Page 1

TM

w w w. i n c r a . c o m

by

O’ M

Before using the INCR A IBOX,

read and follow all of the

instructions and safety information in this owner’s manual.

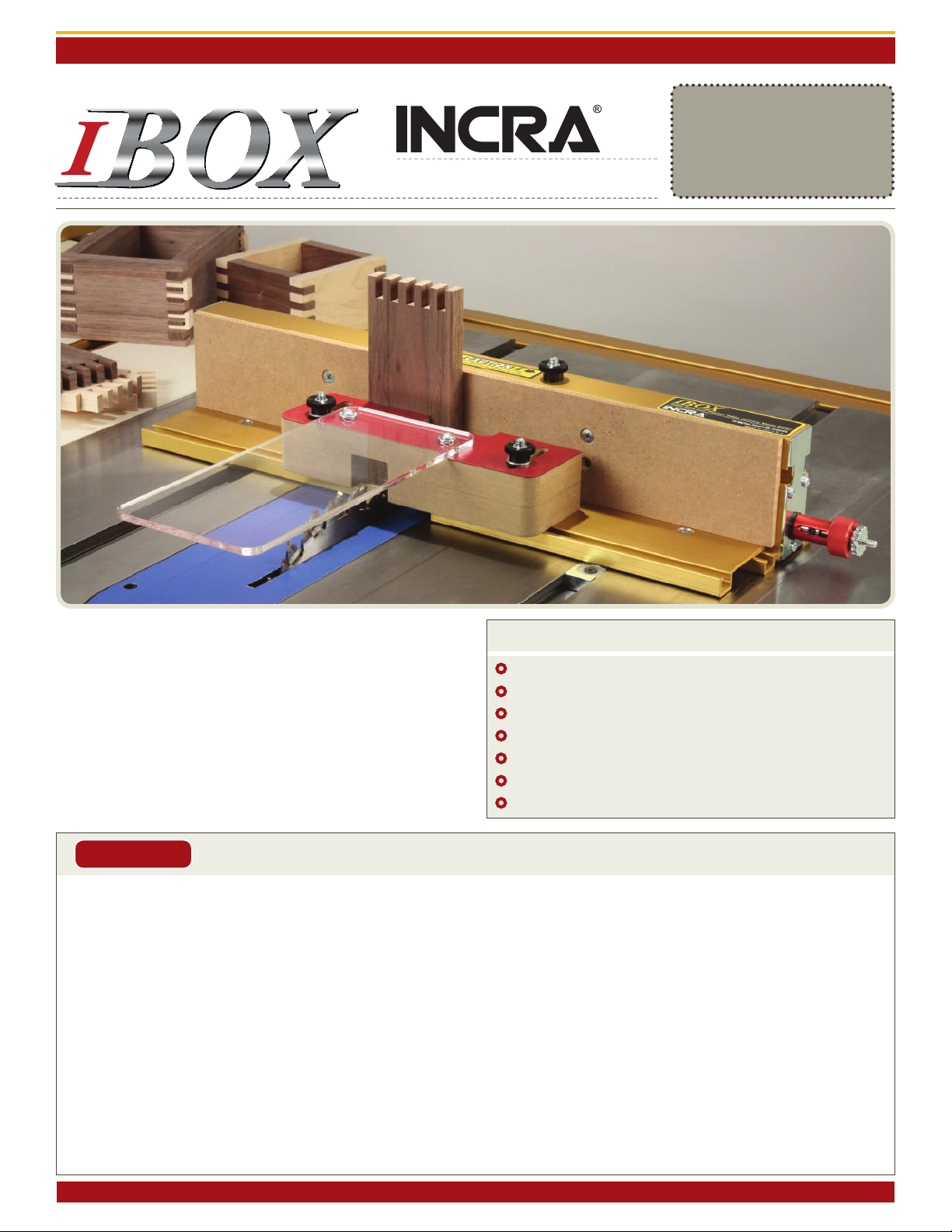

From delicate 1/8” ngers to bold 3/4” joints to exciting new

box joint variations, your New INCRA IBOX is designed to

provide the perfect resource for your next joinery task. The

dual-pitch lead screw driven positioning engine controls both

pin width and spacing with a single adjustment knob while

INCRA’s GlideLOCK™ adjustable miter bar provides smooth

tracking at either your table saw or router table. Before using

your New IBOX, please take the time to read this manual and

be sure to watch the included DVD for some exciting new box

joint techniques, tips and tricks.

SAFETY

Before using the INCR A IBOX, read and follow all instructions

°

and safety information in this manual.

When using the INCRA IBOX in conjunction with any other tool,

°

first read and follow all instructions and safety information in that

tool’s owner’s manual.

Always turn off the power and make sure that the bit or blade is

°

fully stationary before moving any part of the INCRA IBOX to

any new setting.

Always use a wooden handscrew clamp to secure your workpiece

°

to the INCR A IBOX before making any cut.

Before making a cut, always make sure that the blade guards are in

°

place and that the fasteners that secure the stock ledges and blade

guards are securely tightened.

Wear safety glasses, hearing protection and follow all normal shop

°

safety practices.

