Page 1

w w w. i n c r a . c o m

BEFORE USING THE INCR A

MIteR1000HD, READ AND FOLLOW

ALL OF THE INSTRUCTIONS AND

SAFETY INFORMATION IN THIS

OWNER’S MANUAL.

O’ M

high definition

high definition

from incra

SAFETY:

Important safety InstructIons for usIng the INCRA MIteR1000HD

REGISTER

YO U R

When using the INCR A Miter1000HD in conjunction with any other tool, first read and follow all

°

instructions and safety information in that tool’s owner’s manual.

Never let the saw blade come in contact with the aluminum or steel components of the INCRA Miter1000HD.

°

When using the INCR A Miter1000HD, always keep your hands clear of the saw blade and the line of cut.

°

Always turn off the power and make sure that the saw blade comes to a complete stop before changing the setting of any part of

°

the INCRA Miter1000HD.

Always securely tighten the large black clamping knob before starting any cut.

°

Wear safety glasses, hearing protection, and follow all normal shop safety practices.

°

After making any adjustments to the miter angle or fence position of your INCRA Miter1000HD, always verify safe clearance

°

between the blade and fence before turning on the saw.

After making any adjustments to the fence position on the INCR A Miter1000HD, always make sure that the two socket head

°

screws are securely tightened.

When using the INCR A Flip Shop Stop to position a piece for a cut, always hold or otherwise clamp the board between the stop

°

and the blade.

Manufac tured by Taylor D esig n Group, In c. P.O. BOX 810262 Da lla s, TX 75381 ©2 008 by Tayl or De sign Grou p, Inc. All r ight s reserve d.

