Page 1

INCRA

INCRA’S PATENTED LEAD SCREW TECHNOLOGY FOR THE ULTIMATE IN PRECISION WOODWORKING CAPABILITY

OWNER’S MANUAL

Please read this owner’s manual and keep it at

hand for reference.

From typical fence system applications such as

grooving, dadoing, rabbeting, edge forming, and

ripping to advanced joinery functions, your new

INCRA LS Positioner represents the

ultimate in quality precision

tooling for your dream

shop. Incra’s patented lead

screw driven positioning

element sets a new

standard for positioning

accuracy guaranteeing

fence placement to within

two thousandths of an inch

over the full range of the

fence with zero repeatability error.

This translates to perfect cutting results,

regardless of skill level – rst time, every time. If

you are interested in joinery for your next project, you

need not look further than your new LS Positioner for

superior box joint and dovetail capability. Whether

you are cutting a simple equally spaced box joint,

or the exquisite INCRA Double Dovetail, you’ll nd

the simplicity of our template guided joinery system

makes other joint making tools obsolete.

CONTENTS

Systems Configurations ........ 2

Safety .................... 4

Getting Acquainted........... 4

Setup .................... 5

Pro II Fence Installation ....... 6

Wonder Fence Installation ....... 8

Shop Stop ................. 10

Operation ................. 12

Applications................ 14

Adjustments................ 14

Auto Centering Scale.......... 15

Warranty ................. . 16

Page 2

LS Positioner Base

Right Angle Fixture

LS Positioner Carriage

LS Positioner “Standard System”

28” Pro II Fence

13” Telescoping Stop Extender Bar with Stop

Incra Shop Stop

2 INCRA Woodworking Tools & Precision Rules

Page 3

Hi-Rise Fence Cap

Right Angle Fixture

Note: Also available for current Ultra owners, the Incra LS

Upgrade Package includes only the LS Positioner Carriage

Wonder Fence

Heavy Duty Split Fence

and Base as shown in Fig. 1 on page 5.

LS Positioner Base

LS Positioner “Super System”

LS Positioner Carriage

Incra Shop Stop

13” Telescoping Stop Extender Bar with Stop

28” Pro II Fence

INCRA LS Positioner Owner’s Manual 3

Page 4

SAFETY

Important safety instructions for using the INCRA LS Positioner

Before using the INCRA LS Positioner, read and

follow all of the instructions and safety information

in this manual.

When using the INCRA LS Positioner in

conjunction with any other tool, rst read and

follow all instructions and safety information in that

tool’s owner’s manual.

When mounted to a table surface, make sure that

all of the mounting screws are securely tightened

and the INCRA LS Positioner is rmly held in place.

Always turn off the power and make sure that the

bit or blade is fully stationary before moving the

INCRA LS Positioner to any new setting.

Always keep both hands behind the fence when

moving the INCRA LS Positioner to a new setting.

Before making a cut, always make sure that the

carriage clamp is fully engaged and the fence is

securely locked in place.

When using the INCRA LS Positioner with other

tools, make sure that all safety guards and other

safety equipment supplied by the manufacturer of

that tool are securely in place and functional. Never

let the INCRA LS Positioner interfere with another

tool’s safety equipment.

Use appropriate safety devices. Keep hands

clear of the bit or blade. Always use a push stick,

rubber soled push block, or other safety device to

keep your hands safely away from the cutting tool.

Wear safety glasses, hearing protection and

follow all normal shop safety practices.

DO NOT alter or modify the INCRA LS Positioner in

an attempt to use it with non-INCRA accessories.

Never let the bit or blade come into contact with

any part of the INCRA LS Positioner, INCRA Shop

Stop, or INCRA Right Angle Fixture.

GETTING ACQUAINTED

Before setting up and using your new INCRA LS Positioner, take a few moments to become better acquainted with the tool by reviewing the following component descriptions and the illustration in Fig. 1.

Lead Screw Positioning Element

The LS Positioner obtains its great accuracy and

repeatability from the precision lead screw, which

positions the fence in exact increments of

(1mm metric version.)

1

/32”

Auxiliary Scale Slots

Four auxiliary scale slots are provided to allow

additional setups and cutting operations to take

place without altering the primary scale position.

Simply slide the supplied

scale into position as needed for reference.

The friction t holds the scales securely during

cutting operations. These extra slots are great

for advanced joinery using the INCRA templates.

You can even leave your most frequently used

joinery templates from the optional INCRA Master

Reference Guide & Template Library permanently

installed.

1

/32” or 1mm “oating”

Three-Position Carriage Clamp

By pushing the carriage clamp down into the

“unlocked” position, the carriage is free to glide to

the next setting. Pull the clamp up to the center

position for micro adjusting. Pull the clamp up to

the nal position and the carriage is locked solidly

in place.

Hairline Cursor and View Windows

The large hairline cursor and view windows

provide a clear visual reference of the fence

location and span the width of the carriage top

and all ve scale slots. The factory placement of

the cursor can be moved to the rear view window

location for use on smaller router tables.

LS Base

The LS Base contains the threaded segment that

engages with and functions to locate the

carriage. It also houses the three-position carriage

clamp, the hairline cursor, and view windows.