Important safety instructions for using the INCRA IBOX

CONTENTS

Safety ................................................................ 1

Preliminary Setup ............................................ 2

Setting up at the Table Saw ............................ 3

Setting up at the Router Table ....................... 4

Stock Ledges, Blade Guards & Backing Board .... 5

Operations – Cutting a Box Joint .................... 7

Tips and Techniques ......................................... 12

When using the INCRA IBOX with other tools, make sure that all

°

safety guards and other safety equipment supplied by the manufac turer of that tool are securely in place and functional. Never let the

INCRA IBOX interfere with another tool’s safety equipment.

Keep hands safely clear of the bit or blade.

°

DO NOT alter or modify the INCRA IBOX

°

Do not attempt to use the INCR A IBOX with a “wobble” dado

°

blade.

Do not attempt to use the INCRA IBOX with any cutter smaller

°

than 1/8”.

If using with a SawStop table saw, put the SawStop in the Bypass

°

Mode before calibrating, adjusting, or checking blade clearances.

Return it to normal operation before making a cut.

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 ©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Page 2

INCRA I BOX OWNER’S M ANUAL

PRELIMINARY SETUP

Before beginning setup at the table saw or router

table, make sure that the silver micro-adjust knob is

adjusted so that the set screw in the slotted hole on

the red knob is aligned approximately centered on the

engraved line. This is the “home” position and while

not every setup may require this “home” position, it

is a good place to start when moving the IBOX to a

new station. To reset, first loosen the black positioning

lock knob located on the top of the IBOX. Hold the

red knob in place as you rotate the silver micro-adjust

knob until you see the set screw aligned as shown in

Detail 1A. While the black positioning lock knob

is still loose, rotate the red knob to bring the (2) pin

Preliminary Setup

Fig. 1

1) Loosen lock knob

plates together as shown in Detail 1B. You’ll see the

pin plates located just inside the fence cutout. After

adjusting, tighten the black positioning lock

knob, Fig. 1.

Now let’s get set up at your work station. If you are

setting up at the table saw, read the “Setting up at

the Table Saw” section that follows. For the router

table, jump ahead to “Setting up at the Router Table”

beginning on page 4.

Detail 1B

Bring pin

plates

together

2) Hold red knob

and rotate silver

knob to move set

screw to home

position

Detail 1A

Set screw at home

position

Page 2

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 W W W. I NC R A. C OM

Page 3

SETTING UP AT THE TABLE SAW

INCRA I BOX OWNER’S M ANUAL

1. Install Stack Dado or Box Joint Blade of

Choice

After completing the preliminary setup described on

page 2, unplug your table saw and install your preferred

box joint blade. The INCRA IBOX works with

standard stack dado sets as well as 2-piece reversible

blade box joint sets like those produced by Forrest,

Ridge Carbide and Freud. You can cut delicate 1/8”

box joints using standard 1/8” kerf table saw blades,

but you’ll want to choose a blade that features a flat

ground raker tooth or a special box joint grind like

those from Forrest and Ridge Carbide, Fig 2.

If you are setting up one of the reversible blade sets,

begin with the widest cut profile for the setup that

follows. You can change back to a narrow cut blade

configuration later after the setup is complete. If you

are setting up with a standard stack dado set, any cut

width can be used during setup.

