Page 1

Your new INCRA Miter Gauge at

long last solves that frustrating problem

all too familiar to woodworkers –

making perfect miter cuts on the table

saw. Whether you’re constructing a

simple picture frame, complex

compound miters, or a 20-sided object,

your INCRA Miter Gauge delivers

perfect, repeatable accuracy without

trial and error setups – first time, every

time. It’s all made possible by INCRA’s

Angle Indexing System™.

While an

average miter gauge offers positive

stops at 0° and 45° and a good miter

gauge offers stops at 0°, 15°, 221⁄2°,

30°, and 45°, the INCRA Miter Gauge’s

AngleLOCK™ Indexing System

offers

110 stop positions on each side of 0°.

But that’s just half the story. The fence

on your INCRA Miter Gauge is

equipped with INCRA’s patented

Automatic Positioning Control

™

and the

highly versatile INCRA Shop Stop™.

With this combination, you not only

have absolute control over the angle of

your cut, but you also have perfect,

instant control over the length of your

cut as well. Like all INCRA tools, the

INCRA Miter Gauge really does work

EXACTLY as promised.

■

Before using the INCRA Miter Gauge, read

and follow all of the instructions and safety

information in this owner’s manual.

■

When using the INCRA Miter Gauge in

conjunction with any other tool, first read

and follow all instructions and safety

information in that tool's owner's manual.

■

Never let the saw blade come in contact

with the aluminum or steel components of

the INCRA Miter Gauge, including the

fence and the INCRA Shop Stop.

■

When using your INCRA Miter Gauge,

always keep your hands clear of the line of

cut and the saw blade.

■

Always use the tall black knob as a

handle to push your INCRA Miter Gauge

during a cut.

■

Always turn off the power and make sure

that the saw blade comes to a complete

stop before changing the setting of any

part of the INCRA Miter Gauge or INCRA

Shop Stop.

■

Always securely tighten the small black

miter clamping knob before starting any cut.

■

Wear safety glasses, hearing protection,

and follow all normal shop safety

practices.

■

After making any adjustments to the miter

angle or fence position of your INCRA

Miter Gauge, always verify safe clearance

between the blade and fence before

turning on the saw.

■

After making any adjustments to the fence

position on the Incra Miter Gauge, always

make sure the two socket head screws

are securely tightened.

■

Whenever using the INCRA Shop Stop to

position a piece for a cut, always hold or

otherwise clamp the board between the

stop and the blade.

SAFETY

OWNER’S MANUAL

Please read this

owner’s manual

before use and

keep it at hand

for reference.

Important safety instructions for using the INCRA Miter Gauge

®

From the

makers

of the

INCRA JIG!

Page 2

2

Place the INCRA Miter Gauge in

the left hand miter slot at your

table saw. Loosen the (2) 1⁄4-20

socket head cap screws that secure

the fence to the fence mounting

bracket and slide the fence to a

position that leaves safe clearance

between the end of the fence and the

blade. Tighten the (2) 1⁄4-20

fasteners. Fig. 2.

Remove the INCRA Miter Gauge

from the box. Pivot the miter

head around until the hole in the

black bottom plate aligns with the

threaded hole in the miter bar. Insert

the large miter push knob with

washer through the hole and thread

into the miter bar. See Fig. 1.

NOTE:

Do not insert the handle through

the slotted hole.

If the miter slot in your table saw is a

T-slot, attach the “T” clip to the end of

the miter bar as shown in Fig 1A.

1

Hole in bottom plate aligned

over threaded hole in miter bar

Miter push knob

Washer

Bottom plate

Miter bar

FIG. 1

Insert miter push knob through hole in

bottom plate and thread into miter bar.

First: Loosen (2) 1/4-20 socket head cap screws

Clearance between

fence and blade

(at ALL fence angles)

FIG. 2

Position fence

Second: Slide fence

Third: Tighten fasteners

ASSEMBLY

2

FIG. 1A

Assemble miter

bar clip

#10-24 x

5

/16"

flat head screw

T-clip

Miter bar

The method used to join the fence mounting brackets to the miter

head top plate makes it easy to fine-tune the angle of the fence perfectly

perpendicular to your

table top. To adjust, loosen the (3) #10-24 socket head

cap screws that secure the brackets to the top plate and slide a paper or

plastic shim between the bracket and top plate. Placing the shim

behind

the

screws will

decrease

the fence to table angle. Placing the shim in

front

of

the fasteners will

increase

the fence to table angle.