PRODUCT

ONLINE

WWW.INCR A.CO M

Page 2

INCRA M Ite R100 0H D OWNER’S M ANUAL

Assembly and Calibration

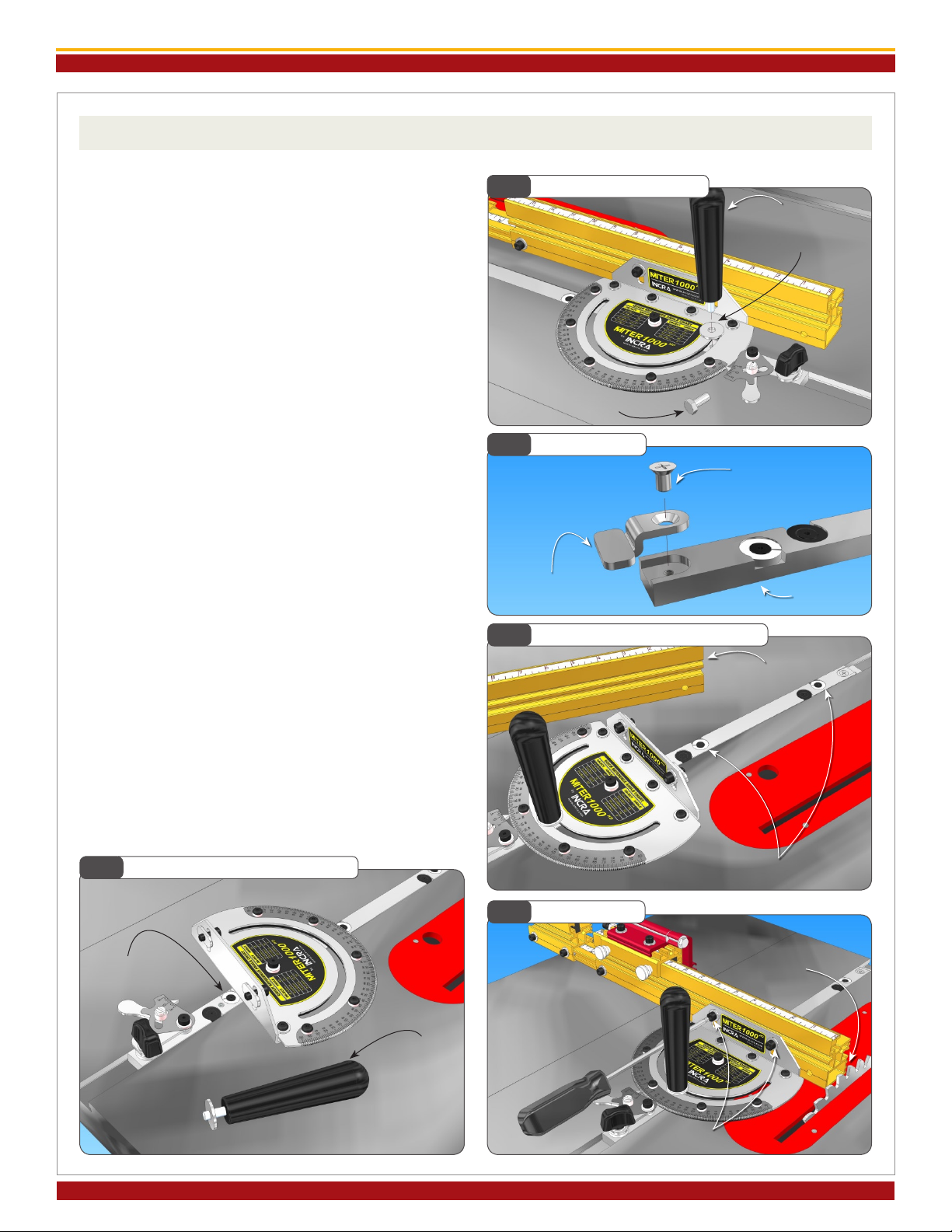

1. Attach Clamping Knob and T-Clip

Remove the hex bolt that secures the protractor head

and replace with the large threaded knob included in

the hardware pack. The washer on the hex bolt must

be used with the threaded knob, Fig. 1. If the Miter

slot in your table saw has a T-slot, attach the T-clip to

the end of the miter bar as shown in Fig. 2.

2. Adjust the Miter Bar

Loosen the (2) fasteners that secure the fence to the

fence-mounting bracket and remove the fence. Adjust

the miter bar at each of the (3) expansion mechanism

locations in the miter bar for a good t in your table

saw’s miter slot. Turning the screw clockwise expands

the mechanism. You’ll nd (2) of the expansion locations in front of the protractor. Adjust these (2) front

expansion points rst, expanding a little at each of the

locations until the bar slides smoothly, Fig. 3.

Remove the large clamping knob with washer and

pivot the protractor head to gain access to the rear

expansion point, Fig. 4. After adjustment, replace the

washer and large clamping knob.

Attach Clamping Knob

Fig. 1

Remove hex bolt

Attach T-Clip

Fig. 2

T-clip (use only in T-slot

miter channels)

Expand Miter Bar to Fit (front)

Fig. 3

Large knob

Washer

#10-24x1/4”

Phillips at head

screw

Miter bar

3. Attach the Fence

Place your Miter1000HD in the preferred miter slot

at your table saw. (Note: Left hand miter slot use

shown. See step 4 to convert fence for use in right

hand miter slot.) Attach the fence to the fence mounting

bracket and slide the fence to a position that leaves

safe clearance between the end of the fence and the

blade. Tighten the (2) 1/4-20 fasteners, Fig. 5.

Expand Miter Bar to Fit (rear)

Fig. 4

Adjust rear

expansion point

Remove knob

and rotate

protractor for

access.

Replace af ter

adjusting

rear expansion point.

Fig. 5

Attach Fence

Fence removed for

access

Adjust (2) front expansion points

Position for safe

clearance between fence

and blade

1/4-20 socket head screws

Page 2

Manufac tured by Taylor D esig n Group, In c. P.O. BOX 810262 Da lla s, TX 75381 W W W. I N CR A . C OM

