Page 1

INCRA

®

Hinge

Crafter

OWNER’S MANUAL

Any Hinge, Any Size, Any Project!

Please read this owner’s manual

and keep it at hand for reference.

So you’ve designed and built

the ultimate jewelry box or

cabinet, and it is with some

apprehension that you

approach that final step,

installing the hinges.

Metal hinges are a pain.

Let’s face it. It’s not so

much the hinge itself, it’s

those darned brass screws.

When you finally do get the

pilot hole centered properly,

the head of the screw is

sure to twist right off during

installation. It makes you

wonder how many brass

screw heads are actually

glued instead of screwed in

the hinge.

What’s the solution? Well, you

could avoid the problem completely with

a lift-off lid, or perhaps a sliding dovetail

top. But let’s not sidestep the issue. The

following set of plans detail step by step

how to shape and cut a wooden hinge

that looks just like the metal version. It is

then glued, not screwed, into mortises cut

into your project. The resulting wooden

hinge makes both the craft and the

craftsman look pretty good.

SAFETY

Important safety instructions for using the INCRA HingeCrafter

■ Before attempting to make wooden hinges with

the INCRA HingeCrafter, read and follow all of the

instructions and safety information in this manual.

■ When using the INCRA HingeCrafter in conjunction

with any tool, first read and follow all instructions and

safety information in that tool’s owner’s manual.

■ Use appropriate safety devices. Keep hands clear

of the blade or bit at all times.

1 INCRA Woodworking Tools & Precision Rules

■ When appropriate, always use a push stick, rubber

soled push block, or other safety device to keep your

hands safely away from the cutting tool.

■ Always work with a full-sized hinge blank. Do

not attempt to cut blanks smaller than the sizes

recommended.

■ Always wear safety glasses and follow all normal

shop safety practices.

Page 2

SUPPLIES

Begin by gathering the necessary supplies to produce your hinges:

■ INCRA HingeCrafter (included)

■ Router Table

■ INCRA Fence Positioner

■ #30 (.128”) x 6” long drill bit (included)

■ Hardwood for hinges

■ 1/8” brass rod (available at some hardware and craft

stores, as well as all welder’s supply stores)

■ Fixed INCRAment™ Templates for 3/8”, 1/2”, 5/8” and

3

/4” spacing from the INCRA Master Template Library

(Templates # 45, 47, 48 and 49)

■ 3/8”, 1/2”, 5/8” or 3/4” bull nose router bit

(Bit size corresponds to hinge barrel diameter)

■ 3/8”, 1/2”, 5/8” or 3/4” straight router bit

(Bit size corresponds to hinge barrel diameter)