Page 3

CALIBRATION

FIG. 3

Adjust miter bar width

FIG. 4

Second:

Loosen (3) #10 socket

head cap screws that

secure fence mounting

bracket to miter head.

First:

Set miter head to 0°. Tighten

miter lock thumbscrew and lock

actuator tooth in place.

3

Expansion

mechanisms

Machinist

square

Fence

FIG. 5

Fence stops

Second:

Slide

1

⁄4 -20 x 3⁄8" socket head cap

screw and washer up to fence mounting

bracket and tighten in place.

Adjust the Miter Bar

Adjust the miter bar at each of the (6)

expansion mechanism locations for a good

fit in your table saw’s miter slot. Turning the

screw clockwise expands the mechanism. You’ll

find three of the expansion locations in front of

the fence and one underneath the fence (you’ll

need to slide the fence for access). Adjust

these forward (4) expansion points first,

expanding a little at each of the locations until

the bar slides smoothly. Finally, remove the

large miter push knob and pivot the miter head

away from the bar for access to the remaining

(2) expansion points.

Adjust Fence Mounting Bracket 90°

to Saw Blade

Set the miter head to read 0° (the tooth on

the actuator should point to 0° on the

scale). Tighten the miter lock and the actuator

thumbscrews. Using the supplied 5⁄32" hex key,

loosen the (3) #10-24 x 5⁄16" socket head cap

screws that secure the fence mounting bracket

to the miter head. Unplug your table saw, then

use a reliable machinist square to set the fence

at 90° to the saw blade. Tighten the (3) socket

head cap screws.

This one-time calibration prepares your INCRA

Miter Gauge for work in the left hand miter slot.

To calibrate for right hand miter slot usage,

reverse the miter gauge as described on page

5, then repeat the above adjustments. Just

remember that the accuracy of The INCRA Miter

Gauge on any subsequent setting is dependent

upon the accuracy of your initial 90° calibration.

It is a good idea to verify your setup with a trial

cut at 90°.

1

2

T-clip

Miter bar

First:

Find a position for the fence that

provides clearance between fence

and blade at ALL miter head angles.

Safety Tip: Fence Stops

After calibrating your INCRA Miter Gauge

for use in the left miter slot, find a single

position for the fence that provides safe

clearance between the fence and blade at

all angles. Loosely assemble one of the

1

⁄4 -20 x 3⁄8" socket head cap screws with

washer and rectangular nut found in your

hardware pack. Slide the nut into the rear

T-slot on the fence and up to the fence

mounting bracket. Make sure the washer

is firmly against the fence mounting

bracket as you tighten the fastener. See

Fig. 5. Repeat for the right miter slot

setup. Now, when the fence is later

removed for work on the opposite side of

the blade, the fence stop will retain your

original position.

Third:

Use a

machinist

square to

adjust fence

at 90° to

sawblade.

Tighten

fasteners.

Page 4

Half-degree Indexing

To adjust the Miter Gauge to 1⁄2° settings, remove the large

miter push knob from the hole in the top plate and thread it

into the slotted hole. See Fig. 8. Before tightening the knob,

rotate the miter head to move the white “minus” sign engraved

in the black plate toward the knob. Tighten the knob. Now at

every tooth setting for the actuator subtract1⁄ 2°. (Example: If

the actuator tooth is locked at 5°, you are at 41⁄ 2°.)

If you want to add1⁄ 2° to every tooth setting, loosen the

miter push knob and rotate the miter head to move the

white minus sign away from the knob.

Continuous Adjustments

NOTE:

For continuous angle adjustment the miter push

knob should be installed in the hole, not the slot, on the

black bottom plate.

If you need angle settings finer than 1⁄ 2° increments, just

pivot the actuator away from the miter head teeth. You’ll

notice a white hairline cursor engraved in the black plate. Use

this hairline as a reference for your adjustments. For continuous

angle adjustments use only the miter lock thumbscrew to hold

your angle.