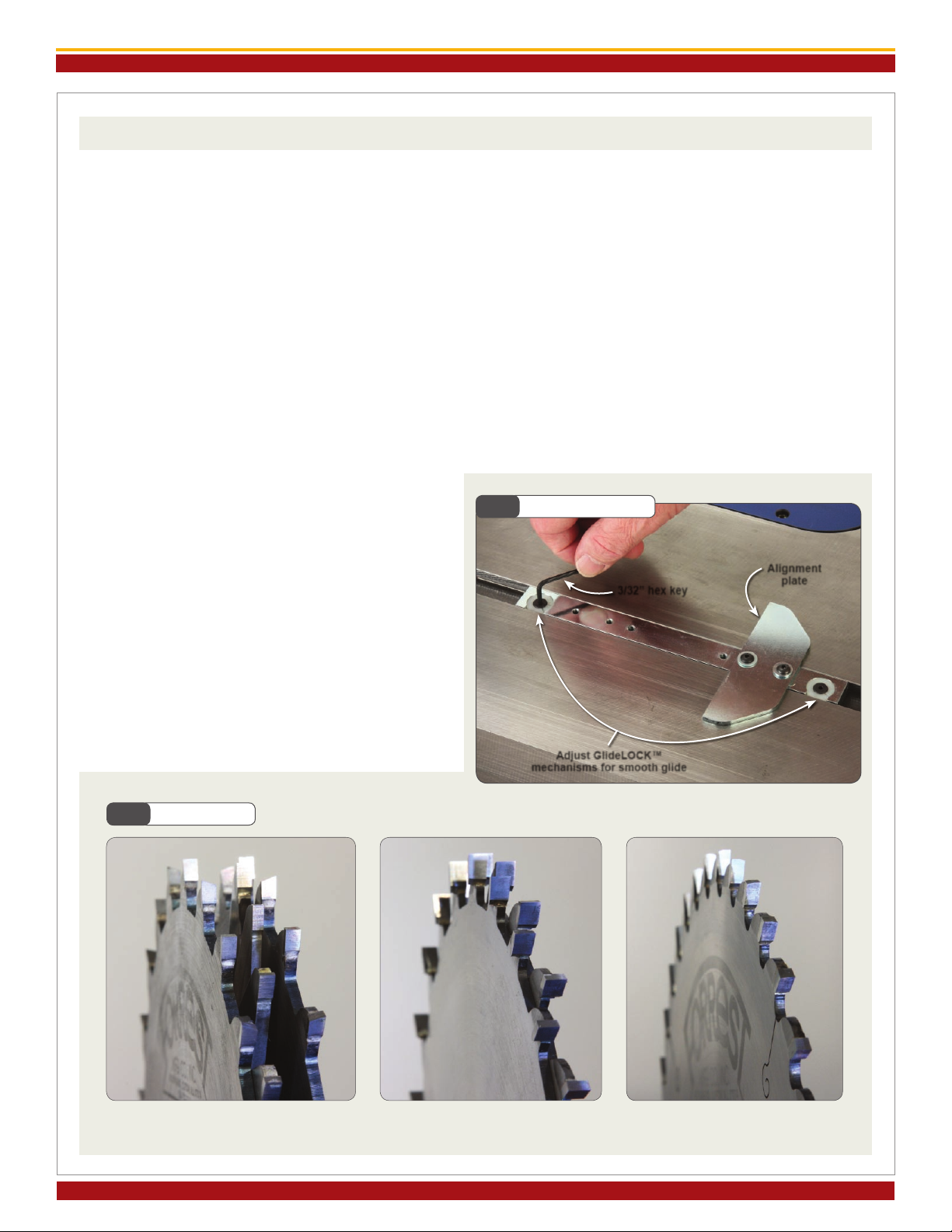

2. Adjust GlideLOCK™ Miter Bar Assembly

Drop the GlideLOCK™ Miter Bar Assembly into

your table saw’s miter slot. Use the left-hand slot for

left tilting saws or the right-hand slot for right tilting

saws. Now adjust the GlideLOCK™ expansion discs

at each end of the bar to adjust the fit for a smooth

glide in your table saw’s miter slot. Turn the fasteners

clockwise to make the glide tighter or counterclockwise for a looser glide, Fig. 3. The alignment

plate is factory squared but can be adjusted as required

by loosening the (2) button head fasteners.

