Page 1

INCRA Build-It

Ta yl o r D e s i g n G ro u p, I nc .

STS M

Manual

w w w . i n c r a . c o m

Page 2

INC RA B uil d- It STS Mort iser M an ual

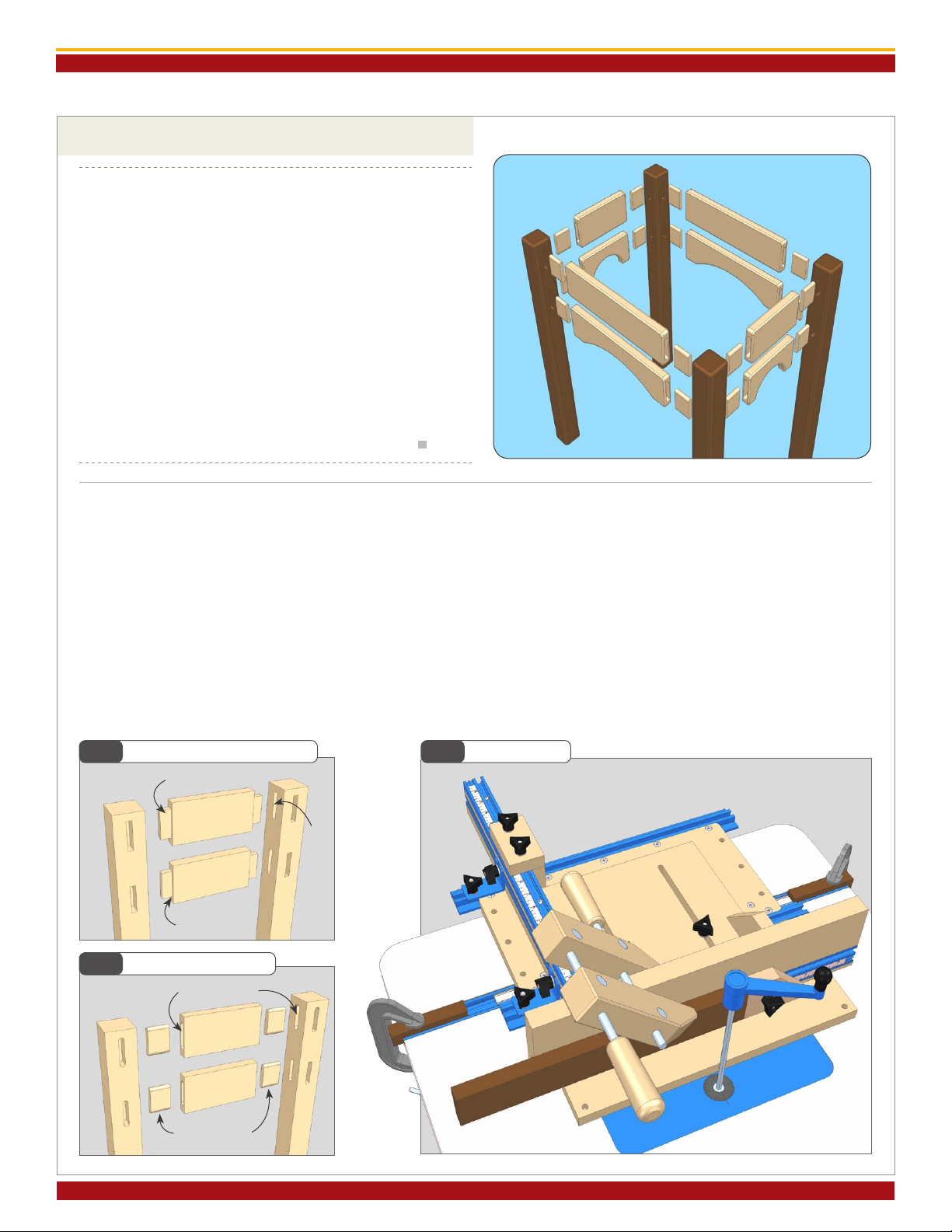

Loose Tenon Joinery

Mortise and tenon joinery as shown in Fig. 1 produces

some of the strongest connections between two pieces of

wood but the setups can be tedious. The mortises are difcult

to place accurately at the router table and the tenons, while

easy enough with the right jig, still require two sets of cuts

to produce. First the shoulders are cut using a miter gauge

followed by the cheeks, which are cut using a tenoning jig. And

all of this to produce what amounts to a square peg for a

round hole. The tenons need to be rounded or the mortises

squared for the nal assembly. We probably don’t need to

mention the additional challenge of making cuts at the table

saw that t well into cuts made at the router table.