Carriage

The reinforced square tube design of the carriage

provides the ultimate in strength and support for

your fence. It supports the lead screw positioning

element and the micro adjust knob.

Stainless Steel Primary Scale

After setting up your INCRA LS Positioner and

“zeroing” to the bit or blade, position this scale to

read 0” under the hairline cursor. Use this scale

as the primary source for readout of fence to bit or

blade distance.

4 INCRA Woodworking Tools & Precision Rules

Page 5

Fence Mounting Bracket

This heavy steel bracket provides a quick and

easy means to attach the Pro II Fence, the Wonder

Fence, or the TS table saw fence.

Micro Adjust Knob

With the carriage clamp in the micro adjust

position, use this knob to ne-tune the location

of your fence in

metric version.) Ball bearing engaged detents on

the knob provide an audible click for each

(1/20mm) of adjustment. The pointer and easy

to read scale give a clear readout of your fence

1

/1000” increments (1/40mm for

1

/1000”

movement. Turning the knob clockwise moves the

fence closer to the cutter. Turn it counterclockwise

and the fence moves away from the cutter. Each

full turn of the knob moves the fence

for the metric version.

1

/32” or 1mm

Micro Adjust Scale Dial

This laser engraved dial provides a clear reference

for micro adjustments. Each mark on the dial

represents

After micro adjusting, the dial can be re-zeroed to

the pointer for future adjustments.

1

/1000” (1/40mm for metric version.)

FIG. 1

SETUP - MOUNTING TO YOUR ROUTER TABLE

Note: If you are setting up a table saw-based LS,

read the Getting Acquainted and Operations section

of this manual, then follow the instructions in the

TS-LS owner’s manual.

Drill Mounting Holes

1

Unlock the carriage clamp and carefully remove

the carriage from the LS base. For maximum access

to fence system range, locate the leading edge of

the LS base the following distance from the center

of your router collet: 19¾” for the 17” (430mm)

range model or 27¾” for the 25” range model, Fig. 2.

Center the LS Base across the width of your table. If

you have a router table top that is not long enough to

handle the full range of your LS Positioner, see the

Tip on page 6 for an easy way to extend your table

dimensions.

INCRA LS Positioner Owner’s Manual 5

Note: While it is permissible to allow some of the

LS Base to overhang the table, a minimum of 4” of

the LS Base must be overlapped onto the table for

secure mounting.

FIG. 2 Locate leading edge of LS Base on your router table

Leading Edge

19¾” (17” model)

27¾” (25” model)

LS Base

Page 6

Extending your router table length

Screw aluminum or steel angle to the

underside of the router table to provide

support arms for a table extension, Fig. 3.

The extension needs to be ush and parallel

to the table top. Shim into alignment as

necessary.

Once you have determined where the leading edge

of the LS Base will be positioned, mark a line on the

table at this spot. The line should be parallel to the

back edge of your router table. Measure back 1”

5

from this line and mark positions for (2)

/16” diameter

mounting holes spaced 5½” apart. Measure back

another 2” further and mark positions for (2) more

5

/16” diameter holes, Fig. 4. (If your table permits,

increase the spacing between the 2 sets of holes.)

Drill the holes.

Attach LS Base to your Router

2

Table

Open the LS Base Mounting Hardware Pack A-21.

Place the (4) ¼-20 x 2” hex bolts through the holes in

the table and loosely fasten with ¼” washers and hex

nuts. Now slide the heads of the bolts into the T-slot

located on the underside of the LS Base, Fig. 5.

Square the base to your table edge and tighten the

fasteners. Now slide the carriage back into the base

and pull the carriage clamp up to lock the carriage in

place.

FIG. 3

Existing

router

table top

Extension

wing

Wood

screws

Aluminum or steel angle

FIG. 4 Drill mounting holes

Mark where leading

edge of LS Base will

be positioned

5

Drill

/16” diameter holes

1”

2” minimum

5½”

Note: If you have an “Incra ready” router table with

T-nuts installed in the pre-drilled mounting holes, use

the (6) ¼-20 x 1¾” pan head Phillips screws with ¼”

washers to attach the LS Base as shown in Fig. 6.

FIG. 5 Aach LS Base to router table

Slide LS

Base onto

heads of hex bolts

¼-20 x 2” hex bolt

¼” flat washer

¼” hex nut

FIG. 6 Mounting for “Incra Ready” router table

PRO II FENCE INSTALLATION

The Pro II Fence, included in both the Standard

and Super System packages, provides a 28”

long reference for all of your cutting operations.

Machined to perfection, it includes a 1” x 1” opening

to handle all of your grooving, dadoing, rabbeting

and joinery applications. The fence top includes

INCRA positioning racks that work in conjunction

with the INCRA Shop Stop for perfectly repeatable

stopped cuts. The self-storing stop extender bar

permits stopped cuts beyond the length of the

fence and the front T-slot allows easy attachment of

user-made sub fences or the Super System Wonder

Fence.

¼-20 x 1¾” pan

head Phillips screws

¼” flat washer

(STANDARD & SUPER SYSTEM ONLY)

6 INCRA Woodworking Tools & Precision Rules

Page 7

Attaching the Pro II Fence

Carefully slide the carriage into the LS Base and pull

the carriage clamp up into the fully locked position.

