Page 1

Owner’ s Manual

Please read this Owner’s

Manual before use and keep it at

hand for reference.

From simple routing operations

such as edge forming, grooving,

dadoing, or rabbeting, to high

quality joinery, your new INCRA

Fence System and Right Angle

Fixture combined with the INCRA

Jig Positioner will provide an

unlimited source of precision and

satisfaction for all your router table

projects. The T-slot design of the

Fence and Right Angle Fixture

permit the easy addition of user

made sub fences and auxiliary

faceplates for specialty

applications. Durable aluminum

construction and double laminated

Fence and Stop ensure reliable

performance for years to come.

SAFETY

Important safety instructions for using the INCRA Fence System

• Before using the INCRA Fence System and Right

Angle Fixture, carefully read and follow all of the

instructions and safety information in this manual.

• Always turn off the power and make sure that the bit or

blade is fully stationary before moving any component

of the INCRA Fence System to any new setting.

• When using the INCRA Fence System and Right Angle

Fixture with any other tools, make sure that all safety

guards and other safety equipment supplied by the

manufacturer of that tool are securely in place and

functional

• Never let any part of the INCRA Fence System or Right

Angle Fixture interfere with another tool’s safety guards

or other safety equipment.

•

www.incra.com

• Use appropriate safety devices. Keep hands clear of

the bit or blade. Always use a push stick, rubber soled

push block, or other safety devices to keep your hands

safely away from the cutting tool.

• Never let the bit or blade come in contact with the

aluminum body of the INCRA Right Angle Fixture.

• Never attempt to hold your work to the INCRA Right

Angle Fixture using your hands alone. Always use a

clamp or other suitable holding device to securely hold

your work to the front face of the fixture.

• Never let the bit or blade come in contact with the

wooden runners on your INCRA Right Angle Fixture.

Always clamp a wooden stop to the outfeed end of the

fence to stop the forward motion of the Right Angle

Fixture before the bit contacts the wooden runners.

Made in America by:

Taylor Design Group, Inc.

PO Box 810262

Dallas, TX 75381

Phone: 972-242-9975

INCRA Products are protected by the following US Patents: #4,793,604, #4,930,221, #5,195,730, #5,725,074, #5,423,360, #5,716,045, #6,237,457, #6,557,601, #6,672,190

2005 by Taylor Design Group, Inc. Printed in the U.S.A. INCRA is a registered trademark of Taylor Design Group, Inc.

©

Other patents granted or pending.