Rotate miter head top plate to

desired angle, then firmly engage

tooth on actuator with teeth on miter

head. The actuator tooth should point

directly to the desired angle on the

scale. Tighten the miter lock

thumbscrew, then tighten the actuator

thumbscrew. Fig. 7.

One-degree Indexing

Loosen the actuator thumbscrew

and pivot the actuator tooth away

from teeth on miter head top plate.

Loosen the miter lock thumbscrew.

See Fig. 6.

OPERATION – Changing the Angle Settings

First:

Loosen actuator thumbscrew

and pivot actuator tooth

away from miter head teeth

FIG. 6

Unlock miter

head top plate

Second:

Loosen

miter lock

thumbscrew

Miter head top plate teeth

Actuator

thumbscrew

Actuator

tooth

First: Rotate miter head

to desired angle and

firmly engage actuator

tooth with teeth on miter

head top plate.

FIG. 7

Rotate and engage

actuator, then relock

Second:

Tighten

miter lock

thumbscrew

Third:

Tighten actuator thumbscrew

1

2

4

1

FIG. 8

For 1⁄2° indexing insert miter

push knob through slotted

hole in bottom plate

Miter push knob

Bottom

plate

Slotted hole

2

1

Caution:

After making any adjustments to

the miter angle of your INCRA Miter

Gauge, always verify safe clearance

between the fence and the blade

before turning on the saw.

Page 5

Converting from Left to Right

Miter Slot Use

Your INCRA Miter Gauge is designed for

use in either the left or right miter slot of

your table saw. Since most of the time

you will be using your INCRA Miter

Gauge in the left hand miter slot, the

instructions that follow describe

converting from left to right miter slot

use. To convert back to the original left

miter slot setup, just reverse the steps.

