Page 1

Flip Shop Stop Instructions

Introduction

As you look at your new INCRA Flip Shop Stop and fence for the first time you

will no doubt see a most interesting detail. The front face of the fence uses a

tongue and groove arrangement to accept a mating feature on the flip arms.

When the flip arm is down with the two opposing tongue and grooves engaged,

it becomes impossible for the sharp corner of a mitered board end to wedge

between the fence and flip arm. Combined with the already famous incremental

positioning capabilities of the Incra saw-toothed racks, you'll soon be duplicating

cut off lengths with machine shop precision.

Tongue and

groove

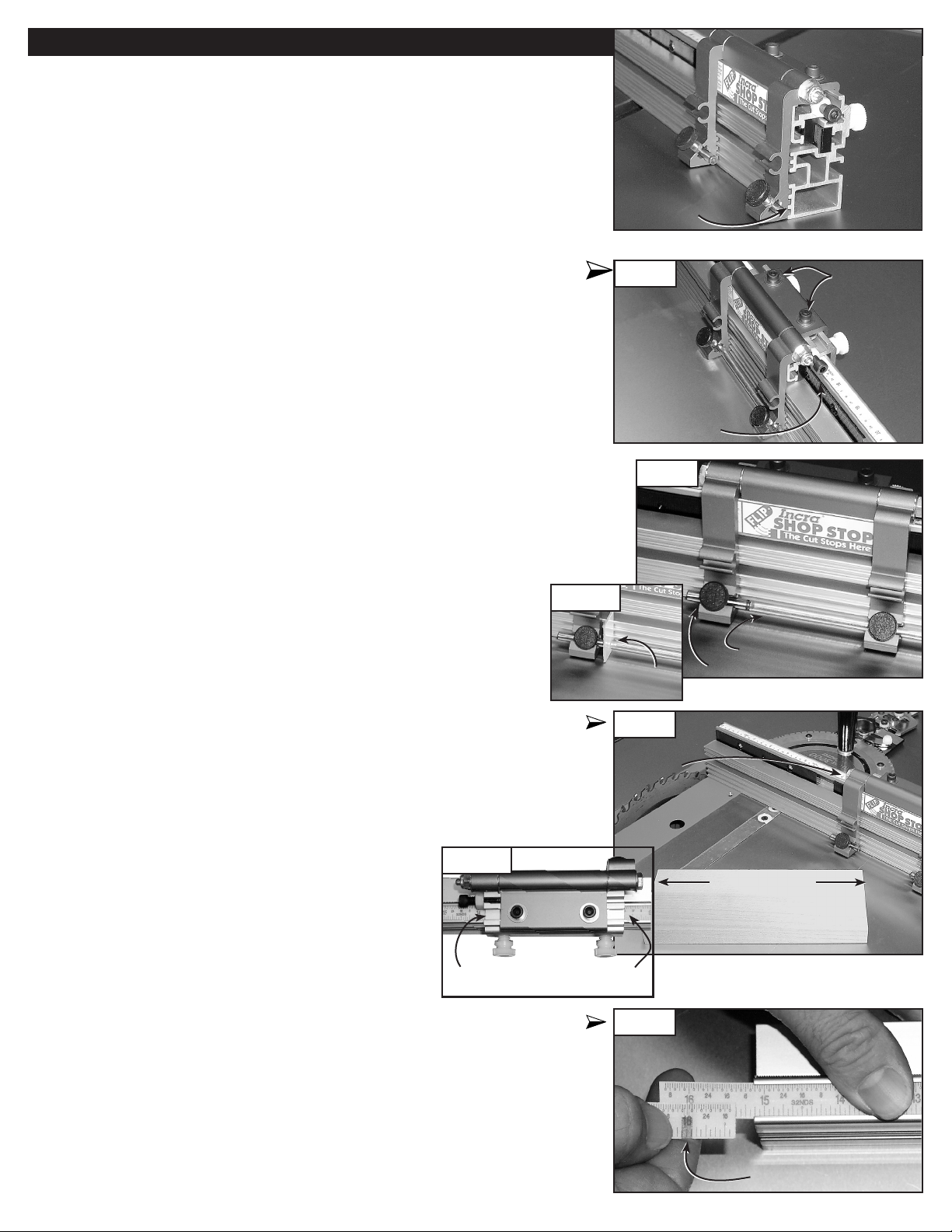

Micro Adjusting

Micro adjusting your stop position can be accomplished in a variety of ways. Use the

supplied hex tool to loosen the two socket head screws located on the top of the stop

body and then turn the micro adjust socket head screw to fine tune the stop position.

Fig 1. When unscrewing the micro adjust screw, apply pressure to the stop body to

keep it against the screw end. After adjustment, always tighten the two socket head

screws on top of the stop body.

When using the stop rods in the flip arms, another way to micro adjust is to simply

shift the position of the rod. A dual rod setup can provide the most controlled means

of adjusting. Place a short rod in one flip arm and a long rod in the other, then

slide the rods to contact each other between the two flip arms before tightening the

thumbscrews. With this setup in place, one rod will be in a "backup" position to the

actual "stop" rod. Fig. 2.