■ Rubber soled push block

GETTING STARTED

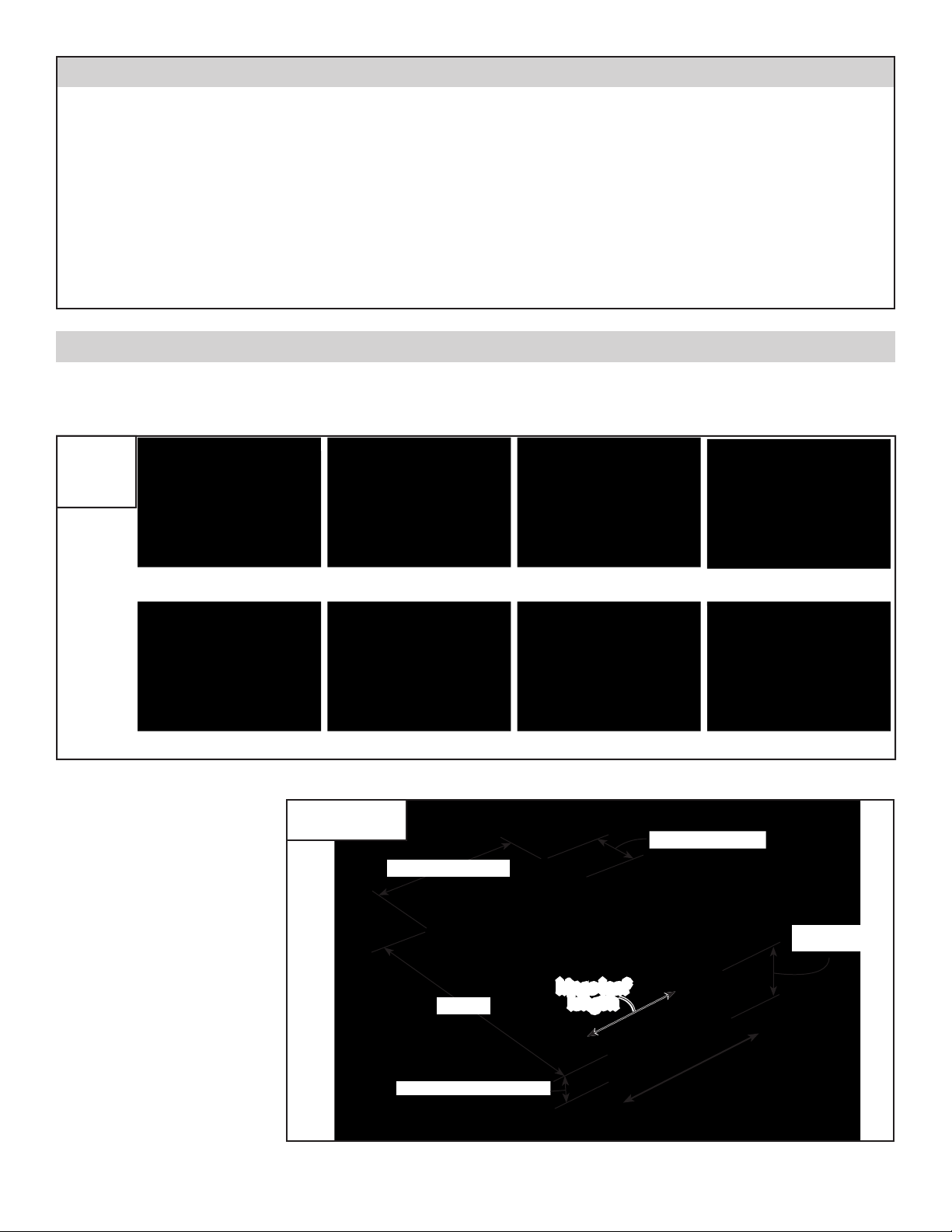

To better understand the process descriptions to follow, let’s first take a look at Fig. 1 showing the various stages of

production.

FIG. 1

Stages of

production

Prepare wood blanks

➀

Cut hinge knuckles

➄

Fig. 2 describes the finished

hinge in terms you will see

referenced later in this booklet.

Note:

Width always refers to

measurements across

the grain, while length

measurements are always

parallel to the grain.

