Page 1

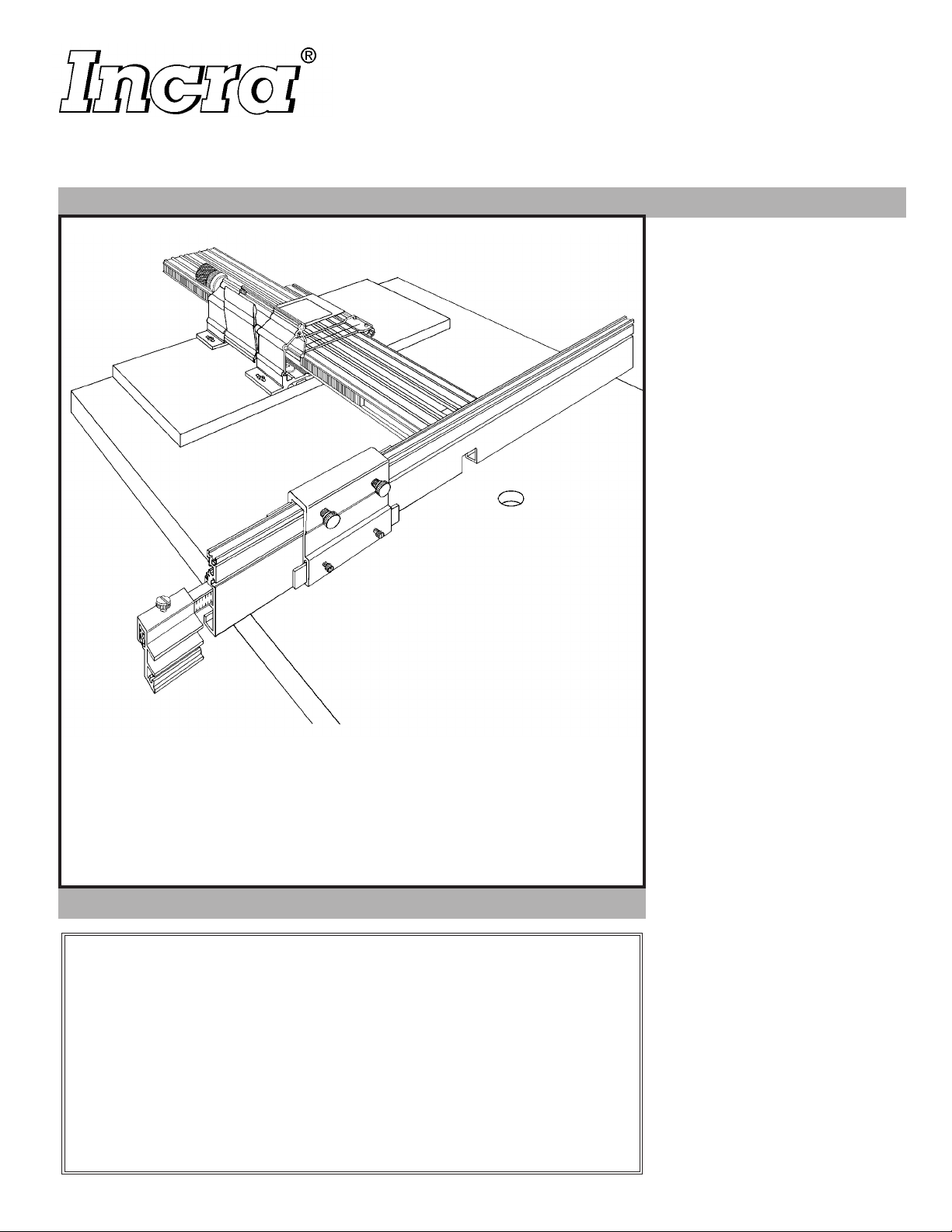

PRO

Fence System

Mounted to your INCRA JIG, the

INCRA PRO Fence System provides

a solid, smooth, and flat guide surface

for the various cutting operations in

your shop. A top-mounted sliding

scale and INCRA’s patented sawtoothed racks provide the means for

easy and extremely accurate stopped

cut setups using the INCRA Stop.

Coupled with the added convenience

and function of a self-storing Stop

Extender Bar with its own sliding

scale and variable stop, the INCRA

PRO Fence System will add new

dimensions to your abilities in the

wood shop.

