Page 1

SAFETY

SAFETY

CONTENTS

CONTENTS

❒ When adjusting the fence opening, never

position the infeed or outfeed fence ends

closer than

1

/8" from the router bit.

❒ After making adjustments to the fence

positions, be sure to tighten the two socket

head cap screws through the large holes in

both the infeed and outfeed fences.

❒ When using fence settings in which the router

bit is partially recessed in the fence opening,

always insure that the bit is centered within

the opening.

❒ Never let the router bit come into contact with

the aluminum body of the INCRA Intelli-Fence

or INCRA Stop.

❒ Whenever using large diameter vertical or

horizontal panel raising bits or any other

large diameter bit, always follow that router

bit manufacturer’s operation and safety

recommendations.

❒ Whenever it is necessary to remove large

amounts of stock, always use multiple side

by side passes to achieve the final cut.

Several shallow cuts are safer and will

yield better results.

Please read this owner’s

manual before use and

keep it at hand for

reference.

The micro adjustable split fence design of

the INCRA Intelli-Fence

™

provides access

to many operations previously reserved

for specialty machines. From the straight

edge cutting abilities of the jointer to the

many edge forming functions performed

by the shaper, your new Intelli-Fence

offers a host of exciting new possibilities

for your router and shaper table.

It all starts with intelligent design

features. The opposing wedge design of

the infeed/outfeed offset mechanisms

permits very fine continuous adjustment of

the fence offset from zero to

1

/8", and each

offset mechanism has its own hairline

cursor and scale marked off in

2

/1000 of an

inch increments. Position the fences

“in-line” for typical router table fence

operations, and with the included table

clamps, you can use the Intelli-Fence in

the freestanding mode. Or, you can mount

it directly to your INCRA Jig Ultra or Pro

for the ultimate router table fence setup.

It’s completely compatible with all INCRA

joint-making accessories. The unique

Hi-Rise

™

fence cap and an adjustable

fence opening take the hassle out of

working with large panels and large router

bits for panel raising operations. All these

features combined with the patented

INCRA Stop and a universal dust

collection port make the INCRA

Intelli-Fence the intelligent choice for

your router or shaper table.

OWNER’S MANUAL

®

Assembly . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting to your Router Table. . . . . . . . 3

Attaching to your INCRA Jig . . . . . . . . . 3

Freestanding Mode . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . 4

Offset Adjustment . . . . . . . . . . . . . . . . . 4

Gap Adjustment . . . . . . . . . . . . . . . . . . 5

Initial Fence and Scale Setup . . . . . . . . 5

Fence Bridge Adjustment . . . . . . . . . . . 6

INCRA Stop . . . . . . . . . . . . . . . . . . . . . 6

In-line Fence Applications . . . . . . . . . . . 6

Vertical Panel Raising. . . . . . . . . . . . . . 6

Joint Making . . . . . . . . . . . . . . . . . . . . . 7

Offset Fence Applications . . . . . . . . . . . 7

Jointing. . . . . . . . . . . . . . . . . . . . . . . . . 7

Shaping . . . . . . . . . . . . . . . . . . . . . . . . 8

Product Information. . . . . . . . . . . . . . . . 8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 8

Important safety instructions for using the INCRA Intelli-Fence:

❒ Before using the INCRA Intelli-Fence, read

and follow all of the instructions and safety

information in this manual.

❒ When using the INCRA Intelli-Fence in

conjunction with any other tool, first read

and follow all instructions and safety

information in that tool’s owner’s manual.

❒ Use appropriate safety devices. Always

use a push stick, rubber soled push block,

or other safety devices to keep your hands

safely away from the cutting tool.

❒ When used in the freestanding mode with

the supplied table clamps, always make

sure the clamping knobs are tightened

securely in place before making any cuts.

❒ If attaching the INCRA Intelli-Fence to your

INCRA Jig Ultra or Pro, always make sure

the carriage clamp on the INCRA Jig is in

the locked position and the base is held

securely in place before making any cuts.

❒ Always turn off the power and make sure

that the router bit has come to a complete

stop before changing the setting of any part

of the INCRA Intelli-Fence or INCRA Stop.

From the makers of

INCRA JIG!