Bull nose-first round

➁

Drill hinge knuckles

➅

FIG. 2

Hinge terminology

overall length

width

Bull nose-second round

➂

Crosscut ends from blanks

➆

knuckle

hinge leaf

hinge leaf

length

length

Increase hinge leaf length

➃

Rip hinge to desired width

➇

barrel

diameter

hinge leaf thickness

2 INCRA Woodworking Tools & Precision Rules

grain direction

Page 3

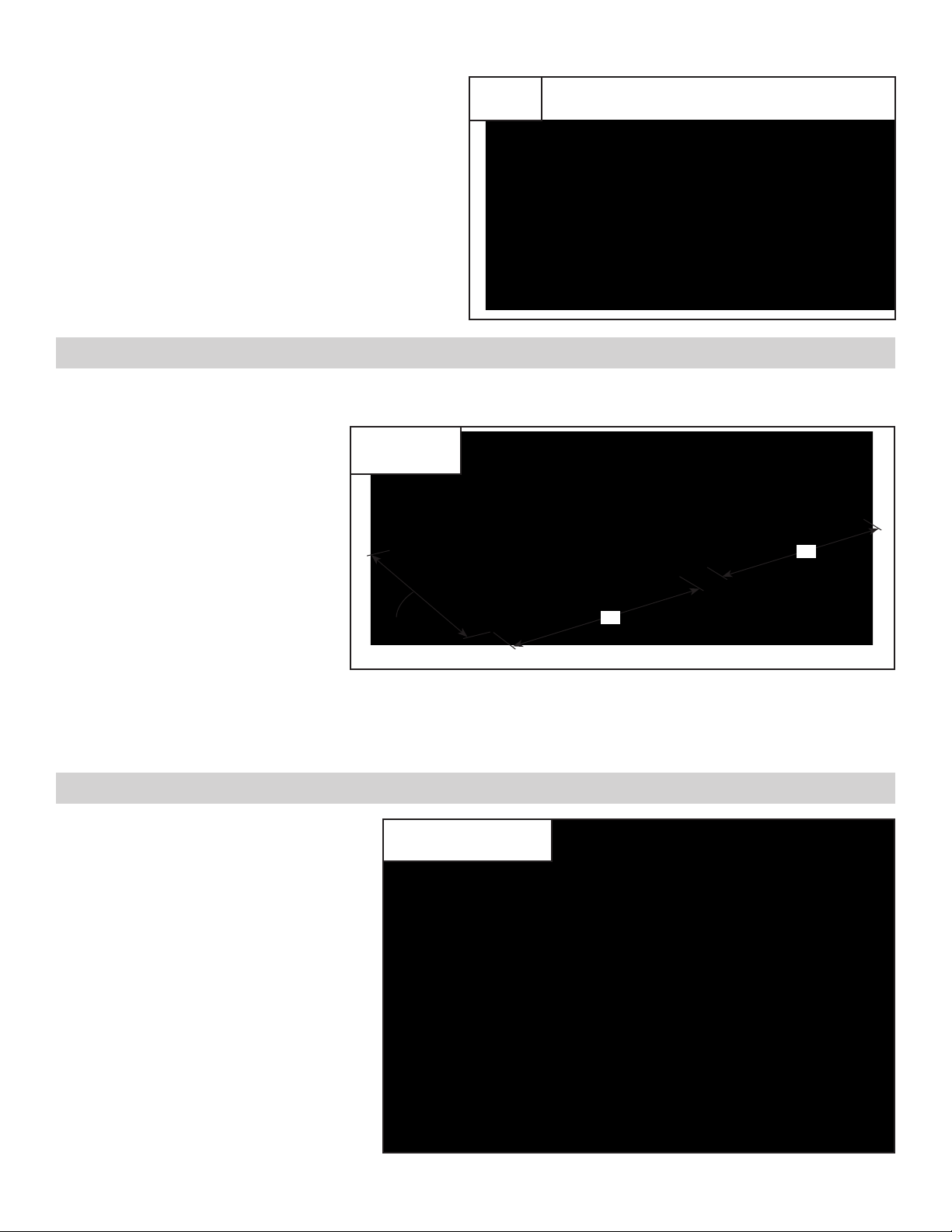

Choosing Your Hinge Size

Your INCRA HingeCrafter will allow you to produce four

hinge barrel sizes with hinge widths up to 10 1/2”. Use

the full-scale hinge profile illustrations shown in Fig. 3

to select the hinge size that you want to make for your

project. The larger 5/8” and 3/4” hinge barrel diameters

can be used for vertical hinge applications such as

cabinet doors, while the smaller 3/8” and 1/2” sizes are

better suited to horizontal applications, such as jewelry

boxes and humidors. The hinge barrel diameter you

select will require the same diameter bull nose bit and

straight bit. For example, if you select the 1/2” barrel

diameter, you will need a 1/2” diameter bull nose bit and a

1

” straight bit for the required cuts.