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We

will repair, without charge, any defects due to faulty material or workmanship, or at our

option, replace the product free. Please return the failing part only, transportation prepaid,

along with a description of the problem to the address on the back of this manual.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA positioning rack in this tool becomes damaged for any reason, Taylor Design

Group will replace it free of charge for as long as you own the tool. Return the damaged

rack, transportation prepaid, and allow 1 to 2 weeks for delivery.

NOTE: Replacements cannot be sent unless damaged racks have been received

by Taylor Design.

Please be sure to

read this Owner’s

Manual before use

and keep it at hand

for future reference.

SAFETY

Important safety instructions

for using the INCRA PRO Fence

System

■ Before using the INCRA PRO Fence

System, read and follow all of the

instructions and safety information in

this manual.

■ When using the INCRA PRO Fence

System in conjunction with any

other tool, first read and follow all

instructions and safety information in

that tool’s owner’s manual.

■ Use appropriate safety devices.

Keep hands clear of the bit or blade.

Always use a push stick, rubber

soled push block or other safety

devices to keep your hands safely

away from the cutting tool.

■ Never let any part of the INCRA

PRO Fence System interfere with

another tool’s safety guards or other

safety equipment.

■ Never let the bit or blade come into

contact with the aluminum body of

the INCRA PRO Fence, INCRA Stop

or Stop Extender Bar.

■ Always turn off the power and

make sure that the bit or blade is

fully stationary before changing the

setting of any part of the INCRA

PRO Fence, INCRA Stop or Stop

Extender Bar.

■ Wear safety glasses, hearing

protection and follow all normal shop

safety practices.

■ When using negative fence settings

in which the bit is partially recessed

in the fence notch, always insure

that the bit is centered within the

notch.

■ Do not use any router bit with a

diameter greater than 3⁄4" without

first mounting a wooden auxiliary

fence as detailed on page 8.

■ When using the Stop Extender

Bar, make sure that it is securely

fastened to the fence with the

supplied mounting hardware. When

not in use, store the Extender

Bar inside the upper T-slot on the

Fence and secure in place with the

supplied hardware.

