Page 1

w w w. in c ra .c o m

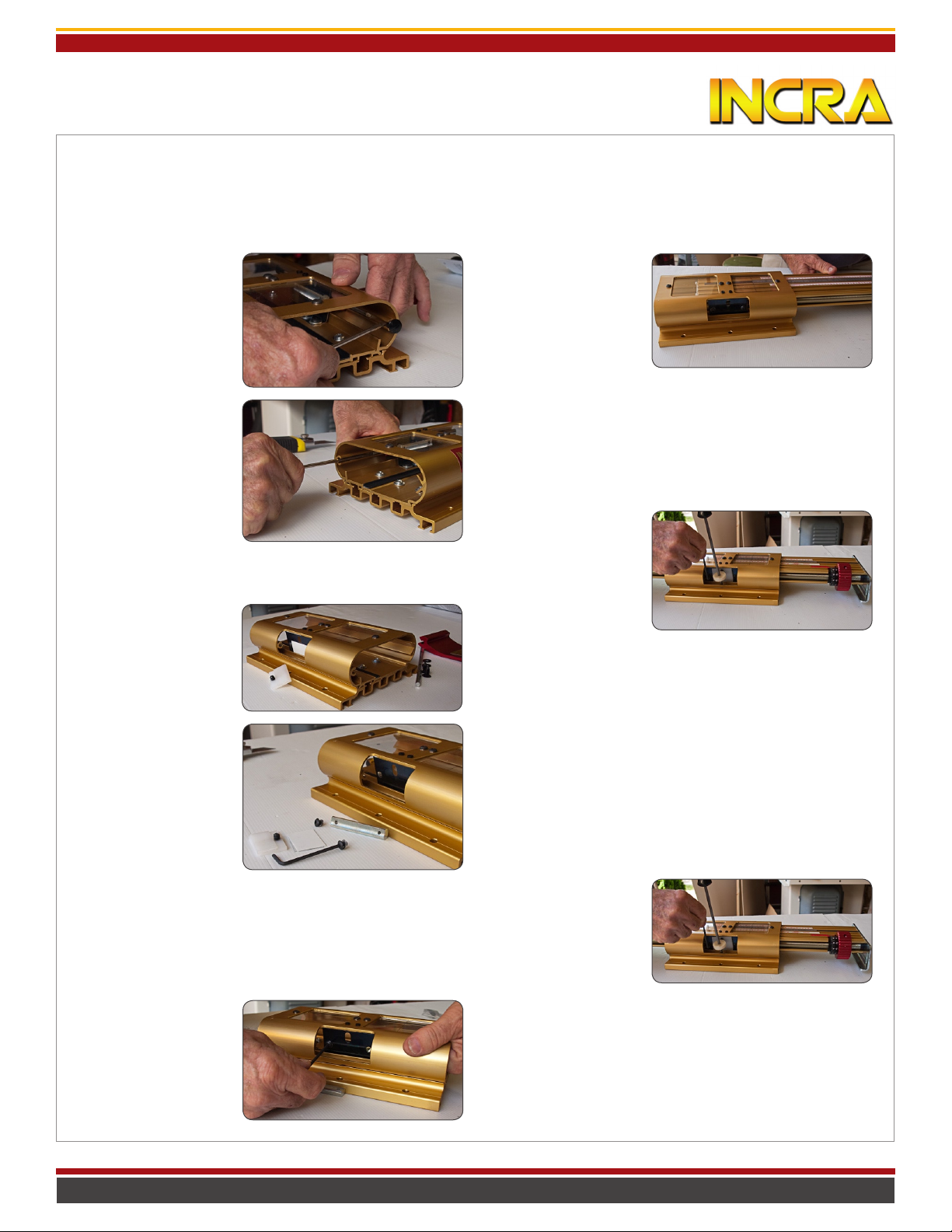

Threaded Segment Replacement Instruction (Base)

Tools required:

Leverage Tool w/nylon collar (supplied), 1/8” hex key, scratch awl

NOTE: If you are converting an Imperial LS Positioner to a Metric model, replace the Imperial Lead Screw Assembly in

your LS Positioner’s Carriage with the Metric Lead Screw Assembly provided BEFORE continuing with these instructions.

®

1. Remove the black

nylon arrow clips from

each end of the Base.

(Replacements are provided so don’t worry if

they break.)

2. Use a scratch awl or

small screwdriver to

push out the pivot rod

that secures the red

clamp handle. As the

rod is removed keep an

eye on the small black

washers on either side

of the red clamp handle.

These will need to be replaced later.

3. Remove the 1/8” thick UHMW clamp bearing pad and the

small collection of thin

plastic shims between

the pad

and the metal spring

engager. Retain all for

later re-assembly.

7. Slide your LS Positioner’s Carriage into the

Base. (NOTE: If you are

converting an Imperial

LS Positioner to a Metric

model, make sure you

have already converted

your LS Carriage to the Metric Lead Screw Assembly before

proceeding.) Position the Carriage so that the Base is approximately centered on the Carriage length.

