Page 1

Owner’s Manual

25971

Please read before use and keep it at hand for reference.

Since its first appearance in woodworking shops around the globe many years

ago, INCRA Jig has established itself as the finest and most versatile woodworking system available. At the top of its list

of features has always been its unparalleled positioning accuracy. As a fence system, INCRA Jig’s amazing precision

allows exact fence placement to within a few thousandths of an inch, regardless of your skill level. As a joint making

machine, these same positioning capabilities permit an endless variety of box joints and all styles of dovetails to be

created. And with decorative joints like the exquisite INCRA Double Dovetail (described in the INCRA Master Reference

Guide and Template Library sold separately), INCRA Jig makes the seemingly impossible quite possible.

This owner’s manual is an ideal companion to the superb instructional DVD included with the purchase of your new

INCRA Jig. Please take an hour or so to view this enjoyable video production. You will see and hear in real life,

everything that is illustrated and written in this manual, and you will soon be on your way to unleashing the awesome

capabilities that the world famous INCRA Jig will put in your shop. As a bonus, you’ll also learn a host of useful

information about general purpose router table techniques that you can apply to all your woodworking projects.

SAFETY

x Before using the INCRA Jig, carefully read and follow

all of the instructions and safety information in this

manual.

x When using the INCRA Jig in conjunction with any

other tool, first read and follow all instructions and

safety information in that tool’s owner’s manual.

x When the INCRA Jig is mounted to a wooden base or

table surface, make sure that all four mounting screws

are securely tightened and the INCRA Jig is firmly held

in place.

x When using the INCRA Jig with a wooden base panel,

always make sure that the base is securely clamped,

screwed or otherwise fastened to the work surface

before making a cut.

x Always turn off the power and make sure that the bit or

blade is fully stationary before moving the INCRA Jig to

any new setting.

Important safety instructions for using the INCRA Jig

x Always keep both hands behind the fence when

moving the INCRA Jig to any new setting.

x Before making a cut, always make sure that the

clamping knob is fully tightened and the jig is securely

locked in place.

x When using the INCRA Jig with other tools, make sure

that all safety guards and other safety equipment

supplied by the manufacturer of that tool are securely

in place and functional. Never let the INCRA Jig

interfere with another tool’s safety equipment.

x Use appropriate safety devices. Keep hands clear of

the bit or blade. Always use a push stick, rubber soled

push block, or other safety devices to keep your hands

safely away from the cutting tool.

x Wear safety glasses, hearing protection and a dust

mask, and follow all normal shop safety practices.