Page 2

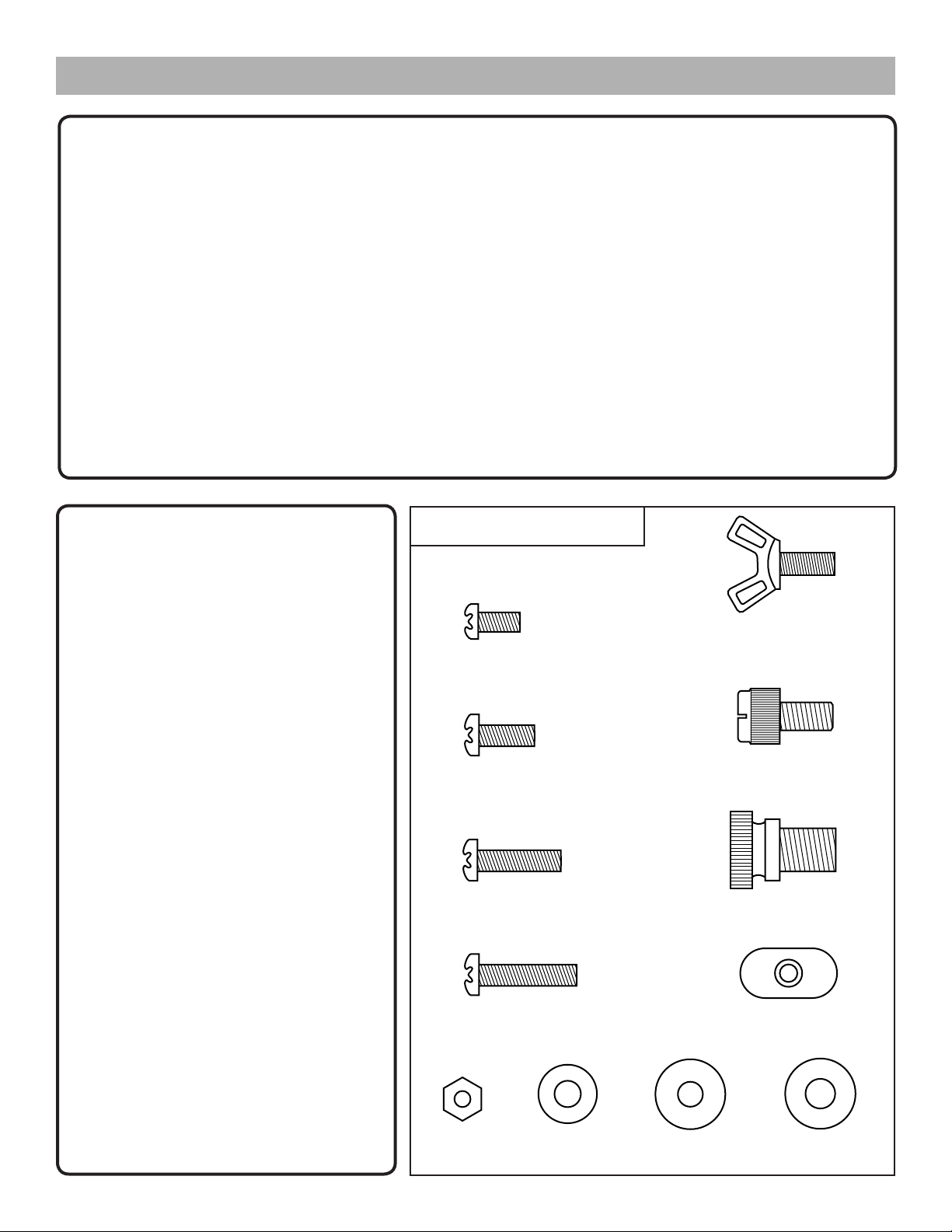

Parts List

28" INCRA PRO FENCE SYSTEM

Fence Assembly

1 ea. 28" INCRA Pro Fence

1 ea. 16" long, 1⁄32" ruled scale

4 ea. 1⁄32" INCRA rack (6" length)

8 ea. #8

8 ea. #8

2 ea. #10

2 ea. #10

–

32 x 3⁄8" phillips pan head screw

–

32 hex nut

–

32 x 1⁄2" phillips pan head screw

–

32 rectangular nut

2 ea. 5⁄8" o.d. x 1⁄32" thick flat washer

2 ea. 5⁄8" o.d. x 1⁄16" thick gold anodized flat washer

INCRA Stop Assembly

1 ea. INCRA Stop

1 ea. 1⁄32" INCRA rack (4" length)

18" INCRA PRO

Fasteners – 1:1 scale drawings

FENCE SYSTEM

Fence Assembly

1 ea. 18" INCRA PRO Fence

1 ea. Fence mounting bracket

1 ea. 16" long, 1⁄32" ruled scale

3 ea. 1⁄32" INCRA rack (6" length)

8 ea. #8

8 ea. #8

2 ea. #10

4 ea. #10

2 ea. #10 flat washer

2 ea. 5⁄8" o.d. x 1⁄32" thick flat washer

2 ea. 5⁄8" o.d. x 1⁄16" thick gold anodized

flat washer

2 ea. #10

2 ea. #10

–

32 x 3⁄8" phillips pan head screw

–

32 hex nut

–

32 x 1⁄2" phillips pan head screw

–

32 rectangular nut

–

32 x 3⁄4" phillips pan head screw

–

32 x 7⁄8" phillips pan head screw

#8 – 32 x 3⁄8"

phillips pan head screw

#10 – 32 x 1⁄2"

phillips pan head screw

#8 – 32 x 3⁄4"

phillips pan head screw

2 ea. 1⁄4"

2 ea. 3⁄8"

2 ea. #8

2 ea. #8

–

20 x 1⁄2" nylon thumbscrew

–

16 x 1⁄2" nylon thumbscrew

–

32 x 3⁄8" phillips pan head screw

–

32 hex nut

1 ea. Plastic stop strip (black) 3⁄4" x 5"

Stop Extender Assembly

1 ea. 28" Extender Bar

1 ea. #10

1 ea. 5⁄8" o.d. nylon washer

1 ea. #10

1 ea. 16" long, 1⁄32" ruled scale

1 ea. Extender Bar Stop

1 ea. 1⁄4"