8. Insert the end of the provided Leverage Tool into the

small hole located on the curved side of the LS Base near

the Metal Spring Engager.

9. Push the Leverage Tool

handle so that the nylon

collar bears against the

Metal Spring Engager.

Push and release the tool

a few times to “seat” the

Threaded Segment properly with the Lead Screw on the LS Carriage. Finally, apply

continuous pressure to the Leverage Tool as you tighten the

(2) button head fasteners to secure the Threaded Segment

to the Metal Spring Engager.

4. Using a 1/8” hex key,

unscrew the (2) button

head fasteners located

on either side of the

clamp bearing pad and

remove the existing

Threaded Segment held

by these fasteners.

5. To gain better access for the Threaded Segment replacement, remove the (2) button head fasteners with washers

that secure one of the acrylic view windows and set the

window and fasteners aside.

6. Replace the Threaded Segment previously removed with

the New Threaded

Segment provided.

DO NOT TIGHTEN THE

BUTTON HEAD FASTENERS AT THIS TIME. They

should remain slightly

loose for the next step.

10. Remove the Leverage Tool and slide the LS Carriage from

side to side within the Base to ensure that the threads between the Threaded Segment and the Lead Screw do not

“grind” against one another. If the threads make contact during

the slide, you must adjust the relative position of the Metal

Spring Engager to move the Threaded Segment away from the

Lead Screw as described in Steps 15-18 below. If the threads

do not grind against one another continue with Step 11 below.

11. Replace the thin plastic shims and 1/8” clamping pad removed in Step

4. The thin plastic shims

will slide between the

Metal Spring Engager and

the protruding “fin” on

the LS Base extrusion. (Fig 35 on Pg 15 of your LS Positioner’s Owner’s Manual offers a good illustration of the shim

placement.) The set screw on the 1/8” UHMW clamp bearing

pad should nest into the slotted hole on the Metal Spring

Engager. Make sure to orient the 1/8” clamp bearing pad so

that the surface with the thick tape adhered to it faces the

Metal Spring Engager.

page 1

Manufactured by: Taylor Design Group, Inc. P.O. BOX 810262 Dallas, TX 753 81 w w w . i n c r a . c o m

Page 2

w w w. in c ra .c o m

Threaded Segment Replacement Instruction (Base)