Adjust Miter Bar

Fig. 3

Alignment

3/32” hex key

plate

Blade Types

Fig. 2

Standard Stack Dado Set 2-Piece Reversible Blade

Box Joint Set

Page 3

Adjust GlideLOCK™

mechanisms for smoot h glide

Special Grind Box Joint Blade

©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Page 4

INCRA I BOX OWNER’S M ANUAL

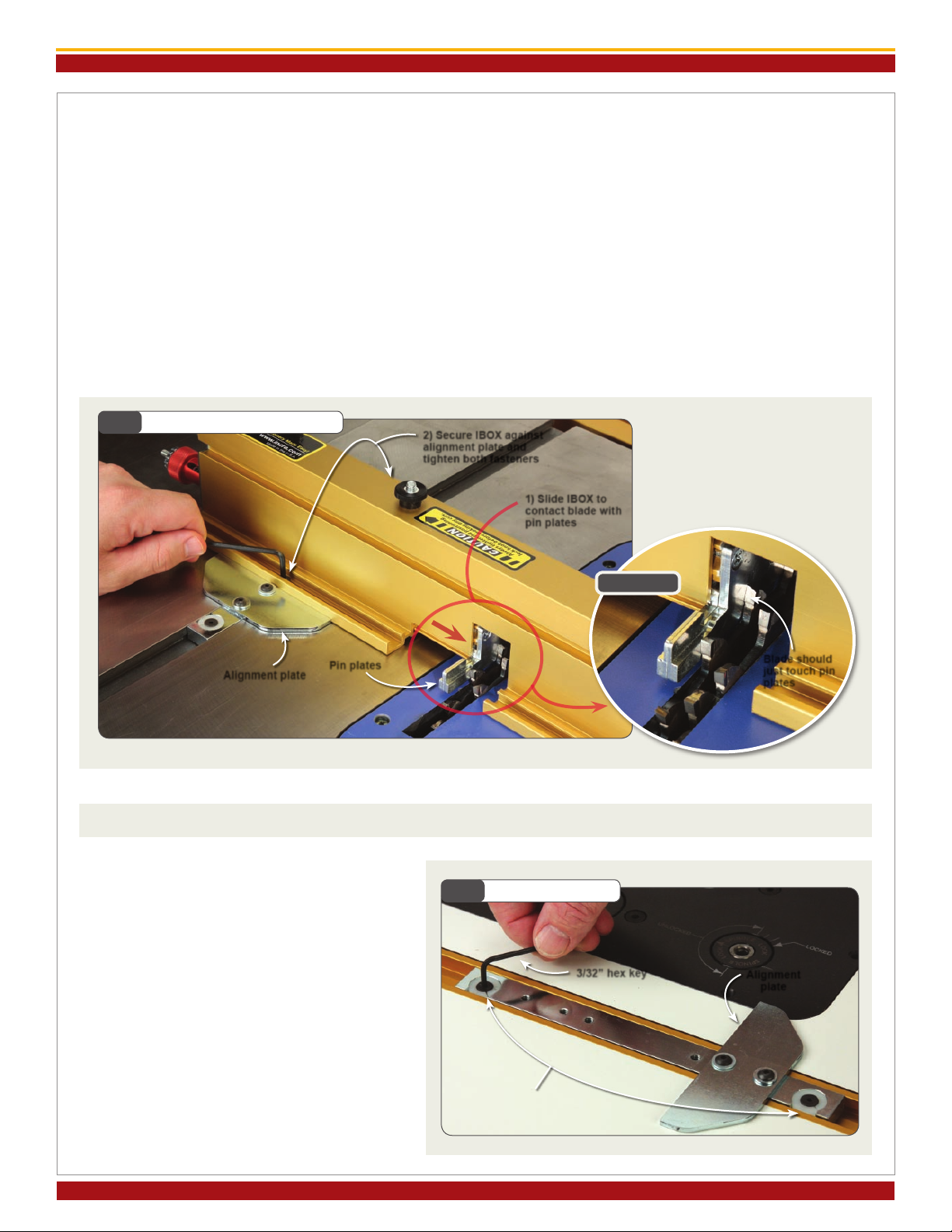

3. Attach IBOX to GlideLOCK™ Miter Bar

Assembly

Position the IBOX fence on the GlideLOCK™ Miter

Bar Assembly with the red knob on the left end for left

tilting saws or on the right end for right tilting saws.

Insert the (2) #10-24 x 3/8” button head fasteners

through the slotted holes in the fence and thread

into the holes on the GlideLOCK™ Miter Bar. Don’t

tighten the fasteners just yet. With your table saw

unplugged, raise the dado up about 1/2” then slide

the IBOX so that the cutter is inside the tall notch

in the fence. Carefully slide the IBOX to the left or

right until the blade “kisses” the steel pin plates on

the IBOX, Fig. 4 and Detail 4A. Make sure that

Attach IBOX to Miter Bar

Fig. 4

2) Secure IBOX against

alignment plate and

tighten both fasteners

the IBOX is firmly in contact with the alignment plate

on the GlideLOCK™ assembly then tighten the (2)

button head fasteners to secure the fence to the bar.

Lower the blade. NOTE: If you later move the

IBOX to another table saw or your router

table, you will need to reset the miter bar’s

position as described in steps 1-3 above for

the table saw or as described in steps 1-2

on page 4 for the router table.

Continue by skipping ahead to the section

titled “STOCK LEDGES, BLADE GUARDS

AND BACKING BOARD” on page 5.

1) Slide IBOX to

contac t blade with

pin plates

Alignment plate

Pin plates

SETTING UP AT THE ROUTER TABLE

1. Adjust GlideLOCK™ Miter Bar

Assembly

Drop the GlideLOCK™ Miter Bar Assembly

into your router table’s miter slot. Now adjust

the GlideLOCK™ expansion discs at each

end of the bar to adjust the fit for a smooth

glide in your router table’s miter slot. Turn the

fasteners clockwise to make the glide tighter

or counterclockwise for a looser glide, Fig. 5.

The alignment plate is factory squared but can

be re-adjusted as required by loosening the (2)

button head fasteners.