–

32 x 1⁄2" thumbscrew

–

32 rectangular nut

–

20 x 1⁄2" nylon thumbscrew

#10 – 32 x 1⁄2" Thumbscrew

1

⁄4 – 20 x 1⁄2" nylon thumbscrew

3

⁄8 – 16 x 1⁄2" nylon thumbscrew

INCRA Stop Assembly

(Same as in the 28" INCRA PRO Fence System)

Stop Extender Assembly

1 ea. 18" Extender Bar

1 ea. #10

1 ea. 5⁄8" o.d. nylon washer

1 ea. #10

1 ea. 16" long, 1⁄32" ruled scale

1 ea. Extender Bar Stop

1 ea. 1⁄4"

–

32 x 1⁄2" thumbscrew

–

32 rectangular nut

–

20 x 1⁄2" nylon thumbscrew

#8 – 32 x 7⁄8"

phillips pan head screw

#8 – 32

hex nut

2

#10 SAE

flat washer

#10 – 32 rectangular nut

5

⁄8" o.d. x 1⁄16"

thick gold flat washer

5

⁄8" o.d. x 1⁄32"

thick flat washer

Page 3

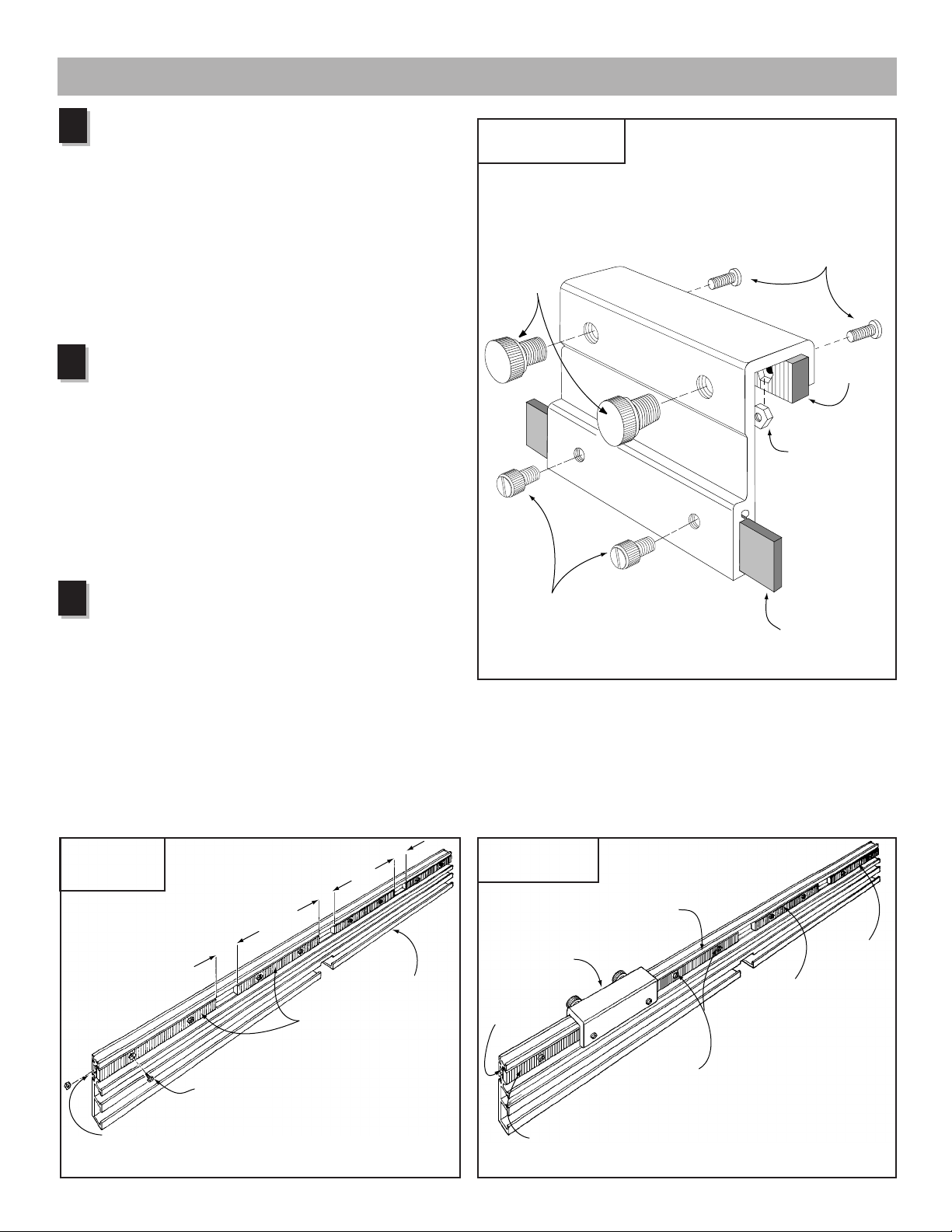

Assembly

Assemble the INCRA Stop

1

Using the (2) #8

and #8

–

32 hex nuts, fasten the 4" long blue INCRA

–

32 x 3⁄8" phillips pan head screws

rack to the INCRA Stop and tighten the screws. See Fig.

1. Slide the 3⁄4" x 5" plastic strip into the slot in the stop

and secure with (2) 1⁄4"

Thread the (2) 3⁄8"

–

20 x 1⁄2" nylon thumbscrews.

–

16 x 1⁄2" nylon thumbscrews

into the INCRA Stop as shown. One or both of these

thumbscrews can be used to clamp the INCRA Stop to

the fence. In use, the plastic strip provides a non-metallic

stop surface which can be shaped for special stop setups

and can be micro adjusted by loosening the smaller

thumbscrews.

2

Loosely install the racks in the

INCRA Fence

Insert the #8

the racks as shown in Fig. 2 and loosely attach the

–

#8

32 hex nuts. Slide each of the hex nuts on the racks

into the smaller T-slot in the back of the INCRA Fence.

Position the two outer racks approximately flush with the

ends of the fence with the remaining two racks spaced

about 15⁄16" apart. (For the 18" INCRA PRO Fence,

leave about 1⁄32" between the ends of the racks.) With

the racks loosely installed, you should be able to shift

each rack from side to side easily with your finger.

–

32 x 3⁄8" phillips pan head screws through

FIG. 1

INCRA Stop Assembly

3

/8 – 16 x 1/2"