Page 3

INCRA M Ite R100 0H D OWNER’S M ANUAL

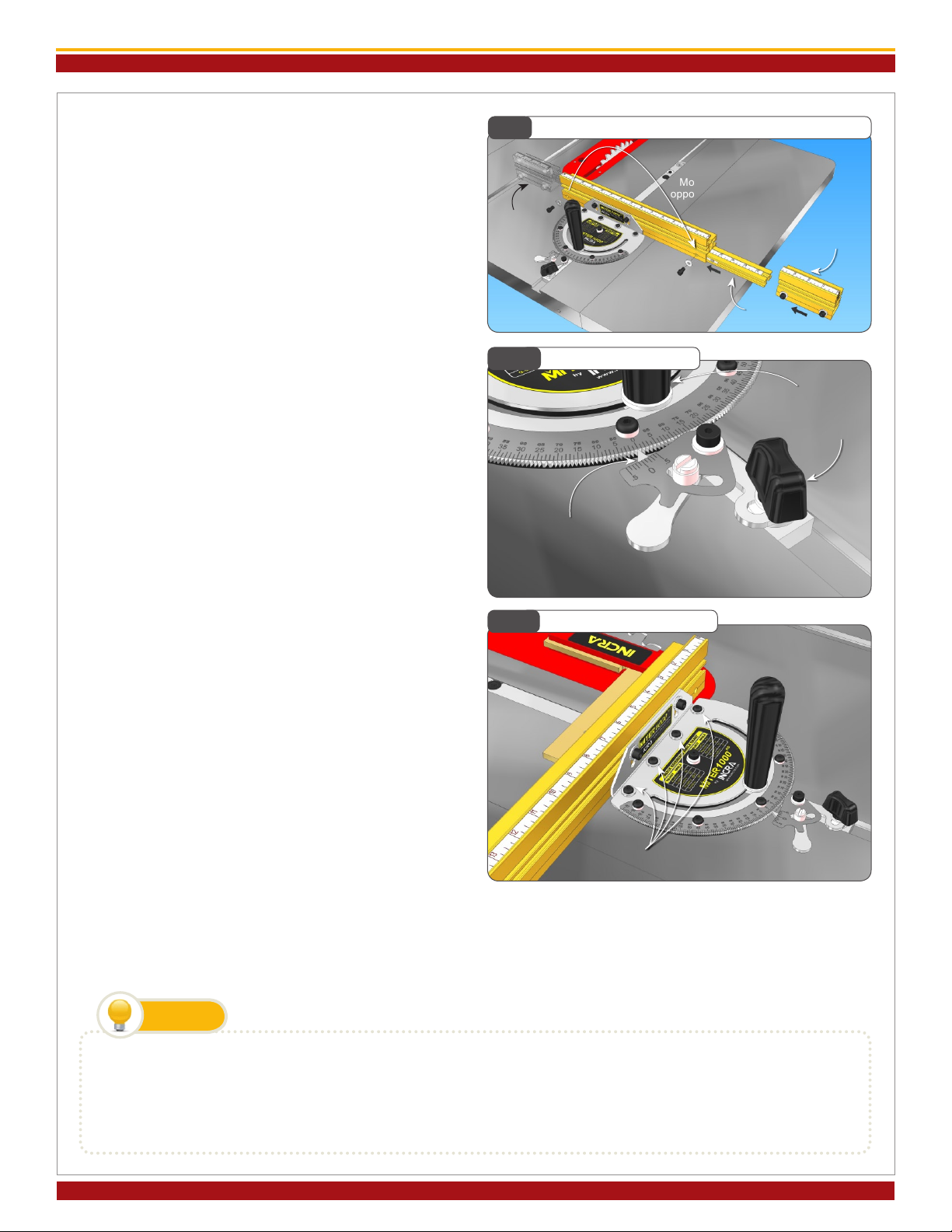

4. Left or Right of Blade

Your new Miter1000HD fence is factory congured

for use to the left of the blade. If you prefer to use

your Miter1000HD in the right hand miter slot just

follow the steps below.

Loosen the 1/4-20 socket head screw located at the

end of the 14” section of the fence, then slide out the

4” section of fence along with the attached extender

bar. Move the socket head screw, washer and rectangular nut to the hole on the opposite end of the fence.

Slide the extender bar assembly into the end of fence,

capturing the rectangular nut in the T-slot on the

extender bar. The higher numbers on the extender

bar scale should be closest to the saw blade. Loosen

the (2) socket head fasteners that secure the 4”

section of fence and reverse it. Tighten all fasteners,

Fig 6. Slide the scale in the top of the fence out

and replace with the included reverse reading (0-14”)

scale.

Converting Fence for use on Right Side of Blade

Fig. 6

Remove

extender bar

assembly

Fig. 7

Actuator tooth

engaged at 0°

opposite end of fence

Set Protractor to 0°

Move fasteners to

Extender bar

4” fence section

Tighten large

clamping knob, then

tighten actuator

thumbscrew

5. Ad j ust Fence Mount ing Bracket 90°

to Saw Blade

Fig. 8

Square Fence to Blade

Set the protractor head to read 0°, engaging the tooth

on the actuator rmly into the 0° notch on the protractor

head, Fig. 7. Tighten the large clamping knob then tighten

the actuator thumbscrew.

Using the supplied 1/8” hex key, loosen the (4) socket

head screws that secure the fence-mounting bracket

to the protractor head. Unplug your table saw, then

use a reliable machinist square to set the fence at 90° to

the saw blade, Fig. 8. Tighten the (4) socket head screws.