1

Page 2

INCRA Fence & Stop - Assembly and Use

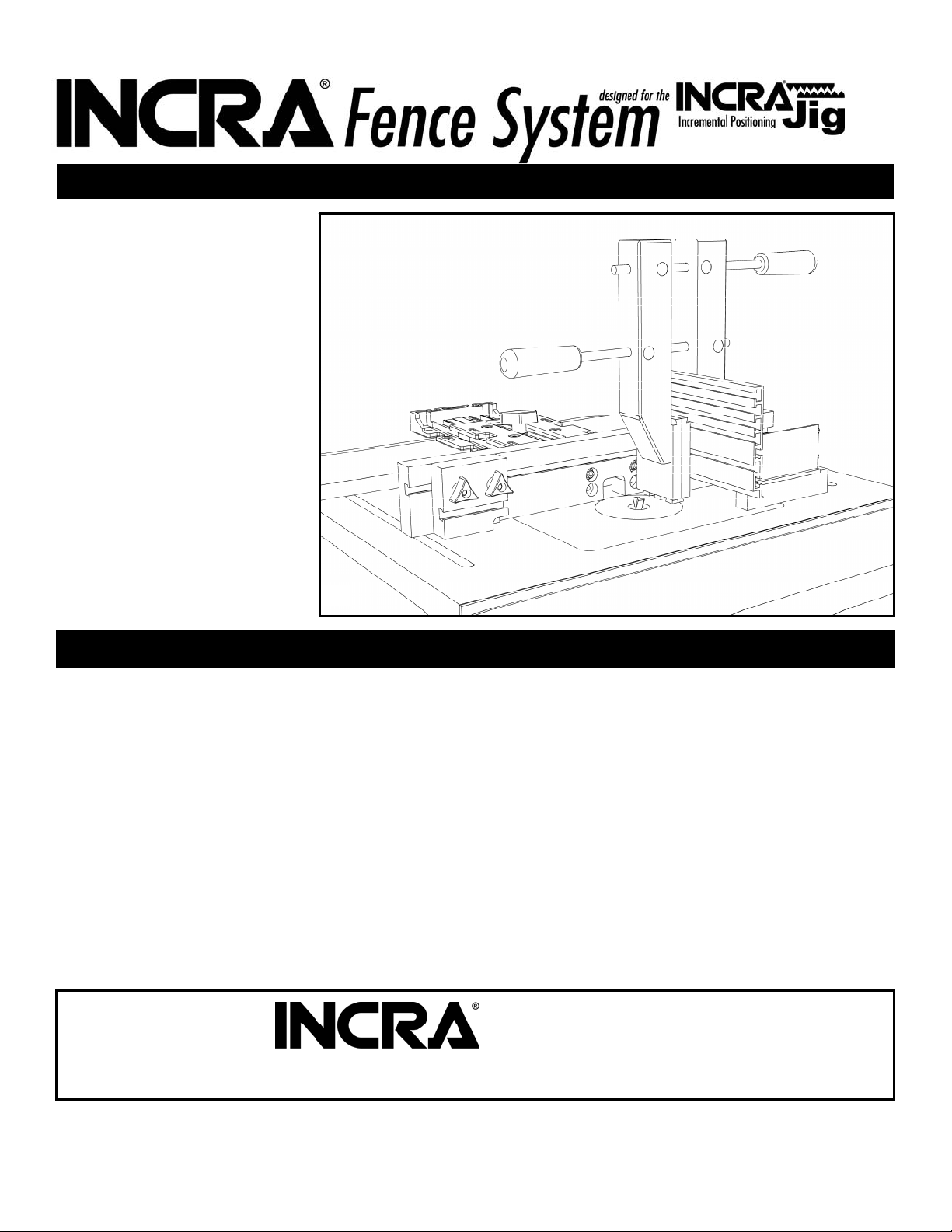

Step 1. Attach the INCRA Jig to

Fig. 1

your router table.

The INCRA Fence System is designed to

work as the “front end” to the INCRA Jig

Base panel

Positioner, so the first step is to attach your

INCRA Jig to your router table. After

following the instructions in the INCRA Jig

owner’s manual for attaching your INCRA

Jig to a wooden base panel, use C-clamps

to attach the base panel to your router

table as shown in Fig. 1. If your router

table is “INCRA-ready” with built-in

mounting slots, you can use the bolt,

washer and knob combination shown in

Fig. 1A for maximum versatility and ease

of use.

Use C-clamps to attach a 3/4” thick by

9” wide plywood or MDF base panel to

your router table …

Step 2. Attach the INCRA Fence to the

INCRA Jig

Open hardware pack D-03. Place a washer on each of

the (2) 1/4-20 x 1 1/4” socket head fasteners and

insert through the upper holes on the fence. Now

loosely thread on the 1/4-20 rectangular nuts.

CAUTION: The raised rim on the two rectangular

nuts MUST FACE AWAY from the fence, as

shown in Fig. 2. Lower the rectangular nuts into the T-

slots located on the front end of the INCRA Jig, then

tighten the fasteners using the included 3/16” hex key.

MUST face AWAY from

Attach wooden base panel

Fig. 2

1/4-20 rectangular

nut (2). Raised rim

the fence

Router table

Attach fence to the INCRA Jig

… or, if your router table is

“INCRA-ready” with built-in

mounting slots, you can attach

the base panel with bolts,

washers and knobs for greater

ease of use

Fig. 1A

1/4-20 x 1 1/4”

socket head cap

screw and washer

(2)

Step 3. Square fence to router table.

After attaching your fence to the INCRA Jig, check

for squareness with your router table top. If any

adjustment is necessary, loosen the fence mounting

screws and insert a paper or plastic shim between

the INCRA Jig and the rear face of the fence, Fig. 3.

A shim placed below the fasteners will increase the

angle between the fence and the table. A shim

placed above the fasteners will decrease the angle.