nylon

thumbscrews

#8 – 32 x 3/8"

phillips pan

head screws

INCRA

rack

#8 – 32 hex nut

3

Tighten the racks on the

INCRA Fence

Begin by tightening the two mounting screws for rack #1,

as shown. Next, clamp the INCRA Stop to your fence

so that it bridges the gap between the ends of racks #1

and #2 (see Fig. 3), and tighten the mounting screws

for rack #2. Now move the INCRA Stop to bridge the

gap between racks #2 and #3 and tighten the mounting

screws for rack #3. Finally, bridge the gap between racks

#3 and #4 and tighten the rack #4 mounting screws. This

process aligns the racks so that the INCRA Stop will

operate accurately along the entire length of the fence.

FIG. 2

Loosely install

fence racks

15⁄16"

15⁄16"

INCRA racks

15⁄16"

28" INCRA PRO Fence

1

/4 – 20 x 1/2"

nylon thumbscrews

FIG. 3

Tighten the racks

Second:

Bridge the gap between

racks #1 and #2 with

the INCRA Stop

Rack #1

Plastic stop strip

Fourth:

Repeat the steps to

tighten racks #3 and #4

Rack #2

Rack #4

Rack #3

#8-

32 x 3/8"

phillips pan head screw

Loosely attach the #8-32 hex nuts to the screws on each

rack then slide the racks in place on the back of the fence

capturing the nuts in this T-slot

Third:

Tighten the rack mounting

screws on rack #2

First:

Tighten this rack’s mounting screws

BEFORE putting on the INCRA Stop

3

Page 4

Mounting the INCRA PRO Fence …

…to the INCRA JIG ULTRA or

ULTRA LITE:

Insert the #10

screws through the thick (gold) washers then through

the holes on the back of the fence mounting bracket.

Place a thin (silver) washer on each screw then loosely

attach the rectangular nut. See Fig. 4. The raised

rim on the rectangular nut should face the mounting

bracket. Now slide the fence onto the thin washer and

rectangular nut so that both are captured in the T-slot

on the back of the fence. Make sure the washer is

captured in the T-slot provided as shown in Detail 4a.

Position the fence so that the carriage is approximately

centered on the fence length and tighten the two

mounting screws.