/2

PREPARE WOOD BLANKS

When selecting stock for your hinges, use close

grained hardwoods such as maple, cherry, walnut

or mahogany for best results. Avoid

highly figured woods such as bird’s-eye

maple or anything “curly”. You’ll need at

least 6” of width in your selection and at

least 12 1/4” of length in order to produce

two blanks. In general, the wider the

wood blank, the more hinges you’ll get.

If you want to make extra wide piano

hinges, prepare stock up to 10 5/8” in

width. (Trimming cuts made later in

the process will remove about 1/8” of

material width.) Thickness plane the

stock to match the hinge barrel diameter

that you have selected. For consistent

results it is important to thickness plane the stock

as accurately as possible. A machinist caliper

is very helpful in producing precise thickness.

Crosscut the stock to yield two 6” blanks, Fig. 4.

FIG. 4

Prepare blanks

6” minimum

width

Caution: Always thickness plane the 12

before cutting to (2) 6” long pieces.

FIG. 3

Hinge size

3

/4” barrel

diameter

5

/8” barrel

diameter

6”

1

/2” barrel

diameter

3

/8” barrel

diameter

6”

1

/4” long blank

BULL NOSE - FIRST ROUND

Bull Nose Bit And Fence Setup

Install in your router the bull nose bit that

matches the hinge barrel diameter you have

selected. The bull nose bit creates lots of

chips in the process of hinge making so

dust collection is a must. If you do not have

a split fence with dust collection capability

such as the WonderFence or the IntelliFence

mounted to the front of your Incra fence

positioner, it will be necessary to make

and attach the wooden auxiliary fence

shown in Fig. 5. This design allows for dust

collection using a standard shop vac wand.

Dimensioned plans for this user-made

auxiliary fence are shown on page 8.

INCRA HingeCrafter 3

FIG. 5

User-made auxiliary fence

Page 4

Adjust the depth of cut on the bull nose bit so that

the roundover is centered on your stock thickness.

Sight down the front face of the fence and position

the fence so that it extends just slightly into the

profile of the bit, Fig. 6. This setup will leave a tiny

flat on the end of your stock after cutting. This

flat is necessary to avoid snipe at the end of the

cut. It is a good idea to make a test cut to adjust

the depth of cut to match your stock thickness and

to adjust the fence position to leave a flat of only

about 1/16”.

FIG. 6

Bit and fence setup

Fence extends slightly

into radius of bit

Bull nose bit

Hinge stock

Place the end grain of the hinge blank against the

fence and, using a good rubber soled push block,

move the stock through the cut. Repeat the cut

on the opposite end of the stock, Fig. 7. The bull

nose cuts should always be made across the grain

as shown. Attempting to produce hinges with the

bull nose cuts made parallel to the grain will result

in hinge knuckles that splinter and break easily.

FIG. 7

Bull nose - first round

BULL NOSE - SECOND ROUND

Now stand the hinge blank on the rounded end

with the face grain against the fence and, using the

rubber soled push block, move the stock through

the cut, Fig. 8. Apply downward pressure to keep

the hinge blank on the table. Repeat the cut on

the opposite end of the blank. After making the

bull nose cuts on all of your blanks, remove the bull

nose cutter and any auxiliary fence you may have

attached.

FIG. 8

Bull nose - second round

Grain direction

4 INCRA Woodworking Tools & Precision Rules

Page 5

INCREASE THE HINGE LEAF LENGTH

In the next series of cuts you will increase the length

of the hinge leaf and determine its final thickness.

While the finished length of the hinge leaf can

be varied to suit your needs, the leaf thickness

is very important to the function of the hinge. If

the hinge leaf thickness is greater than half of the

barrel diameter, the hinge will not fully close when

FIG. 9

Use hinge

blank to

set fence

to bit

distance

assembled. Again, measuring accuracy is important

here. It is suggested that you set the initial depth of

cut described below a little shallow and after the first

cut, measure the leaf and adjust the depth of cut as

necessary.