Loosen socket head screws and adjust

fence using reliable machinist square

This one time c alibr a t ion pre pares your INCR A

Miter1000HD for work in either miter slot. Just remember that the accuracy of the INCRA Miter1000HD at

any subsequent setting is dependent upon the accuracy of your initial 90° calibration. Verify this important

calibration with a test cut and ne tune as necessary.

TIP

Squaring the fence to your table saw top

e method used to join the fence-mounting bracket to the protractor head makes it easy to fine-tune the fence

perfectly perpendicular to your tabletop. To adjust, loosen the (4) socket head screws that secure the bracket and

slide a paper shim between the bracket and the underside of the protractor head. Placing the shim behind the screws

will increase the angle. Placing the shim in front of the screws will decrease the angle.

Page 3

©200 8 by Tay lor D esig n Grou p, In c. All righ ts re ser ved. R ev.12.23.08

Page 4

INCRA M Ite R100 0H D OWNER’S M ANUAL

Operation – Changing Angle Settings

Before using yo u r new INC R A M iter1000HD for

the rst time, take a few moments to review these

important operational procedures.

1. 1° Indexing (including 22-1/2° settings)

Loosen the actuator thumbscrew and pivot the

ac tuator tooth away from the notches located on the

perimeter of the protractor head. Loosen the large

clamping knob and rotate the protractor head and

fence to the desired angle, Fig. 9. Then rmly engage

the tooth on the actuator with the corresponding

notch on the protractor head. The actuator tooth

should point directly to the desired angle on the scale.

Tighten the large clamping knob, then tighten the

actuator thumbscrew, Fig. 10.

2 . C o nt i n uo u s A dj u st m e n ts (f o r a ng l e

settings ner than 1° increments)

Pivot the actuator tooth away from the notches on

the protractor head, aligning the arm over the miter

bar, and tighten the thumbscrew. Now loosen the

small nylon thumbscrew on the actuator and pivot the

1

/

10° vernier cursor toward the scale. Rotate the cur-

sor until it is aligned edge to edge with the scale and

tighten the thumbscrew. When you change miter

angles, just align the desired angle on the scale with

the “0” cursor line, Fig. 11. For 1/10° adjustments,

use the alignments as described in the 1/10° vernier

instructions on page 8.

Miter1000HD

Changing Angles

Fig. 9

Rotate protractor

Fig. 10

Locking the Protractor

Pivot the actuator tooth

away from protractor

Loosen large

clamping knob

and actuator

thumbscrew

Tighten large clamping

knob then tighten

actuator thumbscrew

Fig. 11

Continuous Adjustments

Firmly engage

actuator tooth with

protractor

CAUTION:

AFTER MAKING ANY ADJUSTMENTS TO T H E

Pivot cursor

to scale

MITER ANGLE OF YOUR INCRA MITER1000HD,

ALWAYS VERIFY SAFE CLEARANCE BETWEEN

THE FENCE AND THE BLADE BEFORE TURNING

Pivot actuator tooth away from

protractor and tighten thumbscrew

Page 4

Manufac tured by Taylor D esig n Group, In c. P.O. BOX 810262 Da lla s, TX 75381 W W W. I N CR A . C OM

ON THE SAW.

Page 5

INCRA M Ite R100 0H D OWNER’S M ANUAL

Flip Fence and Flip Shop Stop - Calibration and Operation

As you look at your new INCRA Flip Shop Stop and

Flip Fence for the rst time you will see an interesting

detail. The front face of the fence uses a tongue and

groove arrangement to accept a mating feature on the

ip arms, Fig. 12. When the ip arm is down with

the two opposing features engaged, it becomes

im possible for the sharp corner of a mitered board

end to wedge between the fence and ip arm. Combined with INCRA’s famous incremental positioning

capabilities, you’ll soon be duplicating cut off lengths

with machine shop precision.

Zeroing the Fence Scales

To zero the main fence scale for 90° work, rst set

the protractor to the 0° setting and lock in place.

Clamp the Flip Shop Stop to the fence so that the 0”

mark on the fence scale reads directly under the end

of the gold component of the Flip Shop Stop, Fig. 13.

Now loosen the (2) 1/4-20 socket head screws that

secure the fence to the fence mounting bracket and

slide the fence toward the blade until the Flip Arm on

the stop contacts the blade. Re-tighten the fasteners,

Fig. 13A.