• Split fence design

• Micro adjustable

• Universal dust collection port

• Adjustable fence gap

• Compatible with all INCRA

joint-making accessories

Page 2

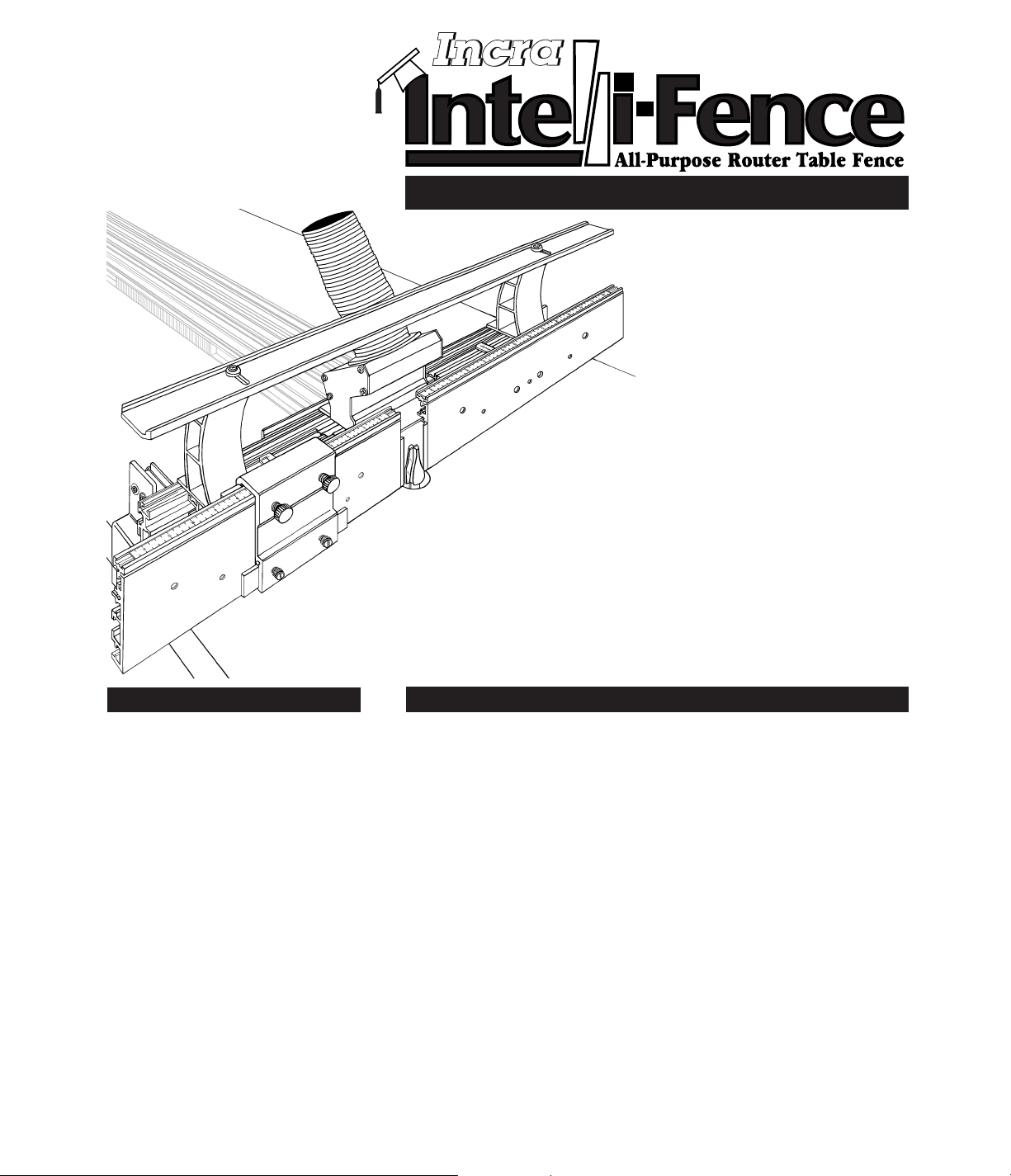

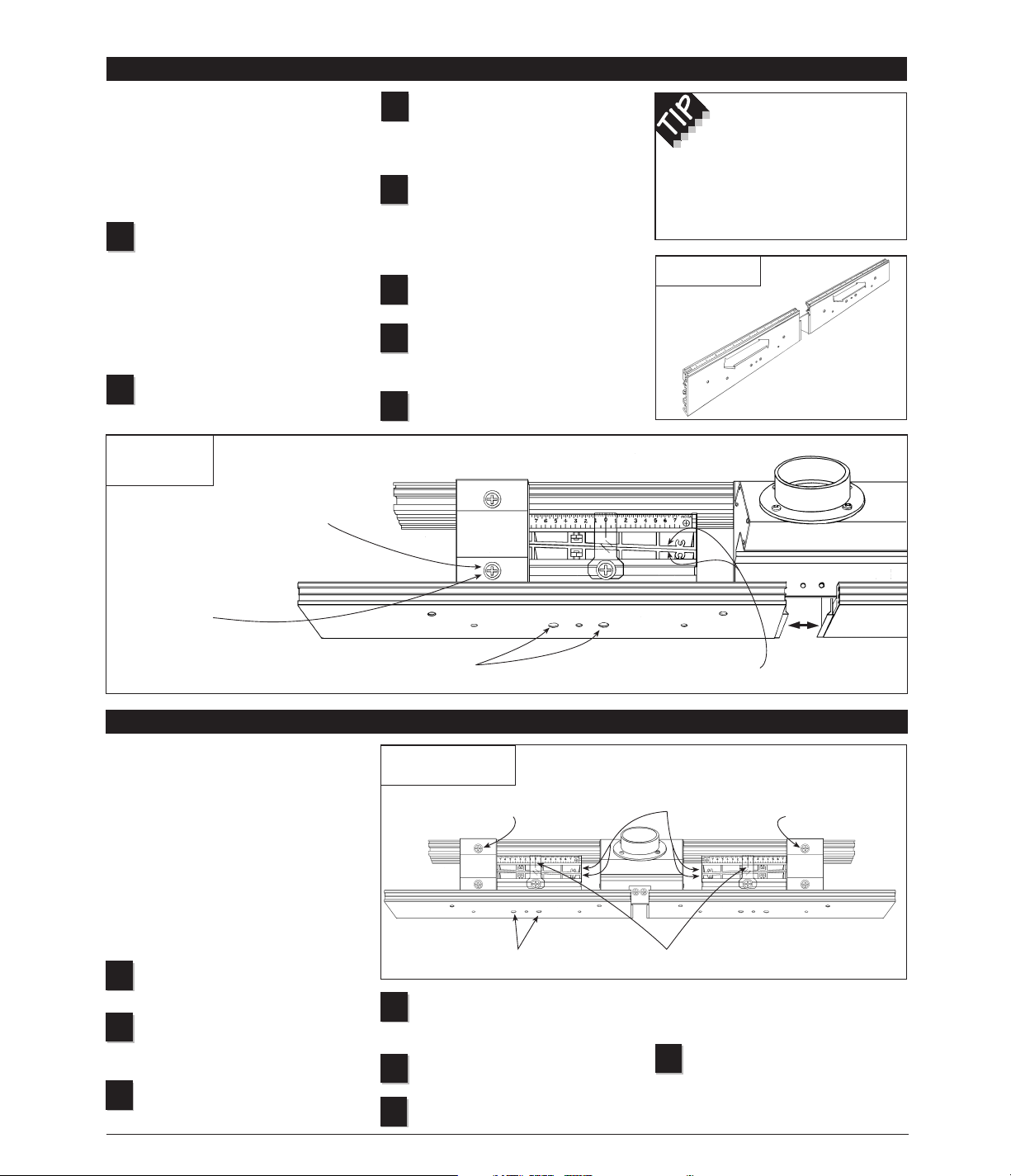

Second: Position inner rack 1" from outer racks

Attach Hi-Rise fence cap

Attach the two Hi-Rise fence cap braces

using (2) #10-32 x

3

/8" phillips pan head

screws, #10 washers and #10-32 rectangular

nuts. See Fig.1. Loosely attach the

rectangular nuts to the screws then slide the

nuts into the two T-slots provided.See Fig 1A.

The two braces should be approximately

centered on the length of the fences and

spaced 16" apart.

Using the (2) #10-32 x

1

/2" phillips pan head

screws,

5

/8" o.d. nylon washers, and #10-32

hex nuts, attach the Hi-Rise fence cap to the

two braces as shown in Fig. 1 The slotted

holes in the fence cap should be aligned to

provide access through the slots to the front

brace mounting screws.Use a straight edge

to align the leading edge of the fence cap

with the front face of the infeed and outfeed

fences and tighten the two cap mounting

screws, Fig. 1A.