Bit diameter

matches hinge

barrel diameter

Install in your router the straight bit that matches the hinge barrel diameter

you have selected. Set the depth of cut for the straight bit to half of the

hinge barrel diameter. For example, if making the 1/2” hinge barrel, install

a 1/2” diameter straight bit and set the depth of cut to 1/4”. Set the initial

fence to bit distance equal to your stock thickness (use your hinge blank as

a gauge), Fig. 9. Now slide your inch scale under the hairline cursor to a

reading equal to the straight bit diameter, Fig. 10.

Place the hinge blank on the router table with the rounded end against the

fence as shown in Fig. 11. Using a rubber soled push block, move the stock

through the cut. Repeat this cut for both ends of both blanks. Now move

the fence back 1/4” and repeat the cuts. Continue stepping the fence back

and cutting, making a final pass at 1 1/4” on the inch scale set previously.

TIP: The final fence setting will produce a hinge leaf length

of 1 1/4”. In other words, the final scale reading is a direct

readout of the dado width just cut, Fig. 12. To decrease the

number of passes when making large quantities of the smaller

barrel hinges, you can substitute a 5/8” or 3/4” diameter cutter.

Set up exactly as described above and finish the cuts at the

same dimension or any other dimension that suits your custom

application. Note: If using a dimension other than 1 1/4”, always

add 1/4” to your final desired hinge leaf length. A subsequent

trimming operation will remove the 1/4”.

Trim The Edges To Remove Tearout

At your table saw, trim about 1/16” from each edge of the hinge

blanks to remove any tear out that may have occurred during the

bull nose or dado cuts, Fig. 13. For extra wide hinge blanks, use

your miter gauge for these trimming cuts.

FIG. 10

Slide scale to a reading equal to

bit diameter

FIG. 11

Lengthen hinge leaf

FIG. 12

Hinge leaf dimensions

1 1/4”

1 1/4”

FIG. 13

Trim edges

Trim edges to remove

CUT HINGE KNUCKLES

Hinge Knuckles - Straight Bit And Fence Setup

Install in your router the straight bit that matches the hinge

any tearout from previous cuts

FIG. 14

Straight bit setup

barrel diameter you have selected. Set the depth of cut to

about 1/16” greater than the thickness of the hinge blank. Zero

the fence to the cutter with the cutter inside the fence opening.

To do this, move the fence to cover the cutter then place a

straightedge across the fence opening. Now micro adjust the

fence backward until the cutter just touches the straightedge,

Fig. 14. Clamp the fence positioner in place.

Adjust fence until bit touches straightedge

INCRA HingeCrafter 5

Page 6

Install the Fixed INCRAment™ template from your INCRA Master

Template Library that corresponds to the hinge barrel diameter you

have selected. For example, if you selected the 1/2” hinge barrel

diameter, use the Fixed INCRAment™ template with 1/2” spacing

(Template #47). Slide the template to position cut #1 on the template

directly under the hairline cursor, Fig. 15.

Cut The Hinge Knuckles

Clamp the two blanks back to back to your INCRA Right Angle Fixture

as shown in Fig.16 and mark the “fence” edges of the pieces. Turn

the router on and take a couple of passes to sneak up to cut #2 on the

template. Proceed by making cuts at each of the even numbered blue

cut marks on the template. Turn off the router.

Unclamp the two blanks and flip to cut the opposite ends. Before

clamping, make sure that the marked “fence” edges are against the

fence. Now proceed by making cuts at each of the odd numbered

blue cut marks on the template beginning with cut #3, Fig. 17

.

FIG. 15

Install Fixed INCRAment™

template

FIG. 16

Mark fence edge

on blanks

Install Fixed INCRAment™

template that matches

hinge barrel diameter

Slide template cut #1

under hairline cursor

DRILL HINGE KNUCKLES

Your HingeCrafter is equipped with four different bushing sizes, one

for each barrel diameter (3/8”, 1/2”, 5/8”, and 3/4”). The spacing set

for the bushings within the HingeCrafter makes matching the barrel

diameter to the correct bushings easy. Just find the bushing section

that allows your hinge knuckles to slide in between the bushings.