Fig. 12

Fig. 13

Flip Shop Stop

Zeroing Fence Scale

Clamp Flip Shop Stop at

0” position

Tongue and groove

Protractor

set at 0°

For stopped cuts beyond the range of the main fence you’ll need to

calibrate the extender bar scale. Clamp the INCRA Flip Shop Stop to

the 4” fence extender. (Use the scale on the short section of fence as

a reference for clamping the stop to the same position each time you

use it.) Now loosen the 1/4-20 socket head screw located at the end

of the longer fence and slide the 4” fence and extender bar out. Use

a tape measure to set the distance between the blade and the ip arm

at 16” and re-tighten the fastener, Fig. 14. Now simply slide the scale

in the extender bar to read 16” at the end of the longer main fence

section, Fig. 14A.

Fig. 14

Setting Extender Bar Scale

Slide extender bar out

until ip arm is 16” from

blade then tighten fastener

Loosen fastener

Clamp

stop to

4” fence

section

Fig. 14A

16” at end of main fence

Fig. 13A

Align Scale

Slide scale to read

Slide Fence to Blade

Slide fenc e until ip

arm contacts blade,

then tighten fasteners

Page 5

©200 8 by Tay lor D esig n Grou p, In c. All righ ts re ser ved. R ev.12.23.08

Page 6

INCRA M Ite R100 0H D OWNER’S M ANUAL

For mitered cutting, a test cut is often the most accurate means of setting the fence and extender bar

scales since measuring to the tooth of a blade set at

an angle to the fence can be difcult. Begin by setting

the desired miter angle and check for safe clearance

between the fence and blade. Clamp the stop to the

fence about 10” away from the blade. Miter a piece of

scrap stock with this setup. Measure the length of the

cut piece, Fig. 14B. Then simply slide the scale on

the fence to read the length of the cut directly under

one end of the stop.

Micro Adjusting

To micro adjust your Flip Shop Stop’s position, begin

by loosening the (2) socket head screws located on

the top of the stop body. Now turn the micro adjust

socket head screw to fine tune the stop position,

Fig. 15. When unscrewing the micro adjust screw,

apply pressure to the stop body to keep it against the

screw end. After adjustment, always tighten the (2)

socket head screws on top of the stop body.

Fig. 14B

Fig. 15

Micro Adjusting

Loosen (2) socket

head screws

Setting Scales for Angled Cuts

Measure length

of cut

Slide scale to

read cut length

here

Flip Arms and Stop Rods

The dual ip arms and stop rods provide a variety of

stop congurations. The ip arms can be used without

the stop rods when you want to take advantage of the

fence/arm tongue and groove feature for stop control

on mitered board ends. Typically, you will use the

longer rod to join the two arms together, Fig. 16. This

produces an arrangement that, when pivoted, moves

both arms simultaneously. The rod can be positioned

so that it is the actual stop surface or it can be positioned slightly behind the front of the arm so that the

aluminum arm is the actual stop surface.

By placing one of the shorter 1-1/2” rods in each of

the two stop arms, you can use the two stop arms

independently, Fig. 17. For example, you can calibrate

one for work to the left of the blade and the other

for work to the right. On one side of the blade you

might want to position the stop rods to provide two

different cut off lengths from one stop position. By

using varying combinations of long or short rods you

can create as much as 7-3/4” between the two stop

positions.

Fig. 16

Fig. 17

Long Stop Rod

Short Stop Rods

Turn this socket head screw

to adjust

Long stop rod used to

join ip arms

Short stop

rods allow

independent

ip arm

use

Page 6

Manufac tured by Taylor D esig n Group, In c. P.O. BOX 810262 Da lla s, TX 75381 W W W. I N CR A . C OM

Page 7

INCRA M Ite R100 0H D OWNER’S M ANUAL

Making a Zero Cleara nce Wooden Su b

Fence

A sub fence can be used to provide tear out control as

well as support for your workpiece up to and beyond the

Fig. 18

Making a Sub Fence

2-1/2” max (see note)

5/16” through hole w/

3/4” dia. x 3/8” deep

counter bore

blade. A good material to use for making your zero

clearance sub fence is 3/4” medium density fiberboard

rectangular nut

(MDF). Use the drill and counter bore dimensions

shown in Fig. 18. Attach using the supplied fasteners. Adjust the length of the fence to accommodate

your application. Note: In applications where the

incremental stopping capability of the Flip Shop Stop

1/4-20 x 3/4”

socket head screw

1/4” at washer

1-1/16”

3/4”

is required, the wooden sub fence can be no taller

than 2-1/2”.

