Page 1

Woodpeckers

PRECISION WOODWORKING TOOLS

®

Side Winder

Router Lift.

INSTALLATION INSTRUCTIONS

Models: SW350

Made in U.S.A. by Woodpeckers Inc.

Protected by one or more of the following U.S.

Patents; 6,505,659; 7,559,347; 7,481,253;

7,108,463 and other patents pending.

SAFETY

Always unplug your router motor before making any

adjustments to the router lift. Refer to your routers’ owners

manual for specific safe operating instructions.

COMPATIBLE ROUTER MOTORS

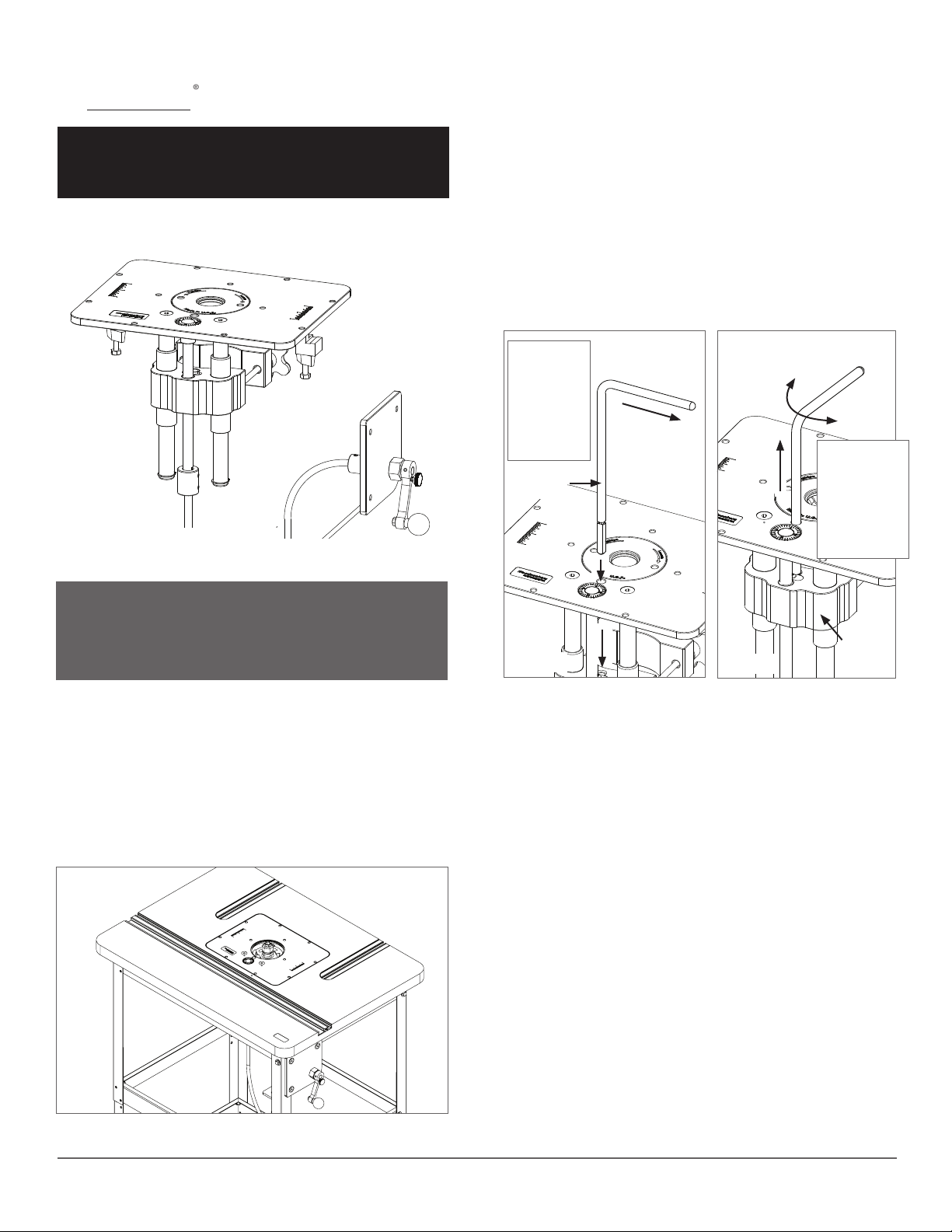

The Woodpeckers® Side Winder 350 Router Lift fits the

Porter-Cable 690/890, Bosch 1617/1618 and Craftsman

models 17542, 17540, 28190 router motors as well as any

router motors 3.5" in diameter.

The wrench

handle must

be pointing

right in order

to fully insert

or remove it.

Once fully

Lift Wrench

Figure 1.

Figure 2.

inserted, rotate

the wrench ¼

turn in either

direction and

completely raise

the carriage.

Carriage

BEFORE YOU BEGIN

The Woodpeckers® Side Winder can be installed in most

router tables with a standard 9¼ x 11¾ opening and a side

panel mounting surface no more than 19" away as in the

side of a cabinet or router table stand. In most cases three

holes will need to be drilled for mounting the side plate.

These instructions assume you’re installing the Side Winder

on a Woodpeckers® Router Table Stand.

Woodpeckers® Router Table Stand, Router Table and Side Winder.

USING THE LIFT WRENCH

You’ll need to know how to use the Lift Wrench to install

your router motor.

STEP 1. To change the carriage height (the carriage is the

part beneath the table that holds the motor), orient the

wrench with the handle pointing right. (Figure 1.)

Insert the wrench until it’s COMPLETELY BOTTOMED OUT.

Once it’s all the way in, try and rotate it. If it doesn’t turn, it

isn’t in. Do not force the wrench. Take it out, push it back

down and try again.

STEP 2. Once it turns easily, simply rotate it ¼ turn in either direction to lock the handle to the carriage. Now you

can raise or lower your router as needed using the wrench.

(Figure 2.)

To install your router motor you need to raise the carriage

all the way up and lock it in place by once again orienting

the handle to the right. Now remove the lift wrench.

Made in the U.S.A. by Woodpeckers Inc., North Royalton, Ohio · Copyright 2010© Woodpeckers Inc. 8/10 Page 1