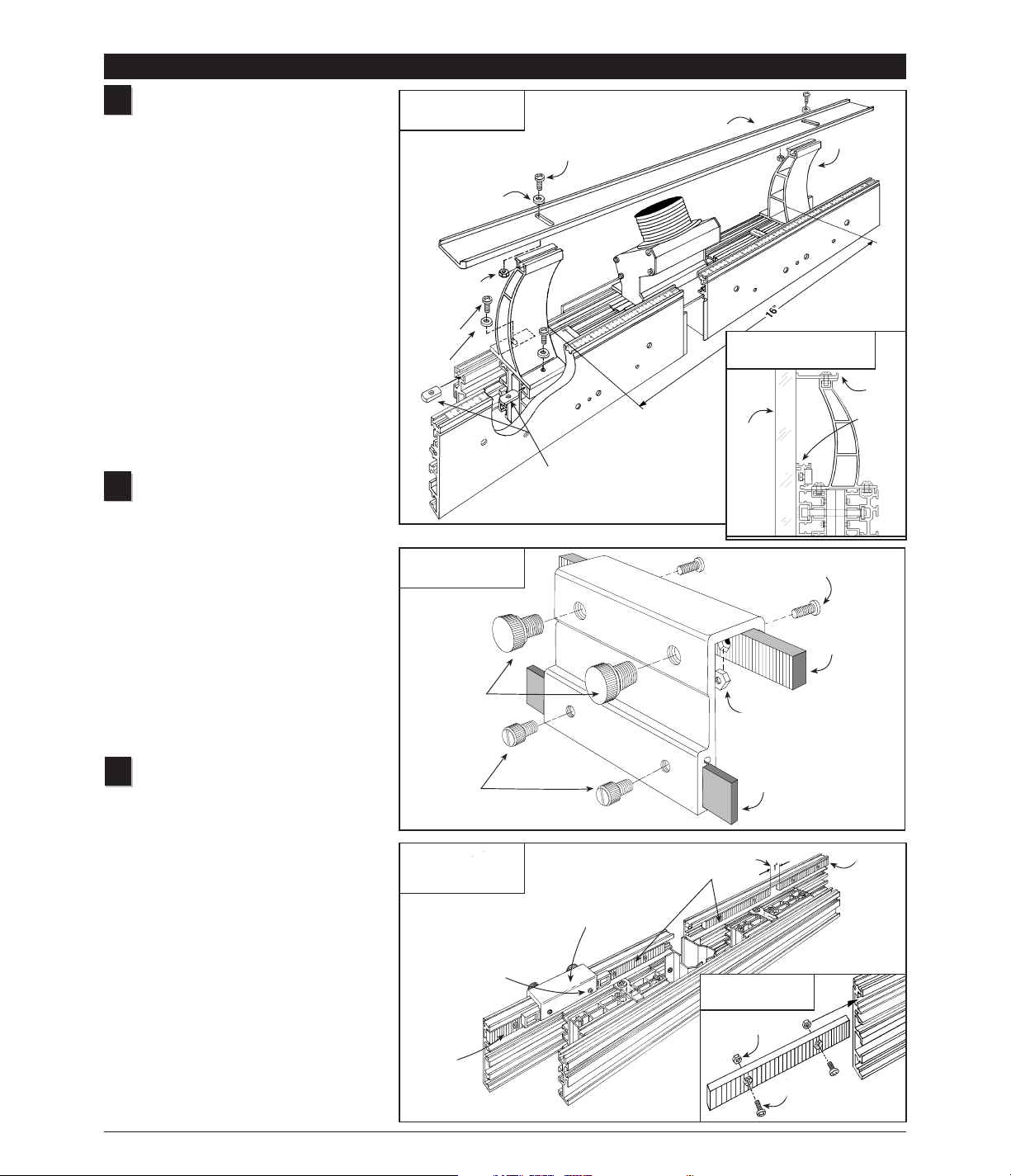

Assemble INCRA Stop

Using the (2) #8-32 x 3/8" phillips pan

head screws and #8-32 hex nuts, fasten one

of the blue INCRA racks to the INCRA Stop

and tighten the screws. See Fig. 2. Slide the

3

/4" x 5" plastic strip into the slot in the stop

and secure with two

1

/4-20 x 1/2" nylon

thumbscrews. Thread the (2)

3

/8-16 x 1/2"

nylon thumbscrews into the INCRA Stop as

shown. One or both of these thumbscrews

can be used to clamp the INCRA Stop to the

fence. In use, the plastic strip provides a

non-metallic stop surface which can be

shaped for special stop setups and can be

micro adjusted by loosening the smaller

thumbscrews.

Install INCRA racks on

infeed/outfeed fences

Insert the #8-32 x 3/8" phillips pan head screws

through the blue INCRA racks as shown in

Detail 3A and loosely attach the #8-32 hex

nuts. Slide the hex nuts on the racks into the

small T-slots on the back of each infeed/outfeed

fence. Place two racks on each fence.

Position the outer racks flush with the fence

ends and tighten the mounting screws.

Loosely position each of the inner racks about

1" from the ends of the outer racks. Now

clamp the INCRA Stop to the infeed fence so

that it bridges the gap between the inner and

outer racks and tighten the inner racks’

mounting screws. Repeat for the outfeed

fence. This bridging process aligns the inner

and outer racks with one another for accurate

INCRA Stop operation.

Caution: Tighten both screws on each rack.

1

2

ASSEMBLY

2

3

FIG. 1

Attach Hi-Rise fence

FIG. 1A

Align fence cap with fence

FIG. 2

Assemble INCRA Stop

FIG. 3

Install INCRA racks on

infeed/outfeed fences

Straight

edge

Hi-Rise fence cap

Fence cap brace

#10-32 x

1

/2" phillips pan head screw

#8-32 x

3

/8" phillips pan

head screw

1

/4-20 x 1/2" nylon thumbscrews

3

/8-16 x 1/2"

nylon thumbscrews

Plastic stop strip

INCRA rack

#8-32 hex nut

Outer

rack

First: Align outer racks flush

with fence end and tighten

mounting screws

Third: Bridge gap with INCRA

Stop and tighten inner racks’

mounting screws

Outer

rack

INCRA Stop

Note: Hi-Rise fence cap, braces,

and dust collection part not shown for clarity

5

/8" o.d. nylon

washer

#10-32 hex nut

Inner racks

DETAIL 3A

Detail of installation

#10-32 x 3/8"