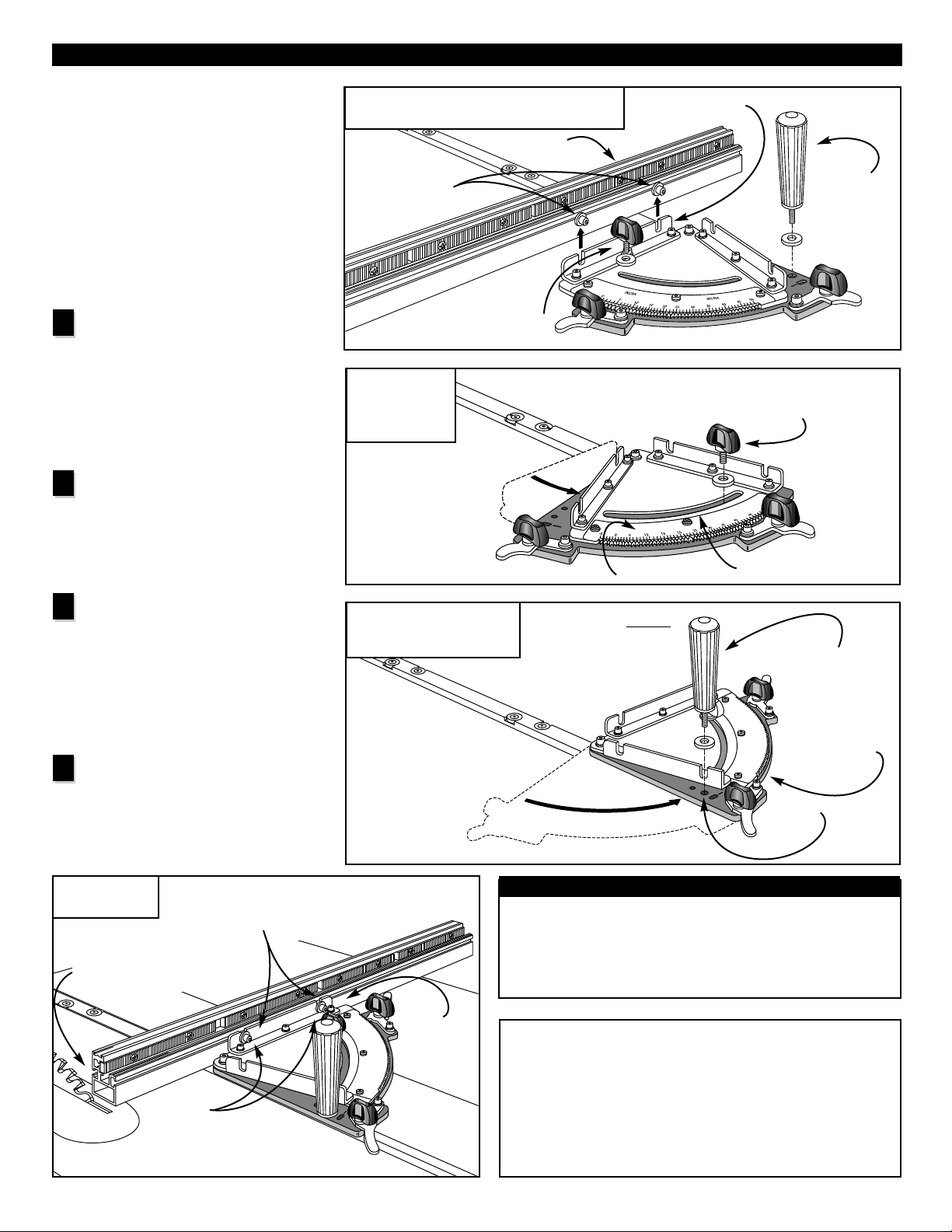

Place the INCRA Miter Gauge in

your table saw's right hand miter

slot. Loosen the (2) 1⁄4-20 socket head

cap screws that secure the fence and lift

the fence straight up and off of the fence

mounting bracket. Remove the large

miter push knob and the small black

miter lock thumbscrew. Fig 9.

Pivot the silver top plate on the

miter head counterclockwise until

you see the threaded hole through the

right end of the slot. Screw the small

black miter lock thumbscrew with washer

into the threaded hole. Fig 10.

Pivot the entire miter head counter-

clockwise until the through hole on

the left side of the black bottom plate

aligns over the threaded hole in the miter

bar. Screw the large miter push knob with

washer into this hole and tighten. Do not

use the slotted hole unless you desire 1⁄2°

indexing. Fig 11.

Lower the fence back onto the fence

mounting bracket. Before tightening

the (2) 1⁄4-20 socket head cap screws,

adjust the fence position to provide safe

clearance between the fence end and the

blade. Tighten the fasteners. Fig 12.

FIG. 9

Remove fence, push knob and miter lock knob

FIG. 10

Pivot top plate

and attach

miter lock knob

REVERSING THE MITER GAUGE

FIG. 11

Pivot miter head and

attach miter push knob

First:

Loosen

1

/4-20

socket head cap

screws and lift

fence off bracket

Fence

Second:

Remove large

miter push

knob

Third: Remove small

miter lock thumbscrew

Fence mounting

bracket

First:

Pivot silver top plate

counterclockwise

Second:

Thread miter lock thumbscrew with washer

into threaded hole at right end of slot.

Top plate

Slot

First:

Pivot entire miter head

until hole on bottom plate

aligns with threaded hole

in miter bar

Second:

Attach push

knob and washer

Bottom plate

Fence

mounting

bracket

Third:

Tighten fasteners

Hole

NOTE:

When using the INCRA Miter Gauge in the

right hand miter slot, use the right hand actuator

and the smaller numbers on the scale to set the

miter head angle.When using the INCRA Miter

Gauge in the left hand miter slot, use the left hand

actuator and the larger numbers on the scale to set

the miter head angle.

Second:

Position fence for safe

clearance between fence

and blade (at ALL angles)

1

2

3

4

First:

Lower fasteners on fence

onto fence mounting bracket

FIG. 12

Reattach fence

5

Do not use the slotted

hole unless you desire

1

/2

° indexing.

Caution:

After making any adjustments to the miter angle

or fence position of your INCRA Miter Gauge,

always verify safe clearance between the blade and

fence before turning on the saw.

Page 6

Zero Clearance

Adding a wooden auxiliary fence to the front

of your INCRA Miter Gauge fence offers

several benefits. Often, the most important

benefit is the ability to add zero clearance

backing for all of your crosscutting and

mitering operations. Azero clearance

auxiliary fence extends beyond the end of the

miter gauge fence and crosses the line of cut

to provide tearout control during a cut. It also

carries any small cutoff pieces safely past the

blade. In the expanded clamping mode, your

INCRA Shop Stop will clamp to your Miter

Gauge fence with auxiliary fences up to 3⁄4"

thick. See Fig. 13.