After identifying the correct section, clamp the HingeCrafter in a

bench vise as shown in Fig. 18. If you don’t have a bench vise, just

clamp the HingeCrafter to the corner of your workbench to allow

drilling from both sides of the fixture.

Slide your hinge blank into the drill guide as shown in Fig. 19 and use

the thumbscrew in one of the threaded holes to clamp the hinge blank

in place. To protect the hinge, slide the provided metal clamp pad

between the hinge and the thumbscrew before tightening. Make sure

that the hinge blank is pressed firmly and squarely into the bushings

before tightening the clamping thumbscrew.

Install the provided #30 (.128”) drill bit in a hand drill and drill the

hinge blank, Fig. 20

the chips are not cleared from time to time, the drill bit will load and

create tearout on the backside of the knuckle, or worse, crack the

hinge. Remember, a clean drill bit drills while a loaded drill bit just

pushes hard. For hole position accuracy, never drill more than one

knuckle beyond the last bushing of the drill guide. To complete the

hole, unclamp and reposition the hinge blank, then drill through the

opposite end of the drill

guide.

IMPORTANT:

Whenever

repositioning the

hinge blank, always

blow sawdust and

wood chips out of

the drill guide before

reinserting the hinge

blank.

. Clear the chips from the drill bit often. If

FIG. 20

Drill knuckles

To avoid tearout,

clear chips from

drill bit often

Clamp stock oriented

as shown to Right

Angle Fixture

FIG. 17

Cut knuckles

Use even numbered blue

marks for this end

Use odd numbered blue

marks for this end

FIG. 18

Clamp

HingeCrafter

in vise

FIG. 19

Clamp hinge

blank in

HingeCrafter

Metal clamp

Thumbscrew

6 INCRA Woodworking Tools & Precision Rules

Page 7

For extra long hinges, first drill one end of the hinge blank, then

unclamp, reposition and drill the opposite end of the hinge blank.

Finally, unclamp and reposition with the center of the hinge in the

HingeCrafter and drill through the existing outer holes to reach the

center. For the longest hinges it will be necessary to complete the

holes in the center by drilling from both ends and in a few cases a

third repositioning is required, Fig. 21.

FIG. 21

Drill extra long hinges

Second: Reposition blank

to drill interior holes

CROSSCUT ENDS

Before removing the hinges from each end of the blank, make the

safety push stick described in the full-scale plan included with this

manual. Use 3/4” plywood and cut out the push stick with a band saw

or scroll saw. Sand the push stick to remove any sharp edges around

the handle.

Set the fence to blade distance at your table saw equal to the hinge

barrel diameter plus 1”. (Example: For the 1/2” barrel diameter set the

fence to 1 1/2”.) With the rounded end of the blank against the fence

and the hinge leaf dado face up, use the push stick to move the blank

through the cut, Fig. 22. Repeat for the opposite end.

CAUTION: Never make the above-described cut with the hinge

leaf dados face down.

RIP HINGE TO FINAL WIDTH

Before cutting your finished hinge to final width, carefully assemble the

two halves of the hinge blank and install the brass hinge pin. If you

experience any difficulty installing the hinge pin, you can run the drill

bit back through the hinge to clean out any chips that may be blocking

the holes. After installing the brass pin, close the hinge and carefully

remove the hinge pin. This aligns the hinge parts for cutting, Fig. 23.

First: Use

HingeCrafter to

drill outer holes

FIG. 22

Crosscut ends

Use safety

push stick

Set fence to blade distance at

hinge barrel diameter plus 1”

FIG. 23

Align hinge parts

Make cut

with hinge

leaf dado

FACE UP

CAUTION: Never make final sizing cuts with the brass pivot pin

installed.