RTD10000168AA

1

Page 2

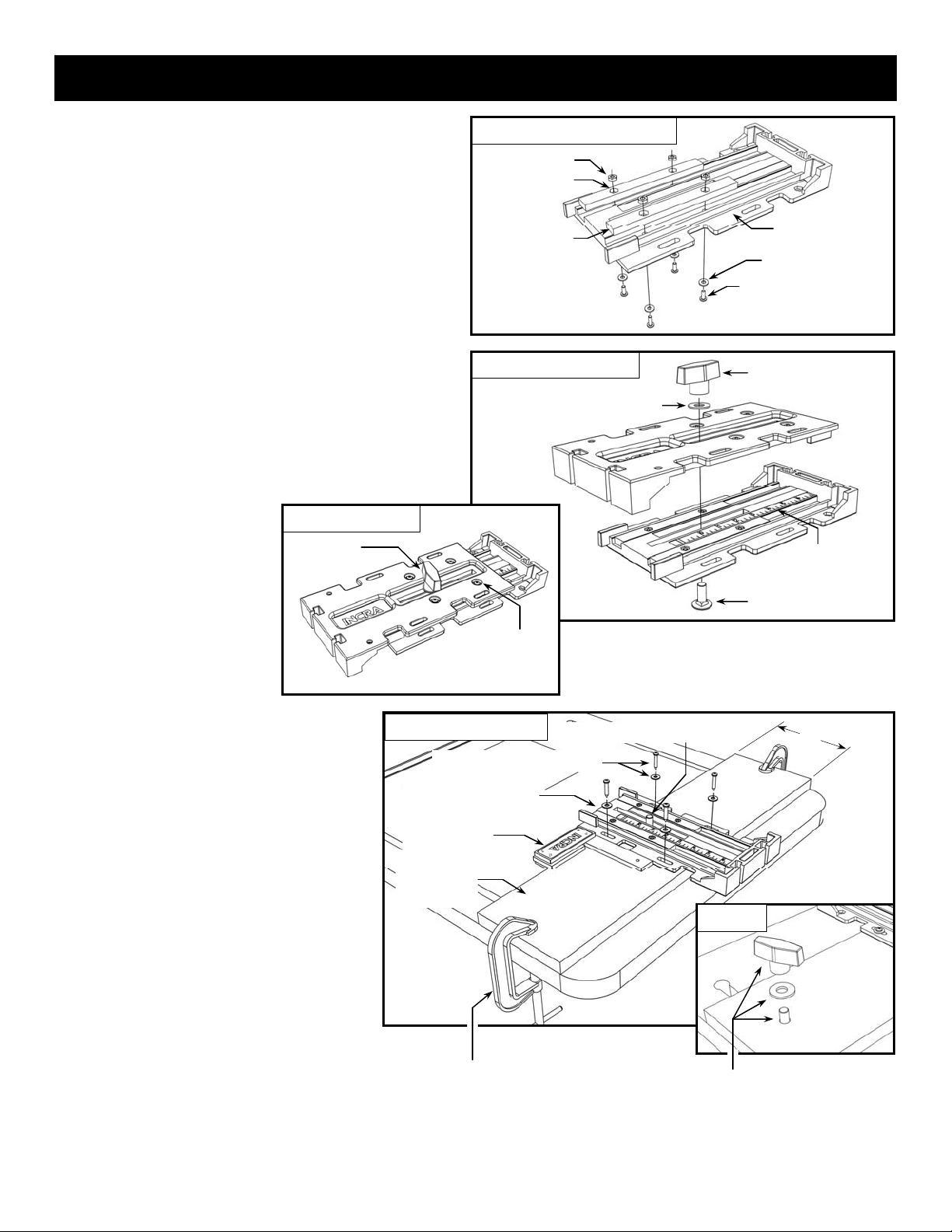

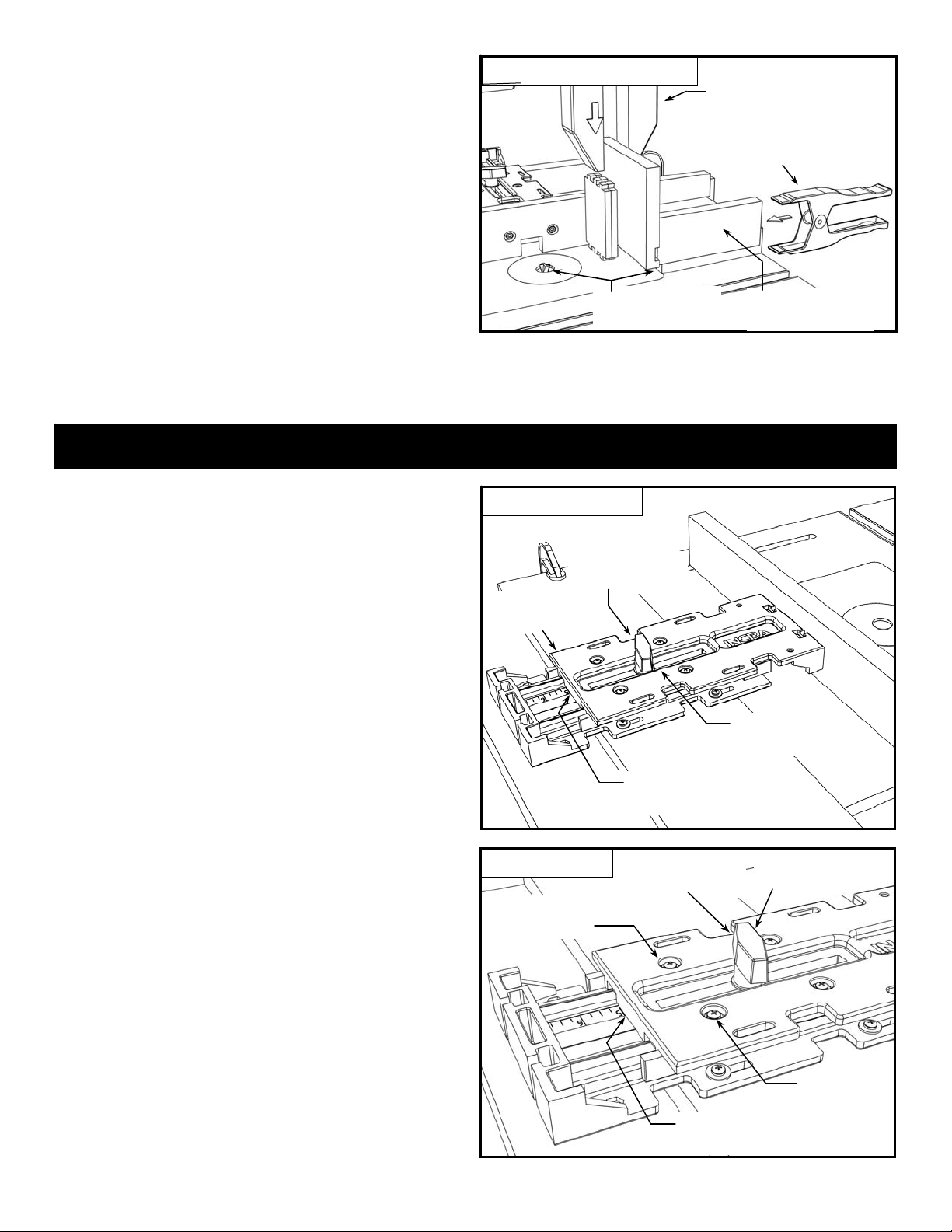

INCRA Jig Assembly

Step 1. Attach sawtooth positioning racks.

Begin by assembling the (4) INCRA sawtooth racks to

the (2) INCRA Jig body halves. Place a rack into one of

the receiving grooves and align the mounting holes.

Now place the 8-32 hex nuts from hardware pack D-01

into the hex recesses on the rack and loosely fasten

using the 8-32 Phillips screws with washers, Fig. 1.

Repeat for all of the remaining racks. For now, finger

tighten only. The racks should still be loose enough to

shift slightly back and forth.

Step 2. Clamp INCRA Jig body halves

together.

IMPORTANT: Before proceeding, make sure that the

racks installed in Step 1 are still a little loose .

Place the two INCRA Jig body halves together as shown

in Fig. 2 and install the carriage bolt, large washer and

2-wing clamping knob from hardware pack D-01.

IMPORTANT: The body half

with the scale should be on

the bottom. Set the top half to

a position of about 5 inches

(not critical) as indicated on the

bottom scale, then tighten the

clamping knob. Now securely

tighten all (8) Phillips screws,

Fig 2A. This procedure aligns

the racks automatically and

perfectly.

Fig. 2A Tighten racks

First: Tighten

clamping knob

Fig. 1 Install INCRA sawtooth racks

8-32 hex nut (8)

Hex nut in recess

Sawtooth rack (4)

Fig. 2

Second: Tighten all (8)

Phillips screws (4 top,

4 bottom)

Clamp halves together

Large washer

INCRA Jig body half (2)

#8 flat washer (8)

8-32 x 7/16“ Phillips screw (8)

2-wing clamping knob

Body half with scale is

on the bottom

Carriage bolt

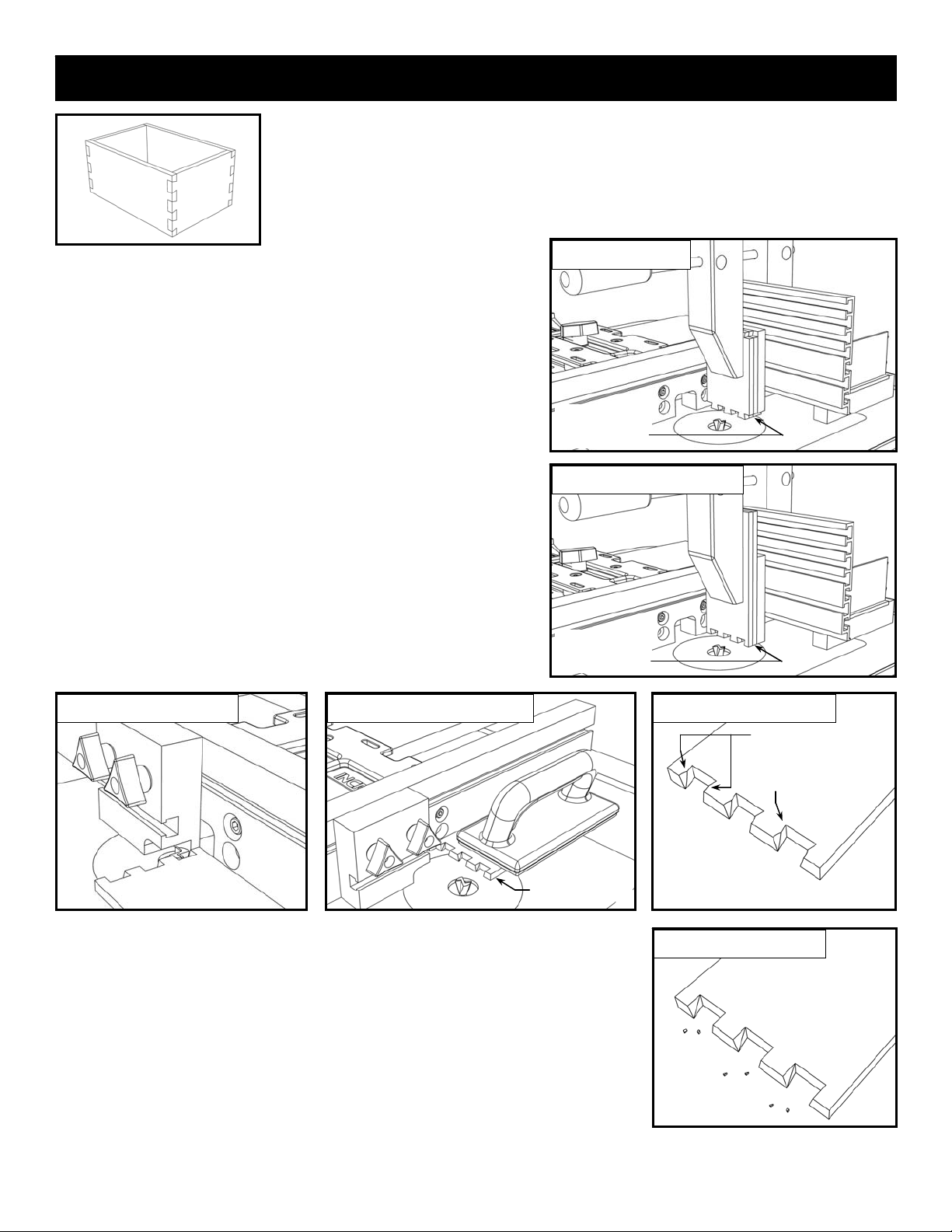

Step 3. Attach INCRA Jig to base

panel.