Page 2

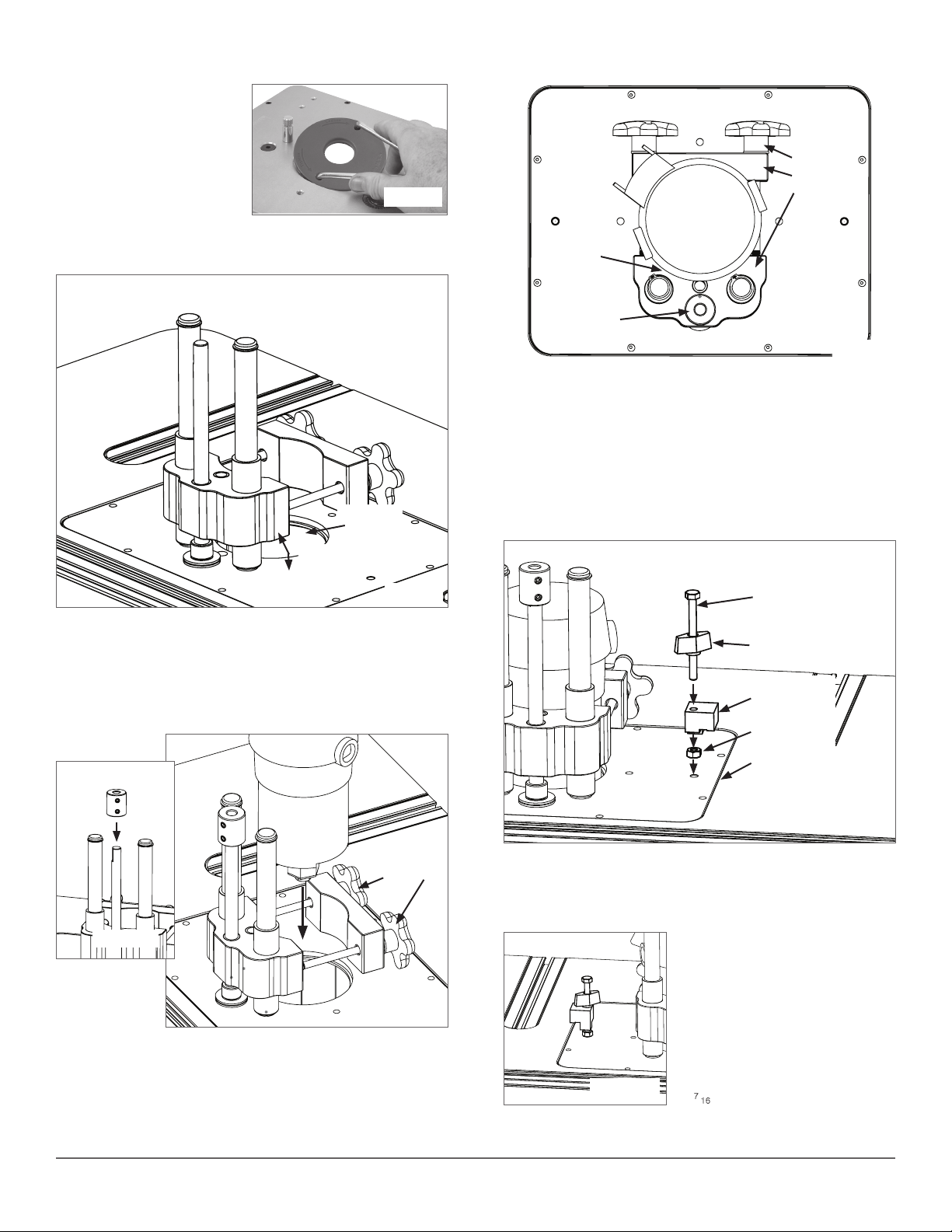

REMOVE THE RING

STEP 3. The Side Winder

comes with one ring installed. This ring needs to

be removed in order to install your motor. Loosen the

ring by turning it CLOCKWISE with the spanner wrench. To put one back in, rotate

it counter-clockwise.

Figure 3.

No ring.

Knobs.

Clamp.

Carriage.

Clearance.

Remove coupling

after motor is

clamped in.

Figure 6.

STEP 6. Evenly snug the two knobs. They are self locking so they won’t spin freely. Before you finish tightening

the knobs, make sure that all parts of the router are well

clear of the two posts and lift rod. Figure 6 shows the approximate position of a PC 690 motor relative to the posts.

Now remove the coupling from the lift rod and set it aside

for later.

Carriage adjusted

close to plate.

Figure 4.

INSTALLING YOUR ROUTER MOTOR

STEP 4. Make sure the carriage has been raised to the

top, locked and the lift wrench has been removed. Then

remove the lift from the table, flip it over and set it back into

the table opening as shown in Figure 4.

Clamp knobs.

Figure 5a.

Figure 5b.

STEP 5. Make sure the clamp knobs are backed off enough

to allow your motor to slide in. Loosely set a coupling on

the lift screw. (Figure 5a). Slowly drop the router into place.

Support the motor so it just begins to go through the opening in the plate. (Figure 5b).

3" long bolt.

T-k nob.

Clamp block.

Hex nut.

Short edge of plate.

Figure 7a.

INSTALL THE TWO CLAMP BLOCKS

STEP 7. Carefully study Figure 7a. Thread one of the small

T-knobs onto a 3" long bolt with the top of the knob going

on the bolt first, toward the hex

head. Now slip a clamp block

onto the bolt oriented as shown

above with the flat side facing

the knob. Then thread a hex nut

about ½" up the bolt. And finally,

thread the bolt into the threaded

hole centered near the short

Figure 7b.

edge of the plate. If needed, use

a 7⁄16" wrench to lightly snug the

bolt into the plate. (cont’d.)