Fig. 5

Adjust Miter Bar

3/32” hex key

Adjust GlideLOCK™

mechanisms for smoot h glide

Detail 4A

Blade should

just touch pin

plates

Alignment

plate

Page 4

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 W W W. I NC R A. C OM

Page 5

INCRA I BOX OWNER’S M ANUAL

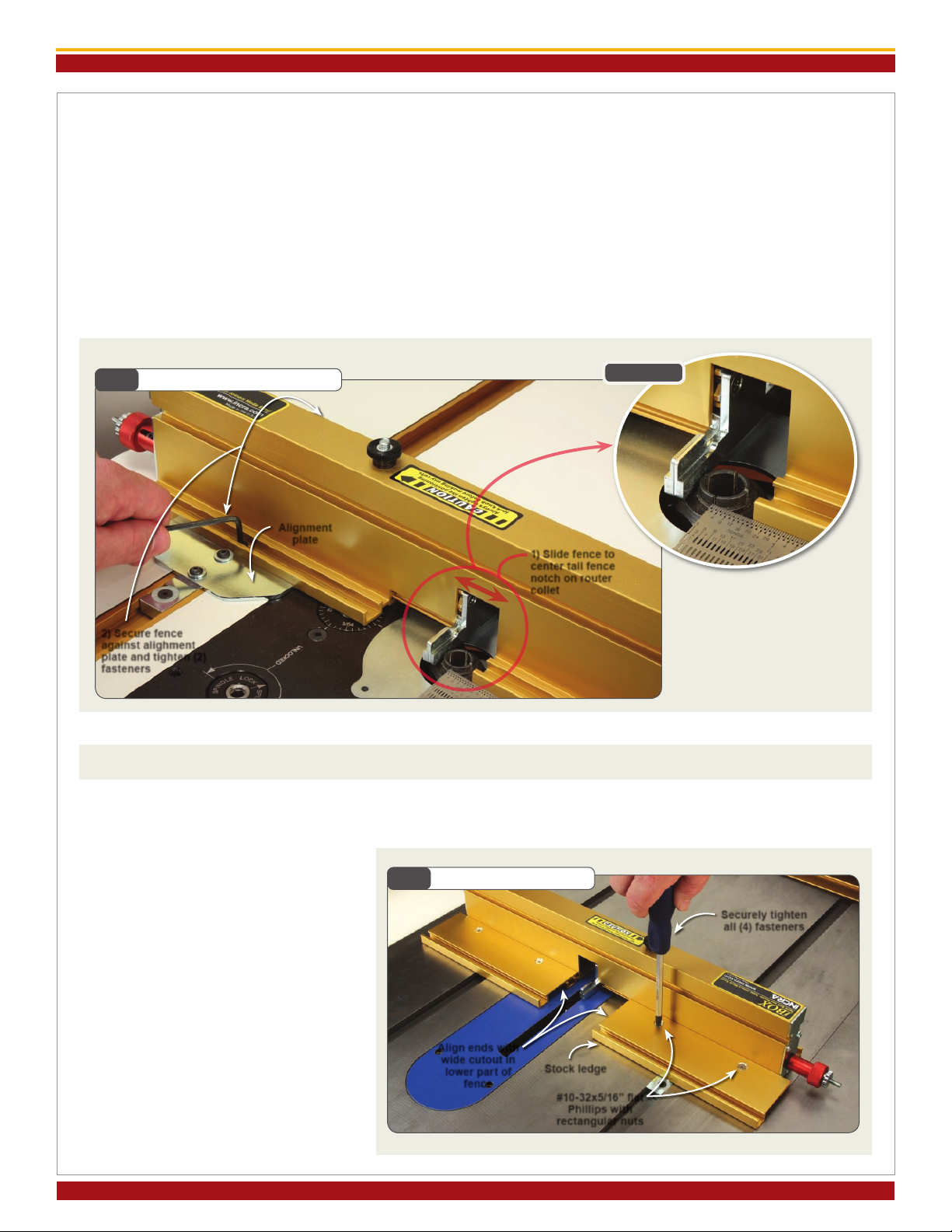

2. Attach IBOX to GlideLOCK™ Miter Bar

Assembly

Position the IBOX fence on the GlideLOCK™ Miter

Bar Assembly with the red knob on the LEFT end of

the IBOX fence. Insert the (2) #10-24 x 3/8” button

head fasteners through the slotted holes in the fence

and thread into the holes on the GlideLOCK™ Miter

Bar. Don’t tighten the fasteners just yet. Slide the

IBOX along the alignment plate until the tall notch on

the fence is centered on your router’s collet, Fig. 6 and

Detail 6A. The center is 9/16” from the edge of the

Attach IBOX to Miter Bar

Fig. 6

Alignment

plate

notch if you would like to use a ruler for the alignment.

Make sure that the IBOX is firmly in contact with

the alignment plate on the GlideLOCK™ Miter Bar

Assembly then tighten the (2) button head fasteners to

secure the fence to the bar. If you move the IBOX to

another router table or your table saw, you will need

to reset the Miter Bar’s position as described in Steps

1-2 above for the router table or steps 1-3 on page 3

for the table saw.

Detail 6A

1) Slide fence to

center tall fence

notch on router

collet

2) Secure fence

against alighment

plate and tighten (2)

fasteners

STOCK LEDGES, BLADE GUARDS & BACKING BOARD

In the following steps you’ll add the Stock Ledges, the Blade Guards and the Backing Board. The photos show the

table saw set up but the steps are identical for the router table.

1. Attach Stock Ledges

Attach Stock Ledges

Insert the (2) #10-32 x 5/16” flat head

Phillips screws through the countersunk

holes in each stock ledge and loosely

thread on the #10-32 rectangular nuts.

The raised rim on the rectangular nuts

should be facing the stock ledge. Slide

the rectangular nuts into the T-slot

on the front of the IBOX fence. For

now, align the ends of the stock ledges

with the wide cutout in the fence and

tighten all (4) fasteners, Fig. 7.

Fig. 7

Align ends with

wide cutout in

lower part of

fence

Stock ledge

#10-32x5/16” at

Phillips with

rectangular nuts

Securely tighten

all (4) fasteners

Page 5

©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Page 6

INCRA I BOX OWNER’S M ANUAL

2. Attach Blade Guards

Before attaching the blade guards you’ll need to

identify the component positions. Turn the IBOX

upside down and support it on a couple of 3/4” stock

scraps. Hold the (2) blade guards with the square

cut corners facing the fence so that the low and high

cutouts in the guards match the low and high fence

notches. The cutouts will only align one way, Fig. 8.

Once you have identified which side each blade guard

mounts to, use the included 1/4-20 x 2-1/4” hex bolts

with washers and 1/4-20 thumb nuts to attach the

guards to the T-slots on the fence and Stock Ledges.

Before tightening the thumb nuts, make sure that the

deep cutouts on the guards are aligned with the blade

notch on the fence, Fig. 9.