To attach the INCRA Jig to your router table,

you’ll need a piece of 3/4” thick by 9” wide

plywood or MDF that’s long enough to span

the width of your router table. Remove the top

half of your INCRA Jig and center the bottom

half, scale side up on the panel. (Be sure the

carriage bolt is properly installed from

underneath as shown.) Center and square the

INCRA Jig on the panel, then attach it with the

#10 x 1” wood screws with washers included

in hardware pack D-02. Now replace the top

half of the INCRA Jig along with the washer

and clamping knob. Secure the base to your

router table with a pair of C-clamps as shown

in Fig. 3, or if your router table is “INCRAready”, with slotted holes, you can attach the

base panel with user provided T-bolts,

washers and clamping knobs, Fig. 3A. Just

drill holes in the base panel to align with your

router table slots.

Fig. 3

Attach to base panel

#10 x 1” wood screw & washer (4)

Bottom INCRA Jig body half

(with measuring scale)

Square INCRA Jig to

base panel

3/4” plywood or

MDF base panel

Carriage bolt in place before mounting

Use C-clamps to attach a 3/4” thick by

9” wide plywood or MDF base panel to

your router table . . .

2

9”

Fig. 3A

… or, if your router table is “INCRA-ready” with

built-in mounting slots, you can attach the base

panel with T- bolts, washers and knobs for

greater ease of use

Page 3

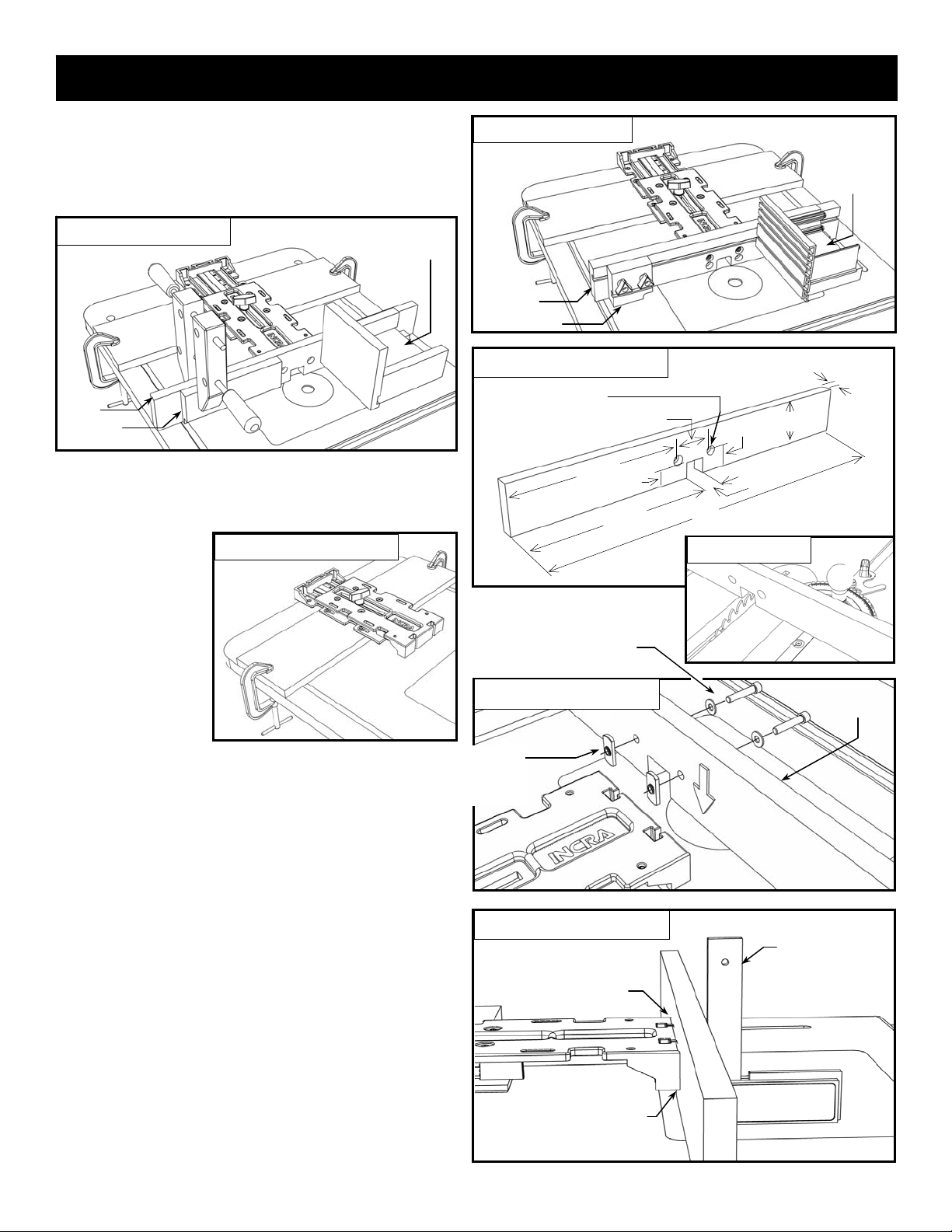

User Made Accessories - Fence

Note: If you have purchased the factory INCRA Fence

System shown in Fig. 4 (recommended), use the

instructions included with that product to assemble and

attach to your INCRA Jig. Follow the instructions below

if you would prefer to make your own, Fig. 5.

Fig. 5

Fence

Stop

User made accessories

Right angle

fixture

Making and attaching your fence.

Begin by making the fence as dimensioned in Fig 6.

Use a straight piece of 3/4” MDF, hardwood or plywood.

Layout the position

for the notch, then

cut the waste away

with multiple side-byside passes at the

table saw using a

miter gauge to guide

the material, Fig. 6A.

Fig. 7

Clamp INCRA Jig to table

Fig. 4

T-slot fence

Stop positioner

Fig. 6

Factory Accessories

User made fence dimensions

5/16” diameter through hole

with 5/8” diameter by 3/8” deep

counter bore (2)

1/4-20 x 7/8 socket head cap

screw and washer (2)

INCRA

Right angle

fixture

3/4”

2 1/2”

”

4

/

3

0

1

1”

”

8

/

3

1

1

1 5/16”

”

4

2

Fig. 6A

4

/

1

1

Cut notch

3”

”

IMPORTANT:

Before attaching the

fence, the INCRA Jig

must first be securely mounted to a 3/4”

wooden base panel and the base panel must

be clamped to your router table. Also make

sure that the INCRA Jig’s clamping knob is

securely tightened, Fig. 3 & Fig. 7.

Attach the fence to your INCRA Jig front end using the

1/4-20 x 7/8” socket head fasteners with washers and

rectangular nuts from hardware pack D-02.

CAUTION: The raised rim on the two rectangular

nuts MUST FACE AWAY from the fence as shown in

Fig. 8. Now slide the rectangular nuts into the T-slots

located at the front end of the INCRA Jig’s top body half

and tighten the fasteners to secure.

After attaching your fence, check for squareness with

your router table top. If any adjustment is necessary,

loosen the mounting screws and insert a paper or plastic

shim between the INCRA Jig and the rear of the fence,

Fig. 9. A shim placed below the fasteners will increase

the angle between the fence and table; a shim placed

above the fasteners will decrease the angle. Tighten the

fasteners to secure the fence.

1/4-20 rectangular nut (2).