Open the Incra Pro II Fence Hardware Pack A-07.

Place a ¼” washer on each of the (2) ¼-20 x ½”

socket head screws and insert through the slotted

holes located on the steel fence mounting bracket.

Loosely thread on the ¼-20 rectangular nuts, then

slide the nuts into the T-slot located on the rear of the

Pro II Fence. Position the fence so that the carriage

is approximately centered on the fence length and

tighten the (2) mounting screws with the supplied hex

tool, Fig. 7.

Installing Pro II Extender Bar

and Stop

Place a ¼” washer on the ¼-20 x 3/8” socket head

screw and insert through one of the holes located

at either end of the Pro II Fence. Loosely thread on

the ¼-20 rectangular nut and slide the extender bar

into the cavity in the fence, capturing the rectangular

nut in the T-slot located on the extender bar. The

scale on the extender bar should be face up. Slide

the extender bar until only about 1” of the bar

remains exposed and tighten the fastener, Fig. 8.

Place a ¼” washer and a

the ¼-20 x 2” socket head screw, insert through the

extruded hole located on the extender bar stop, and

loosely thread on the ¼-20 rectangular nut. Slide

the nut into the T-slot located on the front of the

extender bar. Slide the extender bar stop until the

at side of the stop contacts the end of the Pro II

Fence. Tighten the fastener, then slide the scale to

read 0” at the end of the fence extrusion, Fig. 9.

1

/8” thick nylon washer on

Pro II Fence installation

FIG. 7 Aach Pro II Fence

Pro II

Fen ce

Steel fence

mounting bracket

¼”-20 rectangular nut

FIG. 8 Install Pro II extender bar

¼” flat washer

¼-20 x ½”

socket

head screw

¼” flat washer

Pro II Fence

Pro II

extender

bar

FIG. 9 Install extender bar stop

3

/8”

¼”-20 rectangular nut

Slide scale to

read 0” here

Pro II

extender

bar

Extender bar stop

¼”-20 rectangular nut

1

/8” nylon

washer

Pro II Fence

¼” flat

washer

¼-20 x 2”

socket head

screw

¼-20 x

socket head

screw

FIG. 10

Extender bar

inverted for storage

When not in use, the extender bar and

stop can be stored in the fence. Just

slide the extender bar out, turn it over so

that the scale is face down, and insert back

into the fence. Tighten the fastener to secure

the bar, Fig. 10.

INCRA LS Positioner Owner’s Manual 7

Page 8

Adjusting the Fence Angle

After mounting the Pro II Fence, pull the carriage

clamp up to the fully locked position and check the

angle of the fence to your tabletop using a reliable

square. Any deviation from 90° can be adjusted to

perfection by placing a masking tape shim between

the mounting bracket and the fence as shown in

Fig. 11.

FIG. 11

Adjusting the

fence angle

Place shim here if

angle is greater

than 90º

Mounting an Auxiliary Fence to

your Pro II Fence

Should you have an application requiring the use

of a user-made wooden auxiliary fence, you’ll nd

FIG. 12 Mounting an auxiliary fence

the T-slot in the front face of the Pro II Fence is

5

designed to capture a ¼-20 hex nut. Just use the

dimensions in Fig. 12 to drill and counterbore the

fence, then use (2) ¼-20 Phillips pan head screws,

/16” dia. through holes with 3/4” dia. counterbore

¼-20 hex

nuts

(2) ¼” at washers, and (2) ¼-20 hex nuts to secure

the auxiliary fence to the Pro II Fence. Adjust the

length and thickness of the fence to accommodate

your application.

WONDER FENCE INSTALLATION

While you should read the Safety, Operation and

Applications sections of the included Wonder

Fence owner’s manual, it is not necessary

to read the Fence and Hi-Rise mounting

instructions in that manual. Just follow the

instructions below for proper mounting of the

Wonder Fence and Hi-Rise Fence Cap to your

LS Positioner.

LS Positioner Super System

90º

1¾”

Place shim

here if angle is

less than 90º

14”

(SUPER SYSTEM ONLY)

Attaching the Wonder Fence

to the Pro II or TS Fence

Note: In the 17” (430mm) and 25” Super System

packages, the Wonder Fence front fence halves

are shipped already installed onto the Pro II Fence;

however, you should read and become familiar

with the following installation procedure for future

adjustments or removal.

Insert the supplied hex tool through the (2) large

diameter access holes located on the front of

each Wonder Fence half and loosen the (2) socket

head screws. Do not remove the rectangular

nuts. For a better view of the fasteners, loosen the

thumbscrew and slide the black plastic view panel

located on the top of each fence half, Fig. 13.

8 INCRA Woodworking Tools & Precision Rules

FIG. 13

Use hex tool to loosen fasteners

through two larger holes

Page 9

Slide the (2) rectangular nuts on each Wonder

Fence half into the T-slot located on the front face

of the Pro II, Fig. 14 or the TS Fence, Fig. 15.