phillips pan

head screw

#10 flat

washer

#10-32 rectangular nuts

#8-32

hex nut

#8-32 x 3/8" phillips

pan head screw

Fence

cap

Fence

Page 3

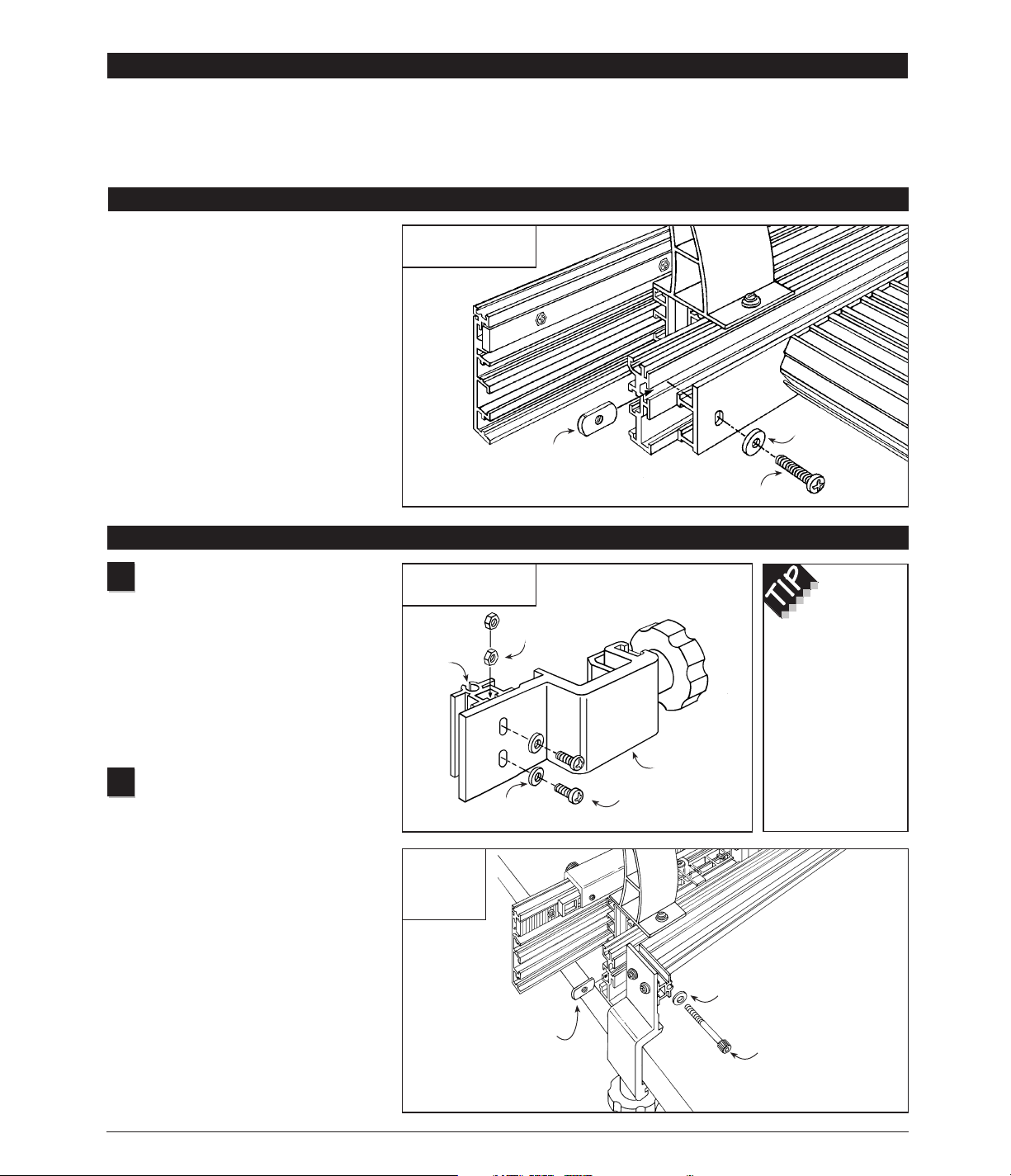

Assemble table clamps

With the table clamps on a flat surface,

insert the (2) #10-32 x

1

/2" phillips pan head

screws through the #10 flat washers then

through the holes in the clamp and loosely

attach the (2) #10-32 hex nuts. See Fig. 5.

Slide the hex nuts into the T-slot in the fence

mounting bracket and tighten the screws.

The ends of the fence mounting bracket

should be flush with the clamp edges.

Repeat for the other clamp.

Attach table clamps to

Intelli-Fence

Position the Intelli-Fence on your router table

with the opening in the fence centered on

your router’s collet.Inser t the

1

/4-20 x 2"

socket head cap screws through the

1

/4"

washers then through the fence mounting

bracket and loosely attach the

1

/4-20

rectangular nuts.Now slide the rectangular

nuts into the T-slots on the rear of the

Intelli-Fence.Tighten the clamping knobs to

secure the clamps to the table edge, then

tighten the two socket head cap screws using

the supplied hex key, Fig. 6.

FIG. 5

Assemble table clamps

3

FIG. 4

Attach to your INCRA Jig

MOUNTING TO YOUR ROUTER TABLE

Important: Your INCRA Jig Ultra or Pro must

be mounted to a

3

/4" plywood base and the

carriage clamp must be in the locked position

before installing the Intelli-Fence.

Insert the supplied #10-32 x 1" phillips pan

head screws through the

5

/8" o.d.(gold)

washers then through the holes on the back of

the INCRA Jig Ultra’s fence mounting bracket.

Loosely attach the (2) #10-32 rectangular nuts.

Now slide the rectangular nuts into the T-slot on

the rear of the Intelli-Fence. Position the fence

so that the INCRA Jig’s carriage is

approximately centered on the fence length

and tighten the two mounting screws.

Note: For mounting to the INCRA Jig Pro use

the shorter #10-32 x

1

/2" screws.

Your new INCRA Intelli-Fence can be used

either by clamping directly to your router

table or by attaching first to your INCRA Jig

Ultra or Pro.Mounting directly to your

INCRA Jig adds incremental positioning

1

Freestanding Mode

2

Note: The table clamps are designed to

work on router tables from 1

1

/8" to 13/8" thick.

To increase the thickness of a table less than

1

1

/8" thick, use double faced tape or glue to

attach a wooden strip to the underside of the

table edge.

#10-32 rectangular nut

#10-32 x 1" phillips pan head screw

5

/8" o.d. gold

washer

#10-32 hex nut

Fence

mounting

bracket

#10 flat washer

Table clamp

#10-32 x

1

/2" phillips

pan head screws

By loosening

the two phillips

head screws on

the table clamps

the fence angle

can be adjusted

perfectly square to

your router table.

FIG. 6

Attach table

clamps to

Intelli-Fence

1

/4" flat washer

1

/4 -20 x 2" socket head

cap screw

1

/4 -20 rectangular nut

Attaching to your INCRA Jig Ultra or Pro

control to the already substantial

features of your INCRA Intelli-Fence.

However, if you don’t already own an

INCRA Jig or you just prefer to use the

Intelli-Fence independent of your

INCRA Jig system, the supplied

clamps and instructions below will

allow you to quickly set up and

use the Intelli-Fence in the

freestanding mode.