To micro adjust the stop rod forward, loosen the thumbscrew that secures it and

place a shim or spacer, equal in thickness to the adjustment required, between the

backup and the stop rod. Slide the stop rod against the shim and tighten the

thumbscrew. Detail 2.

To micro adjust the stop rod backward, first loosen the backup rod and place the

shim or spacer between the backup and stop rods. Slide the backup rod against

the shim and tighten the thumbscrew. Remove the shim, loosen the stop rod

thumbscrew, slide the stop rod to contact the backup rod and tighten in place.

Detail 2

Place shim between

stop & backup rods

Fig. 1

Turn this socket

head screw to

micro adjust

Fig. 2

Loosen (2)

socket head

screws

Long “backup” rod

Short “stop” rod

Zeroing to the Blade

To zero the stop and scale to the blade, begin by locating the fence a safe distance

from the blade and tightening the socket head screws that secure the fence. Clamp the

stop to the fence about 10" away from the blade. Crosscut a piece of scrap stock with

this setup. Measure the length of the cut piece. Fig 3. If the cut piece measurement

is some multiple of 1⁄32" (i.e.: 101⁄32, 101⁄16, 103⁄32, 101⁄8 etc.), slide the scale on the

fence to read the length of the piece directly under one end of

the stop. Detail 3.

If the cut piece measurement is not a multiple of 1⁄32 (example:

101⁄64), micro adjust the stop forward 1⁄64", and recut the board.

When the test cut measurement equals some multiple of 1⁄32",

slide the scale on the fence to read the length of the piece

directly under one end of the stop. Note: When zeroing the

scale for mitering setups, the test cuts must be made with the

fence locked to the selected angle.

About your Fence Scales

All INCRA products use overlapping 16" long Lexan scales. The overlap allows finetuning the scale from one end to the other to agree with the high degree of accuracy

provided by the Incra saw toothed positioning racks. These scales are printed initially

in 16" lengths (0-16", 16-32", 32-48" etc.). As they are slid into the scale slot on the

fence, the ends are overlapped and aligned using the optical window located at the

end of the second scale. Fig 4. The friction fit will keep the scales in place. If you

wish, you can use a small piece of double faced tape at the overlap to ensure that

the scales move together when changing your zeroed setups for mitering.