Position the Wonder Fence halves so that your

router collet is centered in the opening between

the fences, then tighten the (2) socket head screws

on each fence half. Slide the view panel back in

place and tighten the thumbscrew.

FIG. 14 Aaching Wonder Fence to the Pro II Fence

Rectangular nuts

slide into T-slot

on front of Pro II

Fen ce

Wonder Fence

Pro II

Fen ce

FIG. 15 Aaching Wonder Fence to the TS-LS Fence

Attaching the Wonder Fence Hi-Rise Fence Cap

Attach the Fence Cap Braces

1

Open the Wonder Fence Hi-Rise Fence

Hardware Pack A-09. Place a ¼” washer on each

of the (2) ¼-20 x

thread one screw into each of the (2) dual pilot

rectangular nuts. Place a ¼” washer on a ¼-20 x ½”

socket head screw and insert through the hole on the

front of each fence brace. Loosely thread the screw

into the remaining hole on the dual pilot rectangular

nut, Fig. 16. Repeat for the remaining fence brace

and dual pilot nut.

3

/8 button head screws and loosely

FIG. 16

Fence cap

brace

3

¼-20 x

buon head

screw

/8”

Wonder Fence

¼-20 x

½” socket

head screw

¼” flat

washer

Dual pilot

rectangular nut

Rectangular nuts

slide into T-slot on

front of TS Fence

TS Fence

Slide the dual pilot nut on each fence brace

assembly into the T-slot located on the top of the

Pro II Fence. Use the forward T-slot located on the

5

TS Fence. Space the two braces 7

/8” apart on

the fence. Tighten all (4) fasteners, Fig. 17.

Open the Wonder Fence Brace Support Hardware

Pack A-10. Place a ¼” washer on each of the (2)

¼-20 x ½” socket head screws supplied and insert

through the slotted holes located on the support

brackets. Loosely thread on a ¼-20 rectangular

nut, then slide the nut into the T-slot located on the

rear of the Pro II Fence.

Position the support brackets directly under the

fence cap braces. Slide the support brackets up

to rmly contact the underside of the fence cap

braces, then tighten the socket head screws,

Fig. 18.

Note: Support brackets are not required for use

on the TS Fence.

FIG. 17

Dual pilot rectangular

nuts captured in T-slot

FIG. 18

Fence cap

brace

Fence cap

brace

”

5

8

/

7

¼-20 x ½” socket

head screw

Support

bracket

¼” flat

washer

¼-20 rectangular nuts captured in

T-slot in rear of Pro II Fence

INCRA LS Positioner Owner’s Manual 9

Page 10

Attach the Cap Extender

2

Place a ¼” washer on each of the (2) #10-32

x ½” Phillips pan head screws and insert through

the slotted holes located in the fence cap extender.

Loosely thread a #10-32 hex nut onto each fastener,

then slide the hex nuts into the T-slot located on

the top of each fence cap brace. Position the cap

extender so you can later gain access to the socket

head fasteners on each fence cap brace through

the slotted holes. Pull the cap extender forward

until it rmly contacts the back of each brace and

tighten the (2) Phillips head screws. See Fig. 19 and

Detail 19A.

FIG. 19 Aach cap extender

First: Insert

fasteners and

slide #10-32

hex nuts into

T-slot on top

of braces

Brace

#10-32 x ½”

Phillips screw with

¼” flat washer

Third: Slide

cap extender

forward to

contact brace,

then tighten

screws

Second: Position cap

extenders to allow future

access to socket head

screws through sloed

hole

Fence cap extender

DETAIL 19A

3

Attach and Align Fence Cap

Place the 24” long fence cap on top of the cap

5

extender and attach using the (2) ¼-20 x

/8” socket

head cap screws with ¼” washers and lock nuts.

Use a straightedge to align the leading edge of the

fence cap with the front face of the Wonder Fence

and tighten the two cap mounting screws, Fig. 20.

To remove the fence cap and braces, just remove the

two fasteners that secure the braces to the top of the

Pro II or TS Fence and lift the entire unit off, Fig. 21.

Place the fasteners back into the threaded holes in

the dual pilot rectangular nuts for storage.

SHOP STOP

FIG. 20 Aach and align fence cap

¼-20 x 5/8” socket head screws

First: Aach

fence cap to

cap extender

FIG. 21

To remove fence

cap and braces,

unscrew the

(2) ¼-20 x

socket head

screws

5

/8”

Fence cap

Second:

Use

straight-edge to

align fence cap, then

tighten screws

When used in conjunction with your new Pro II

Shop Stop

Fence or Wonder Fence, the INCRA Shop Stop

provides the same precise positioning capabilities

that your LS Positioner offers. The patented

incremental positioning of INCRA’s saw-toothed

racks found on the Shop Stop and your INCRA

fence allow perfectly repeatable stop locations

1

at any multiple of

/32” (1mm for metric version.)

The two-piece body can be micro adjusted to any

position between steps and can be congured to

clamp to your fence even when using wooden sub

fences up to ¾” thick. Follow the instructions on

the next page to set up and use the Shop Stop.

10 INCRA Woodworking Tools & Precision Rules

Page 11

Shop Stop Assembly

After removing the Shop Stop from the packaging,

loosen the two white nylon thumbscrews and clamp

the stop to the outfeed end of your INCRA fence.