To achieve a silky smooth carriage motion, it

is important that your table surface be flat and

-smooth, and that the carriage be installed parallel

to it. If you find that your carriage tends to bind slightly

during some portions of its travel, the following

additional step should take care of it. Simply place 3

or 4 pieces of paper under the infeed end of the fence

before tightening the screws in the final step of the

fence mounting procedure described above, and then

remove the paper. If the problem still persists, either

add a few more pieces of paper, or place the paper

under the other end of the fence before tightening.

–

32 x 11⁄8" phillips pan head

FIG. 4

Mounting to your INCRA JIG

ULTRA or ULTRA LITE

Fence

mounting

bracket

INCRA PRO Fence

Detail 4a

Thick (gold)

washer

Thin washer

captured here

#10 - 32 x 11⁄8"

phillips pan

head screw

Thick (gold)

5

⁄8" o.d. flat

Thin (silver)

5

⁄8" o.d. flat

washer

Raised rim on rectangular nut

faces the mounting bracket

washer

…to the INCRA JIG PRO:

Important: Your INCRA JIG PRO must be mounted to

a 3⁄4" plywood base and the cam clamp must be in the

locked position before installing the fence.

Insert the #10

through the thicker (gold) 5⁄8" o.d. flat washer then

through slot “A” (see Fig. 5). While holding the screw

in place, add the thin 5⁄8" o.d. flat washer then thread

on the rectangular nut. The raised rim around the

threaded hole on the nut should face the washer. With

the rectangular nut still loose, slide your INCRA PRO

Fence onto the washer and rectangular nut so that

both are captured in the T-slot in the back of the fence.

Make sure the washer is captured in the slot provided

as shown in Detail 5a. Repeat the above fastener

installation for slot “B”, sliding the fence to capture the

washer and rectangular nut. Position the fence so that

the mounting bracket is centered on the length of the

fence and securely tighten the two machine screws.

–

32 x 1⁄2" phillips pan head screw

FIG. 5

Mounting to your

INCRA JIG PRO

INCRA PRO Fence

4

Slot “A”

Detail 5a

Thick washer

Thin washer

captured here

Rectangular nut

Thin 5⁄8" o.d.

flat washer

Thick

(gold)

5

⁄8" o.d.

flat

washer

Slot “B”

#10 - 32 x 1⁄2"

phillips pan

head screw

Page 5

…to the Original INCRA JIG:

Note: Only the 18" INCRA PRO Fence can be

mounted to the Original INCRA JIG.

Important: Your Original INCRA JIG must be mounted

to a 3⁄4" plywood base and the black clamping knob

must be fully tightened before installing the fence.

Attach the fence mounting bracket supplied with

your 18" INCRA PRO Fence to the front end of your

Original INCRA JIG using the two #10

pan head screws, #10 flat washers and rectangular

nuts as shown in Fig 6. The “L” feature on the fence

mounting bracket should rest on the top of your INCRA

JIG as shown in Detail 6a.

–

32 x 3⁄4" phillips

FIG. 6

Attach fence

mounting bracket

#10 flat

washer

#10 – 32 x 3/4"

phillips pan

head screw

Detail 6a

“L” feature

Fence mounting bracket

Rectangular nuts

Top of

INCRA

Jig

Insert the #10

–

32 x 7⁄8" phillips pan head screw

through the thicker (gold) 5⁄8" o.d. flat washer, then

through hole “A” (see Fig. 7) on the fence mounting

bracket. While holding the screw in place, add the thin

5

⁄8" o.d. flat washer then thread on the rectangular nut.

FIG. 7

Mounting to your

INCRA JIG

The raised rim around the threaded hole on the nut

should face the washer. With the rectangular nut still

loose, slide your INCRA PRO Fence onto the washer

and rectangular nut so that both are captured in the

T-slot in the back of the fence. Make sure the washer

is captured in the slot provided as shown in Detail

7a. Repeat the above fastener installation for hole “B”,

sliding the fence to capture the washer and rectangular

nut. Position the fence so that the mounting bracket

is centered on the length of the fence and securely

tighten the two machine screws.

Adjusting the Fence Angle

#10-32 x 7⁄8"

phillips pan head screws

Fence

mounting

bracket

Hole “A”

Detail 7a

Thick (gold) washer

Thin washer

captured here

Rectangular nut

Thin (silver)

5

⁄8" o.d. flat washer

Thick

(gold)

5

⁄8" o.d.

flat

washer

Hole “B”

After mounting the INCRA PRO Fence, clamp

your INCRA Jig to the stationary tool of your

choice and with the INCRA Jig set to midrange, check the angle of your fence to the

table using a machinist’s or carpenter’s square.