Raised rim MUST face AWAY

from the fence

Fig. 8

Fig. 9

Attach fence to INCRA Jig

Square Fence to router table

Place shim between top of jig and

fence to decrease angle

Place shim between bottom of jig

and fence to increase angle

3

Fence

Square

Page 4

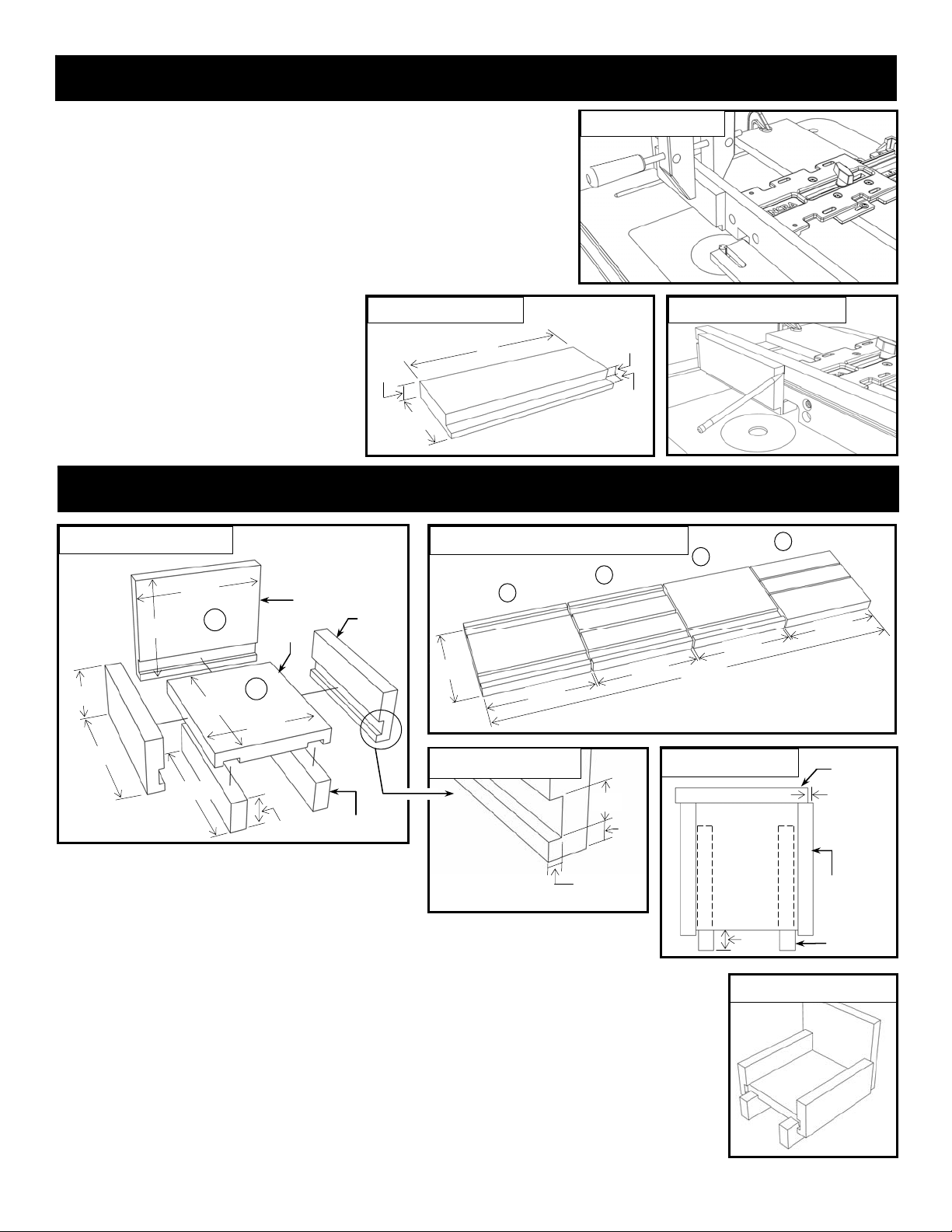

User Made Accessories - Stop

Making a Stop Positioner

Fig. 10

Stop positioner

Your stop positioner is useful for limiting the length of cuts made at the

router table. Just position the stop and secure it to the fence with a

wooden hand screw clamp, Fig 10. This is perfect for the stopped

cuts required for the dovetail pin cuts described in the joinery section of

this manual.

The simple design shown in Fig. 11 includes a rabbeted area that

allows moving the stop over the top of the cutter for very short stopped

cuts. 3/4” MDF will make a good stop material.

TIP: When making fine adjustments

Fig. 11

Stop dimensions

relative to an initial stop position, place a

mark on the front face of the fence along

the leading edge of the stop positioner,

Fig. 12. Now when you loosen the clamp

and slide the stop you can easily gauge

how much you have moved the positioner.

8”

3/4”

3”

1/2”

1/2”

User Made Accessories - Right Angle Fixture

Fig. 13

2 5/8”

Right Angle Fixture

6 1/2”

5 1/2”

6 1/2”

Material:

3/4” MDF

Faceplate

B

Base

Side (2)

Fig. 13A

”

2

/

1

5

A

5 1/2”

Right Angle Fixture cutting diagram

A

A

e

d

i

S

e

s

a

B

”

2

/

1

6

S

e

d

i

/

1

6

Fig. 12

”

2

Marking stop position

B

t

a

l

p

ce

a

F

6

”

8

/

3

6

2

C

r

e

n

n

u

R

r

e

n

n

u

R

e

”

2

/

1

e

t

s

a

W

”

2

/

1

6

6 1/2”

6 1/2”

1 3/8”

Runner (2)

Making a Right Angle Fixture

This simple Right Angle Fixture is an important

accessory for joinery. Use it to guide your material

Fig. 13B

All grooves are 3/4”

wide by 1/4” deep

and located 3/8”

from the material

edge

Groove detail

Fig. 13C

3/4”

3/8”

1/4”

for the vertical cuts required for dovetails and box

joints as shown beginning on page 7.

To make the design shown in Figs. 13 & 14, begin with (4) identical pieces of 3/4”

MDF, cut to 5 1/2” x 6 1/2”. Cut (2) pieces “A”, (1) piece “B” and (1) piece “C” as shown in

Fig 13A. To cut ALL the grooves as shown in Fig. 13B, set a 3/4” diameter router bit to 1/4”

depth of cut, and set the fence-to-bit distance at 3/8”. Check the fit of the material in the

grooves, then fine tune as necessary. Now, rip (1) piece “A” to yield (2) 2 5/8” wide Side

pieces. Then rip the final uncut blank “C” to yield the (2) 1 3/8” Runners.

To assemble, first glue the (2) Runners to the Base, allowing 3/4” of overhang as shown in

Fig. 13C. Now glue the Faceplate and the (2) Sides to the Base. Make sure that the

Faceplate is offset 1/8” from the fence Side piece as shown in Fig. 13C, and that the

Faceplate and the fence Side piece are square to your table top.

4

Top view

Base

3/4”

Fig. 14

Faceplate

1/8”

This Side bears

against fence

Runner (2)

Finished Fixture

Page 5

Right angle fixture operation.

Before clamping a workpiece to your Right Angle Fixture,

always press the fixture against your fence, then

immobilize by clamping it to the table with a spring clamp,

Fig. 15. When positioning the workpiece against the

faceplate, make sure that the edges of the boards are

against the fence and the ends are contacting the table

surface, then clamp in place using a wooden handscrew

clamp.

CAUTION: Do not allow any part of your

hands to hang below the body of the Right

Angle Fixture. Always keep hands well away

from the bit.

Fig. 15

Right angle fixture operation

Avoid contacting wooden

runners with router bit

Third: Position stock against fence and

clamp with a wooden jaw clamp

Second: Immobilize with spring

clamp (acts like a “third hand”)

First: Push Right Angle

Fixture against the fence

TIP: To avoid contacting the wooden runners with the

router bit, clamp your stop to the outfeed end of the fence

to stop the forward travel before contact.