Page 4

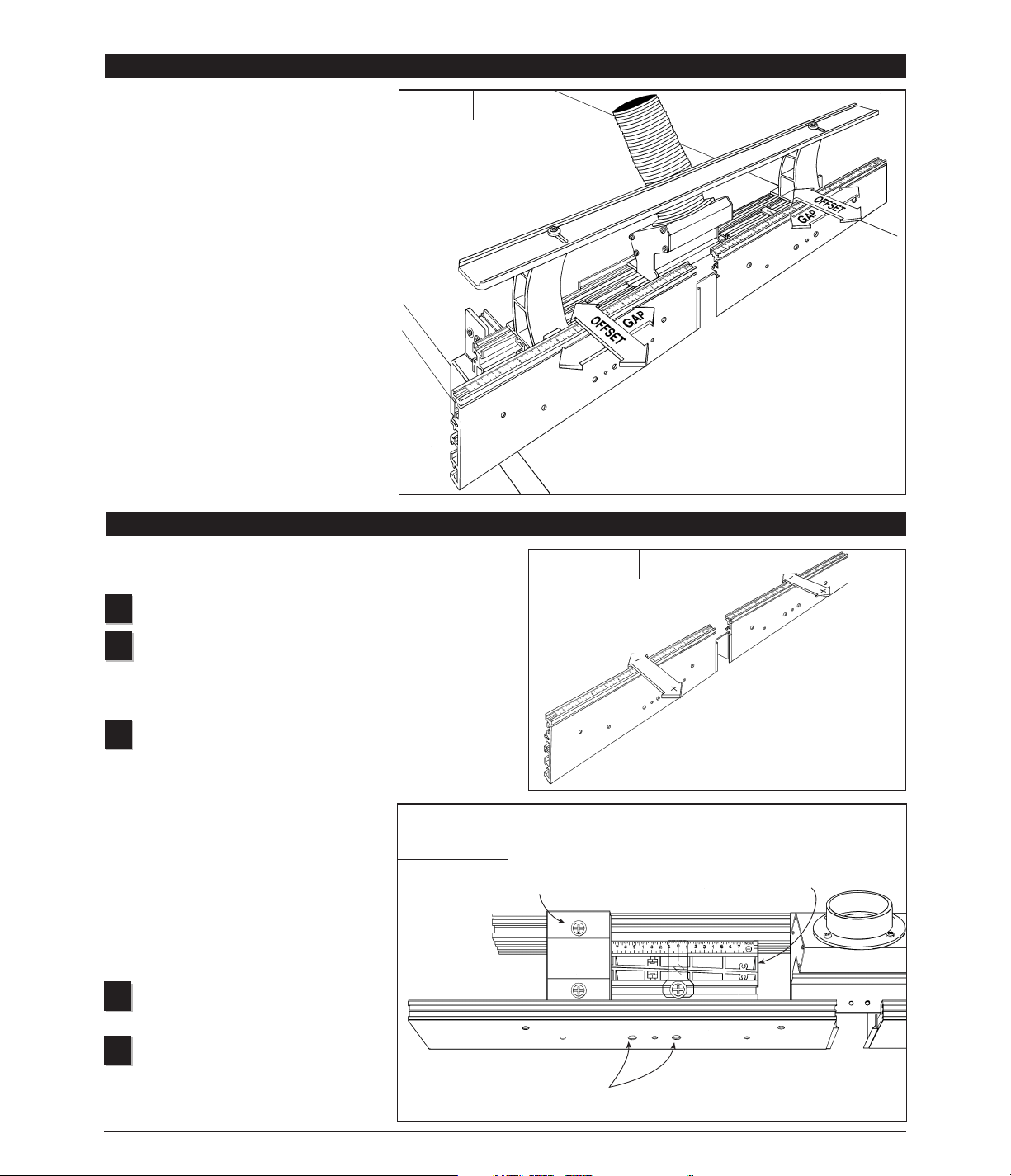

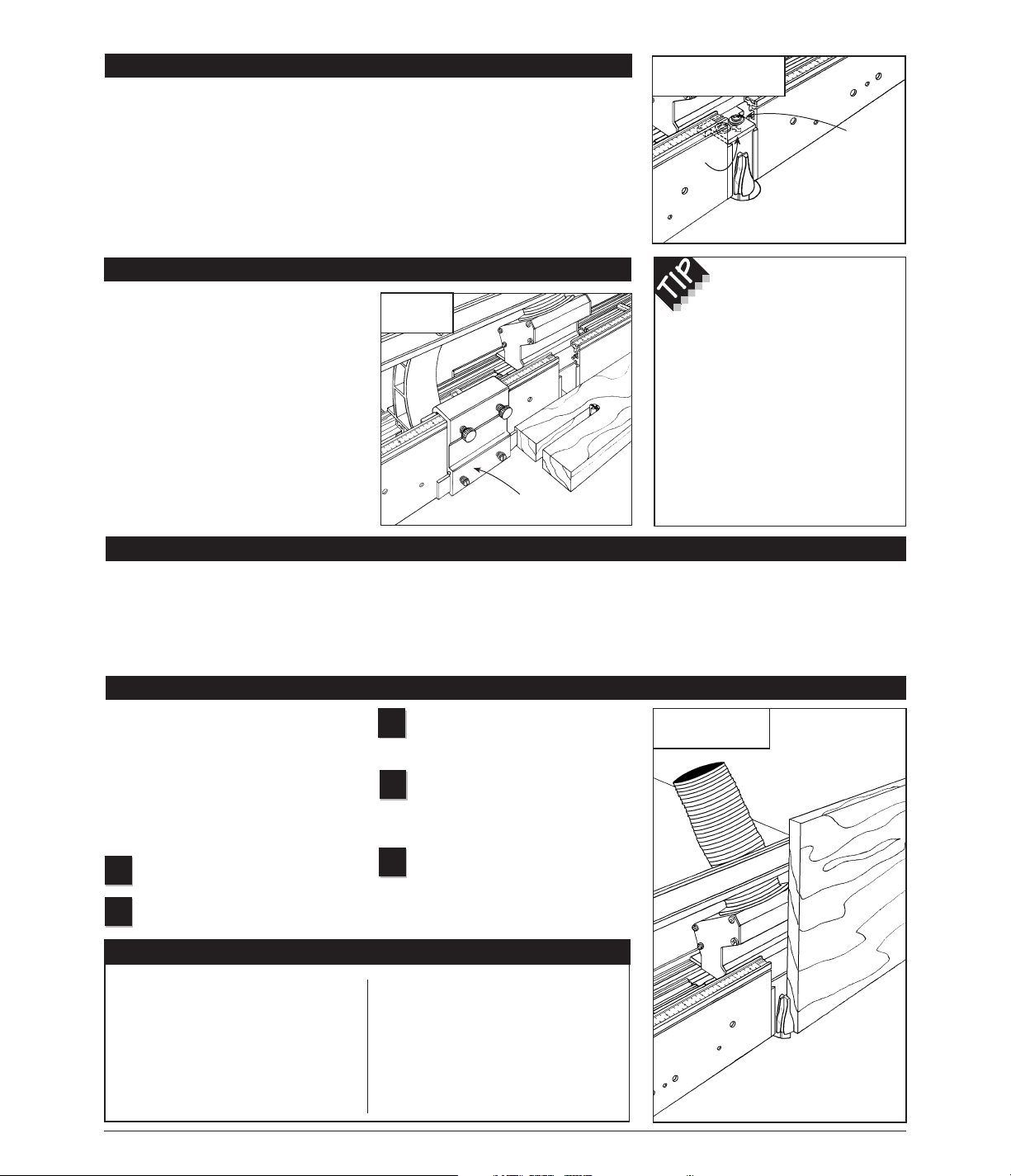

Follow these steps to adjust either the infeed or outfeed fence for

“in-line” or “offset” fence applications, see Fig 7:

Loosen the rear mounting screws on the Hi-Rise fence brace.

Using the supplied hex key, loosen the two socket head

screws through the large holes in the fence. Loosen each

screw one to two full turns, depending on the amount of

adjustment range needed.

Adjust the fence by sliding the rear wedge:

(+) to move the fence forward, slide the wedge

to the left to move the (+) end of the scale

toward the hairline cursor.

(-) To move the fence backward, slide the

wedge to the right to move the (-) end of the

scale toward the hairline cursor.

Note: The numbers on the scale represent

hundredths of an inch. Each of the smaller

tick marks on the top of the scale represent

.002" (two thousandths of an inch).

Tighten the two socket head screws

through the large holes in the fence.

Tighten the rear mounting screw on the

Hi-Rise fence brace.