Identify Guard Components

Fig. 8

3. Attach Backing Board & Deflector Shield

Insert (2) #10-32 x 1/2” flat head Phillips screws

into the upper holes on the provided backing board.

Thread on (2) #10-32 rectangular nuts then slide the

nuts into the T-slot on the front face of the IBOX

fence, Fig. 10. Center the backing board on the

fence length and tighten the fasteners. The alternate

holes on the backing board allow you to flip the board

over when needed for a fresh backing surface. Using

the (2) #8 x 1” pan head Phillips wood screws and #8

flat washers, attached the deflector shield to the front

blade guard so that the deflector projects forward over

the cutter. Fig. 11 provides dimensions for making

your own backing boards for future use.

Attach Blade Guards

Fig. 9

Deep notch on guards

should align with mat ing

notch on fence

Fig. 10

Attach Backing Board and Deector Shield

Deector shield

Backing board

#10-32x1/2 at

Phillips with

rectangular nuts (2)

#8x1” pan head sc rews

with washers (2)

2-3/4”

Blade notch and deep cut on

guards aligned (rear view of

fence shown)

Fig. 11

1”

1”

4-7/8”

Backing Board Dimensions

1/4” MDF

8”

17-3/4”

1/4-20x 2-1/4” bolt (4)

1/4-20 thumb

nuts (4)

1/4” washer (4)

Page 6

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 W W W. I NC R A. C OM

Page 7

OPERATIONS – CUTTING A BOX JOINT

Whether you are cutting box joints at the table saw or the router table, the set up

routines are the same. We’ll detail the routines in this section with images from

the table saw, but be sure to review the included DVD to see both stations in action.

INCRA I BOX OWNER’S M ANUAL

GET READY…

1. PrepareYour Box-Making Stock

You’ll want to begin by preparing your stock. You’ll need

one piece of scrap stock for a test cut. Mark one edge

of all 4 of the box boards. We’ve used a Sharpie for

clarity, but a pencil mark will work just fine, Fig. 12.

2. Install Your Cutter or Blade of Choice

UNPLUG YOUR TABLE SAW OR ROUTER

TABLE

the router table, a 2-flute standard straight bit will

work fine. At your table saw you can use a standard

stack dado, a reversible blade box joint set or a 1/8”

blade with either a flat ground raker tooth or one of

the custom ground box joint blades available, Fig 13.

and install the blade or cutter of choice. At

Fig. 12

Prepare Stock

4 pieces for box with

reference line on one

edge

CAUTION:

DO NOT USE THE IBOX

WITH WOBBLE DADO

SETS OR THIN KERF 3/32”

SAW BLADES!

3. Stock Ledges Apart, Pin Plates Together

Bring the IBOX to your table. Loosen and slide the

blade guard to the side for a clear view. Also loosen

and slide both stock ledges away from the center of

fence to provide clearance during setup. Double check

to make sure that the pin plates are together. If you

need to adjust the pin plates, loosen the positioning

lock knob located on top of the fence and turn the red

knob counterclockwise to bring the pin plates together,

Fig. 14 and Detail 14A.

Fig. 14

Stock Ledges Apart, Pin Plates Together

Slide blade guard to

the sid e

Scrap piece for test cut

Fig. 13

Blade Types

Standard Stack Dado Set Reversible Blade

Box Joint Set

Page 7

Slide stock ledges apart

to provide clearance in

the center

Special Grind Box Joint

Blade

Detail 14A

Pin plates

together

2-Flute Straight Bit

©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Page 8

INCRA I BOX OWNER’S M ANUAL

GET SET…

1. “Kiss” Calibrate

With the positioning lock knob loose, you need to

“kiss” calibrate the IBOX (YOUR TABLE SAW

OR ROUTER TABLE SHOULD STILL BE

UNPLUGGED)

miter channel to a position adjacent to your cutter.

Now hold the red knob as you rotate the silver

micro-adjust knob to move the pin plates. You’ll want

the pin plates to just touch the blade, Fig. 15 and

Detail 15A. If you are setting up at the router table,

you may need to rotate the cutter by hand to confirm

that the cutter just touches the pin plates. This “kiss”

calibration step zeros the IBOX to the edge of your

cutter. Subsequent adjustments to the pin plates

made by turning the red knob will not alter this initial

calibration.

2. Adjust Pin Plates for Test Cut

With the positioning lock knob still loose, rotate the

red knob clockwise to move the nearest pin plate

. To do this, slide the IBOX in your

Detail 15A

about 1/8” or more away from the blade, Fig. 16.

You’ll notice that the pin plates will simultaneously

move away from each other as they move away from

the blade. This is OK. Your “kiss” calibration setting

is automatically retained. Tighten the black

positioning lock knob located on top of the

IBOX fence.

3. Position Stock Ledges

Slide the blade side stock ledge to about 1/8” from the

cutter then re-tighten the fasteners. For reference,

the blade side stock ledge refers to the

stock ledge that is nearest to the cutter

while the pin plate side stock ledge refers

to the stock ledge that is on the other side

of (and nearest to) the pin plates. Slide the

pin plate side stock ledge up to contact the pin plates

and re-tighten the fasteners, Fig. 17. Slide the IBOX

back and forth in the miter slot to make sure that the

blade is clear of both the pin plates and the blade side

stock ledge.