Basic Operation and Calibration

Note: All subsequent illustrations

reflect use of the factory accessories.

Basic INCRA Jig operation

To move your INCRA Jig’s fence from one scale setting to

another, loosen the clamping knob two full turns and lift the

rear of the INCRA Jig’s upper body. This disengages the

saw-toothed racks and allows you to slide the Jig forward.

Slide to align the rear of the upper body over the desired

mark on the scale, then lower the upper body to re-engage

the racks. You should be able to shift the upper body from

side to side easily when the racks are engaged properly.

Tighten the clamping knob, Fig 16.

TIP: A wooden jaw clamp works BEST! One-handed

clamps typically don’t have enough holding power, and a

C-clamp can mar your work, and can be difficult to handle.

Fig. 16

Second: Lift back

end of upper body

Basic operation

First: Loosen clamping

knob 2 full turns

Fourth: Lower body then

tighten clamping knob

Third: Slide upper body to desired

alignment over scales

INCRA Jig calibration

Initially, the alignment between the scale and body may

appear slightly off, but the one-time-only adjustment is

easy. Loosen the four Phillips head screws that secure the

upper racks, then loosen the clamping knob about one-half

turn. Now shift the upper body slightly forward or

backward until the rear of the upper body aligns clearly

over any scale mark. Tighten the clamping knob, then

secure the racks by re-tightening all four Phillips head

screws, Fig. 17. From now on, the scale will align perfectly

at all INCRA Jig settings.

Fig. 17

First: Loosen all (4)

5

Calibration

Phillips screws

Second: Loosen clamping

knob 1/2 turn

Third: Shift upper body until desired

alignment over scales is achieved

Fourth: Tighten

clamping knob

Fifth: Tighten all (4)

Phillips screws

Page 6

Applications - Common Cuts

Grooving, dadoing, rabbeting and edge forming.

Box joints, dovetails and the exotic INCRA Double and Double-Double joinery may be the icing on the

cake, but everyday cutting applications such as grooving, dadoing, rabbeting and edge forming are the

real bread and butter benefits of owning an INCRA Jig. Each of these common cutting operations requires

a different way of calibrating the fence to the

cutter. For grooving and dadoing, you will

typically zero the fence to the INSIDE edge

of the router bit. For rabbeting, you will zero

the fence to the OUTSIDE edge of the bit.

And for edge forming, you will often add a

pair of sub fences to accommodate the

larger diameter of most edge forming bits.

A quick look at the illustrations below will

show how you can quickly and easily

calibrate your INCRA Jig for each of these

types of cuts.

Fig. 18

Grooving and dadoing

Fig. 19

Fig. 19A

Zeroing for grooving and dadoing

First: Lock upper body at 0”

Third: While continuing to nudge

Second: loosen clamps and

slide base panel forward

towards the cutter

the base panel forward, sight

along the fence until the gap of

light between the fence and the

cutter disappears.

Fourth: Re-tighten the base

panel clamps. The fence is

now zeroed to the inside edge

When setting up for most common cutting

operations, the first step us usually to set

the INCRA Jig to a reading of zero, as

shown in Fig. 19A. The base panel is

then moved forward until the fence is

“zeroed” to the desired edge of the bit.

of the cutter

Fig. 20

Fig. 22

Rabbeting

Edge forming

Fig. 21

First: Lock upper

body at 0”

Fig. 23

Zeroing for rabbeting

Zeroing for edge forming

First: Lock upper

body at 0”

Second: Loosen clamps and slide base panel

forward until the fence covers the cutter

Third: Hold straight-edge

against fence

Fourth: Tap base panel

backward until cutter “kisses”

the straight-edge

Fifth: Re-tighten the base panel clamps.

The fence is now zeroed to the outside

edge of the cutter

Second: Loosen clamps and slide base panel

forward until sub fences cover the cutter

Third: Hold straight-edge

against fence at level of

cutter bearing

Fourth: Tap base panel

backward until bearing

touches straight-edge

Fifth: Re-tighten the base panel

clamps. The fence is now zeroed to

the cutter bearing

6

Page 7

Applications - Joinery

Joinery represents one of the most exciting applications

for your new INCRA Jig. Just by applying a little technique

to the extreme accuracy built into your INCRA Jig, you’ll

soon be able to add joinery for box and drawer making to

your list of shop skills. The two included templates will

allow you to produce 3/8” box joints and 1/2” Sliding, Half

Blind, Through and Corner Post Dovetails. The included

variations technique will allow you to produce dozens of

pattern variations on each of the four joint types.

We’ll begin with a look at two simple, but important setup

operations that must take place before using your INCRA

Jig for joint making at the router table. They are:

1. Setting the router bit depth of cut.

2. Centering the bit on your workpiece and

installing the template.

Set the router bit depth of cut for Box Joints

After installing the appropriate diameter straight bit for the

template pattern selected (3/8” for the included template),

simply raise or lower the bit to set the depth of cut at slightly

greater than the thickness of the stock you will be cutting.

See Fig. 24.

TIP: When making box joints, use a stock thickness equal

to the diameter of the straight bit used to cut the joint.

For even more variety,

including Double Dovetails

and Double-Double Box

Joints, the optional Master

Reference Guide and

Template Library contains a

large selection of new

joinery templates. While

designed for the larger 16”

Ultra and LS Positioner

models, the templates can

be cut to length to fit your

New INCRA Jig to provide an

impressive array of styles

and joint types for your

projects.

Fig. 24

Depth of cut - Box Joints

Raise or lower the bit to

slightly greater than the

thickness of your stock

B

Board to be joined

d

r

a

o

b

f

o

d

u

o

r

p

t

s

u

j

t

i

Set the router bit depth of cut for Dovetails

As with any dovetail jig, the depth of cut of your dovetail

bit will determine whether your joint is too loose, too tight,

or just right. Just a little practice using the following steps

will ensure that your dovetail joints will always fit perfectly.

Install the dovetail bit recommended for your template

selection and adjust the bit height to the approximate

depth of cut suggested under the joint diagram for that

cutter, (1/4” for the 1/2”-14

o

bit or 3/8” for the 1/2”-10o bit.)

Set the INCRA Jig to zero on the scale and tighten the

clamping knob. Then loosen the base panel clamps and

slide the unit forward until the fence covers about half of

the bit, then re-tighten the clamps, Fig. 25.

Test cuts for setting the depth of cut

Clamp two pieces of square cut stock to your Right Angle

Fixture and make a cut at the zero setting. Move the

fence back to a scale reading equal to the “Spacing to

Set Depth of Cut” listed under the diagram for the

selected template (7/8” for the included template) and

tighten the clamping knob. Now, make a second cut on

your stock as shown in Fig. 26.

Fig. 25

Fourth: Re-tighten clamps

Second: Lock upper body to “0”

Fig. 26

Depth of cut - Dovetails

Dovetail test cuts

First: Clamp two boards to

Right Angle Fixture

Second: Make first cut

at “0” setting.

Third: Loosen clamps and slide base

panel forward until fence covers

about half of the cutter

First: Set bit height to

recommended approximate depth

of cut shown on page 16

Third: Move fence back to dimension listed under

“Spacing to Set Depth of Cut” in pattern design

(7/8” for included dovetail template ). Then make

the second cut

7

Page 8

Unclamp the two boards and test the fit by joining them as

shown in Fig. 27. As with any dovetail jig, a little trial and

error is needed to achieve a snug fitting joint. To tighten

the fit, raise the bit up slightly; to loosen the fit, lower the

bit slightly. Just remember this phrase: “Heighten to

tighten, lower to loosen”. After adjusting the bit height,

make a new set of trial cuts on a fresh uncut corner of the

boards. After a few adjustments and trial cuts, you’ll have

a perfect fit.