Now loosen the #10-32 x 3½” Phillips head screw

and slide the red vertical stop arm onto the hex nut,

Fig. 22. Make sure that the indexing lip on the arm

wraps around the front of the stop body and that

the arm is at against the end of the body, Fig. 23.

Tighten the fastener to secure the arm a short

distance above your

router table to provide

clearance for sawdust.

The fastener and stop

arm can be reversed

for use at either end of

your fence.

FIG. 23 Top view of vertical stop arm

Indexing

lip

FIG. 22 Shop Stop assembly

Vertical stop arm

Shop Stop

#10-32 x 3½” Phillips head screw

#10-32

hex nut

slides into

T-slot on

vertical

stop arm

#10 flat washer

Micro Adjusting

Fine-tuning the position of your Shop Stop relative

to a cutter is easy and accurate. Just loosen the

two black thumbscrews on top of the Shop Stop

1

body about

/8 turn, then turn the machine screw

located at the end of the stop, Fig. 24. Each full

turn of the screw moves the stop surface exactly

1

/32” (approx. 1mm.) When turning the screw

counterclockwise, push the stop body toward the

screw. Always tighten the two black thumbscrews

after micro adjusting.

Expanded Clamping Mode

The two-piece design of the INCRA Shop Stop

permits use of a ¾” thick wooden auxiliary fence

without interfering with the stop’s ability to clamp

to your INCRA Fence. To change the stop to

expanded clamping mode, loosen the two black

thumbscrews and slide the stop body (red) off of

the stop cap (gold). Now slide the (2) rectangular

nuts on the stop body into the alternate T-slot on

the cap, Fig. 25. Tighten the two clamping knobs.

FIG. 24 Micro adjusting

First: Loosen both black thumbscrews.

Leave both white thumbscrews fully

tightened if already installed on fence

Second: Turn

micro adjust

screw to move

stop body

position

Third: Tighten

both black

thumbscrews

Stop body

FIG. 25 Converting from standard to expanded clamping mode

Standard Mode Expanded Mode

Stop body

Small gap

INCRA LS Positioner Owner’s Manual 11

Loosen black thumbscrews

and slide stop body off of cap

Stop cap

Large gap

Reassemble stop body to

stop cap as shown

Page 12

Zeroing the Shop Stop

In order for your INCRA Shop Stop to

accurately locate your work piece for a

cut, you must rst “zero” your Shop Stop

to the cutter and position the sliding scale

on your fence. For most applications at

the router table you will be using your

Shop Stop on the outfeed fence to limit

the length of a cut relative to the front end

of a board. Follow the steps detailed in

Fig. 26 to zero to your cutter.

Once the Shop Stop is zeroed to the

router bit as shown in Fig. 26, you now

have the choice of setting the sliding

scale on your INCRA Fence to one of

three initial positions. See Fig. 27 and

Detail 27A.

FIG. 26

Fourth: Slide scale

to read directly

under end of stop

cap. Use one of the

initial scale seings

from Fig. 27

Third: Loosen black thumbscrews 1/8 turn

and micro adjust until stop arm touches

end of board. Retighten thumbscrews.

Second: Clamp Shop Stop

to fence with the vertical

stop arm as close as

possible to the board

First: Slide square cut

board to contact “high

spot” on the router bit

DETAIL 27A

C

B

A

FIG. 27

OPERATION

Moving to a New Scale Setting

Moving the fence to any new scale setting is

just as easy as moving any other fence you’ve

used before. Push the carriage clamp down to

unlock the carriage, then slide the fence as you

sight through the hairline cursor. When you see

your measurement under the hairline cursor,

pull the clamp up to the locked position, Fig. 28.

Remember that the LS Positioner will only clamp

1

every

don’t try to clamp in between scale marks. It just

won’t work!

/32” or 1mm with the metric version, so

Although the clamping pressure has

been factory adjusted, you may wish

to ne-tune the pressure to suit your

individual feel. If so, use the thin plastic

shims provided and follow the instructions

beginning on page 14.

Slide scale on fence to one of

three initial positions

A: Slide scale to 0” for

a direct readout of

dimension “A”

(Total length of cut)

B: Slide scale to “minus

½ of bit diameter”

for direct readout of

C

B

A

dimension “B”

C: Slide scale to “minus

bit diameter” for direct

readout of dimension “C”

CAUTION: For your safety, keep your hands

behind the fence when moving to any new

scale setting.

FIG. 28 Moving to any new scale seing

First: Unlock carriage clamp

Third:

Return

clamp to

upright

Second: Slide fence as

you view scale through

hairline cursor

“locked”

position

12 INCRA Woodworking Tools & Precision Rules

Page 13

Micro Adjusting your Fence

Position

The micro adjust feature of your LS Positioner allows for

precise positioning of the fence to any location between

1

/32” or 1mm incremental spacing of the lead screw.

the

You’ll nd this feature extremely handy the next time

you need to widen a mortise by a hair for a great tting

mortise and tenon joint. Use the micro adjuster for a

awless t when cutting grooves to accept inlay strips or

to loosen up a tight tting tongue and groove joint. You’ll

nd it especially useful for setup operations like “zeroing”

to your cutter, or “centering” for joinery. Here’s a step-bystep look at operating your LS Positioner’s micro adjuster.