Made in the U.S.A. by Woodpeckers Inc., North Royalton, Ohio · Copyright 2010© Woodpeckers Inc. 8/10 Page 2

Page 3

DO NOT OVERTIGHTEN THE BOLT. Overtightening will

damage the plate. Snug the hex nut against the plate. (Figure 7b). Repeat the same steps for the other clamp block.

Clamp block.

Drill 9⁄32 hole in these

two locations.

Clamp knob.

Figure 8.

STEP 8.

Once your router motor and the two clamp blocks

have been installed, remove the Side Winder from the table

and set it back in, right side up. From underneath the table

rotate the clamp blocks in place and tighten the two knobs.

The clamp blocks hook under the edge of the table opening.

(Figure 8).

Side panel.

Figure 10.

STEP 10. Using the side panel as a guide, drill two

9

⁄32 dia.

holes through the router table stand. Fasten the panel in

place using the remaining two connector bolts and nuts.

(Figure 10).

Pin.

1st

2nd

Coupling.

Flex shaft.

Figure 11.

STEP 11. First slip the pin into a coupling until it bottoms

out. Tighten the set screw onto the flat of the pin. Now

push the flex shaft into the other end of the coupling. Tighten the remaining set screw onto the flex shaft. Now loosen

the first set screw and remove the pin. You’ll need it for the

next step. (Figure 11).

STEP 12. Insert the pin into the

Connector bolt.

remaining coupling and tighten

the set screw on the flat just like

before. Set the coupling aside

Figure 9.

for now and thread the bare end

of the flex shaft up through the

bearing in the bracket. Secure

SIDE CRANK INSTALLATION ON A

WOODPECKERS® ROUTER TABLE STAND

This section assumes you’re installing the Side Winder onto

a Woodpeckers® Router Table Stand.

STEP 9. Remove the existing hex bolt from the inside corner of the router table stand and attach the side panel using

one of the connector bolts and hex nuts. (Figure 9).

the coupling onto the end of the

flex shaft. Now both ends of the

flex shaft should have couplings

attached and the end going up

through the bracket should have

the pin installed as well. (Figure

12).

Flex shaft.

Bracket.

Figure 12.

Made in the U.S.A. by Woodpeckers Inc., North Royalton, Ohio · Copyright 2010© Woodpeckers Inc. 8/10 Page 3

Page 4

Figure 13.

Flat on lift rod.

Coupling / set screw.

STEP 13. Apply a dab of grease to the outside of the pin

and insert it through the hole in the bolt. This will take

some effor t. Be careful not to kink the flex shaft. Bend

it just enough to get the pin through the hole. Optionally

you can loosen the large bolt holding the bracket to the

side panel. Do not completely remove the bolt. When finished m

re-tighten the large bolt.

ake sure the bracket is hanging straight down and

(Figure 13).

Set screw.

Figure 14.

STEP 14. From the outside, slip the crank handle onto the

pin, align the end of the pin with the face of the handle,

align the set screw with the flat spot on the pin and tighten

the screw. (Figure 14).

Double check that the handle has a little bit of in and out

play. If it’s tight, the handle will not crank freely.

Figure 16.

STEP 16. Rotate the crank handle so that the set screws in

the coupling on the other end of the flex shaft align to the

flat spot on the lift rod. Slip the coupling onto the lift rod

and tighten the screw. (Figure 16).

TESTING THE CRANK ASSEMBLY

Test the crank assembly by slowly turning the handle and

watching the round scale on the top of the lift. If the scale

isn’t turning when you’re rotating the crank handle then one

of the set screws isn’t tight. It’s most likely to be one of the

set screws at either end of the flex shaft locking it to the

coupling. Double check that those two screws are tight.

After that make sure that the set screws in the handle and

couplings are against the flats on each shaft.

6"- 8"

Lift rod.