The final sizing of your finished hinge must be accomplished by

making the cuts using a crosscut box or miter gauge

carrier as shown in Figs. 24 and 25. Although these cuts

FIG. 24

Crosscut box

appear to be crosscuts, they are in fact short grain rip

cuts and require backing support for safe cutting. Each

of the methods of cutting shown provides necessary

backing support for the hinge blank on both sides of the

cut. Dimensioned plans for the miter gauge carrier can

be found on page 8. Hold the squared end of the hinge

assembly firmly against your crosscut box or miter gauge

carrier back fence

as you make the

cut. Determine

FIG. 25

Miter gauge carrier

the final cut width

depending on the

requirements for

your application. In

general, the smallest

hinge should have

five knuckles for

maximum strength

(three on one side

and two on the

other).

Install, then remove brass pin

to align hinge parts for cuing

NOTE: Owner’s manual photos

show the blade guard removed

for instructional clarity only. You

should use your blade guard and

other safety equipment whenever

appropriate to protect yourself.

Refer to your equipment manuals

for proper safety instructions.

INCRA HingeCrafter 7

Page 8

AUXILIARY FENCE PLANS

These auxiliary fence plans are intended for users who

do not own an INCRA WonderFence or another fence

with a wide cutter gap to accommodate the larger bull

nose router bits and dust collection.

3

Rip

/4” thick plywood to 3” wide and crosscut to yield

two pieces 22” long and one piece 28” long. Cut a

1

/4” deep groove on the 28” piece and one of the 22”

pieces as shown in Fig. 26. Adjust the width of the

groove for a good fit with the remaining 22” plywood

piece. Cut the fence openings on the 22” piece as

shown. Glue up the three pieces making sure to

check the fence for square before the glue sets. Cut

1

/4” x 3/4” x 3” fillers for the groove openings at the

ends of the 28” piece. Glue in place.

To use your auxiliary fence, clamp the 28” piece to

your existing INCRA fence with the appropriate sized

opening over the bull nose bit. The smaller opening

can be used with the

3

/8” and 1/2” bull nose bits. Use

the larger opening for the 5/8” and 3/4” bits. Protect

the rear of your INCRA fence by placing scrap wood

pads between the fence and your clamps. For dust

extraction, slide a standard shop vac wand into the

opening on the outfeed side of the fence, Fig. 27.

FIG. 26

User-made auxiliary fence

1”

1

/4” deep x 3/4” wide grooves

1

/4”x3/4”x3”

1”

FIG. 27

Clamp auxiliary

fence to Incra fence

28”

Insert vacuum

wand here

1 1/4”

1 7/8”

22”

3”

1”

1 3/8”

MITER GAUGE CARRIER

1

Rip and crosscut the stock as shown in Fig. 28.

Before gluing the pieces together, dry assemble the

parts to your miter gauge at the table saw. Allow 5” of

FIG. 28

Miter gauge carrier

/4” dia. through holes

with 5/8”dia. by 1/4” deep

counter bore

the fence to cross the line of cut. Mark hole locations

that will align with those in your miter gauge. Drill the

two 1/4” mounting holes and then counter bore with

a 5/8” forstner bit to a depth of 1/4”. Glue the fence

1”

to the support base, taking care to align the two

parts flush along the back edge. Attach to your miter

gauge using #10-32 x 1 1/2” pan head Phillips machine

screws with washers and hex nuts. In use, set the

blade depth to cut only through the thickness of the

hinge blank.

2”

1

/2”

4”

5”

18”

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects due

to faulty material or workmanship, or at our option, replace the product free of charge. Please return the failing

component only, postage prepaid, along with a description of the problem to the address below. This warranty does

not apply to parts which have been subjected to improper use, alteration, or abuse.

Made in America by:

Taylor Design Group, Inc.

Printed in the U.S.A.

■

P.O. Box 810262 ■ Dallas, Texas 75381 ■ Tel: (972) 242-9975 ■ Fax: (972) 243-4277

■

© 2004 Taylor Design Group, Inc.

■

INCRA is a registered trademark of Taylor Design Group, Inc.

■

www.incra.com

8 INCRA Woodworking Tools & Precision Rules

Loading...

Loading...