Loose tenon joinery on the other hand provides all of the

strength benets without the tedious setups. In loose tenon

joinery all of the pieces to be joined receive an identical

mortise, while the tenon itself is simply a short cutoff from

a long piece of stock, thickness planed, ripped and rounded

over to t the mortise, Fig. 2. And, while locating the

mortises at a router table is still a problem using conventional

methods, you’ll nd perfectly located slots easy with this

new slot-mortising jig, Fig. 3. This jig takes advantage of

the ease of vertical router adjustment provided by the wave

Mortise and Tenon Joinery

Fig. 1

cheeks

mortise

shoulders

Fig. 3

of router lifts on the market today. If you own a router lift

and a router table with a miter slot, you’ll love the versatility

and ease of use of this great jig. Just clamp your material in

place and slide the jig back and forth between two stops as

you slowly raise the cutter using the lift’s crank handle. If

you do not already own these two pieces of equipment, read

on, since the acquisition of these tools is, in many cases,

considerably less than the cost of slot mor tising tools

currently available on the market.

STS Mortiser

Loose Tenon Joinery

Fig. 2

slot mortise

loose tenons

Page 1

Page 3

INC RA B uil d- It STS Mort iser M an ual

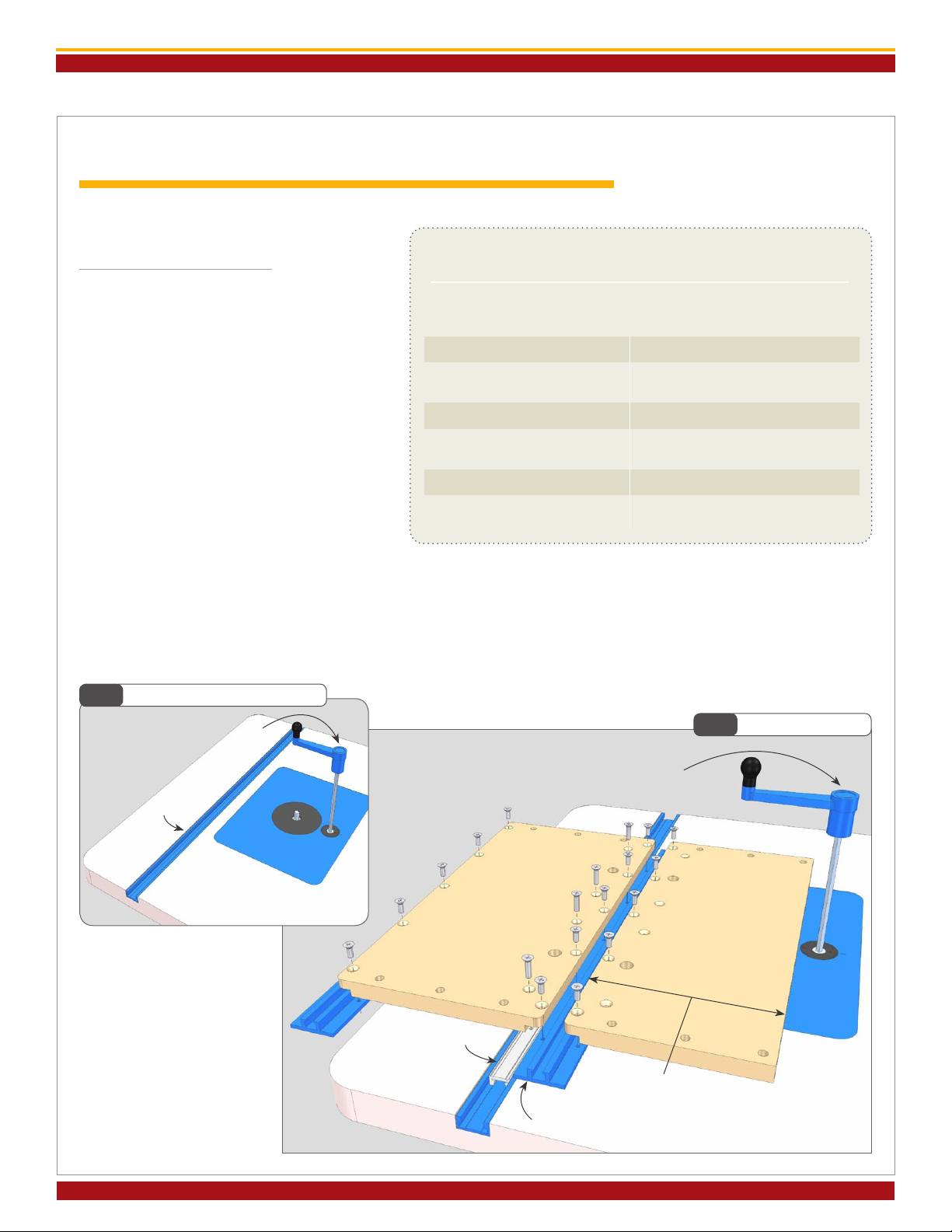

Making the STS (Slot-Tenon-Slot) Mortiser

Build-It Platform

Materials List:

1. In typical router table cutting operations,

router lifts are installed in the table with the

crank handle located so that it is between the

To assemble the STS Mortiser you’ll need:

(2) Small Build-It Panel

router bit and your router table’s miter slot.

In order to use your new STS Mortiser, you’ll

need to rotate the router lift in your table

(2) T-Slot Panel Connector

(1) 18” Miter Slider

opening so that the router bit is between the

miter slot and the crank handle, Fig. 4.

CAUTION:

ALWAYS RETURN THE LIFT TO THE ORIGINAL

SETUP AFTER USING THE STS MORTISER.

(1) Pair Build-It Brackets

(1) Pkg. Build-It Knobs

(1) Build-It Clamp

2. Attach the Miter Slider and (2) T-Slot Panel Connectors

