Page 1

PRL-V2 Precision Router Lift

By Woodpeckers

MADE IN THE

USA

SAFETY

Always unplug your router motor

before making any adjustments

to the router lift.

Refer to your router’s owner’s

manual for specific safe

operation instructions.

INSTALLING A PC-7518 ROUTER MOTOR

Set the lift face down in the opening of your router table.

Alternatively, you can set it on two spacers at least 1” thick.

Make sure the lift carriage is set as close to the plate as

possible (approximately 2-1/4”). If the carriage requires

coarse adjustment, jump ahead to the section on using the

Lift Wrench on page 3, then return here once the carriage

has been moved up against the gear box.

Ensure the four (4) clamp screws are loose enough to allow for the motor to be inserted. Next,

carefully insert the motor until the motor contacts the plate. Rotate the motor so that the cord and

speed adjustment are clear of the posts. Make sure no part of the router interferes with the lift.

Make sure that none of the motor pins are being clamped by the pads.

Now tighten the clamp screws. Only three are accessible at this point. Flip the lift right side up

and set it into the table opening. Use the lift wrench to lower the carriage a couple of inches. Now

tighten the fourth screw.

page 1page 4

Page 2

w w w . i n cr a . c o m

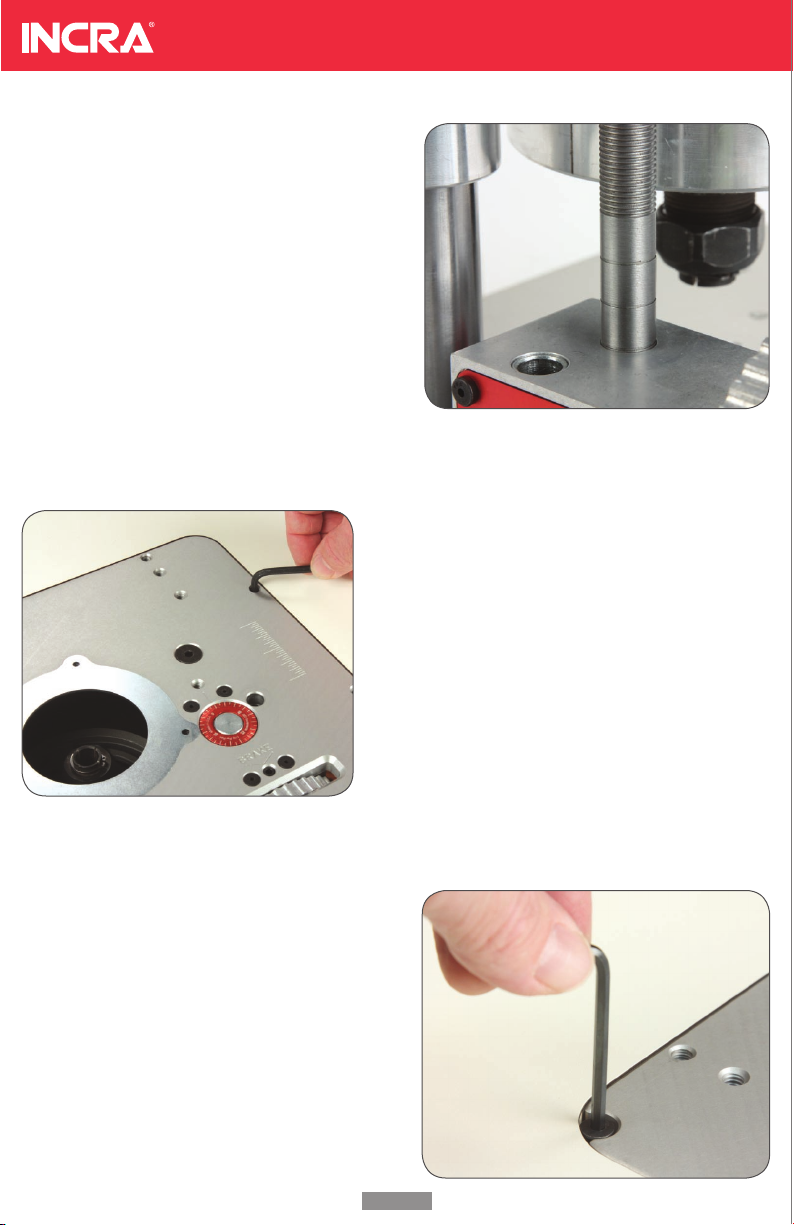

SETTING THE FINE ADJUSTMENT

LIFT ROD

The thumb wheel allows for a total of 3/4” of fine

adjustment. It’s helpful to start out in the middle of

this range. Take a look at the lift rod. You’ll notice

three grooves spaced 3/8” apart. The three grooves

represent the beginning, middle, and end of travel.