Sometimes, as a result of the plywood base

not being perfectly flat, the angle may be

slightly more or less than 90°. To correct the

angle, place a masking tape shim along the

length of the mounting bracket between the

bracket and the fence as shown in Fig. 8.

FIG. 8

Adjusting the

fence angle

Table top

5

Place shim here if angle

is greater than 90°

90°

Place shim here if angle

is less than 90°

Page 6

Installing the Extender Bar

Fig.9 shows the proper placement for your Stop

Extender Bar. Insert the Extender Bar with the scale

facing the front of the fence, then slide the bar in the

T-slot until the ends are flush and lock in place using

the supplied #10

–

32 x 1⁄2" thumbscrew, 5⁄ 8" o.d. nylon

washer and rectangular nut as shown.

A second Stop Extender Bar can be purchased

should you want to increase the stop range beyond both

ends of your INCRA PRO Fence.

CAUTION: Always install the Extender Bar in the UPPER

T-slot, never the lower one.

Extender Bar Stop

Position the Extender Bar about 2" beyond the fence end

and using the supplied 1⁄4"

attach the Extender Bar Stop. See Fig. 10. The Stop can

be used on either end of the Extender Bar to increase

your stop range beyond the ends of the INCRA PRO

Fence. When not in use, the Stop can be turned around

and locked to the Extender Bar (see Fig. 11). This storage

position places the Stop out of the way, leaving the front

face of the INCRA PRO Fence uninterrupted for through

cut operations.

–

20 x 1⁄2" nylon thumbscrew,

FIG. 9

Extender bar

#10 – 32 x 1⁄2"

thumbscrew

5

⁄8" o.d.

nylon washer

Front face of fence

Extender bar

Rectangular nut

FIG. 10

Extender Bar Stop

1

⁄4" – 20 x 1⁄2"

nylon thumbscrew

Extender Bar Stop

Applications

INCRA Stop

When used in conjunction with your new INCRA PRO

Fence, the INCRA Stop provides the same precise rack

positioning capabilities that your INCRA Jig offers. The

sliding scale in the top of your fence becomes a versatile

reference for use in setting stop positions at the router

table and the drill press. The sliding plastic stop strip

on the INCRA Stop permits micro-adjusting of the stop

positions between 1⁄32" steps. The Stop can function

on either the outfeed or infeed end of the fence with any

thickness of stock, even rabbeted boards. Two INCRA

Stops can work together at opposite ends of the fence for

many advanced operations, such as multiple mortises and

slots.

FIG. 11

Extender Bar Stop

storage position

FIG. 12

INCRA Stop

6

Page 7

Zeroing the INCRA Stop to

the End of a Board

For most applications, you will be using your

INCRA Stop on the outfeed end of the INCRA

Fence to control the length of a cut relative to

the front end of the board. Here is how to set

the initial scale position for this type of setup:

After installing the bit you wish to use,

set the fence to bit distance at about 1".

1

Place a square cut piece of scrap stock

against the fence with the end of the board

against the infeed side of the bit. Turn the bit to

find the high spot.

FIG. 13

Top view of

stop setup

INCRA

Stop

First:

Slide the board

up to contact

the “high spot”

on the bit

Next, lock the INCRA Stop to the fence on

the outfeed side of the bit with the plastic

2

stop strip as close as possible to the end

of the board. Adjust the position of the stop

strip until both the strip and the bit contact the

end of the board. See Fig. 13.

You now have the choice of setting

the sliding scale to one of three initial

3

positions:

In most cases, you will simply slide the

A

scale to align the 0" mark on the scale

with the end of the INCRA Stop nearest the

bit. When set to this initial position, the scale

reading at any subsequent INCRA Stop location

will give you a direct readout of the total length

of the cut. (See Dimension “A”, Fig. 14.)

If you wish the subsequent scale readings

B

to reflect the distance from the front end of

the board to the center of the cut (Dimension

“B”, Fig. 14), slide the scale to an initial reading

under the end of the INCRA Stop equal to

minus one half of the bit diameter. Example:

If you are using a 1⁄2" diameter bit, complete

Steps 1 and 2 above then slide the scale to

read negative 1⁄4".