to one of the Build-It Panels and place in your router table’s

miter slot as shown in, Fig. 5.

Router Table Conguration

Fig. 4

(2) 18” Incra T-Track Plus

(1) 18” Incra T-Track Regular

(1) 3/4” x 10” x 10” plywood

(1) 3/4” x 2-1/4” x 28” hardwood

(1) 1” x 4” x 18” hardwood

(1) 1-1/4” x 1-3/4” x 18” hardwood

Adjust the Miter Slider for a smooth glide in the miter slot.

Cut the remaining Build-It Panel at your table saw to fill

the gap between the panel connector and your router lift’s

crank handle. Attach the panel.

miter slot

crank handle

Install router lift with

cutter between crank handle

and miter slot

Miter Slider

crank handle

Cut Build-It Panel to t

between Panel Connector and crank handle

Panel Connector

Build-It Platform

Fig. 5

Page 2

Page 4

INC RA B uil d- It STS Mort iser M an ual

Fence and Stop Positioner

3. Prepare a straight, at piece of hardwood to the dimensions

shown in Fig. 6 and Detail 6A. Cut the groove shown and

install the T-Track and T-Track Plus. Build the stop positioner

as shown in Fig. 8 using 3/4” hardwood.

T-Track Fence

Fig. 6

18” T-Track Plus

18” T-Track

Regular

4. Attach the stop positioner to the fence using 1/4-20 x 1-1/2”

hex bolts with washers and clamping knobs, then attach the

fence to the Build-It Platform using (2) Build-It Brackets with

the included 1/4-20 x 1” hex bolts, washers and clamping knobs.

Square the fence to the “cut” edge of the Built-It Platform

and tighten the clamping knobs, Fig. 9.

Fence and Stop Positioner

Fig.7

Stop Positioner

Fig.8

3

/4”

11/8”

2”

21/16”

Add Fence and Stop to Build-It Platform

Fig.9

clamping knobs

1

/4”- 20 x 11/2”

hex bolts

18”

square fence to

this edge of platform

Detail 6A

3

/4” wide x 1/2” deep

groove

13/4”

11/4”

5

/8”

5

”

23/16”

1

/2”

3

/16

dia holes

Right Angle Faceplate Assembly

5. Starting with a 10” x 10” piece of 3/4” plywood, cut 5/16”

wide x 8” long slots through the material as shown in Fig. 11.

On a 4” x 18” piece of

1” thick hardwood, cut

Fig.10

Right Angle

Faceplate Assembly

the groove as shown

and inlay an 18” T-Track

Plus.

Fasten with the #8 x

1

/2” pan head Phillips

screws.