4"- 5"

Position of side crank.

SIDE WINDER INSTALLATION ON

NON-WOODPECKERS

®

ROUTER TABLE STANDS.

The Woodpeckers® Side Winder can be installed on non-

Figure 15.

Woodpeckers® cabinets and router table stands. The

above illustration shows the general location of the crank

STEP 15. Install the brake knob into the threaded hole in

the handle. (Figure 15). Do not tighten the brake knob until

it’s needed. It’s typically used when doing heavy routing.

handle relative to the router table top and router lift. It’s recommended that the side panel be mounted in its entirety

and not disassembled.

Made in the U.S.A. by Woodpeckers Inc., North Royalton, Ohio · Copyright 2010© Woodpeckers Inc. 8/10 Page 4

Page 5

GENERAL OPERATING INFORMATION

LEVELING THE PLATE

Before adjusting the leveling

screws you need to loosen

the clamp knobs underneath

the table. There are eight set

screws around the perimeter

for adjusting the height of the

plate relative to the table. Initial

leveling should be done with

just four of the screws, two each on opposite ends of the

plate. Once the plate feels flush, use a block of wood to

make sure it doesn’t catch going either direction then adjust the remaining screws.

ADJUSTING THE SCALE

The adjustable scale is used

to reference the amount of

height change relative to a

starting position. One rotation equals 1⁄32". Each line

equals .001".

can be adjusted by applying downward finger pressure then rotating it in either

direction. Built in friction

keeps it from free spinning.

The scale

Adjustable scale.

ROUTINE MAINTENANCE

The Side Winder is made primarily from aluminum and steel

parts. The steel parts will have a light coating of petroleum

jelly when it leaves the factory. After unpacking, if necessary,

clean aluminum parts, including the main plate, with mineral

spirits or lacquer thinner. Do not use any water based cleaner.

The two steel posts should be wiped with a clean rag and

lubricated with petroleum jelly or a very light machine oil. The

flex shaft can be periodically sprayed with a lubricant such as

WD40 then wiped dry.

Minor surface rust on any steel parts can be removed with

abrasive nylon pads like a scotch bright pad. All steel parts

should be kept lubricated with petroleum jelly or thin machine

oil, particularly the posts and lift screw.

CHANGING BITS

First use the spanner

wrench to remove the Twist

Lock Ring. Now use the lift

wrench to raise the router

chuck completely above

the plate. Use the wrenches supplied with your router to change the bit. (Image

may not match your Side

Winder but the process is

the same.

Made in the U.S.A. by Woodpeckers Inc., North Royalton, Ohio · Copyright 2010© Woodpeckers Inc. 8/10 Page 5

Page 6

w w w. i nc ra .c o m

Side Winder Side Crank Installation on INCRA

Router Table Stands

Note: This addendum replaces Fig/Step 10 & Fig/Step 11 of the Woodpecker provided mounting instructions.

Please follow all assembly instructions of the original manual up to Fig/Step 10 before using this addendum.

If your INCRA router table stand is already assembled you will first need to remove the table top and remove the

front top stretcher. Remove the lower 1/4-20 x 1/2” hex bolt from the left end of the stretcher, Fig. 1. Loosely

attach the Side Winder Crank’s side panel to the stretcher using the provided 1/4-20 x 7/8” hex bolt, washer

and square nut. Place another 1/4-20 x 7/8” hex bolt with washer

through the lower hole on the Crank’s side panel and add the large

gold washer to the fastener before loosely threading on the square

nut, Fig. 2.

Re-assemble the stretcher to the stand sliding all 3 of the square

nuts on the left end of the stretcher into the t-slot in the leg.

Make sure the Crank’s

side panel is parallel

Fig.2

to the leg before

tightening all of the

mounting bolts,

Fig. 3.

Fig.1

Remove front

stretcher and remove

lower hex bolt from

left end

®

Using the remaining

hole in the side

panel as a guide,

drill a 9/32” hole

through the front

stretcher, Fig. 4.