Fig. 15

“Kiss” Calibrate

1) Loosen locking knob

Fig. 16

Blade

should just

touch the

pin plates

Adjust Pin Plates for Test Cut

clockwise until approx.

1/8” between blade and

1/8” approx.

After adjustment

tighten positioning

lock knob!

Rotate red knob

closet pin plate

Fig. 17

Position Stock Ledges

Slide to 1/8”

from blade and

tighten fasteners

silver knob

Slide to contact

pin plate and tighten

fasteners

2) Hold

red

Knob

in place

3) Rotate

until pin

plates

“kiss” t he

blade

Blade side

stock ledge

Page 8

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 W W W. I NC R A. C OM

Pin plate side

stock ledge

Page 9

INCRA I BOX OWNER’S M ANUAL

4. Set Depth of Cut

Set a piece of the wood prepared for your box on the

stock ledge and raise your cutter to a depth of cut

that will cut just slightly through your stock thickness,

Fig. 18. This will produce pins that will protrude only

slightly through the adjacent board when assembled.

These slight protrusions can later be sanded flush. For

a decorative look, the blade can be raised an additional

1/16” to 1/8” and the resulting “through” pins can be

hand chamfered with a sanding block.

5. Position and Secure Blade Guard

Re-position the blade guard so that the view cutouts

on the front and rear guards align. Sandwich your test

cut board between the front blade guard and the fence

then tighten the black thumb nuts to secure the guard,

Fig. 19. The blade guard also functions as a vertical

stock support, so apply light pressure to hold the

blade guard against the stock as you tighten the thumb

nuts.

6. Make a Test Cut

Stand your test cut piece on end on the blade side

stock ledge between the fence and the blade guard

and slide it up to contact the pin plates. Use a small

wooden handscrew clamp as shown to clamp your

board to the fence as shown, Fig. 20. Plug in your

table saw or router table then make a test cut. Turn

off the motor after completing the cut.

7. Adjust Pin Plates to Fit Test Cut

Loosen the Phillips screws that secure the pin plate

side stock ledge and either one of the thumbnuts

that holds the blade guard. Loosen the positioning

lock knob located on the top of the IBOX fence and

rotate the red knob to open or close the pin plates

until the test cut just made fits over the fingers on

the pin plates (Both pins should be inside the test

cut). You should feel a little friction when you raise

or lower the board but you don’t want it loose. You

can view the pin plates as they are adjusted through

the view cutout in the top of the blade guard, or you

can simply slide the blade guard to the stock ledge on

either side of the blade as shown, Fig. 21. Tighten

the positioning lock knob and the fasteners

that secure the pin plate side stock ledge.

If moved, re-position the blade guard and

re-tighten the thumbnuts. This pin plate

adjustment automatically sets the required distance

between the pins and the blade, so no further

adjustments are required. Now let’s make our box!

Fig. 18

Fig. 20

Set Depth of Cut

Place box side

on stock ledge

adjacent to blade

Make Test Cut

Raise cutter to slightly

above stock thickness

Slide stock to contact pin

plates, tighten handscrew

clamp and make test cu t

Fig. 19

Fig. 21

guard and tighten

Position and Secure Blade Guard

Adjust Pin Plates to Fit Test Cut

4) Reset blade

all fasteners

Board for test cut sandwiched

betwe en fence and blade guard

View cutouts on front and rear

guards aligned

Deep notch in guard

should b e aligned wit h

blade

2) Loosen locking knob

3) Turn red knob until

pin plates t inside

test cut

Blade side

stock ledge

Page 9

1) Loosen blade guard

and pin plate side stock

ledge fasteners

©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Page 10

INCRA I BOX OWNER’S M ANUAL

GO…

NOTE: In the photos below, we have moved the blade guard aside after each cut for

clarity. DO NOT MAKE ANY CUTS WITHOUT FIRST POSITIONING AND SECURING

THE BLADE GUARDS!

1. First Cut - Front/Back Parts

If your box-making stock is a different thickness than

the test cut stock you’ll want to reset the blade guard

as described in Step 5 on page 9, otherwise, place one

of the boards on the blade side stock ledge between

the fence and the blade guard and advance the marked

edge up to contact the pin plates. Clamp the board

with your wooden handscrew and make the cut, Fig. 22.

2. Step, Cut and Repeat - Front/Back Parts

Slide the IBOX clear of the cutter then unclamp and

move the board to set the groove previously cut over

the pin plates. Re-clamp and cut again, Fig. 23. Repeat

this step until you have completed the cuts across

the width of your board. Repeat steps 1-2 on the

remaining ends of the first 2 boards.

Fig. 22

First Cut - Front/Back Parts

Reference mar k

3. Set Up - Side Parts

After cutting the final end of the first 2 boards, take

one of them and set it on the pin plate side stock

ledge with the marked edge facing the pin plates and

advance it to set the first groove over the pin plates.

Take one of the remaining 2 (uncut) boards and stand

it on the blade side stock ledge and advance

the marked edge to contact the marked edge on

the first board. Clamp the board with your wooden

handscrew, Fig. 24.