Tighten the fasteners to secure the fence.

Fig. 3

Place shim between top of jig and

Square Fence to the router table

fence to decrease angle

Place shim between bottom of jig

and fence to increase angle

2

Square

Page 3

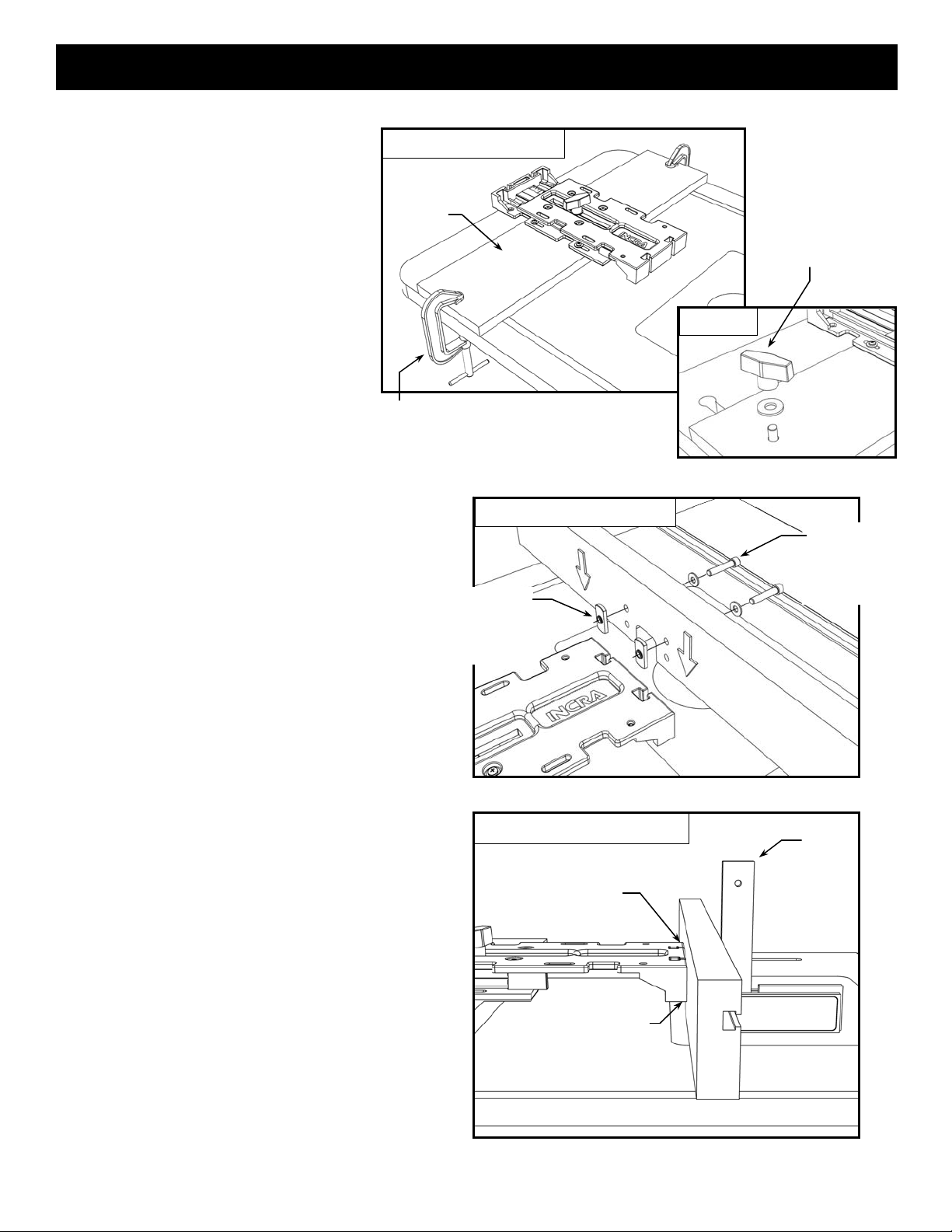

Step 4. Assemble and attach stop

positioner.