Large washer

Square

nuts

1/4-20x7/8

hex bolt with

washers

this bolt only

Place a flat washer

on the remaining 1/4-20 x 7/8” hex bolt and insert through the

hole on the side panel. Add a split lockwasher and a square nut

then tighten the assembly in place, Fig. 5.

Continue with Fig/Step 12 in the Side Winder Owner’s Manual.

Fig.4 Fig.5

Drill 9/32”

hole through

stretcher

Fig.3

Re-assemble Stretcher to Stand

Square nuts

captured in

T-Slot on Leg

1/4-20x7/8

hex bolt with

washer.

Secure with

lockwasher

and

square nut

Manufactured by:

Taylor Design Group, Inc.

P.O. BOX 8102 62 Dallas, TX 753 81

www.in c ra .co m

INCRA is a Registered Trademark of Taylor Design Group

©2009 Taylor Design Group, Inc.

INCR A Tools are pro tect ed by one o r more of the f oll owing US pat ents :

#4, 793, 604, #4,93 0,2 21, #5 ,195,73 0, # 5,2 75,074 , #5, 42 3,3 60, # 5,716,04 5, #6,2 37,457,

#6,5 57,601, #6,67 2,190. Other patents grante d or pen din g. rev.11.03.10

MADE IN THE

USA

Page 7

w w w. i nc ra .c o m

Side Winder Side Crank Installation on

INCRA Table Saw Systems

Note: This addendum replaces Fig/Step 10 & Fig/Step

11 of the Woodpecker provided mounting instructions.

Please follow all assembly instructions of the original

manual up to Fig/Step 10 before using this addendum.

Add a large flat washer to each of the 3/8-16 x 3/4” hex bolts and

thread a 3/8-16 rectangular nut onto the end of each bolt.

Slide the rectangular nut on each of the bolt assemblies into the

T-slot located on the underside of your INCRA TS System’s front

rail and position the bolts close to your router, Fig. 1. (You’ll be

able to adjust the final position after full assembly.)

Slide the slotted end on each

of the mounting brackets all the

way onto the bolts as shown

in Fig. 2 then position the

brackets so that the 2 holes

are approximately 4- 1/4” apart.

Finger tighten the 2 bolts.

Fig.2

Fig.1

3/8-16 x 3/4

hex bolts

with washer

®

Rectangular

nut captured

in T-slot

Attach the Side Winder Crank’s

side panel to the brackets using

(2) 1/4-20 x 1-1/2” hex bolts with

washers and hex nuts, Fig. 3.

Be sure to place a split lock washer on the end of the bolt before

threading on and tightening the hex nuts. Tighten the (2) 3/8-16

hex bolts that secure the brackets to the underside of the rails.

Continue with Fig/Step 12 in the Side Winder Owner’s Manual.

TIP: Moving the bracket/crank assembly to the left or right along

the rail can improve how easily you are able to rotate the crank

handle. After you have attached the flex shaft to your router,

try sliding the bracket/crank assembly to different positions left

or right to find the easiest crank rotation. In general, the more

relaxed the lower loop or “U-turn” is on the flex shaft, the easier

the crank will rotate.

Manufactured by:

Taylor Design Group, Inc.

P.O. BOX 8102 62 Dallas, TX 753 81

www.in c ra .co m

INCRA is a Registered Trademark of Taylor Design Group

©2009 Taylor Design Group, Inc.

INCR A Tools are pro tect ed by one o r more of the f oll owing US pat ents :

#4, 793, 604, #4,93 0,2 21, #5 ,195,73 0, # 5,2 75,074 , #5, 42 3,3 60, # 5,716,04 5, #6,2 37,457,

#6,5 57,601, #6,67 2,190. Other patents grante d or pen din g. rev.11.03.10

Mounting

brackets4-1/4”

Fig.3

Side

panel

1/4-20 hex

bolts with

washers &

hex nuts

MADE IN THE

USA

Loading...

Loading...