See Fig. 29 as you follow the steps.

Set Carriage Clamp to Micro Adjust

1

Position

Lower the carriage clamp to completely unclamp the

carriage, then raise the carriage clamp to the center

position. This center position for the carriage clamp

softens the clamping pressure on the carriage to permit movement during micro adjusting.

Micro Adjust the Fence Position

2

Rotate the red micro adjust knob located at the

forward end of the carriage. Turn the knob clockwise

to move the fence toward the cutter, or counterclockwise to move the fence away from the cutter. Ball

bearing engaged detents on the knob provide an

audible click for each

version) of fence movement.

Lock the Carriage Clamp

3

Pull the carriage clamp up to lock the carriage

in place. Gauging the distance moved when micro

adjusting is easy. A full turn of the knob equals

(1mm for metric version.) For smaller adjustments,

the black dial is marked in

After micro adjusting, you can re-zero the dial to the

pointer by rotating the dial (not the red knob) with

your ngers. See Fig. 30.

1

/1000” (1/20mm for metric

1

/32”

1

/1000” (1/40mm) increments.

FIG. 29

Third: Turn

micro adjust

knob to finetune fence

position

Fourth: Pull

carriage clamp

up to “locked”

position

FIG. 30

Micro adjusting

Re-zeroing the micro adjust dial

After micro adjusting, rotate the

dial (not the knob) to align the

zero with the pointer

For a truly precise “zeroed” setup, follow

the instructions above, then move the

fence to a scale reading of ¼” and make a

test cut on a piece of scrap stock. (Make sure

the scrap stock has a straight and square fence

bearing edge.) Use a pair of machinist calipers to

measure the distance between the groove and the

edge of the board. If it does not measure exactly

.250”, just use the micro adjuster to accurately ne-

tune the remaining distance.

Second: Pull carriage clamp up to

center “micro adjust” position

First: Push

carriage

clamp down

to “unlock”

Micro adjust knob

Micro adjust dial

Pointer

0

Zeroing the Fence to Your Cutter

In order to ensure accurate cutting results from any

fence for general purpose routing, the fence must rst

be “zeroed” to the cutter, Fig. 31. To zero your fence,

unlock the carriage clamp and slide the fence up to

the edge of the cutter. Sight down the length of the

fence to check for a gap between the fence and the

cutter. Fine-tune any remaining distance by micro

FIG. 31

First: “Unlock”

carriage clamp and

slide fence up to

cuer

Third: Lock carriage

clamp

Zeroing the fence to your cuer

Second: Raise carriage

clamp to “micro adjust”

position and rotate

micro adjust knob until

gap between fence and

cuer disappears

adjusting the fence position. When the gap of light

disappears, the cutter will be “zero” distance from

the fence. Check to make sure that the router bit is

safely centered in the opening in the fence. Return the

carriage clamp to the locked position, then slide the

measuring scale to read 0” under the hairline cursor.