To assemble the stop positioner, insert the (2) 1/4-20 x

1 3/4” hex bolts from hardware pack D-03 through the

holes on the stop. Add the two washers and loosely

attach the 1/4-20 thumb knobs. Now slide the hex bolt

heads into the T-slot on the outfeed end of the INCRA

Fence, Fig. 4. Position the stop as needed, and tighten

the thumb knobs before use.

Using the stop positioner.

Use the stop positioner to limit the length of cuts made

with your INCRA Fence System. The cutaway notch

permits the stop to be positioned safely inside your

cutter’s diameter for applications such as dovetail pin

cuts shown in Fig 5.

TIP: The un-notched end of the stop can also be used

for the stopping surface by simply rotating the stop 180

degrees before attaching it to the fence’s T-slot.

Fig. 4

1/4-20 x 1 3/4” hex

bolt (2)

Stop positioner

Fig. 5

Attach stop positioner

1/4” flat washer (2)

1/4-20 thumb knob (2)

Using the stop positioner

TIP: Marking the stop’s position before

making fine adjustments.

When making fine adjustments relative to an initial stop

position, place a reference mark on the front face of the

fence along the leading edge of the stop positioner, Fig

6. Now, when you loosen the thumb knobs to reposition

the stop, you an easily gauge how much you have

moved the positioner. After use, the pencil mark is

easily wiped off the hard laminate surface on the front

face of the fence.

Fig. 7

User made sub fences

1/4-20 x 3/4” socket head screw (4)

1/4” washer (4)

1/4-20 square nut (4)

Fig. 6

Mark stop position

User made sub fences.

User made sub fences for variable gap width and zero

clearance applications can be attached to the T-slot on the

front of the fence. Just cut to size, drill and counter bore

the MDF or plywood fences, using the dimensions shown in

Fig 7A. You can attach sub fences up to 3/4” thick with the

1/4-20 x 3/4” socket head cap screws, washers and square

nuts supplied in hardware pack D-04, Fig. 7A.

Fig. 7A

5/16” diameter through hole

with 5/8” diameter by 3/8”

deep counter bore (2)

Sub fence dimensions

3/4”

5”

6”

2”

10”