TIP

To avoid the saw blade pulling your workpiece into the cut, add a strip of adhesive backed sandpaper to the front

face of the wooden sub fence.

1/4-20

Expanded Flip Stop Clamping Mode

The two-part body design of the INCRA Flip Shop

Fig. 19

Expanded Flip Stop Clamping Mode

Gold component

Stop allows for use with up to a 3/4” thick wooden sub

fence. To expand the INCRA Flip Shop Stop, loosen

the (2) socket head screws located on the top of the

stop body, then slide the upper portion of the stop

off. Now slide the upper portion back on, capturing

the rectangular nuts in the second T-slot located on

the lower portion (gold component) of the stop body,

Sub fence

Loosen socket head

screws and slide red

assembly into 2nd T-slot

on gold c omponent

Fig.19.

WARRANTY

TAYLOR DESIGN GROUP, INC. WARRANTS THIS PRODUCT FOR ONE YEAR FROM DATE OF PURCHASE. WE

WILL REPAIR ANY DEFECTS DUE TO FAULTY MATERIAL OR WORKMANSHIP, OR AT OUR OPTION, REPLACE

THE PRODUCT FREE OF CHARGE. PLEASE RETURN THE FAILING COMPONENT ONLY, POSTAGE PREPAID,

ALONG WITH A DESCRIPTION OF THE PROBLEM TO THE ADDRESS BELOW. THIS WARRANTY DOES NOT

APPLY TO PARTS WHICH HAVE BEEN SUBJECTED TO IMPROPER USE, ALTERATION, OR ABUSE.

LIFETIME WARRANTY ON POSITIONING RACKS

IF AN INCRA POSITIONING RACK IN THIS TOOL BECOMES DAMAGED FOR ANY REASON, TAYLOR DESIGN

GROUP WILL REPLACE IT FREE OF CHARGE FOR AS LONG AS YOU OWN YOUR TOOL. RETURN THE DAMAGED RACK, POSTAGE PREPAID, PLEASE ALLOW 1 TO 2 WEEKS FOR DELIVERY.

Page 7

©200 8 by Tay lor D esig n Grou p, In c. All righ ts re ser ved. R ev.12.23.08

Page 8

INCRA M Ite R100 0H D OWNER’S M ANUAL

0° 1/10° left of 0° 2/10° left of 0° 3/10° left of 0°

9/10° left of 0°8/10° left of 0°

Your new M it er1000 HD fea tu res severa l enhanceme nt s not incl uded w it h the

standard M it er100 0. Am on g these i s the new 1/10° ver ni er cursor.

For readi ngs in 1° increments using the cursor, just align any of the protractor scale

marks with the “0” ma rk on the cursor. For 1/10° adjust ments, you wil l notice 5 marks

on either side of the “ 0” mark on the cursor. As you gentl y rotate the protractor you

will read the scale as fol lows: At 1/10° rotat ion, the rst mark aligns 1° away from the

original start ing point. At 2 /10 ° rota tion, the second mark aligns 2 ° away. At 3/10 °

rotat ion, the third mark aligns 3° away, etc. For 6/10 ° through 9/10 ° of rotat ion, watch

for al ignment s using the m arks on the opposite side of t he “0” cursor mark.

Sound complicated? It’s not! Just study th e examples on t his page.

5/10° lef t of 0° 6/10° left of 0° 7/10° left of 0°4/10° left of 0 °

Using Your New

1/10

° Vernier Cursor

Manufactured by:

Taylor Design Group, Inc.

P.O. BOX 8102 62 Dallas, TX 753 81

www.incra.com

INCRA is a Registered Trademark of Taylor Design Group, Inc.

©200 8 Taylor Design Group, Inc.

INCR A Tools are pro tect ed by one o r more of the f oll owin g US pat ents :

#4, 793, 60 4, #4,93 0,2 21, #5,195,73 0, # 5,2 75,074 , #5, 42 3,3 60, # 5,716,04 5, # 6,2 37,457,

#6,5 57,601, #6,67 2,190. Other patents grante d or pendin g.

Page 8

Manufac tured by Taylor D esig n Group, In c. P.O. BOX 810262 Da lla s, TX 75381 W W W. I N CR A . C OM

MADE IN THE

USA

©200 8 by Tay lor D esig n Grou p, In c. All righ ts re ser ved. R ev.12.23.08

Loading...

Loading...