First: Loosen rear

brace mounting screw

FIG. 7

Offset adjustment–

top view

4

Offset adjustment

Offset Adjustment

Offset Adjustment

5

4

OPERATION

1

2

3

Operation

The infeed and outfeed fences of the

Intelli-Fence can be moved independently

in two directions to provide a variety of

setup configurations. By making the

offset

adjustments

described below, you can

position the fences “in-line” for standard

routing operations such as grooving,

rabbeting, and joint making, or you can

“offset” the infeed and outfeed fences for

specialty cutting applications such as

shaping or jointing an edge. The

gap

adjustment

allows adjustment of the opening

between the infeed and outfeed fences from

5

/8" to 33/4". Follow the step by step

instructions below to familiarize yourself with

these two basic adjustments, then do the

initial fence and scale setup described on

page 5 and you’ll be ready to put your new

Intelli-Fence to work.

Caution: Always turn off the power and

make sure the router bit has come to a

complete stop before changing the setting

of any part of the Intelli-Fence.

Second: Loosen (2) socket head

screws through large holes in fence

Third: Slide rear wedge to

adjust fence offset

Fourth: Re-tighten (2) socket head screws

Note: Hi-Rise fence cap removed for clarity

Fifth: Re-tighten rear brace mounting screw

Page 5

Initial Fence and Scale Set Up

(In-line/mid-range position)

Initial Fence and Scale Setup (In-line/mid-range position)

Tighten the two socket head screws

through the large holes in both the

infeed and outfeed fence.

Tighten the rear mounting screws

on each of the Hi-Rise braces.

Test the in-line setup by sliding a

straight edged board down the

length of the fences. Fine-tune either the

infeed or outfeed fence as necessary.

Once the fences are located in line

with one another slide the infeed

and outfeed scales to read “0” under the

hairline cursors.

5

FIG. 9

In-line/mid-range position

In order to position the scales for

accurate readout, the infeed/outfeed

fences must first be positioned in-line

with one another with the adjustment

wedges at mid-range. Once the scales

are positioned you’ll easily be able to

return the infeed/outfeed fences to this

in-line/mid-range position for standard

in-line fence applications.You’ll also find

the in-line/mid-range position a good

starting point for any of the offset fence

applications. Here’s how, see Fig 9:

Loosen the rear mounting screws

on both Hi-Rise fence braces.

Loosen the two socket head screws

through the large holes in both the

infeed and outfeed fence.

Slide the rear wedge on each fence

to align the ends of the rear wedge

flush with the ends of the front wedge.

3

1

2

4

6

7

First: Loosen rear brace mounting screws

on both fence cap braces

Second: Loosen (2) socket head screws through

large holes in both infeed and outfeed fence

Third: Align ends of front

and rear wedges flush

Fifth: Tighten rear

mounting screws on

both fence cap braces

Sixth: Fine tune as necessary, then slide

scales to read “

0

” under hairline cursor

Fourth: Re-tighten all

(4) socket head screws

Note: Hi-Rise fence cap removed for clarity

5

Note the scale setting, then hold

the front and rear wedges together

as you slide the outfeed fence to open or

close the gap.

Make sure the scale setting is still

the same (slide the rear wedge to

adjust if necessary) then tighten the two

socket head screws through the large

holes in the fence.

Tighten the front screws on the

Hi-Rise fence brace.

Align and tighten the Hi-Rise fence

cap if it was moved to access the

fence brace screws (see Fig.1A, page 2).

Repeat Steps 1-6 for the infeed

fence.

4

5

6

7

Follow these steps to adjust the opening

between the infeed and outfeed fences,

see Fig. 8:

Caution: When adjusting the fence

opening, never position the fence ends

closer than

1

/8" from the router bit.

Loosen the front mounting screw on

the Hi-Rise fence brace. You can

either use a long shank phillips screw

driver to access the screw through the

slotted opening in the red fence cap or

simply loosen the fence cap retaining

screws and pivot the fence cap to provide

access to the front fence brace screw.

Using the supplied hex key, loosen the

two socket head cap screws through

the large holes in the outfeed fence.

3

1

2

Gap adjustments

FIG. 8

Gap adjustments–

top view

First: Loosen front brace

mounting screw

Second: Loosen (2) socket head screws

through large holes in fence

Fourth: Re-tighten (2)

socket head screws

Fifth: Tighten front brace

mounting screw

Note: Hi-Rise fence cap removed for clarity

To avoid accidentally

changing the fence offset, it

is usually best to begin in any

Intelli-Fence setup by making

the fence gap adjustment before

setting the fence offset.