Tip: When the fit is too loose, the trial cuts provide a

gauge to let you know how much to raise the bit. Just join

the trial pieces end to end and gently pull the boards to

wedge the dovetails apart, Fig. 27. The gap that appears

is equal to the distance you need to raise your dovetail bit

to achieve a tight fit, Fig. 28.

Heighten to tighten

Or

Lower to loosen

Fig. 27

Gap

Fit is too loose

Fig. 28

Perfect fit

Raise the bit

this much . . .

. . . to produce a

perfect fit

Centering the router bit on your workpiece

Rout a test groove

NOTE: The following instructions apply to Dovetails AND Box Joints.

After setting your router bit depth of cut, you will position your INCRA Jig and

install the joinery template. This is accomplished through a setup operation

called “centering”. Centering locates your INCRA Jig so that the router bit is

aligned with the center of the stock width you select. Once you find the center,

install the joinery template and you’ll be ready to cut a perfect joint. The simple

steps to follow should always be used when setting up for joint making.

Begin by cutting a piece of 3/4” thick stock to the same

width as the boards you wish to join later on. Mark the

center of this board’s width on one end and place the

board face down on the router table with the

center of the board aligned with the

approximate center of the bit, Fig. 29.

First: Lock upper

body to 3”

Set your INCRA Jig to 3” on the scale and

tighten the clamping knob. Then loosen the

Fig. 30A

clamps that secure the base panel, and slide

it forward until the fence contacts the edge of

the board. Make sure the center mark on the

board is still aligned with the approximate

center of the bit, then re-tighten the clamps,

Figs. 30 and 30A.

Fig. 30

Set initial fence position

Fig. 29

Align center of board with

approximate center of bit

Align board with bit

Second: Loosen clamps and slide base

3/4” stock

panel forward until fence contacts

edge of centering board

Turn the router on, and using a good rubber

soled push block, cut a groove along the

entire length of the board, Fig. 31. Now turn the stock end

for end and make a second pass over the router bit. The

second pass should widen the groove slightly (unless you

are already perfectly centered). Make sure you have turned

the stock end for end before making the second pass. (This

places the center mark at the back of the board.)

With the router off, turn the cutter to it’s widest profile. Slide

the test board against the fence to rest just over the cutter.

There should be a

small gap between

Fig. 32

the edge of the bit

and one side of the

groove, Fig. 32.

Small gap on one

side of the bit

Fig. 31

First: Rout a groove along the

entire length of the stock

8

Rout test groove

Second: Rotate board end-

for-end and make a second

pass over the bit

Page 9

Fine-tune fence position and install template

To center the router bit on the test board, loosen the clamps

that secure the base panel to your router table. As you hold

the board against the fence, tap the base until you see an

equal gap on both sides of the cutter, Figs. 33 & 34. If your

test piece is thick enough, you can flip it over and repeat the

test cuts to confirm that the cutter is centered on the board.

Once you are familiar with the process, one set of test cuts

should do it.

Now that you have found the center of your board, you can

install the joinery template. Place a piece of template tape

to overlap the right side of the template near the end. Slide

the template into the receiving slot and align the mark

representing the suggested center cut with the end of the

INCRA Jig’s upper body. You’ll find the suggested center

cut listed under the diagram of each template pattern on

page 16. Hold the template in place as you press the

template tape to the lower body, Detail 33A.

TIP: Common cellophane tape works great too.

Fig. 34

Center board over bit

Now, let’s do

some joinery.

Equal gap on both sides of cutter

Fig. 33

Second: Loosen clamps and slide

base panel until you see an equal

gap on both sides of the cutter

First: Hold centering

Align board with bit and install template

(see Fig. 34)

board to fence

Fig. 33A

Third: Slide template

(lower numbers first) into

receiving channel.

Fourth: Align suggested “Center Cut” mark

with rear of upper INCRA Jig body

Note: Template numbers

increase towards the back

of the INCRA Jig

Fifth: Adhere template with a

piece of template tape

Half Blind Dovetails

Half Blind Dovetails

The easiest of the dovetail joints, half blind dovetails, add strength and

beauty to your projects. They are also the most versatile of the many

joints you can cut with your INCRA Jig. In fact, many of the decorative

joints we’ve designed over the years are just variations on the half blind

technique you are about to learn. Once you’ve mastered the steps

below, you’ll find these decorative joints (the Corner Post Dovetail on

Half blind dovetails

Install the template

After centering as shown on Pages 8 & 9, select and install the

Dovetail Template. (Refer to Page 16 and Figs. 33 & 33A).

Determine joint layout (pins or tails?)

The first step in making ANY dovetail, whether it be Half

Blind, Sliding, Through or Corner Post is to decide which

half of the joint will be the pins and which half will be the

tails. Refer to the instructions in Figs. 61 and 62 on page

14 to determine which series of cuts to use for each half of

the joint.

Cut the Tails

To cut the tails for a half blind dovetail, begin by cutting a

dovetail shaped rabbet on both ends of the two boards, Fig 35. The rabbet should be 7/32” wide as shown in Fig. 35A.

Don’t cut the full rabbet in a single pass. Instead, start with a light 1/32” scoring pass then use three or four light side by

side passes to sneak up on the final rabbet width. You can use the 1/32” scale in your INCRA Jig as a reference so

you’ll know how much you have widened the rabbet with each pass.

page 11 and the Double Dovetail in the optional Master Reference

Guide and Template Library) quite easy to complete.

Cut dovetail shaped rabbets

7/32”

Rout dovetail shaped

rabbet cuts on both ends

of the tail boards

Fig. 35A

9

Fig. 35

Rabbet width

Page 10

Tail Cuts - Continued

Now, clamp the two tail boards to your Right Angle

Fixture as shown in Fig. 36 and make the tail series of

cuts. The first cut for any tail board will always remove

the edge of the stock. To keep this first cut clean and

splinter-free, it’s a good idea to return to a 1/32” scoring

pass, then sneak up to the first visible mark on the

template in one or two passes. The first visible mark

determines which cut lines to use on the template for the

remainder of the tail cuts. If the first mark is a “B” cut for

example, simply move the INCRA Jig from one “B” cut to

the next “B” cut until you have cut across the full width of

your material. After completing the cuts, flip the boards

end for end and repeat.

Fig. 36

Cut the tails

Handscrew clamp

Fence

Right angle fixture

Clamp two tail boards

with rabbets facing

outward as shown

Pin Cuts

Move the INCRA Jig to the first pin cut on the template that will position the

cutter outside the fence. Since the pin sockets are stopped cuts, bring the

stop positioner just up to the outside diameter of the cutter and clamp in

place, Fig. 37. This stop setup will always (and intentionally) produce a

socket that is just a little short, so we’ll only cut one end of one piece

at this time, then adjust as necessary. Using a rubber soled push

block, move the stock into the cut until you just touch the stop. Don’t

force the material against the stop. Now move the fence from one pin

cut to the next until you have cut across the full width of your material, Fig.

38. After making the cuts, check the fit between this board and one of the

tail boards. Adjust

the stop position

Fig. 38

Pin cuts - final

as necessary to

control the socket

length for a

perfect, flush fit

(See Tip and Fig.

38A at right).

Now make the

final pin cuts on

both ends of both

boards.

Position stop as close as

possible to the outfeed

Stop positioner

side of the bit

Fig. 37

Set stop positioner

Tip: After making your first series of

pin cuts, check the fit with one of your

tail boards. If the tail board won’t fit

all the way into the pin board, just

measure the distance it protrudes,

Fig 38A. This is the distance you

need to move the stop away from the

bit to achieve a flush fit.