Use the thumb wheel to adjust the lift rod to the

middle groove which is the middle of the adjust-

ment range. It may be necessary to adjust the lift

rod to see all three grooves.

SETTING THE PLATE FLUSH

The (10) threaded holes around the perimeter of the

plate are for access to the leveling screws mounted

into your INCRA Router Table. Insert the supplied

5/32” hex key through these holes to adjust. If you

have purchased the PRL-V2 for use in other (non-

Incra) router tables, insert the included set screws

into the threaded holes for leveling.

LOCKING THE PRL-V2 IN YOUR

TABLE RECESS

Lift the PRL-V2 from your router table recess and

thread the included socket head cam screw into

the hole located at the corner of the plate. Thread

the fastener in until the top of the screw is just

below the top of the plate. Carefully lower the

PRL-V2 back into the router table, making sure the

cam screw is rotated to clear the opening in your

table top. Turn the fastener clockwise to lock the

PRL-V2 in your table.

Page 3

USING THE LIFT WRENCH

To use the lift wrench, orient the black grip so that it is

parallel to the front edge of the plate with the flat side

pointing to the left. Insert the wrench (compressing the

spring) until it bottoms out in the carriage. As you rotate

the wrench in either direction, the locking mechanism will

release, allowing the router to be raised or lowered.

Once the router is near the desired position (within 3/8”

or less), re-orient the wrench handle to the original posi-

tion, pointing left and parallel with the front edge of the

plate. This will lock the motor in place and allow for fine

tuning with the thumb wheel.

NOTE: The wrench comes pre-assembled with an assist spring.

This spring is rated to lift most of the weight of the PC-7518 mo-

tor. The spring eliminates the need to hold down the plate while

making course adjustments. The spring can be easily removed by

simply loosening the small set screw in the white plastic foot.

PRL-V2 Precision Router Lift

By Woodpeckers

The PRL-V2 also features a brake. For most routers, the

brake isn’t necessary. However if you experience vibra-

tion while routing, the brake will prevent the bit height

from changing on its own. A 1/8” hex key is supplied for

the brake. DO NOT OVER TIGHTEN THE BRAKE. A little

pressure is all that is required.

In spite of having a brake, it is imperative to make sure

the vibration isn’t being caused by dirt, dust or rust on

the router bit shank, collet or collet taper. Make sure

these surfaces are completely clean. Apply a small amount of light machine oil to the inside of the

taper before re-assembly. . Run-out typically causes vibration and can lead to premature router bit

failure.

page 3page 2

Page 4

Taylor Design Group, Inc.

P.O. BOX 810262 Dallas, T X 7538 1

w w w. i n c r a .c o m

INC RA is a Re giste red Tradema rk of Ta ylo r De sign Grou p

©20 08 Tayl or Des ign Gr oup, In c.

INC RA Too ls are pro tecte d by one or m ore of the fo llow ing US pat ents : # 4,79 3,60 4, #4 ,93 0,22 1,

#5 ,195,73 0, #5 ,275, 074, # 5,4 23,36 0, # 5,716,0 45, # 6,23 7,45 7, #6 ,557,6 01, #6 ,672 ,190. Ot her

pat ents g rante d or pe ndin g. rev. 09.25 .08

CHANGING MAGNA-LOCK RING

To remove the ring insert, slide the included 3/32”

hex key into the access hole and lift up. When

inserting the new ring, orient the plate so that the

access hole feature on both the PRL-V2 and the

Magna-Lock ring are aligned and carefully lower the

ring into the recess. TIP: The Magna-Lock ring is

keyed to fit only one way. If it doesn’t align on the

first try, flip it over and try again.

CHANGING BITS

First remove the Magna-Lock ring. Now use the

lift wrench to raise the router collet completely

above the plate. Use the wrenches supplied

with your router to change the bit.

MICRO-ADJUSTING

The thumb wheel permits easy fine adjustments to

your depth of cut without any special tools. Rotat-

ing the thumb wheel to the left raises the router bit;

rotating to the right lowers the bit.

The red micro adjust scale disc behind the thumb

wheel can be zeroed to any position. It is typically

set to zero once the router bit is at the desired

height. Then you can easily make a specific, fine

adjustment with the thumb wheel while the scale tracks the movement. The scale is adjusted by

rotating the knurled disc in either direction using your finger.

Loading...

Loading...