Page 3

Fig.11

1”

Faceplate and Base

10”

5

21/2”

/

1”

” wide

16

slots

21/2”

4”

1”

1

/4”-20 x 1”

hex bolts (4)

10”

18”

1

/4”

11/4” wide x 1/2” deep groove

18” T-Track Plus

Page 5

INC RA B uil d- It STS Mort iser M an ual

6. Cut the right angle supports and faceplate

stops to the dimensions shown in Fig. 12.

All (4) pieces have identical dimensions.

Drill a 5/16” diameter hole through (2) of the

pieces and set aside for later use as faceplate

stops.

Glue up the right angle faceplate assembly, placing

the right angle supports about 1/4” away from

the edge of the base, Fig 13.

Fig.14

Attach Faceplate Assembly to Build-It Platform

Fig.12

Right Angle Supports and Faceplate Stops

right angle supports

21/4”

90°

45°

4”

right

angle

support

4”

11/8”

11/8”

faceplate stops

5

/16” dia

hole (2)

faceplate

faceplate

assembly

1

/4”-20 x 11/2”

hex bolts

Build-It Platform

7. Secure the right angle faceplate assembly to your Build-It

Platform using (2) 1/4-20 x 1-1/2” hex bolts with washers and

clamping knobs as shown in Fig. 14.

Slide the slotted base of the faceplate assembly up to the TTrack Fence and tighten the clamping knobs. Attach the (2)

faceplate stops to the assembly using (2) 1/4-20 x 1-1/2” hex

bolts with washers and clamping knobs, Fig 15.

base

Fig.13

1

/4”-20 x 11/2”

hex bolts

1

/4” approx.

Glue Faceplate Assembly

Attach Faceplate Stops

Fig.15

4”

Page 4

Page 6

INC RA B uil d- It STS Mort iser M an ual

Operation

For your rst mortise, you’ll cut a slot about 4” long through the “throat plate” Build-It Panel that overlaps the cutter at

your router table. Since most loose tenon applications in 3/4” stock work well with a 3/8” tenon, we’ll cut the slot with

a 3/8” straight bit. (The longer the cutter

length, the deeper you’ll be able to cut your

Fig.16

slot mortises later on.) Install the cutter and

lower the bit below your tabletop. Place the

STS Mortiser on your router table and center

it on the length of your miter slot. Now

clamp a 3/4” x 3/4” x 3” block of wood into

the infeed and outfeed ends of the miter slot

2” from the ends of the Miter Slider, Fig. 16.

Slide the right angle faceplate assembly and

T-Track fence away from the area directly

above the cutter and turn the router on.

Use your router lift crank handle to raise

the cutter 1/16” per pass as you slide the jig

back and forth between the two stop blocks

clamped to the table.

CAUTION: ALWAYS START AND STOP ANY

SLOT CUTTING OPERATION WITH THE

JIG POSITIONED AGAINST THE OUTFEED

STOP BLOCK. When you have cut through the throat plate, turn off the router. The throat plate provides support for your

work piece and zero clearance for tear out control. If you choose to cut mortises with a larger or smaller diameter cutter,

additional throat plates can be produced. Your new STS Mortiser is now ready to use.

Cut Slot Through Throat Plate

Slide STS Jig between two stop

blocks as you slowly raise cutter

Miter Slider

2”

infeed

stop block

Build-It “throat plate”

2”

3

/8”

outfeed

stop block

straight bit

For typical slot mortising there are four steps to locating a slot on your work piece.

Step 1

Set Length of Slot

To set the length of your slot, raise the cutter through

Fig.18

Setting Slot Length

slide faceplate to cutter and clamp in place

the slotted hole in the throat plate panel and slide

the faceplate assembly up to (but not touching)

the cutter. Before tightening the faceplate assembly

clamping knobs, make sure that it is pressed securely

against the T-Track fence. Slide a faceplate stop into

each end of the T-Track on the faceplate. In setting

the stops, you will always use the 8” mark on the faceplate

scale to represent the “center” of your slot length. To

set up for a 2” long slot, set

Fig.17

Slot Length

the outfeed faceplate stop

to 7” and the infeed stop

to 9”. In other words, the

distance between the two

stops is equal to your slot

length, Fig. 18.

Page 5

set distance between stops equal

to desired slot length

(use 8” mark on scale as center)

Page 7

INC RA B uil d- It STS Mort iser M an ual

Slide the STS Mortiser forward until the cutting wing on the cutter contacts the infeed faceplate stop. Now clamp a block of

3

/4” scrap wood into the miter slot against the outfeed end of the Miter Slider, Fig. 19. This will set the forward or outfeed

travel limit. Now pull the jig back until the cutter contacts the outfeed faceplate stop and clamp a block of 3/4” scrap into

the miter slot against the infeed end of the Miter Slider, Fig 20. This sets the rearward or infeed travel limit.