3

Page 4

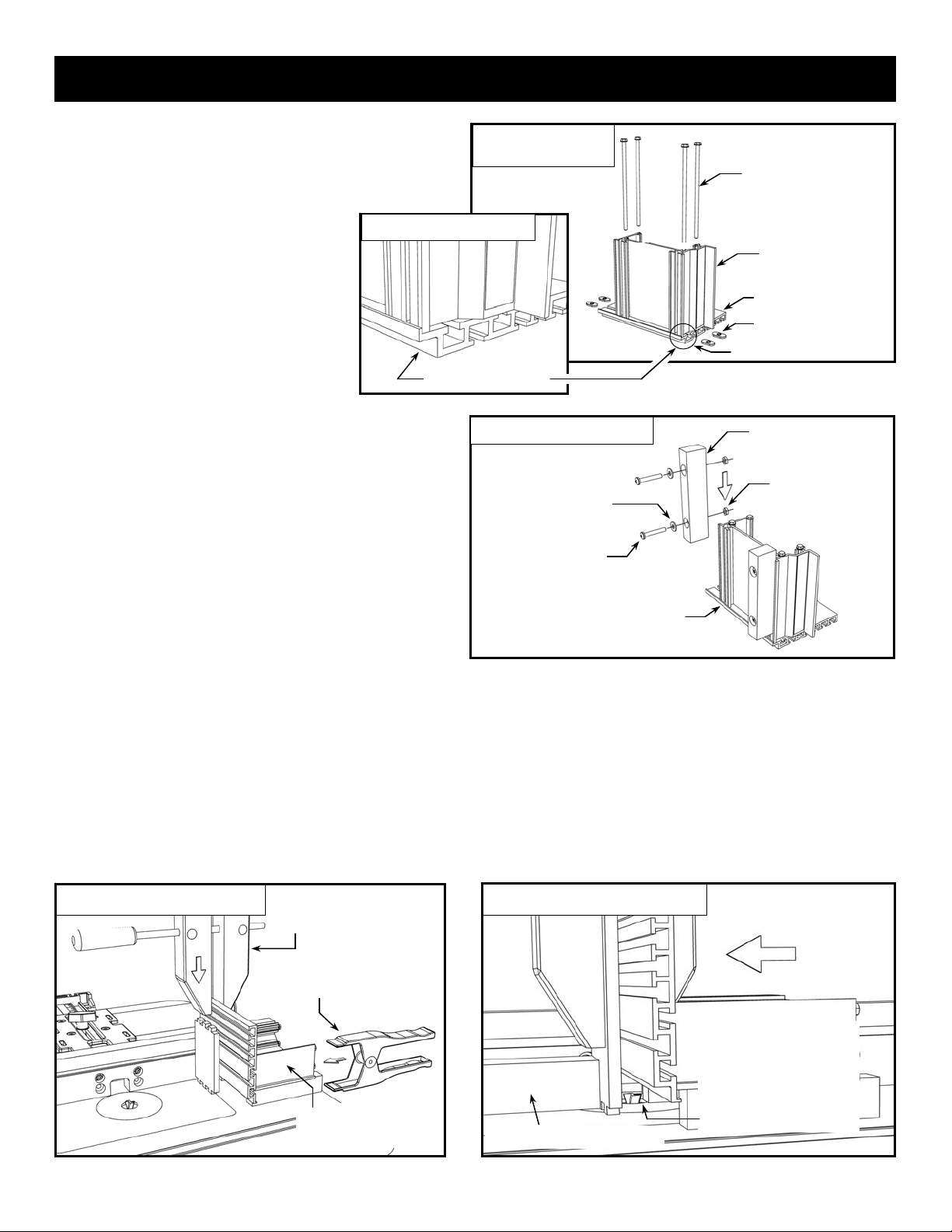

INCRA Right Angle Fixture - Assembly and Use

Step 1. Attach faceplate to base.

Attach the INCRA Right Angle Fixture faceplate to the

INCRA Right Angle Fixture base using the (4) supplied

10-32 x 5 1/2” hex bolts and rectangular

nuts. Insert the bolts through the four

holes in the base and loosely attach the

Fig. 8A

(4) rectangular nuts. Now slide the T-slots

on the back of the faceplate over the

rectangular nuts, Fig. 8. Make sure the

two surfaces marked with an “x” in Fig. 8A

are aligned flush, then securely tighten the

x

x

hex bolts.

Step 2. Attach wooden runners.

Attach the two wooden runners to the bottom of your

Right Angle Fixture base using the (4) 10-32 x 1 1/4”

Phillips screws, washers and hex nuts as shown in

Fig 9. Each runner should extend about 1/2” beyond

the rear of the base.

Fig. 8

Assemble Right Angle Fixture

Faceplate alignment

Align surfaces marked “x”

Fig. 9

Attach wooden runners

#10 washer (4)

10-32 x 1 1/4”

Phillips screw (4)

10-32 x 5 1/2” hex bolts (4)

Right angle fixture base

Right angle fixture faceplate

10-32 rectangular nuts (4)

See detail in Fig. 8A

Wooden runner (2)

10-32 hex nut (4)

Right Angle Fixture operation.

Before clamping a work piece to your Right Angle Fixture,

always press the fixture against your fence, then

immobilize by clamping it to the table with a spring clamp,

Fig. 10. When positioning the work piece against the

faceplate, make sure that the edges of the boards are

against the fence and the ends are contacting the table

surface, then clamp in place using a wooden handscrew

clamp.

Fig. 10

Using the Right Angle Fixture

Third: Position stock against fence and

clamp with a wooden jaw clamp

Second: Immobilize with spring

clamp (acts like a “third hand”)

First: Push Right Angle

Fixture against the fence

T-slot on bottom of Right

Angle Fixture (4)

CAUTION: Do not allow any part of your

hands to hang below the aluminum body of

the Right Angle Fixture. Always keep hands

well away from the bit.

To avoid contacting the wooden runners with the router bit,

clamp a wooden stop block to the outfeed end of the fence

to stop the forward travel before contact, Fig. 11.

Fig. 11

Wooden stop block clamped to fence

Avoid contacting wooden runners

Avoid making contact between the

wooden runners and the router bit by

clamping a wooden stop block to the

outfeed side of the fence to stop the

forward travel of the Right Angle

Fixture

4

Loading...

Loading...