If you want the scale reading for future

C

INCRA Stop locations to reflect the

distance between the end of the board and the

outfeed edge of the cutter (Dimension “C”, Fig.

14), then slide the scale to an initial reading

equal to minus the bit diameter.

Dual INCRA Stop

Operations

Using the same setup process described above

and a second

precise positioning of mortises on a board quite

simple. The INCRA Jig Projects and Techniques

book covers this technique fully and includes

several unique projects which feature dual

INCRA Stop operations.

INCRA Stop

, you will find the

Second:

Lock the INCRA Stop to the

fence and adjust the position

of the plastic stop strip to

contact the end of the board

Third:

Slide the scale to read one of

the initial scale settings as

described in Fig. 14 below

FIG. 14

Initial scale

setting

FIG. 15

Dual stop

operations

A

A

A

A

B

C

A

-A.

A

Slide scale to 0" for a direct readout of Dimension “A”

B.

Slide scale to “minus 1/2 of the bit diameter” for a direct

A

readout of Dimension “B”

-C.

Slide scale to “minus diameter of the bit” for a direct

readout of Dimension “C”

7

Page 8

X-Y Positioner for the Drill Press

Used at your drill press, your new INCRA Jig and INCRA

PRO Fence System are the ultimate in X-Y positioning

control. You can quickly and accurately locate and drill

any pattern of holes by simply moving the INCRA Jig

and the INCRA Stop to the desired settings. A cribbage

board is a good example of a project that requires this

ability. And since you can locate any hole to within a few

thousandths of an inch, you will find this technique great

for making perfect dowel joints.

Mounting an Auxiliary Fence to

Your INCRA PRO Fence

If you should desire to use a router bit with a diameter

greater than 3⁄4", you must first mount a wooden auxiliary

fence to your INCRA PRO Fence. The following

information should help in determining the dimensions of

the auxiliary fence, see Fig. 17.

Thickness (A): The thickness of the auxiliary fence should

be 11⁄2 times the diameter of the router bit you plan to use.

(Example: To use a 1" diameter router bit, your auxiliary

fence should be 11⁄2" thick.)

Height (B): The height of the auxiliary fence should be 3"

minimum.

Length (C): Cut the length of the auxiliary fence to match

the length of your INCRA PRO Fence, either 18" or 28".

Fence Notch Width (D): At least 1⁄4" greater than the

diameter of the router bit.

Fence Notch Height (E): At least 1⁄4" greater than the

maximum depth of cut you plan to use with the router bit.

To mount the auxiliary fence to your INCRA PRO

Fence, you will need (2) #8

flat washers and (2) #8

machine screws should be slightly less than the thickness

of the auxiliary fence. Drill two 3⁄16" dia. through holes

in the auxiliary fence in the locations shown in Fig. 18.

Now, using a 1⁄2" diameter drill bit, counterbore the hole

locations.

Note: Adjust the depth of the counterbore so that the

screw, when installed in the counter bore with the #8 flat

washer, extends slightly less than 3⁄4" through the back of

the auxiliary fence. Loosely attach the #8

the screws then slide the hex nuts into the T-slot located

on the front face of the INCRA PRO Fence. Tighten the

machine screws to secure the auxiliary fence in place.

FIG. 18

Hole/Counterbore locations

–

32 machine screws, (2) #8

–

32 hex nuts. The length of the

–

32 hex nuts to

3

⁄16" dia. through hole,

1

⁄2" dia. counterbore

(See Note above for

counterbore depth)

FIG. 16

X-Y Positioning at

the drill press

FIG. 17

Auxiliary fence

D

E

C

B

A

For short term auxiliary fence applications, you

might find it convenient to use an aggressive

double-faced tape to attach the auxiliary fence. We

recommend #ST501 manufactured by SpecTape of Texas.

Call 1-800-442-1338 for your nearest distributor, or check

with your INCRA dealer. Do not use standard double-faced

carpet tape.

41⁄2"

21⁄32"

Made in America by: TAYLOR DESIGN GROUP, INC. P.O. BOX 810262------Dallas, TX 75381

Printed in the U.S.A. © 1993, Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc. RV02-97

18" Fence

7" 14"9"

21⁄32"

8

28" Fence

Loading...

Loading...