Fig.19

1st: slide jig

forward until cutter contacts

infeed faceplate stop

Now, we need to locate the slot on your workpiece. To

begin we’ll set the distance from the end of the slot to the

end of your board. Simply slide either the infeed or outfeed

faceplate stop away from its current position the distance

Set Forward Travel Limit

2nd: clamp stop block into

miter slot against end of

Step 2

Set Distance from End of Slot to End of Workpiece

Miter Slider

from the end of your workpiece (after setting a 2” length of

slot), slide the outfeed faceplate stop to read 6” and tighten

the clamping knob, Fig. 22.

Remove the remaining faceplate stop.

Fig.20

2nd: clamp

stop block into

miter slot against

end of Miter Slider

you choose. For instance if you wanted to start the slot 1”

Set Rearward Travel Limit

1st: slide jig back until cutter

contacts outfeed faceplate stop

Fig.21

Slot to Board

End Distance

Fig.22

Setting Slot to Board End Distance

workpiece to beginning of slot

Page 6

distance from end of

nal stop

position

original stop

position

Page 8

INC RA B uil d- It STS Mort iser M an ual

Step 3

Set Distance from Edge of Slot to

Edge of Workpiece

You’ll rst want to zero the faceplate to the edge of the cutter.

Loosen the clamping knobs that secure the faceplate assembly

and slide it forward to contact the cutting wing of the bit.

(You may need to rotate the cutter to nd the “high spot”

of the cutting wing.) Hold the faceplate assembly steady as

you slide the T-Track fence stop positioner up to contact the

back of the faceplate assembly’s base and tighten the clamping

knobs. Note the position of the stop on the scale in the top

Fig.24

Setting Slot to Board Edge Distance

T-Track

fence stop

1st: slide faceplate to contact

cutter, then slide T-Track

fence stop to contact back

of faceplate assembly

of the T-Track fence. (We suggest you slide the scale to read

at one of the whole inch numbers, or slide it to read at zero

if you don’t mind some of the scale hanging out of the end

of the fence.)

To set the cutter-to-faceplate distance, simply move the

T-Track stop positioner away from the back of the base

using the sc ale on the top of the T-Track fence as

a reference. Tighten the clamping knobs, then slide the

faceplate assembly back to contact the stop and tighten the

clamping knobs, Fig. 24. For example, if we start with the

stop positioner set at 8” and

then move it to 8 -1/2” along

wi t h the face pl ate assembly,

there should be 1/2” between

the faceplate and cutter.

2nd: using

scale as a reference,

slide stop away

by an amount equal

to desired slot-to-

edge distance

3rd: slide faceplate assembly

to stop and clamp in place

Step 4

Cutting the Slot

Now you can clamp your workpiece in

place and start the cutting process. Lower

the cutter until it is just ush with the top

of the Build-It throat plate. For horizontally

oriented material, place the board end

against the faceplate stop and clamp to

the faceplate. Always begin and end

each cut with the jig against the

outfeed travel limit block. Turn on

the router and, using your router lift’s crank

handle, raise the cutter 1/16” and slide the

jig between the two limit stops, Fig. 25.

After each cut cycle, raise the cutter 1/16”

until you reach the desired depth. You’ll

have to count the crank handle rotations

to keep up with how deep your cut is.

Fig.25

Cutting a Slot Mortise

Fig.23

ALWAYS begin and end each

cut with jig against the outfeed

travel limit stop block

Slot to Board

Edge Distance

clamp horizontal

material to

faceplate with

end against

faceplate stop

Page 7

Page 9

INC RA B uil d- It STS Mort iser M an ual

Vertically held stock will often interfere with full rotations of

the crank handle but your local hardware store has an easy

solution.

Fig.26A

Fig.26

A Hex Driver

for Ratchet

Just purchase a hex driver for your ratchet set as shown and

use half rotations of the crank mechanism, Figs. 26 & 26A.

In many cases, a T-handle hex key will work as well, Fig. 27

& 27A.

Fig.27

Fig.27A

T Handle

Hex Key

To avoid interference when cutting vertical boards,

use a ratchet along with a hex driver

Making Loose Tenon Stock

Of course, slot mortises can be fun to cut with your new jig,

but you’ll need loose tenons to put it all together. When

preparing loose tenon stock, it’s a good idea to make

several sizes of long stock all at once then cut to length later

as needed.