INCRA LS Positioner Owner’s Manual 13

Fourth: Slide

stainless steel

primary scale to

read 0” under the

hairline cursor

Page 14

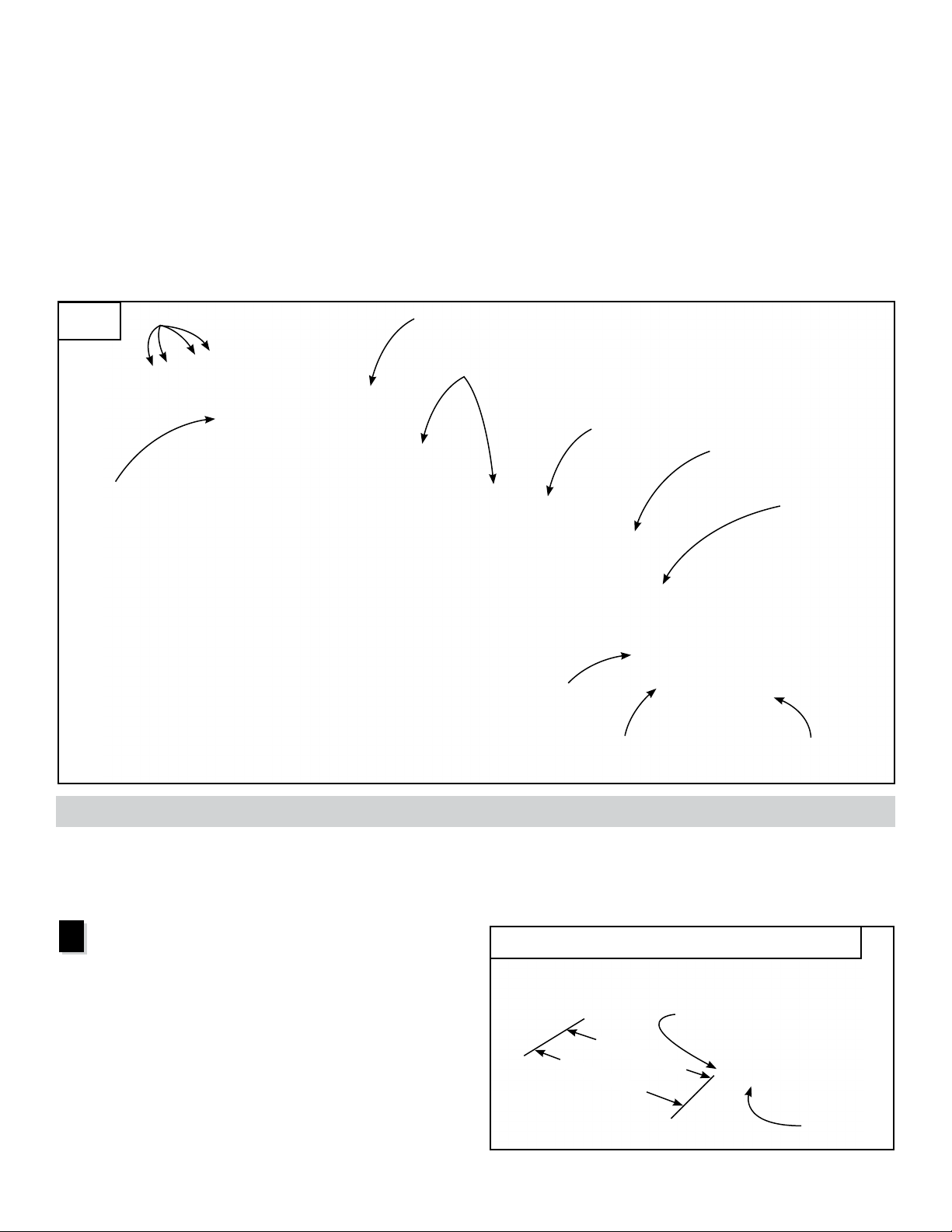

APPLICATIONS

General Purpose Fence

The essence of your INCRA LS Positioner is its

ability to accurately position your board for a

cutting operation. In a nutshell, it is a precision

fence system. Even when used as a joint maker,

you are simply applying a method of work to a

very accurate fence system to produce the many

possible joints. Above all else, the LS Positioner

gives you the ability to make a cut exactly where

you want it, Fig. 32.

Using your LS Positioner as a general-purpose

fence is just as easy as using any other fence in

your shop. In fact, it shares in common four things

that all fences have: the straight edge or fence that

your board will be pushed along as you make a cut,

a scale, a hairline cursor, and a clamp. You will use

your LS Positioner as you would any fence. That

is, rst you’ll unclamp the carriage, then you’ll look

through the hairline cursor as you move the fence.

When you see your measurement come under the

hairline, you’ll clamp the fence in place.

Of course, this is where the comparison ends

because unlike other fences, when you clamp the

LS Positioner in place, it is exactly where you want

it to be. Just get the mark on the scale close to

the hairline cursor and the Automatic Positioning

Control™ of the patented Lead Screw mechanism

moves the fence to the exact location as you pull

the carriage clamp up to lock the fence in place. It

really is that easy. You’re sure to nd many cutting

situations in your shop where the precision of the

LS Positioner will benet you and your work.

FIG. 32 Incra LS Positioner

Joint Making

Joint making represents one of the most exciting

applications for your INCRA LS Positioner. Just

by applying a little technique to the considerable

precision of the LS Positioner, you’ll be able to add

joinery for box and drawer making to your list of

shop skills. The INCRA Master Reference Guide &

Template Library

included with the

Standard and Super

System Packages is

a complete source

book for joinery,

including step-bystep instructions for

box joints, half blind

dovetails, through

dovetails, the INCRA

double dovetail and

the double-double

box joint, Fig. 33.

FIG. 33 Master Reference Guide

ADJUSTMENTS

All of the components and features of your new

INCRA LS Positioner have been factory set

and should require no further adjustment. If,

however you wish to adjust or recalibrate these

components, the following information is provided

to assist in performing the adjustments.

Adjusting the Clamping Pressure

The LS Positioner carriage clamp assembly was

designed to make it easy for the operator to adjust

14 INCRA Woodworking Tools & Precision Rules

the clamping pressure using the carriage clamp pad

shims supplied in Hardware Pack A-22. Here’s how:

Unlock the carriage clamp and press the

black UHMW bearing pad forward with your nger as

you use a

passes through it. Slide the black UHMW bearing pad

up and out of the LS Base.

Note: Do not pull the carriage clamp up with the

black UHMW bearing pad removed.

1

/8” hex key to remove the set screw that

1

/8” thick

Page 15

You’ll notice one or more thin plastic shims in the

cavity behind the metal spring engager, Fig. 34.

To change the clamping pressure, simply add or

remove shims. If you want to increase clamping

pressure, add one of the supplied shims. If you want

to decrease clamping pressure, remove one of the

thin shims. The matte nish shim is .005”, the clear

shim is .010” and the white shim is .020”. When

making adjustments, add or remove only .005”

at a time, and keep the thinner shims between

the metal spring engager and the white shim,

Fig. 35. Press the metal spring engager forward

with your nger and slide the black UHMW bearing

pad between the shims and the carriage clamp.