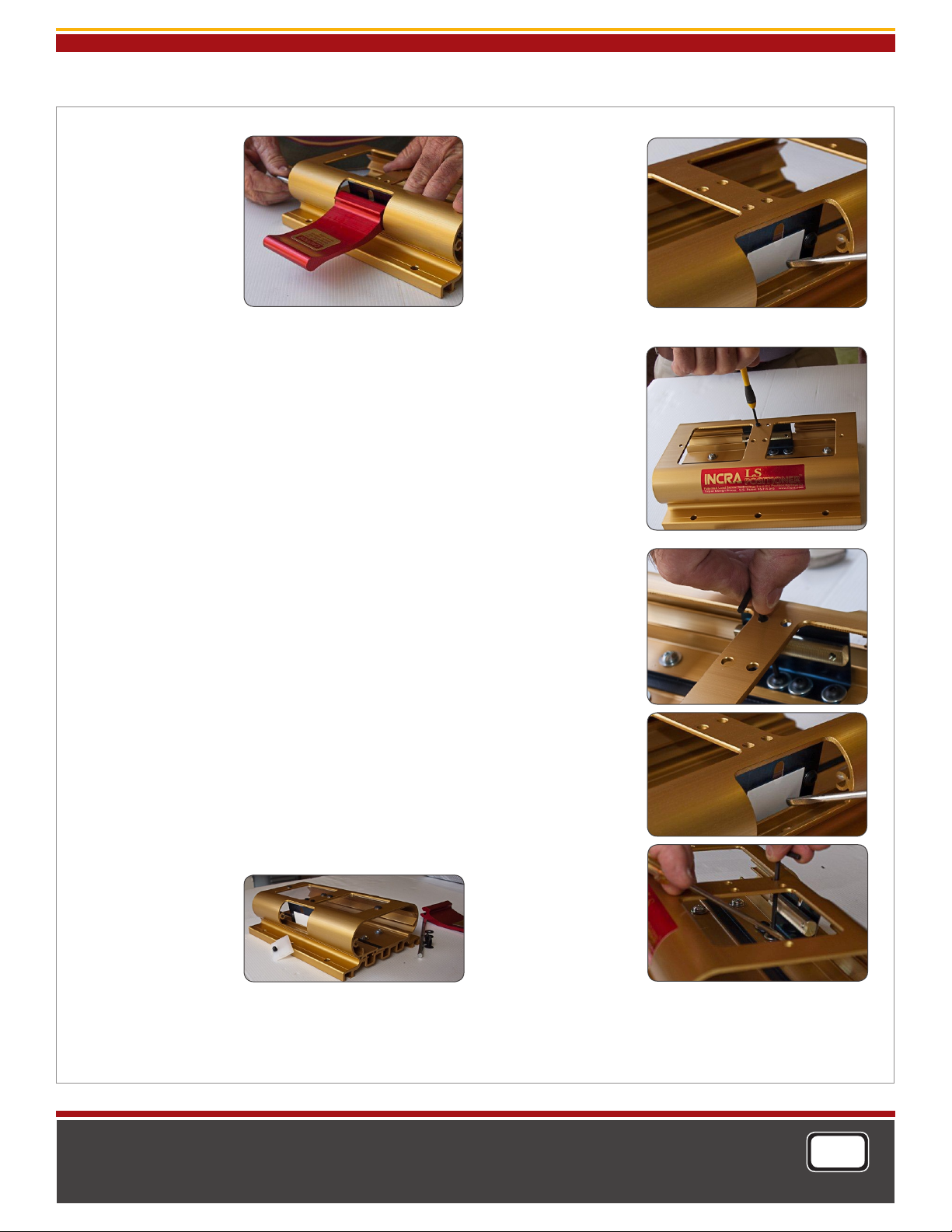

12. Using the 7” long

steel pivot rod, replace

the red clamp handle.

Be sure to place one of

the black nylon washers removed in Step

3 onto the pivot rod

on either side of the

clamp handle. (You

can use a small amount

of grease as an aid to

hold the washer in place.) Hold the clamp handle horozontally pressing it against the UHMW clamp bearing pad as you

advance the pivot rod into the LS Base extrusion, passing

through the first black nylon washer followed by the clamp

handle, the final black nylon washer and into the other end

of the LS Base. Cap off each end of the LS Base extrusion

with the provided black nylon arrow clips. Check that the

operation of the red clamping handle is correct, horizontal

for free sliding movement, midway for micro adjustment and

vertical for full lock. Be sure to test the feel of the unit at

each of these points.

Horizontal = Free sliding, no grinding.

Midway = Able to turn Micro Adjust Knob.

Vertical = Fully locked NO Movement.

If clamping pressure is too tight or too loose, you’ll find

complete instructions on fine tuning your clamping pressure

using the provided shims in your LS Positioner’s Owner’s

manual on beginning at the bottom of Page 14.

13. Carefully slide the LS Carriage out of the Base and re-attach the view window or windows previously removed. If

both view windows were removed, place the one with

the hairline in the opening at the forward end of the base.

(Make sure that the printed hairline is face down.)

If the threads between the Lead Screw in the LS Carriage

and the Threaded Segment in the LS Base make contact

or grind against each other when sliding the Carriage from

position to position, it will be necessary to adjust the Metal

Spring Engager to move the Threaded Segment away from

the Lead Screw. Follow

Steps 15-18 below to

adjust the Metal Spring

Engager’s position.

14. Remove the Red

clamp handle along

with the 1/8” UHMW

clamp bearing pad and plastic shims as described in Steps

1-4 above then carefully slide the LS Carriage out of the

Base.

15. Use a set of Feeler

Gauges (or multiple pieces of the provided plastic

shims, .020”, .010” &

.005” thick) to gauge the

gap between the Metal

Spring Engager and the

vertical “fin” in the LS Base

extrusion. You will need

to DECREASE this gap in

the adjustment process so

it is important to know what the gap is to begin with.

16. Remove both Acrylic

view windows from the

LS Base as well as the

(2) black nylon slotted

head set screws located

between the windows to

gain access to the button head fasteners that

secure the Metal Spring

Engager to the LS Base

extrusion.

17. Using a long 1/8” hex

key, loosen all (4) of the

button head screws. Use

your set of feeler gauges

or the provided plastic

shims as an aid in gauging

the distance as you move

the Metal Spring Engager

assembly closer to the

vertical “fin” on the LS

Base extrusion. Just a

few thousandths should

be all that is required

to create the necessary

clearance (one of the

thinnest shims). Tighten

all (4) button head fasteners. Carefully slide the

LS Carriage back into the

Base to check for clearance between the Lead

Screw and the Threaded

Segment and fine tune as

necessary. Once clearance is achieved, thread

the black nylon slotted

head set screws into the

holes located between the view window openings on the

LS Base. Screw the set screws down until just before they

make contact with the top of the LS Carriage. Now continue

re-assembly beginning with Step 11.

Photography: Grahame Waterson

Manufactured by:

Taylor Design Group, Inc.

P.O. BOX 8102 62 Dallas, TX 753 81

www.in c ra .co m

page 2

INCRA is a Registered Trademark of Taylor Design Group

©2010 Taylor Design Group, Inc.

INCR A Tools are pro tect ed by one o r more o f the f ollowing U S pate nts:

#4, 793, 604, #4 ,93 0,2 21, #5 ,195,73 0, #5 ,275,074 , #5, 423 ,360, # 5,716, 04 5, #6 ,23 7,457,

#6,5 57,601, #6,67 2,190. Other p aten ts gr ante d or pen ding. rev.03 .10.2010

MADE IN THE

USA

Loading...

Loading...