For instance, you can thickness plane material to match your

slot width then rip lengths of stock to 1”, 2” and 3” wide.

Roundover the edges with a bullnose bit that matches the slot

cutter’s diameter, Fig. 28.

Faceplate stops can be installed in a variety of ways to

support your workpiece

Fig.28

3” wide

Page 8

Loose Tenon Stock

roundover edges with

bull nose bit

1” wide

2” wide

Page 10

INC RA B uil d- It STS Mort iser M an ual

Tips

By removing the faceplate assembly and using the T-Track

fence along with one of the Build-It hold down clamps, you

can cut slot mortises and dados across the grain. And by

angling the fence across the Build-It platform you can angle

the mortises as well.

Fig.29

Cross Grain Mortises

Build-It Clamp

through mortise

A stop positioner should always be clamped to the T-Track

fence at the left end of your material and a Build-It Clamp

should be used to prevent slippage during the cut, Fig. 29.

And again, always start and stop each cut cycle with the jig

against the outfeed travel limit stop block.

Need to cut a mortise in the middle of a longer

board? Just use a square to place a mark all

the way up the faceplate and in line with the 8”

mark on the faceplate scale, Fig. 30.

(Remember the 8” mark will always be used as

the center of your slot length.) Now place a

mark on your board at the center of the desired

slot location.

The mark should be placed on the board edge

opposite where the mortise will be cut.

Align this mark with the faceplate mark when

clamping your material, Fig. 31.

Fig.30

vertical mark on faceplate at 8”

Fig.31

Cutting Mortise in the Middle of Long Stock

align marks when

clamping material

mark center of slot

location on edge opposite where

slot is to be placed

Page 9

Page 11

INC RA B uil d- It STS Mort iser M an ual

As in most woodworking projects, the alignment between

parts is an important part of the nished look of the

construction. Sometimes, you’ll want a ush alignment as

shown in Fig. 32, while other projects may require offset

alignments, Fig. 33. Either way, you’ll want to be able to

control and maintain the alignment selected. This is often

accomplished through the use of reference marks placed

on the individual parts. These marks are then used to

ensure the correct face or edge of the material is placed

against the fence when setting up for a cutting operation.

Work piece reference marks used with your STS Mortiser

will also help in determining whether you will need an infeed

or outfeed faceplate stop when setting the slot to end of

board distance.

For example, in order to keep the ush alignments shown

in Fig. 34, you’ll mark the surfaces that you want aligned

and the surfaces that will receive a cut. We have used

the letter “F” to designate the surface that will be placed

against the faceplate, and the letter “C” to represent the

surface that will receive the cut. The pieces are numbered

1, 2 & 3. When cutting the #1 piece, it would be necessary

to use an infeed faceplate stop in order to position surface

“F” against the faceplate, with surface “C” face down over

the cutter, Fig. 35.

When cutting the same mortise on the #3 piece, however,

the setup would require the use of an outfeed stop in

order to position the material with the “F” surface against

the faceplate and the “C” sur face f ace down, Fig. 36.

The procedure is the same for offset alignments, except

that the edge-to-cutter distance is changed when setting

up for the cuts on piece #2.

Fig.33

Fig.32

ush alignment

Fig.34

Reference Marks

1

F

C

offset

alignment

3

2

F

F

F

C

Fig.35

Using Infeed Faceplate Stop

“F” mark is against

the faceplate

infeed

faceplate stop

piece #1

“C” mark is face

down over cutter

Page 10

Fig.36

Using Outfeed Faceplate Stop

outfeed faceplate stop

piece #3

“F” mark is

against the faceplate

“C” mark is

face down

Page 12

w w w . i n c r a . c o m

INCR A Build-It

STS M M

Taylor Design Group, Inc.

P.O. BOX 810262

Dallas, TX 75381

www.incra.com

INCRA Tools a re protected by one o r more of the following U.S. patents:

#4,793,604, #4,93 0,2 21, #5,195,730, #5, 275,074, #5,423,360, #5,716,045, #6, 237,457,

#6,557,601, #6,672,190.

Othe r patents granted or pending. INCRA is a Registe red Tradema rk of

Taylo r Design Group, Inc.

©2 00 7 Ta yl or D es ig n Group, Inc. R ev. 0 6.0 8.07

Loading...

Loading...