Fig. 23

Step, Cut and Repeat

Repeat this step

to complete all

cuts

Slide board to contact

pin plate, cla mp and cut

Note: Blade guard moved

aside for clarity only. Do

not make cuts without

blade guard in place!

Unclamp board and set

previous cut over pin

plates. Re- clamp and

cut again

Fig. 24

Setup - Side Parts

Slide side par t to contact

front/back part , clamp

then remove front/back

part

Blade side

stock ledge

Reference mar k

edge to edge

Use previously cut front/

back part to set position of

Pin plate side

stock ledge

side part

Page 10

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 W W W. I NC R A. C OM

Page 11

INCRA I BOX OWNER’S M ANUAL

4. First Cut - Side Parts

Remove the previously cut board from the pin plate

side stock ledge and set aside. Make the cut, Fig. 25.

5. Second Cut - Side Parts

Slide the IBOX clear of the cutter then unclamp and

advance the board on the blade side stock ledge to

contact the pin plates, clamp in place and make the

cut, Fig. 26.

6. Step, Cut and Repeat - Side Parts

Slide the IBOX clear of the cutter then unclamp and

Fig. 25

First Cut - Side Parts

move the board to set the groove previously cut

over the pin plates. Re-clamp and cut again, Fig. 27.

Repeat this step until you have completed the cuts

across the width of your board. Repeat steps 3-6 on

the remaining ends of the final 2 boards.

7. Assemble

Assemble the box with all marked edges facing up,

Fig. 28.

Fig. 26

Second Cut - Side Parts

Fig. 27

Step, Cut and Repeat - Side Parts

Repeat this step

to complete all

cuts

First Cut

Unclamp board

and set

previous cut over

pin plates.Re -

clamp and

cut again

Fig. 28

Assemble

Slide stock to contact

pin plate, cla mp and cut

Marked edges

facing up

Page 11

©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Page 12

INCRA I BOX OWNER’S M ANUAL

TIPS & TECHNIQUES

ADJUSTING THE FIT Fine adjustments to the

fit of a joint can be made by loosening the positioning

lock knob and holding the red knob as you rotate the

silver micro-adjusting knob. Turning the silver knob

clockwise makes the pin larger for a tighter fit, while

turning the knob counterclockwise makes the pin

smaller for a looser fit. (It may be helpful to remember

the phrase, “Righty Tighty, Lefty Loosey”.) Use the laser

cut slit on the silver knob and the engraved marks

on the end of red knob to gauge movement, Fig. 29.

Each mark represents .001” (one thousandth of an

inch). After adjusting, always tighten the positioning

lock knob located on top of the IBOX fence extrusion.

STOCK MARKING TIP

Here’s a way to be sure

that your wood is fully seated on the stock ledge before

you begin each cut. Before cutting, stand each of your

boards against the face of the fence and place a pencil

mark across the board along the top of the fence, Fig. 30.

That way, if the board is not fully seated, you’ll easily see

it in comparing the mark to the top of the fence, Fig. 31.

CENTERED JOINERY

In theory, just multiplying

your cut width by an odd number should give you

a board width that when cut will have an equal pin

width on the outside edges of 2 of your boards. In

practice it doesn’t work out quite that way. You need

exact measurements of both the pin and groove width

and a degree in higher math for the formula to work

in your favor. Suffice it to say that it is easier just to

make your stock 1/8” to 1/4” wider than the “Kerf x

Odd Number” formula and then trim off the excess

after cutting the joints. If you are interested in a more

creative approach to a centered joint, check out the

“decorative techniques” in the included DVD.

WATCH THE INCLUDED DVD

There is no substitute for seeing it done. You’ll

find these tips and many more as well as some new

and interesting techniques for your New INCRA

IBOX!

Fig. 29

Adjusting the Fit

1) Loosen positioning

lock knob

2) Hold red knob

in place

Each mark on

scale represents

0.001” adjustment

3) Rotate silver knob

clockwise to tighten the t

counterclock wise to loosen

4) Tighten positioning lock knob

Fig. 30

Manufac tured by Taylor D esig n Group, In c. P.O. Box 810262 Dalla s, TX 75381 W W W. I NC R A. C OM

Stock Marking Tip

Manufactured by:

Taylor Design Group, Inc.

P.O. Box 810262 Da ll as, TX 75381

www.incra.com

With stock seated

on support ledge,

place a mark along

back of board

at the top of the

fence

INCRA is a Registered Trademark of Taylor Design Group, Inc.

©2012 Taylor Design Group, Inc.

INCR A Tools are pro tect ed by one o r more of the f oll owin g US pat ents :

#4, 793, 60 4, #4,93 0,2 21, #5,195,73 0, # 5,2 75,074 , #5, 42 3,3 60, # 5,716,04 5, # 6,2 37,457,

#6,5 57,601, #6,67 2,190. Other patents grante d or pendin g. rev. 2.9.2 012

Fig. 31

Page 12

Don’t Make That Cut

If line is angled to

top of fence, board

is not seated

MADE IN THE

USA

©2012 by Tay lor D esig n Gro up, In c. Al l rig hts r eser ved.

Loading...

Loading...