Note: You will notice a piece of thick tape adhered

to one face of the black UHMW clamping pad.

When reinstalling the clamping pad, make sure

the taped surface is facing away from the carriage

clamp, Fig. 34.

Press the UHMW bearing pad forward and reinstall

the set screw.

FIG. 34

FIG. 35

Clamping pressure adjustment

Taped surface this face

Thin plastic shim

Clamping pressure adjustment

Metal spring engager

Black UHMW bearing pad

Set screw

Metal spring

engager

Thin plastic shims

Place adjustment shims

between white shim and

metal spring engager

CAUTION: Whenever making clamping

pressure adjustments, always make sure

that adequate pressure remains to hold the

carriage rigidly in place when clamped in

the fully extended position.

Realigning the Fence Racks

To check or adjust the alignment between the

INCRA positioning racks attached to the back of

your Pro II Fence, begin by loosening the fasteners

securing the racks to the fence. Align the rst rack

ush with the end of your fence and tighten the

fasteners. Now, clamp the INCRA Shop Stop to

your fence so that it bridges the gap between the

ends of racks #1 and #2 as shown in Fig. 36 and

tighten the mounting screws for rack #2. Next,

move the Shop Stop to bridge the gap between

racks #2 and #3 and tighten the mounting screws

for rack #3. Finally, bridge the gap between

racks #3 and #4 and tighten the rack #4 mounting

screws. This process aligns the racks so that the

Shop Stop will operate accurately along the entire

length of the fence. The racks on the Wonder

Fence can be aligned in the same way.

FIG. 36

Second: Bridge the

gap between racks

#1 and #2 with

the Shop Stop

Rack #1

Realigning fence racks

First: Tighten this rack’s

mounting screws

Rack #2

White shim

Fourth: Repeat

the steps to

tighten racks #3

and #4

Rack #4

Rack #3

Third: Tighten the

mounting screws

for rack #2

AUTO CENTERING SCALE (ImperIal model only

Before installing any of the INCRA joinery templates

in preparation for cutting a dovetail or box joint you

must first position your fence so that the router bit

is aligned with the center of your board’s width.

This can be done using the manual “centering”

method described on pages 3-4 of the INCRA Master

method does require a trial cut on a scrap of wood

but it will work on any width of stock. However, if

you are working with a board width that is some

1

multiple of

⁄16” you’ll find the INCRA Auto Centering

Scale provides a quick and easy way to find the

center that requires no trial cuts!

)

Reference Guide & Template Library. The manual

INCRA LS Positioner Owner’s Manual 15

Page 16

Positioning the Auto Centering

Scale (Imperial Model Only)

Install the router bit recommended for the

1

selected joint pattern and set the depth of cut

as described on pages 2-3 of the INCRA Master

Reference Guide & Template Library.

Zero the fence to your cutter with the router bit

2

behind the fence rather than in front. To do this,

slide your fence to cover the router bit (the bit should

be inside the notch just slightly behind the front face

of the fence) and place your jig in the micro adjust

mode. Place a straight board against the fence and

micro adjust the fence position until you see the

router bit just barely touching the board, Fig 37. Pull

the carriage clamp up to lock your jig.

Slide the INCRA Auto Centering Scale into one

3

of the scale slots. You’ll notice on the right end

of the scale the words “Router Bit Diameter” and an

arrow pointing to the following numbers:

1

⁄2, 5⁄8, 3⁄4, 7⁄8, 1. Slide the scale to position the

number that matches your router bit diameter directly

under the hairline cursor. Fig. 38

1⁄8, 1⁄4, 3⁄8,

Using the Auto Centering Scale

Unlock and slide the fence until you see the

dimension on the scale that matches your selected

stock width directly under the hairline cursor. Lock

the fence in place. Example: If you are centering on

a 6” wide board, slide your fence until you see the 6”

mark on the Auto Centering Scale under the cursor

and lock the jig in place. Now slide your joinery

template into one of the scale slots, position the

suggested center cut mark directly under the hairline

cursor and you are ready to cut the joint.

FIG. 37 Zero fence to cuer

Micro adjust fence until

router bit just touches

piece of wood

Board pressed

against fence

FIG. 38

Position Auto Centering Scale under hairline cursor

Slide mark that

matches your bit

diameter under cursor

Note: Your Auto Centering Scale has marks

on the top edge that are closer together

than the marks on the bottom edge. When

reading the scale, each mark along the top

represents

along the bottom edge represents

board width.

1⁄16” of board width. Each mark

Fen ce

1⁄8” of

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects

due to faulty material or workmanship, or at our option, replace the product free of charge. Please return the

failing component only, postage prepaid, along with a description of the problem to the address below. This

warranty does not apply to parts which have been subjected to improper use, alteration, or abuse.

Made in America by:

Taylor Design Group, Inc.

Printed in the U.S.A. © 2010 Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc.

16 INCRA Woodworking Tools & Precision Rules

P.O. Box 810262

Dallas, Texas 75381

Tel: (972) 242-9975

Fax: (972) 243-4277

Web Site: www.incra.com

02/05

Loading...

Loading...