Fig. 38A

Pin cuts - final adjustment

Pin board

Beginner’s Tip

After making a half blind dovetail, you may notice that the joint looks

symmetrical, but the edges of the two boards do not align flush, Fig. 39. This

simply means that when you centered your material as described on page 8,

you were close but not quite perfect. Of

course practice DOES make perfect, but

there is another method for cutting the tail

boards that will ensure a flush alignment

regardless of how well your board was

centered. Just make sure when you clamp

the tail boards to the Right Angle Fixture

that the dovetail shaped rabbets on all of

the boards face the cutter, Fig. 40. That’s

all it takes! Remember that even if you use

this procedure, you should still center first to

ensure a symmetrical looking joint.

Fig. 39

Tail cuts - beginner’s tip

Boards not flush

10

Tail board

Move stop block this far back

to achieve a flush fit

Fig. 40

Dovetail shaped rabbets face cutter

Page 11

Corner Post Dovetail

Corner Post Dovetails

The Corner Post Dovetail is a beautiful and deceptively simple variation on

the half blind technique that you have just learned. If you have mastered

the half blind, then you have already just about mastered the Corner Post.

In fact, in the final series of cuts, you will join four boards together using the

exact same steps used to produce a half blind. If you have not made a half

blind joint yet, you should go back to Page 9 to review that section before

continuing. Now, let’s take a stepby-step look at this beautiful

Corner post dovetails

Stock requirements

For this decorative joint, you’ll need the same four pieces required for any

half blind joint (two short pieces and two long pieces) plus a piece of

contrasting color stock about 8” long to make the corner post. All should be

the same thickness and width, Fig. 41. Since this joint is based on half

blind techniques, the stock thickness must be greater than your depth of cut.

Make the long sides for corner posts

After centering (page 8), set the fence to a scoring pass position and

tighten the clamping knob. Clamp the two long boards, along with a

backing board to the Right Angle Fixture. Starting with a scoring cut,

advance to the first visible mark on the template in one or two passes.

The first visible mark determines which cut lines to use on the template

for the remainder of the cuts. If the first mark is a “B” cut for example,

simply move the INCRA Jig from one “B” cut to the next “B” cut until you

have cut across the full width of your material. After completing the

cuts, flip the boards end for end and repeat the cuts, Fig. 42.

Corner Post joint.

Fig. 42

Fig. 41

(2) short pieces

(2) long pieces

The bottom piece is 8” long and is

Stock requirements

a contrasting color

Cut long sides

All (5) pieces are

equal in width and

thickness.

Make the corner posts

To make the corner posts, set the INCRA Jig to the first mark on the

template that exposes the cutter in front of the fence, then tighten the

clamping knob. If you used a “B” cut on the previous series of cuts,

then the corner post series will be the “A” cuts and visa versa. Using a

rubber soled push block, cut a groove through the entire length of the

corner post piece. Now move the fence from one mark to the next to

cut the grooves across the full width of the corner post piece, Fig. 43.

At your table saw, use a miter gauge with a wooden auxiliary fence to

crosscut the corner post stock. Fig 44. You’ll need four corner post

pieces per box. Each piece should be about 1/16” longer than the

thickness of your box side material to allow for flush belt sanding later

on.

Glue the corner posts to the side pieces

Use a brush to apply glue to two of the corner post pieces, then apply

glue to both ends of the mating box side. Slide the corner post pieces

onto each end of the box side and center so that the corner post

overhangs each face of the larger piece slightly. We’ll sand them flush

later. Place scrap wood clamping

pads at each end and clamp. Wipe

off excess glue squeeze out and set

aside. Repeat the glue-up

procedure for the remaining pieces

and set aside to dry for about 30

minutes, Fig 45. Unclamp and belt

sand the corner post sections flush

with the faces of the two boards.

Fig. 45

Glue corner

post pieces

11

Fig. 43

Fig. 44

Clamp two long sides with backing

board to Right Angle Fixture

Rout corner post blank

Rout grooves along full length of blank

Cross cut corner post pieces

Page 12

Corner Post Tail Cuts

From this point forward all we are doing is using standard

half blind dovetail techniques to join the four rectangles of

wood. Here is a quick review.

Use the remaining short pieces of your material for the

tails. To cut the tail boards, we’ll begin with the dovetail

shaped rabbets. Move the INCRA Jig to a scoring pass

position and tighten the

clamping knob. Make the

scoring pass across both ends

of both pieces. Increase the

full rabbet width to 7/32” with

three subsequent passes,

moving the fence back 1/16”

for each cut, Fig. 46 and

Detail 46A.

Fig. 46A

Rabbet width

7/32”

Fig. 46

Cut dovetail shaped rabbets

Rout dovetail shaped

rabbet cuts on both ends

of the tail boards

Now, clamp the two tail boards to your Right Angle

Fixture as shown in Fig. 47 and make the tail series of

cuts. The first cut for any tail board will always remove

the edge of the stock. To keep this first cut clean and

splinter-free, it’s a good idea to return to a 1/32” scoring

pass, then sneak up to the first visible mark on the

template in one or two passes. Make the tail series of

cuts across the width of your material. After completing

the cuts, flip the boards end-for-end and repeat the cuts.

Corner Post Pin Cuts

Slide the stop positioner just up to the outside diameter of

the cutter and clamp in place, Fig. 48. This stop setup will

always produce a socket that is a little short, so cut one

end of one piece at this time, then adjust the stop position

as necessary before making the final cuts on both ends of

both pieces. See the tip on page 4 for more information on

Fig. 48

Set stop positioner

Fig. 49

Fig. 47

Cut the tails

Handscrew clamp

Fence

Right angle fixture

Clamp two tail boards

with rabbets facing

outward as shown

adjusting the stop position. Remember, if you used the “B”

cuts when cutting the tails, you’ll use the “A” cuts for the

pins and visa versa, Fig. 49. After completing the pin cuts,

assemble both pin boards to one of the tails, then add the

other tail board and drive the tails home. Try this

spectacular joint on your next jewelry box project.

Pin cuts - final

Stop positioner

Position stop as close as

possible to the outfeed

side of the bit

Fig. 50

Completed Corner Post

At this point, you can cut the

pins just like you would on any

other half blind dovetail (see

page 10)

12

Page 13

Through Dovetail

Through Dovetails

When preparing stock for a through dovetail, always remember that the stock thickness

must be equal to or slightly less than the depth of cut. It is a good idea to FIRST set your

router bit depth of cut as described on page 7 before preparing your stock, since you must

make the stock match the cutter depth. You cannot raise or lower the cutter to match your

stock thickness! Follow the instructions below to add this traditional interlocking joint to

Through dovetails

Install the template

After centering as shown on Pages 8 & 9, select and install the

Dovetail Template. (Refer to Page 16 and Figs. 33 & 33A).

Tail Cuts

Clamp the two tail boards to your Right Angle Fixture with a backing

board as shown in Fig. 51 and make the tail series of cuts. Use the

shorter of your stock lengths for the tails. The first cut for any tail

board will always remove the edge of the stock. To keep this first cut

clean and splinter-free, it’s a good idea to start with a 1/32” scoring

pass, then sneak up to the first visible mark on the template in one or

two passes. The first visible mark determines which cut lines to use

on the template for the remainder of the tail cuts. Make the tail series

of cuts across the width of your material. After completing the cuts,

flip the boards end for end and repeat the cuts.

your skills resume.