Gap Adjustment

Third: Holding front and rear wedges

together, slide fence to open or close gap

Page 6

SAFETY

FIG. 12

Vertical panel raising

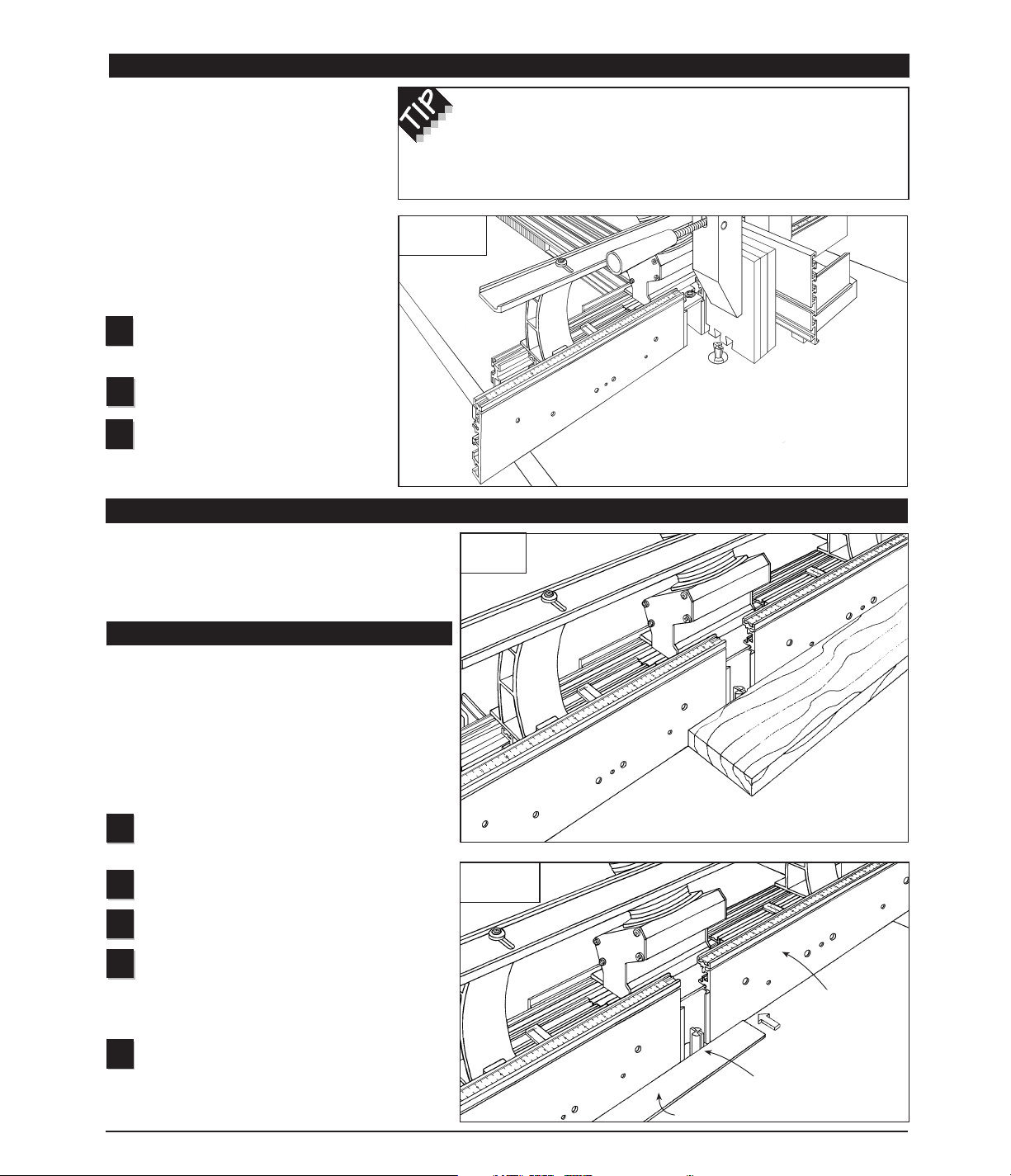

Adjust infeed/outfeed fences to the

in-line/mid-range position as

described on page 5.

Use a straight edge to adjust the

Hi-Rise fence cap in line with the

infeed and outfeed fences. (See Fig. 1A

on page 2.)

Remember: Do not make the full

width of the cut in a single pass.

Instead, use several light side-by-side

passes, moving the fence back

1

⁄16" or

so after each pass.

5

3

4

6

IN-LINE FENCE APPLICATIONS

Once set to the in-line/mid-range

position as described on page 5, your

new INCRA Intelli-Fence can be used

for a variety of typical in-line fence

applications, including grooving,

dadoing, and edge forming operations

such as rabbeting, chamfering, and

roundovers. You’ll also find the in-line

position useful for many specialty

operations. With the Hi-Rise fence cap,

you’ll be able to use vertical panel

raising bits to make raised panels for

cabinetry, and since its design is

compatible with all INCRA joint-making

accessories, you’ll be able to use the

Intelli-Fence in conjunction with

your INCRA Jig Ultra or Pro as a

joint-making fence.

Vertical Panel Raising

The introduction of the vertical panel

raising bit has made cutting the reveal on

a raised panel a relatively simple

operation for the router table. You’ll find

your new Intelli-Fence, with its built-in

dust collection, adjustable fence gap,

and Hi-Rise fence cap, perfect for this

operation.The setup is as follows, Fig 12:

Install vertical panel raising bit and

set appropriate depth of cut.

Adjust fence gap as necessary

(see Gap Adjustment on page 5).

1

2

❒

Whenever using large diameter

vertical or horizontal panel

raising bits or any other large

diameter bit, always follow

that router bit manufacturer’s

operation and safety

recommendations.

❒

Whenever it is necessary to

remove large amounts of

stock, always use multiple

side-by-side passes to achieve

the final cut. Several shallow

cuts are safer and will yield

better results.

FIG. 11

INCRA Stop

When used in conjunction with your new

INCRA Intelli-Fence, the INCRA Stop

provides the same precise rack positioning

capabilities that made the INCRA Jig

famous. The sliding scale in the top of the

fence becomes a versatile reference for use

in setting stop positions at the router table.

The adjustable plastic stop permits micro

adjusting of the stop positions anywhere

between the

1

⁄32" tooth spacing on the

INCRA racks. The bi-directional design

allows the INCRA Stop to function on the

infeed or outfeed end of the fence with any

thickness of stock.

INCRA STOP

INCRA Stop

INCRA Stop

The fence bridge can be

mounted with either the narrow

or wide end in the opening

between the infeed and outfeed

fences.With the narrow end forward

the fence opening will be 5⁄8".This

opening is great for smaller joint

making bits like the 1⁄4" and 3⁄8"

straight or the 1⁄4", 5⁄16", and 3⁄8"

dovetails. With the wider end of the

fence bridge forward the opening is

increased to 11⁄8", perfect for use

with larger dovetail bits.

FIG. 10

Fence bridge adjustment

The adjustable fence bridge is used during

joint making to provide support for narrow

vertically held stock as it is moved past the

opening between the infeed and outfeed

fences. For all other cutting operations the

fence bridge can be positioned behind the

front face of the Intelli-Fence and tightened

in place. For use during joint making, first

return the fences to the in-line/mid-range

position described above. Loosen the

screws that secure the fence bridge and

slide it forward into the opening between

the fences. Adjust the fence gap as

described on page 5 to close the fence

ends on the bridge. Now use a straight

edge to locate the fence bridge flush with

the front face of the fence and tighten the

mounting screws.See Fig 10.