Extending Stop Range

or Fence Height

Another reason to add an auxiliary fence to

your INCRA Miter Gauge is to extend the

stopping range or fence height when used in

conjunction with the INCRA Shop Stop. By

adding a 3⁄4" plywood or hardwood auxiliary

fence that extends beyond the end of the

miter gauge fence away from the blade and

using the Shop Stop in the standard clamping

mode, you can clamp the stop directly to the

auxiliary fence. Using the Shop Stop in this

way allows the use of taller auxiliary fences

as well.

Attaching an Auxiliary Fence

For auxiliary fence applications where

incremental use of the Shop Stop is required,

the wooden auxiliary fence should be flush

with the top of the INCRA Miter Gauge fence.

Use the dimensions shown in Fig. 14.

Provided in your hardware pack are

1

⁄4-20 x 3⁄4" fasteners with washers

and nuts.

AUXILIARY FENCES

FIG. 13

Zero clearance auxiliary fence

FIG. 14

Auxiliary fence

dimensions

3

⁄4" thick zero

clearance wooden

auxiliary fence

INCRA Shop Stop shown

in expanded mode

2

1

⁄16"

1

1

⁄32"

3

⁄4"

1

⁄4" flat washer

1

⁄4"-20 x 3⁄4

socket head

cap screw

1

⁄4 -20 hex

nut or

rectangular

nut

5

⁄16" thru hole with

3

⁄4" dia. x 3⁄8" deep counterbore

6

NOTE:

Set the INCRA Shop Stop to expanded mode

as described in the Shop Stop owner’s

manual (page 3, Fig. 7) when using an

auxiliary fence up to 3⁄4" thick.

To increase holding power when

crosscutting or mitering, add a strip

of adhesive backed sandpaper to

the front face of your wooden

auxiliary fence. Asandpaper with a

150 to 180 grit works best.

Page 7

ABOUT YOUR FENCE SCALES

7

Fig. 15

Align scales using

optical window

All Incra products use overlapping 16" long Lexan scales. The

overlap allows fine-tuning the scale from one end to the other

to agree with the high degree of accuracy provided by the

Incra saw toothed positioning racks. These scales are printed

initially in 16" lengths (0-16", 16-32", 32-48" etc.). As they are

slid into the scale slot on the fence, the ends are overlapped

and aligned using the optical window located at the end of the

second scale. Fig 15. The friction fit will keep the scales in

place. If you wish, you can use a small piece of double faced

tape at the overlap to ensure that the scales move together

when changing your zeroed setups for mitering.

Page 8

8

Made in America by:

Taylor Design Group, Inc. ■P.O. Box 810262 ■Dallas, Texas 75381 09/2000

Printed in the U.S.A. © 1999, 2000 Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc.

PRODUCT INFORMATION

For a product information update on the complete

INCRA line of tools, please see your nearest dealer. If

you are unable to locate a store nearby, or if you have

trouble finding a particular product, we will honor your

order directly.

For a product information brochure, call, write or fax to:

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, TX 75381

Tel: (972) 418-4811 Fax: (972) 243-4277

Web Site: www.incra.com

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will

repair any defects due to faulty material or workmanship, or at our option, replace the product

free of charge. Please return the failing component only, postage prepaid, along with a

description of the problem to the address below. This warranty does not apply to parts which

have been subjected to improper use, alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA linear positioning rack in this tool becomes damaged for ANY reason,

Taylor Design Group will replace it free of charge for as long as you own your tool.

Return the damaged rack, transportation prepaid, and allow 1 to 2 weeks for delivery.

PARTS AND OPTIONAL ACCESSORIES

PART # PART DESCRIPTION PRICE

SHOPSTOP INCRA Shop Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 32.95

Add a second Shop Stop to your IncraLOCK™Cut-off Fence

MITERFNC27 27" IncraLOCK™Cut-off Fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 34.95

Extra 27" IncraLOCK™Cut-off fence with positioning racks

MITERFNC52 52" IncraLOCK™Cut-off Fence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 49.95

Extended 52" IncraLOCK™Cut-off fence with positioning racks

Loading...

Loading...