Fig. 51

Two SHORT sides

with backing board

Fig. 52

Cut the tails

Pin cuts - vertical series

Pin Cuts

After completing the tail cuts, clamp the two long pieces of material to

the Right Angle Fixture with a backing board as shown in Fig. 52 and

make the vertical series of cuts for your pin boards. Remember, if you

used the “B” cuts when cutting the tails, you’ll use the “A” cuts for the

pins and visa versa. After completing the cuts across one end of your

boards, flip the material over and repeat the vertical pin series of cuts.

Fig. 53

Now, we’ll repeat the pin series of cuts again. This time with the material face down

on the table. Return your INCRA Jig to the first pin cut on the template. With the

router off, slide one of the pieces to nest the cutter inside the existing cut. You need

to stop the cut just before the cutter contacts the end of the existing cut. Slide a stop

positioner up to the end of the board and clamp in place, Fig. 53. Slide the board

back away from the cutter, turn the router on and using a rubber soled push block,

make the horizontal pin series of cuts on both ends of both boards, Fig. 54.

Pin cuts - set the stop

Fig. 54

Pin cuts - horizontal series

Two LONG sides with

backing board

See detail in Fig. 55

Fig. 55

Fig. 56

Pin cuts - remove tabs

Whittle off these triangles of

wood from each pin.

Cut straight back to corner

Completed pin cuts

If you try to assemble your pin and tail pieces at this moment, you would find that a

small triangle of wood blocks the two pieces from sliding together. To complete the

joint, all that you need to do is whittle off this triangle of wood. This can be

accomplished with a pocket knife, a razor knife or a chisel. Just follow the line of the

cut that was started straight back into the corner, Figs. 55 and 56. Now assemble for

a perfect through dovetail.

13

Page 14

Determine dovetail joint layout.

The first step in making ANY dovetail joint, whether it

be Half Blind, Sliding, Through or Corner Post is to

determine which half of the joint will be the pins and

which half will be the tails. Follow the instructions in

Figs. 61 and 62 to decide which series of template

cuts to use for each half.

Fig. 62

Board to be cut

Determine joint layout

Pins (solid wood on ends)

C

Center of board is

L

aligned with “Center

Cut” on template.

Fig. 61

Tail boards are always cut vertically,

clamped to the Right Angle Fixture

and have “open cuts” on the outside

Pins or tails?

edges.

Pin boards are cut horizontally and will

always have partial pins (solid wood) on the

outer edges of the boards

1

/

8

”

Dovetail Variations

The drawings at right show several

variations on a standard equally spaced

dovetail joint. Although these joint

patterns look quite different from one

another, they all have one thing in

common. They are all made using the

same equally spaced dovetail template.

By learning the variations technique

described below, you can customize the

joint pattern produced by any template.

This technique works not only for Half

Blind dovetails as pictured, but also for

Box Joints, Through Dovetails and even

the Corner Post Dovetails. In general,

pattern variations can be designed by

observing a few simple rules.

Tails (open cuts on ends)

Suggested Center Cut is 5A

To determine pins and tails, align the center of the board with cut “5A” on the dovetail diagram on

page 16 and observe where the edges overlap the full scale joint diagram. This will determine which

series of cuts will be the pins, and which will be tails. Pins have solid wood on the outside edges, and

m

i

n

i

m

u

m

Fig. 57

tails have mating open cuts on the outside edges. In this example, the pins are the “A” series and

the tails are the “B” series of cuts. Pins and tails are determined entirely by the width of the board.

IMPORTANT: Avoid just a “sliver” of solid wood on the outside edges of the pins. If necessary, use

a slightly wider board to allow at least 1/8” of solid wood on both edges of the pins.

Fig. 58 Fig. 59 Fig. 60

Pin and tail board characteristics

Fig. 61 details the characteristics of a common pin and tail

board. This information is useful in trying to visualize a

pattern modification using the variations technique.

Select cuts to omit

Variations are created by OMITTING cuts on one half of

the joint, and then ADDING them to the other half of the

joint. Layout the board on the full scale dovetail pattern on

page 16 to help you decide whether to omit cuts from the

pins or the tails. Leaving cuts off of the tail side, for

example, creates wider tails, Fig. 58. Leaving cuts off of

the pin side creates wider pins, Fig. 59. Although a bit

more complicated, cuts can be left off of both sides of the

diagram, resulting in a pattern variation that has both wider

pins and wider tails, Fig. 60.

Always modify the pattern symmetrically

For example, if you decide to omit the first two “A” cuts on

your stock’s width, you should also omit the last two “A”

cuts.

Cut the joint

Any cuts omitted from one half of the joint will be used to

modify the other half of the joint. If you decide, for

example, to omit cuts 2A and 7A when you are cutting the

“A” series of cuts on the first half of the joint, JUST ADD

cuts 2A and 7A to all of the “B” series of cuts on the

second half of the joint to automatically produce the proper

mating fit. It’s really that simple, give it a try sometime.

Dozens of pattern variations are possible for each joint

type.

14

Page 15

Box Joints

Box Joints

This simple but effective interlocking joint technique is the easiest of all. You’ll

cut your material two pieces at a time with a backing board, using the “A” cuts

for two of the boards and the “B” cuts for the other two.

Let’s get started.

Box joint

Install the template

After centering as shown on Pages 8 & 9, select and install the

Box Joint Template. (Refer to Page 16 and Figs. 33 & 33A).

Clamp two pieces of your stock to the Right Angle Fixture with a

backing board as shown in Fig. 63. Begin with a scoring pass,

then advance to the first visible mark on the template in one or two

passes. The first visible mark determines which cut lines to use on

the template for the remainder of the cuts on these two boards. If

the first mark is a “B” cut for example, simply move the INCRA Jig

from “B” cut to “B” cut until you have cut across the full width of

your material. After completing the cuts, flip the boards end for

end and repeat the cuts.

Now clamp the final two boards to the Right Angle Fixture with a

backing board as shown in Fig. 64 and make the alternate series

of cuts remaining on the template on both ends of your boards.

Fig. 63 First series of cuts

Fig. 64 Second series of cuts

Maintenance

Keeping the saw-toothed racks on your INCRA Jig clean of debris and sawdust is all that is necessary to keep the unit in

top shape. Occasionally remove the clamping knob and blow out the racks. An old toothbrush is a great tool to remove

embedded sawdust and chips. An occasional spray of dry lubricant on the threads of the clamping knob and carriage

bolt will make it easier to clamp and unclamp.

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects due to

faulty material or workmanship, or at our option, replace the product free of charge. Please return the failing component

only, postage prepaid, along with a description of the problem to the address below. This warranty does not apply to

parts that have been subjected to improper use, alteration or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group will replace it free of

charge for as long as you own your tool. Return the damaged rack, postage prepaid, and allow 1 to 2 weeks for delivery.

NOTE: Replacements cannot be sent unless damaged racks have been received by Taylor Design Group, Inc.

Made in America by:

Taylor Design Group, Inc.

PO Box 810262

www.incra.com

INCRA Products are protected by the following US Patents: #4,793,604, #4,930,221, #5,195,730, #5,725,074, #5,423,360, #5,716,045, #6,237,457, #6,557,601, #6,672,190

2005 by Taylor Design Group, Inc. Printed in the U.S.A. INCRA is a registered trademark of Taylor Design Group, Inc.

©

Other patents granted or pending.

Dallas, TX 75381

Phone: 972-242-9975

15

Page 16

3/8” Box Joint Template

Suggested Center Cut: 6B

Template Identification: Notch punched in this end

1/2” Dovetail Template

Suggested Center Cut: 5A

Approximate Rabbet Width: 7/32”

Spacing to Set Depth of Cut: 7/8”

Template Identification: This end NOT PUNCHED

Depth of Cut Chart

16

16

Loading...

Loading...