Detail 3

Slide scale to read board’s

length under either end of stop

Fig. 3

Clamp stop

to fence

Measure test

cut length

Fig. 4

Align scales using

optical window

Page 2

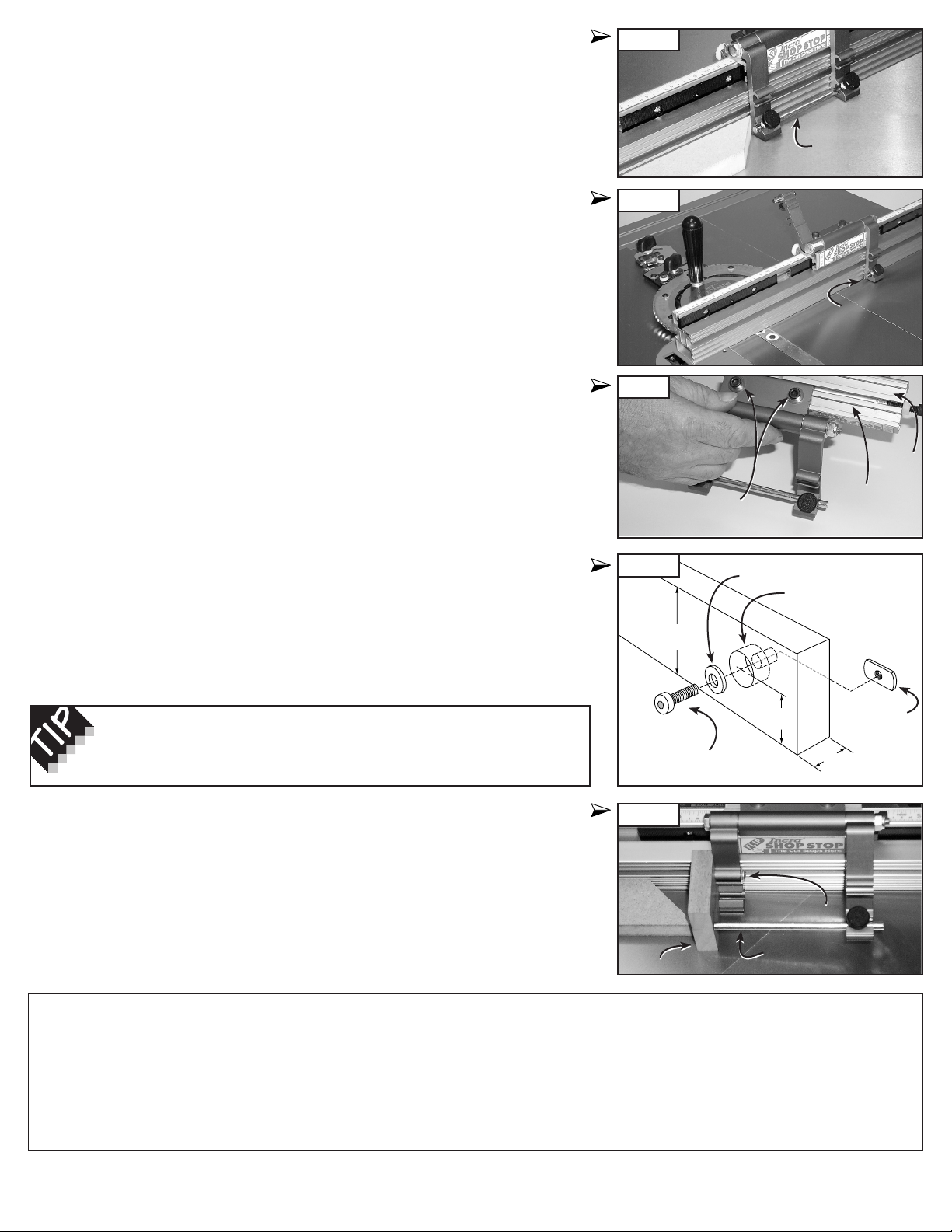

Flip Arms and Stop Rods

The dual flip arms and stop rods provided permit a variety of stop configurations. The

flip arms can be used without the stop rods when you want to take advantage of the

fence/arm tongue and groove feature for stop control on mitered board ends. Typically

you will use the longer rod to join the two arms together. Fig 5. This produces an

arrangement that, when pivoted, moves both arms simultaneously. The rod can be

positioned so that it is the actual stop surface or it can be positioned slightly behind the

front of the arm so that the aluminum arm is the actual stop surface.

Fig. 5

Long stop rod

joins flip arms

By placing one of the shorter 11⁄2" rods in each of the two stop arms, you can use the

two stop arms independently. Fig 6. For example, you can calibrate one for work to the

left of the blade and the other for work to the right. On one side of the blade you might

want to position the stop rods to provide two different cut off lengths from one position.

Just pivot the arm nearest the blade up and the second arm is ready. By using varying

combinations of long or short rods you can create as much as 73⁄4" between the two

stop positions.

Expanded Clamping Mode

The two part body design of the INCRA Flip Stop allows for the use of a 3⁄4" wooden

subfence. The subfence can be used to provide tear out control as well as support

for your workpiece up to and beyond the blade. To expand the Incra Flip Shop Stop,

loosen the two socket head screws located on the top of the stop body, then slide

the upper portion of the stop off. Now slide the upper portion back on, capturing the

rectangular nuts in the second T-slot located on the lower portion of the stop body,

Fig 7.

Making a Zero Clearance Wooden Subfence

A good material to use for making your zero clearance subfence is 3⁄4" medium density

fiberboard (MDF). Use the drill and counterbore dimensions shown to the right. Fig 8.

Adjust the length of the fence to accommodate your application.

*Note: In applications where the incremental stopping capability of the Flip Shop Stop

is required, the wooden fence can be no taller than 21⁄2".

To avoid the saw blade pulling your workpiece into the cut,

add a strip of adhesive backed sandpaper to the front face

of the wooden subfence.

Fig. 6

Fig. 7

Loosen these

fasteners, slide out of

first T-slot and into second

Fig. 8

2 1/2"

*

(See note)

1

/4-20 x 3/4"

socket head

cap screw

1

/4" flat washer

1 1/16"

Short stop

rods allow flip

arms to be used

independently

First Tslot

Second T-slot

5

/16" thru hole

w/ 3/4" dia. x 3/8"

------deep counterbore

1

/4-20

rectangular

nut

3

/4"

Making a Wooden Auxiliary Stop Surface

Fig. 9

In some applications you may discover that making and attaching a wooden stop

surface to one of the flip arms can be beneficial. Use a wood screw to attach the

wooden auxiliary stop through the slotted hole located midway up the flip arm. You

can equip the second flip arm with the longer stop rod to provide outboard support for

the auxiliary stop. Fig 9.

Auxiliary stop

Wood screw

fastener

Long stop rod used for

additional support

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects due to faulty material or workmanship,

or at our option, replace the product free of charge. Please return the failing component only, postage prepaid, along with a description of the

problem to the address below. This warranty does not apply to parts which have been subjected to improper use, alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an INCRA positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group will replace it free of charge for as long as you

own your tool. Return the damaged rack, postage prepaid, and allow 1 to 2 weeks for delivery.

Made by: Taylor Design Group, Inc. ■ P.O. Box 810262 ■ Dallas, Texas 75381 ■ Web Site: www.incra.com 07-2002

Printed in the U.S.A. © 2000, Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc.

Loading...

Loading...