Track and Shop Stop at

the drill press. Any project that requires a series of precisely

located holes can easily be produced, then duplicated again

and again with the aid of the INCRA Track. Locating a dr ill

position in your project has never been easier. Simply mount

your INCRA Track to a flat, straight piece of 1⁄2" or 3⁄4"

plywood as shown in Fig. 20 below, then clamp to your drill

press table. You can band saw a cutout in the plywood piece

if you want to give clearance for the drill press column.

Every miter, compound miter, and radial arm saw made today

provides a fence to help hold your stock during mitering,

crosscutting or dadoing. But with few exceptions, none offers a

stop to ensure the location of your cut. You’ll find that adding an

INCRA Track section on both sides of your blade will give you

perfect control of your cut locations. To set up the track at your

radial arm saw, simply drill holes through your existing wooden

fence to align with the T-slot in the rear of the INCRA Track and

screw in place.(Fig. 17) For extra long crosscut applications

you can mount multiple track sections end to end. For miter

and compound miter stations, place the saw on a flat table or

bench, then construct plywood boxes for both sides of the saw.

The boxes should match in height the distance from the bench

top to the top of your saw’s base. (Fig. 18) Attach the plywood

boxes to your table top, then screw INCRA Track to both boxes

with the front of the INCRA Track in line with the existing fence

on your miter saw. (Fig. 19) If you want to extend the fence

track closer to the blade for short cutoffs and don't mind

reducing some of your crosscut capacity, overlap the INCRA

Track onto the miter saw’s base before screwing in place.

NOTE:

If you are extending the INCRA Track toward the blade

over your miter saw’s base and your miter saw’s standard

fence is taller than 13⁄4", you must place a 1⁄2" spacer block

between the rear of the INCRA Track and the front of your

saw’s standard fence.

DRILL PRESS

FIG. 20

Drill press fence

FIG. 21

INCRA Track at the drill press

Existing fence must be

no taller than 1 3/4".

3

/4" or 1/2" plywood

Cutout for

column clearance

#10 wood

screw

#10 flat

washer

Plywood box used

to extend miter

saw base

Plywood boxes

match height of

miter saw base

INCRA Track

Miter saw

Page 8

PARTS AND OPTIONAL ACCESSORIES

Part # Part Description Price

SHOPSTOP INCRA Shop Stop ........................................................... $ 32.95

Add a second Shop Stop to your INCRA Fence or INCRA Track for mortising and other applications

TRACK18 18" Track Section .......................................................... $ 27.95

TRACK36 36" Track Section .......................................................... $ 42.95

TRACK52 52" Track Section .......................................................... $ 52.95

Add one or more individual INCRA Track sections for placing the Shop Stop on both sides of the

cutter, or extending the stopping range. Track sections include incremental racks, sliding scales, and

complete mounting hardware.

TRACKSYS18 18" Track plus Shop Stop ................................................... $ 52.95

TRACKSYS36 36" Track plus Shop Stop ................................................... $ 72.95

TRACKSYS52 52" Track plus Shop Stop ................................................... $ 82.95

Buy the complete INCRA Track System and save. Includes specified length of INCRA Track section,

INCRA Shop Stop, incremental racks, sliding scales, and complete mounting hardware.

IMS1 18" Miter Slider............................................................. $ 15.95

IMS2 24" Miter Slider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 21.95

This aluminum runner adjusts for perfect sliding action in ANY standard

Wonʼtwarp,shrink,orswelllikewoodenrunners.Includesplansforawidevarietyofshop-madejigs

and fixtures. (one per package)

3

⁄4" x 3⁄8" miter gauge slot.

PRODUCT INFORMATION

For a product information update on the complete

INCRA line of tools, please see your nearest dealer. If

you are unable to locate a store nearby, or if you have

trouble finding a particular product, we will honor your

order directly.

For a product information brochure, call, write or fax to:

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, TX 75381

Tel: (972) 242-9975 Fax: (972) 242-9985

Web Site: www.incra.com

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any

defects due to faulty material or workmanship, or at our option, replace the product free of charge.

Please return the failing component only, postage prepaid, along with a description of the problem to

the address below. This warranty does not apply to parts which have been subjected to improper use,

alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group will

replace it free of charge for as long as you own your tool. Return the damaged rack, transportation

prepaid, and allow 1 to 2 weeks for delivery.

NOTE:

Replacements cannot be sent unless damaged racks have been received by Taylor Design Group.

Made in America by:

Taylor Design Group, Inc. ■ P.O. Box 810262 ■ Dallas, Texas 75381 ■ Web Site: www.incra.com rev.9/13

Printed in the U.S.A. © 2013, Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc.

8 INCRA Woodworking Tools & Precision Rules

Loading...

Loading...