Fence Bridge Adjustment

Loosen

mounting screws

and slide fence

bridge forward for joint

making applications

Use straight edge to align fence

bridge flush with fences

Fence

bridge

Page 7

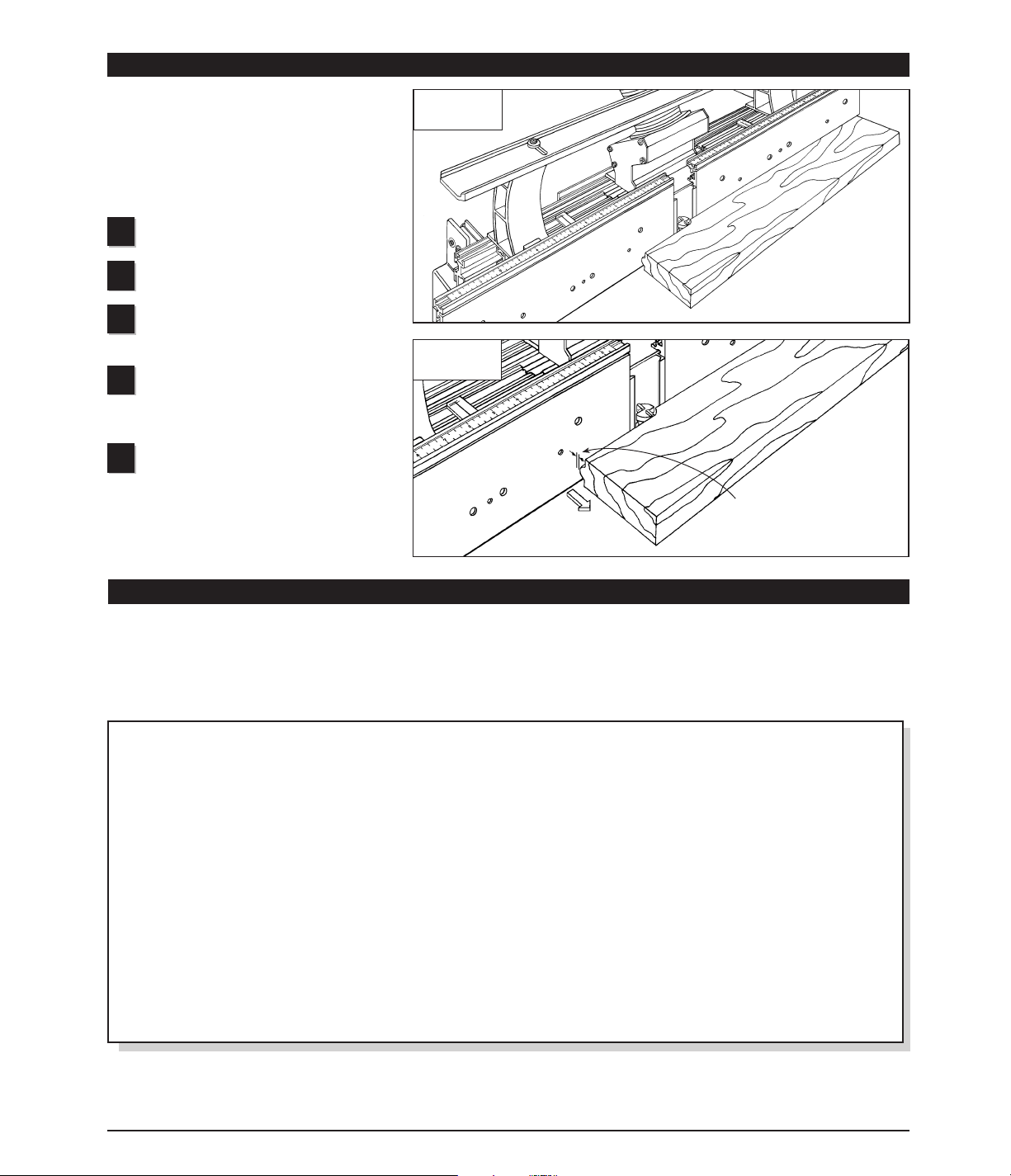

Jointing

Most woodworking projects require that your boards begin

with at least one straight edge. This one straight edge then

becomes the reference surface for subsequent

perpendicular or parallel cuts. By using your Intelli-Fence

and the technique described below, you’ll be able to put a

perfectly straight edge on your board at the router table

and, because of the higher RPM of the router, you’ll find

the freshly jointed edge far smoother than any jointer

machine can produce.

Install a

1

/2" diameter (or larger) straight bit and set

the depth of cut to slightly greater than the thickness

of stock to be joined.

Adjust fence gap as necessary (see Gap Adjustment

on page 5).

Adjust infeed/outfeed fences to the in-line/mid-range

position as described on page 5.

Adjust the location of the Intelli-Fence at your router

table to place the outfeed fence in line with the

outermost cutting arc of the router bit. (A straight edge

placed against the outfeed fence can be used to help

align the fence with the cutter.) Fig.15.

Micro adjust the infeed fence backward (-). The

reading on the scale will represent the amount of

stock you wish to remove from the board’s edge on each

pass. A light cut (infeed cursor reading between -1 and -2)

will yield the smoothest results.

Adding an INCRA Jig Ultra or Pro to your

Intelli-Fence makes precise placement of

multiple side-by-side cuts a cinch. One such

operation requiring this kind of precision is

joint making. Once placed in the

in-line/mid-range position, your new

Intelli-Fence becomes a perfect replacement

for the standard straight fence commonly

used with the INCRA Jig. It is completely

compatible with all of the INCRA jointmaking accessories, including the INCRA

Right Angle Fixture, Stop, and joinery

templates. The setup follows, see Fig 13:

Adjust infeed/outfeed fences to the

in-line/mid-range position as described

on page 5.

Position fence bridge and adjust fence

gap as described on page 6.

Follow the instructions for the joint you

wish to cut as detailed in the INCRA

Master Reference Guide and Template

Library.

One of the most valuable features of the Intelli-Fence is

the ability to offset the infeed and outfeed fences. The

offset fence adds a whole new dimension to the router

table, allowing it to perform two new operations—

jointing, and shaping.

2

FIG. 14

Jointing

7

OFFSET FENCE APPLICATIONS

1

FIG. 15

Jointing setup

First: Position Intelli-Fence to

align fence with cutting wing

on the router bit

Second: Micro

adjust infeed fence

backward (-)

Straight edge

3

4

5

3

1

2

FIG. 13

Joint Making

Joint Making (INCRA Jig Ultra or Pro required)

Clearance is provided for between the Hi-Rise fence cap, the braces and

all INCRA joint-making accessories. However, since the Hi-Rise fence cap and

braces are not necessary for joinery, you may remove them from the Intelli-Fence

if you prefer. Just reverse the assembly instr uctions descr ibed on page 2.

Outfeed fence

Infeed fence

Page 8

For a product information brochure, call, write or fax to:

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, TX 75381

Tel: (972) 418-4811 Fax: (972) 243-4277

Web Site: www.incra.com

PRODUCT INFORMATION

8

Made in America by:

Taylor Design Group, Inc.

■

P.O.Box 810262 ■Dallas, Texas 75381 1195

Printed in the U.S.A. © 1995, Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc.

WARRANTY

Taylor Design Group, Inc.warrants this product for one year from date of purchase.We will repair

any defects due to faulty mater ial or workmanship, or at our option, replace the product free of

charge. Please return the failing component only, postage prepaid, along with a description of the

problem to the address below. This warranty does not apply to parts which have been subjected to

improper use, alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group

will replace it free of charge for as long as you own your tool. Return the damaged rack, postage

prepaid, and allow 1 to 2 weeks for deliver y.

NOTE:

Replacements cannot be sent unless damaged racks have been received by Taylor Design Group.

FIG. 16

Shaping

FIG. 17

Shaping setup

Distance between stock and

outfeed fence – micro adjust

outfeed fence forward by this

amount

Outfeed fence

Infeed fence

Many shaping operations involve the removal of

the entire edge of a square piece of stock as it is

moved past the cutter. Once the stock is

removed from the edge, it becomes necessary to

support the freshly cut surface by moving the

outfeed fence forward. Although similar to

jointing, the setup is slightly different. Here’s how:

Install router bit and set desired depth of

cut.

Adjust fence gap as necessary (see Gap

Adjustment on page 5).

Adjust infeed/outfeed fences to the

in-line/mid-range position as described on

page 5.

Adjust the location of the Intelli-Fence at

your router table to achieve the desired cut

profile. Use a scrap piece of wood and make trial

cuts to help in determining the fence position.

Make a fresh test cut about 3" long on a

piece of scrap stock, then turn off the

router. You’ll notice a gap between the freshly

cut surface and the outfeed fence, Fig. 17.

Simply micro adjust the outfeed fence forward by

this amount to support the stock’s edge as it

passes the cutter.

2

5

3

4

1

Shaping

For a product information update on the complete

INCRA line of tools, please see your nearest dealer.

If you are unable to locate a store nearby, or if you

have trouble finding a particular product, we will

honor your order directly.

Loading...

Loading...